Solid State Additive Manufacturing of Thermoset Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

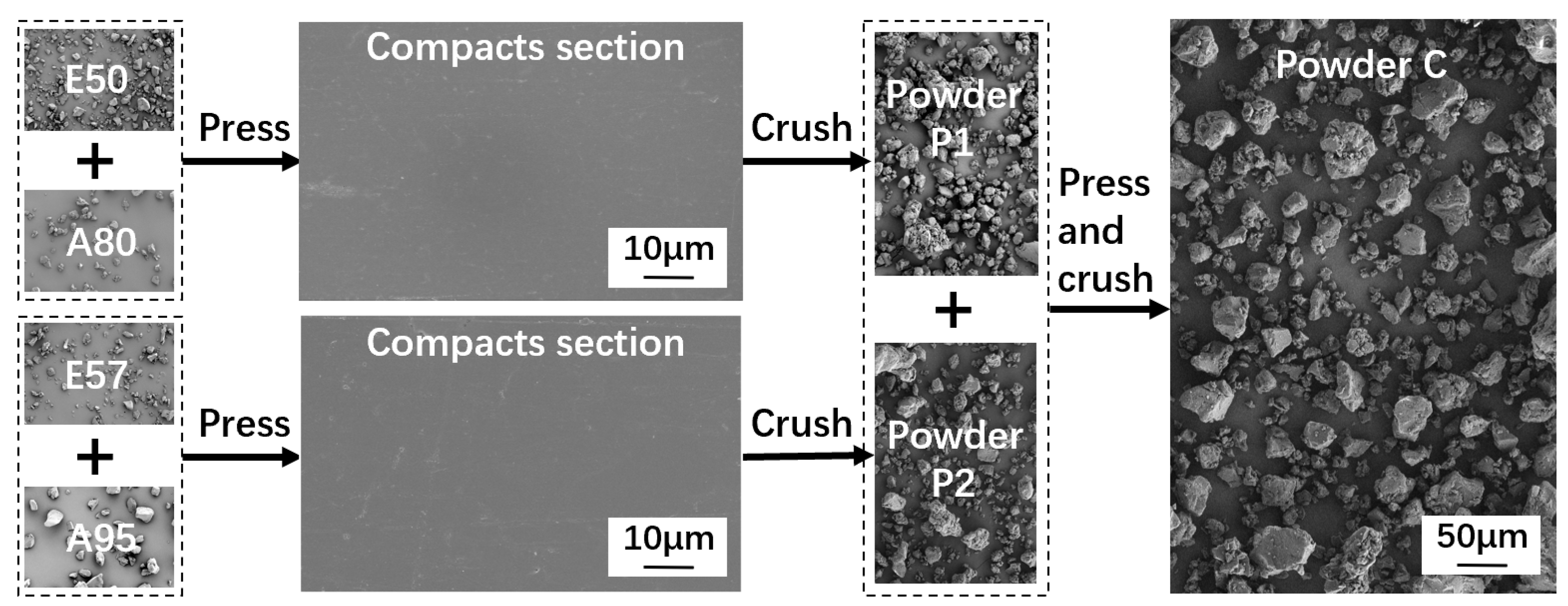

2.2. Powder Fabrication Process

2.3. Three-Dimensional Printing Procedure

2.4. Curing Process

2.5. Experimental Characterization

2.5.1. Microstructural Analysis

2.5.2. Mechanical Property Analysis

2.5.3. Thermo-Property Analysis

3. Results and Discussion

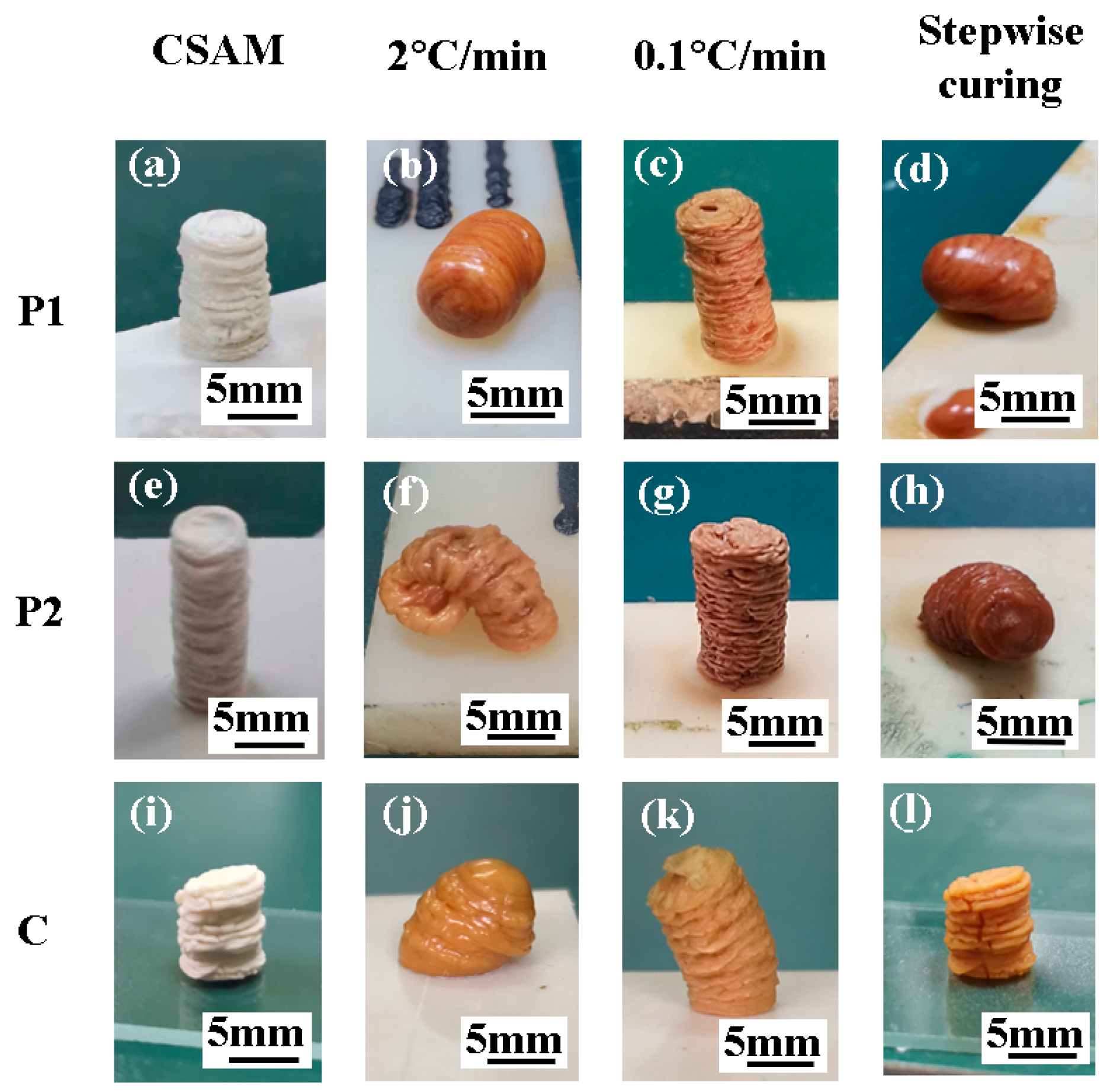

3.1. Deposited Sample Morphology Analysis

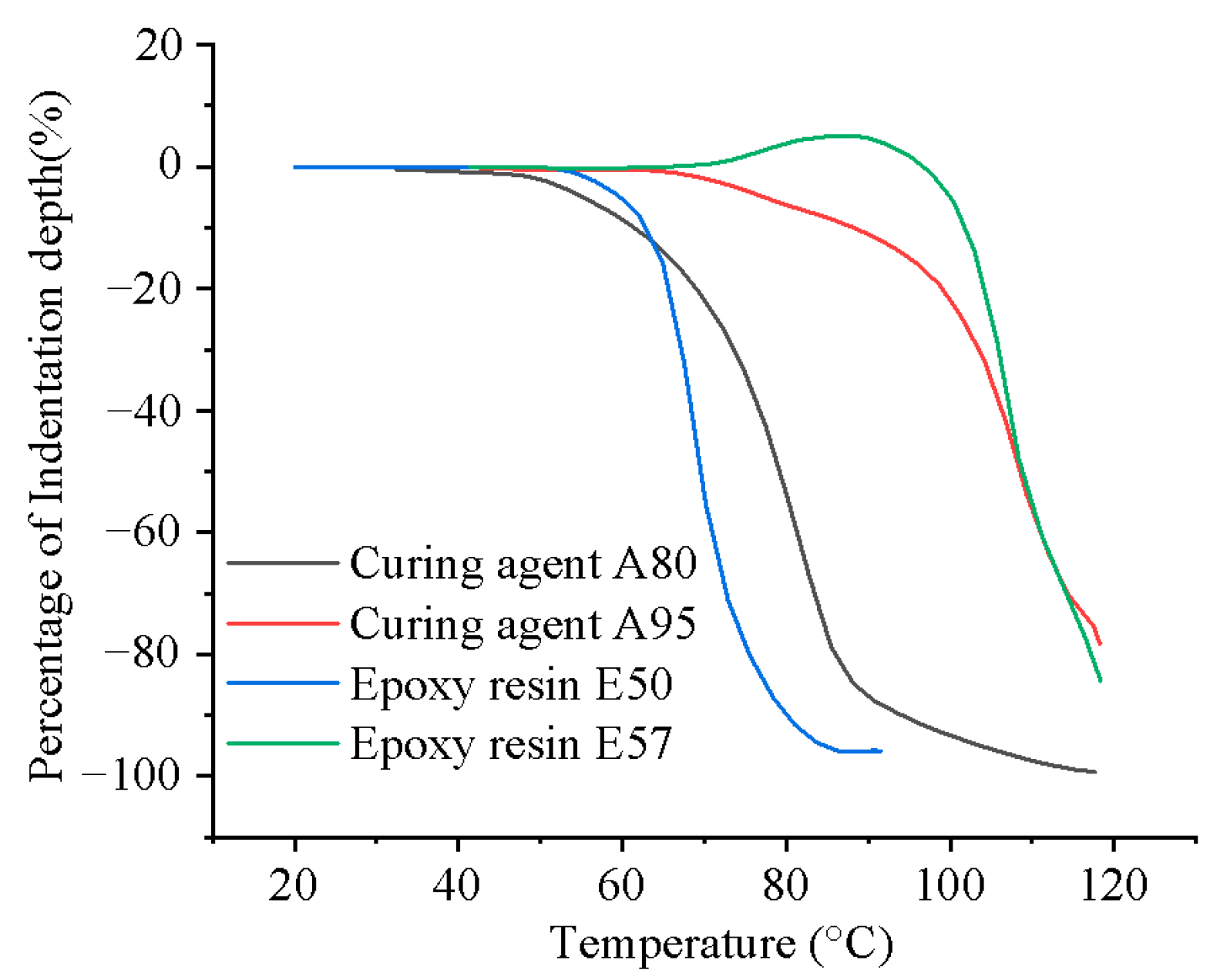

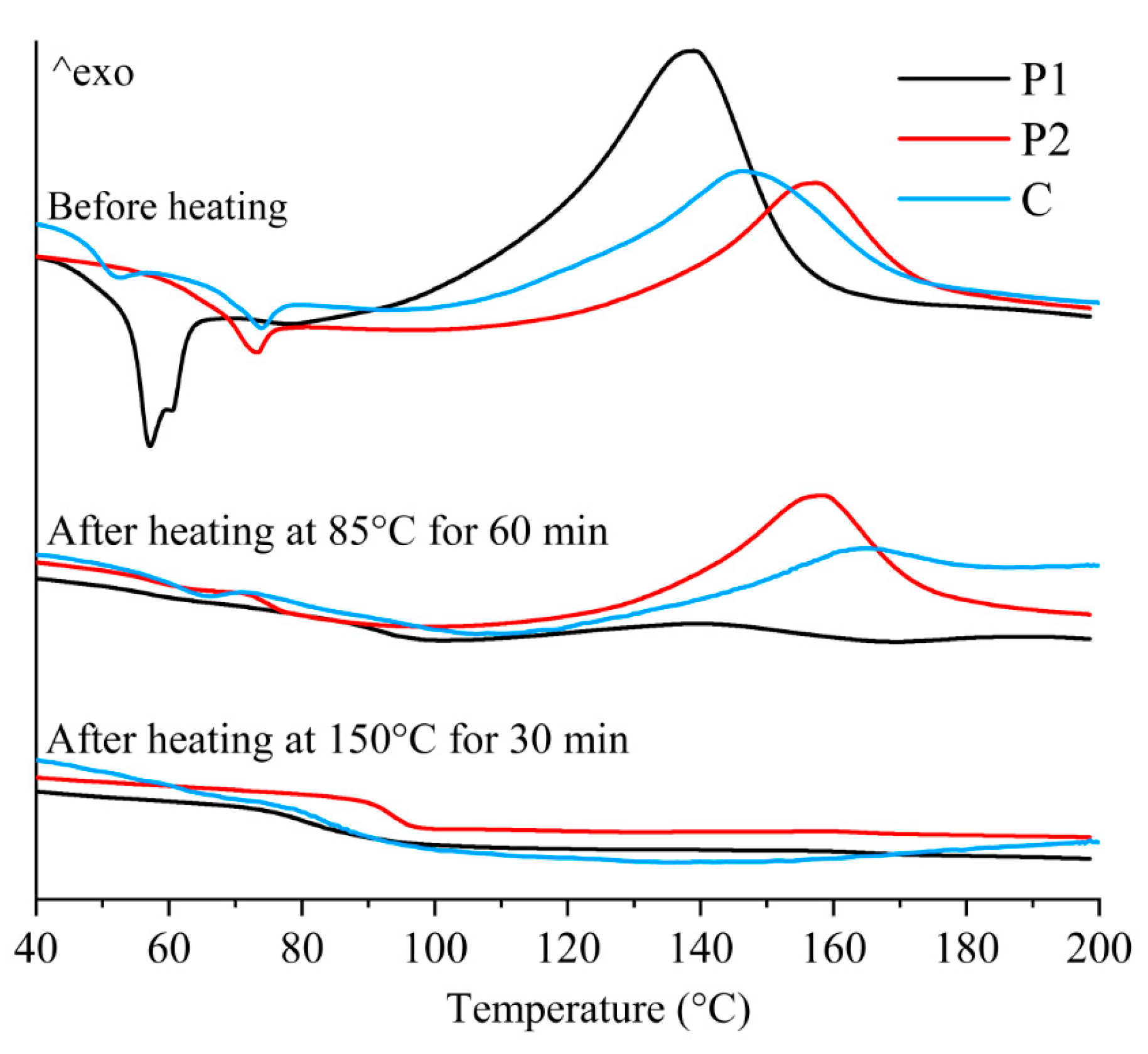

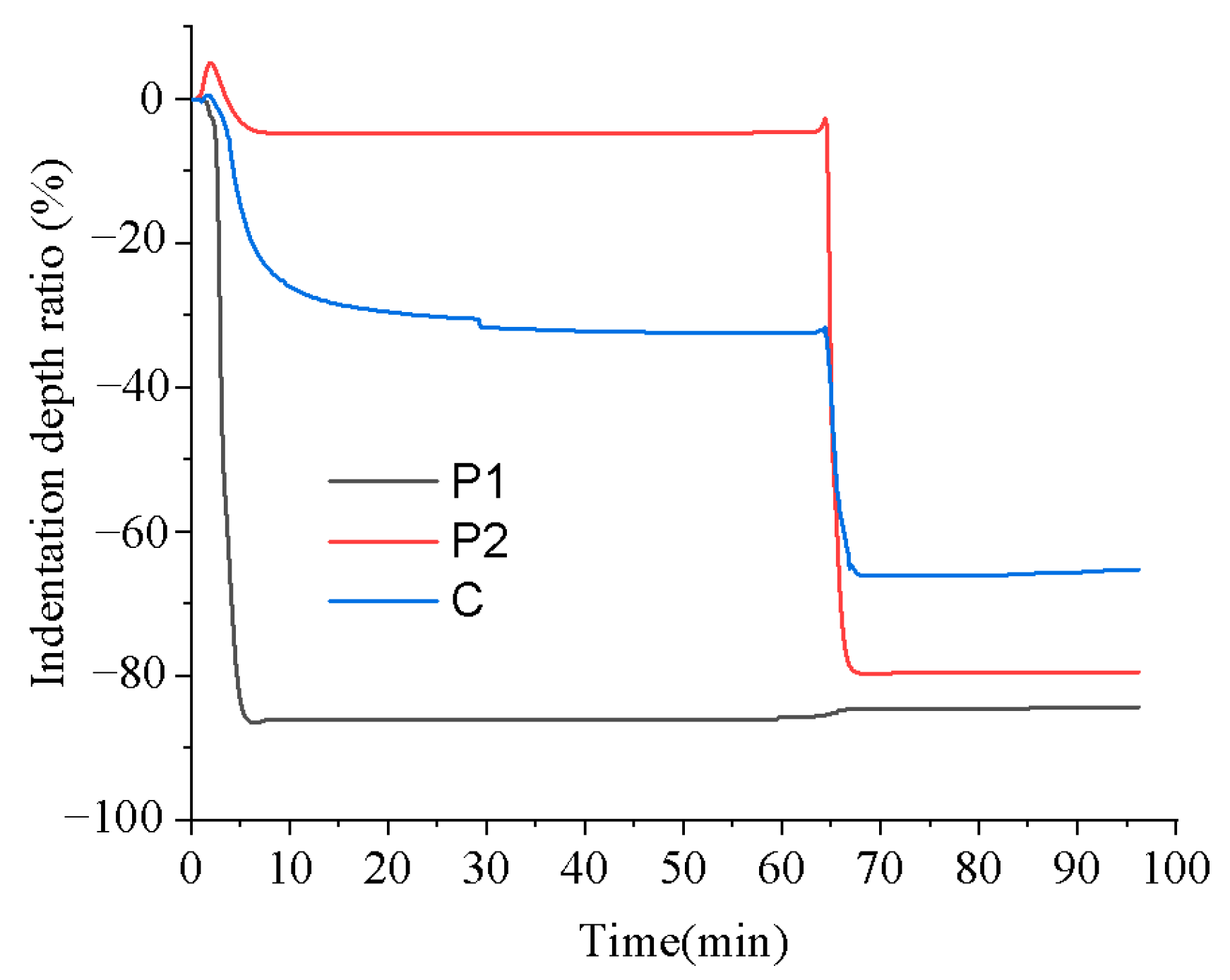

3.2. Deposition and Curing Mechanism Analysis

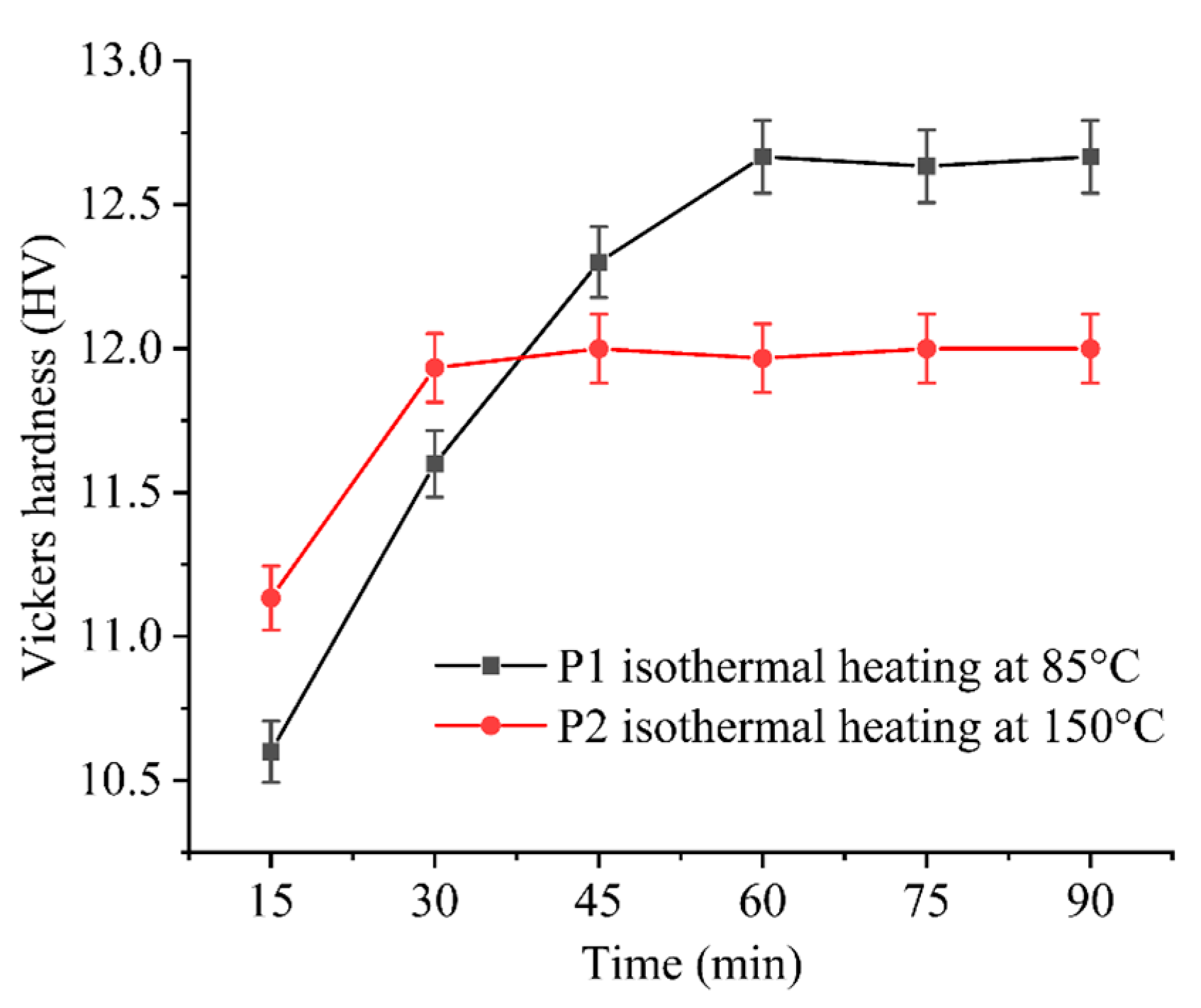

3.3. Mechanical Property Evaluation

4. Conclusions

- (1)

- The samples printed using P1, P2, and C remained solid throughout the CSAM process. During the progressive curing, the samples printed using C showed better deformation resistance than those using P1 and P2, and the mechanical properties after the progressive curing were comparable to those using low temperature-rate curing methods, while the curing time was reduced from 16.7 h to 1.5 h.

- (2)

- During the CSAM process, severe plastic deformation occurred because of the high-speed particle impact, accompanied by heat generation, which led to local melting to promote a good bond at the contact surface of the particles and form small pores.

- (3)

- During the stepwise curing process, the sequential curing reactions of P1 and P2 components in composite C allowed the uncured P2 and cured P1 to alternately remain solid, providing structural support and minimizing deformation in the stepwise curing process.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- D’Aloia, A.G.; Proietti, A.; Bidsorkhi, H.C.; Tamburrano, A.; de Bellis, G.; Marra, F.; Bregnocchi, A.; Sarto, M.S. Electrical, mechanical and electromechanical properties of graphene-thermoset polymer composites produced using acetone-DMF solvents. Polymers 2018, 10, 82. [Google Scholar] [CrossRef]

- Daungkumsawat, J.; Okhawilai, M.; Charoensuk, K.; Prastowo, R.B.; Jubsilp, C.; Karagiannidis, P.; Rimdusit, S. Development of lightweight and high-performance ballistic helmet based on poly (benzoxazine-co-urethane) matrix reinforced with aramid fabric and multi-walled carbon nanotubes. Polymers 2020, 12, 2897. [Google Scholar] [CrossRef] [PubMed]

- Morici, E.; Dintcheva, N.T. Recycling of thermoset materials and thermoset-based composites: Challenge and opportunity. Polymers 2022, 14, 4153. [Google Scholar] [CrossRef]

- Han, D.; Yang, C.; Fang, N.X.; Lee, H. Rapid multi-material 3D printing with projection micro-stereolithography using dynamic fluidic control. Addit. Manuf. 2019, 27, 606–615. [Google Scholar] [CrossRef]

- Sano, Y.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of discontinuous and continuous fibre composites using stereolithography. Addit. Manuf. 2018, 24, 521–527. [Google Scholar] [CrossRef]

- Lei, D.; Yang, Y.; Liu, Z.; Chen, S.; Song, B.; Shen, A.; Yang, B.; Li, S.; Yuan, Z.; Qi, Q.; et al. A general strategy of 3D printing thermosets for diverse applications. Mater. Horiz. 2019, 6, 394–404. [Google Scholar] [CrossRef]

- Yuan, J.; Chen, C.; Yao, D.; Chen, G. 3D printing of oil paintings based on material jetting and its reduction of staircase effect. Polymers 2020, 12, 2536. [Google Scholar] [CrossRef]

- Tamez, M.B.A.; Taha, I. A review of additive manufacturing technologies and markets for thermosetting resins and their potential for carbon fiber integration. Addit. Manuf. 2021, 37, 101748. [Google Scholar] [CrossRef]

- Jiang, P.; Ji, Z.; Zhang, X.; Liu, Z.; Wang, X. Recent advances in direct ink writing of electronic components and functional devices. Prog. Addit. Manuf. 2018, 3, 65–86. [Google Scholar] [CrossRef]

- Casanova-Batlle, E.; Guerra, A.J.; Ciurana, J. Continuous based direct ink write for tubular cardiovascular medical devices. Polymers 2020, 13, 77. [Google Scholar] [CrossRef] [PubMed]

- Rosenthal, M.; Henneberger, C.; Gutkes, A.; Bues, C.-T. Liquid deposition modeling: A promising approach for 3D printing of wood. Eur. J. Wood Prod. 2018, 76, 797–799. [Google Scholar] [CrossRef]

- Yang, H.; Ji, F.; Li, Z.; Tao, S. Preparation of hydrophobic surface on PLA and ABS by fused deposition modeling. Polymers 2020, 12, 1539. [Google Scholar] [CrossRef]

- Compton, B.G.; Lewis, J.A. 3D-printing of lightweight cellular composites. Adv. Mater. 2014, 26, 5930–5935. [Google Scholar] [CrossRef]

- Zeng, Z.; Deng, X.; Cui, J.; Jiang, H.; Yan, S.; Peng, B. Improvement on selective laser sintering and post-processing of polystyrene. Polymers 2019, 11, 956. [Google Scholar] [CrossRef] [PubMed]

- Wudy, K.; Drummer, D. Infiltration behavior of thermosets for use in a combined selective laser sintering process of polymers. JOM 2019, 71, 920–927. [Google Scholar] [CrossRef]

- Burgos Pintos, P.; Moreno Sánchez, D.; Delgado, F.J.; Sanz de León, A.; Molina, S.I. Influence of the carbon fiber length distribution in polymer matrix composites for large format additive manufacturing via fused granular fabrication. Polymers 2023, 16, 60. [Google Scholar] [CrossRef]

- Fontana, L.; Giubilini, A.; Arrigo, R.; Malucelli, G.; Minetola, P. Characterization of 3D printed polylactic acid by fused granular fabrication through printing accuracy, porosity, thermal and mechanical analyses. Polymers 2022, 14, 3530. [Google Scholar] [CrossRef]

- Li, W.; Yang, K.; Yin, S.; Yang, X.; Xu, Y.; Lupoi, R. Solid-state additive manufacturing and repairing by cold spraying: A review. J. Mater. Sci. Technol. 2018, 34, 440–457. [Google Scholar] [CrossRef]

- Bagherifard, S.; Monti, S.; Zuccoli, M.V.; Riccio, M.; Kondás, J.; Guagliano, M. Cold spray deposition for additive manufacturing of freeform structural components compared to selective laser melting. Mater. Sci. Eng. A Struct. Mater. 2018, 721, 339–350. [Google Scholar] [CrossRef]

- Ravi, K.; Deplancke, T.; Ogawa, K.; Cavaillé, J.-Y.; Lame, O. Understanding deposition mechanism in cold sprayed ultra high molecular weight polyethylene coatings on metals by isolated particle deposition method. Addit. Manuf. 2018, 21, 191–200. [Google Scholar] [CrossRef]

- Khalkhali, Z.; Rothstein, J.P. Characterization of the cold spray deposition of a wide variety of polymeric powders. Surf. Coat. Technol. 2020, 383, 125251. [Google Scholar] [CrossRef]

- ISO 16700:2016; Microbeam Analysis—Scanning Electron Microscopy—Guidelines for Calibrating Image Magnification. ISO: Geneva, Switzerland, 2016.

- ASTM E384-17; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Sova, A.; Kosarev, V.F.; Papyrin, A.; Smurov, I. Effect of ceramic particle velocity on cold spray deposition of metal-ceramic coatings. J. Therm. Spray Tech. 2011, 20, 285–291. [Google Scholar] [CrossRef]

- Winnicki, M. Advanced functional metal-ceramic and ceramic coatings deposited by low-pressure cold spraying: A review. Coatings 2021, 11, 1044. [Google Scholar] [CrossRef]

- Assadi, H.; Schmidt, T.; Richter, H.; Kliemann, J.-O.; Binder, K.; Gärtner, F.; Klassen, T.; Kreye, H. On parameter selection in cold spraying. J. Therm. Spray Tech. 2011, 20, 1161–1176. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.; Tong, C.; DeRosset, W.; Helfritch, D. Analysis of the impact velocity of powder particles in the cold-gas dynamic-spray process. Mater. Sci. Eng. A Struct. Mater. 2004, 368, 222–230. [Google Scholar] [CrossRef]

- Zahiri, S.H.; Antonio, C.I.; Jahedi, M. Elimination of porosity in directly fabricated titanium via cold gas dynamic spraying. J. Mater. Process. Technol. 2009, 209, 922–929. [Google Scholar] [CrossRef]

- Ren, Y.Q.; King, P.C.; Yang, Y.S.; Xiao, T.Q.; Chu, C.; Gulizia, S.; Murphy, A.B. Characterization of heat treatment-induced pore structure changes in cold-sprayed titanium. Mater. Charact. 2017, 132, 69–75. [Google Scholar] [CrossRef]

- Hong, B.; Wang, K.; Gu, P. Cold spray-based additive manufacturing of thermosets. J. Therm. Spray Tech. 2022, 31, 2003–2012. [Google Scholar] [CrossRef]

- Wicks, D.A.; Wicks, Z.W. Blocked isocyanates III: Part A. Mechanisms and chemistry. Prog. Org. Coat. 1999, 36, 148–172. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, B.; Wang, K.; Li, Y.; Ren, S.; Gu, P. Solid State Additive Manufacturing of Thermoset Composites. Polymers 2024, 16, 2416. https://doi.org/10.3390/polym16172416

Hong B, Wang K, Li Y, Ren S, Gu P. Solid State Additive Manufacturing of Thermoset Composites. Polymers. 2024; 16(17):2416. https://doi.org/10.3390/polym16172416

Chicago/Turabian StyleHong, Bo, Kaifeng Wang, Yang Li, Shuhan Ren, and Peihua Gu. 2024. "Solid State Additive Manufacturing of Thermoset Composites" Polymers 16, no. 17: 2416. https://doi.org/10.3390/polym16172416

APA StyleHong, B., Wang, K., Li, Y., Ren, S., & Gu, P. (2024). Solid State Additive Manufacturing of Thermoset Composites. Polymers, 16(17), 2416. https://doi.org/10.3390/polym16172416