Toughening Polylactic Acid with Ultrafine Fully Vulcanized Powdered Natural Rubber Graft-Copolymerized with Poly(styrene-co-acrylonitrile): Tailoring the Styrene–Acrylonitrile Ratio for Enhanced Interfacial Interactions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used

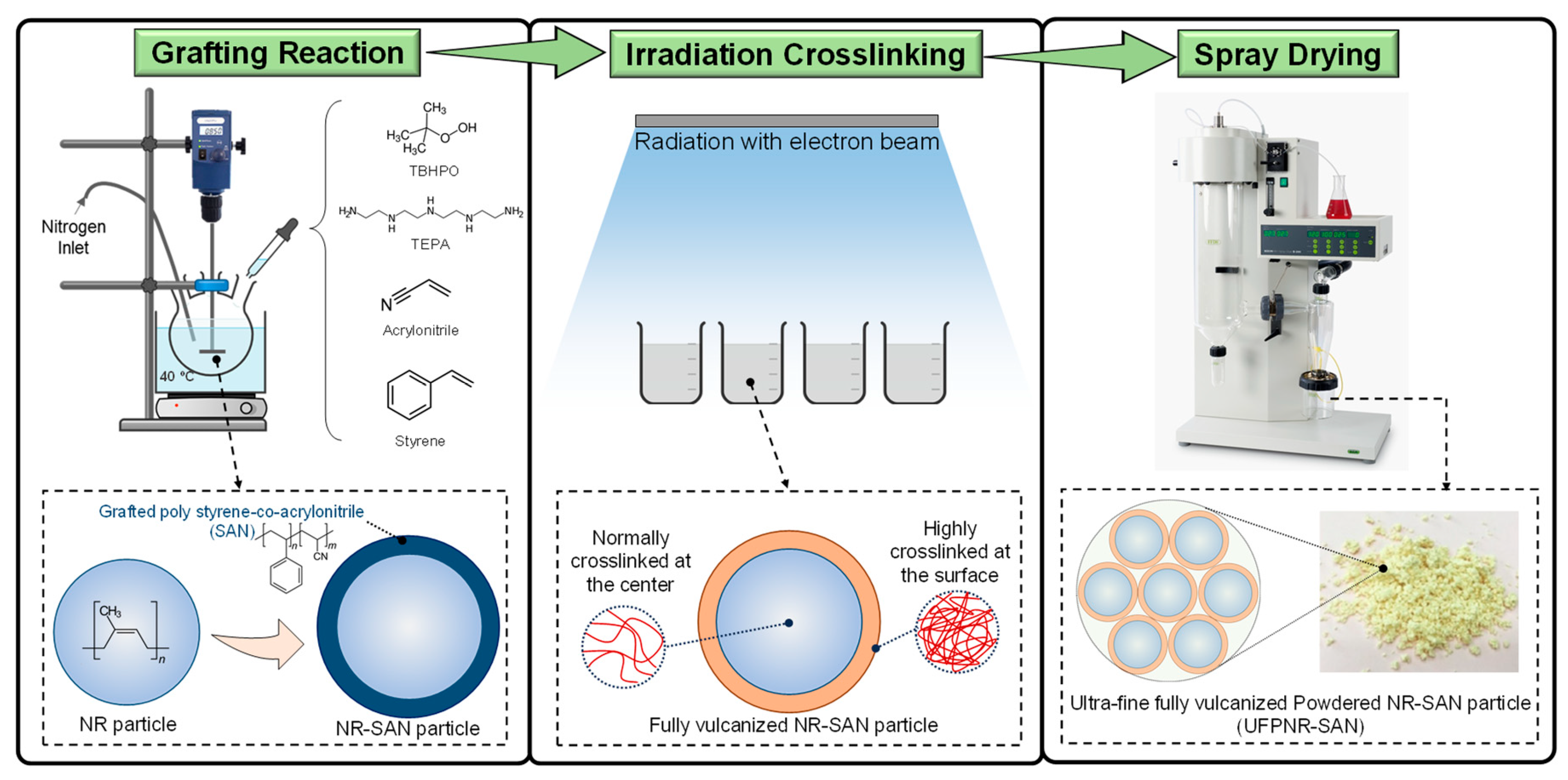

2.2. Preparation of Ultrafine Fully Vulcanized Powdered Natural Rubber Grafted-Copolymerized with Poly(styrene-co-acrylonitrile) (UFPNR-SAN)

2.3. Preparation of PLA/UFPNR-SAN Composites

2.4. Characterizations

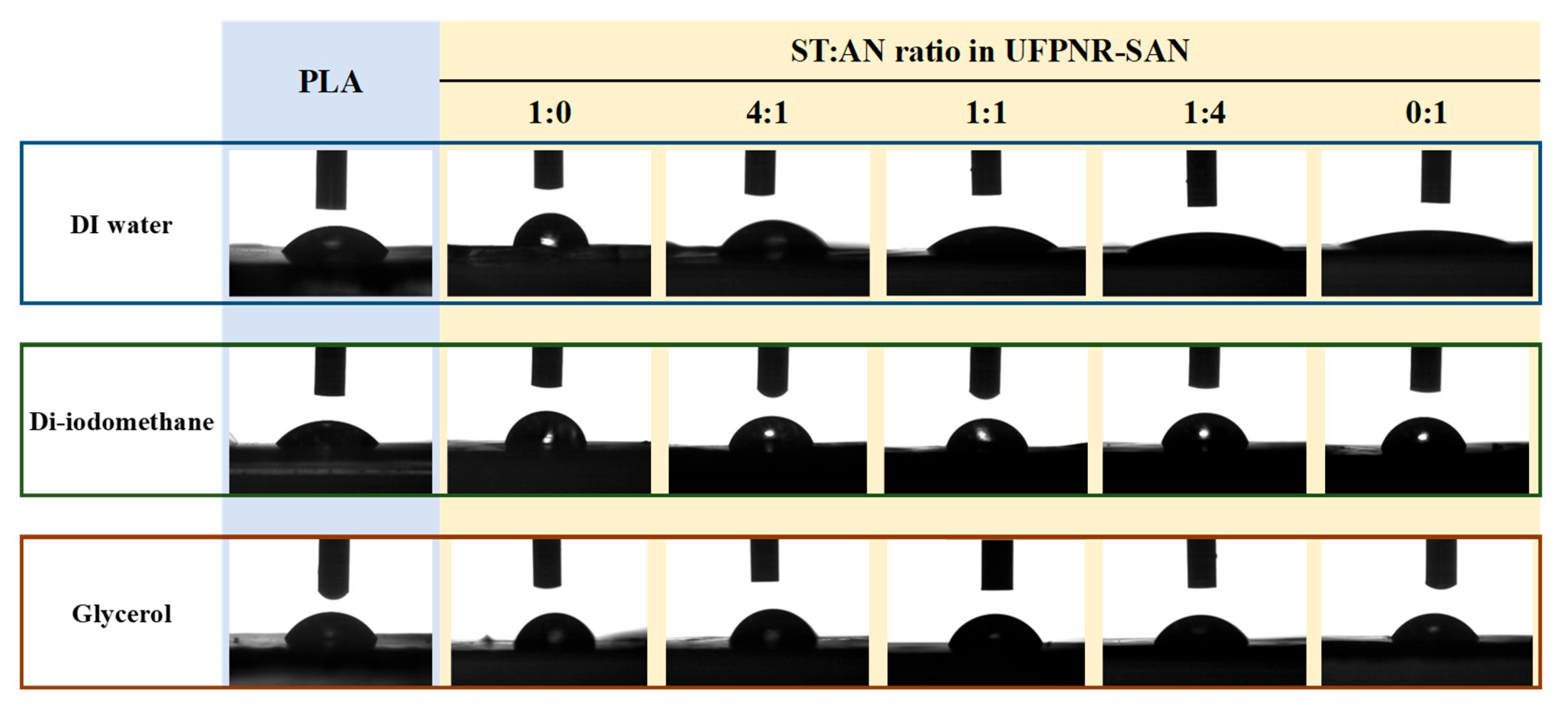

2.4.1. Estimation of Interfacial Interactions between PLA and UFPNR-SAN Using Contact Angle Measurements

2.4.2. Morphological Characterization of the Composites

2.4.3. Mechanical Tests of the Composites

2.4.4. Thermal Analysis of the Composites

2.4.5. Dynamic Mechanical Analysis of the Composites

3. Results and Discussion

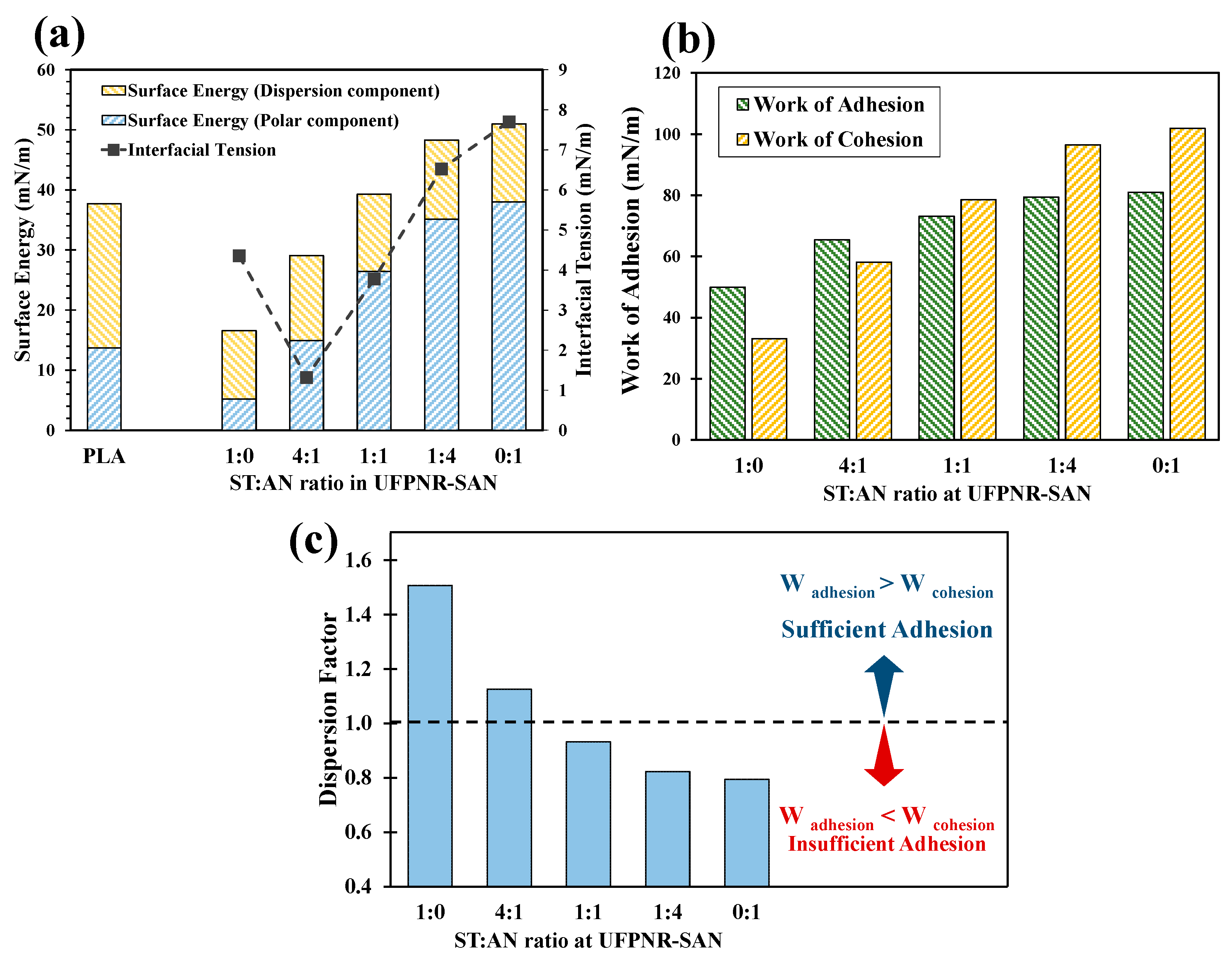

3.1. Interfacial Interactions between PLA and UFPNR-SAN

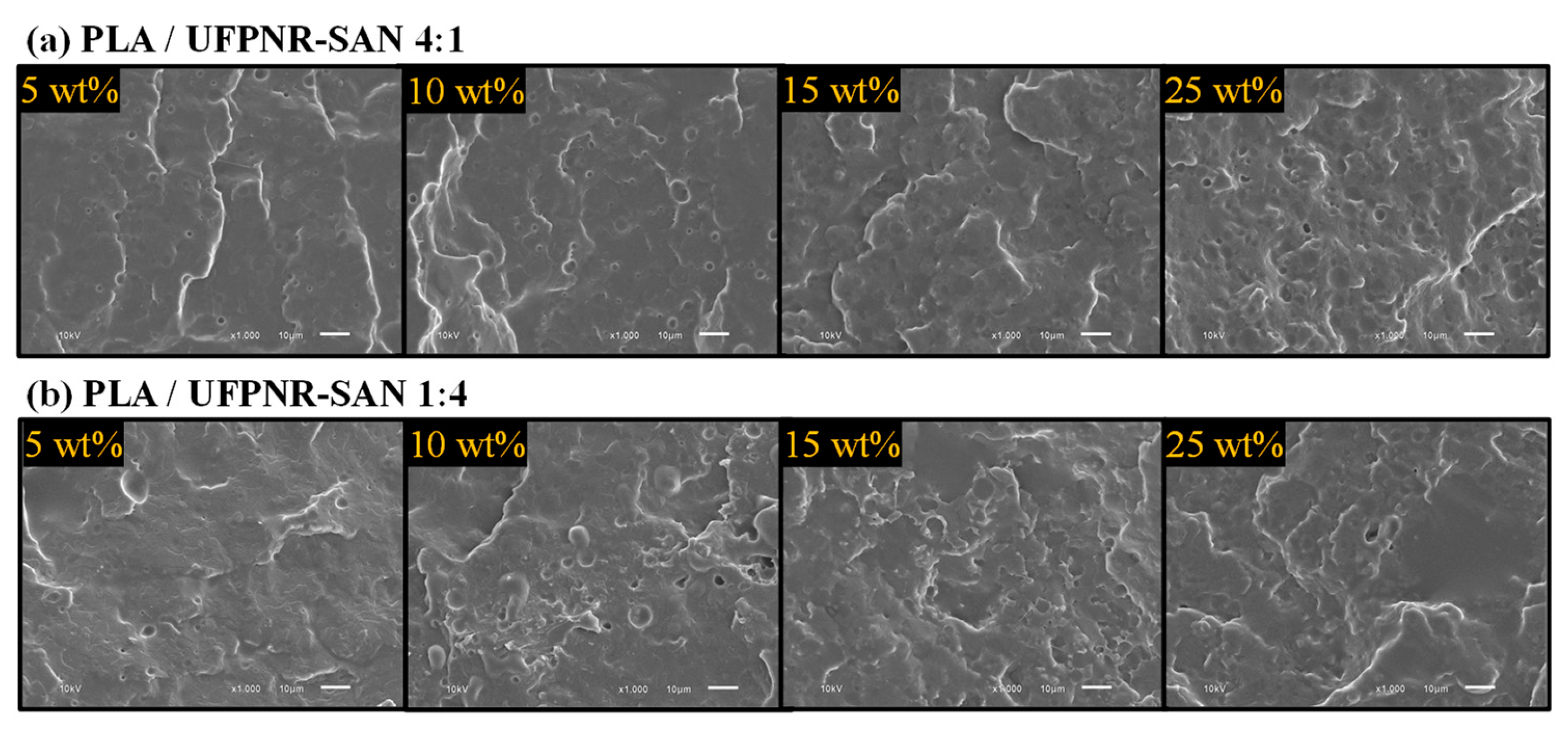

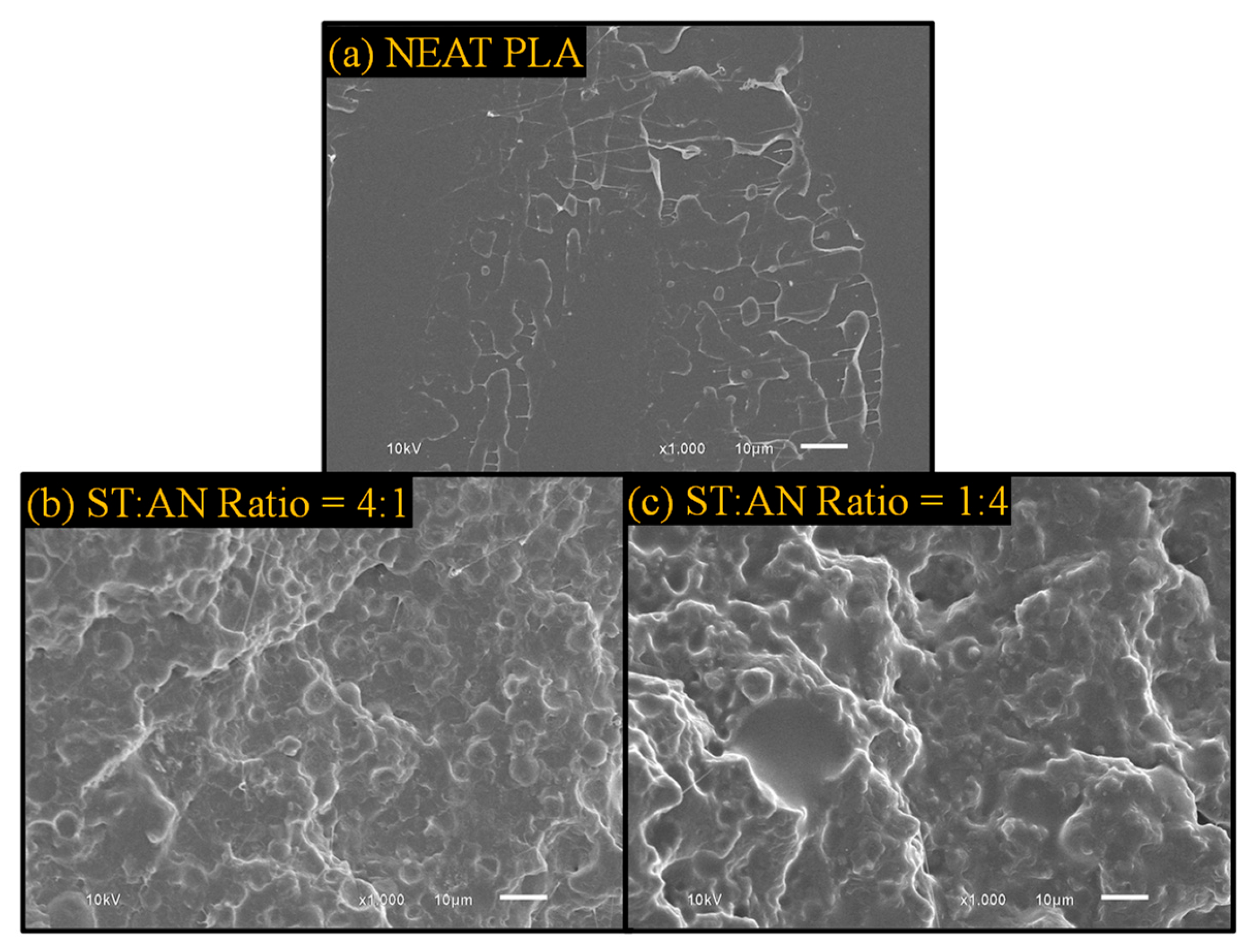

3.2. Morphological Analysis of the Composites

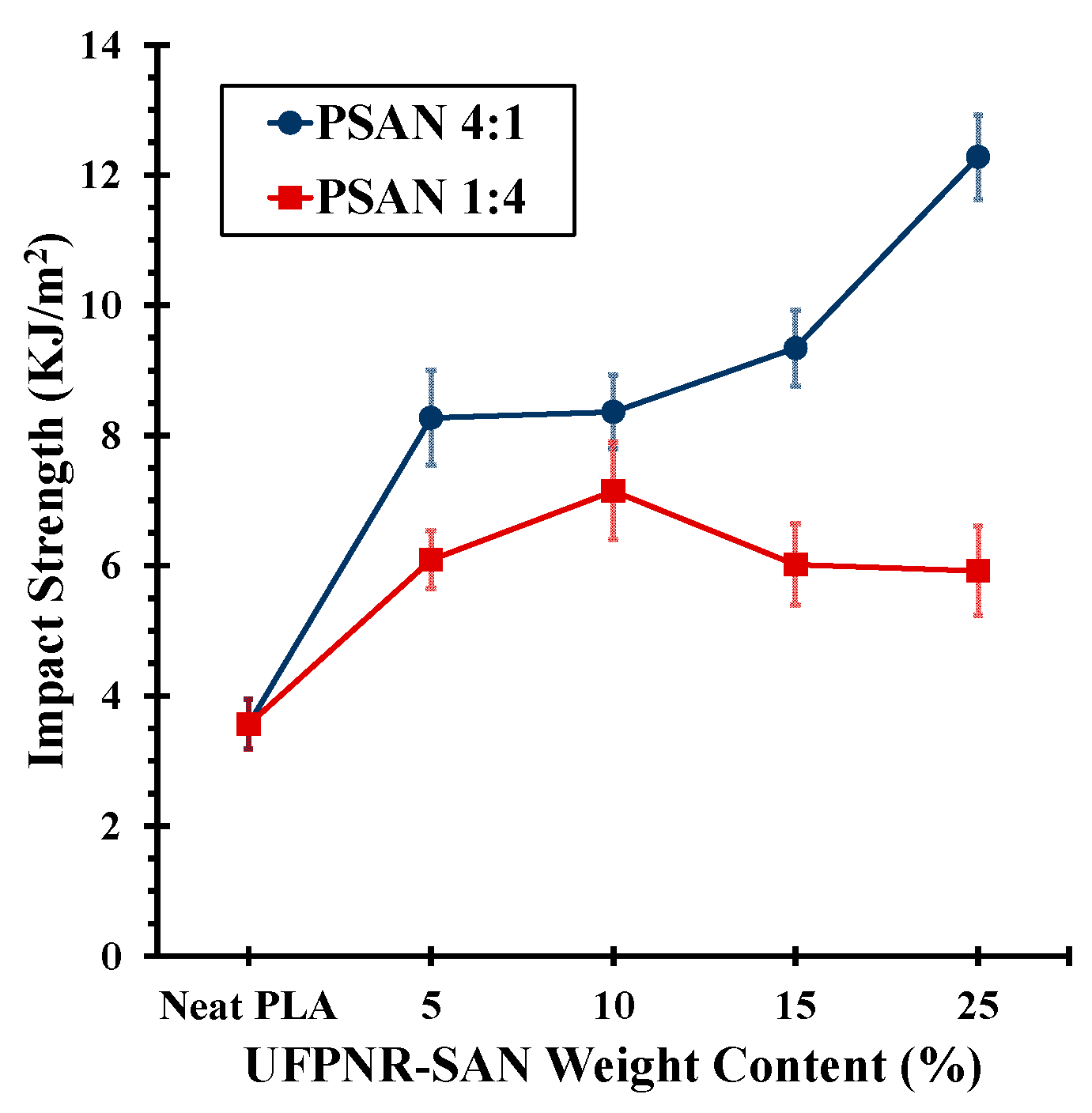

3.3. Mechanical Properties of the Composites

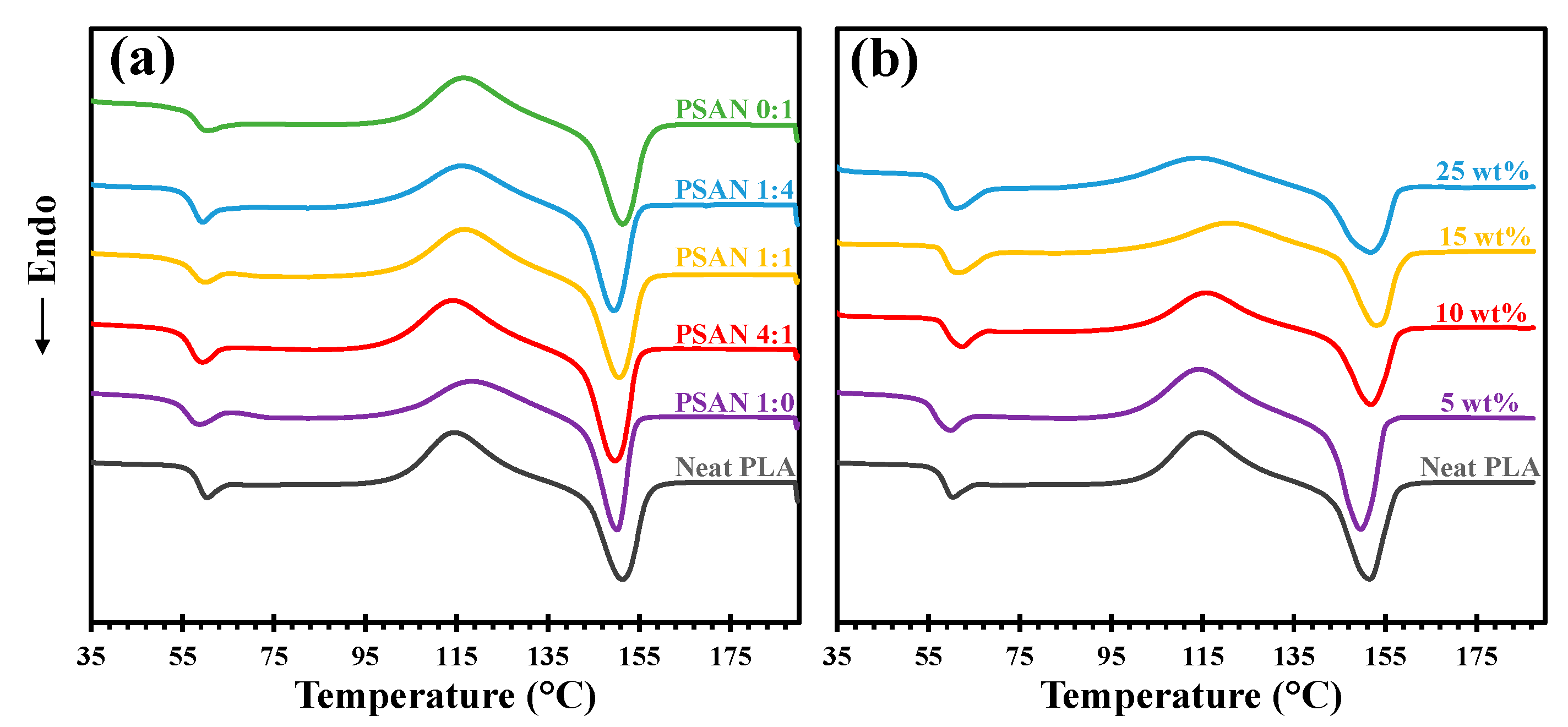

3.4. Crystallization Analysis and Thermal Properties of the Composites

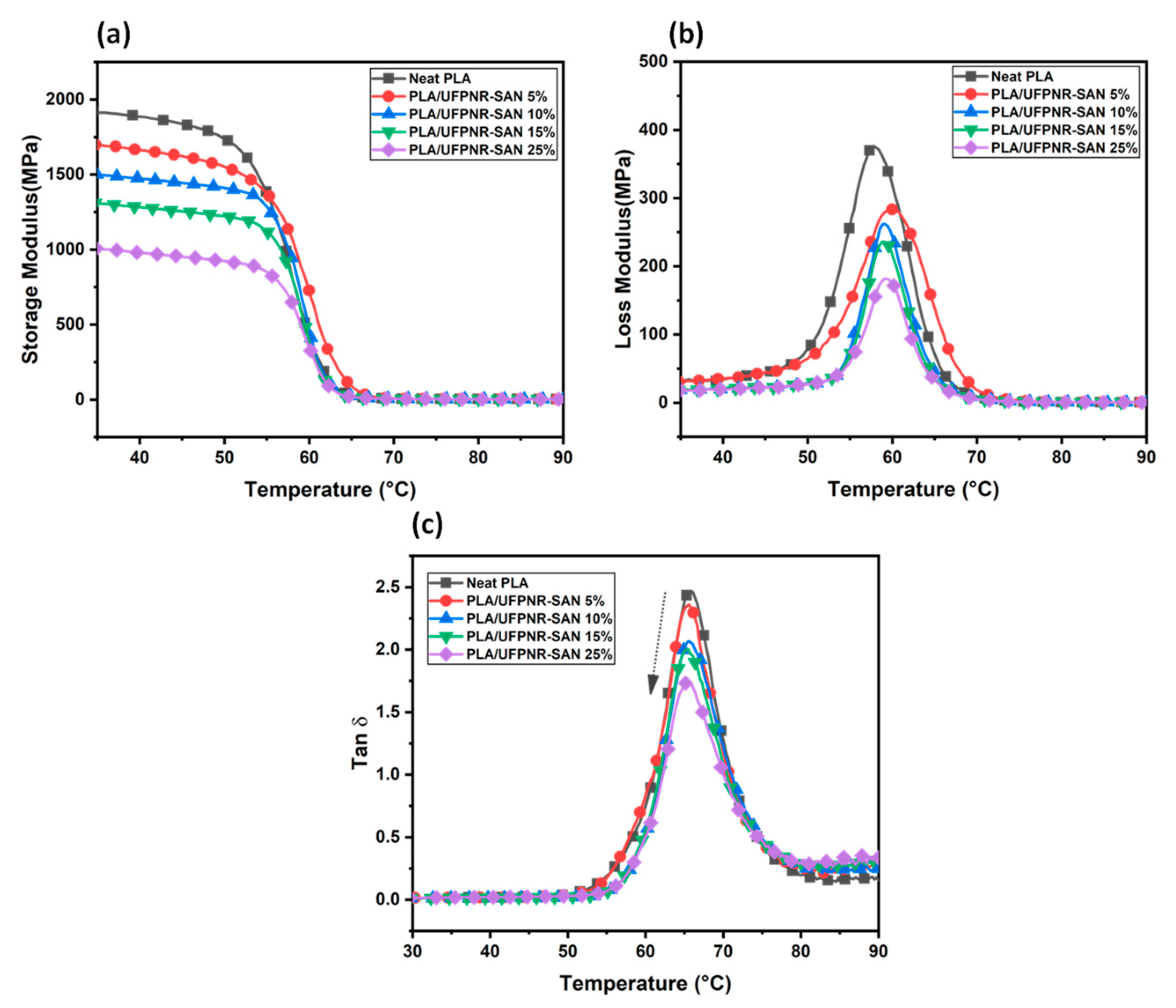

3.5. Viscoelastic Properties of the Composites

4. Conclusions

- Adjusting the ST:AN ratio during the grafting reaction onto NR effectively tailored the surface energy of the UFPNR-SAN particles, influencing their interfacial interactions with PLA. UFPNR-SAN particles with a 4:1 ST:AN ratio exhibited optimal compatibility with PLA, due to their minimum interfacial tension with PLA as well as their sufficient particle–matrix interfacial.

- SEM analysis revealed that UFPNR-SAN particles with a 4:1 ST:AN adhesion at processing temperature ratio exhibited comparatively superior dispersion within the PLA matrix. This enhanced dispersion was attributed to the aforementioned enhanced compatibility.

- The significance of the ST:AN ratio in UFPNR-SAN formulations became evident in flexural tests. Specifically, the 4:1 ST:AN ratio demonstrated optimal interfacial interactions, leading to fully ductile behavior in flexural tests. This formulation exhibited superior performance by preventing crack formation at the back face of the flexural specimens, distinguishing it from other ratios.

- The superiority of the 4:1 ST:AN ratio extended to the Izod impact strength, with UFPNR-SAN at this ratio indicating the highest improvement in impact strength at a fixed weight content of 5 wt%. This superiority persisted in PLA/UFPNR-SAN composites with higher weight contents of UFPNR-SAN.

- Adjusting UFPNR-SAN particles by grafting the appropriate ratio of ST and AN monomers with different polarities proved to be a successful strategy for optimizing interfacial interactions, leading to higher level of compatibility, improved morphology, and ultimately higher toughness at identical weight contents of toughening fillers.

- The DSC thermograms revealed that the degree of crystallinity in the PLA phase of the molded specimens was not notably affected by the ST:AN ratio in UFPNR-SAN or by its weight content. Consequently, the improved toughness and ductility observed in PLA/UFPNR-SAN composites were exclusively attributed to the toughening mechanisms of UFPNR-SAN incorporated into PLA, along with the favorable microstructure resulting from optimized interfacial interactions during melt blending.

- The DSC and DMA results revealed that the addition of UFPNR-SAN had no effect on the Tg of the PLA/UFPNR-SAN composites. Furthermore, the TGA measurements indicated that the UFPNR-SAN particles had no negative influence on PLA’s thermal stability.

- Overall, these findings highlight the potential of the PLA/UFPNR-SAN composite for applications needing both strength and ductility, especially when bio-based and sustainable materials are a priority.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sinclair, R.G. The Case for Polylactic Acid as a Commodity Packaging Plastic. J. Macromol. Sci. Part A Pure Appl. Chem. 2006, 33, 585–597. [Google Scholar] [CrossRef]

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Saini, P.; Arora, M.; Kumar, M.N.V.R. Poly(Lactic Acid) Blends in Biomedical Applications. Adv. Drug Deliv. Rev. 2016, 107, 47–59. [Google Scholar] [CrossRef] [PubMed]

- Södergård, A.; Stolt, M. Properties of Lactic Acid Based Polymers and Their Correlation with Composition. Prog. Polym. Sci. 2002, 27, 1123–1163. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, H.; Wang, X.; Yu, X.; Zhou, W.; Peng, S. Super Tough Poly(Lactic Acid) Blends: A Comprehensive Review. RSC Adv. 2020, 10, 13316–13368. [Google Scholar] [CrossRef]

- Gerrard, J.; Kandlikar, M. Is European End-of-Life Vehicle Legislation Living up to Expectations? Assessing the Impact of the ELV Directive on ‘Green’ Innovation and Vehicle Recovery. J. Clean. Prod. 2007, 15, 17–27. [Google Scholar] [CrossRef]

- Babu, R.P.; O’Connor, K.; Seeram, R. Current Progress on Bio-Based Polymers and Their Future Trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef]

- Ruz-Cruz, M.A.; Herrera-Franco, P.J.; Flores-Johnson, E.A.; Moreno-Chulim, M.V.; Galera-Manzano, L.M.; Valadez-González, A. Thermal and Mechanical Properties of PLA-Based Multiscale Cellulosic Biocomposites. J. Mater. Res. Technol. 2022, 18, 485–495. [Google Scholar] [CrossRef]

- Bouzouita, A.; Notta-Cuvier, D.; Raquez, J.M.; Lauro, F.; Dubois, P. Poly(Lactic Acid)-Based Materials for Automotive Applications. Adv. Polym. Sci. 2018, 282, 177–219. [Google Scholar] [CrossRef]

- Aslan, B.; Ramaswamy, S.; Raina, M.; Gries, T. Bio-Composites: Processing of Thermoplastic Biopolymers and Industrial Natural Fibres from Staple Fibre Blends Up to Fabric for Composite Applications. Tekst. Mühendis 2012, 19, 46–51. [Google Scholar] [CrossRef]

- Svatík, J.; Lepcio, P.; Ondreáš, F.; Zárybnická, K.; Zbončák, M.; Menčík, P.; Jančář, J. PLA Toughening via Bamboo-Inspired 3D Printed Structural Design. Polym. Test. 2021, 104, 107405. [Google Scholar] [CrossRef]

- Ramot, Y.; Haim-Zada, M.; Domb, A.J.; Nyska, A. Biocompatibility and Safety of PLA and Its Copolymers. Adv. Drug Deliv. Rev. 2016, 107, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Visco, A.; Scolaro, C.; Raj, A.; Yousfi, M.; Prashantha, K.; Samuel, C. Morphologies, Compatibilization and Properties of Immiscible PLA-Based Blends with Engineering Polymers: An Overview of Recent Works. Polymers 2024, 16, 1776. [Google Scholar] [CrossRef] [PubMed]

- Gzyra-Jagieła, K.; Sulak, K.; Draczyński, Z.; Podzimek, S.; Gałecki, S.; Jagodzińska, S.; Borkowski, D. Modification of Poly(Lactic Acid) by the Plasticization for Application in the Packaging Industry. Polymers 2021, 13, 3651. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Jiang, Y.; Lv, S.; Liu, X.; Gu, J.; Chen, Q.; Zhang, Y. Preparation of Plasticized Poly (Lactic Acid) and Its Influence on the Properties of Composite Materials. PLoS ONE 2018, 13, e0193520. [Google Scholar] [CrossRef] [PubMed]

- Zych, A.; Perotto, G.; Trojanowska, D.; Tedeschi, G.; Bertolacci, L.; Francini, N.; Athanassiou, A. Super Tough Polylactic Acid Plasticized with Epoxidized Soybean Oil Methyl Ester for Flexible Food Packaging. ACS Appl. Polym. Mater. 2021, 3, 5087–5095. [Google Scholar] [CrossRef]

- Wu, N.; Zhang, H.; Fu, G. Super-Tough Poly(Lactide) Thermoplastic Vulcanizates Based on Modified Natural Rubber. ACS Sustain. Chem. Eng. 2017, 5, 78–84. [Google Scholar] [CrossRef]

- Burzic, I.; Pretschuh, C.; Kaineder, D.; Eder, G.; Smilek, J.; Másilko, J.; Kateryna, W. Impact Modification of PLA Using Biobased Biodegradable PHA Biopolymers. Eur. Polym. J. 2019, 114, 32–38. [Google Scholar] [CrossRef]

- Injorhor, P.; Inphonlek, S.; Ruksakulpiwat, Y.; Ruksakulpiwat, C. Effect of Modified Natural Rubber on the Mechanical and Thermal Properties of Poly(Lactic Acid) and Its Composites with Nanoparticles from Biowaste. Polymers 2024, 16, 812. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Zhu, Y.; He, Y.; Xiao, L.; Xu, P.; Puglia, D.; Ma, P. Preparation of Toughened Poly(Lactic Acid)-Poly(ε-Caprolactone)-Lignin Nanocomposites with Good Heat- and UV-Resistance. Ind. Crops Prod. 2022, 183, 114965. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, S.; Yang, K.; Yu, W.; Shi, J.; Zheng, Q. Preparation of Graphene-Modified PLA/PBAT Composite Monofilaments and Its Degradation Behavior. J. Mater. Res. Technol. 2022, 20, 3784–3795. [Google Scholar] [CrossRef]

- Zafar, R.; Lee, W.; Kwak, S.Y. A Facile Strategy for Enhancing Tensile Toughness of Poly(Lactic Acid) (PLA) by Blending of a Cellulose Bio-Toughener Bearing a Highly Branched Polycaprolactone. Eur. Polym. J. 2022, 175, 111376. [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, W.Q.; Weng, Y.; Zeng, J.B.; Li, Y.D. Morphological Control and Interfacial Compatibilization of Fully Biobased PLA/ENR Blends via Partial Crosslinking ENR with Sebacic Acid. Ind. Crops Prod. 2022, 180, 114707. [Google Scholar] [CrossRef]

- Qiao, J.; Wei, G.; Zhang, X.; Zhang, S.; Gao, J.; Zhang, W.; Liu, Y.; Li, J.; Zhang, F.; Zhai, R.; et al. Fully Vulcanized Powdery Rubber Having a Controllable Particle Size, Preparation and Use Thereof. U.S. Patent US6423760B1, 23 July 2002. [Google Scholar]

- Qiao, J. Elastomeric Nano-Particle and Its Applications in Polymer Modifications. Adv. Ind. Eng. Polym. Res. 2020, 3, 47–59. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Jiang, L.; Qiao, J. Advances in Toughened Polymer Materials by Structured Rubber Particles. Prog. Polym. Sci. 2019, 98, 101160. [Google Scholar] [CrossRef]

- Zhao, Q.; Ding, Y.; Yang, B.; Ning, N.; Fu, Q. Highly Efficient Toughening Effect of Ultrafine Full-Vulcanized Powdered Rubber on Poly(Lactic Acid)(PLA). Polym. Test. 2013, 32, 299–305. [Google Scholar] [CrossRef]

- Lin, Y.; Amornkitbamrung, L.; Mora, P.; Jubsilp, C.; Hemvichian, K.; Soottitantawat, A.; Ekgasit, S.; Rimdusit, S. Effects of Coagent Functionalities on Properties of Ultrafine Fully Vulcanized Powdered Natural Rubber Prepared as Toughening Filler in Rigid PVC. Polymers 2021, 13, 289. [Google Scholar] [CrossRef] [PubMed]

- Longsiri, K.; Mora, P.; Peeksuntiye, W.; Jubsilp, C.; Hemvichian, K.; Karagiannidis, P.; Rimdusit, S. Ultrafine Fully Vulcanized Natural Rubber Modified by Graft-Copolymerization with Styrene and Acrylonitrile Monomers. Bioresour. Bioprocess 2022, 9, 85. [Google Scholar] [CrossRef] [PubMed]

- Rimdusit, N.; Jubsilp, C.; Mora, P.; Hemvichian, K.; Thuy, T.T.; Karagiannidis, P.; Rimdusit, S. Radiation Graft-Copolymerization of Ultrafine Fully Vulcanized Powdered Natural Rubber: Effects of Styrene and Acrylonitrile Contents on Thermal Stability. Polymers 2021, 13, 3447. [Google Scholar] [CrossRef] [PubMed]

- Taewattana, R.; Jubsilp, C.; Suwanmala, P.; Rimdusit, S. Effect of Gamma Irradiation on Properties of Ultrafine Rubbers as Toughening Filler in Polybenzoxazine. Radiat. Phys. Chem. 2018, 145, 184–192. [Google Scholar] [CrossRef]

- Wongkumchai, R.; Amornkitbamrung, L.; Mora, P.; Jubsilp, C.; Rimdusit, S. Effects of Coagent Incorporation on Properties of Ultrafine Fully Vulcanized Powdered Natural Rubber Prepared as Toughening Filler in Polybenzoxazine. SPE Polym. 2021, 2, 191–198. [Google Scholar] [CrossRef]

- Khoshkava, V.; Kamal, M.R. Effect of Surface Energy on Dispersion and Mechanical Properties of Polymer/Nanocrystalline Cellulose Nanocomposites. Biomacromolecules 2013, 14, 3155–3163. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Dong, H.; Li, M.; Wang, L.; Liu, Y.; Wang, L.; Fu, S. Fabrication of Polylactic Acid-Modified Carbon Black Composites into Improvement of Levelness and Mechanical Properties of Spun-Dyeing Polylactic Acid Composites Membrane. ACS Sustain. Chem. Eng. 2019, 7, 688–696. [Google Scholar] [CrossRef]

- ASTM D4703-16.2; Standard Practice for Compression Molding Thermoplastic Materials into Test Specimens, Plaques, or Sheets. ASTM International: West Conshohocken, PA, USA, 2016.

- ISO 19403-2:2017; Paints and Varnishes—Wettability—Part 2: Determination of the Surface Free Energy of Solid Surfaces by Measuring the Contact Angle. British Standards Institution: London, UK, 2020.

- Hobbs, S.Y.; Dekkers, M.E.J.; Watkins, V.H. Effect of Interfacial Forces on Polymer Blend Morphologies. Polymer 1988, 29, 1598–1602. [Google Scholar] [CrossRef]

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM D256-10; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2010.

- Maroufkhani, M.; Katbab, A.A.; Liu, W.; Zhang, J. Polylactide (PLA) and Acrylonitrile Butadiene Rubber (NBR) Blends: The Effect of ACN Content on Morphology, Compatibility and Mechanical Properties. Polymer 2017, 115, 37–44. [Google Scholar] [CrossRef]

- Liu, H.; Song, W.; Chen, F.; Guo, L.; Zhang, J. Interaction of Microstructure and Interfacial Adhesion on Impact Performance of Polylactide (PLA) Ternary Blends. Macromolecules 2011, 44, 1513–1522. [Google Scholar] [CrossRef]

- Wang, S.Y.; Jiang, C.; Xie, H.H.; Zeng, J.B.; Li, Y.D. Compatibilization of Polylactide/Poly(Butylene Adipate-Co-Terephthalate) Blends with Epoxidized Natural Rubber as a Reactive Compatibilizer. Ind. Crops Prod. 2023, 205, 117447. [Google Scholar] [CrossRef]

- Huang, Y.; Müller, M.T.; Boldt, R.; Zschech, C.; Gohs, U.; Wießner, S. A New Strategy to Improve Viscoelasticity, Crystallization and Mechanical Properties of Polylactide. Polym. Test. 2021, 97, 107160. [Google Scholar] [CrossRef]

| Sample | Contact Angle (deg) | Surface Energy at 25 °C (mN/m) | Surface Energy at 170 °C (mN/m) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| DI Water | Di-Iodomethane | Glycerol | σP | σd | Total | σP | σd | Total | |

| PLA | 53.5 ± 1.3 | 46.7 ± 1.7 | 62.4 ±2.0 | 16.9 | 29.5 | 46.4 | 13.7 | 24.0 | 37.7 |

| UFPNR-SAN 1:0 | 81.7 ± 1.4 | 75.9 ± 2.2 | 75.9 ± 3.7 | 8.5 | 18.5 | 27.0 | 5.2 | 11.3 | 16.6 |

| UFPNR-SAN 4:1 | 57.6 ± 3.0 | 67.1 ± 1.1 | 71.7 ± 3.8 | 20.2 | 19.0 | 39.3 | 14.9 | 14.1 | 29.1 |

| UFPNR-SAN 1:1 | 41.1 ± 4.2 | 71.2 ± 3.1 | 66.0 ± 4.9 | 33.1 | 16.2 | 49.2 | 26.4 | 12.8 | 39.3 |

| UFPNR-SAN 1:4 | 24.9 ±0.8 | 70.4 ± 1.7 | 61.6 ± 3.2 | 42.1 | 15.8 | 57.9 | 35.1 | 13.2 | 48.3 |

| UFPNR-SAN 0:1 | 19.5 ± 2.7 | 71.4 ± 4.2 | 59.5 ± 3.4 | 45.0 | 15.4 | 60.4 | 38.0 | 13.0 | 51.0 |

| Sample | Interfacial Tension (mN/m) | Work of Adhesion (mN/m) | Work of Cohesion (mN/m) | Dispersion Factor |

|---|---|---|---|---|

| UFPNR-SAN 1:0 | 4.4 | 49.9 | 33.1 | 1.51 |

| UFPNR-SAN 4:1 | 1.3 | 65.4 | 58.1 | 1.13 |

| UFPNR-SAN 1:1 | 3.8 | 73.2 | 78.5 | 0.93 |

| UFPNR-SAN 1:4 | 6.5 | 79.4 | 96.5 | 0.82 |

| UFPNR-SAN 0:1 | 7.7 | 81.0 | 102.0 | 0.79 |

| Sample | ST:AN Ratio a | UFPNR Content (wt%) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Impact Strength (KJ/m2) |

|---|---|---|---|---|---|

| Neat PLA | - | - | 105.8 ± 0.92 | 3.45 ± 0.08 | 3.56 ± 0.38 |

| PSAN 1:0 (5%) b | 1:0 | 5 | 90.8 ± 4.65 | 3.26 ± 0.07 | 6.5 ± 0.56 |

| PSAN 4:1 (5%) | 4:1 | 5 | 90.7 ± 0.8 | 3.32 ± 0.02 | 8.27 ± 0.73 |

| PSAN 4:1 (10%) | 4:1 | 10 | 74.6 ± 3.26 | 2.83 ± 0.07 | 8.36 ± 0.57 |

| PSAN 4:1 (15%) | 4:1 | 15 | 63.0 ± 1.86 | 2.49 ± 0.07 | 9.34 ± 0.58 |

| PSAN 4:1 (25%) | 4:1 | 25 | 44.6 ± 2.26 | 1.81 ± 0.06 | 12.28 ± 0.65 |

| PSAN 1:1 (5%) | 1:1 | 5 | 90.2 ± 2.24 | 3.35 ± 0.08 | 6.86 ± 0.46 |

| PSAN 1:4 (5%) | 1:4 | 5 | 89.0 ± 2.25 | 3.24 ± 0.06 | 6.09 ± 0.45 |

| PSAN 1:4 (10%) | 1:4 | 10 | 73.7 ± 1.42 | 2.92 ± 0.08 | 7.15 ± 0.75 |

| PSAN 1:4 (15%) | 1:4 | 15 | 60.8 ± 1.01 | 2.43 ± 0.07 | 6.02 ± 0.63 |

| PSAN 1:4 (25%) | 1:4 | 25 | 37.4 ± 1.86 | 1.67 ± 0.10 | 5.92 ± 0.68 |

| PSAN 0:1 (5%) | 0:1 | 5 | 90.4 ± 3.47 | 3.15 ± 0.18 | 5.95 ± 0.37 |

| Sample | ST:AN Ratio a | UFPNR (wt%) | Tg (°C) | Tm (°C) | ΔHc (J/gr) | ΔHm (J/gr) | Xc (%) c |

|---|---|---|---|---|---|---|---|

| Neat PLA | - | - | 57 | 151 | 21.90 | 21.83 | 0.0 |

| PSAN 1:0 (5%) b | 1:0 | 5 | 58 | 151 | 19.66 | 19.74 | 0.1 |

| PSAN 4:1 (5%) | 4:1 | 5 | 56 | 151 | 22.11 | 22.35 | 0.3 |

| PSAN 4:1 (10%) | 4:1 | 10 | 58 | 152 | 19.40 | 20.10 | 0.8 |

| PSAN 4:1 (15%) | 4:1 | 15 | 57 | 153 | 17.59 | 17.84 | 0.3 |

| PSAN 4:1 (25%) | 4:1 | 25 | 57 | 152 | 17.44 | 17.79 | 0.5 |

| PSAN 1:1 (5%) | 1:1 | 5 | 56 | 150 | 21.87 | 21.90 | 0.0 |

| PSAN 1:4 (5%) | 1:4 | 5 | 57 | 151 | 20.70 | 20.86 | 0.2 |

| PSAN 0:1 (5%) | 0:1 | 5 | 57 | 151 | 18.52 | 18.60 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gholami, R.; Lawan, I.; Ebrahimi, S.; Pattulee, A.; Ahn, C.-H.; Rimdusit, S. Toughening Polylactic Acid with Ultrafine Fully Vulcanized Powdered Natural Rubber Graft-Copolymerized with Poly(styrene-co-acrylonitrile): Tailoring the Styrene–Acrylonitrile Ratio for Enhanced Interfacial Interactions. Polymers 2024, 16, 2254. https://doi.org/10.3390/polym16162254

Gholami R, Lawan I, Ebrahimi S, Pattulee A, Ahn C-H, Rimdusit S. Toughening Polylactic Acid with Ultrafine Fully Vulcanized Powdered Natural Rubber Graft-Copolymerized with Poly(styrene-co-acrylonitrile): Tailoring the Styrene–Acrylonitrile Ratio for Enhanced Interfacial Interactions. Polymers. 2024; 16(16):2254. https://doi.org/10.3390/polym16162254

Chicago/Turabian StyleGholami, Reza, Ibrahim Lawan, Sahar Ebrahimi, Achiraya Pattulee, Cheol-Hee Ahn, and Sarawut Rimdusit. 2024. "Toughening Polylactic Acid with Ultrafine Fully Vulcanized Powdered Natural Rubber Graft-Copolymerized with Poly(styrene-co-acrylonitrile): Tailoring the Styrene–Acrylonitrile Ratio for Enhanced Interfacial Interactions" Polymers 16, no. 16: 2254. https://doi.org/10.3390/polym16162254

APA StyleGholami, R., Lawan, I., Ebrahimi, S., Pattulee, A., Ahn, C.-H., & Rimdusit, S. (2024). Toughening Polylactic Acid with Ultrafine Fully Vulcanized Powdered Natural Rubber Graft-Copolymerized with Poly(styrene-co-acrylonitrile): Tailoring the Styrene–Acrylonitrile Ratio for Enhanced Interfacial Interactions. Polymers, 16(16), 2254. https://doi.org/10.3390/polym16162254