A Cost-Effective Approach to Creating Large Silicone Rubber Molds Using Advanced Rigid Polyurethane Foam

Abstract

1. Introduction

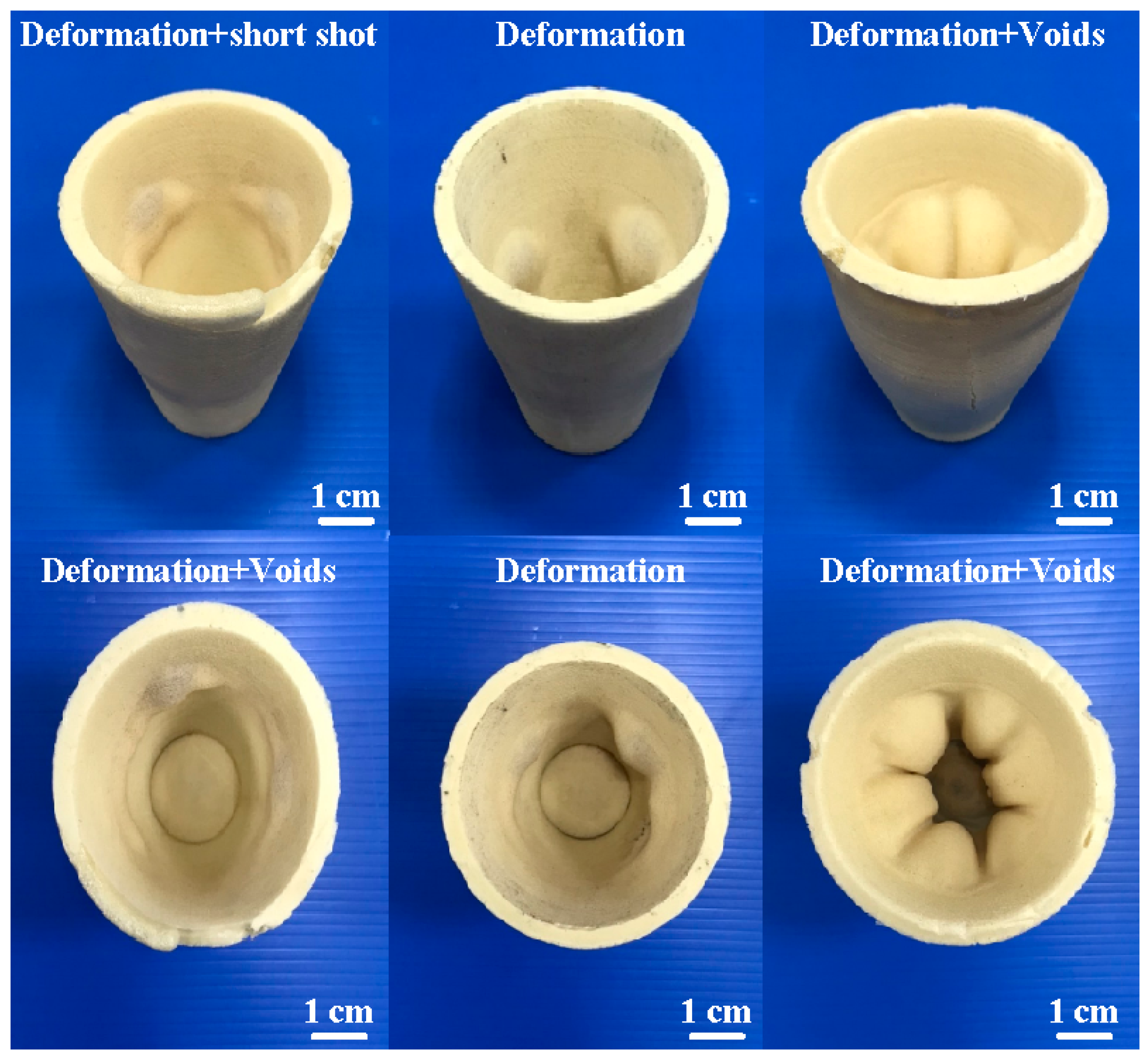

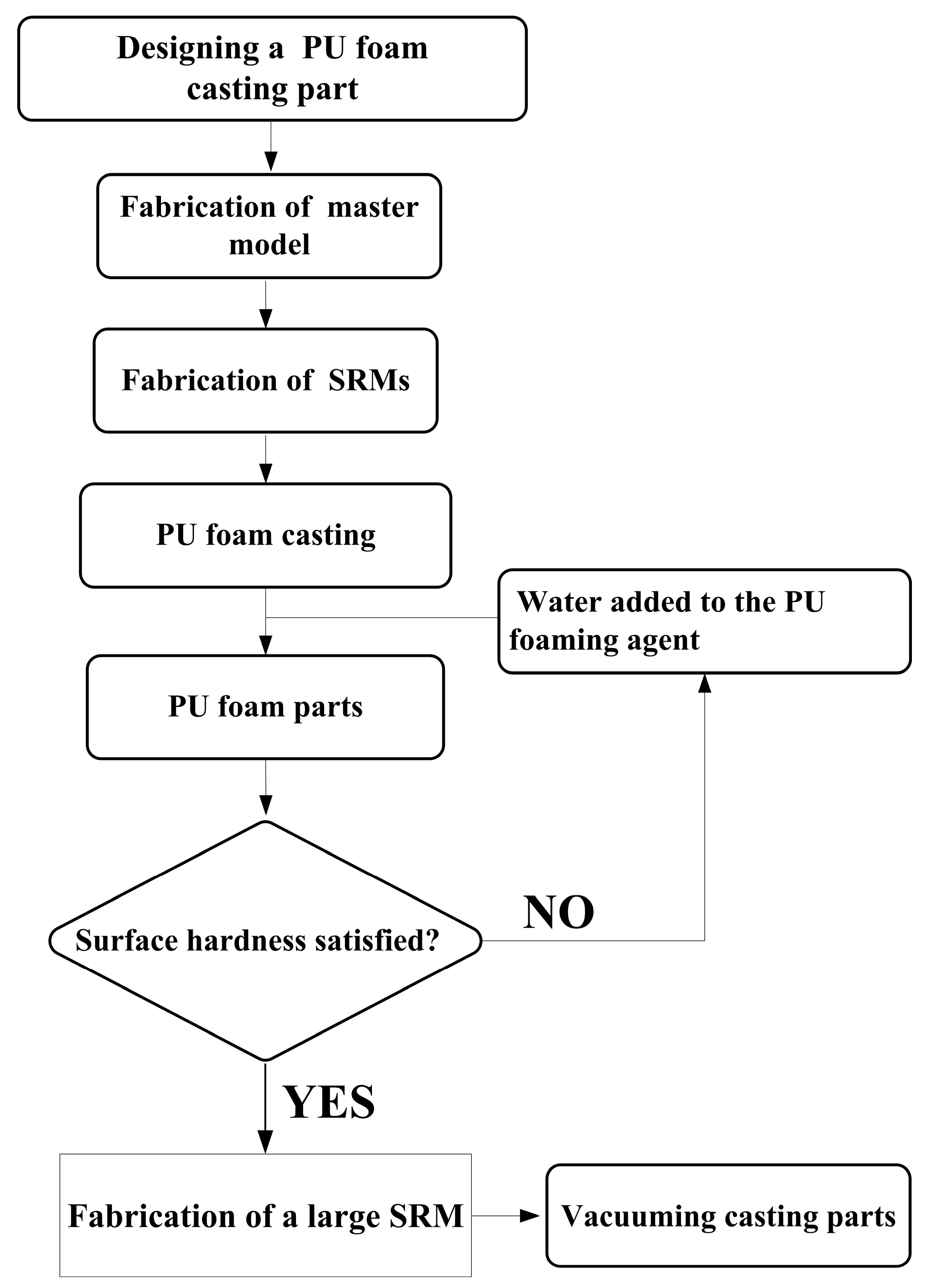

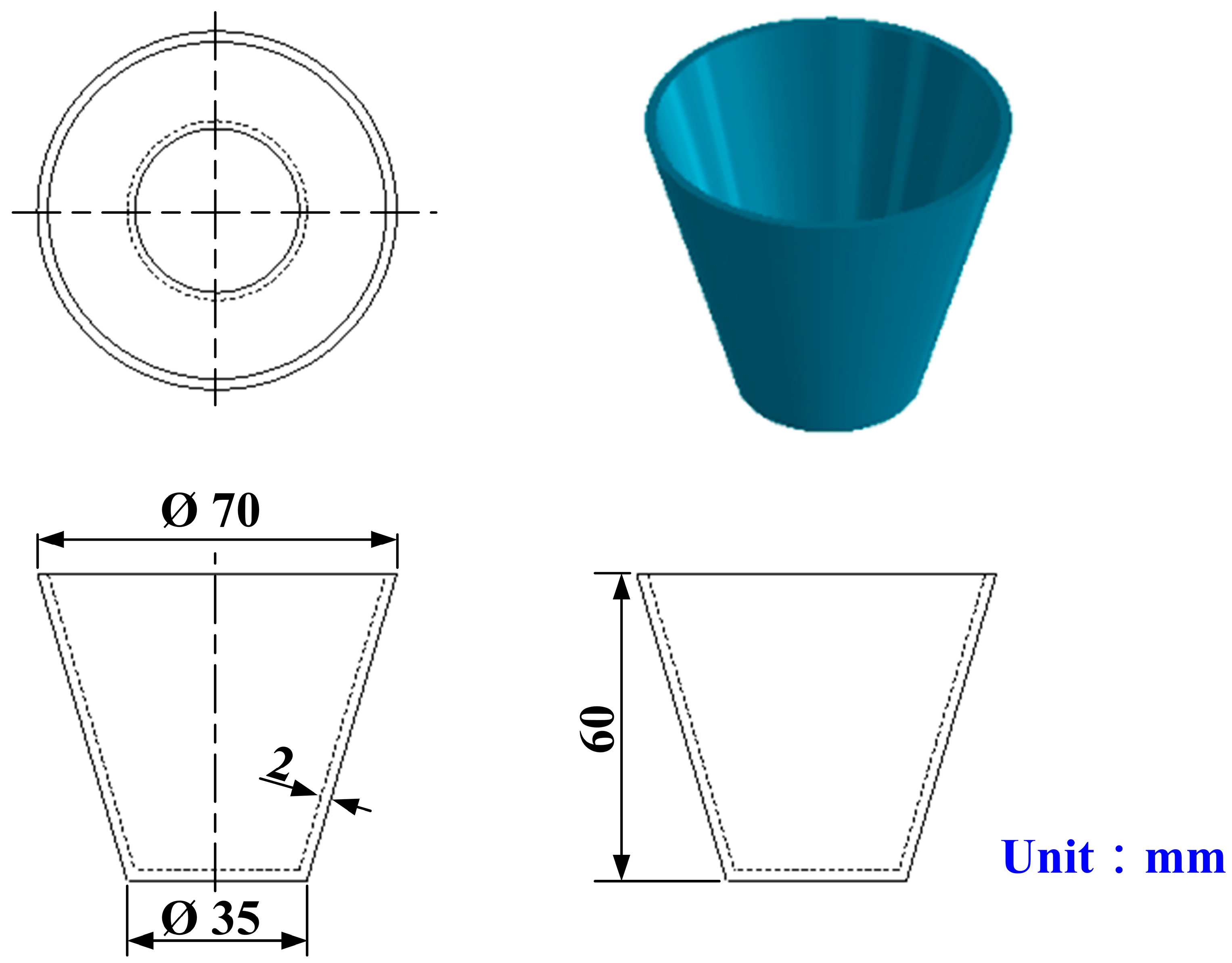

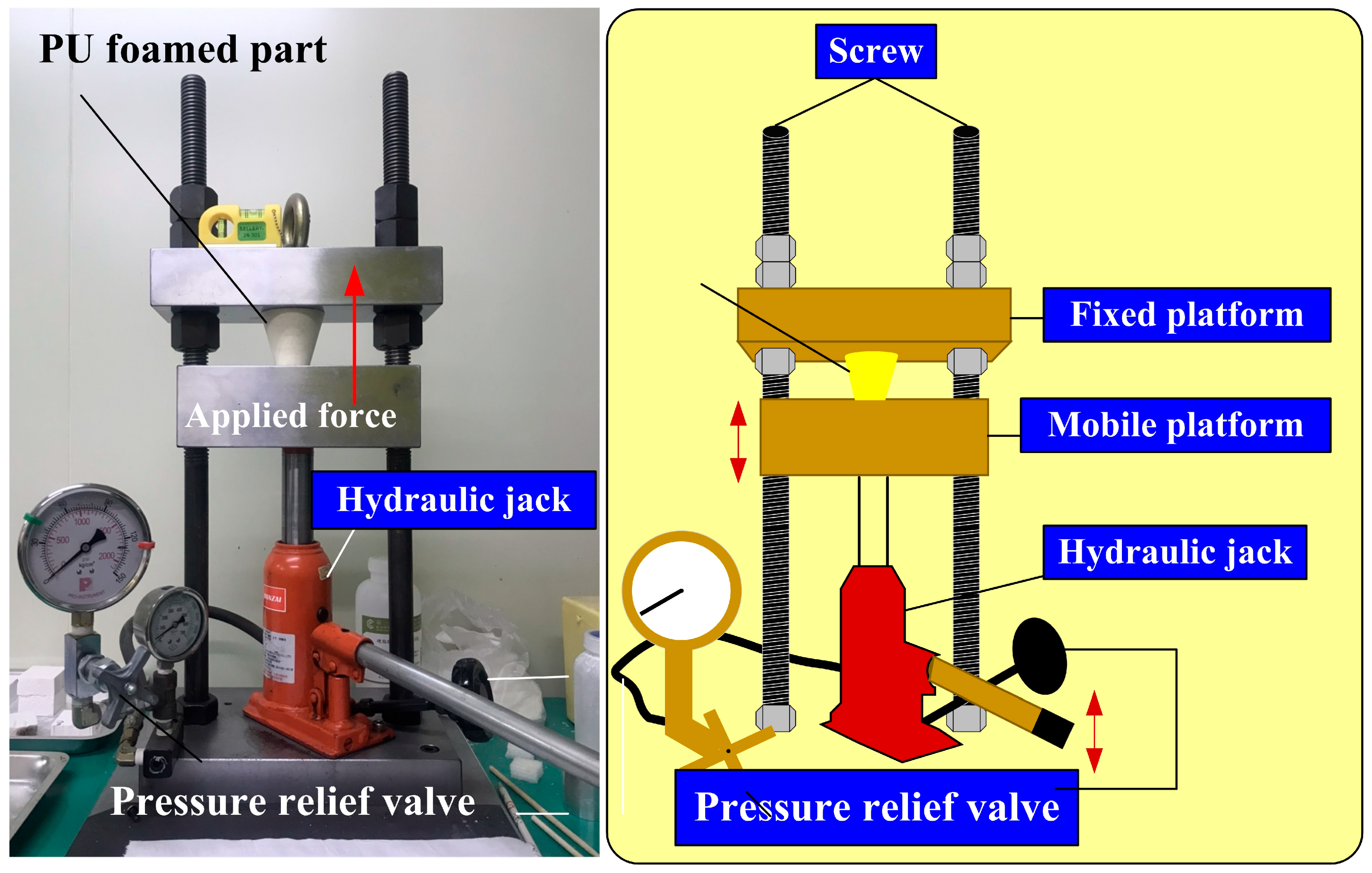

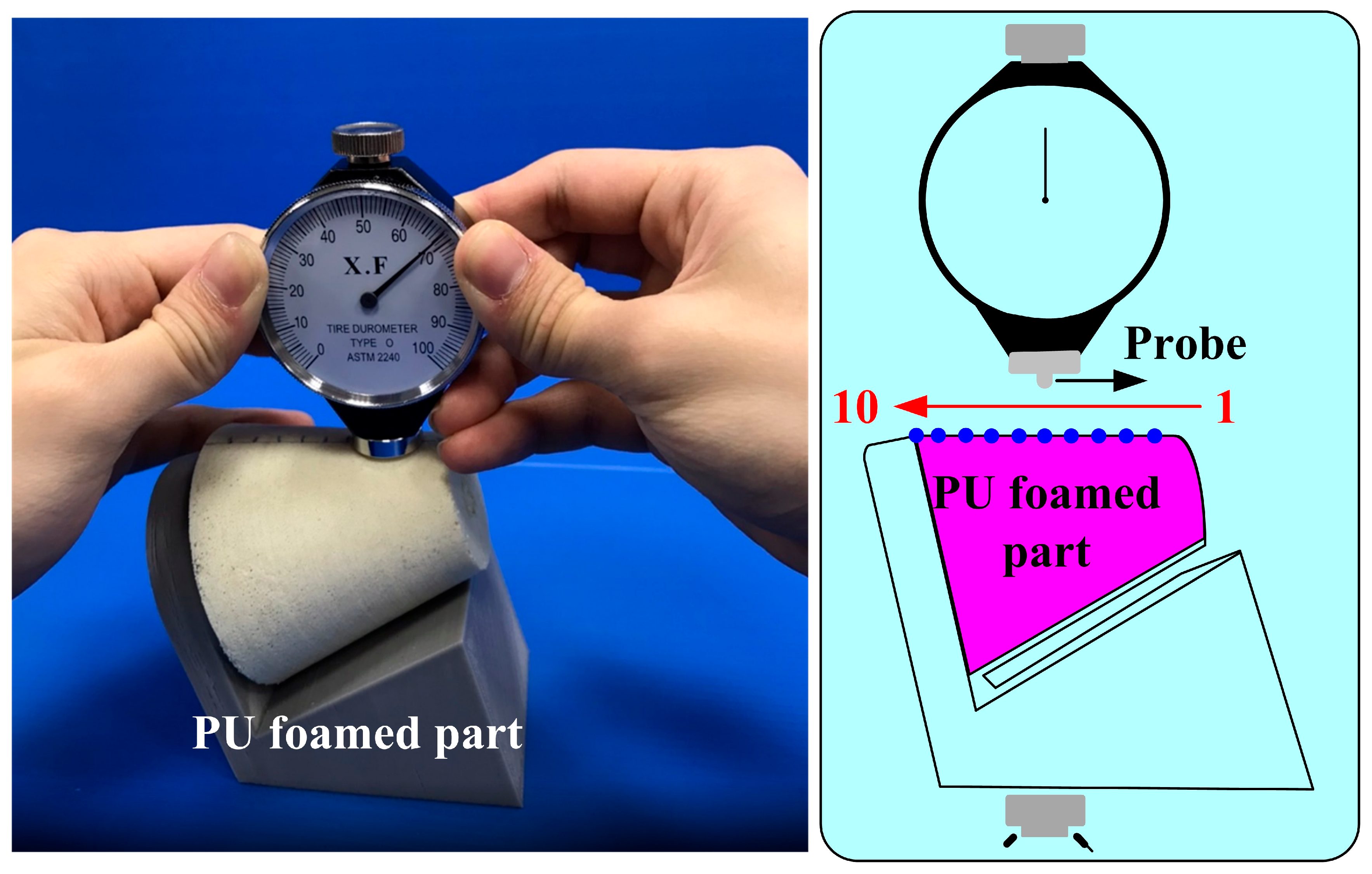

2. Experimental Details

3. Results and Discussion

4. Conclusions

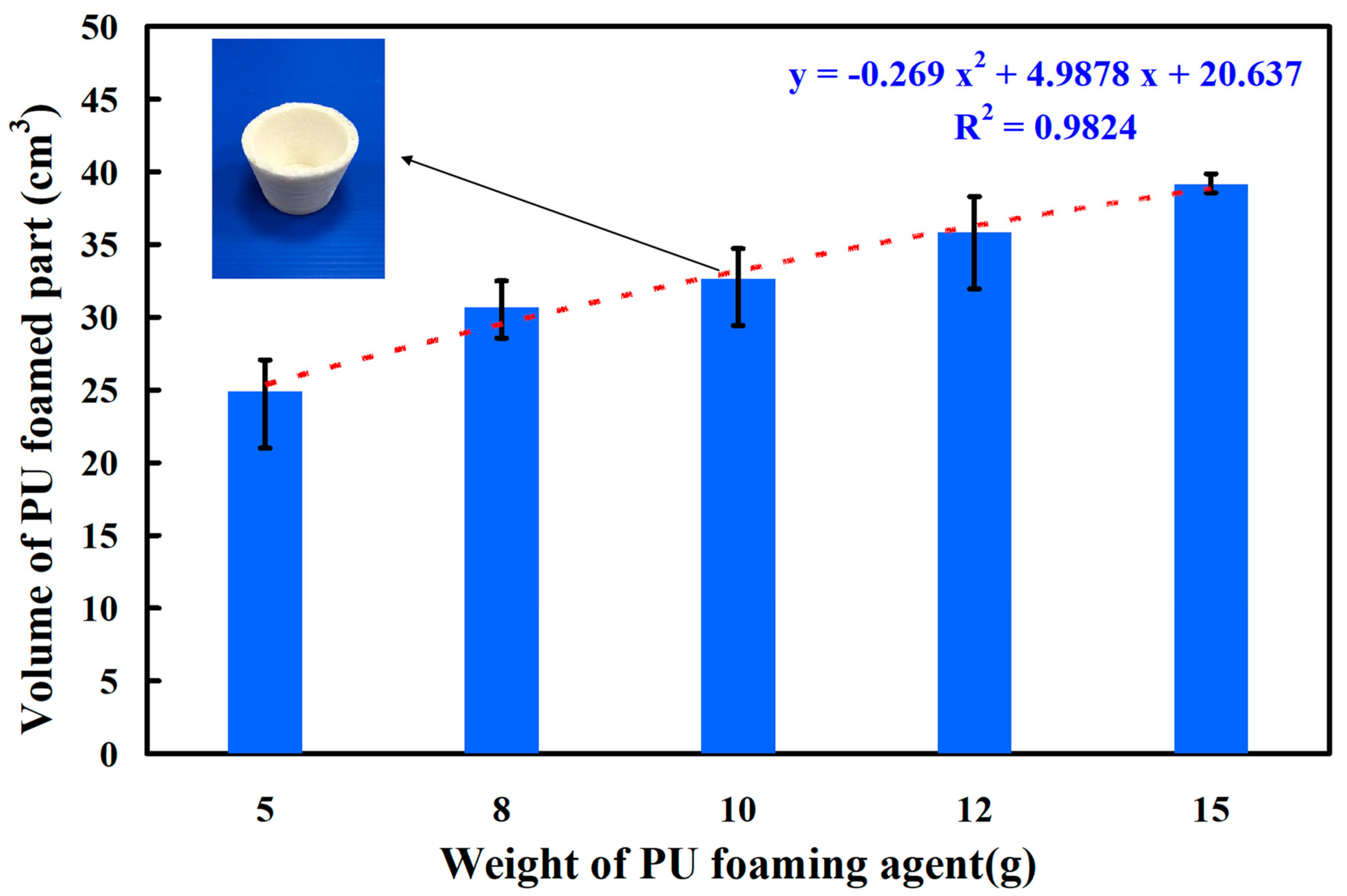

- The deformation of SRM (y) can be determined by the wall thickness of silicone rubber mold (x) according to the trend equation of y = −0.0575 x2 − 0.5495 x + 3.1475 with a correlation coefficient of 0.9951. In addition, the volume of a PU foam part (y) can be determined by the weight of a PU foaming agent (x) according to the trend equation of y = −0.269 x2 + 4.9878 x + 20.637 with a correlation coefficient of 0.9824.

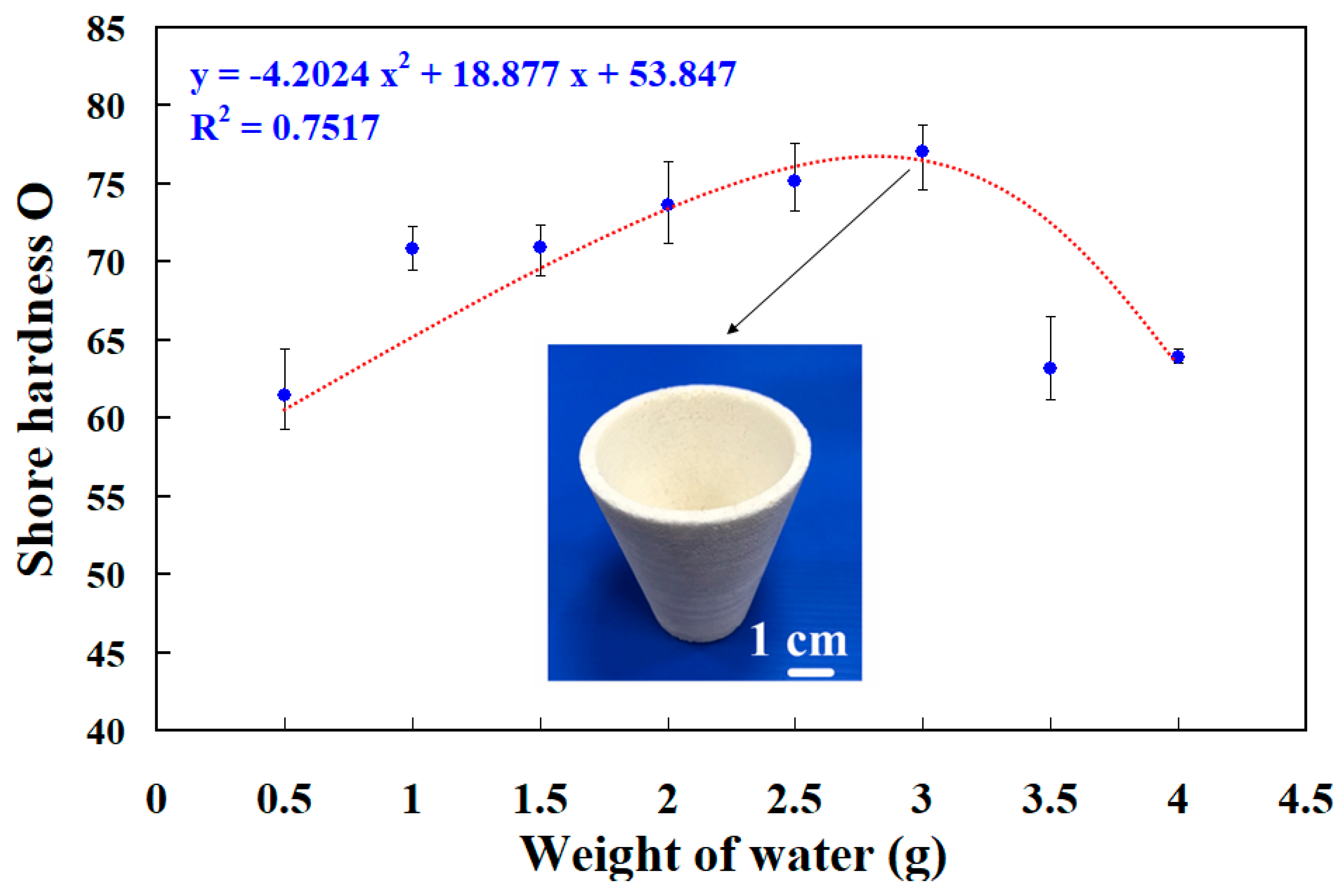

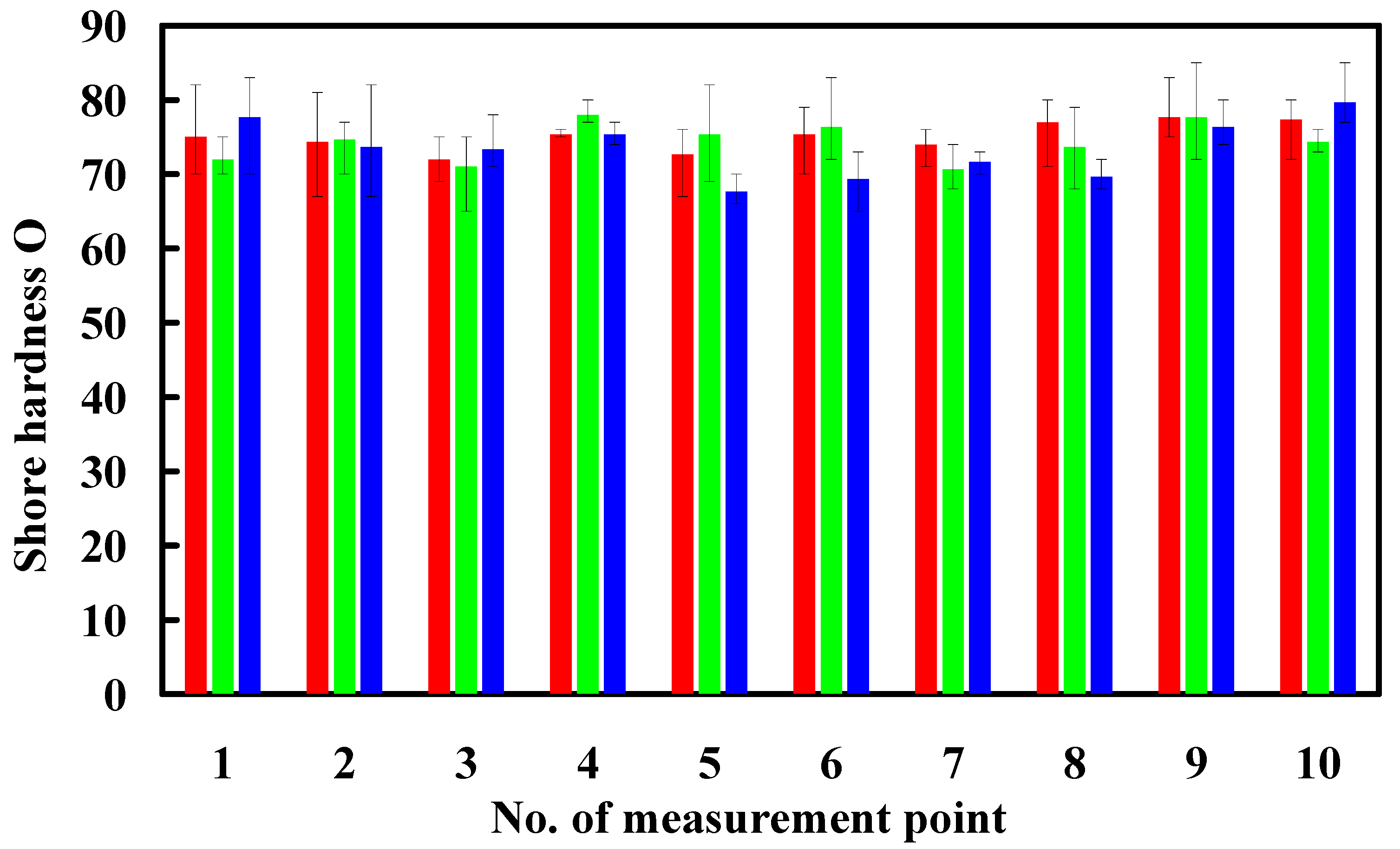

- The weight ratio of foaming agent and water with the highest surface hardness can be achieved at 5:1. The surface hardness of the PU foam part (y) can be determined by the water weight (x) according to the prediction equation of y = −4.2024 x2 + 18.877 x + 53.847 with a correlation coefficient of 0.7517. The average surface hardness of the surface of the fabricated PU foam part has a Shore O hardness value of about 75.

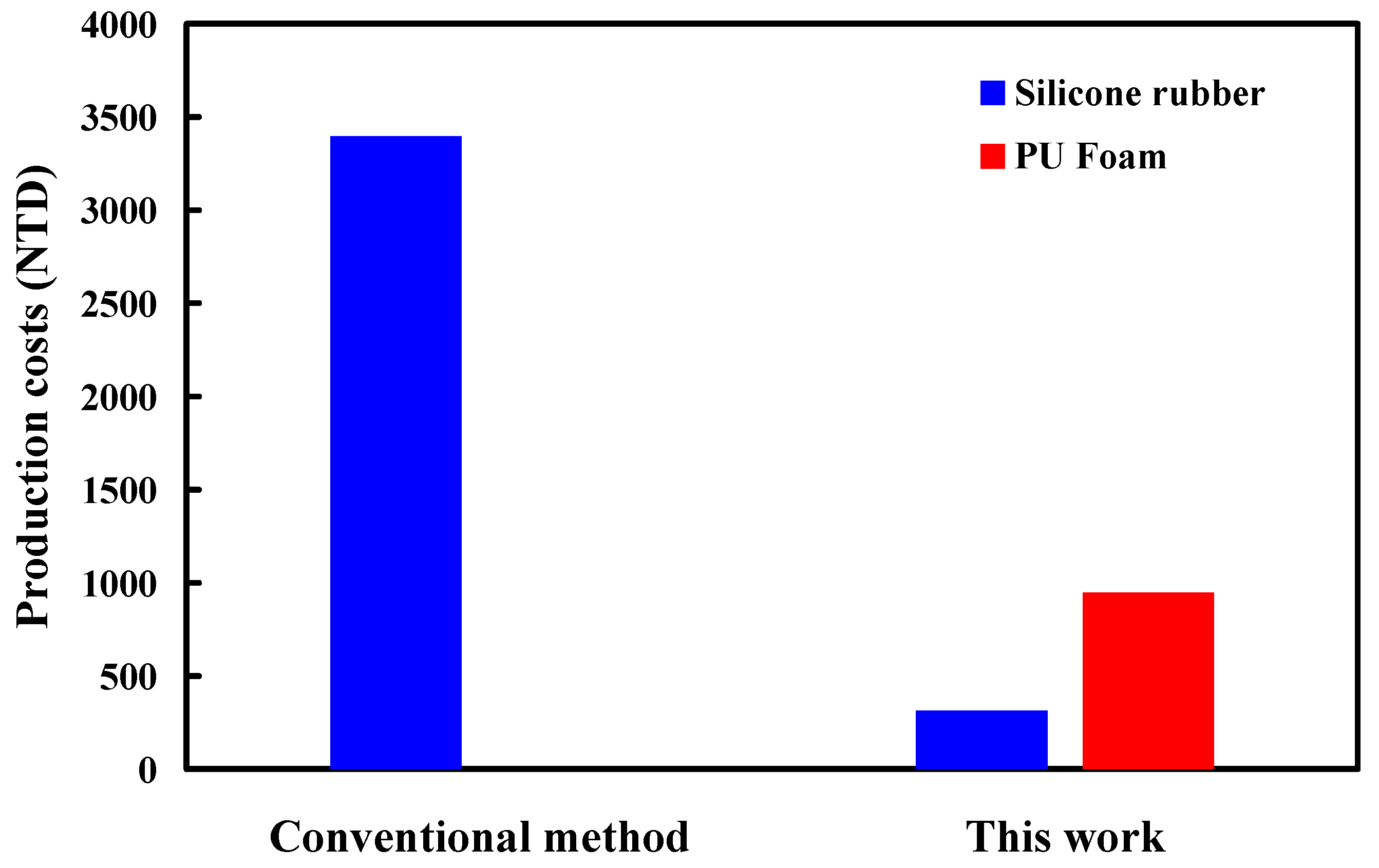

- The foam parts made with 1.5 g of water added to 15 g of foaming agent have the least internal pores because the interior of the foamed part made is the densest. The PU foam part had excellent mechanical properties when the PU foaming agent was added to 3 g of water based on both the surface hardness and compressive strength of the PU foam parts. Taking the car shell of a sports car as an example, the proposed method using rigid polyurethane-foamed parts as backing materials can save about 62% of the rapid tool production cost.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Basha, M.M.; Sankar, M.R. Finishing of additively manufactured stainless steel features by the eco-friendly electrolyte: Plasma and surface interaction science. J. Manuf. Process. 2024, 119, 609–625. [Google Scholar] [CrossRef]

- Rajendran, P.; Ganesan, A. Numerical and experimental investigation of direct rapid tooling for sheet metal forming using selective laser sintering. J. Manuf. Process. 2024, 120, 555–567. [Google Scholar] [CrossRef]

- Kuo, C.C. A cost-effective approach to the rapid fabrication of functional metal prototypes. Mater. Tehnol. 2014, 48, 581–585. [Google Scholar]

- Kuo, C.C.; Lin, P.H.; Xu, J.Y.; Lin, Z.X.; Wang, Z.H.; Lai, Z.J.; Huang, S.H. Cooling efficiency enhancement using a rapid tool with a surface-cooled waterfall cooling channel. Int. J. Adv. Manuf. Technol. 2024, 132, 1127–1136. [Google Scholar] [CrossRef]

- Biswal, R.; Ganesan, A. Experimental investigation of design parameters on geometrical accuracy of selective laser sintered parts. J. Manuf. Process. 2023, 108, 48–61. [Google Scholar] [CrossRef]

- Koppka, S.; Oberleiter, B.; Kwinda, T.I.; Steimecke, M.; Enke, D. Fabrication of 2D and 3D shaped controlled porous glasses via selective laser sintering and its effect on glass structure and microstructure. J. Manuf. Process. 2023, 93, 173–192. [Google Scholar] [CrossRef]

- Juarez, D.; Balart, R.; Boronat, T.; Reig, M.J.; Ferrandiz, S. Validation of the use of SEBS blends as a substitute for liquid silicone rubber in injection processes. Mater. Manuf. Process. 2013, 28, 1215–1221. [Google Scholar] [CrossRef]

- Azim, R.; Islam, M.T. Design of a wideband planar antenna on an epoxy-resin-reinforced woven-glass material. Mater. Tehnol. 2015, 49, 193–196. [Google Scholar] [CrossRef]

- Kuo, C.C.; Lin, C.Y. Development of bridge tooling for fabricating mold inserts of aspheric optical lens. Mater. Und Werkst. 2011, 42, 1019–1024. [Google Scholar] [CrossRef]

- Kuo, C.C. A simple and cost-effective method for fabricating epoxy-based composites mold inserts. Mater. Manuf. Process. 2012, 27, 383–388. [Google Scholar] [CrossRef]

- Kuo, C.C.; Lin, C.Y. Rapid manufacturing of plastic aspheric optical lens. Mater. Und Werkst. 2012, 43, 495–502. [Google Scholar] [CrossRef]

- Cortazar-Noguerol, J.; Cortés, F.; Sarría, I.; Elejabarrieta, M.J. Preload Influence on the Dynamic Properties of a Polyurethane Elastomeric Foam. Polymers 2024, 16, 1844. [Google Scholar] [CrossRef] [PubMed]

- Malewska, E.; Kurańska, M.; Tenczyńska, M.; Prociak, A. Application of Modified Seed Oils of Selected Fruits in the Synthesis of Polyurethane Thermal Insulating Materials. Materials 2024, 17, 158. [Google Scholar] [CrossRef]

- Ahir, M.; Bodhak, C.; Gupta, R.K. Harnessing Enhanced Flame Retardancy in Rigid Polyurethane Composite Foams through Hemp Seed Oil-Derived Natural Fillers. Polymers 2024, 16, 1584. [Google Scholar] [CrossRef]

- Li, C.; Zhang, G.; Yuan, B. Exceptional Performance of Flame-Retardant Polyurethane Foam: The Suppression Effect on Explosion Pressure and Flame Propagation of Methane-Air Premixed Gas. Materials 2023, 16, 7602. [Google Scholar] [CrossRef] [PubMed]

- Zemła, M.; Michałowski, S.; Prociak, A. Synthesis and Characterization of Flame Retarded Rigid Polyurethane Foams with Different Types of Blowing Agents. Materials 2023, 16, 7217. [Google Scholar] [CrossRef] [PubMed]

- Sture, B.; Yakushin, V.; Vevere, L.; Cabulis, U. Influence of Long-Term Storage and UV Light Exposure on Characteristics of Polyurethane Foams for Cryogenic Insulation. Materials 2023, 16, 7071. [Google Scholar] [CrossRef] [PubMed]

- Ran, M.; Zhou, X.; Yan, Y.; Jiang, R.; Zhou, X. Grouting Mechanism of Polyurethane Composite Materials in Asphalt Pavement Subsidence. Materials 2023, 16, 7052. [Google Scholar] [CrossRef] [PubMed]

- del Amo, J.; Iswar, S.; Vanbergen, T.; Borreguero, A.M.; De Vos, S.D.E.; Verlent, I.; Willems, J.; Rodriguez Romero, J.F. Polyurethane Composites Recycling with Styrene–Acrylonitrile and Calcium Carbonate Recovery. Materials 2024, 17, 2844. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Z.; Liu, Y.; Ma, W.; Zhang, Z.; Zhao, C.; Yang, C. On the Crush Behavior and Energy Absorption of Sustainable Beverage Cans and Their Polyurethane Foam-Filled Structures: An Experimental Study. Materials 2024, 17, 2655. [Google Scholar] [CrossRef]

- Kitayama, S. Process parameters optimization in plastic injection molding using metamodel-based optimization: A comprehensive review. Int. J. Adv. Manuf. Technol. 2022, 121, 7117–7145. [Google Scholar] [CrossRef]

- Yun, D.; Kim, J.H. Performance enhancements of PU composite foams reinforced with starfish particles chemically treated by silane derivatives. Adv. Powder Technol. 2024, 35, 104349. [Google Scholar] [CrossRef]

- Fu, K.; Zhang, L.; Zhang, W.; Ma, Q.; Zheng, X.; Chang, C. Sustainable production and evaluation of bio-based flame-retardant PU foam via liquefaction of industrial biomass residues. Ind. Crops Prod. 2024, 210, 118100. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Wrona, M.; Su, Q.Z.; Vera, P.; Nerín, C.; Hu, C.Y. Influence of cooking conditions on the migration of silicone oligomers from silicone rubber baking molds to food simulants. Food Chem. 2021, 347, 128964. [Google Scholar] [CrossRef] [PubMed]

- ASTM D2240-15(2021); Standard Test Method for Rubber Property—Durometer Hardness. ASTM: West Conshohocken, PA, USA, 2021.

- Baisukhan, A.; Nakkiew, W. Enhancing surface integrity in friction stir welding through deep rolling and post-weld heat treatment. J. Adv. Join. Process. 2024, 9, 100223. [Google Scholar] [CrossRef]

- Österreicher, J.A.; Pfeiffer, C.; Kunschert, G.; Weinberger, T.; Schlögl, C.M.; Suppan, W.; Radlmayr, K.M. Dissimilar friction stir welding and post-weld heat treatment of Ti-6Al-4V and AA7075 producing joints of unprecedented strength. J. Adv. Join. Process. 2024, 9, 100213. [Google Scholar] [CrossRef]

- Keshavarzi, S.; Bouazara, B.; Momen, G.; Jafari, R. Hydrophobicity and icephobicity of micropillared silicone rubber surfaces fabricated by compression molding. Results Surf. Interfaces 2023, 12, 100132. [Google Scholar] [CrossRef]

- Sokol, M.B.; Sokhraneva, V.A.; Groza, N.V.; Mollaeva, M.R.; Yabbarov, N.G.; Chirkina, M.V.; Trufanova, A.A.; Popenko, V.I.; Nikolskaya, E.D. Thymol-Modified Oleic and Linoleic Acids Encapsulated in Polymeric Nanoparticles: Enhanced Bioactivity, Stability, and Biomedical Potential. Polymers 2024, 16, 72. [Google Scholar] [CrossRef]

- Dalcin, R.L.; de Menezes, V.M.; da Silva Rocha, A.; de Moraes, S.P.; Affonso, L.B.; Cousseau, T.; da Silva, C.H. Correlation between roughness, film thickness, and friction coefficient with pitting wear resistance of spur gears. Int. J. Adv. Manuf. Technol. 2023, 129, 5473–5492. [Google Scholar] [CrossRef]

- Tyagi, R.; Tripathi, A.; Kumar, R.; Jain, A.; Pillai, P. On FFF-based 3D printing of wear resistive ABS-Graphene nanocomposites for rapid tooling in wet condition. Diam. Relat. Mater. 2024, 142, 110794. [Google Scholar] [CrossRef]

- Walsh, E.; Maclean, N.; Turner, A.; Alsuleman, M.; Prasad, E.; Halbert, G.; ter Horst, J.H.; Markl, D. Manufacture of tablets with structurally-controlled drug release using rapid tooling injection moulding. Int. J. Pharm. 2022, 624, 121956. [Google Scholar] [CrossRef] [PubMed]

- Arman, S.; Lazoglu, I. A comprehensive review of injection mold cooling by using conformal cooling channels and thermally enhanced molds. Diam. Relat. Mater. 2023, 127, 2035–2106. [Google Scholar] [CrossRef]

- Si, J.; Lan, K.; Cui, Z.; Wang, Q.; Zeng, S.; Liu, X.; Gong, C. Constructing salt-resistant 3D foams with hierarchical interconnected channels by vacuum casting method for efficient solar evaporation of hypersaline water. Desalination 2024, 576, 117339. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, H.; Xu, R.; Liu, B.; Feng, J.; Ji, P.; Liang, J.; Liang, G. Modification of microstructure and mechanical properties in H13 steel by introducing oxide particles using vacuum casting. J. Mater. Res. Technol. 2024, 30, 3141–3151. [Google Scholar] [CrossRef]

- Lan, S.; Jiao, F. Modeling of heat source in grinding zone and numerical simulation for grinding temperature field. Diam. Relat. Mater. 2019, 103, 3077–3086. [Google Scholar] [CrossRef]

- Puerta, A.P.V.; Sanchez, D.M.; Batista, M.; Salguero, J. Criteria selection for a comparative study of functional performance of Fused Deposition Modelling and Vacuum Casting processes. J. Manuf. Process. 2018, 35, 721–727. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Z.; Xu, C.; Du, J.; Su, G.; Zhang, P.; Meng, X. Modeling and prediction of cutting temperature in the machining of H13 hard steel of multi-layer coated cutting tools. Int. J. Adv. Manuf. Technol. 2021, 115, 3731–3739. [Google Scholar] [CrossRef]

- Sama, S.R.; Wang, J.; Manogharan, G. Non-conventional mold design for metal casting using 3D sand-printing. J. Manuf. Process. 2018, 34 Pt B, 765–775. [Google Scholar] [CrossRef]

- Mendoza, S.; Lamberson, L. Damage tolerancing in carbon fiber-reinforced polymer (CFRP) laminates under combined impact fatigue and environmental conditioning. Compos. Part A Appl. Sci. Manuf. 2024, 180, 108062. [Google Scholar] [CrossRef]

- He, D.; Kim, H.C.; Sommacal, S.; Stojcevski, F.; Soo, V.K.; Lipiński, W.; Morozov, E.; Henderson, L.C.; Compston, P.; Doolan, M. Improving mechanical and life cycle environmental performances of recycled CFRP automotive component by fibre architecture preservation. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107749. [Google Scholar] [CrossRef]

- Zhang, Q.; Hou, D.; Li, Z.; Wang, H.; Dong, S. Evaluation of the Thermal Stability and Micro-Modification Mechanism of SBR/PP-Modified Asphalt. Polymers 2024, 16, 456. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Rosas, O.; Blanco, S.; Flores, M.; Shirai, K.; Farfan-Cabrera, L.I. Partially Deacetylated and Fibrillated Shrimp Waste-Derived Chitin as Biopolymer Emulsifier for Green Cutting Fluids—Towards a Cleaner Production. Polymers 2022, 14, 525. [Google Scholar] [CrossRef] [PubMed]

- Iqhrammullah, M.; Marlina; Hedwig, R.; Karnadi, I.; Kurniawan, K.H.; Olaiya, N.G.; Mohamad Haafiz, M.K.; Abdul Khalil, H.P.S.; Abdulmadjid, S.N. Filler-Modified Castor Oil-Based Polyurethane Foam for the Removal of Aqueous Heavy Metals Detected Using Laser-Induced Breakdown Spectroscopy (LIBS) Technique. Polymers 2020, 12, 903. [Google Scholar] [CrossRef] [PubMed]

- Zamani, P.; Zabihi, O.; Ahmadi, M.; Zamani, M.R.; Zohuriaan-Mehr, M.J.; Kannangara, T.; Joseph, P.; Naebe, M. Assessing sustainability and green chemistry in synthesis of a Vanillin-based vitrimer at scale: Enabling sustainable manufacturing of recyclable carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2024, 179, 108016. [Google Scholar] [CrossRef]

- Dasari, S.S.; Wright, A.J.K.; Carroll, J.M.; Sarmah, A.; Carey, D.G.; Nagabandi, N.; Tran, T.Q.; Green, M.J. Freeform additive manufacturing of carbon fiber reinforced composites using dielectric barrier discharge-assisted Joule heating. Compos. Part A Appl. Sci. Manuf. 2024, 179, 108047. [Google Scholar] [CrossRef]

- Air, A.; Prusty, B.G. Manufacturing feasibility of a bend free ellipsoidal composite pressure vessel using automated fibre placement. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107968. [Google Scholar] [CrossRef]

- Boix Rodríguez, N.; Moroni, F.; Lutey, A.H.; Favi, C. Sustainable design and life cycle engineering of adhesive joints for polymeric products: Assessment of surface activation technologies. Int. J. Adv. Manuf. Technol. 2024, 130, 1279–1306. [Google Scholar] [CrossRef]

- Patel, V.; Wouters, H.; Baghdadchi, A.; De Backer, J.; Igestrand, M.; Azimi, S.; Andersson, J. Robotic friction stir welding in lightweight battery assembly of extrusion-cast aluminium alloys. J. Adv. Join. Process. 2023, 8, 100156. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Gurumurthy, N.; Chen, H.-W.; Huang, S.-H. Analysis of temperature history, fatigue behavior and surface hardness in rotary friction welded dissimilar polymer rods with variable rotational speeds. J. Adv. Join. Process. 2024, 9, 100211. [Google Scholar] [CrossRef]

- Yoshida, K.; Teramoto, S.; Gong, J.; Kobayashi, Y.; Ito, H. Enhanced Marine Biodegradation of Polycaprolactone through Incorporation of Mucus Bubble Powder from Violet Sea Snail as Protein Fillers. Polymers 2024, 16, 1830. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, C.-C.; Lu, Y.-Q.; Huang, S.-H.; Farooqui, A. A Cost-Effective Approach to Creating Large Silicone Rubber Molds Using Advanced Rigid Polyurethane Foam. Polymers 2024, 16, 2210. https://doi.org/10.3390/polym16152210

Kuo C-C, Lu Y-Q, Huang S-H, Farooqui A. A Cost-Effective Approach to Creating Large Silicone Rubber Molds Using Advanced Rigid Polyurethane Foam. Polymers. 2024; 16(15):2210. https://doi.org/10.3390/polym16152210

Chicago/Turabian StyleKuo, Chil-Chyuan, Yi-Qing Lu, Song-Hua Huang, and Armaan Farooqui. 2024. "A Cost-Effective Approach to Creating Large Silicone Rubber Molds Using Advanced Rigid Polyurethane Foam" Polymers 16, no. 15: 2210. https://doi.org/10.3390/polym16152210

APA StyleKuo, C.-C., Lu, Y.-Q., Huang, S.-H., & Farooqui, A. (2024). A Cost-Effective Approach to Creating Large Silicone Rubber Molds Using Advanced Rigid Polyurethane Foam. Polymers, 16(15), 2210. https://doi.org/10.3390/polym16152210