Exploring the Feasibility of Polysaccharide-Based Mulch Films with Controlled Ammonium and Phosphate Ions Release for Sustainable Agriculture

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Carboxymethyl Cellulose Dispersions, Chitosan-Sodium Alginate Dispersions, and Calcium Chloride Solution

2.3. Preparation of Composite Films

2.4. Enrichment of Composite Films with Ammonium Phosphate Monobasic

2.5. Interaction of Composite Films with Water

2.6. Thermal and Mechanical Properties of Composite Films

2.7. Attenuated Total Reflection-Fourier Transform Infrared Spectroscopy (ATR-FTIR)

2.8. X-ray Diffraction (XRD)

2.9. Release Kinetics of PO43− and NH4+ Ions by Films

3. Results and Discussion

3.1. Macroscopic Properties of Polysaccharide-Based Biodegradable Composite Films

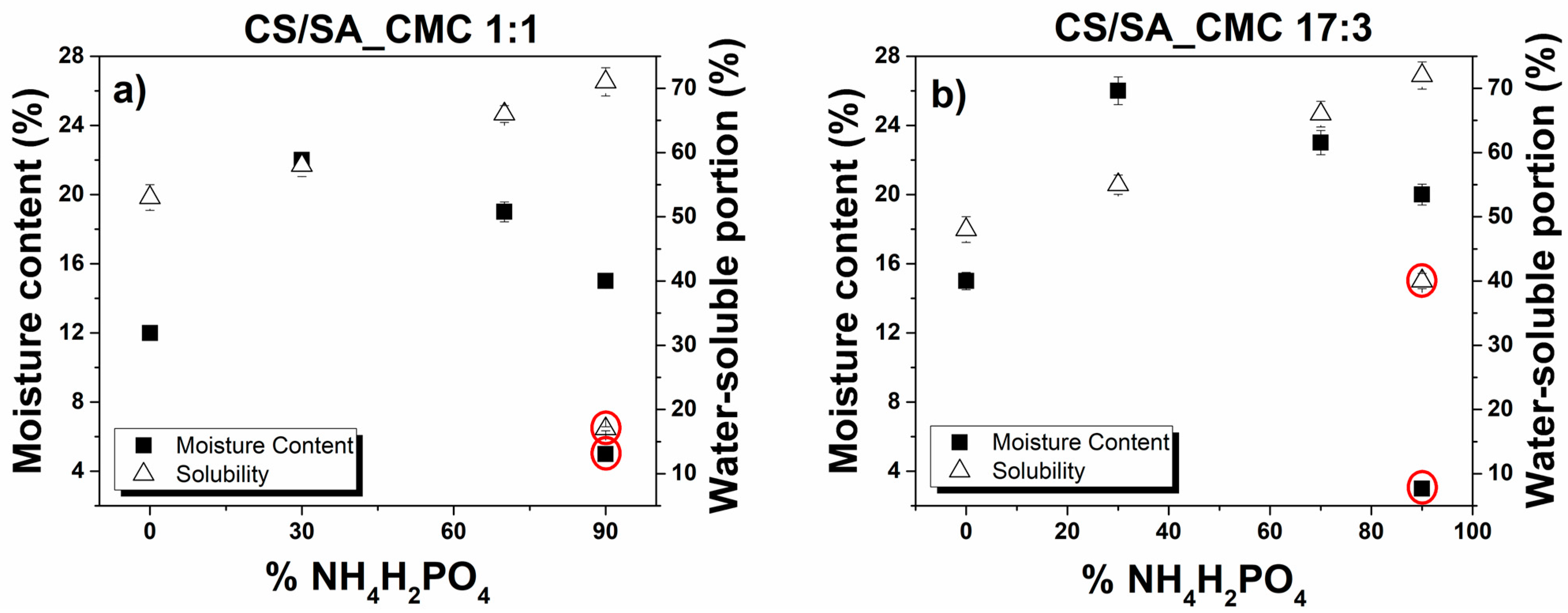

3.1.1. Effect of Adding NH4H2PO4 Salt

3.1.2. Effect of Adding CaCl2 Crosslinker

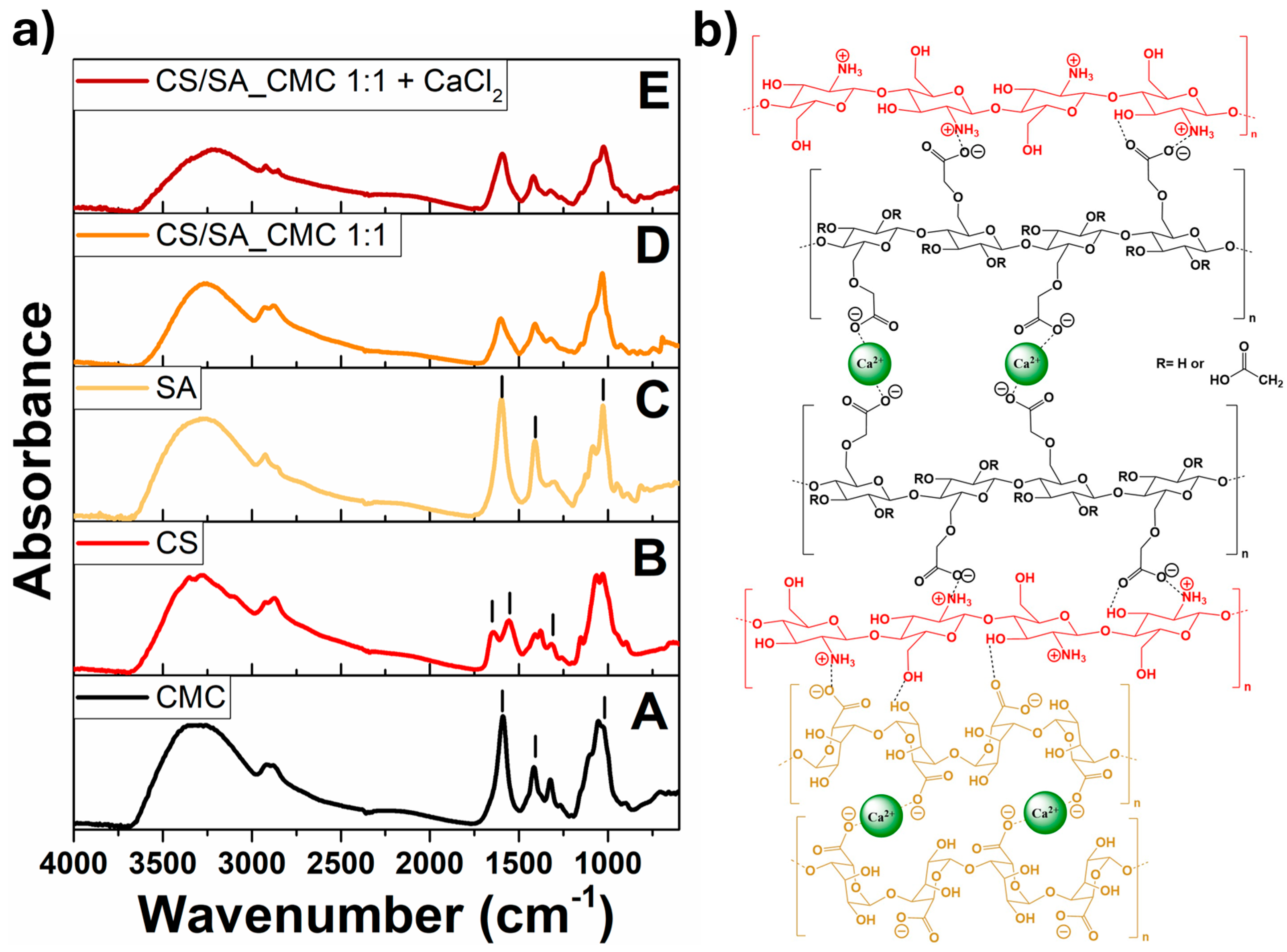

3.2. Structural Characterization of Polysaccharide-Based Composite Crosslinked Films

3.2.1. ATR-FTIR Spectroscopy

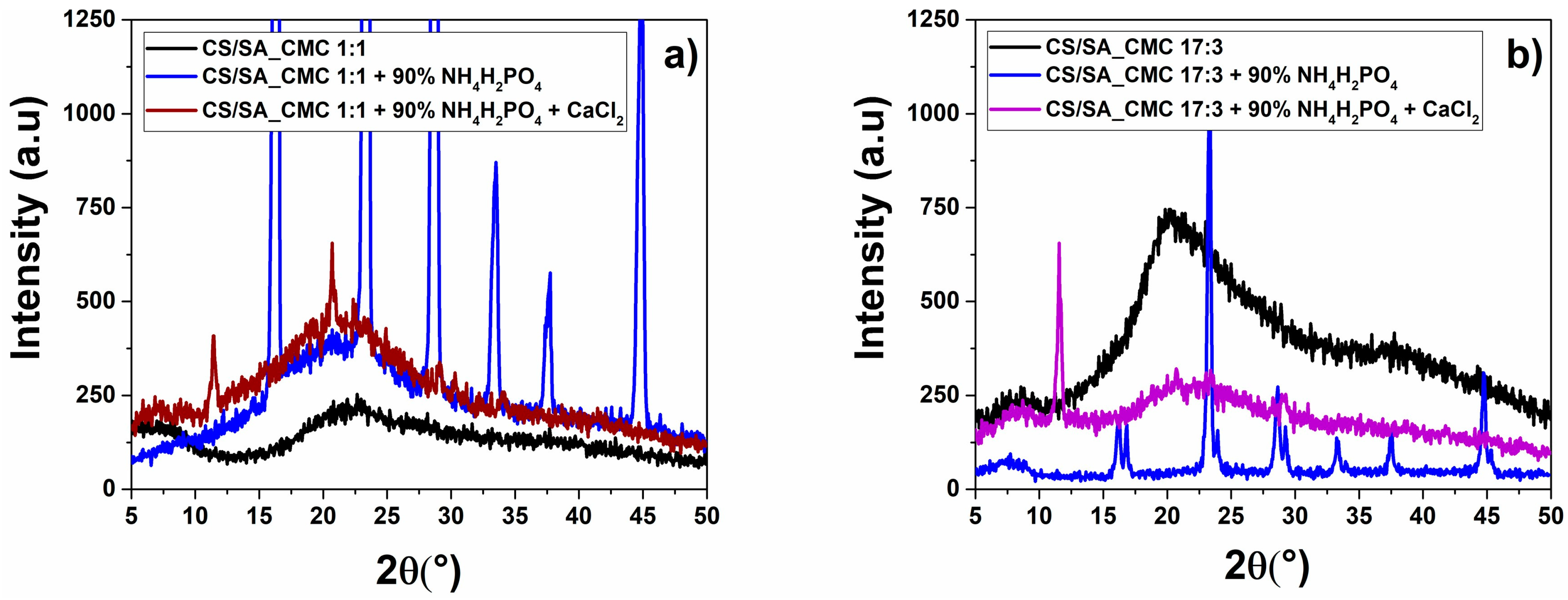

3.2.2. XRD Analysis and Crystalline Structure of Composite Films

3.3. Release Kinetics of PO43− and NH4+ Ions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Mechanical, Thermal, and Morphology Properties of Poly(Lactic Acid) Plasticized with Poly(Ethylene Glycol) and Epoxidized Palm Oil Hybrid Plasticizer. Polym. Eng. Sci. 2016, 56, 1169–1174. [Google Scholar] [CrossRef]

- Serrano-Ruiz, H.; Martin-Closas, L.; Pelacho, A.M. Biodegradable Plastic Mulches: Impact on the Agricultural Biotic Environment. Sci. Total Environ. 2021, 750, 141228. [Google Scholar] [CrossRef]

- Akhtar, H.M.S.; Riaz, A.; Hamed, Y.S.; Abdin, M.; Chen, G.; Wan, P.; Zeng, X. Production and Characterization of CMC-Based Antioxidant and Antimicrobial Films Enriched with Chickpea Hull Polysaccharides. Int. J. Biol. Macromol. 2018, 118, 469–477. [Google Scholar] [CrossRef]

- Rillig, M.C. Microplastic in Terrestrial Ecosystems and the Soil? Environ. Sci. Technol. 2012, 46, 6453–6454. [Google Scholar] [CrossRef] [PubMed]

- Bandopadhyay, S.; Martin-Closas, L.; Pelacho, A.M.; DeBruyn, J.M. Biodegradable Plastic Mulch Films: Impacts on Soil Microbial Communities and Ecosystem Functions. Front. Microbiol. 2018, 9, 819. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, A.L.; Miler, M.; Torley, P.J.; Sopade, P.A.; Halley, P.J. Amylose Content and Chemical Modification Effects on the Extrusion of Thermoplastic Starch from Maize. Carbohydr. Polym. 2008, 74, 907–913. [Google Scholar] [CrossRef]

- Meghana, M.C.; Nandhini, C.; Benny, L.; George, L.; Varghese, A. A Road Map on Synthetic Strategies and Applications of Biodegradable Polymers. Polym. Bull. 2023, 80, 11507–11556. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Mao, L.; Qi, H.; Xu, D.; Huang, H.; Liu, M.; Wen, Y.; Deng, F.; Zhang, X.; Wei, Y. Preparation of Fluorescent Cellulose Nanocrystal Polymer Composites with Thermo-Responsiveness through Light-Induced ATRP. Cellulose 2020, 27, 743–753. [Google Scholar] [CrossRef]

- Yuan, H.; Kida, T.; Tanaka, R.; Cai, Z.; Nakayama, Y.; Shiono, T. Synthesis and Properties of Block Copolymers Composed of Norbornene/Higher α-Olefin Gradient Segments Using Ansa -Fluorenylamidodimethyltitanium-[Ph3C][B(C6F5)4] Catalyst System. Polym. Chem. 2021, 12, 189–195. [Google Scholar] [CrossRef]

- Patel, G.B.; Singh, N.L.; Singh, F. Modification of Chitosan-Based Biodegradable Polymer by Irradiation with MeV Ions for Electrolyte Applications. Mater. Sci. Eng. B 2017, 225, 150–159. [Google Scholar] [CrossRef]

- Aleksanyan, K.V. Polysaccharides for Biodegradable Packaging Materials: Past, Present, and Future (Brief Review). Polymers 2023, 15, 451. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Ning, R.; Qin, M.; Liang, J.; Jiang, J.; Sun, W.; Liu, X.; Zi, M. Sustainable and Hydrophobic Polysaccharide-Based Mulch Film with Thermally Stable and Ultraviolet Resistance Performance. Carbohydr. Polym. 2022, 295, 119865. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Song, X.; Ma, Z.; Zhang, X.; Shu, D.; Nan, J. Al2O3/PVdF-HFP-CMC/PE Separator Prepared Using Aqueous Slurry and Post-Hot-Pressing Method for Polymer Lithium-Ion Batteries with Enhanced Safety. Electrochim. Acta 2016, 212, 416–425. [Google Scholar] [CrossRef]

- Yang, W.; Wang, J.; Yang, Q.; Pei, H.; Hu, N.; Suo, Y.; Li, Z.; Zhang, D.; Wang, J. Facile Fabrication of Robust MOF Membranes on Cloth via a CMC Macromolecule Bridge for Highly Efficient Pb(II) Removal. Chem. Eng. J. 2018, 339, 230–239. [Google Scholar] [CrossRef]

- Kostag, M.; El Seoud, O.A. Sustainable Biomaterials Based on Cellulose, Chitin and Chitosan Composites—A Review. Carbohydr. Polym. Technol. Appl. 2021, 2, 100079. [Google Scholar] [CrossRef]

- Kulig, D.; Zimoch-Korzycka, A.; Jarmoluk, A.; Marycz, K. Study on Alginate–Chitosan Complex Formed with Different Polymers Ratio. Polymers 2016, 8, 167. [Google Scholar] [CrossRef]

- Varaprasad, K.; Raghavendra, G.M.; Jayaramudu, T.; Seo, J. Nano Zinc Oxide–Sodium Alginate Antibacterial Cellulose Fibres. Carbohydr. Polym. 2016, 135, 349–355. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Li, Y.; Li, L. Enhanced Stability and Mechanical Strength of Sodium Alginate Composite Films. Carbohydr. Polym. 2017, 160, 62–70. [Google Scholar] [CrossRef] [PubMed]

- Bt Ibrahim, S.F.; Mohd Azam, N.A.N.; Mat Amin, K.A. Sodium Alginate Film: The Effect of Crosslinker on Physical and Mechanical Properties. IOP Conf. Ser. Mater. Sci. Eng. 2019, 509, 012063. [Google Scholar] [CrossRef]

- Treenate, P.; Monvisade, P. Crosslinker Effects on Properties of Hydroxyethylacryl Chitosan/Sodium Alginate Hydrogel Films. Macromol. Symp. 2017, 372, 147–153. [Google Scholar] [CrossRef]

- Tan, J.; Luo, Y.; Guo, Y.; Zhou, Y.; Liao, X.; Li, D.; Lai, X.; Liu, Y. Development of Alginate-Based Hydrogels: Crosslinking Strategies and Biomedical Applications. Int. J. Biol. Macromol. 2023, 239, 124275. [Google Scholar] [CrossRef]

- Costa, M.J.; Marques, A.M.; Pastrana, L.M.; Teixeira, J.A.; Sillankorva, S.M.; Cerqueira, M.A. Physicochemical Properties of Alginate-Based Films: Effect of Ionic Crosslinking and Mannuronic and Guluronic Acid Ratio. Food Hydrocoll. 2018, 81, 442–448. [Google Scholar] [CrossRef]

- Paşcalău, V.; Popescu, V.; Popescu, G.L.; Dudescu, M.C.; Borodi, G.; Dinescu, A.; Perhaiţa, I.; Paul, M. The Alginate/k-Carrageenan Ratio’s Influence on the Properties of the Cross-Linked Composite Films. J. Alloys Compd. 2012, 536, S418–S423. [Google Scholar] [CrossRef]

- Choi, I.; Lee, Y.; Lyu, J.S.; Lee, J.-S.; Han, J. Characterization of Ionically Crosslinked Alginate Films: Effect of Different Anion-Based Metal Cations on the Improvement of Water-Resistant Properties. Food Hydrocoll. 2022, 131, 107785. [Google Scholar] [CrossRef]

- Li, J.; Wu, Y.; He, J.; Huang, Y. A New Insight to the Effect of Calcium Concentration on Gelation Process and Physical Properties of Alginate Films. J. Mater. Sci. 2016, 51, 5791–5801. [Google Scholar] [CrossRef]

- Fazilah, A.; Maizura, M.; Abd Karim, A.; Bhupinder, K.; Rajeev, B.; Uthumporn, U.; Chew, S.H. Physical and mechanical properties of sago starch-alginate films incorporated with calcium chloride. Int. Food Res. J. 2011, 18, 1027–1033. [Google Scholar]

- McHugh, T.H.; Krochta, J.M. Sorbitol- vs Glycerol-Plasticized Whey Protein Edible Films: Integrated Oxygen Permeability and Tensile Property Evaluation. J. Agric. Food Chem. 1994, 42, 841–845. [Google Scholar] [CrossRef]

- Pak, E.S.; Ghaghelestani, S.N.; Najafi, M.A. Preparation and Characterization of a New Edible Film Based on Persian Gum with Glycerol Plasticizer. J. Food Sci. Technol. 2020, 57, 3284–3294. [Google Scholar] [CrossRef] [PubMed]

- Lan, W.; He, L.; Liu, Y. Preparation and Properties of Sodium Carboxymethyl Cellulose/Sodium Alginate/Chitosan Composite Film. Coatings 2018, 8, 291. [Google Scholar] [CrossRef]

- Vejan, P.; Khadiran, T.; Abdullah, R.; Ahmad, N. Controlled Release Fertilizer: A Review on Developments, Applications and Potential in Agriculture. J. Control. Release 2021, 339, 321–334. [Google Scholar] [CrossRef]

- Jarosiewicz, A.; Tomaszewska, M. Controlled-Release NPK Fertilizer Encapsulated by Polymeric Membranes. J. Agric. Food Chem. 2003, 51, 413–417. [Google Scholar] [CrossRef] [PubMed]

- Ciaramitaro, V.; Piacenza, E.; Meo, P.L.; Librici, C.; Calvino, M.M.; Conte, P.; Lazzara, G.; Chillura Martino, D.F. From Micro to Macro: Physical-Chemical Characterization of Wheat Starch-Based Films Modified with PEG200, Sodium Citrate, or Citric Acid. Int. J. Biol. Macromol. 2023, 253, 127225. [Google Scholar] [CrossRef] [PubMed]

- Ford, J.L.; Mitchell, K.; Rowe, P.; Armstrong, D.J.; Elliott, P.N.C.; Rostron, C.; Hogan, J.E. Mathematical Modelling of Drug Release from Hydroxypropylmethylcellulose Matrices: Effect of Temperature. Int. J. Pharm. 1991, 71, 95–104. [Google Scholar] [CrossRef]

- Arora, G.; Malik, K.; Singh, I. Formulation and evaluation of mucoadhesive matrix tablets of taro gum: Optimization using response surface methodology. Polim. Med. 2011, 41, 23–24. [Google Scholar] [PubMed]

- Piacenza, E.; Presentato, A.; Alduina, R.; Scurria, A.; Pagliaro, M.; Albanese, L.; Meneguzzo, F.; Ciriminna, R.; Chillura Martino, D.F. Cross-Linked Natural IntegroPectin Films from Citrus Biowaste with Intrinsic Antimicrobial Activity. Cellulose 2022, 29, 5779–5802. [Google Scholar] [CrossRef]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Tröger, J.; Muñoz, K.; Frör, O.; Schaumann, G.E. Plastic Mulching in Agriculture. Trading Short-Term Agronomic Benefits for Long-Term Soil Degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef] [PubMed]

- Menossi, M.; Cisneros, M.; Alvarez, V.A.; Casalongué, C. Current and Emerging Biodegradable Mulch Films Based on Polysaccharide Bio-Composites. A Review. Agron. Sustain. Dev. 2021, 41, 53. [Google Scholar] [CrossRef]

- Rao, K.M.; Rao, K.S.V.K. Synthesis and Characterization of Biodegradable Poly (Vinyl Caprolactam) Grafted on to Sodium Alginate and Its Microgels for Controlled Release Studies of an Anticancer Drug. J. Appl. Pharm. Sci. 2013, 3, 61–69. [Google Scholar]

- Gao, C.; Pollet, E.; Avérous, L. Properties of Glycerol-Plasticized Alginate Films Obtained by Thermo-Mechanical Mixing. Food Hydrocoll. 2017, 63, 414–420. [Google Scholar] [CrossRef]

- Xiao, C.; Lu, Y.; Liu, H.; Zhang, L. Preparation and Characterization of Konjac Glucomannan and Sodium Carboxymethylcellulose Blend Films. J. Appl. Polym. Sci. 2001, 80, 26–31. [Google Scholar] [CrossRef]

- Trevisol, T.C.; Fritz, A.R.M.; De Souza, S.M.A.G.U.; Bierhalz, A.C.K.; Valle, J.A.B. Alginate and Carboxymethyl Cellulose in Monolayer and Bilayer Films as Wound Dressings: Effect of the Polymer Ratio. J. Appl. Polym. Sci. 2019, 136, 46941. [Google Scholar] [CrossRef]

- Martino, V.P.; Pollet, E.; Avérous, L. Novative Biomaterials Based on Chitosan and Poly(ε-Caprolactone): Elaboration of Porous Structures. J. Polym. Environ. 2011, 19, 819–826. [Google Scholar] [CrossRef]

- Homez-Jara, A.; Daza, L.D.; Aguirre, D.M.; Muñoz, J.A.; Solanilla, J.F.; Váquiro, H.A. Characterization of Chitosan Edible Films Obtained with Various Polymer Concentrations and Drying Temperatures. Int. J. Biol. Macromol. 2018, 113, 1233–1240. [Google Scholar] [CrossRef] [PubMed]

- Boateng, J.S.; Matthews, K.H.; Stevens, H.N.E.; Eccleston, G.M. Wound Healing Dressings and Drug Delivery Systems: A Review. J. Pharm. Sci. 2008, 97, 2892–2923. [Google Scholar] [CrossRef] [PubMed]

- Gal, A.; Nussinovitch, A. Plasticizers in the Manufacture of Novel Skin-Bioadhesive Patches. Int. J. Pharm. 2009, 370, 103–109. [Google Scholar] [CrossRef] [PubMed]

- Menossi, M.; Salcedo, F.; Rivilli, N.; Nicolini, A.T.; Alvarez, V.A.; Ludueña, L.N. Biodegradable Mulch Films Based on Starch/Poly (Lactic Acid)/Poly (ε-Caprolactone) Ternary Blends. J. Polym. Environ. 2023, 31, 2114–2137. [Google Scholar] [CrossRef]

- Lian, Z.; Zhang, Y.; Zhao, Y. Nano-TiO 2 Particles and High Hydrostatic Pressure Treatment for Improving Functionality of Polyvinyl Alcohol and Chitosan Composite Films and Nano-TiO 2 Migration from Film Matrix in Food Simulants. Innov. Food Sci. Emerg. Technol. 2016, 33, 145–153. [Google Scholar] [CrossRef]

- Sheela, T.; Bhajantri, R.F.; Ravindrachary, V.; Rathod, S.G.; Pujari, P.K.; Poojary, B.; Somashekar, R. Effect of UV Irradiation on Optical, Mechanical and Microstructural Properties of PVA/NaAlg Blends. Radiat. Phys. Chem. 2014, 103, 45–52. [Google Scholar] [CrossRef]

- Gholizadeh, B.S.; Buazar, F.; Hosseini, S.M.; Mousavi, S.M. Enhanced Antibacterial Activity, Mechanical and Physical Properties of Alginate/Hydroxyapatite Bionanocomposite Film. Int. J. Biol. Macromol. 2018, 116, 786–792. [Google Scholar] [CrossRef]

- Li, J.; Ma, J.; Chen, S.; He, J.; Huang, Y. Characterization of Calcium Alginate/Deacetylated Konjac Glucomannan Blend Films Prepared by Ca2+ Crosslinking and Deacetylation. Food Hydrocoll. 2018, 82, 363–369. [Google Scholar] [CrossRef]

- Han, Y.; Wang, L. Sodium Alginate/Carboxymethyl Cellulose Films Containing Pyrogallic Acid: Physical and Antibacterial Properties. J. Sci. Food Agric. 2017, 97, 1295–1301. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Yang, X.; Qiao, C.; Li, Y.; Li, T.; Xu, C. Effects of Chitosan Quaternary Ammonium Salt on the Physicochemical Properties of Sodium Carboxymethyl Cellulose-Based Films. Carbohydr. Polym. 2018, 184, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Salama, H.E.; Abdel Aziz, M.S.; Alsehli, M. Carboxymethyl Cellulose/Sodium Alginate/Chitosan Biguanidine Hydrochloride Ternary System for Edible Coatings. Int. J. Biol. Macromol. 2019, 139, 614–620. [Google Scholar] [CrossRef]

- Yalçınkaya, S.; Demetgül, C.; Timur, M.; Çolak, N. Electrochemical Synthesis and Characterization of Polypyrrole/Chitosan Composite on Platinum Electrode: Its Electrochemical and Thermal Behaviors. Carbohydr. Polym. 2010, 79, 908–913. [Google Scholar] [CrossRef]

- Fernandes Queiroz, M.; Melo, K.; Sabry, D.; Sassaki, G.; Rocha, H. Does the Use of Chitosan Contribute to Oxalate Kidney Stone Formation? Mar. Drugs 2014, 13, 141–158. [Google Scholar] [CrossRef] [PubMed]

- Nainggolan, I.; Nasution, T.I.; Ahmad, K.R. Milk Powder Quality Degradation Detection Using Chitosan Film Based Sensor. J. Phys. Conf. Ser. 2018, 1116, 042024. [Google Scholar] [CrossRef]

- Guinesi, L.S.; Cavalheiro, É.T.G. Influence of Some Reactional Parameters on the Substitution Degree of Biopolymeric Schiff Bases Prepared from Chitosan and Salicylaldehyde. Carbohydr. Polym. 2006, 65, 557–561. [Google Scholar] [CrossRef]

- Sartori, C.; Finch, D.S.; Ralph, B.; Gilding, K. Determination of the Cation Content of Alginate Thin Films by FTi.r. Spectroscopy. Polymer 1997, 38, 43–51. [Google Scholar] [CrossRef]

- Ibrahim, S.M.; Abou El Fadl, F.I.; El-Naggar, A.A. Preparation and Characterization of Crosslinked Alginate–CMC Beads for Controlled Release of Nitrate Salt. J. Radioanal. Nucl. Chem. 2014, 299, 1531–1537. [Google Scholar] [CrossRef]

- Ortega-Toro, R.; Collazo-Bigliardi, S.; Talens, P.; Chiralt, A. Influence of Citric Acid on the Properties and Stability of Starch-polycaprolactone Based Films. J. Appl. Polym. Sci. 2016, 133, 42220. [Google Scholar] [CrossRef]

- Matet, M.; Heuzey, M.-C.; Pollet, E.; Ajji, A.; Avérous, L. Innovative Thermoplastic Chitosan Obtained by Thermo-Mechanical Mixing with Polyol Plasticizers. Carbohydr. Polym. 2013, 95, 241–251. [Google Scholar] [CrossRef] [PubMed]

- Vidal Urquiza, T.K.; Perales Pérez, O.; Gálvez Saldaña, M. Effect of the Cross-Linking with Calcium Ions on the Structural and Thermo-Mechanical Properties of Alginate Films. MRS Proc. 2011, 1355, 1113550616. [Google Scholar] [CrossRef]

- Kittur, F.S.; Vishu Kumar, A.B.; Tharanathan, R.N. Low Molecular Weight Chitosans—Preparation by Depolymerization with Aspergillus Niger Pectinase, and Characterization. Carbohydr. Res. 2003, 338, 1283–1290. [Google Scholar] [CrossRef] [PubMed]

- Julkapli, N.M.; Ahmad, Z.; Akil, H.M.; Bin Mohamed, A.A. X-ray Diffraction Studies of cross Linked Chitosan with Different cross Linking Agents for Waste Water Treatment Application; AIP Publishing: Kuala Lumpur, Malaysia, 2010; pp. 106–111. [Google Scholar]

- Epure, V.; Griffon, M.; Pollet, E.; Avérous, L. Structure and Properties of Glycerol-Plasticized Chitosan Obtained by Mechanical Kneading. Carbohydr. Polym. 2011, 83, 947–952. [Google Scholar] [CrossRef]

- Berger, J.; Reist, M.; Mayer, J.M.; Felt, O.; Peppas, N.A.; Gurny, R. Structure and Interactions in Covalently and Ionically Crosslinked Chitosan Hydrogels for Biomedical Applications. Eur. J. Pharm. Biopharm. 2004, 57, 19–34. [Google Scholar] [CrossRef] [PubMed]

- Heredia, N.S.; Vizuete, K.; Flores-Calero, M.; Pazmiño V., K.; Pilaquinga, F.; Kumar, B.; Debut, A. Comparative Statistical Analysis of the Release Kinetics Models for Nanoprecipitated Drug Delivery Systems Based on Poly(Lactic-Co-Glycolic Acid). PLoS ONE 2022, 17, e0264825. [Google Scholar] [CrossRef] [PubMed]

- Shoaib, M.H.; Tazeen, J.; Merchant, H.A.; Yousuf, R.I. Evaluation of drug release kinetics from ibuprofen matrix tablets using HPMC. J. Pharm. Sci. 2006, 19, 119–124. [Google Scholar]

- Vueba, M.L.; Batista De Carvalho, L.A.E.; Veiga, F.; Sousa, J.J.; Pina, M.E. Role of Cellulose Ether Polymers on Ibuprofen Release from Matrix Tablets. Drug Dev. Ind. Pharm. 2005, 31, 653–665. [Google Scholar] [CrossRef]

| Dispersion Acronym | Description |

|---|---|

| CS/SA | 1.5 g of CS and 1.5 g of SA with added 2 g of GLY (2.0% w/v to the total volume of the CS/SA dispersion) in 100 mL of a 2.0% v/v aqueous acetic acid solution. |

| CMC | 1.5 g of CMC in 100 mL of water. |

| CS/SA_CMC 1:1 | 50 g of CS/SA dispersion and 50 g of CMC dispersion, weight ratio of 1:1. |

| CS/SA_CMC 17:3 | 85 g of CS/SA dispersion and 15 g of CMC dispersion, weight ratio of 17:3. |

| CS/SA_CMC 1:1 + 30% or 70% or 90% NH4H2PO4 | Addition of 0.12 g, 0.28 g, and 0.36 g of NH4H2PO4 (30%, 70%, and 90%, respectively, than to total dry polymer mass, ~0.4 g) to the CS/SA_CMC dispersion in a weight ratio of 1:1. |

| CS/SA_CMC 17:3 + 30% or 70% or 90% NH4H2PO4 | Addition of 0.12 g, 0.28 g, and 0.36 g of NH4H2PO4 (30%, 70%, and 90%, respectively than to total dry polymer mass, ~0.4 g) to the CS/SA_CMC dispersion in a weight ratio of 17:3. |

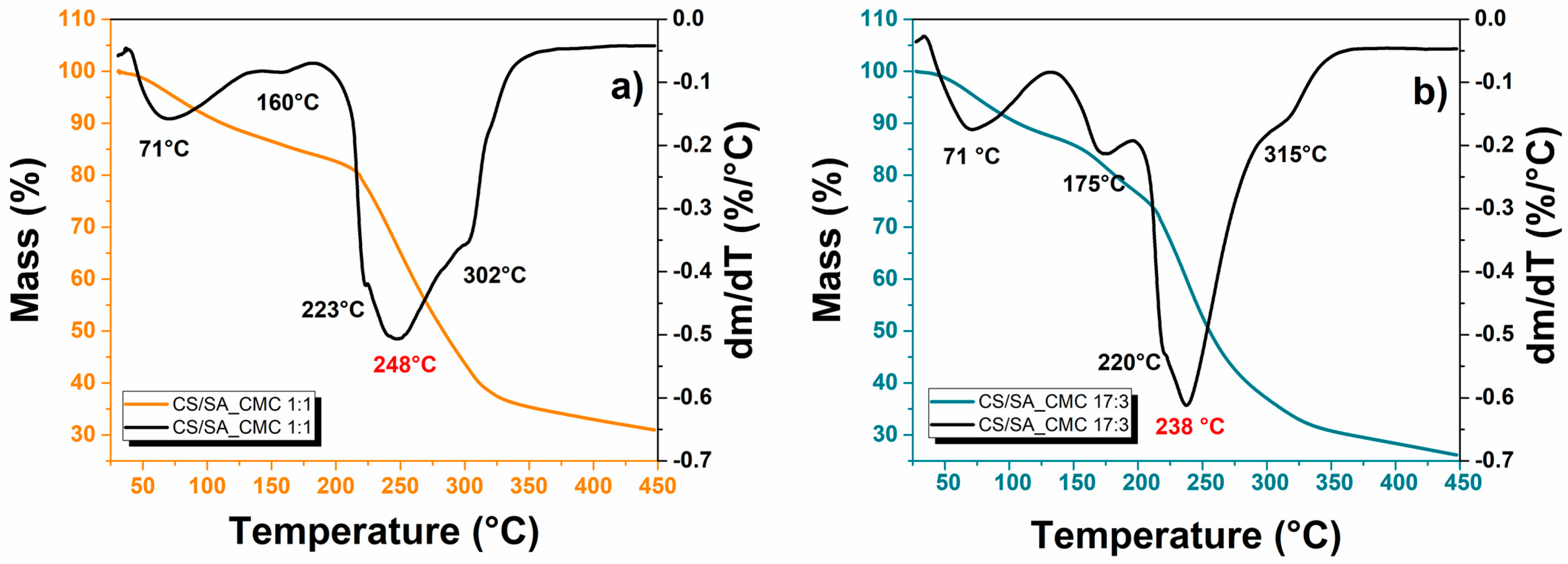

| Samples | DTG1 (°C) | DTG2 (°C) | DTG3 (°C) | Weight Loss (%) at 200 °C | Residue (%) at 450 °C |

|---|---|---|---|---|---|

| CS/SA_CMC 1:1 | 71 | 160 | 248 | 17 | 32 |

| CS/SA_CMC 17:3 | 71 | 175 | 238 | 23 | 26 |

| Samples | σ (MPa) | ε (%) | E (MPa) |

|---|---|---|---|

| CS/SA_CMC 1:1 | 15.9 ± 0.5 | 79.7 ± 2.5 | 88.8 ± 2.7 |

| CS/SA_CMC 17:3 | 7.86 ± 0.25 | 43.7 ± 1.2 | 35.9 ± 1.1 |

| Samples | DS (%) | ||||

|---|---|---|---|---|---|

| NH4H2PO4 (%) | 0 | 30 | 70 | 90 | 90 + CaCl2 |

| CS/SA_CMC 1:1 | 1968 ± 39 | 524 ± 14 | 459 ± 13 | 325 ± 9 | 75 ± 2 |

| CS/SA_CMC 17:3 | 1524 ± 31 | 286 ± 9 | 147 ± 4 | 134 ± 4 | 80 ± 2 |

| Samples | DC (%) |

|---|---|

| CS/SA_CMC 1:1 | 20.8 |

| CS/SA_CMC 1:1 + 90% NH4H2PO4 | 51.4 |

| CS/SA_CMC 1:1 + 90% NH4H2PO4 + CaCl2 | 26.3 |

| CS/SA_CMC 17:3 | 28.9 |

| CS/SA_CMC 17:3 + 90% NH4H2PO4 | 50.3 |

| CS/SA_CMC 17:3 + 90% NH4H2PO4+ CaCl2 | 17.2 |

| Samples | PO43− | NH4+ | ||

|---|---|---|---|---|

| n | R2 | n | R2 | |

| CS/SA_CMC 1:1 + 90% NH4H2PO4 | 0.034 ± 0.007 | 0.92 | 0.169 ± 0.035 | 0.96 |

| CS/SA_CMC 17:3 + 90% NH4H2PO4 | 0.032 ± 0.003 | 0.96 | 0.102 ± 0.030 | 0.89 |

| CS/SA_CMC 1:1 + 90% NH4H2PO4 + CaCl2 | 0.129 ± 0.022 | 0.90 | 0.157 ± 0.050 | 0.83 |

| CS/SA_CMC 17:3 + 90% NH4H2PO4 + CaCl2 | 0.146 ± 0.024 | 0.95 | 0.655 ± 0.085 | 0.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciaramitaro, V.; Piacenza, E.; Paliaga, S.; Cavallaro, G.; Badalucco, L.; Laudicina, V.A.; Chillura Martino, D.F. Exploring the Feasibility of Polysaccharide-Based Mulch Films with Controlled Ammonium and Phosphate Ions Release for Sustainable Agriculture. Polymers 2024, 16, 2298. https://doi.org/10.3390/polym16162298

Ciaramitaro V, Piacenza E, Paliaga S, Cavallaro G, Badalucco L, Laudicina VA, Chillura Martino DF. Exploring the Feasibility of Polysaccharide-Based Mulch Films with Controlled Ammonium and Phosphate Ions Release for Sustainable Agriculture. Polymers. 2024; 16(16):2298. https://doi.org/10.3390/polym16162298

Chicago/Turabian StyleCiaramitaro, Veronica, Elena Piacenza, Sara Paliaga, Giuseppe Cavallaro, Luigi Badalucco, Vito Armando Laudicina, and Delia Francesca Chillura Martino. 2024. "Exploring the Feasibility of Polysaccharide-Based Mulch Films with Controlled Ammonium and Phosphate Ions Release for Sustainable Agriculture" Polymers 16, no. 16: 2298. https://doi.org/10.3390/polym16162298

APA StyleCiaramitaro, V., Piacenza, E., Paliaga, S., Cavallaro, G., Badalucco, L., Laudicina, V. A., & Chillura Martino, D. F. (2024). Exploring the Feasibility of Polysaccharide-Based Mulch Films with Controlled Ammonium and Phosphate Ions Release for Sustainable Agriculture. Polymers, 16(16), 2298. https://doi.org/10.3390/polym16162298