Study on Low Temperature Cracking Resistance of Carbon Fiber Geogrid Reinforced Asphalt Pavement Surface Combined Body

Abstract

1. Introduction

2. Materials and Methods

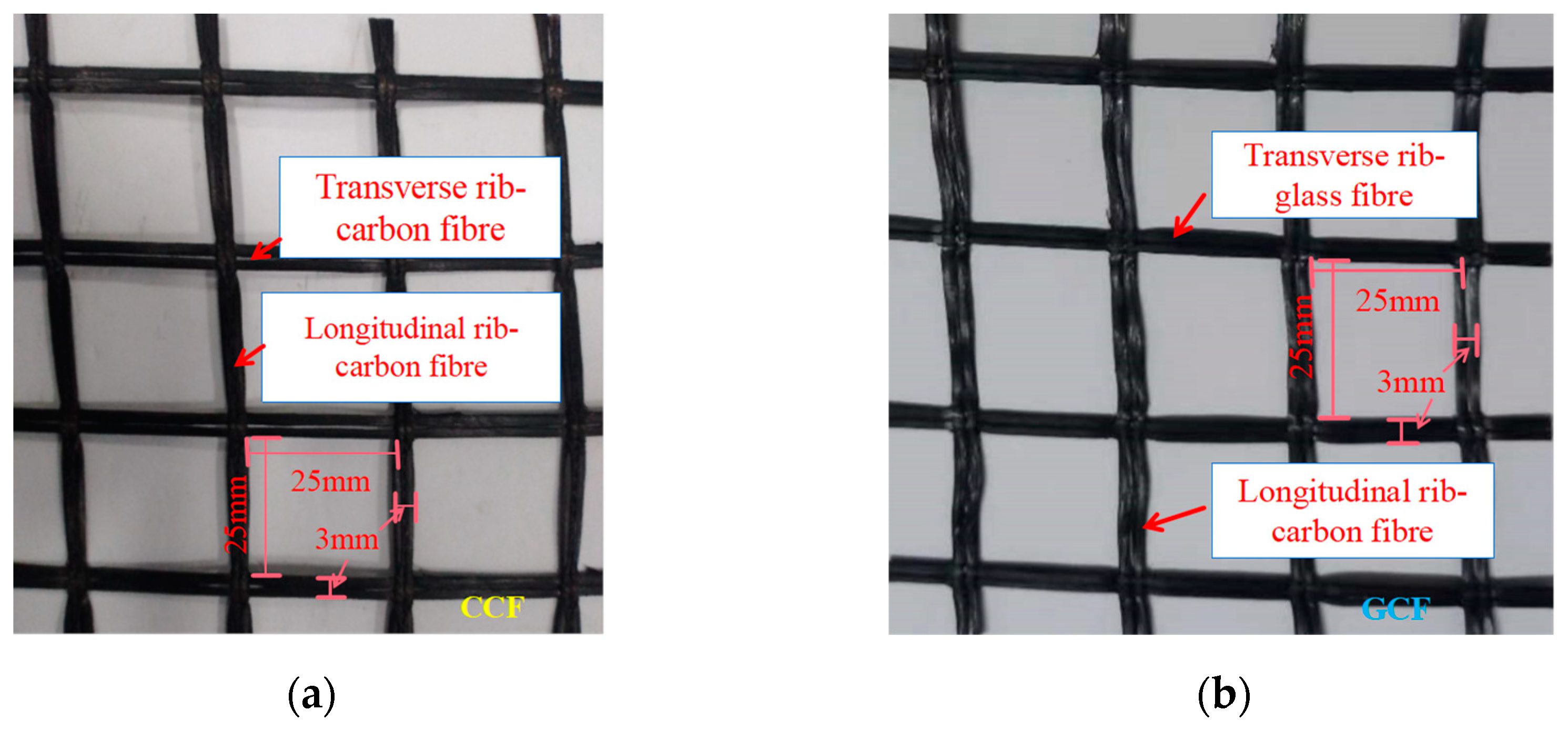

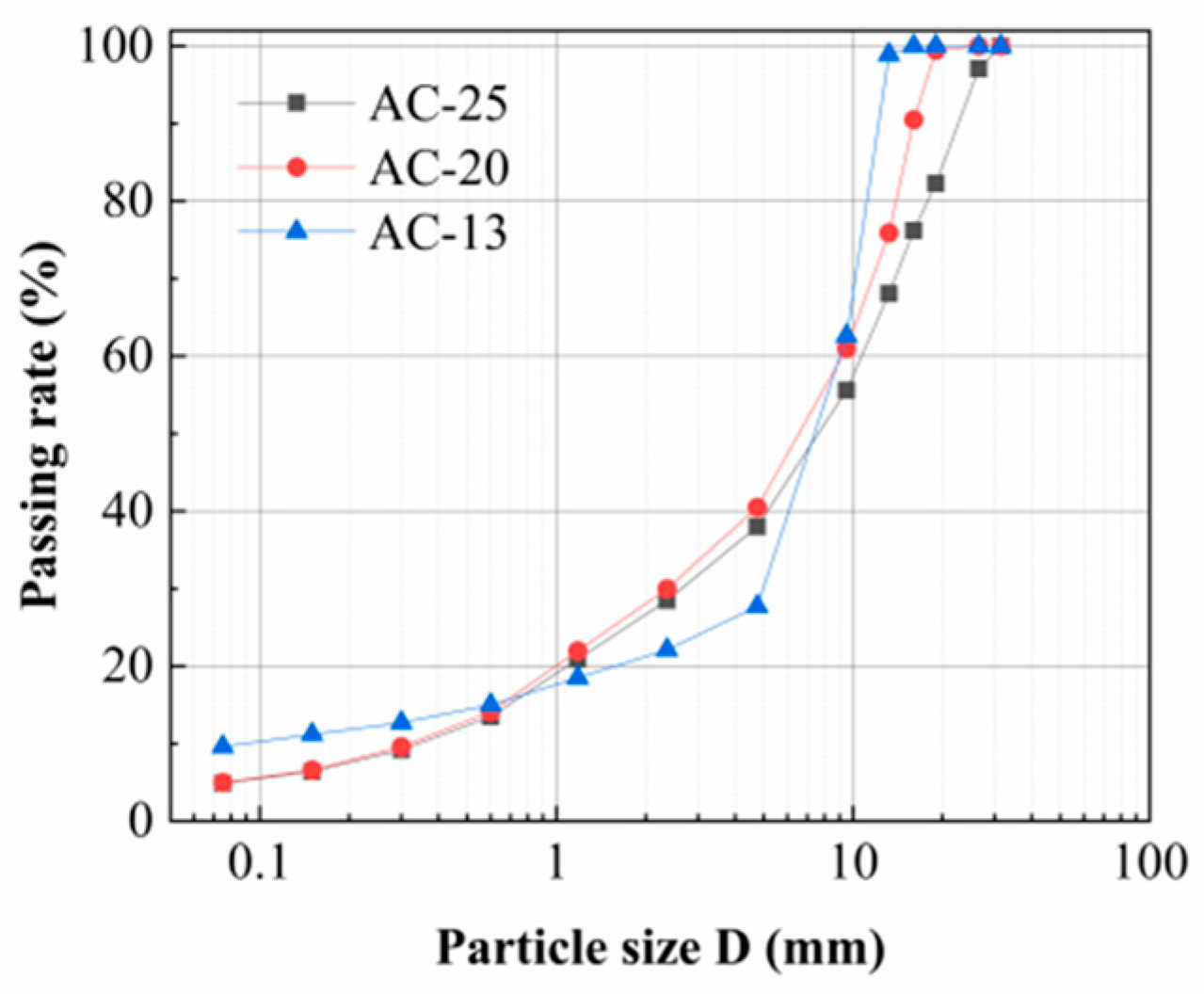

2.1. Materials

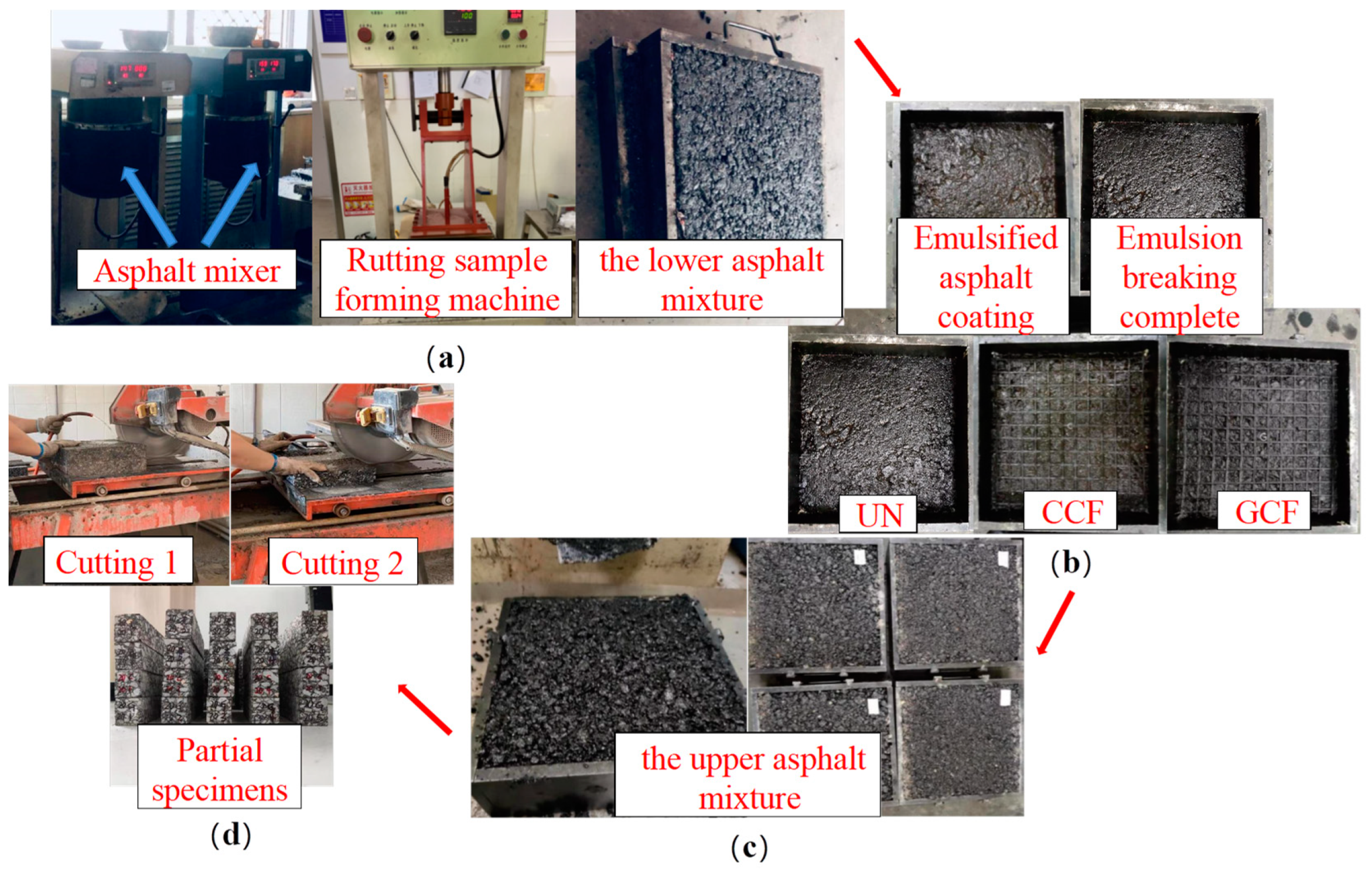

2.2. Specimen Preparation

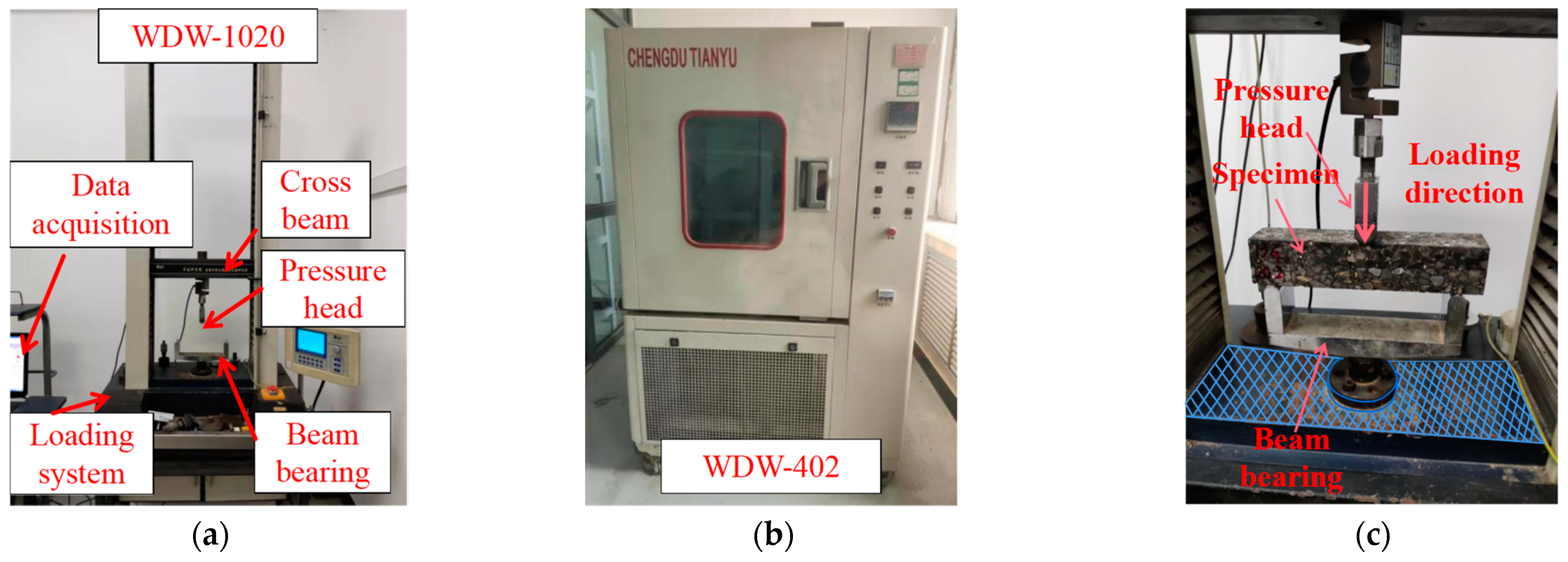

2.3. Low-Temperature Bending Damage Test

2.4. Interface Observations

3. Results

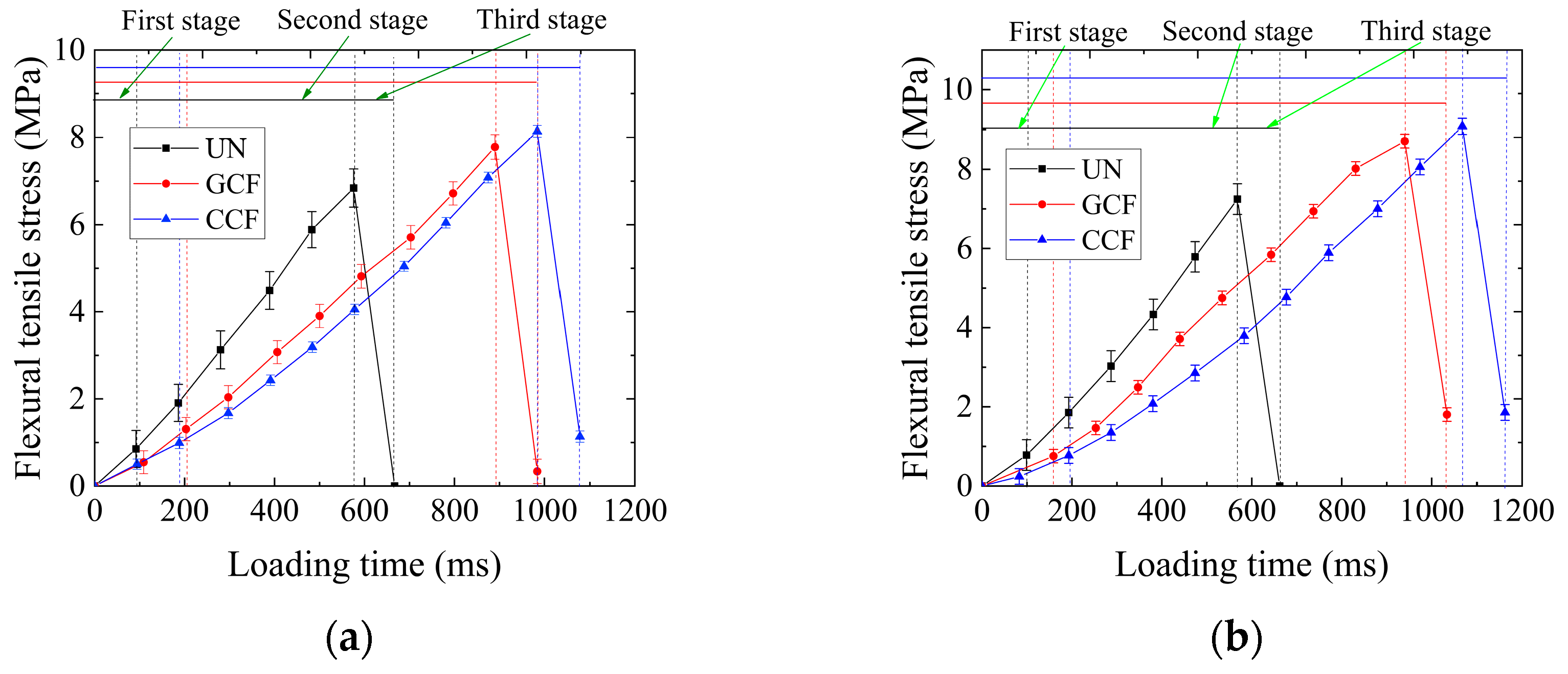

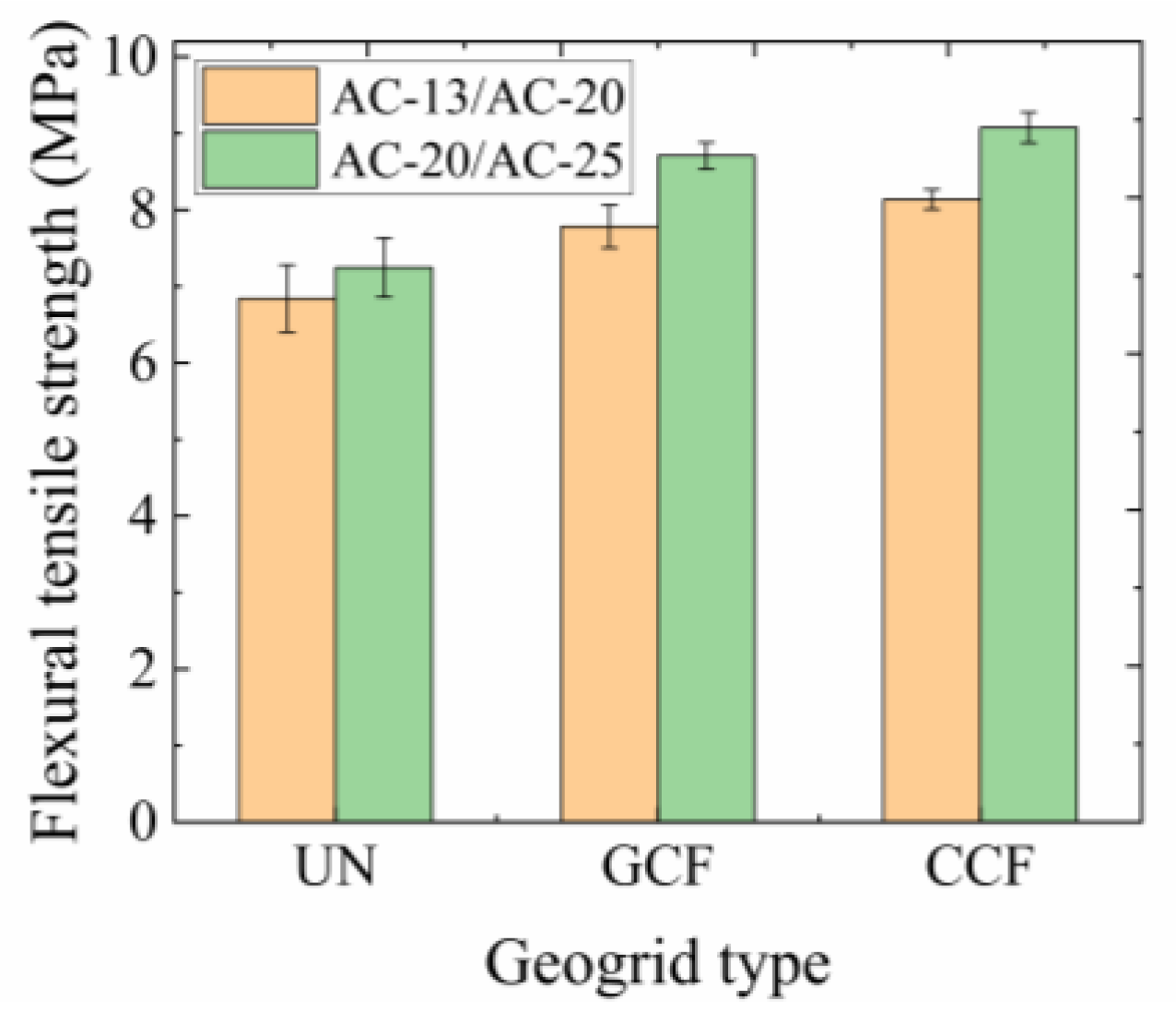

3.1. Effect of Reinforcements on Flexural Tensile Strength

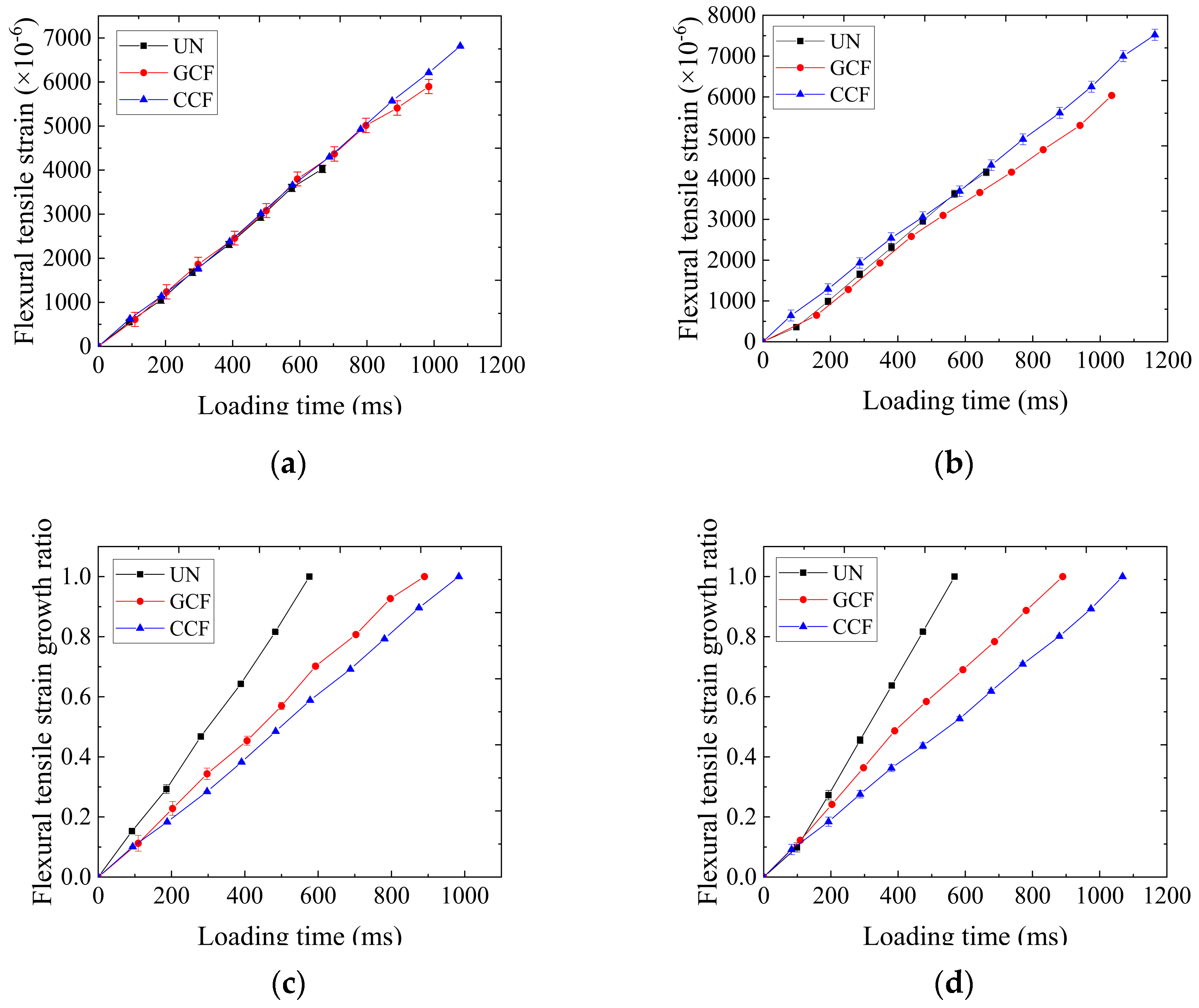

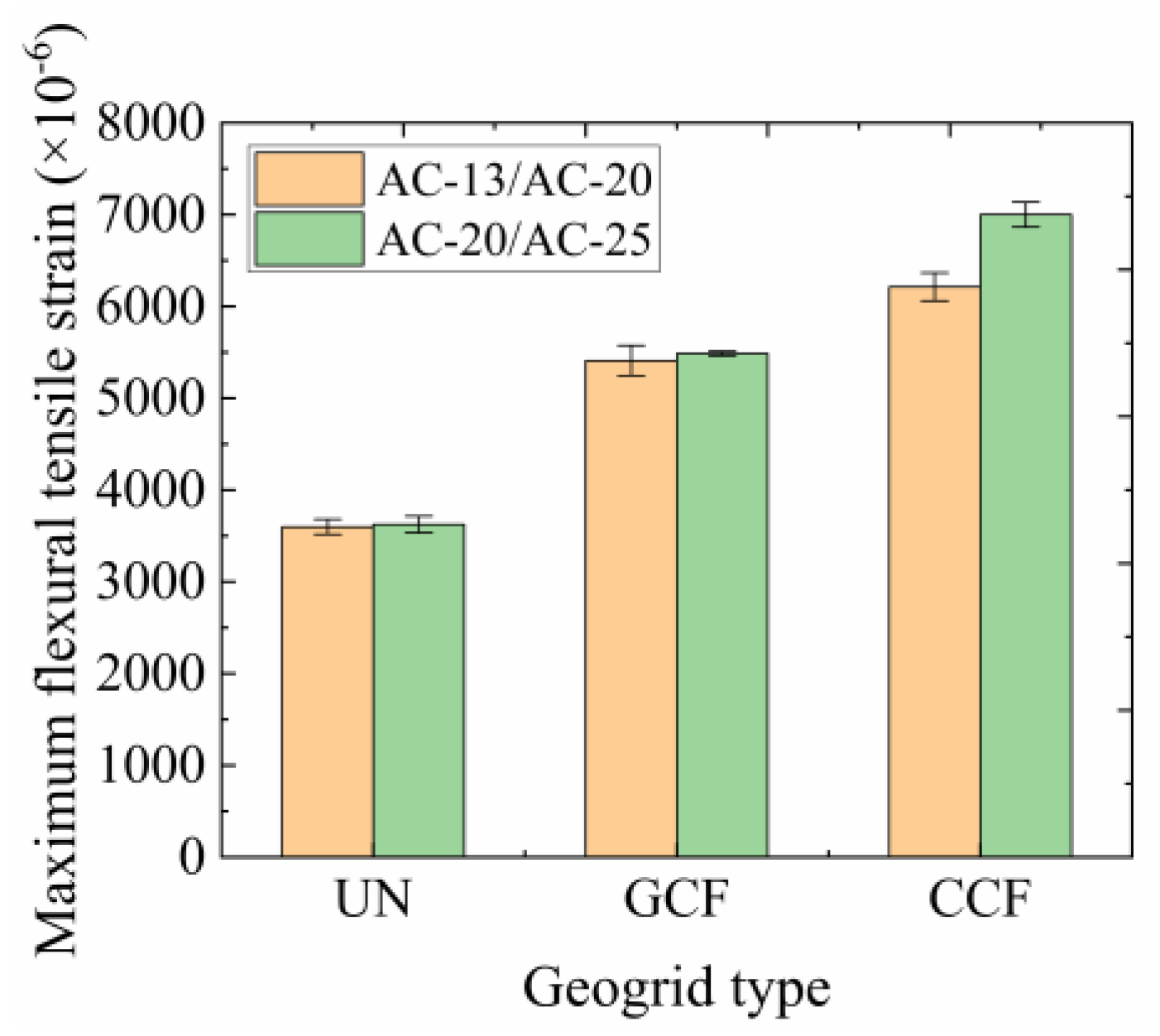

3.2. Effect of Reinforcements on Flexural Tensile Strain

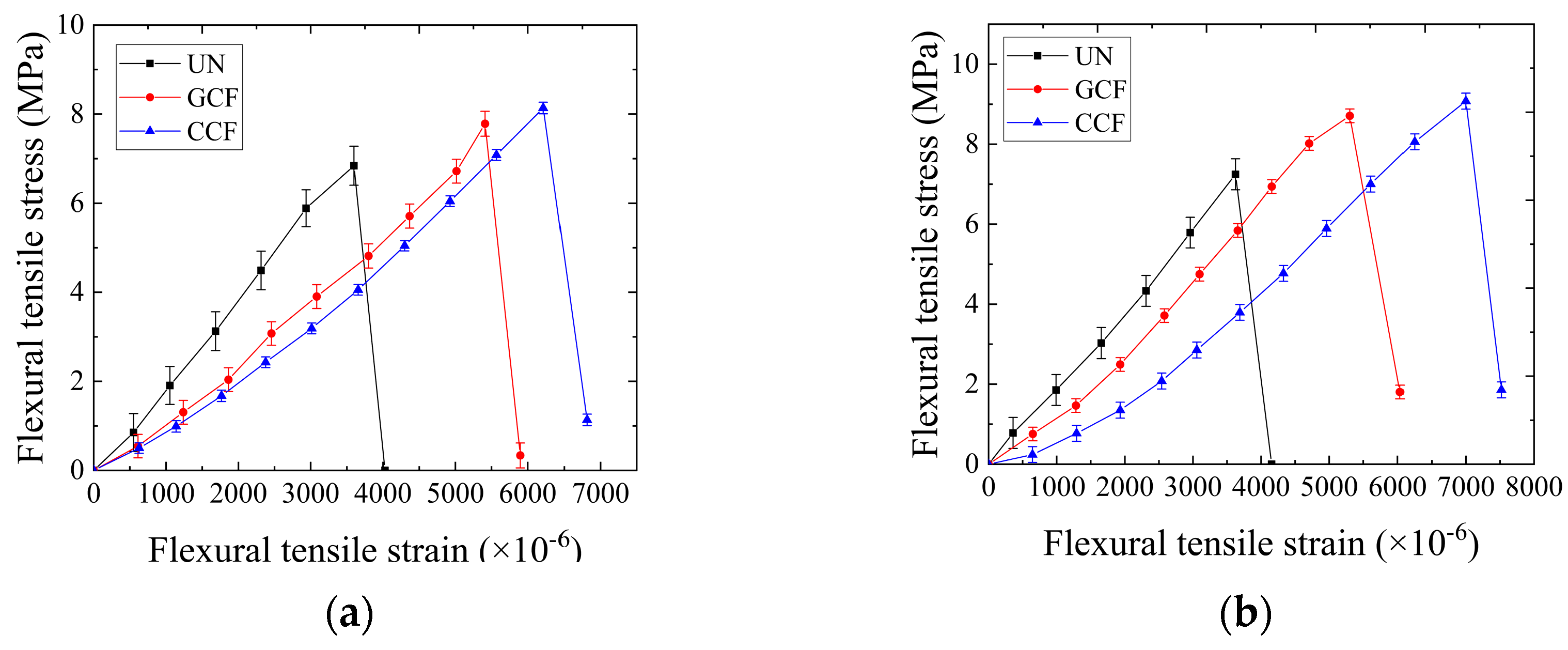

3.3. Relationship between Flexural Tensile Stress and Flexural Tensile Strain

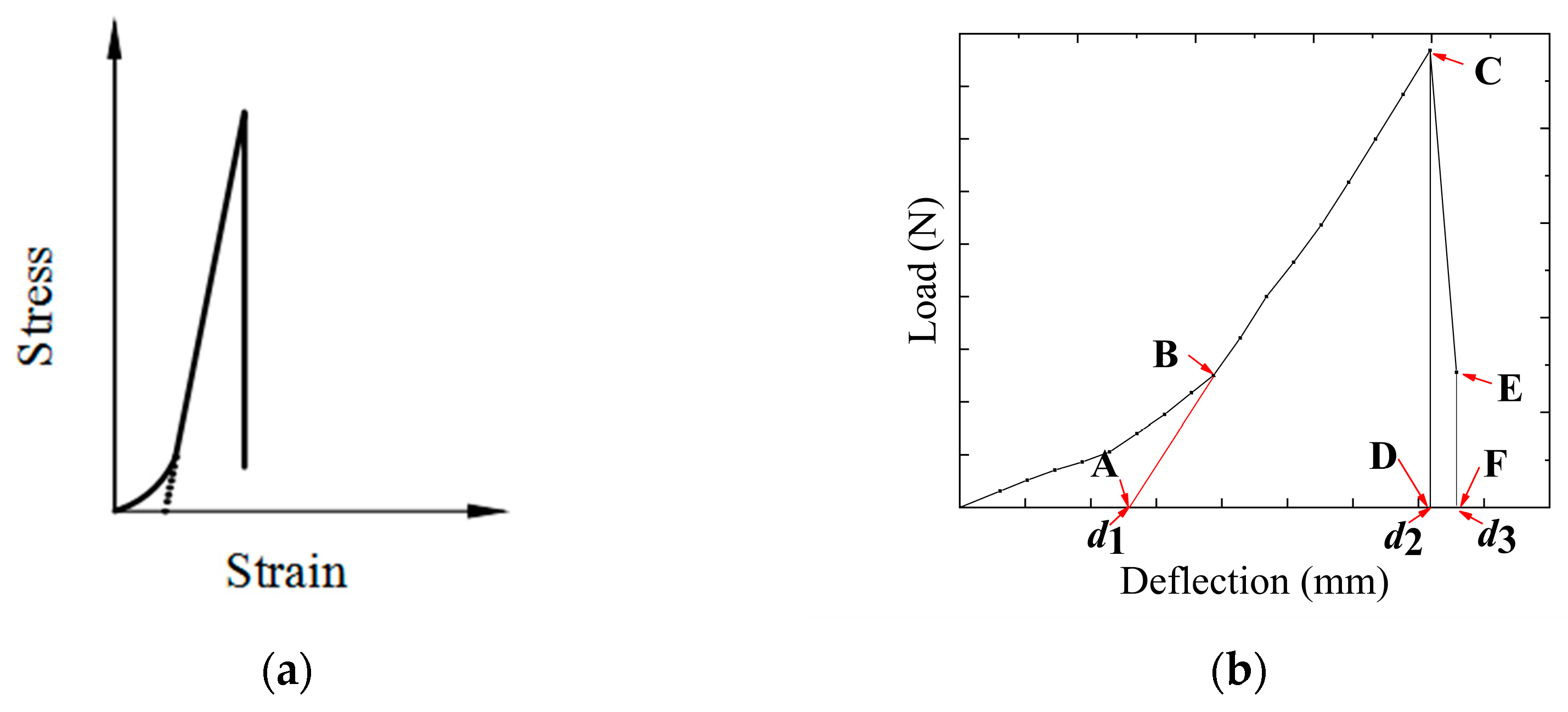

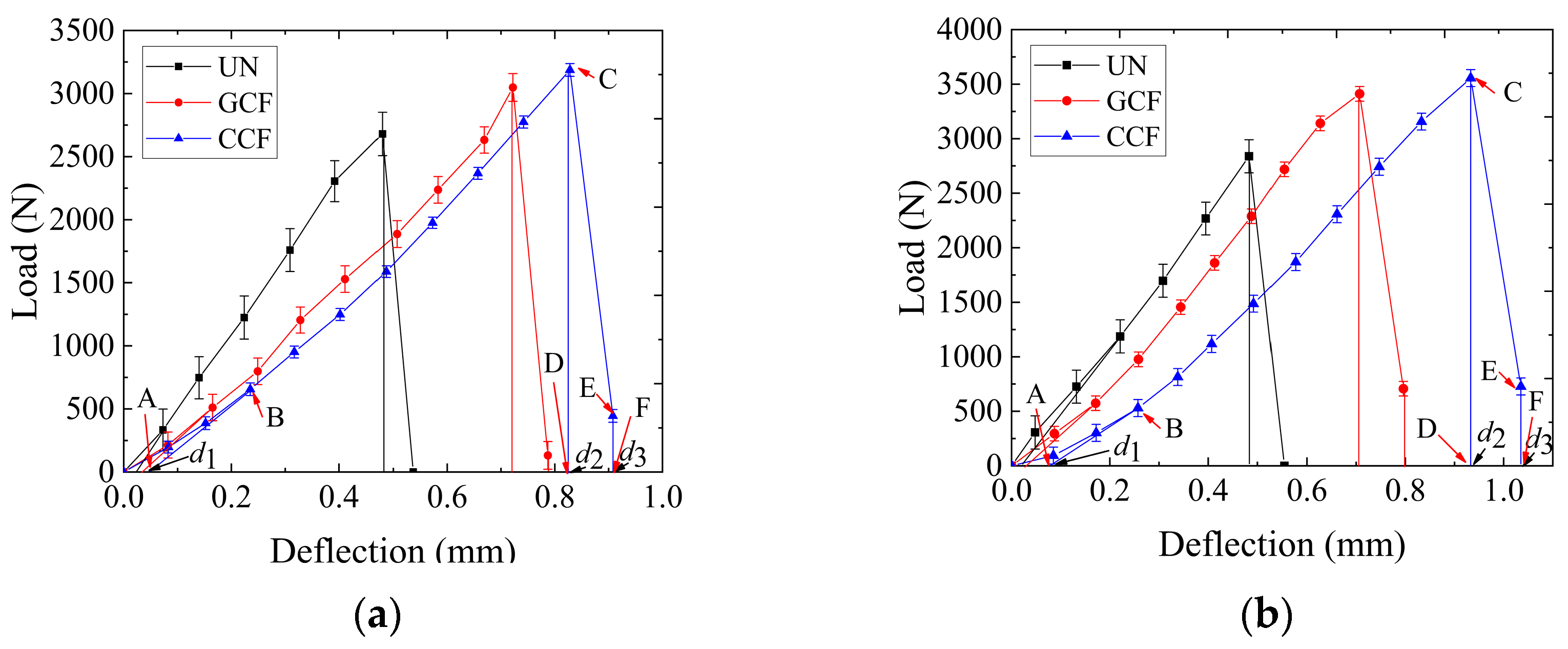

3.4. Effect of Reinforcements on Fracture Energy

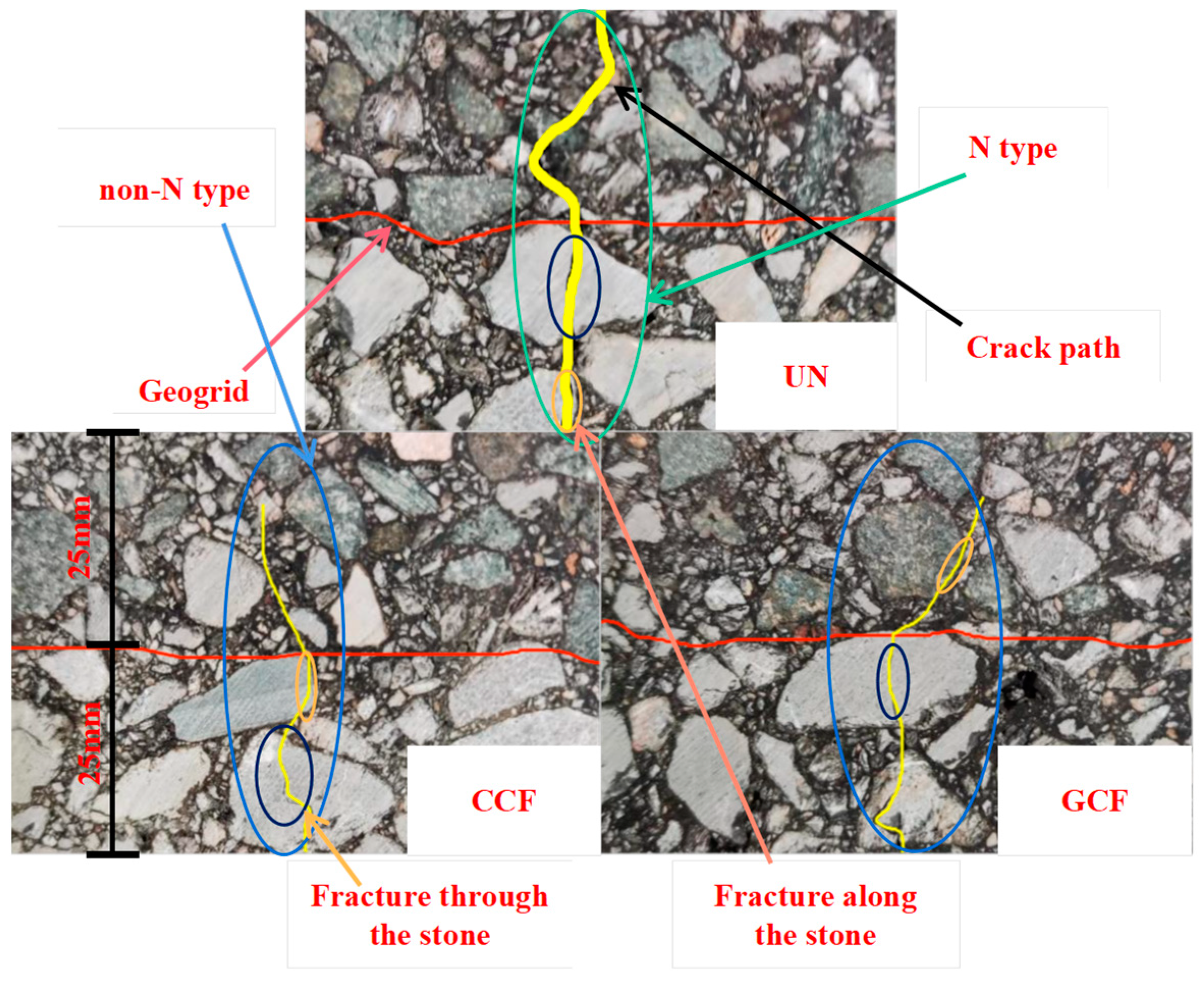

3.5. Interface Observations

4. Discussion

5. Conclusions

- (1)

- The flexural tensile strength and maximum flexural strain of carbon fiber-based geogrid reinforcement both increase, while the flexural stiffness decreases accordingly. The performance difference in the longitudinal and transverse ribs plays a certain role in improving the low-temperature cracking resistance of carbon fiber-based geogrid reinforcement. The improvement in flexural tensile strength of the CCF is similar to that of the GCF. Geogrid reinforcement extends the time to reach cracking by 54.5–88.0%.

- (2)

- The SCB type has an important influence in improving the flexural tensile strength and maximum flexural tensile strain of carbon fiber-based geogrid reinforcement. In this test, under reinforced conditions, the improvement in the low-temperature cracking resistance of AC-20/AC-25 is better than that of AC-13/AC-20, by 16.26–24.57%.

- (3)

- The ratio range of the aperture sizes to the major particle sizes in the dense gradation is an important factor in improving the low-temperature cracking resistance of carbon fiber-based geogrid reinforcements. In this test, when the ratio range is 1.32–2.63, the improvement in the low-temperature cracking resistance of carbon fiber-based geogrid reinforcement is more significant.

- (4)

- The relationship curve of flexural tensile stress versus flexural tensile strain for carbon fiber-based geogrid reinforcement is similar to the Type I stress–strain curve. During the test, there is an obvious strain softening phenomenon, but no obvious yield zone.

- (5)

- The fracture energy of carbon fiber-based geogrid reinforcement increases with the increase in the overall ultimate tensile strength of geogrid. Fracture energy consists of bending absorption energy and toughness energy, with bending absorption energy accounting for more than 80%. Therefore, improving the bending absorption energy is an important way to improve the low-temperature cracking resistance of carbon fiber-based geogrid reinforcements.

- (6)

- The crack propagation path of unreinforced geogrids generally shows as an “N-type”, while the crack propagation path of carbon fiber-base geogrid reinforcements is generally a “non-N-type”. The transverse ribs play a major role in changing the crack propagation pattern of carbon fiber-based geogrid reinforcements. The fracture type of carbon fiber-based geogrid reinforcements is a mixed plastic–brittle fracture, which can provide a reference for the road failure analysis of geogrid-reinforced asphalt pavement.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Yee, P.; Aida, B.; Hesp, S.A.; Marks, P.; Tam, K.K. Analysis of Premature Low-Temperature Cracking in Three Ontario, Canada, Pavements. Transp. Res. Rec. 2006, 1962, 44–51. [Google Scholar] [CrossRef]

- Martins, Z.; Arturs, V. Comparison of two low-temperature cracking tests for use in performance-based asphalt mixture design. Int. J. Pavement Eng. 2020, 21, 1461–1469. [Google Scholar]

- Chen, F.; Zhang, L.; Feng, J.; Ma, Y.; Zhao, Y. Research progress on test methods for low temperature crack resistance of asphalt mixture. Mater. Bull. 2021, 35 (Suppl. S2), 127–137. [Google Scholar]

- Judycki, J.; Jaczewski, M.; Ryś, D.; Pszczoła, M.; Jaskuła, P.; Glinicki, A. Field investigation of low-temperature cracking and stiffness moduli on selected roads with conventional and high modulus asphalt concrete. IOP Conf. Ser. Mater. Sci. Eng. 2017, 236, 012002. [Google Scholar] [CrossRef]

- Luo, P. Research on Fracture Test Method and Evaluation Index of Asphalt Mixture Based on Semi-Circular Bending Test. Master’s Thesis, Chang’an University, Xi’an, China, 2017. (In Chinese). [Google Scholar]

- Hui, G.; Bo, X. Research on Climatic Influencing Factors of Low Temperature Cracking Index of Asphalt Pavement in Cold Area. IOP Conf. Ser. Earth Environ. Sci. 2021, 651, 042032. [Google Scholar]

- Gnanendran, C.T. Strain measurement and interpretation of stabilizing force in geogrid reinforcement. Geotext. Geomembr. 2001, 19, 177–194. [Google Scholar] [CrossRef]

- Szwed, A.; Kamińska, I. Mitigation of Low-temperature Cracking in Asphalt Pavement by Selection of Material Stiffness. Procedia Eng. 2015, 111, 748–755. [Google Scholar] [CrossRef]

- Wang, Z. Experimental Study on High and Low Temperature Performance of Carbon Fiber Geogrid Reinforced Asphalt Mixture. Master’s Thesis, Shijiazhuang Railway University, Shijiazhuang, China, 2022. (In Chinese). [Google Scholar]

- Cao, W.Z.; Zheng, J.J.; Zhang, J.; Zhang, R.J. Field test of a geogrid-reinforced and floating pile-supported embankment. Geosynth. Int. 2016, 23, 348–361. [Google Scholar] [CrossRef]

- Cao, W.; Zheng, J.; Yan, Y. Numerical simulation of pile-supported variable stiffness reinforced cushion composite foundation. J. Geotech. Eng. 2017, 39 (Suppl. S2), 83–86. (In Chinese) [Google Scholar]

- Avesani Neto, J.O. Application of the two-layer system theory to calculate the settlements and vertical stress propagation in soil reinforcement with geocell. Geotext. Geomembr. 2019, 47, 32–41. [Google Scholar] [CrossRef]

- Yang, G.; Zuo, Z.; Liu, Y.; Wang, Z.; Wang, H.; Yu, F. Experimental study on tensile mechanical properties of geocell strips. J. Geotech. Eng. 2021, 43, 760–767. (In Chinese) [Google Scholar]

- Khodaii, A.; Fallah, S.; Nejad, F.M. Effects of geosynthetics on reduction of reflection cracking in asphalt overlays. Geotext. Geomembr. 2008, 27, 1–8. [Google Scholar] [CrossRef]

- Wang, X.; Liu, K.; Li, S. Study on the anti-reflective crack performance of asphalt overlay interlayer materials. J. Build. Mater. 2010, 13, 247–252 + 271. (In Chinese) [Google Scholar]

- Nejad, F.M.; Noory, A.; Toolabi, S.; Fallah, S. Effect of using geosynthetics on reflective crack prevention. Int. J. Pavement Eng. 2015, 16, 477–487. [Google Scholar] [CrossRef]

- Gonzalez-Torre, I.; Calzada-Perez, M.A.; Vega-Zamanillo, A.; Castro-Fresno, D. Evaluation of reflective cracking in pavements using a new procedure that combine loads with different frequencies. Constr. Build. Mater. 2015, 75, 368–374. [Google Scholar] [CrossRef]

- Gonzalez-Torre, I.; Calzada-Perez, M.A.; Vega-Zamanillo, A.; Castro-Fresno, D. Experimental study of the behaviour of different geosynthetics as anti-reflective cracking systems using a combined-load fatigue test. Geotext. Geomembr. 2015, 43, 345–350. [Google Scholar] [CrossRef]

- Nejad, F.M.; Asadi, S.; Fallah, S.; Vadood, M. Statistical-experimental study of geosynthetics performance on reflection cracking phenomenon. Geotext. Geomembr. 2016, 4, 178–187. [Google Scholar] [CrossRef]

- Saride, S.; Kumar, V. Influence of geosynthetic-interlayers on the performance of asphalt overlays on pre-cracked pavements. Geotext. Geomembr. 2017, 45, 184–196. [Google Scholar] [CrossRef]

- Lee, J.-H.; Baek, S.-B.; Lee, K.-H.; Kim, J.-S.; Jeong, J.-H. Long-term performance of fiber-grid-reinforced asphalt overlay pavements: A case study of Korean national highways. J. Traffic Transp. Eng. (Engl. Ed.) 2019, 6, 366–382. [Google Scholar] [CrossRef]

- Ling, J.; Wei, F.; Gao, J.; Zhang, J.; Tian, Y.; Li, Y. New Test Method for Measuring Reflective Cracking in Hot-Mix Asphalt Overlay Pavements. Transp. Res. Rec. 2019, 2673, 327–336. [Google Scholar] [CrossRef]

- Solatiyan, E.; Bueche, N.; Vaillancourt, M.; Carter, A. Permeability and mechanical property measurements of reinforced asphalt overlay with paving fabrics using novel approaches. Mater. Struct. 2020, 53, 1–15. [Google Scholar] [CrossRef]

- Zofka, A.; Maliszewski, M.; Maliszewska, D. Glass and carbon geogrid reinforcement of asphalt mixtures. Road Mater. Pavement Des. 2017, 18 (Suppl. S1), 717–744. [Google Scholar] [CrossRef]

- Zofka, A.; Maliszewski, M.; Zofka, E.; Paliukaitė, M.; Žalimienė, L. Geogrid Reinforcement of Asphalt Pavements. Balt. J. Road Bridge Eng. 2017, 12, 181–186. [Google Scholar] [CrossRef]

- Canestrari, F.; Belogi, L.; Ferrotti, G.; Graziani, A. Shear and flexural characterization of grid-reinforced asphalt pavements and relation with field distress evolution. Mater. Struct. 2015, 48, 959–975. [Google Scholar] [CrossRef]

- Wang, J.; Lv, S.; Liu, J.; Peng, X.; Lu, W.; Wang, Z.; Xie, N. Performance evaluation of aged asphalt rejuvenated with various bio-oils based on rheological property index. J. Clean. Prod. 2023, 385, 135593. [Google Scholar] [CrossRef]

- Liu, C.; Du, J.; Wu, C.; Liu, K.; Jiang, K. Low-Temperature Crack Resistance of Wood Tar-Based Rejuvenated Asphalt Based on Viscoelastic Rheological Method. Int. J. Pavement Res. Technol. 2021, 15, 1340–1353. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Sandra, E. Towards critical low-temperature relaxation indicators for effective rejuvenation efficiency evaluation of rejuvenator-aged bitumen blends. J. Clean. Prod. 2023, 426, 139092. [Google Scholar] [CrossRef]

- Lin, P.; Liu, X.; Ren, S.; Li, Y.; Xu, J.; Li, M. Unraveling the influence of fibers on aging susceptibility and performance of high content polymer modified asphalt mixtures. Case Stud. Constr. Mater. 2023, 18, e02211. [Google Scholar] [CrossRef]

- Jin, X.; Feng, C.; Creighton, C.; Hameed, N.; Parameswaranpillai, J.; Salim, N.V. On the structural evolution of textile grade polyacrylonitrile fibers during stabilization and carbonization: Towards the manufacture of low-cost carbon fiber. Polym. Degrad. Stab. 2021, 186, 109536. [Google Scholar] [CrossRef]

- Choi, D.; Kil, H.-S.; Lee, S. Fabrication of low-cost carbon fibers using economical precursors and advanced processing technologies. Carbon 2018, 142, 610–649. [Google Scholar] [CrossRef]

- Jo, A.Y.; Yoo, S.H.; Chung, Y.S.; Lee, S. Effects of ultraviolet irradiation on stabilization of textile-grade polyacrylonitrile fibers without photo-initiator for preparing carbon fibers. Carbon 2018, 144, 440–448. [Google Scholar] [CrossRef]

- Yoo, S.H.; Park, S.; Park, Y.; Lee, D.; Joh, H.I.; Shin, I.; Lee, S. Facile method to fabricate carbon fibers from textile-grade polyacrylonitrile fibers based on electron-beam irradiation and its effect on the subsequent thermal stabilization process. Carbon 2017, 118, 106–113. [Google Scholar] [CrossRef]

- Lin, P.; Tang, C.; Chen, Z. Numerical and experimental study of deformation and failure behavior in a double rock specimen system. Earthquake 1999, 19, 413–418. (In Chinese) [Google Scholar]

- Xie, H.P.; Chen, Z.H.; Zhou, H.W.; Yi, C.; Chen, Z.J. Study on two-body mechanical model based on interaction between structural body and geo-body. Chin. J. Rock Mech. Eng. 2005, 24, 1457–1464. (In Chinese) [Google Scholar]

- Zuo, J.; Chen, Y.; Song, H. Study progress of failure behaviors and nonlinear model of deep coal-rock combined body. J. Cent. South Univ. (Sci. Technol.) 2021, 52, 2510–2521. (In Chinese) [Google Scholar]

- JTG E50; Test Methods of Geosynthetics for Highway Engineering. China Communications Press: Beijing, China, 2006.

- JTG E20; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- JTG F40; Technical Specifications for Construction of Highway Asphalt Pavements. China Communications Press: Beijing, China, 2004.

- He, J. Study on the Attenuation Law of Long-Term Skid Resistance of Asphalt Pavement with Limestone and Basalt Mixed Aggregates. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2023. (In Chinese). [Google Scholar]

- Wang, D. Asphalt Pavement Skid Resistance of the Surface Mixed Limestone and Basalt Aggregate. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2015. (In Chinese). [Google Scholar]

- Ding, Z. The Research on Durability of Limestone Used for Asphalt Pavement Surface Layer. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2013. (In Chinese). [Google Scholar]

- JTG E42; Test Methods of Aggregate for Highway Engineering. China Communications Press: Beijing, China, 2005.

- Li, G.; Zhang, B.; Yu, Y. Soil Mechanics, 2nd ed.; Tsinghua University Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Graziani, A.; Pasquini, E.; Ferrotti, G.; Virgili, A.; Canestrari, F. Structural response of grid-reinforced bituminous pavements. Mater. Struct. 2014, 47, 1391–1408. [Google Scholar] [CrossRef]

- Han, B.; Ling, J.; Shu, X.; Gong, H.; Huang, B. Laboratory investigation of particle size effects on the shear behavior of aggregate-geogrid interface. Constr. Build. Mater. 2018, 158, 1015–1025. [Google Scholar] [CrossRef]

- Brown, S.F.; Kwan, J.; Thom, N.H. Identifying the key parameters that influence geogrid reinforcement of railway ballast. Geotext. Geomembr. 2007, 25, 326–335. [Google Scholar] [CrossRef]

- Indraratna, B.; Hussaini, S.K.K.; Vinod, J.S. On the shear behavior of ballast-geosynthetic interfaces. Geotech. Test. J. 2011, 35, 305–312. [Google Scholar] [CrossRef]

- Palmeira, E.M.; Góngora, I.A. Assessing the Influence of Some Soil–Reinforcement Interaction Parameters on the Performance of a Low Fill on Compressible Subgrade. Part I: Fill Performance and Relevance of Interaction Parameters. Int. J. Geosynth. Ground Eng. 2016, 2, 1. [Google Scholar] [CrossRef]

- Sweta, K.; Hussaini, S.K.K. Effect of shearing rate on the behavior of geogrid-reinforced rail road ballast under direct shear conditions. Geotext. Geomembr. 2018, 46, 251–256. [Google Scholar] [CrossRef]

- Xue, L. Investigation of the Fracture Resistance of Asphalt Mixtures at Low Temperatures with a Semi Circular Bend Test; University of Minnesota: Mineapolis, MN, USA, 2005. [Google Scholar]

- Wagoner, M.P.; Buttlar, W.G.; Paulion, G.H. Laboratory Testing Suite for Material Characterization of Asphalt Concrete Mixtures; University of Illinoisat Urbana-Champaign: Champaign, IL, USA, 2009. [Google Scholar]

- Li, Z.; Chen, S.; Liao, W.; Chen, H. Evaluation of Anti-cracking Performance of Modified HMA in Stress Absorbing Layers under Low Temperature. China J. Highw. Transp. 2012, 25, 29–35. (In Chinese) [Google Scholar]

- Medina, N.F.; Medina, D.F.; Hernández-Olivares, F.; Navacerrada, M.A. Mechanical and thermal properties of concrete incorporating rubber and fibers from tyre recycling. Constr. Build. Mater. 2017, 144, 563–573. [Google Scholar] [CrossRef]

- Zhao, H. Study on Microwave Characteristics and Road Performance of Asphalt Mixture Mixed with Magnetite. Ph.D. Thesis, Highway College of Chang’an University, Xi’an, China, 2016. (In Chinese). [Google Scholar]

- Zhu, C.; Cheng, Y.; Liang, C.; Xiao, B. Road performance test of diatomite-basalt fiber composite modified asphalt mixture. J. Jilin Univ. (Eng. Ed.) 2020, 50, 165–173. (In Chinese) [Google Scholar]

- Xu, C.; Liao, X. Researches on interacton mechanism between geogrid and sand by pull-out tests. Rock Soil Mech. 2011, 32, 423–428. (In Chinese) [Google Scholar]

- Zhang, X. Crack of Highway Pavement and Low Temperature Crack Resistance of Isolation Layer in Sichuan Tibetan Zone. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2020. (In Chinese). [Google Scholar]

- Wang, B. Study on Fatigue Characterization of Asphalt Pavemet under Vehile Loads. Ph.D. Thesis, Chang’an University, Xi’an, China, 2008. (In Chinese). [Google Scholar]

| Index | GCF | CCF | |

|---|---|---|---|

| Ultimate tensile strength (kN/m) | Transverse | 50 | 80 |

| Longitudinal | 80 | 80 | |

| Ultimate elongation(%) | Transverse | ≤3 | ≤2 |

| Longitudinal | ≤2 | ≤2 | |

| Thickness (mm) | 0.6 | 0.6 | |

| Aperture size (mm × mm) | 25 × 25 | 25 × 25 | |

| Items | Measured Value | Standardized Requirements |

|---|---|---|

| Penetration, 25 °C, 5 s, 100 g (0.1 mm) | 57.8 | 30~60 |

| Ductility, 5 cm/min,10 °C (cm) | 25.1 | ≥20 |

| Softening point (°C) | 64.4 | ≥60 |

| Items | Measured Value | Standardized Requirements |

|---|---|---|

| Basalt/Limestone | ||

| Crushed stone value (%) | 8.67/18.77 | ≤26 |

| Polished stone value (PSV) | 41.4/39.5 | ≥38 |

| Los Angeles wear value (%) | 7.60/26.89 | ≤28 |

| Asphalt Mixture | AC-13 | AC-20 | AC-25 |

|---|---|---|---|

| Asphalt–aggregate ratio (%) | 4.8 | 4.3 | 3.7 |

| SCB Type | GCF | CCF |

|---|---|---|

| SEFCCF (%) | SEFGCF (%) | |

| AC-13/AC-20 | 13.77 | 18.93 |

| AC-20/AC-25 | 20.17 | 25.24 |

| SCB Type | Geogrid Type | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| UN | GCF | CCF | |||||||

| Gf | QB | Gt | Gf | QB | Gt | Gf | QB | Gt | |

| AC-13/AC-20 | 294.78 | 262.28 | 32.50 | 491.56 | 447.58 | 43.98 | 590.71 | 528.90 | 61.81 |

| AC-20/AC-25 | 320.68 | 277.80 | 42.88 | 571.50 | 493.51 | 77.99 | 735.83 | 642.88 | 92.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Yang, G.; Wang, X.; Liang, X.; Liu, M.; Zhang, H. Study on Low Temperature Cracking Resistance of Carbon Fiber Geogrid Reinforced Asphalt Pavement Surface Combined Body. Polymers 2024, 16, 2168. https://doi.org/10.3390/polym16152168

Wang Z, Yang G, Wang X, Liang X, Liu M, Zhang H. Study on Low Temperature Cracking Resistance of Carbon Fiber Geogrid Reinforced Asphalt Pavement Surface Combined Body. Polymers. 2024; 16(15):2168. https://doi.org/10.3390/polym16152168

Chicago/Turabian StyleWang, Zhiqiang, Guangqing Yang, Xin Wang, Xunmei Liang, Mengfan Liu, and Hao Zhang. 2024. "Study on Low Temperature Cracking Resistance of Carbon Fiber Geogrid Reinforced Asphalt Pavement Surface Combined Body" Polymers 16, no. 15: 2168. https://doi.org/10.3390/polym16152168

APA StyleWang, Z., Yang, G., Wang, X., Liang, X., Liu, M., & Zhang, H. (2024). Study on Low Temperature Cracking Resistance of Carbon Fiber Geogrid Reinforced Asphalt Pavement Surface Combined Body. Polymers, 16(15), 2168. https://doi.org/10.3390/polym16152168