Enhancing Blue Polymer Light-Emitting Diode Performance by Optimizing the Layer Thickness and the Insertion of a Hole-Transporting Layer

Abstract

1. Introduction

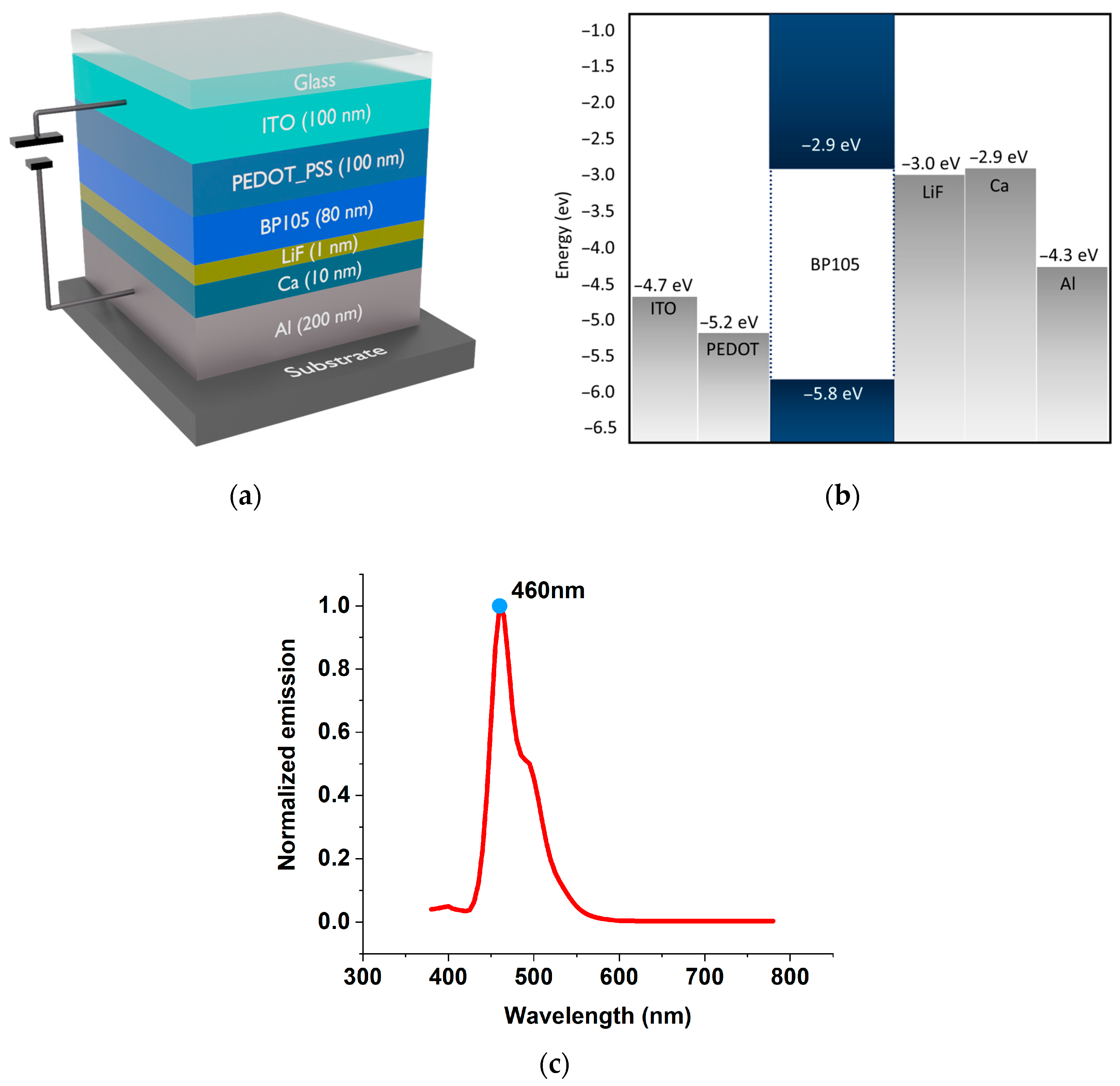

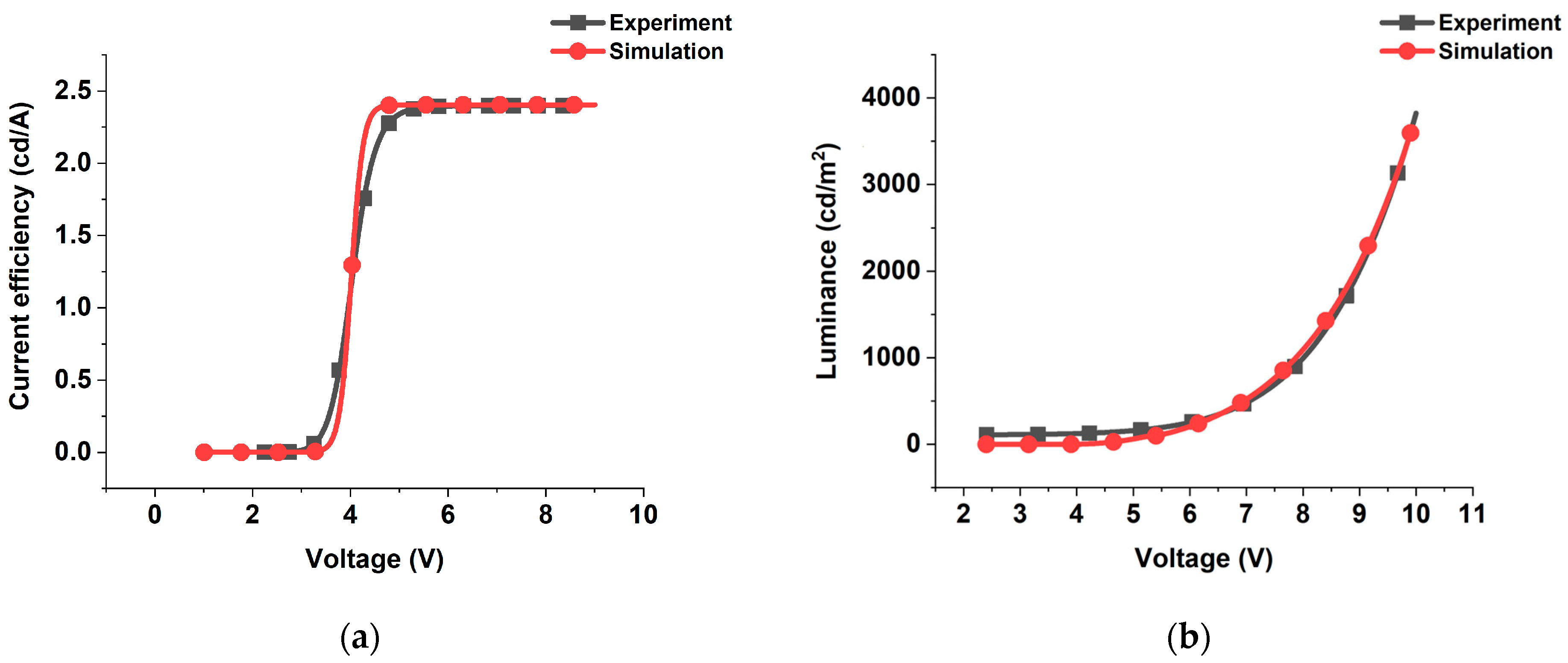

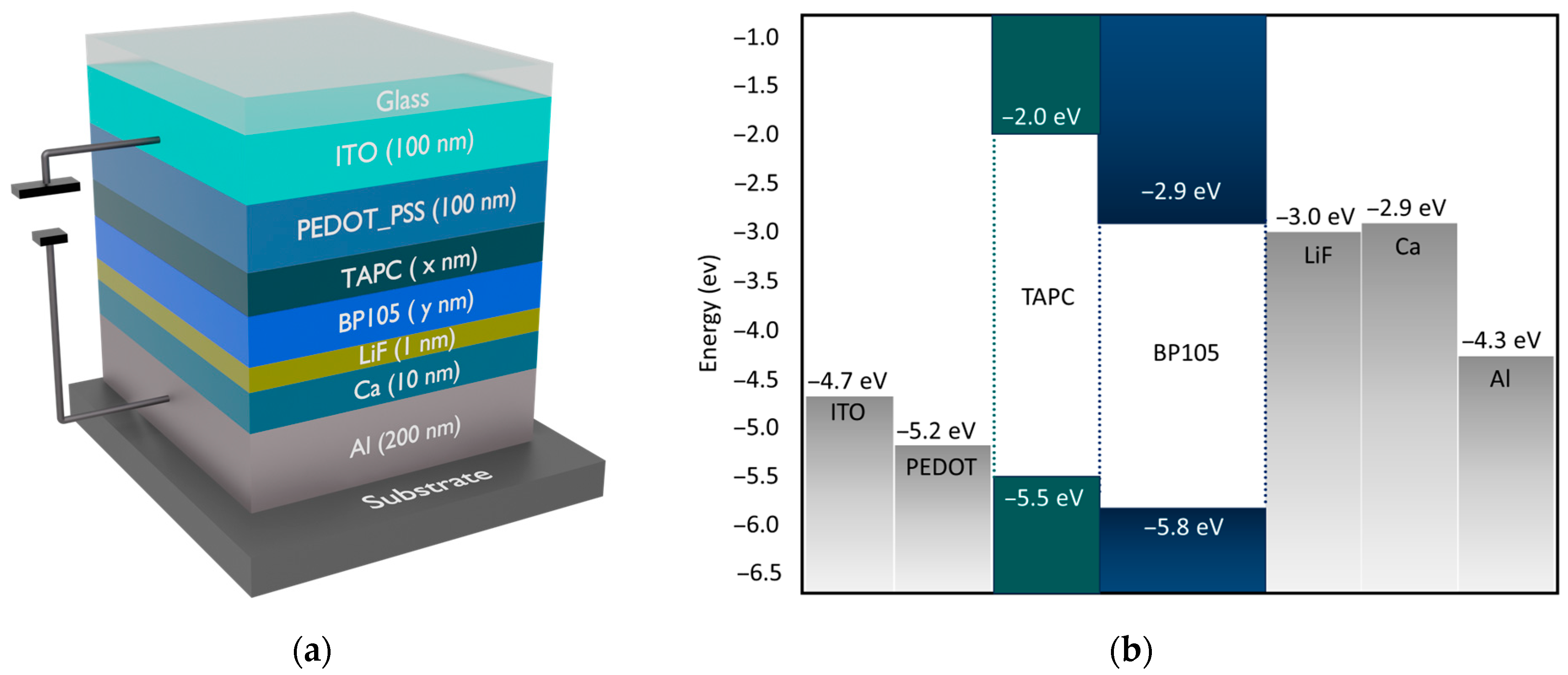

2. Numerical Simulation of the Experimental Model

3. Device Optimization

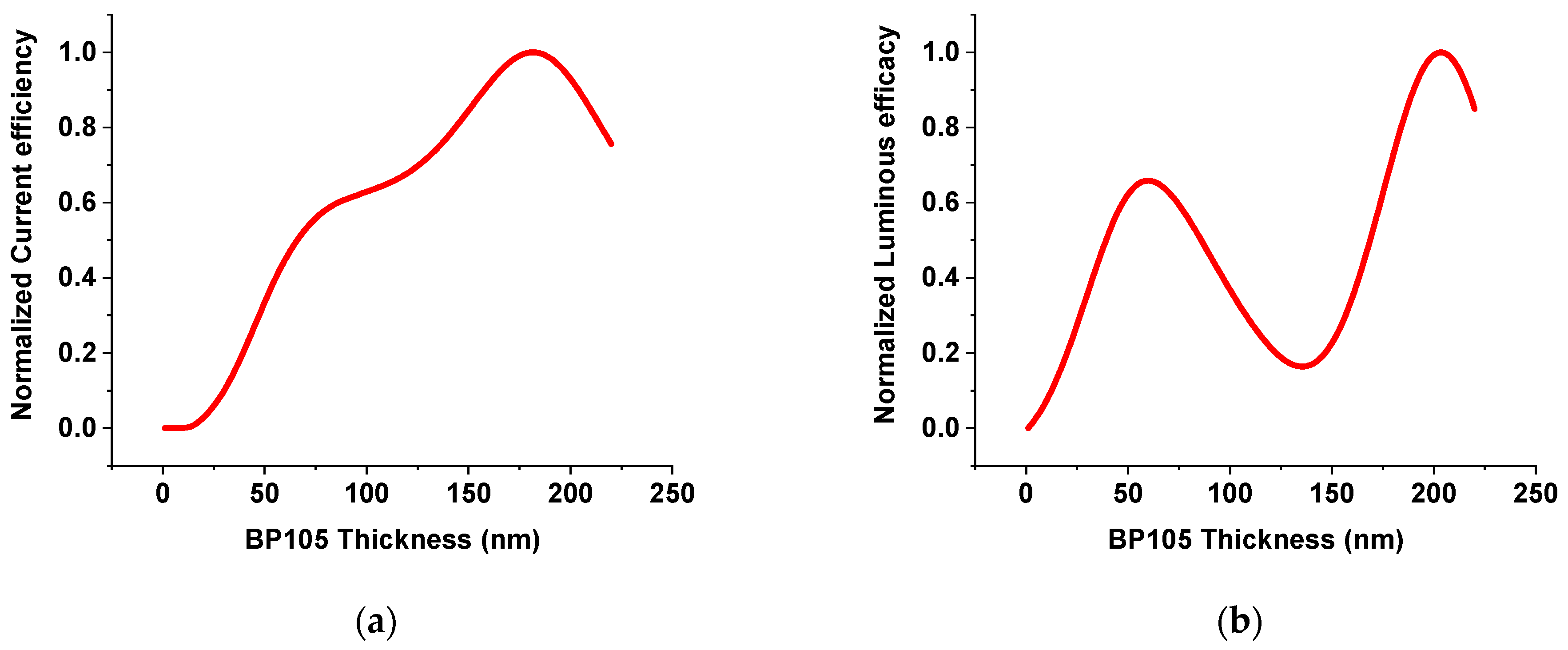

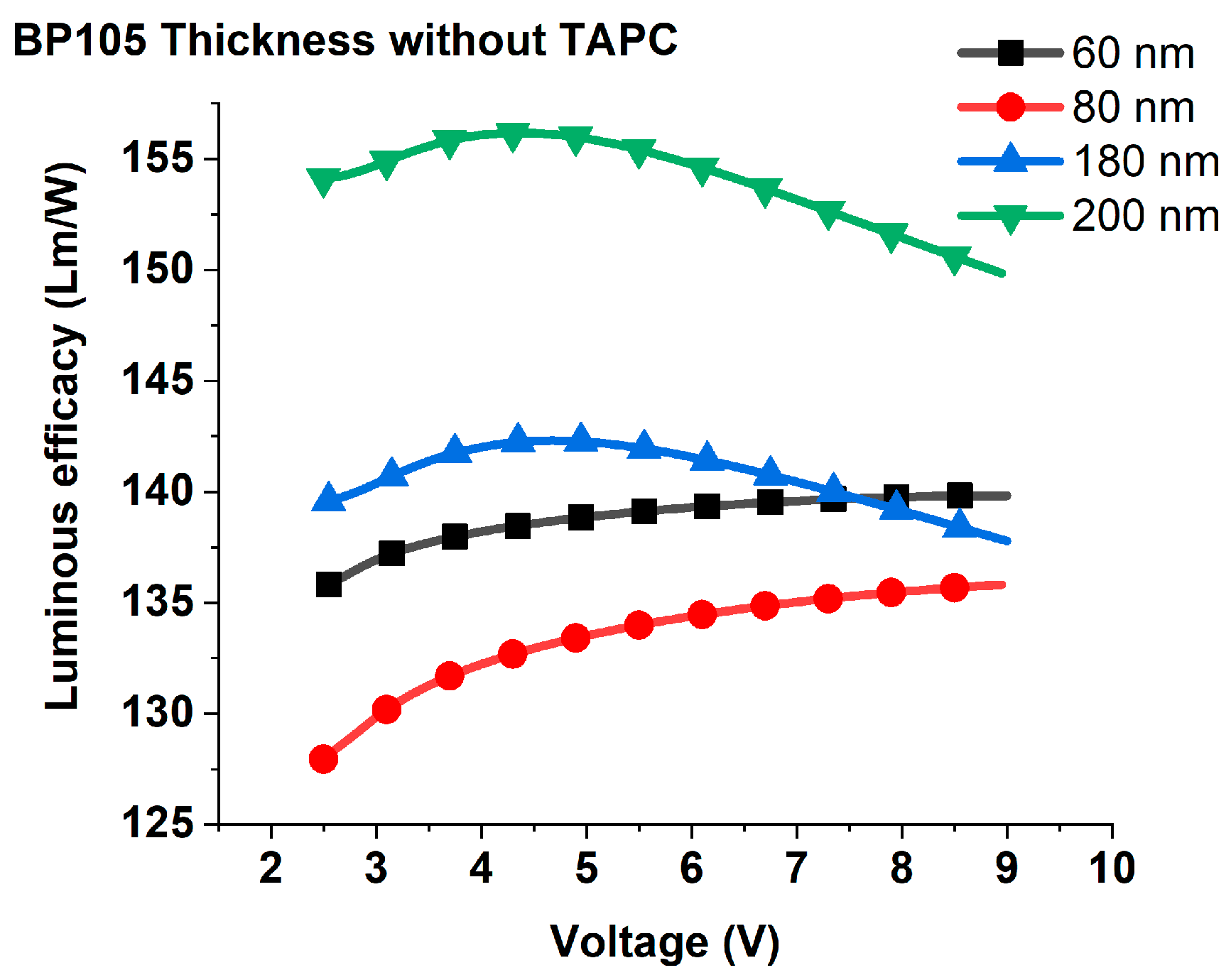

3.1. Varying Thickness of Active Layer

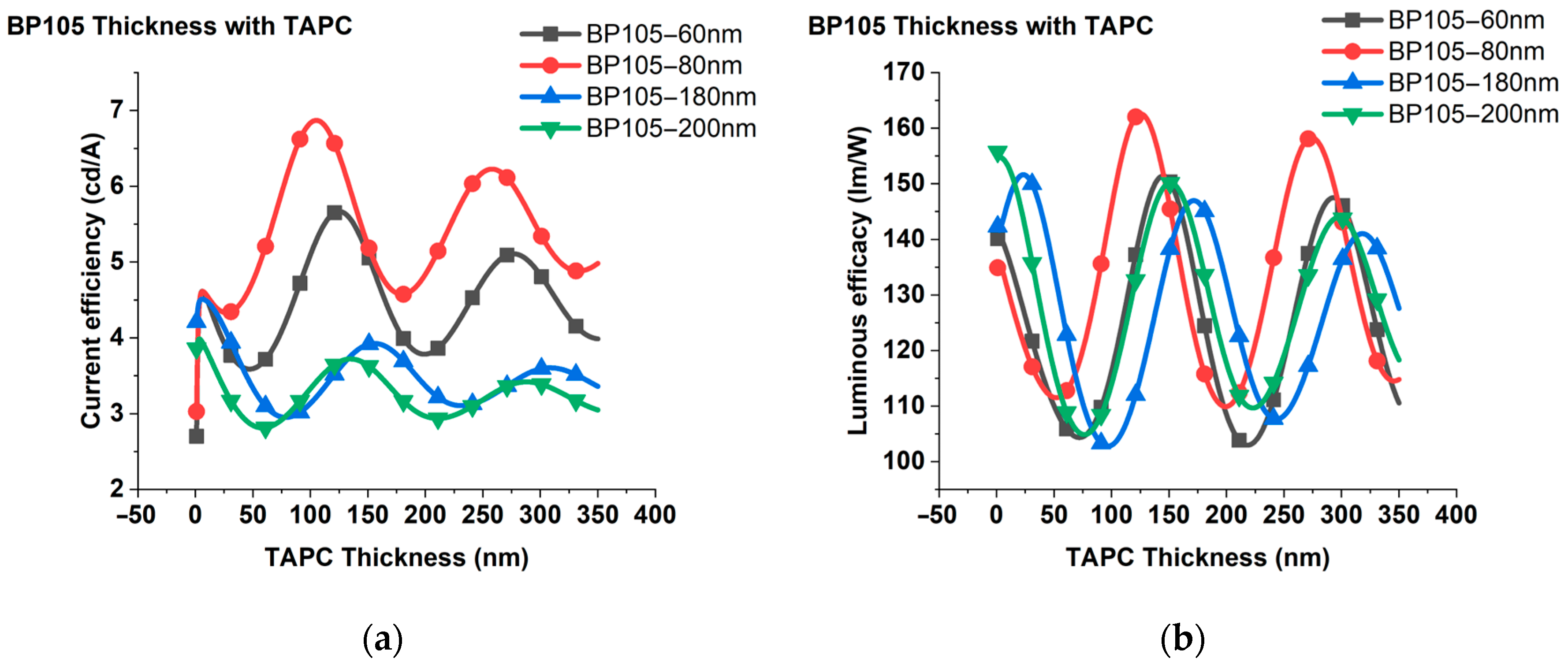

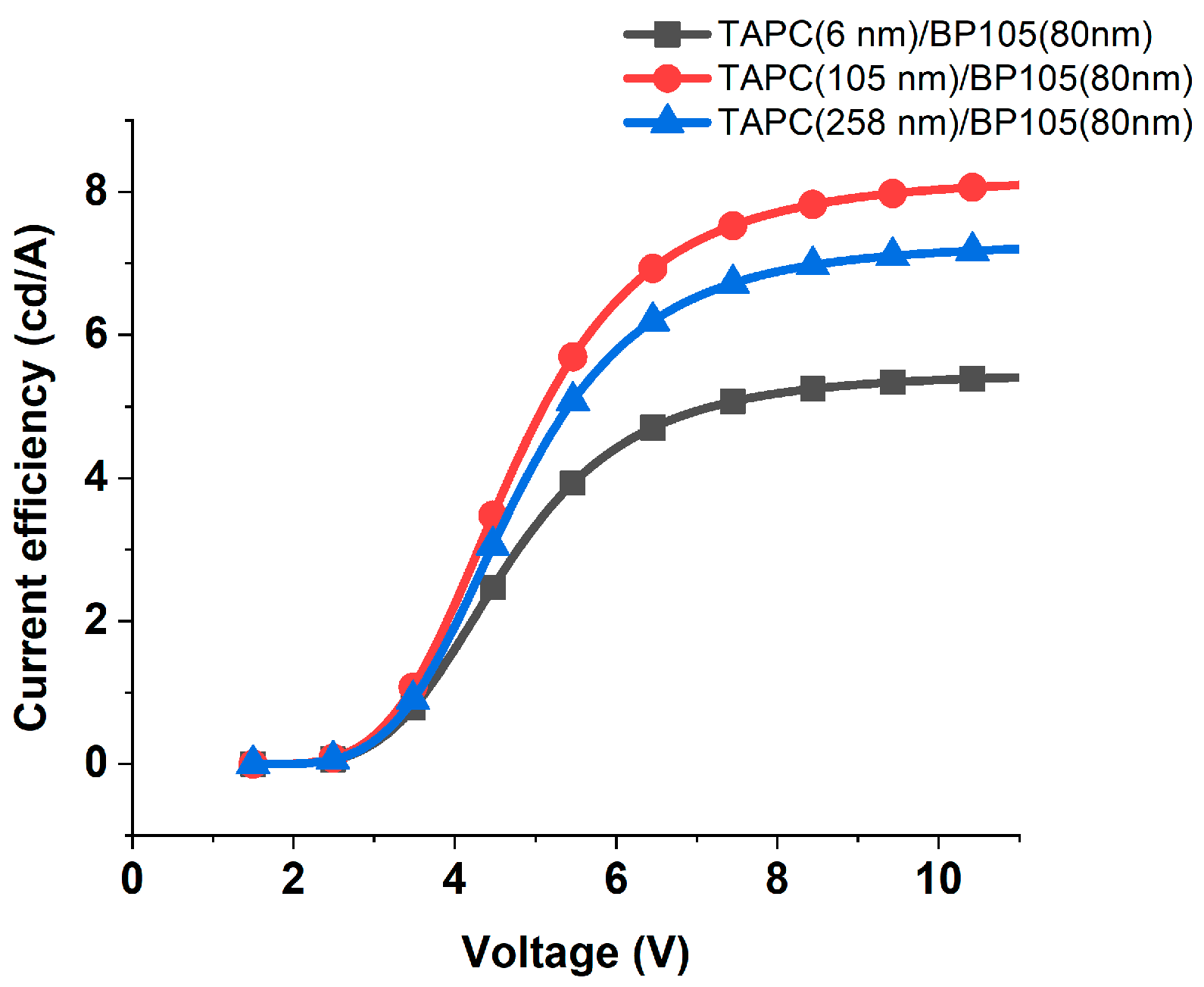

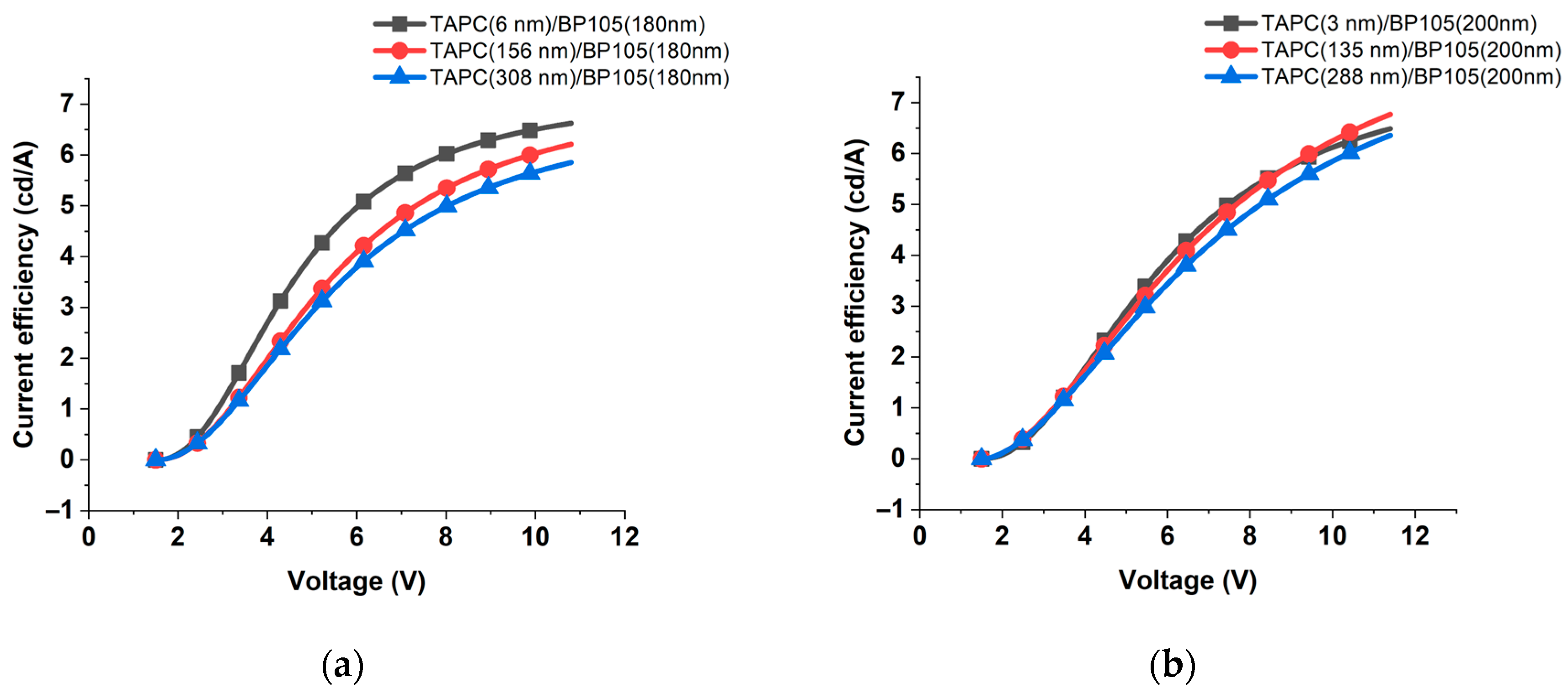

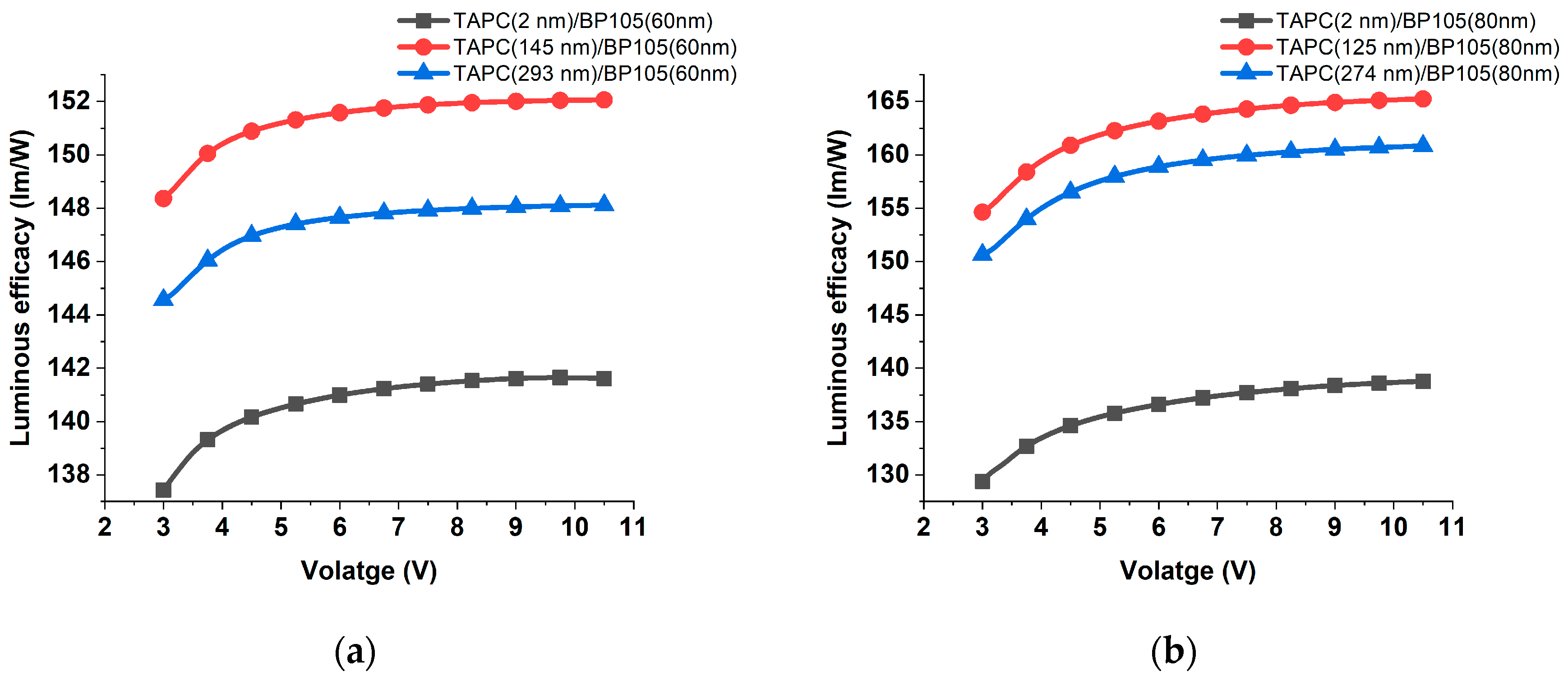

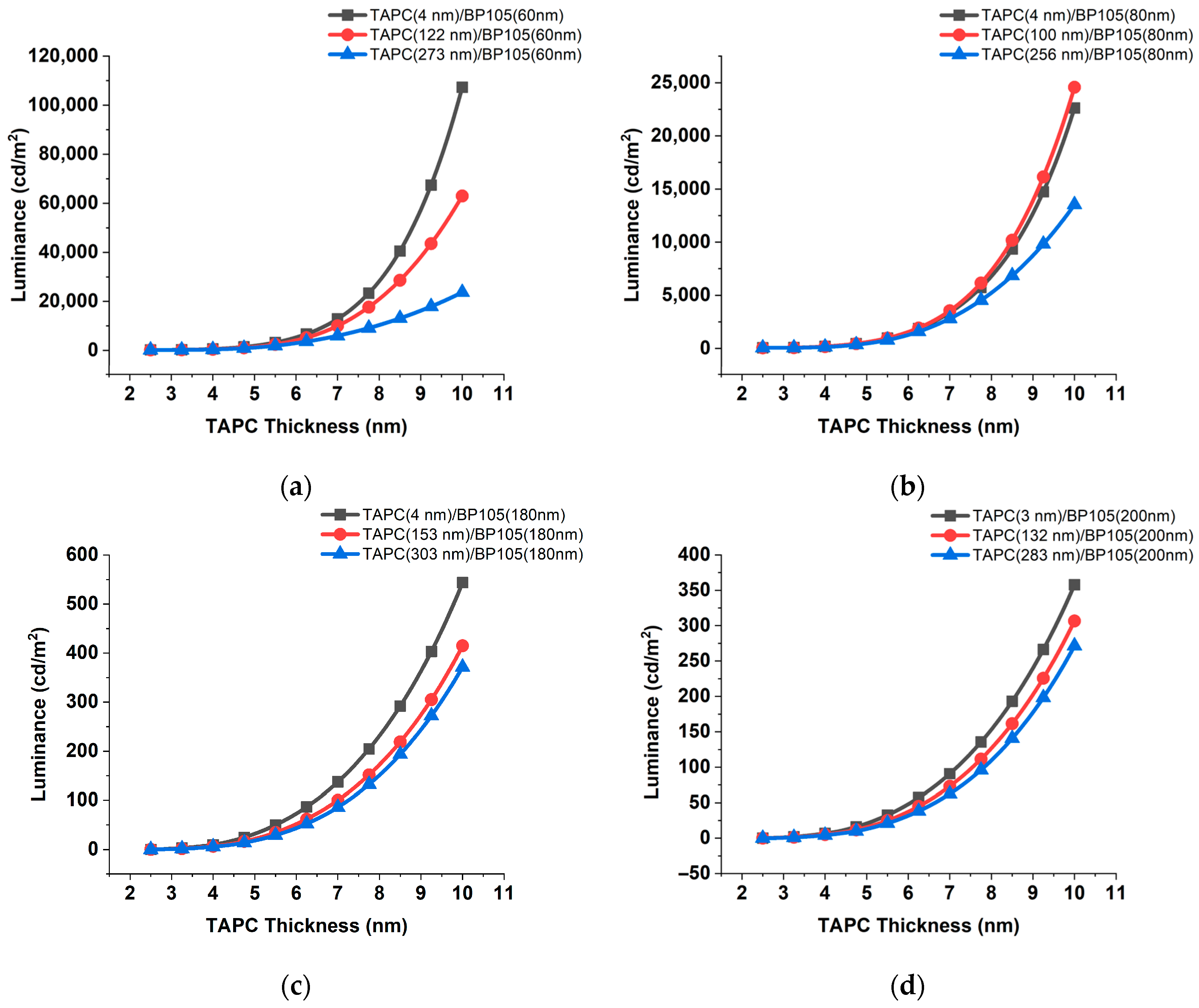

3.2. Effect of Insertion of HTL Layer on the Performance of the OLED

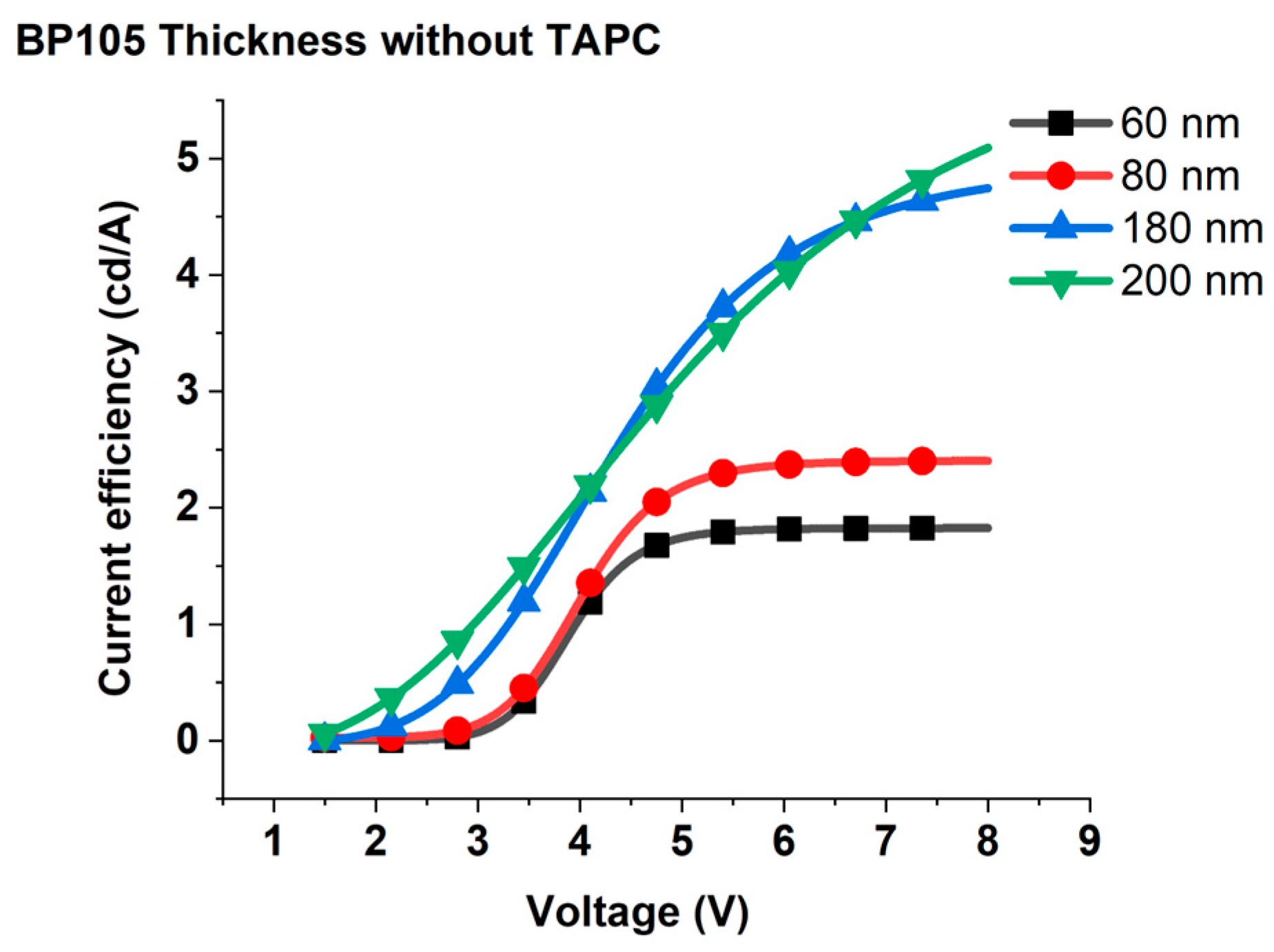

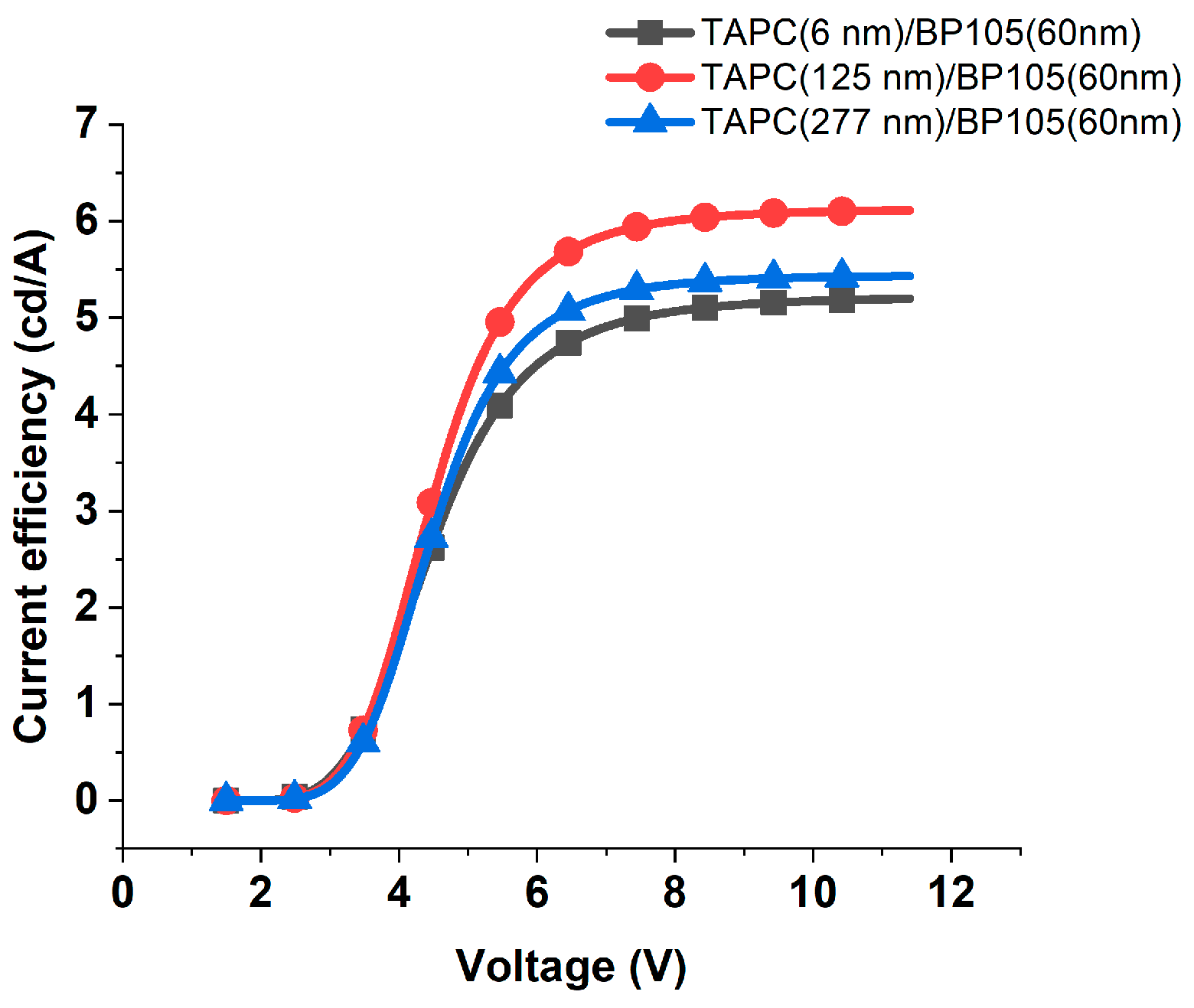

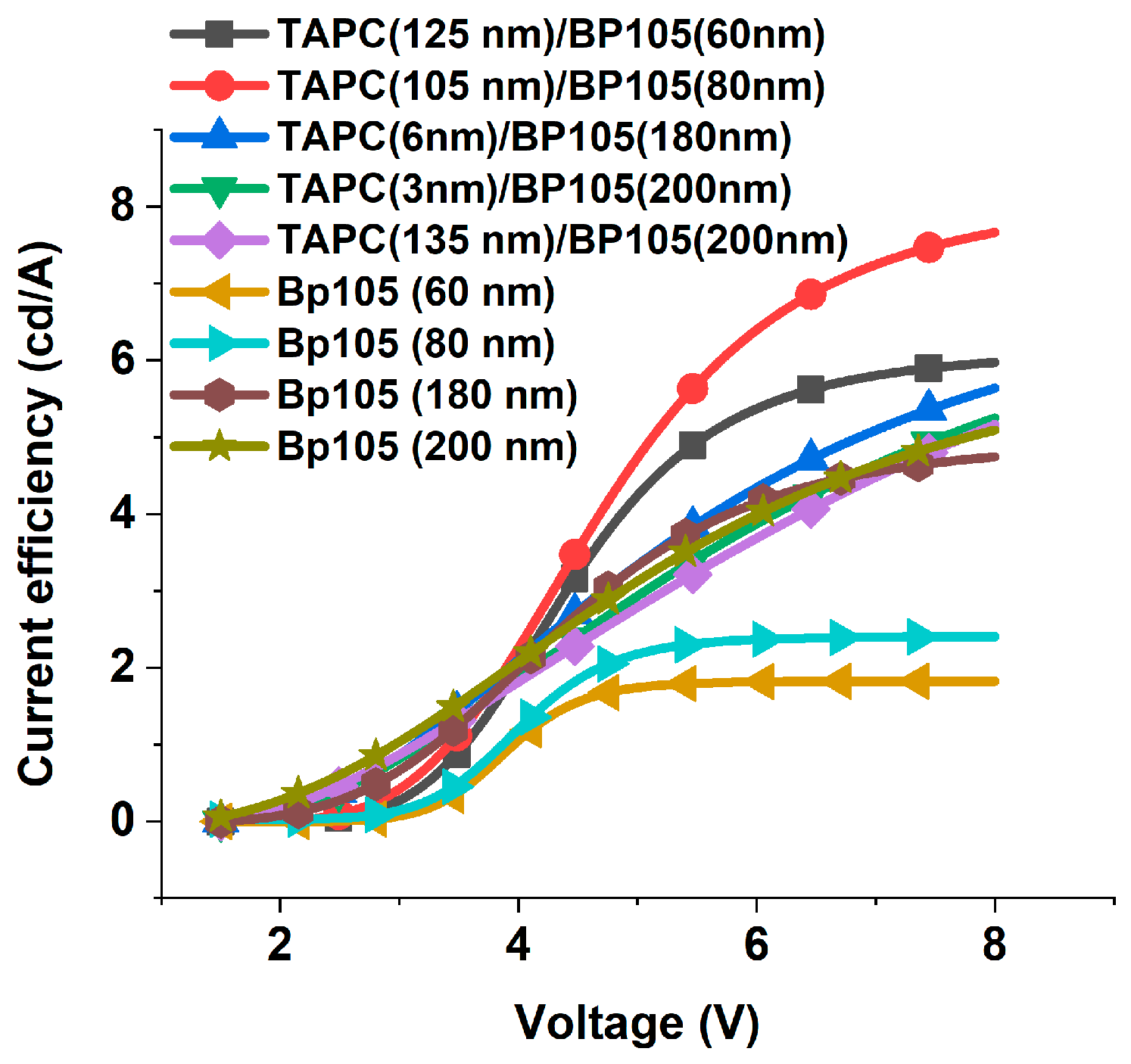

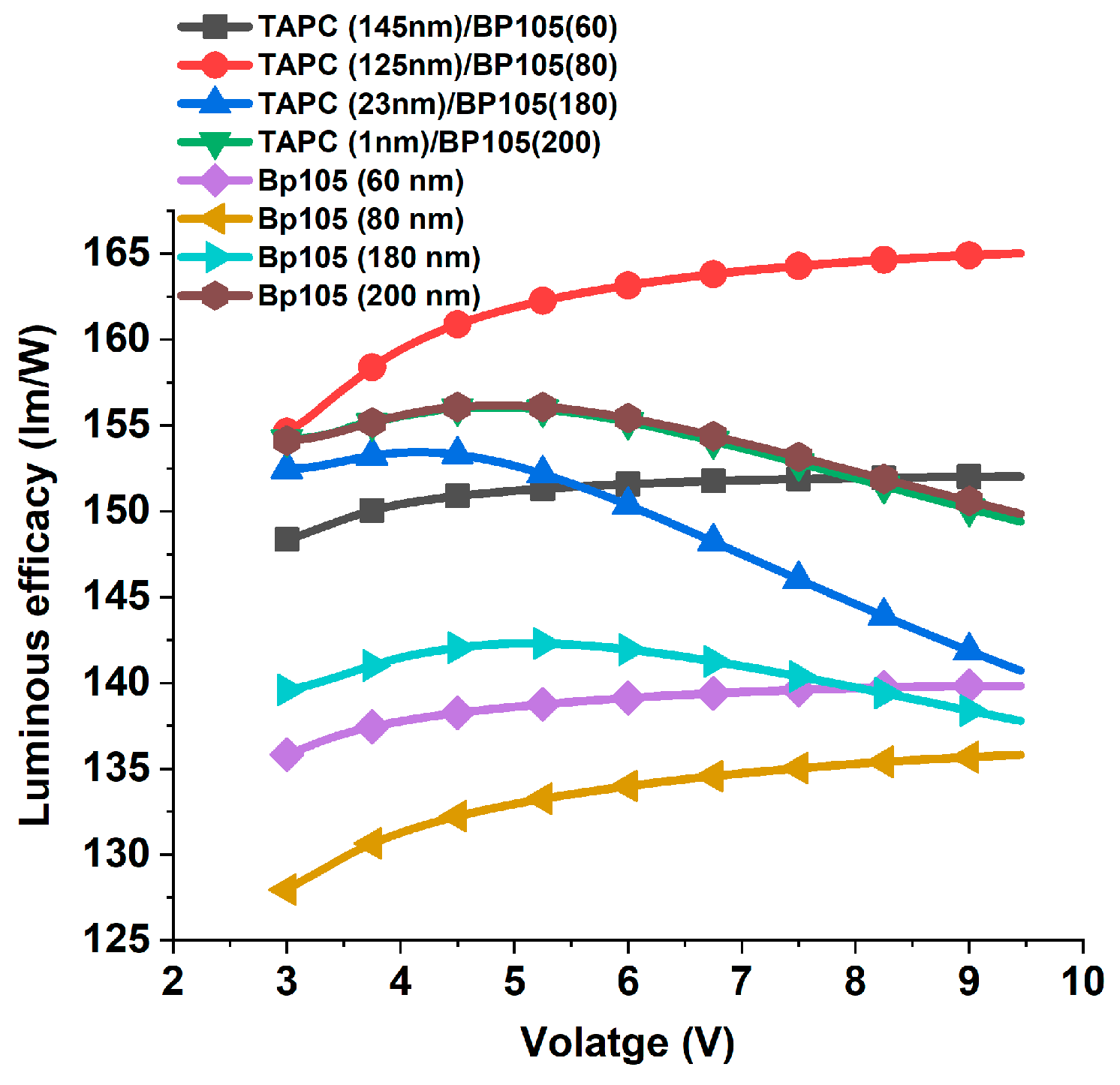

3.3. Comparison of the Performance of the PLED with and without TAPC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| OLED | Organic Light-Emitting Diode |

| HTL | Hole-transport Layer |

| ETL | Electron Transport Layer |

| EML | Emission Layer |

| EGDM | Extended Gaussian Disorder Model |

| DOS | Density of States |

| ITO | Indium Tin Oxide |

| PEDOT:PSS | Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate |

| TAPC | 1,1-bis[(di-4-tolylamino)phenyl]cyclohexane (a common HTL material) |

| BP105 | A specific blue-emitting polymer |

| LiF | Lithium Fluoride |

| Ca | Calcium |

| Al | Aluminum |

References

- Friend, R.H.; Gymer, R.W.; Holmes, A.B.; Burroughes, J.H.; Marks, R.N.; Taliani, C.; Bradley, D.D.C.; Dos Santos, D.A.; Brédas, J.L.; Lögdlund, M.; et al. Electroluminescence in conjugated polymers. Nature 1999, 397, 121–128. [Google Scholar] [CrossRef]

- Méhes, G.; Sandanayaka, A.S.D.; Ribierre, J.-C.; Goushi, K. Physics and Design Principles of OLED Devices. In Handbook of Organic Light-Emitting Diodes; Springer: Tokyo, Japan, 2020; pp. 1–73. [Google Scholar] [CrossRef]

- Movla, H.; Ghaffari, S.; Ahmadinasab, H. Effects of the active region thickness on the exciton generation mechanisms in polymer light emitting diodes. Optik 2016, 127, 1814–1816. [Google Scholar] [CrossRef]

- Dahal, E.; Allemeier, D.; Isenhart, B.; Cianciulli, K.; White, M.S. Characterization of higher harmonic modes in Fabry–Pérot microcavity organic light emitting diodes. Sci. Rep. 2021, 11, 8456. [Google Scholar] [CrossRef] [PubMed]

- Papatryfonos, K.; de Oliveira, E.R.C.; Lanzillotti-Kimura, N.D. Effects of surface roughness and top layer thickness on the performance of Fabry-Perot cavities and responsive open resonators based on distributed Bragg reflectors. arXiv 2024, arXiv:2309.13649. [Google Scholar] [CrossRef]

- Hong, K.; Lee, J.-L. Review paper: Recent developments in light extraction technologies of organic light emitting diodes. Electron. Mater. Lett. 2011, 7, 77–91. [Google Scholar] [CrossRef]

- Siddiqui, I.; Kumar, S.; Tsai, Y.-F.; Gautam, P.; Shahnawaz; Kesavan, K.; Lin, J.-T.; Khai, L.; Chou, K.-H.; Choudhury, A.; et al. Status and Challenges of Blue OLEDs: A Review. Nanomaterials 2023, 13, 2521. [Google Scholar] [CrossRef] [PubMed]

- ZGarza, C.F.; Born, M.; Hilbers, P.A.J.; van Riel, N.A.W.; Liebmann, J. Visible Blue Light Therapy: Molecular Mechanisms and Therapeutic Opportunities. Curr. Med. Chem. 2019, 25, 5564–5577. [Google Scholar] [CrossRef]

- Prasad, A.; Du, L.; Zubair, M.; Subedi, S.; Ullah, A.; Roopesh, M.S. Applications of Light-Emitting Diodes (LEDs) in Food Processing and Water Treatment. Food Eng. Rev. 2020, 12, 268–289. [Google Scholar] [CrossRef]

- Lee, S.H.; Won, H.J.; Ban, S.; Choi, H.; Jung, J.H. Tomato Fruit Growth and Nutrient Accumulation in Response to Blue and Red Light Treatments during the Reproductive Growth Stage. Horticulturae 2023, 9, 1113. [Google Scholar] [CrossRef]

- Fluxim, A.G. Simulation Software Setfos (Version 5.4). Available online: www.fluxim.com (accessed on 28 May 2024).

- Tseng, S.-R.; Meng, H.-F.; Yeh, C.-H.; Lai, H.-C.; Horng, S.-F.; Liao, H.-H.; Hsu, C.-S.; Lin, L.-C. High-efficiency blue multilayer polymer light-emitting diode fabricated by a general liquid buffer method. Synth. Met. 2008, 158, 130–134. [Google Scholar] [CrossRef]

- Huang, P.; Chou, C.; Chang, M.; Huang, W.; Lee, C.; Han, Y.; Liu, S. The Effect of Controlled Dopant Concentration on the Performance of Blue Polymer Light-emitting Diodes. J. Chin. Chem. Soc. 2011, 58, 326–331. [Google Scholar] [CrossRef]

- Neukom, M.; Züfle, S.; Jenatsch, S.; Ruhstaller, B. Opto-electronic characterization of third-generation solar cells. Sci. Technol. Adv. Mater. 2018, 19, 291–316. [Google Scholar] [CrossRef] [PubMed]

- Knapp, E.; Ruhstaller, B. The role of shallow traps in dynamic characterization of organic semiconductor devices. J. Appl. Phys. 2012, 112, 024519. [Google Scholar] [CrossRef]

- Ruhstaller, B.; Carter, S.A.; Barth, S.; Riel, H.; Riess, W.; Scott, J.C. Transient and steady-state behavior of space charges in multilayer organic light-emitting diodes. J. Appl. Phys. 2001, 89, 4575–4586. [Google Scholar] [CrossRef]

- Ruhstaller, B.; Knapp, E.; Perucco, B.; Reinke, N.; Rezzonico, D.; Mller, F. Advanced Numerical Simulation of Organic Light-emitting Devices. In Optoelectronic Devices and Properties; InTech: Houston, TX, USA, 2011. [Google Scholar] [CrossRef]

- Altazin, S.; Penninck, L.; Ruhstaller, B. Outcoupling Technologies: Concepts, Simulation, and Implementation. In Handbook of Organic Light-Emitting Diodes; Springer: Tokyo, Japan, 2018; pp. 1–22. [Google Scholar] [CrossRef]

- van Mensfoort, S.L.M.; Billen, J.; Carvelli, M.; Vulto, S.I.E.; Janssen, R.A.J.; Coehoorn, R. Predictive modeling of the current density and radiative recombination in blue polymer-based light-emitting diodes. J. Appl. Phys. 2011, 109, 064502. [Google Scholar] [CrossRef]

- Cheng, H.; Feng, Y.; Fu, Y.; Zheng, Y.; Shao, Y.; Bai, Y. Understanding and minimizing non-radiative recombination losses in perovskite light-emitting diodes. J. Mater. Chem. C Mater. 2022, 10, 13590–13610. [Google Scholar] [CrossRef]

- Ahmad, V.; Sobus, J.; Greenberg, M.; Shukla, A.; Philippa, B.; Pivrikas, A.; Vamvounis, G.; White, R.; Lo, S.-C.; Namdas, E.B. Charge and exciton dynamics of OLEDs under high voltage nanosecond pulse: Towards injection lasing. Nat. Commun. 2020, 11, 4310. [Google Scholar] [CrossRef] [PubMed]

- Hart, K.; Hart, S.; Selvaggi, J.P. Modified charge carrier density for organic semiconductors modeled by an exponential density of states. J. Comput. Electron. 2021, 20, 259–266. [Google Scholar] [CrossRef]

- Tian, Y.; Gan, Z.; Zhou, Z.; Lynch, D.W.; Shinar, J.; Kang, J.-H.; Park, Q.-H. Spectrally narrowed edge emission from organic light-emitting diodes. Appl. Phys. Lett. 2007, 91, 143504. [Google Scholar] [CrossRef]

- Jiang, N.; Ma, G.; Song, D.; Qiao, B.; Liang, Z.; Xu, Z.; Wageh, S.; Al Ghamdi, A.A.; Zhao, S. Defects in lead halide perovskite light-emitting diodes under electric field: From behavior to passivation strategies. Nanoscale 2024, 16, 3838–3880. [Google Scholar] [CrossRef] [PubMed]

| BP105 Thickness (Peaks) | TAPC Thickness (Peaks) | |||

|---|---|---|---|---|

| Current Efficiency | Luminous Efficacy | Luminance | ||

| Current efficiency | 80 nm | 6 nm | 2 nm | 4 nm |

| 105 nm * | 125 nm * | 100 nm * | ||

| 258 nm | 274 nm | 256 nm | ||

| 180 nm * | 6 nm * | 23 nm * | 4 nm * | |

| 156 nm | 171 nm | 153 nm | ||

| 308 nm | 318 nm | 303 nm | ||

| Luminous efficacy | 60 nm | 6 nm | 2 nm | 4 nm * |

| 125 nm * | 145 nm * | 122 nm | ||

| 277 nm | 293 nm | 273 nm | ||

| 200 nm * | 3 nm * | 1 nm * | 3 nm * | |

| 135 nm | 151 nm | 132 nm | ||

| 288 nm | 289 nm | 283 nm | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saad, A.; Hamad, N.; Redoy, R.A.F.; Zhao, S.; Wageh, S. Enhancing Blue Polymer Light-Emitting Diode Performance by Optimizing the Layer Thickness and the Insertion of a Hole-Transporting Layer. Polymers 2024, 16, 2347. https://doi.org/10.3390/polym16162347

Saad A, Hamad N, Redoy RAF, Zhao S, Wageh S. Enhancing Blue Polymer Light-Emitting Diode Performance by Optimizing the Layer Thickness and the Insertion of a Hole-Transporting Layer. Polymers. 2024; 16(16):2347. https://doi.org/10.3390/polym16162347

Chicago/Turabian StyleSaad, A., N. Hamad, Rasul Al Foysal Redoy, Suling Zhao, and S. Wageh. 2024. "Enhancing Blue Polymer Light-Emitting Diode Performance by Optimizing the Layer Thickness and the Insertion of a Hole-Transporting Layer" Polymers 16, no. 16: 2347. https://doi.org/10.3390/polym16162347

APA StyleSaad, A., Hamad, N., Redoy, R. A. F., Zhao, S., & Wageh, S. (2024). Enhancing Blue Polymer Light-Emitting Diode Performance by Optimizing the Layer Thickness and the Insertion of a Hole-Transporting Layer. Polymers, 16(16), 2347. https://doi.org/10.3390/polym16162347