Biodegradable Biobased Polymers: A Review of the State of the Art, Challenges, and Future Directions

Abstract

1. Introduction

2. Nomenclature Used in Review Paper

- Biobased: Defined as completely or partially composed of or derived from biomass. This can include sources such as animal, plant, or forestry materials [12].

- Biobased polymer: This is a polymer-derived biomass based on monomers derived from biomass. Furthermore, it can be shaped by flow throughout the various processing stages. The IUPAC organization recommends utilizing the term “Biobased polymer” over the term “bioplastic” [12].

- Biodegradability: Defined as a substance capable of breaking down and degrading through biological activity [12].

- Biodegradable: Represents macromolecules and/or polymeric substances susceptible to biological degradation [12].

- Biodegradation: Represents degradation due to a cell-related phenomenon. This excludes the in vitro activity of enzymes separated from their natural environments [12].

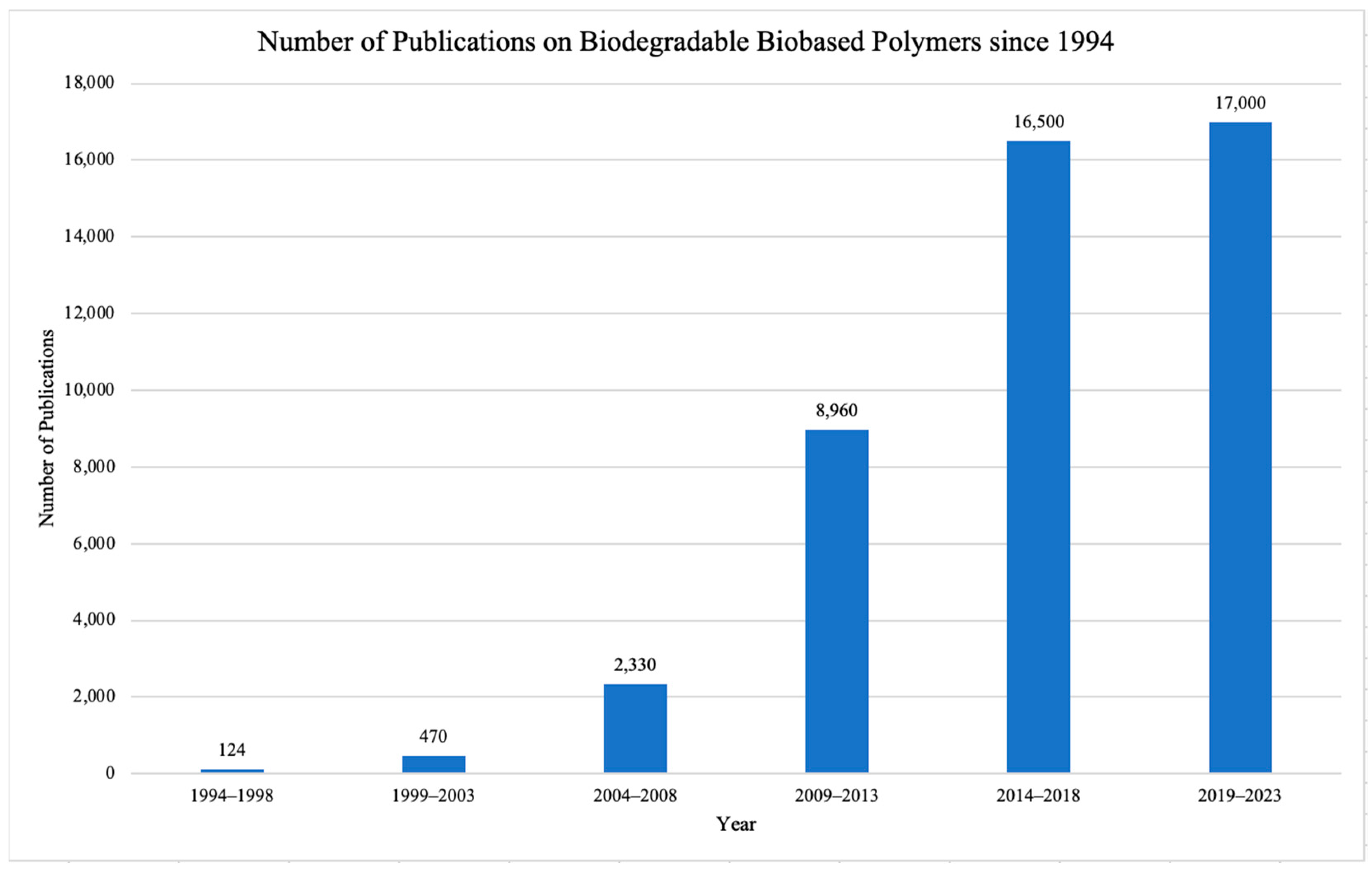

3. Current State and Improvements on the Synthesis of Biodegradable Biobased Polymers

3.1. Green Chemistry Principles

- Developing circular processes.

- Using renewable feedstock.

- Using benign chemical reactants to develop benign chemical products.

- Performing reactions with a catalyst that contains abundant metals, enzymes, photons, or electrons.

- The products and reactants have weak and non-covalent interactions.

- The products and reactants are recyclable, inert, abundant, easily separable, and have low toxicity.

- Products separate from the reaction mixture without requiring additional energy or materials.

- Atom, step, and solvent economical processes.

- End-of-life maintenance.

- Proper molecule design to lower environmental impact throughout the life cycle

- Minimizing hazards and maximizing function to improve performance.

- Reduce required fresh feedstock to increase profit.

3.2. Biomass Sources

3.3. Biobased Monomers

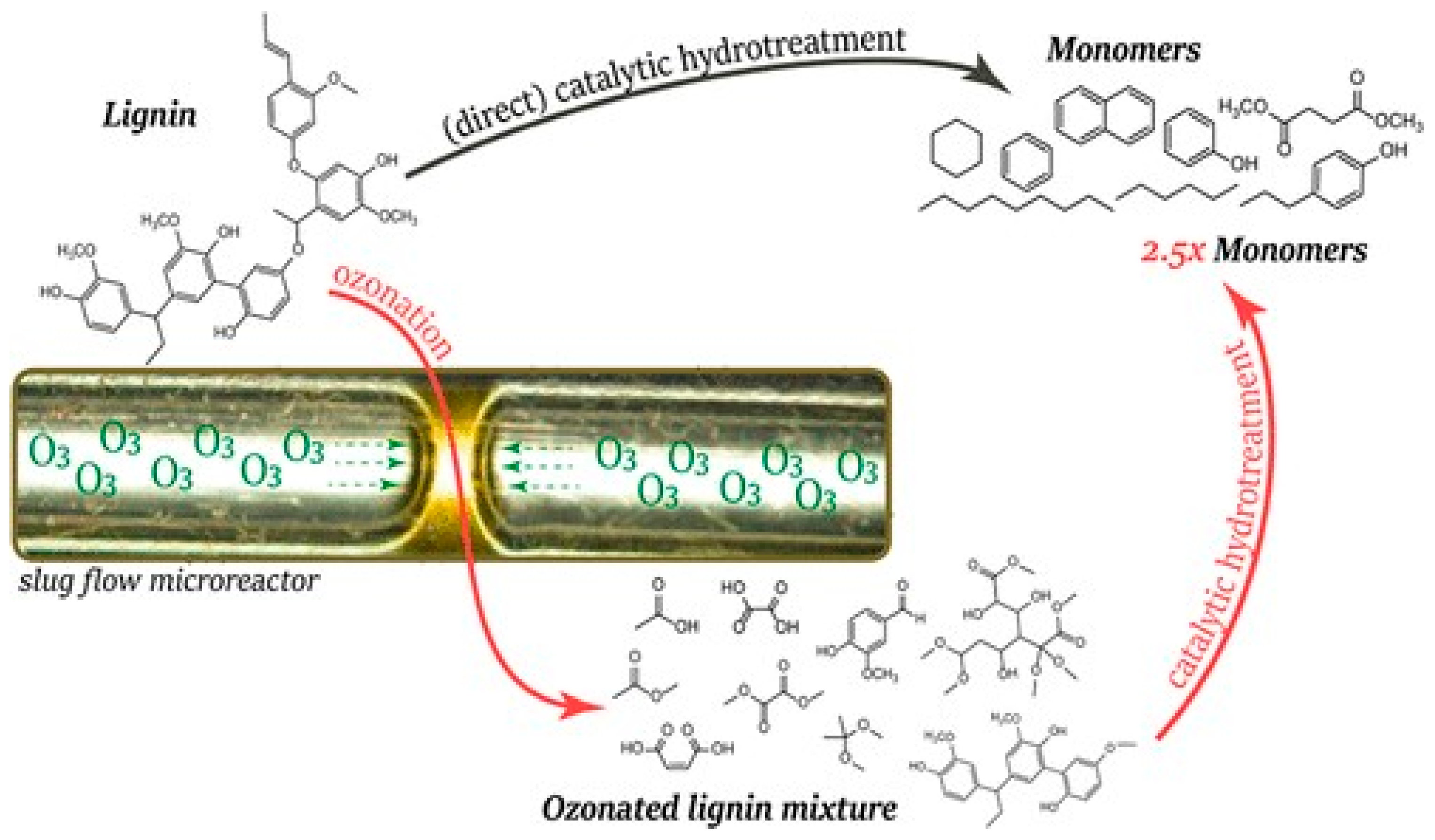

3.3.1. Continuous Flow Ozonolysis

3.3.2. Fermentation

3.4. Polymerization Techniques

3.4.1. Ring-Opening Polymerization (ROP)

3.4.2. Controlled Radical Polymerization (CRP)

4. Current State and Advancements on Material Properties

4.1. Mechanical Properties

4.2. Thermal Properties

4.3. Barrier Properties

5. Techno-Commercial Analysis

5.1. Introduction to Techno-Commercial Analysis

5.2. Financial Assessment Using Case Study of PLA

5.2.1. Cost–Benefit Analysis of PLA Production

− production price of corn starch

+ production price of cassava starch

+ price of cassava starch

5.2.2. NPV and Sensitivity Analysis of PLA Production

5.3. Market Trends and Demands

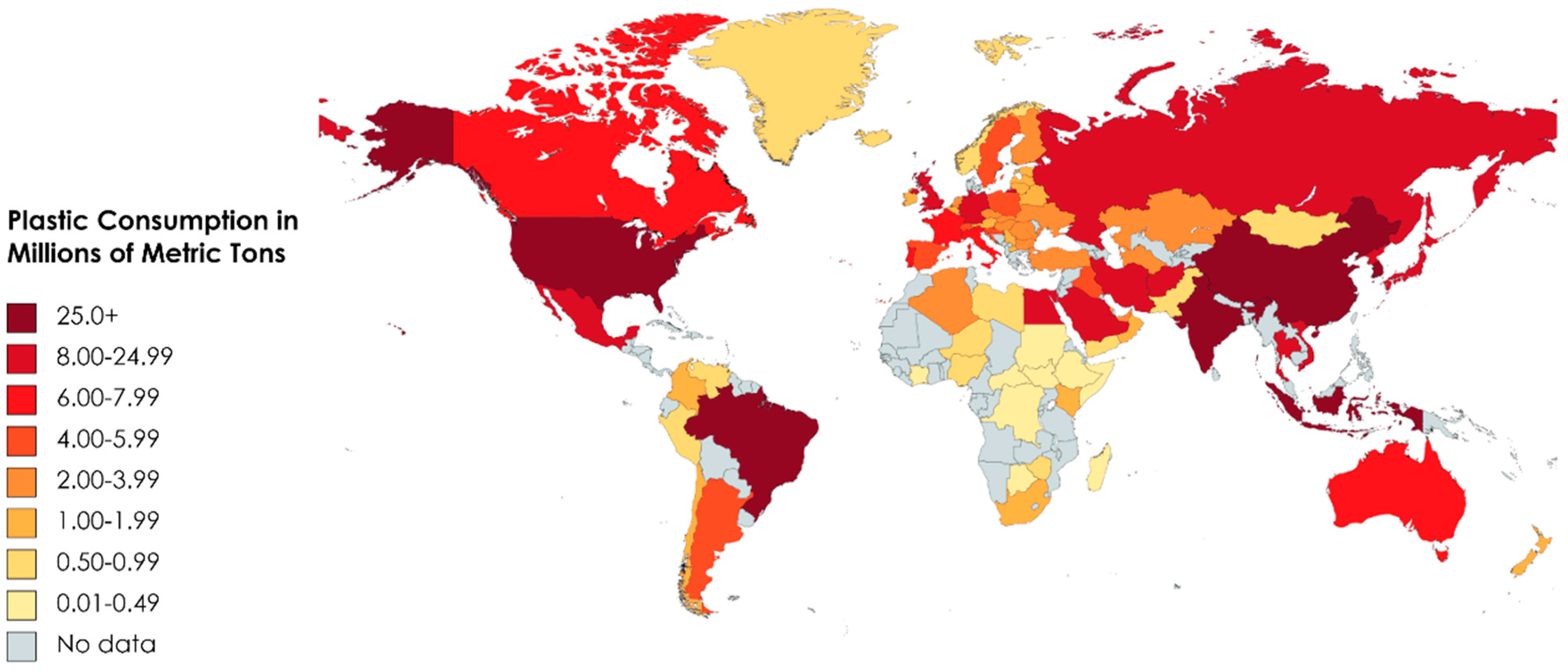

5.3.1. Current Market and Demands

5.3.2. Potential for Future Market and Demands

5.4. Commercial Impact of Technological Innovations

5.5. Government Initiatives towards Biodegradable Biobased Polymers and the Commercial Impact

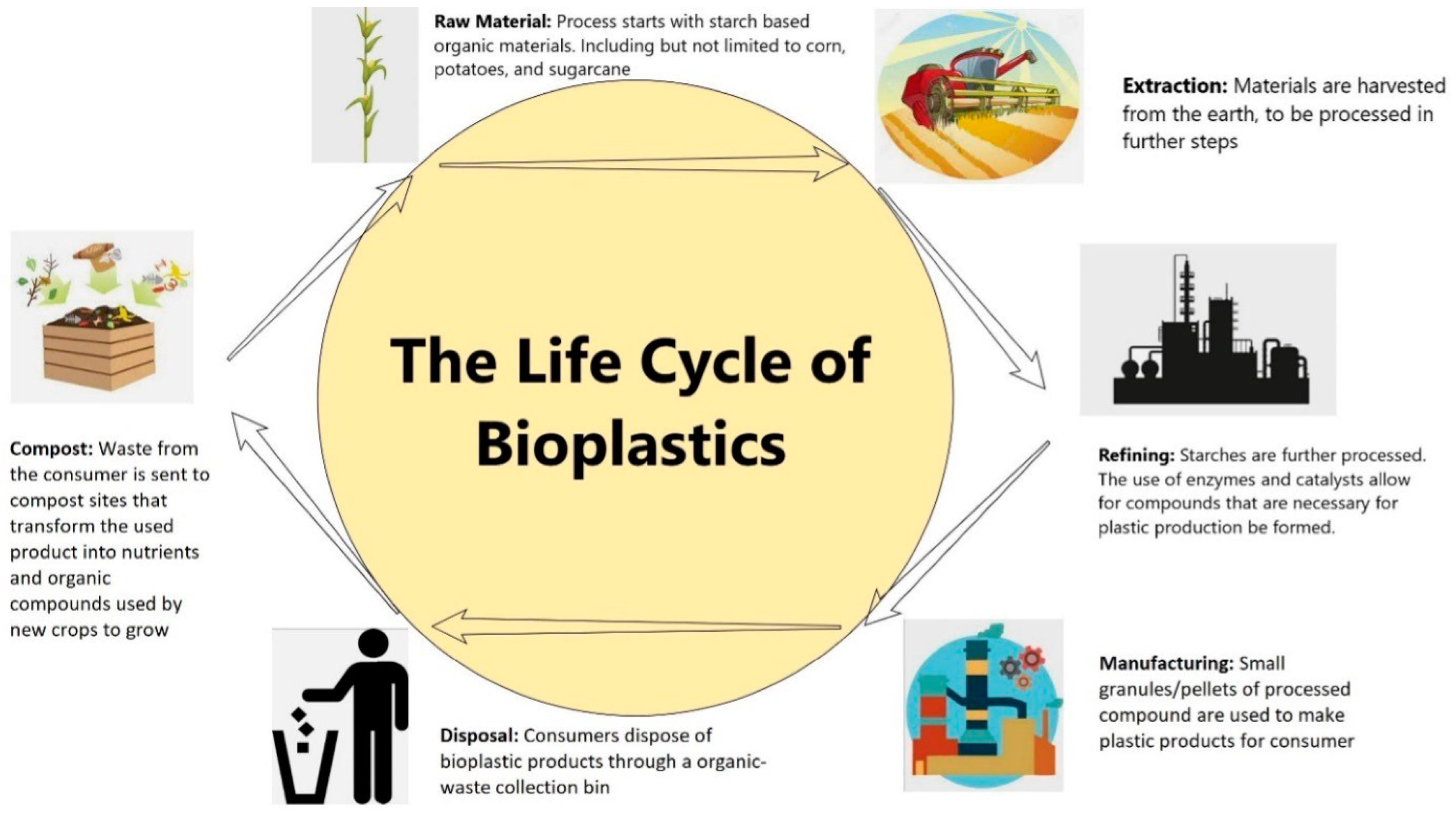

5.6. Life Cycle and Cradle-to-Grave Assessment

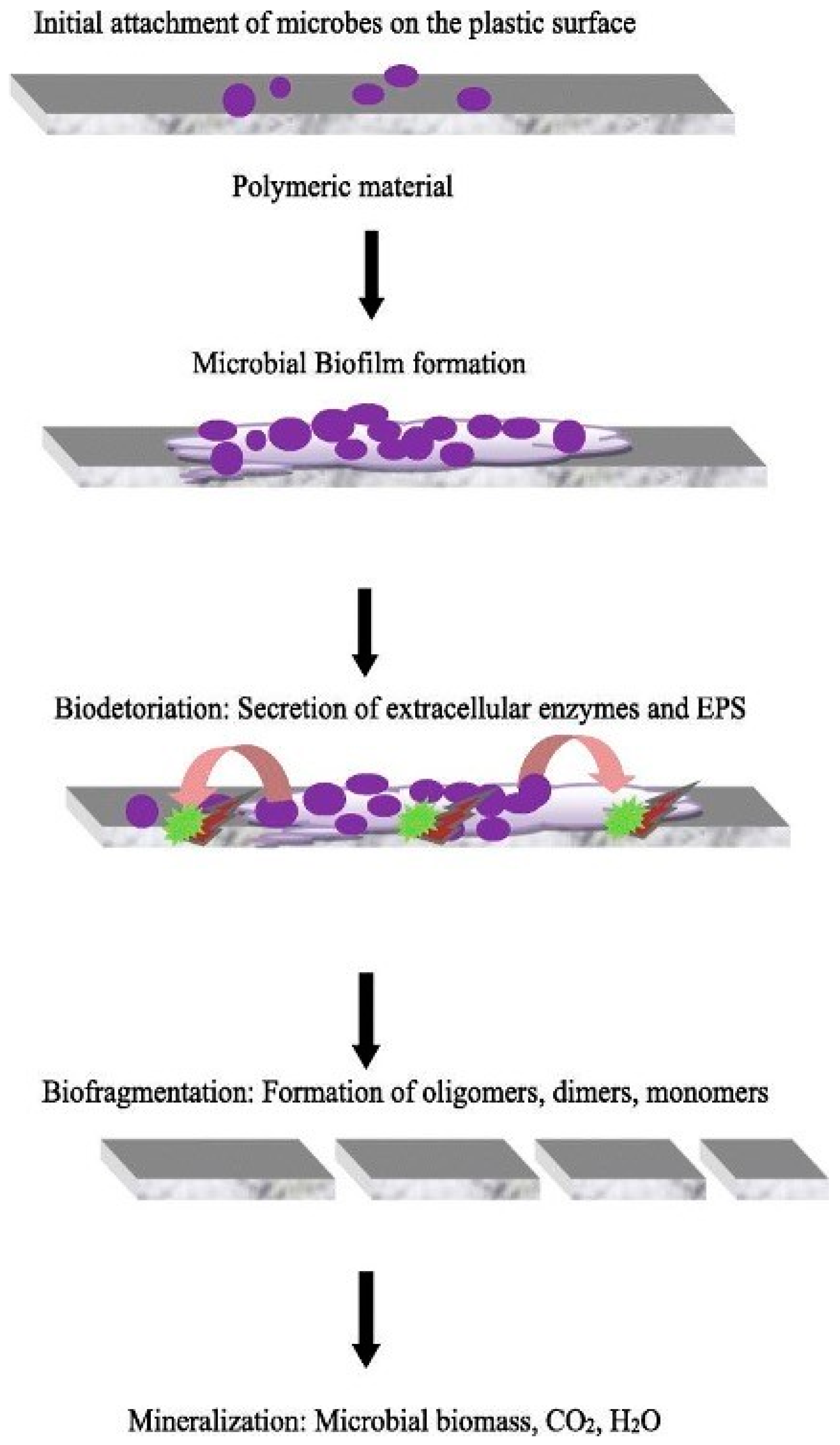

6. Assessment on the End-of-Life of Biodegradable Biobased Polymers

6.1. Analysis of Biodegradation Rates of Biopolymers under Different Mediums

6.1.1. Compost

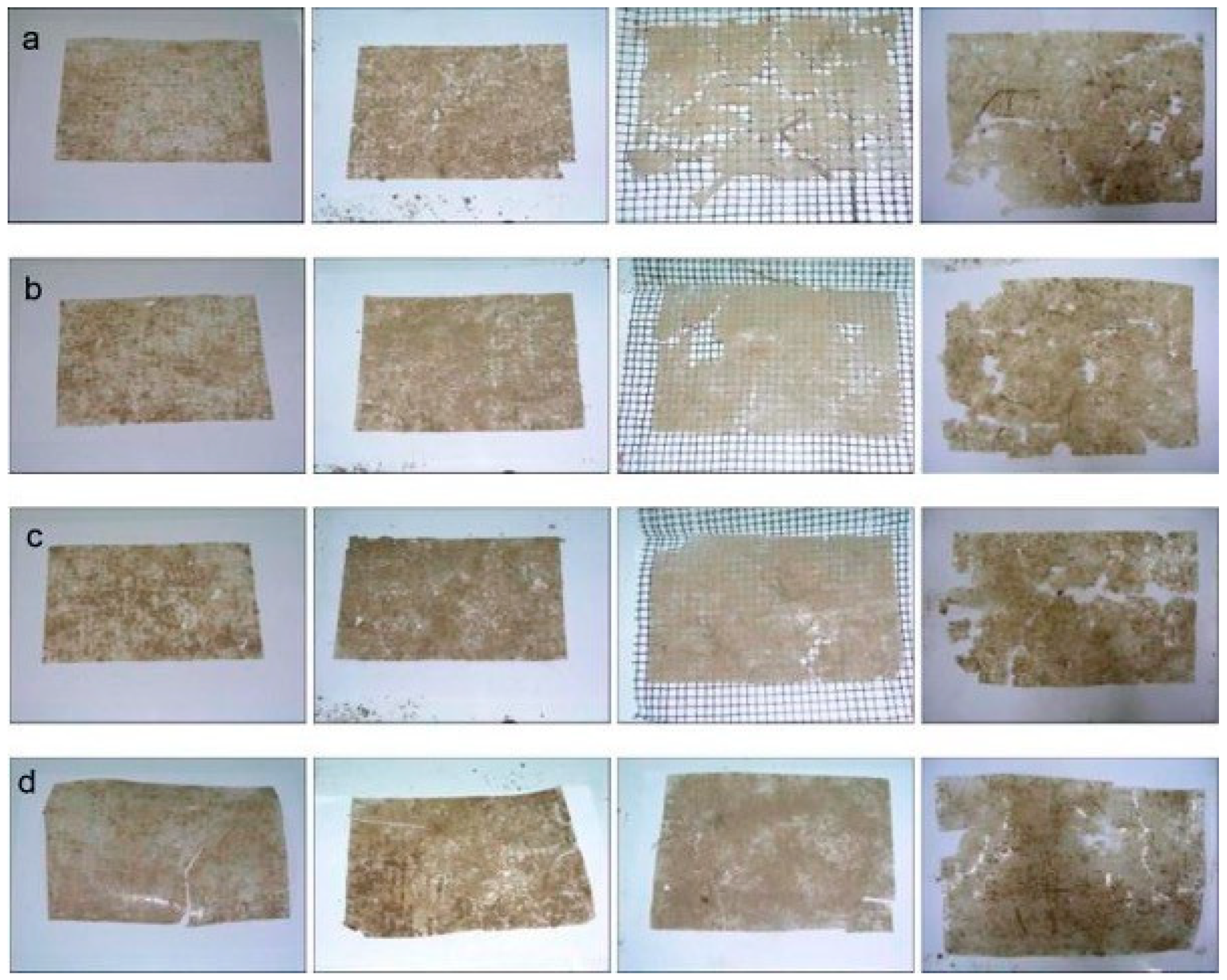

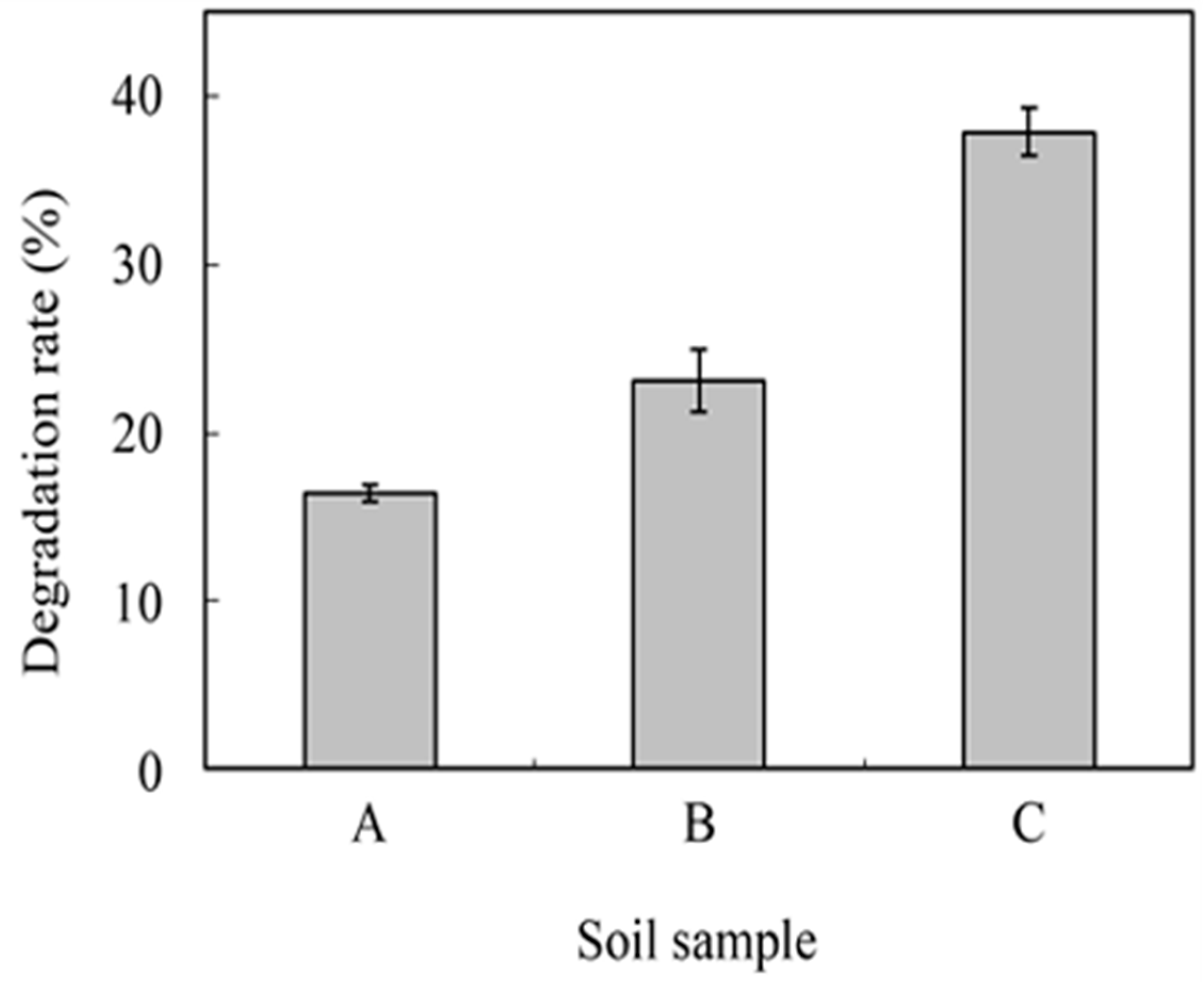

6.1.2. Soil

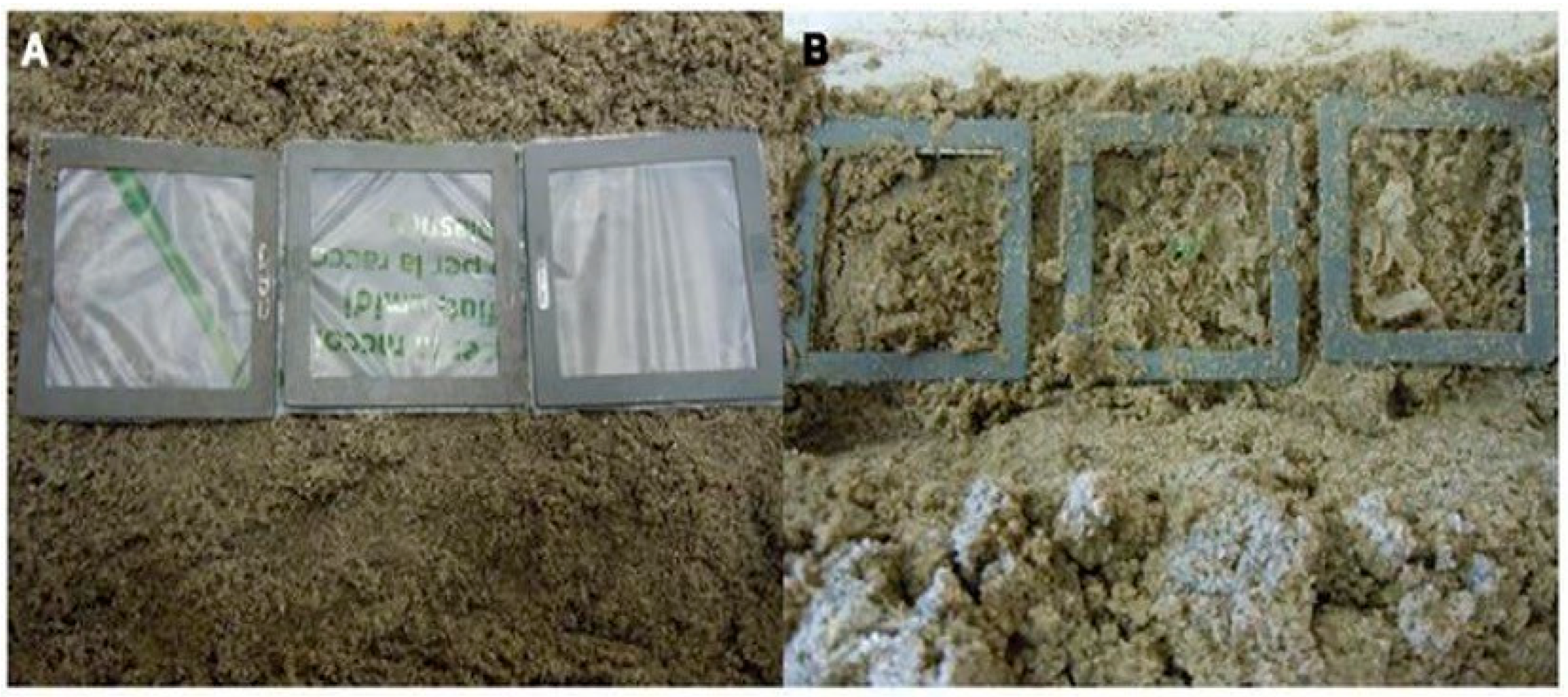

6.1.3. Water

6.2. Advancements on Reusability of Biodegradable Biobased Polymers

6.2.1. Self-Healing Polymers

6.2.2. Memory Shape Polymers

6.3. Advancements on Recycling Biodegradable Biobased Polymers

7. Summary

8. Recommendations for Future Research

8.1. Improving Biodegradation Processes

8.2. Reducing Microplastics and Subsequent Impacts on Environments

8.3. Developing a Standardized Testing Procedure for Bioplastic Degradation

8.4. Analyzing Compost Compositions and Environments

8.5. Developing an End-to-End Production Process

8.6. Identifying and Focusing on Materials with the Highest Potential

Funding

Conflicts of Interest

References

- Shah, M.; Rajhans, S.; Pandya, H.A.; Mankad, A.U. Bioplastic for future: A review then and now. World J. Adv. Res. Rev. 2021, 9, 56–67. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Mei, L.; Song, C.; Cui, X.; Wang, P. The in vivo degradation, absorption and excretion of PCL-based implant. Biomaterials 2006, 27, 1735–1740. [Google Scholar] [CrossRef] [PubMed]

- Kalia, S.; Avérous, L. Biodegradable and Biobased Polymers for Environmental and Biomedical Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Pan, Y.; Farmahini-Farahani, M.; O’Hearn, P.; Xiao, H.; Ocampo, H. An overview of bio-based polymers for packaging materials. J. Bioresour. Bioprod. 1996, 1, 106–113. [Google Scholar] [CrossRef]

- Rujnic-Sokele, M.; Pilipovic, A. Challenges and opportunities of biodegradable plastics: A mini review. Waste Manag. Res. J. Sustain. Circ. Econ. 2017, 35, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Koller, M.; Mukherjee, A.; Obruca, S.; Zinn, M. Polyhydroxyalkanoates (PHA): Microbial synthesis of natural polyesters. In Microbial Production of High-Value Products; Springer: Berlin/Heidelberg, Germany, 2022; pp. 185–236. [Google Scholar]

- DiGregorio, B.E. Biobased Performance Bioplastic: Mirel. Chem. Biol. 2009, 16, 1–2. [Google Scholar] [CrossRef]

- Nampoothiri, K.M.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Muthusamy, M.S.; Pramasivam, S. Bioplastics–An Eco-friendly Alternative to Petrochemical Plastics. Curr. World Environ. J. 2019, 14, 49–59. [Google Scholar] [CrossRef]

- Folino, A.; Karageorgiou, A.; Calabrò, P.S.; Komilis, D. Biodegradation of wasted bioplastics in natural and industrial environments: A review. Sustainability 2020, 12, 6030. [Google Scholar] [CrossRef]

- Vert, M.; Doi, Y.; Hellwich, K.-H.; Hess, M.; Hodge, P.; Kubisa, P.; Rinaudo, M.; Schué, F. Terminology for biorelated polymers and applications (IUPAC Recommendations 2012). Pure Appl. Chem. 2012, 84, 377–410. [Google Scholar] [CrossRef]

- Xie, W.; Li, T.; Tiraferri, A.; Drioli, E.; Figoli, A.; Crittenden, J.C.; Liu, B. Toward the Next Generation of Sustainable Membranes from Green Chemistry Principles. ACS Sustain. Chem. Eng. 2020, 9, 50–75. [Google Scholar] [CrossRef]

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef] [PubMed]

- Morales, A.; Labidi, J.; Gullón, P.; Astray, G. Synthesis of advanced biobased green materials from renewable biopolymers. Curr. Opin. Green Sustain. Chem. 2021, 29, 100436. [Google Scholar] [CrossRef]

- Wellenreuther, C.; Wolf, A. Innovative Feedstocks in Biodegradable Bio-Based Plastics: A Literature Review; Tech. Rep. 194; Hamburg Institute of International Economics: Hamburg, Germany, 2020; Available online: https://hdl.handle.net/10419/228761 (accessed on 7 July 2024).

- Figueirêdo, M.B.; Keij, F.W.; Hommes, A.; Deuss, P.J.; Venderbosch, R.H.; Yue, J.; Heeres, H.J. Efficient Depolymerization of Lignin to Biobased Chemicals Using a Two-Step Approach Involving Ozonation in a Continuous Flow Microreactor Followed by Catalytic Hydrotreatment. ACS Sustain. Chem. Eng. 2019, 7, 18384–18394. [Google Scholar] [CrossRef]

- Chen, C.; Chen, X.; Liu, L.; Wu, J.; Gao, C. Engineering Microorganisms to Produce Bio-Based Monomers: Progress and Challenges. Fermentation 2023, 9, 137. [Google Scholar] [CrossRef]

- Imao, K.; Konishi, R.; Kishida, M.; Hirata, Y.; Segawa, S.; Adachi, N.; Matsuura, R.; Tsuge, Y.; Matsumoto, T.; Tanaka, T.; et al. 1,5-Diaminopentane production from xylooligosaccharides using metabolically engineered Corynebacterium glutamicum displaying beta-xylosidase on the cell surface. Bioresour. Technol. 2017, 245, 1684–1691. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Pu, Z.; Kang, H.; Mi, J.; Liu, S.; Qi, H.; Zhang, L. Zwitterionic peptides encircling-assisted enhanced catalytic performance of lysine decarboxylase for cadaverine biotransformation and mechanism analyses. Chem. Eng. Sci. 2022, 251, 117447. [Google Scholar] [CrossRef]

- Yu, Y.; Zhu, X.; Xu, H.; Zhang, X. Construction of an energy-conserving glycerol utilization pathways for improving an-aerobic succinate production in Escherichia coli. Metab. Eng. 2019, 56, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Naz, F.; Abdur, R.M.; Mumtaz, F.; Elkadi, M.; Verpoort, F. Advances in cyclic ester ring-opening polymerization using heterogeneous catalysts. Appl. Organomet. Chem. 2023, 37, e7296. [Google Scholar] [CrossRef]

- Chen, Z.-H.; Wang, X.-Y.; Tang, Y. Reversible complexation mediated polymerization: An emerging type of organocata-lytically controlled radical polymerization. Polym. Chem. 2022, 13, 2402–2419. [Google Scholar] [CrossRef]

- Lee, S.-H.; Wang, S. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos. Part A Appl. Sci. Manuf. 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Anugrahwidya, R.; Armynah, B.; Tahir, D. Bioplastics Starch-Based with Additional Fiber and Nanoparticle: Characteristics and Biodegradation Performance: A Review. J. Polym. Environ. 2021, 29, 3459–3476. [Google Scholar] [CrossRef]

- Ganesh, A.; Rajan, R.; Simon, S.M.; Thankachan, S. An overview on metal oxide incorporated bionanocomposites and their potential applications. Nano-Struct. Nano-Objects 2024, 38, 101126. [Google Scholar] [CrossRef]

- Omerović, N.; Djisalov, M.; Živojević, K.; Mladenović, M.; Vunduk, J.; Milenković, I.; Knežević, N.; Gadjanski, I.; Vidić, J. Antimicrobial nanoparticles and biodegradable polymer composites for active food packaging applications. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2428–2454. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Cai, W.; Ye, D.; Zhu, Y.; Cui, M.; Xi, J.; Liu, J.; Xing, W. Bio-based polyphenol tannic acid as universal linker between metal oxide nanoparticles and thermoplastic polyurethane to enhance flame retardancy and mechanical properties. Compos. Part B Eng. 2021, 224, 109206. [Google Scholar] [CrossRef]

- Vieira, I.R.S.; de Carvalho, A.P.A.D.; Conte-Junior, C.A. Recent advances in biobased and biodegradable polymer nanocomposites, nanoparticles, and natural antioxidants for antibacterial and antioxidant food packaging applications. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3673–3716. [Google Scholar] [CrossRef] [PubMed]

- Babaei-Ghazvini, A.; Acharya, B.; Korber, D.R. Antimicrobial Biodegradable Food Packaging Based on Chitosan and Met-al/Metal-Oxide Bio-Nanocomposites: A Review. Polymers 2021, 13, 2790. [Google Scholar] [CrossRef]

- Wawrzyńczak, A.; Chudzińska, J.; Feliczak-Guzik, A. Metal and metal oxides nanoparticles as nanofillers for biodegradable polymers. ChemPhysChem 2024, 25, e202300823. [Google Scholar] [CrossRef]

- Chen, J.-K.; Shen, C.-R.; Yeh, C.-H.; Fang, B.-S.; Huang, T.-L.; Liu, C.-L. N-Acetyl Glucosamine Obtained from Chitin by Chitin Degrading Factors in Chitinbacter tainanesis. Int. J. Mol. Sci. 2011, 12, 1187–1195. [Google Scholar] [CrossRef]

- Schrempf, H. Recognition and degradation of chitin by streptomycetes. Antonie Van Leeuwenhoek 2001, 79, 285–289. [Google Scholar] [CrossRef]

- Garrison, T.F.; Murawski, A.; Quirino, R.L. Bio-Based Polymers with Potential for Biodegradability. Polymers 2016, 8, 262. [Google Scholar] [CrossRef] [PubMed]

- Yatigala, N.S.; Bajwa, D.S.; Bajwa, S.G. Compatibilization improves physicomechanical properties of biodegradable bi-obased polymer composites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 315–325. [Google Scholar] [CrossRef]

- Ferraz, F.A.; Muniz, A.S.; Santos Oliveira, A.R.D.; Ferreira César-Oliveira, M.A. Bio-based comb-like copolymers derived from alkyl 10-undecenoates and maleic anhydride. J. Polym. Sci. Part A Polym. Chem. 2018, 56, 1039–1045. [Google Scholar] [CrossRef]

- Quirino, R.L.; Larock, R.C. Rice hull biocomposites, part 2: Effect of the resin composition on the properties of the composite. J. Appl. Polym. Sci. 2011, 121, 2050–2059. [Google Scholar] [CrossRef]

- Mangaraj, S.; Yadav, A.; Bal, L.M.; Dash, S.K.; Mahanti, N.K. Application of Biodegradable Polymers in Food Packaging Industry: A Comprehensive Review. J. Packag. Technol. Res. 2019, 3, 77–96. [Google Scholar] [CrossRef]

- Agarwal, S.; Singhal, S.; Godiya, C.B.; Kumar, S. Prospects and Applications of Starch Based Biopolymers. Int. J. Environ. Anal. Chem. 2023, 103, 6907–6926. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, Q.; Zhang, Q. Rheological and mechanical properties of bioplastics based on gluten- and glutenin-rich fractions. J. Cereal Sci. 2009, 50, 376–380. [Google Scholar] [CrossRef]

- Barkhad, M.S.; Abu-Jdayil, B.; Mourad, A.H.I.; Iqbal, M.Z. Thermal Insulation and Mechanical Properties of Polylactic Acid (PLA) at Different Processing Conditions. Polymers 2020, 12, 2091. [Google Scholar] [CrossRef] [PubMed]

- de Beukelaer, H.; Hilhorst, M.; Workala, Y.; Maaskant, E.; Post, W. Overview of the mechanical, thermal and barrier properties of biobased and/or biodegradable thermoplastic materials. Polym. Test. 2022, 116, 107803. [Google Scholar] [CrossRef]

- Armentano, I.; Fortunati, E.; Burgos, N.; Dominici, F.; Luzi, F.; Fiori, S.; Jiménez, A.; Yoon, K.; Ahn, J.; Kang, S.; et al. Bio-based PLA_PHB plasticized blend films: Processing and structural characterization. LWT 2015, 64, 980–988. [Google Scholar] [CrossRef]

- Qi, L.; Chen, C.; Chen, L.; Yu, L.; Huang, J.; Wang, S.; Wang, Z.; Shi, X.; Chen, C. Scalable fabrication of biodegradable, thermally insulating, fire-proof bioplastic foams via rapid magnetic force assisted squeezing and ambient drying. Chem. Eng. J. 2023, 468, 143595. [Google Scholar] [CrossRef]

- Xiao, W.; Wang, P.; Song, X.; Liao, B.; Yan, K.; Zhang, J.-J. Facile Fabrication of Anisotropic Chitosan Aerogel with Hydro-phobicity and Thermal Superinsulation for Advanced Thermal Management. ACS Sustain. Chem. Eng. 2021, 9, 9348–9357. [Google Scholar] [CrossRef]

- Cai, W.; Lin, B.; Qi, L.; Cui, T.; Li, Z.; Wang, J.; Li, S.; Cao, C.; Rahman, M.Z.; Hu, X.; et al. Bio-based and fireproof radiative cooling aerogel film: Achieving higher sustainability and safety. Chem. Eng. J. 2024, 488, 150784. [Google Scholar] [CrossRef]

- Burgess, S.K.; Leisen, J.E.; Kraftschik, B.E.; Mubarak, C.R.; Kriegel, R.M.; Koros, W.J. Chain Mobility, Thermal, and Mechanical Properties of Poly(ethylene furanoate) Compared to Poly(ethylene terephthalate). Macromolecules 2014, 47, 1383–1391. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Kim, Y.T.; Min, B.; Kim, K.W. General Characteristics of Packaging Materials for Food System. In Innovations in Food Packaging; Han, J.V., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 13–35. [Google Scholar] [CrossRef]

- Brown, W.E. Plastics in Food Packaging; Marcel Dekker, Inc.: New York City, NY, USA, 1992. [Google Scholar]

- Koros, W.J. Barrier Polymers and Structures: Overview; American Chemical Society: Washington, DC, USA, 1990; pp. 1–21. [Google Scholar]

- Loos, K.; Zhang, R.; Pereira, I.; Agostinho, B.; Hu, H.; Maniar, D.; Sbirrazzuoli, N.; Silvestre, A.J.D.; Guigo, N.; Sousa, A.F.A. Perspective on PEF Synthesis, Properties, and End-Life. Front. Chem. 2020, 8, 585. [Google Scholar] [CrossRef]

- Burgess, S.K.; Wenz, G.B.; Kriegel, R.M.; Koros, W.J. Penetrant transport in semicrystalline poly(ethylene furanoate). Polymer 2016, 98, 305–310. [Google Scholar] [CrossRef]

- Hwang, K.-R.; Jeon, W.; Lee, S.Y.; Kim, M.-S.; Park, Y.-K. Sustainable bioplastics: Recent progress in the production of bio-building blocks for the bio-based next-generation polymer PEF. Chem. Eng. J. 2020, 390, 124636. [Google Scholar] [CrossRef]

- Burgess, S.K.; Karvan, O.; Johnson, J.R.; Kriegel, R.M.; Koros, W.J. Oxygen sorption and transport in amorphous poly(ethylene furanoate). Polymer 2014, 55, 4748–4756. [Google Scholar] [CrossRef]

- Burgess, S.K.; Mikkilineni, D.S.; Daniel, B.Y.; Kim, D.J.; Mubarak, C.R.; Kriegel, R.M.; Koros, W.J. Water sorption in poly(ethylene furanoate) compared to poly(ethylene terephthalate). Part 2: Kinetic sorption. Polymer 2014, 55, 6870–6882. [Google Scholar] [CrossRef]

- Burgess, S.K.; Mikkilineni, D.S.; Daniel, B.Y.; Kim, D.J.; Mubarak, C.R.; Kriegel, R.M.; Koros, W.J. Water sorption in poly(ethylene furanoate) compared to poly(ethylene terephthalate). Part 1: Equilibrium sorption. Polymer 2014, 55, 6861–6869. [Google Scholar] [CrossRef]

- Sun, L.; Wang, J.; Mahmud, S.; Jiang, Y.; Zhu, J.; Liu, X. New insight into the mechanism for the excellent gas properties of poly(ethylene 2,5-furandicarboxylate) (PEF): Role of furan ring’s polarity. Eur. Polym. J. 2019, 118, 642–650. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, C.; Yang, F.; Weng, Y. Gas barrier properties of furan-based polyester films analyzed experimentally and by molecular simulations. Polymer 2021, 233, 124200. [Google Scholar] [CrossRef]

- Fei, X.; Wang, J.; Zhu, J.; Wang, X.; Liu, X. Biobased Poly(ethylene 2,5-furancoate): No Longer an Alternative, but an Irreplaceable Polyester in the Polymer Industry. ACS Sustain. Chem. Eng. 2020, 8, 8471–8485. [Google Scholar] [CrossRef]

- Chiarakorn, S.; Permpoonwiwat, C.; Nanthachatchavankul, P. Cost Benefit Analysis of Bioplastic Production in Thailand. Econ. Public Policy 2011, 3, 44–73. [Google Scholar]

- Conner, C.; Jen, J.J.; Bosecker, R.R. 2007 Census of Agriculture; United States Department of Agriculture National Agricultural Statistics Service: Washington, DC, USA, 2011.

- Statista Research Department. Distribution of Global Plastic Materials Production in 2022, by Region. Available online: https://www.statista.com/statistics/281126/global-plastics-production-share-of-various-countries-and-regions/ (accessed on 29 May 2024).

- Milbrandt, A.; Coney, K.; Badgett, A.; Beckham, G.T. Quantification and evaluation of plastic waste in the United States. Resour. Conserv. Recycl. 2022, 183, 106363. [Google Scholar] [CrossRef]

- Borrelle, S.B.; Ringma, J.; Law, K.L.; Monnahan, C.C.; Lebreton, L.; McGivern, A.; Murphy, E.; Jambeck, J.; Leonard, G.H.; Hilleary, M.A.; et al. Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science 2020, 369, 1515–1518. [Google Scholar] [CrossRef] [PubMed]

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef]

- Yan, H.; Cordier, M.; Uehara, T. Future Projections of Global Plastic Pollution: Scenario Analyses and Policy Implications. Sustainability 2024, 16, 643. [Google Scholar] [CrossRef]

- Brizga, J.; Hubacek, K.; Feng, K. The Unintended Side Effects of Bioplastics: Carbon, Land, and Water Footprints. One Earth 2020, 3, 45–53. [Google Scholar] [CrossRef]

- Weiss, M.; Haufe, J.; Carus, M.; Brandão, M.; Bringezu, S.; Hermann, B.; Patel, M.K. A Review of the Environmental Impacts of Biobased Materials. J. Ind. Ecol. 2012, 16, S169–S181. [Google Scholar] [CrossRef]

- Garside, M. Annual Production of Plastics Worldwide from 1950 to 2022. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 29 May 2024).

- Joseph, T.M.; Unni, A.B.; Joshy, K.S.; Mahapatra, D.K.; Haponiuk, J.; Thomas, S. Emerging Bio-Based Polymers from Lab to Market: Current Strategies, Market Dynamics and Research Trends. C 2023, 9, 30. [Google Scholar] [CrossRef]

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef] [PubMed]

- Plastics Europe. Plastics—the Fast Facts 2023. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2023/ (accessed on 29 May 2024).

- Li, Y.; Wang, S.; Qian, S.; Liu, Z.; Weng, Y.; Zhang, Y. Depolymerization and Re/Upcycling of Biodegradable PLA Plastics. ACS Omega 2024, 9, 13509–13521. [Google Scholar] [CrossRef] [PubMed]

- Ghomi, E.R.; Khosravi, F.; Ardahaei, A.S.; Dai, Y.; Neisiany, R.E.; Foroughi, F.; Wu, M.; Das, O.; Ramakrishna, S. The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material. Polymers 2021, 13, 1854. [Google Scholar] [CrossRef]

- Taib, N.-A.A.B.; Rahman, R.; Huda, D.; Kuok, K.K.; Hamdan, S.; Bin Bakri, M.K.; Bin Julaihi, M.R.M.; Khan, A. A review on poly lactic acid (PLA) as a biodegradable polymer. Polym. Bull. 2022, 80, 1179–1213. [Google Scholar] [CrossRef]

- Mehmood, A.; Raina, N.; Phakeenuya, V.; Wonganu, B.; Cheenkachorn, K. The current status and market trend of polylactic acid as biopolymer: Awareness and needs for sustainable development. Mater. Today Proc. 2023, 72, 3049–3055. [Google Scholar] [CrossRef]

- Vicente, D.; Proença, D.N.; Morais, P.V. The Role of Bacterial Polyhydroalkanoate (PHA) in a Sustainable Future: A Review on the Biological Diversity. Int. J. Environ. Res. Public Heal. 2023, 20, 2959. [Google Scholar] [CrossRef] [PubMed]

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent advances in biodegradable polymers for sustainable applications. Npj Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Jiang, G.; Hill, D.J.; Kowalczuk, M.; Johnston, B.; Adamus, G.; Irorere, V.; Radecka, I. Carbon Sources for Polyhydroxyalkanoates and an Integrated Biorefinery. Int. J. Mol. Sci. 2016, 17, 1157. [Google Scholar] [CrossRef]

- Verma, S.K.; Prasad, A.; Katiyar, V. State of art review on sustainable biodegradable polymers with a market overview for sustainability packaging. Mater. Today Sustain. 2024, 26, 100776. [Google Scholar] [CrossRef]

- Price, S.; Kuzhiumparambil, U.; Pernice, M.; Ralph, P. Techno-economic analysis of cyanobacterial PHB bioplastic production. J. Environ. Chem. Eng. 2022, 10, 107502. [Google Scholar] [CrossRef]

- Lepe, P.T.; Heredia, K.V.; Namur, E.C.; Fabián, G.C.S.; GarcíaEnriquez, S. Economics and commercialization of bioplastics. In Bioplastics for Sustainability; Elsevier: Amsterdam, The Netherlands, 2024; pp. 271–309. [Google Scholar]

- Platnieks, O.; Gaidukovs, S.; Thakur, V.K.; Barkane, A.; Beluns, S. Bio-based poly (butylene succinate): Recent progress, challenges and future opportunities. Eur. Polym. J. 2021, 161, 110855. [Google Scholar] [CrossRef]

- Rajgond, V.; Mohite, A.; More, N.; More, A. Biodegradable polyester-polybutylene succinate (PBS): A review. Polym. Bull. 2023, 81, 5703–5752. [Google Scholar] [CrossRef]

- Nghiem, N.P.; Kleff, S.; Schwegmann, S. Succinic Acid: Technology Development and Commercialization. Fermentation 2017, 3, 26. [Google Scholar] [CrossRef]

- Fei, X.; Wang, J.; Zhang, X.; Jia, Z.; Jiang, Y.; Liu, X. Recent Progress on Bio-Based Polyesters Derived from 2,5-Furandicarbonxylic Acid (FDCA). Polymers 2022, 14, 625. [Google Scholar] [CrossRef] [PubMed]

- Gandini, A.; Silvestre, A.J.D.; Neto, C.P.; Sousa, A.F.; Gomes, M. The furan counterpart of poly(ethylene terephthalate): An alternative material based on renewable resources. J. Polym. Sci. Part A Polym. Chem. 2008, 47, 295–298. [Google Scholar] [CrossRef]

- Gomes, M.; Gandini, A.; Silvestre, A.J.D.; Reis, B. Synthesis and characterization of poly(2,5-furan dicarboxylate)s based on a variety of diols. J. Polym. Sci. Part A Polym. Chem. 2011, 49, 3759–3768. [Google Scholar] [CrossRef]

- Jiang, M.; Liu, Q.; Zhang, Q.; Ye, C.; Zhou, G. A series of furan-aromatic polyesters synthesized via direct esterification method based on renewable resources. J. Polym. Sci. Part A Polym. Chem. 2012, 50, 1026–1036. [Google Scholar] [CrossRef]

- Avantium. FDCA Flagship Plant-YXY Technology. 2022. Available online: https://avantium.com/technologies/yxy/ (accessed on 19 July 2024).

- de Jong, E.; Dam, M.A.; Sipos, L.; Gruter, G.-J.M. Furandicarboxylic Acid (FDCA), A Versatile Building Block for a Very Interesting Class of Polyesters. In Biobased Monomers, Polymers, and Materials; Smith, P.B., Gross, R.A., Eds.; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2012; Volume 1105, pp. 1–13. ISBN 0-8412-2767-5. [Google Scholar]

- de Jong, E.; Visser, H.R.A.; Dias, A.S.; Harvey, C.; Gruter, G.-J.M. The Road to Bring FDCA and PEF to the Market. Polymers 2022, 14, 943. [Google Scholar] [CrossRef]

- Lee, J.A.; Ahn, J.H.; Kim, I.; Li, S.; Lee, S.Y. Synthesis, Characterization, and Application of Fully Biobased and Biodegradable Nylon-4,4 and -5,4. ACS Sustain. Chem. Eng. 2020, 8, 5604–5614. [Google Scholar] [CrossRef]

- Fyfe, C.A.; Randall, L.H.; Burlinson, N.E. Water penetration in nylon 6,6: Absorption, desorption, and exchange studied by NMR microscopy. J. Polym. Sci. Part A Polym. Chem. 1993, 31, 159–168. [Google Scholar] [CrossRef]

- Reuvers, N.J.W.; Huinink, H.P.; Fischer, H.R.; Adan, O.C.G. Quantitative Water Uptake Study in Thin Nylon-6 Films with NMR Imaging. Macromolecules 2012, 45, 1937–1945. [Google Scholar] [CrossRef]

- Laredo, E.; Grimau, M.; Sánchez, F.; Bello, A. Water Absorption Effect on the Dynamic Properties of Nylon-6 by Dielectric Spectroscopy. Macromolecules 2003, 36, 9840–9850. [Google Scholar] [CrossRef]

- Wayman, C.; Niemann, H. The fate of plastic in the ocean environment—A minireview. Environ. Sci. Process. Impacts 2021, 23, 198–212. [Google Scholar] [CrossRef] [PubMed]

- Lau, W.W.Y.; Shiran, Y.; Bailey, R.M.; Cook, E.; Stuchtey, M.R.; Koskella, J.; Velis, C.A.; Godfrey, L.; Boucher, J.; Murphy, M.B.; et al. Evaluating scenarios toward zero plastic pollution. Science 2020, 369, 1455–1461. [Google Scholar] [CrossRef] [PubMed]

- Alves, B. Plastic Waste Management Market Size Worldwide in 2021 and 2022, with a Forecast to 2027. Available online: https://www.statista.com/statistics/1357622/projected-global-plastic-waste-management-market-size/ (accessed on 19 July 2024).

- Kunduru, K.R.; Basu, A.; Domb, A.J. Biodegradable polymers: Medical applications. In Encyclopedia of Polymer Science and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 1–22. [Google Scholar]

- Alaswad, S.O.; Mahmoud, A.S.; Arunachalam, P. Recent Advances in Biodegradable Polymers and Their Biological Applications: A Brief Review. Polymers 2022, 14, 4924. [Google Scholar] [CrossRef] [PubMed]

- Oleksy, M.; Dynarowicz, K.; Aebisher, D. Advances in Biodegradable Polymers and Biomaterials for Medical Applications—A Review. Molecules 2023, 28, 6213. [Google Scholar] [CrossRef] [PubMed]

- Morone, P.; Tartiu, V.E.; Falcone, P. Assessing the potential of biowaste for bioplastics production through social network analysis. J. Clean. Prod. 2015, 90, 43–54. [Google Scholar] [CrossRef]

- OECD. Policies for Bioplastics in the Context of a Bioeconomy. In OECD Science, Technology and Industry Policy Papers 10; OECD Publishing: Paris, France, 2013. [Google Scholar]

- Escobar, N.; Haddad, S.; Boerner, J.; Britz, W. Land use mediated GHG emissions and spillovers from increased consumption of bioplastics. Environ. Res. Lett. 2018, 13, 125005. [Google Scholar] [CrossRef]

- Iles, A.; Martin, A.N. Expanding bioplastics production: Sustainable business innovation in the chemical industry. J. Clean. Prod. 2013, 45, 38–49. [Google Scholar] [CrossRef]

- Morais, A.M.M.B.; Morais, R.M.S.C.; Drew, D.; Mustakhimov, I.; Lackner, M. Biodegradable Bio-based Plastics Toward Climate Change Mitigation. In Handbook of Climate Change Mitigation and Adaptation; Springer International Publishing: Cham, Switzerland, 2022; pp. 1987–2029. [Google Scholar]

- Kurian, J.V. A New Polymer Platform for the Future—Sorona® from Corn Derived 1,3-Propanediol. J. Polym. Environ. 2005, 13, 159–167. [Google Scholar] [CrossRef]

- Food and Agriculture Organisation of the United Nation. FAOSTAT; FAO: Rome, Italy, 2019. [Google Scholar]

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Patel, M.K.; Bechu, A.; Villegas, J.D.; Bergez-Lacoste, M.; Yeung, K.; Murphy, R.; Woods, J.; Mwabonje, O.N.; Ni, Y.; Patel, A.D.; et al. Second-generation bio-based plastics are becoming a reality–Non-renewable energy and greenhouse gas (GHG) balance of succinic acid-based plastic end products made from lignocellulosic biomass. Biofuels Bioprod. Biorefining 2018, 12, 426–441. [Google Scholar] [CrossRef]

- Razza, F.; Cerutti, A.K. Life cycle and environmental cycle assessment of biodegradable plastics for agriculture. In Soil Degradable Bioplastics for a Sustainable Modern Agriculture; Springer: Berlin/Heidelberg, Germany, 2017; pp. 169–185. [Google Scholar]

- Ita-Nagy, D.; Vázquez-Rowe, I.; Kahhat, R.; Chinga-Carrasco, G.; Quispe, I. Correction to: Reviewing environmental life cycle impacts of biobased polymers: Current trends and methodological challenges. Int. J. Life Cycle Assess. 2021, 26, 633. [Google Scholar] [CrossRef]

- Harding, K.; Dennis, J.; Vonblottnitz, H.; Harrison, S. Environmental analysis of plastic production processes: Comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J. Biotechnol. 2007, 130, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Khoo, H.H.; Tan, R.B.H. Environmental impacts of conventional plastic and bio-based carrier bags: Part 2: End-of-life options. Int. J. Life Cycle Assess. 2010, 15, 338–345. [Google Scholar] [CrossRef]

- Khoo, H.H.; Tan, R.B.H.; Chng, K.W.L. Environmental impacts of conventional plastic and bio-based carrier bags: Part 1: Life cycle production. Int. J. Life Cycle Assess. 2010, 15, 284–293. [Google Scholar] [CrossRef]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Sustainability assessments of bio-based polymers. Polym. Degrad. Stab. 2013, 98, 1898–1907. [Google Scholar] [CrossRef]

- Madival, S.; Auras, R.; Singh, S.P.; Narayan, R. Assessment of the environmental profile of PLA, PET and PS clamshell con-tainers using LCA methodology. J. Clean. Prod. 2009, 17, 1183–1194. [Google Scholar] [CrossRef]

- Posen, I.D.; Jaramillo, P.; Landis, A.E.; Griffin, W.M. Greenhouse gas mitigation for U.S. plastics production: Energy first, feedstocks later. Environ. Res. Lett. 2017, 12, 034024. [Google Scholar] [CrossRef]

- Leejarkpai, T.; Mungcharoen, T.; Suwanmanee, U. Comparative assessment of global warming impact and eco-efficiency of PS (polystyrene), PET (polyethylene terephthalate) and PLA (polylactic acid) boxes. J. Clean. Prod. 2016, 125, 95–107. [Google Scholar] [CrossRef]

- Hermansson, F.; Janssen, M.; Gellerstedt, F. Environmental evaluation of Durapulp bio-composite using LCA—Comparison of two different applications. J. Sci. Technol. For. Prod. Process. 2016, 5, 68–76. [Google Scholar]

- Deng, Y.; Achten, W.M.; Van Acker, K.; Duflou, J.R. Life cycle assessment of wheat gluten powder and derived packaging film. Biofuels Bioprod. Biorefining 2013, 7, 429–458. [Google Scholar] [CrossRef]

- Hermann, B.G.; Blok, K.; Patel, M.K. Twisting biomaterials around your little finger: Environmental impacts of bio-based wrappings. Int. J. Life Cycle Assess. 2010, 15, 346–358. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Hirao, M.; Narita, K.; Sugiyama, E.; Oliveira, S.; Chapman, S.; Arakaki, M.M.; Cappra, C.M. Environmental Performance of Biomass-Derived Chemical Production: A Case Study on Sugarcane-Derived Polyethylene. J. Chem. Eng. Jpn. 2013, 46, 319–325. [Google Scholar] [CrossRef]

- Liptow, C.; Tillman, A. A Comparative Life Cycle Assessment Study of Polyethylene Based on Sugarcane and Crude Oil. J. Ind. Ecol. 2012, 16, 420–435. [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Faaij, A.P.C.; Lundquist, L.; Schenker, U.; Briois, J.F.; Patel, M.K. Life cycle impact assessment of bio-based plastics from sugarcane ethanol. J. Clean. Prod. 2015, 90, 114–127. [Google Scholar] [CrossRef]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- Nair, N.; Sekhar, V.; Nampoothiri, K.; Pandey, A. Biodegradation of biopolymers. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 739–755. [Google Scholar]

- Lambert, S.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef]

- Meereboer, K.W.; Misra, M.; Mohanty, A.K. Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem. 2020, 22, 5519–5558. [Google Scholar] [CrossRef]

- Pérez-Arauz, A.; Aguilar-Rabiela, A.; Vargas-Torres, A.; Rodríguez-Hernández, A.-I.; Chavarría-Hernández, N.; Vergara-Porras, B.; López-Cuellar, M. Production and characterization of biodegradable films of a novel polyhydroxyalkanoate (PHA) syn-thesized from peanut oil. Food Packag. Shelf Life 2019, 20, 100297. [Google Scholar] [CrossRef]

- Woolnough, C.A.; Yee, L.H.; Charlton, T.S.; Foster, L.J.R. A Tuneable Switch for Controlling Environmental Degradation of Bioplastics: Addition of Isothiazolinone to Polyhydroxyalkanoates. PLoS One 2013, 8, e75817. [Google Scholar] [CrossRef] [PubMed]

- Kalita, N.K.; Bhasney, S.M.; Kalamdhad, A.; Katiyar, V. Biodegradable kinetics and behavior of bio-based polyblends under simulated aerobic composting conditions. J. Environ. Manag. 2020, 261, 110211. [Google Scholar] [CrossRef] [PubMed]

- Sarasa, J.; Gracia, J.M.; Javierre, C. Study of the biodisintegration of a bioplastic material waste. Bioresour. Technol. 2009, 100, 3764–3768. [Google Scholar] [CrossRef] [PubMed]

- ASTM D5338; Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials Under Controlled Composting Conditions, Incorporating Thermophilic Temperatures, 3rd ed. ASTM International: West Conshohocken, PA, USA, 2021.

- Kale, G.; Auras, R.; Singh, S.P.; Narayan, R. Biodegradability of polylactide bottles in real and simulated composting condi-tions. Polym. Test. 2007, 26, 1049–1061. [Google Scholar] [CrossRef]

- Tyagi, P.; Agate, S.; Velev, O.D.; Lucia, L.; Pal, L. A Critical Review of the Performance and Soil Biodegradability Profiles of Biobased Natural and Chemically Synthesized Polymers in Industrial Applications. Environ. Sci. Technol. 2022, 56, 2071–2095. [Google Scholar] [CrossRef] [PubMed]

- Degli Innocenti, F. Handbook of Biodegradable Polymers; Bastioli, C., Ed.; Rapra Technology Limited: Shawbury, UK, 2005. [Google Scholar]

- Rudnik, E.; Briassoulis, D. Degradation behaviour of poly(lactic acid) films and fibres in soil under Mediterranean field conditions and laboratory simulations testing. Ind. Crop. Prod. 2011, 33, 648–658. [Google Scholar] [CrossRef]

- Adhikari, D.; Mukai, M.; Kubota, K.; Kai, T.; Kaneko, N.; Araki, K.S.; Kubo, M. Degradation of Bioplastics in Soil and Their Degradation Effects on Environmental Microorganisms. J. Agric. Chem. Environ. 2016, 5, 23–34. [Google Scholar] [CrossRef]

- Suyama, T.; Tokiwa, Y.; Ouichanpagdee, P.; Kanagawa, T.; Kamagata, Y. Phylogenetic Affiliation of Soil Bacteria That Degrade Aliphatic Polyesters Available Commercially as Biodegradable Plastics. Appl. Environ. Microbiol. 1998, 64, 5008–5011. [Google Scholar] [CrossRef]

- Blinková, M.; Boturová, K. Influence of bacteria on degradation of bioplastics. IOP Conf. Ser. Earth Environ. Sci. 2017, 92, 012004. [Google Scholar] [CrossRef]

- El Abed, N.; Özogul, F. The risks of marine micro/nano-plastics on seafood safety and human health. In Advances in Food and Nutrition Research; Elsevier: Amsterdam, The Netherlands, 2023; pp. 229–271. [Google Scholar]

- Andrady, A.L. Persistence of plastic litter in the oceans. In Marine Anthropogenic Litter; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Ghattas, A.-K.; Fischer, F.; Wick, A.; Ternes, T.A. Anaerobic biodegradation of (emerging) organic contaminants in the aquatic environment. Water Res. 2017, 116, 268–295. [Google Scholar] [CrossRef] [PubMed]

- Vogel, T.M.; Criddle, C.S.; McCarty, P.L. ES&T Critical Reviews: Transformations of halogenated aliphatic compounds. Environ. Sci. Technol. 1987, 21, 722–736. [Google Scholar] [CrossRef] [PubMed]

- Neilson, A.H.; Allard, A.-S. Environmental Degradation and Transformation of Organic Chemicals; Taylor & Francis: London, UK, 2007. [Google Scholar]

- Rücker, C.; Kümmerer, K. Modeling and predicting aquatic aerobic biodegradation—A review from a user’s perspective. Green Chem. 2012, 14, 875–887. [Google Scholar] [CrossRef]

- Dilkes-Hoffman, L.S.; Lant, P.A.; Laycock, B.; Pratt, S. The rate of biodegradation of PHA bioplastics in the marine environment: A meta-study. Mar. Pollut. Bull. 2019, 142, 15–24. [Google Scholar] [CrossRef] [PubMed]

- Tosin, M.; Weber, M.; Siotto, M.; Lott, C.; Degli Innocenti, F. Laboratory Test Methods to Determine the Degradation of Plastics in Marine Environmental Conditions. Front. Microbiol. 2012, 3, 225. [Google Scholar] [CrossRef]

- Imam, S.H.; Gordon, S.H.; Shogren, R.L.; Tosteson, T.R.; Govind, N.S.; Greene, R.V. Degradation of Starch–Poly(β-Hydroxybutyrate-Co-β-Hydroxyvalerate) Bioplastic in Tropical Coastal Waters. Appl. Environ. Microbiol. 1999, 65, 2. [Google Scholar] [CrossRef] [PubMed]

- Judawisastra, H.; Sitohang, R.D.R.; Marta, L. Water absorption and its effect on the tensile properties of tapioca starch/polyvinyl alcohol bioplastics. IOP Conf. Ser. Mater. Sci. Eng. 2017, 223, 012066. [Google Scholar] [CrossRef]

- Tsuji, H.; Suzuyoshi, K. Environmental degradation of biodegradable polyesters 2. Poly(ε-caprolactone), poly[(R)-3-hydroxybutyrate], and poly(L-lactide) films in natural dynamic seawater. Polym. Degrad. Stab. 2002, 75, 357–365. [Google Scholar]

- Deroiné, M.; César, G.; Le Duigou, A.; Davies, P.; Bruzaud, S. Natural Degradation and Biodegradation of Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate) in Liquid and Solid Marine Environments. J. Polym. Environ. 2015, 23, 493–505. [Google Scholar] [CrossRef]

- Ganesh, K.A.; Anjana, K.; Hinduja, M.; Sujitha, K.; Dharani, G. Review on plastic wastes in marine environment—Biodegradation and biotechnological solutions. Mar. Pollut. Bull. 2020, 150, 110733. [Google Scholar]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797, Correction in Nature 2002, 415, 817. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Liang, C.; Wang, R.; Yao, X.; Guo, P.; Yuan, W.; Liu, Y.; Song, Y.; Li, Z.; Xie, X. The fabrication of a highly efficient self-healing hydrogel from natural biopolymers loaded with exosomes for the synergistic promotion of severe wound healing. Biomater. Sci. 2020, 8, 313–324. [Google Scholar] [CrossRef] [PubMed]

- Guadagno, L.; Vertuccio, L.; Barra, G.; Naddeo, C.; Sorrentino, A.; Lavorgna, M.; Raimondo, M.; Calabrese, E. Eco-friendly polymer nanocomposites designed for self-healing applications. Polymer 2021, 223, 123718. [Google Scholar] [CrossRef]

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 2008, 33, 479–522. [Google Scholar] [CrossRef]

- Alauzen, T.; Ross, S.; Madbouly, S. Biodegradable shape-memory polymers and composites. Phys. Sci. Rev. 2023, 8, 2049–2070. [Google Scholar] [CrossRef]

- Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-Like Malleable Materials from Permanent Organic Networks. Science 2011, 334, 965–968. [Google Scholar] [CrossRef] [PubMed]

- Lucherelli, M.A.; Duval, A.; Avérous, L. Biobased vitrimers: Towards sustainable and adaptable performing polymer materials. Prog. Polym. Sci. 2022, 127, 101515. [Google Scholar] [CrossRef]

- Wu, J.; Yu, X.; Zhang, H.; Guo, J.; Hu, J.; Li, M.-H. Fully Biobased Vitrimers from Glycyrrhizic Acid and Soybean Oil for Self-Healing, Shape Memory, Weldable, and Recyclable Materials. ACS Sustain. Chem. Eng. 2020, 8, 6479–6487. [Google Scholar] [CrossRef]

- Capelot, M.; Unterlass, M.M.; Tournilhac, F.; Leibler, L. Catalytic Control of the Vitrimer Glass Transition. ACS Macro Lett. 2012, 1, 789–792. [Google Scholar] [CrossRef]

- Hao, C.; Liu, T.; Zhang, S.; Brown, L.; Li, R.; Xin, J.; Zhong, T.; Jiang, L.; Zhang, J. A High-Lignin-Content, Removable, and Glycol-Assisted Repairable Coating Based on Dynamic Covalent Bonds. ChemSusChem 2019, 12, 1049–1058. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, T.; Hao, C.; Wang, L.; Han, J.; Liu, H.; Zhang, J. Preparation of a lignin-based vitrimer material and its potential use for recoverable adhesives. Green Chem. 2018, 20, 2995–3000. [Google Scholar] [CrossRef]

- Badia, J.; Ribes-Greus, A. Mechanical recycling of polylactide, upgrading trends and combination of valorization techniques. Eur. Polym. J. 2016, 84, 22–39. [Google Scholar] [CrossRef]

- Briassoulis, D.; Pikasi, A.; Hiskakis, M. Recirculation potential of post-consumer /industrial bio-based plastics through mechanical recycling—Techno-economic sustainability criteria and indicators. Polym. Degrad. Stab. 2021, 83, 109217. [Google Scholar] [CrossRef]

- Kumar, R.; Sadeghi, K.; Jang, J.; Seo, J. Mechanical, chemical, and bio-recycling of biodegradable plastics: A review. Sci. Total. Environ. 2023, 882, 163446. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Sutera, F.; Gulino, E.F.; Morreale, M. Degradation and Recycling of Films Based on Biodegradable Polymers: A Short Review. Polymers 2019, 11, 651. [Google Scholar] [CrossRef] [PubMed]

- García-Depraect, O.; Bordel, S.; Lebrero, R.; Santos-Beneit, F.; Börner, R.A.; Börner, T.; Muñoz, R. Inspired by nature: Microbial production, degradation and valorization of biodegradable bioplastics for life-cycle-engineered products. Biotechnol. Adv. 2021, 53, 107772. [Google Scholar] [CrossRef] [PubMed]

- Wierckx, N.; Prieto, M.A.; Pomposiello, P.; de Lorenzo, V.; O’Connor, K.; Blank, L.M. Plastic waste as a novel substrate for industrial biotechnology. Microb. Biotechnol. 2015, 8, 900–903. [Google Scholar] [CrossRef]

- Tournier, V.; Topham, C.M.; Gilles, A.; David, B.; Folgoas, C.; Moya-Leclair, E.; Kamionka, E.; Desrousseaux, M.-L.; Texier, H.; Gavalda, S.; et al. An engineered PET depolymerase to break down and recycle plastic bottles. Nature 2020, 580, 216–219. [Google Scholar] [CrossRef]

| PLA Production Case 1 (Million USD) | PLA Production Case 2 (Million USD) | HDPE Production (Million USD) | |

|---|---|---|---|

| Direct Cost - Operating Cost | 225 | 246 | 77 |

| - Investment Cost | 330.74 | 330.74 | 108.74 |

| Indirect Cost - CH4 Emissions | 20 | 10 | 13 |

| - CO2 Emissions | 10 | 10 | 124 |

| - CO Emissions | - | - | 1 |

| - SO2 Emissions | - | - | 3 |

| - NO2 Emissions | - | - | 2 |

| - Opportunity Cost of Land | 0.92 | 0.92 | 0.92 |

| - Total Indirect Costs | 30.92 | 20.92 | 143.92 |

| Total Cost | 586.66 | 597.66 | 329.66 |

| Benefits - Direct Benefits | 300 | 300 | 143 |

| - Indirect Benefits | 294 | - | - |

| Total Benefits | 594 | 300 | 143 |

| Net Benefits | 7.34 | −297.66 | −186.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jha, S.; Akula, B.; Enyioma, H.; Novak, M.; Amin, V.; Liang, H. Biodegradable Biobased Polymers: A Review of the State of the Art, Challenges, and Future Directions. Polymers 2024, 16, 2262. https://doi.org/10.3390/polym16162262

Jha S, Akula B, Enyioma H, Novak M, Amin V, Liang H. Biodegradable Biobased Polymers: A Review of the State of the Art, Challenges, and Future Directions. Polymers. 2024; 16(16):2262. https://doi.org/10.3390/polym16162262

Chicago/Turabian StyleJha, Swarn, Bhargav Akula, Hannah Enyioma, Megan Novak, Vansh Amin, and Hong Liang. 2024. "Biodegradable Biobased Polymers: A Review of the State of the Art, Challenges, and Future Directions" Polymers 16, no. 16: 2262. https://doi.org/10.3390/polym16162262

APA StyleJha, S., Akula, B., Enyioma, H., Novak, M., Amin, V., & Liang, H. (2024). Biodegradable Biobased Polymers: A Review of the State of the Art, Challenges, and Future Directions. Polymers, 16(16), 2262. https://doi.org/10.3390/polym16162262