Investigation of Toughening Mechanisms in Elastomeric Polycarbonate Blends through Morphological and Mechanical Characterization at Small and Medium Strain Rates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.2.1. PC Blending

2.2.2. Injection Molding

2.3. Material Characterization

2.3.1. Blend Morphology

2.3.2. Quasi-Static and Medium-Strain-Rate Tensile Tests

2.3.3. Impact Tests

2.3.4. Fracture Morphology

3. Results and Discussion

3.1. PC Blends Morphology and Rubber Phase Distribution

3.2. Quasi-Static and Medium-Strain-Rate Tensile Characterization

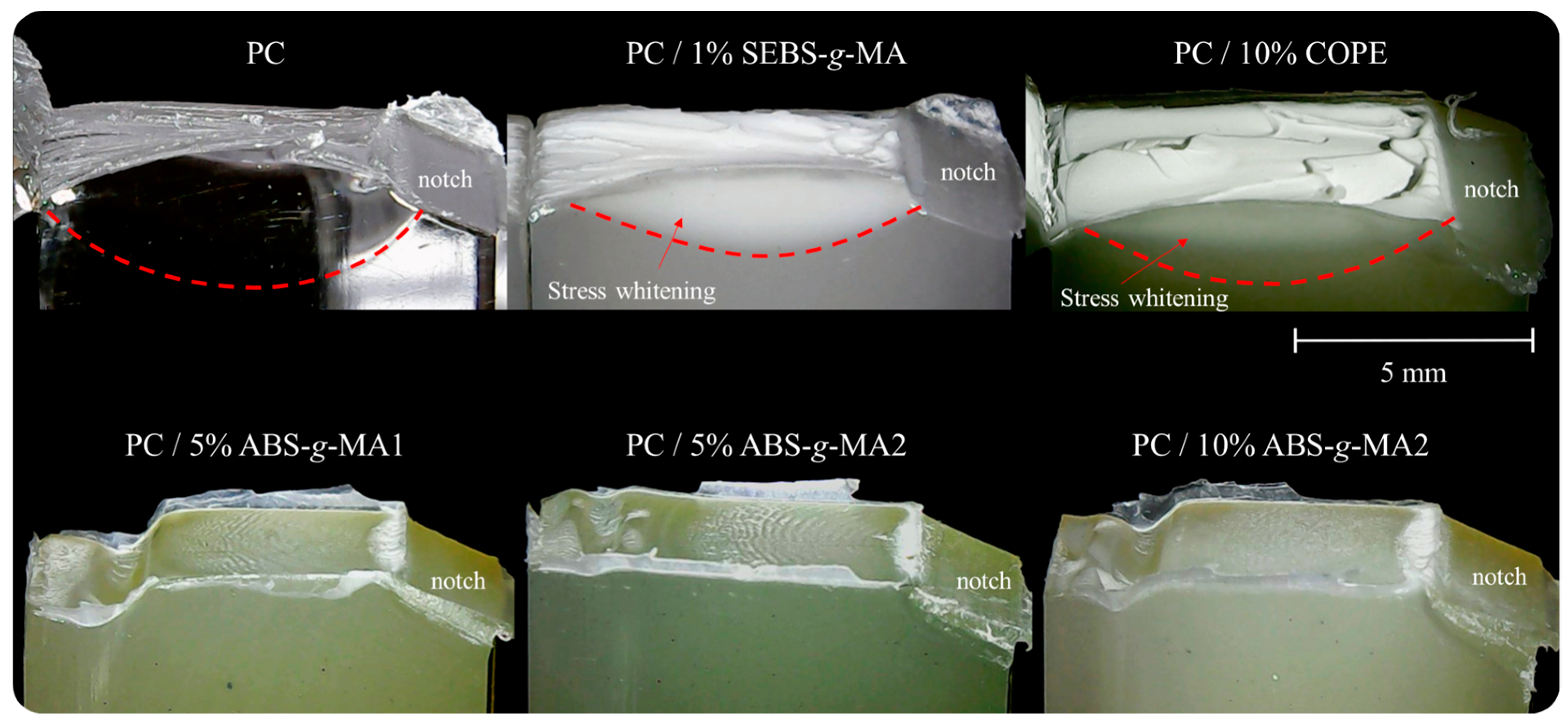

3.3. Impact Tests and Fracture Behavior

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yee, A.F. The yield and deformation behaviour of some polycarbonate blends. J. Mater. Sci. 1977, 12, 757–765. [Google Scholar] [CrossRef]

- Lee, M.-P.; Hiltner, A.; Baer, E. Fractography of injection molded polycarbonate acrylonitrile-butadiene-styrene terpolymer blends. Polym. Eng. Sci. 1992, 32, 909–919. [Google Scholar] [CrossRef]

- Rodrigues, P.V.; Ramoa, B.; Machado, A.V.; Cardiff, P.; Nóbrega, J.M. Assessing the Compressive and Impact Behavior of Plastic Safety Toe Caps through Computational Modelling. Polymers 2021, 13, 4332. [Google Scholar] [CrossRef] [PubMed]

- Inberg, J.P.F.; Gaymans, R.J. Polycarbonate and co-continuous polycarbonate/ABS blends: Influence of notch radius. Polymer 2002, 43, 4197–4205. [Google Scholar] [CrossRef]

- Sivaraman, P.; Manoj, N.R.; Barman, S.; Chandrasekhar, L.; Mishra, V.S.; Kushwaha, R.; Samui, A.B.; Chakraborty, B.C. Thermoplastic copolyether ester elastomer toughened polycarbonate blends: 1. Mechanical properties and morphology of the blends. Polym. Test. 2004, 23, 527–532. [Google Scholar] [CrossRef]

- Cho, K.; Yang, J.; Il, B.; Chan, K.; Park, E. Notch sensitivity of polycarbonate and toughened polycarbonate. J. Appl. Polym. Sci. 2003, 89, 3115–3121. [Google Scholar] [CrossRef]

- Lombardo, B.S.; Keskkula, H.; Paul, D.R. Influence of ABS type on morphology and mechanical properties of PC/ABS blends. J. Appl. Polym. Sci. 1994, 54, 1697–1720. [Google Scholar] [CrossRef]

- Wong, A.C.-Y. Polycarbonate Effects on Selected Mechanical Properties of Polycarbonate/Acrylonitrile-Butadiene-Styrene (PC/ABS) Binary Blending Systems. Polym. Plast. Technol. Eng. 2003, 42, 171–180. [Google Scholar] [CrossRef]

- Balakrishnan, S.; Neelakantan, N.R. Mechanical properties of blends of polycarbonate with unmodified and maleic anhydride grafted ABS. Polym. Int. 1998, 45, 347–352. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Zhang, Y.; Peng, Z.; Zhang, Y.; Zhou, W. Effects of ABS-g-MAH on mechanical properties and compatibility of ABS/PC alloy. J. Appl. Polym. Sci. 2001, 81, 831–836. [Google Scholar] [CrossRef]

- Yin, Z.; Wang, T. Investigation of tensile deformation behavior of PC, ABS, and PC/ABS blends from low to high strain rates. Appl. Math. Mech. 2012, 33, 455–464. [Google Scholar] [CrossRef]

- Rodrigues, P.V.; Ramoa, B.; Torres, A.R.; Castro, M.C.R.; Machado, A.V. Enhancing the Interface Behavior on Polycarbonate/Elastomeric Blends: Morphological, Structural, and Thermal Characterization. Polymers 2023, 15, 1773. [Google Scholar] [CrossRef]

- Sivaraman, P.; Manoj, N.R.; Barman, S.; Chandrasekhar, L.; Mishra, V.S.; Samui, A.B.; Chakraborty, B.C. Thermoplastic copolyether ester elastomer toughened polycarbonate blends: 2. Thermal and rheological studies. Polym. Test. 2004, 23, 645–649. [Google Scholar] [CrossRef]

- Sivaraman, P.; Manoj, N.R.; Mishra, V.S.; Raut, R.D.; Samui, A.B.; Chakraborty, B.C. Thermoplastic copolyether ester elastomer toughened polycarbonate blends 3. Microhardness and abrasion resistance of the blends. Polym. Test. 2005, 24, 241–243. [Google Scholar] [CrossRef]

- Kumar, S.; Maiti, S.N. Studies on Polycarbonate and Polydimethylsiloxane Rubber Blends. Polym. Plast. Technol. Eng. 2007, 46, 427–433. [Google Scholar] [CrossRef]

- Garhwal, A.; Maiti, S.N. Influence of styrene–ethylene–butylene–styrene (SEBS) copolymer on the short-term static mechanical and fracture performance of polycarbonate (PC)/SEBS blends. Polym. Bull. 2016, 73, 1719–1740. [Google Scholar] [CrossRef]

- Garhwal, A.; Maiti, S.N. Fabrication of Super Tough Polycarbonate/Styrene-Etylene-Butylene-Styrene Grafted Maleic Anhydride (SEBS-g-MA) Blends: Morphological, Short Term Static Mechanical and Fracture Performance Interpretation. Polym. Plast. Technol. Mater. 2019, 58, 113–125. [Google Scholar] [CrossRef]

- Huang, J.J.; Keskkula, H.; Paul, D.R. Rubber toughening of an amorphous polyamide by functionalized SEBS copolymers: Morphology and Izod impact behavior. Polymer 2004, 45, 4203–4215. [Google Scholar] [CrossRef]

- Horiuchi, S.; Matchariyakul, N.; Yase, K.; Kitano, T.; Choi, H.K.; Lee, Y.M. Compatibilizing effect of maleic anhydride functionalized SEBS triblock elastomer through a reaction induced phase formation in the blends of polyamide6 and polycarbonate: 2. Mechanical properties. Polymer 1997, 38, 59–78. [Google Scholar] [CrossRef]

- Nikfar, N.; Izadi-Vasafi, H.L. Goudarzi. Assessment of the Microstructure and Mechanical Properties of Polycarbonate (PC)/Acrylonitrile Butadiene Rubber (NBR) Blends Reinforced with Multi-wall Carbon Nanotubes. J. Macromol. Sci. Part B 2019, 58, 760–771. [Google Scholar] [CrossRef]

- Xu, H.; Tang, S.; Yang, L.; Hou, W. Toughening of polycarbonate by core-shell latex particles: Influence of particle size and spatial distribution on brittle-ductile transition. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 1970–1977. [Google Scholar] [CrossRef]

- Parker, D.S.; Sue, H.-J.; Huang, J.; Yee, A.F. Toughening mechanisms in core-shell rubber modified polycarbonate. Polymer 1990, 31, 2267–2277. [Google Scholar] [CrossRef]

- Wu, J.; Mai, Y.-W.; Yee, A.F. Fracture toughness and fracture mechanisms of polybutylene-terephthalate/polycarbonate/impact-modifier blends. J. Mater. Sci. 1994, 29, 4510–4522. [Google Scholar] [CrossRef]

- Dar, U.A.; Xu, Y.J.; Zakir, S.M.; Saeed, M.-U. The effect of injection molding process parameters on mechanical and fracture behavior of polycarbonate polymer. J. Appl. Polym. Sci. 2017, 134, 29. [Google Scholar] [CrossRef]

- Siviour, C.R. High strain rate characterization of polymers. AIP Conf. Proc. 1793, 60029, 2017. [Google Scholar] [CrossRef]

- Siviour, C.R.; Jordan, J.L. High Strain Rate Mechanics of Polymers: A Review. J. Dyn. Behav. Mater. 2016, 2, 15–32. [Google Scholar] [CrossRef]

- ISO 527-1:2019(E); Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 179-1:2010(E); Plastics—Determination of Charpy Impact Properties—Part 1: Non-Intrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2010.

- Lee, S.-N.; Stolarski, V.; Letton, A.; Laane, J. Studies of bisphenol—A–polycarbonate aging by Raman difference spectroscopy☆In honour of Professor Giuseppe Zerbi on the occasion of his 65th birthday.☆. J. Mol. Struct. 2000, 521, 19–24. [Google Scholar] [CrossRef]

- de León, A.S.; Domínguez-Calvo, A.; Molina, S.I. Materials with enhanced adhesive properties based on acrylonitrile-butadiene-styrene (ABS)/thermoplastic polyurethane (TPU) blends for fused filament fabrication (FFF). Mater. Des. 2019, 182, 108044. [Google Scholar] [CrossRef]

- Reggio, D.; Saviello, D.; Lazzari, M.; Iacopino, D. Characterization of contemporary and historical acrylonitrile butadiene styrene (ABS)-based objects: Pilot study for handheld Raman analysis in collections. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 242, 118733. [Google Scholar] [CrossRef]

- Huan, S.; Lin, W.; Sato, H.; Yang, H.; Jiang, J.; Ozaki, Y.; Wu, H.; Shen, G.; Yu, R. Direct characterization of phase behavior and compatibility in PET/HDPE polymer blends by confocal Raman mapping. J. Raman Spectrosc. 2007, 38, 260–270. [Google Scholar] [CrossRef]

- Balakrishnan, S.; Neelakantan, N.; Saheb, D.; Jog, J.P. Rheological and morphological behaviour of blends of polycarbonate with unmodified and maleic anhydride grafted ABS. Polymer 1998, 39, 5765–5771. [Google Scholar] [CrossRef]

- Li, S.; Tang, R.; Jing, B.; Dai, W.; Zou, X. Phase morphology and interfacial characteristics of polycarbonate/acrylonitrile-ethylene-propylene-diene-styrene blends compatibilized by styrene-maleic anhydride copolymers. J. Appl. Polym. Sci. 2015, 132, 42103. [Google Scholar] [CrossRef]

- Werner, E.; Güth, U.; Brockhagen, B.; Döpke, C.; Ehrmann, A. Examination of Polymer Blends by AFM Phase Images. Technologies 2023, 11, 56. [Google Scholar] [CrossRef]

- Chen, M.; Yao, D.; Kim, B. Eliminating Flow Induced Birefringence And Minimizing Thermally Induced Residual Stresses In Injection Molded Parts*. Polym. Plast. Technol. Eng. 2001, 40, 491–503. [Google Scholar] [CrossRef]

- Klein, R.J.; Billade, N.S.; Lince, S.D.; Bryant, M.T. Combined Birefringence-Tensile Testing of Medical Plastics and Comparison to Finite Element Analysis. In Proceedings of the SPE ANTEC®: 2017, Anaheim, CA, USA, 8–10 May 2017; pp. 1764-1768. [Google Scholar]

- dos Anjos, E.G.R.; Braga, N.F.; Ribeiro, B.; Escanio, C.A.; Cardoso, A.D.M.; Marini, J.; Antonelli, E.; Passador, F.R. Influence of blending protocol on the mechanical, rheological, and electromagnetic properties of PC/ABS/ABS-g-MAH blend-based MWCNT nanocomposites. J. Appl. Polym. Sci. 2022, 139, 51946. [Google Scholar] [CrossRef]

- Aranda-Ruiz, J.; Ravi-Chandar, K.; Loya, J.A. On the double transition in the failure mode of polycarbonate. Mech. Mater. 2020, 140, 103242. [Google Scholar] [CrossRef]

| Composition [wt.%] | PC | ABS | ABS-g-MA1 | ABS-g-MA2 | SEBS-g-MA | COPE |

|---|---|---|---|---|---|---|

| PC | 100 | - | - | - | - | - |

| PC/5 ABS | 95 | 5 | - | - | - | - |

| PC/10 ABS | 90 | 10 | - | - | - | |

| PC/5 ABS-g-MA1 | 95 | - | 5 | - | - | - |

| PC/10 ABS-g-MA1 | 90 | - | 10 | - | - | - |

| PC/5 ABS-g-MA2 | 95 | - | - | 5 | - | - |

| PC/10 ABS-g-MA2 | 90 | - | - | 10 | - | - |

| PC/1 SEBS-g-MA | 99 | - | - | - | 1 | - |

| PC/10 COPE | 90 | - | - | - | - | 10 |

| PC | ABS | ABS-g-MA1 | ABS-g-MA2 | SEBS-g-MA | COPE | ||||

|---|---|---|---|---|---|---|---|---|---|

| 100 | 5 | 10 | 5 | 10 | 5 | 10 | 1 | 10 | |

| Quasi-static | |||||||||

| [MPa] | 64 | 0% | 1% | 1% | 2% | 2% | 4% | 2% | 2% |

| [GPa] | 1.8 | 4% | 2% | 0% | 7% | 4% | 10% | 1% | 1% |

| [%] | 55 | 8% | 10% | 2% | 9% | 2% | 10% | 18% | 60% |

| [MPa] | 30 | 7% | 9% | 4% | 9% | 1% | 12% | 19% | 59% |

| Medium strain rate | |||||||||

| [MPa] | 78 | 3% | 3% | 3% | 4% | 3% | 5% | 2% | 2% |

| [GPa] | 3.1 | 4% | 9% | 2% | 3% | 7% | 11% | 1% | 5% |

| [%] | 41 | 11% | 33% | 3% | 34% | 1% | 31% | 47% | 114% |

| [MPa] | 27 | 9% | 37% | 6% | 40% | 1% | 37% | 47% | 111% |

| Specimen | Impact Strength (kJ/m2) | |

|---|---|---|

| v-Notch | No Notch | |

| PC | 94 ± 4 | 272 ± 26 |

| PC/5% ABS-g-MA1 | 21 ± 2 | 265 ± 8 |

| PC/5% ABS-g-MA2 | 16 ± 2 | 268 ± 7 |

| PC/10% ABS-g-MA2 | 17 ± 1 | 254 ± 6 |

| PC/1% SEBS-g-MA | 78 ± 2 | 259 ± 2 |

| PC/10% COPE | 89 ± 1 | 277 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, P.V.; Ramoa, B.; Castro, M.C.R.; Machado, A.V. Investigation of Toughening Mechanisms in Elastomeric Polycarbonate Blends through Morphological and Mechanical Characterization at Small and Medium Strain Rates. Polymers 2024, 16, 2303. https://doi.org/10.3390/polym16162303

Rodrigues PV, Ramoa B, Castro MCR, Machado AV. Investigation of Toughening Mechanisms in Elastomeric Polycarbonate Blends through Morphological and Mechanical Characterization at Small and Medium Strain Rates. Polymers. 2024; 16(16):2303. https://doi.org/10.3390/polym16162303

Chicago/Turabian StyleRodrigues, Pedro Veiga, Bruno Ramoa, Maria Cidália R. Castro, and Ana Vera Machado. 2024. "Investigation of Toughening Mechanisms in Elastomeric Polycarbonate Blends through Morphological and Mechanical Characterization at Small and Medium Strain Rates" Polymers 16, no. 16: 2303. https://doi.org/10.3390/polym16162303

APA StyleRodrigues, P. V., Ramoa, B., Castro, M. C. R., & Machado, A. V. (2024). Investigation of Toughening Mechanisms in Elastomeric Polycarbonate Blends through Morphological and Mechanical Characterization at Small and Medium Strain Rates. Polymers, 16(16), 2303. https://doi.org/10.3390/polym16162303