Research on the Application of New Building Recycled Insulation Materials for Walls

Abstract

1. Introduction

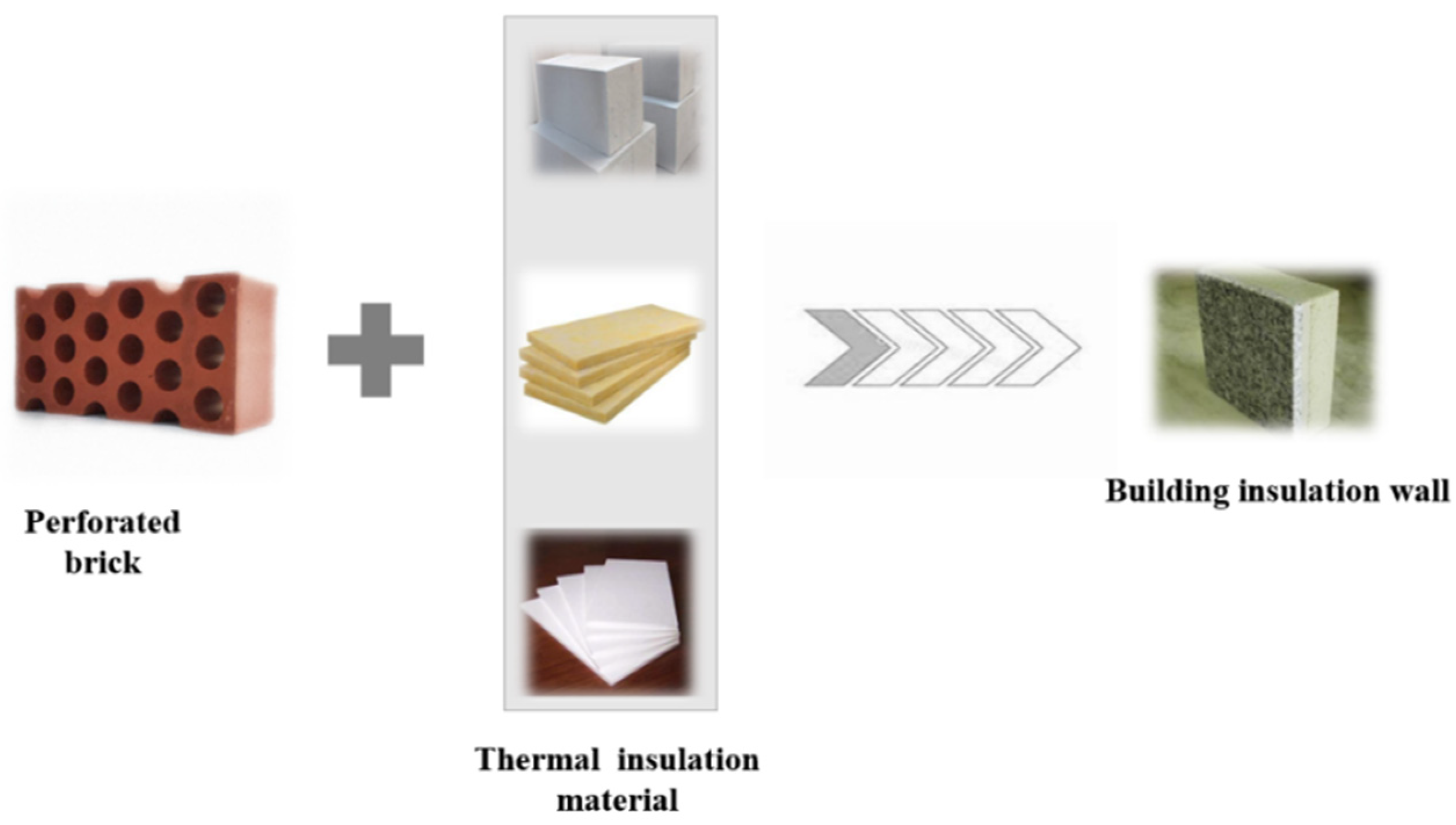

1.1. Traditional Ordinary Building Wall

1.2. Traditional Wall Materials

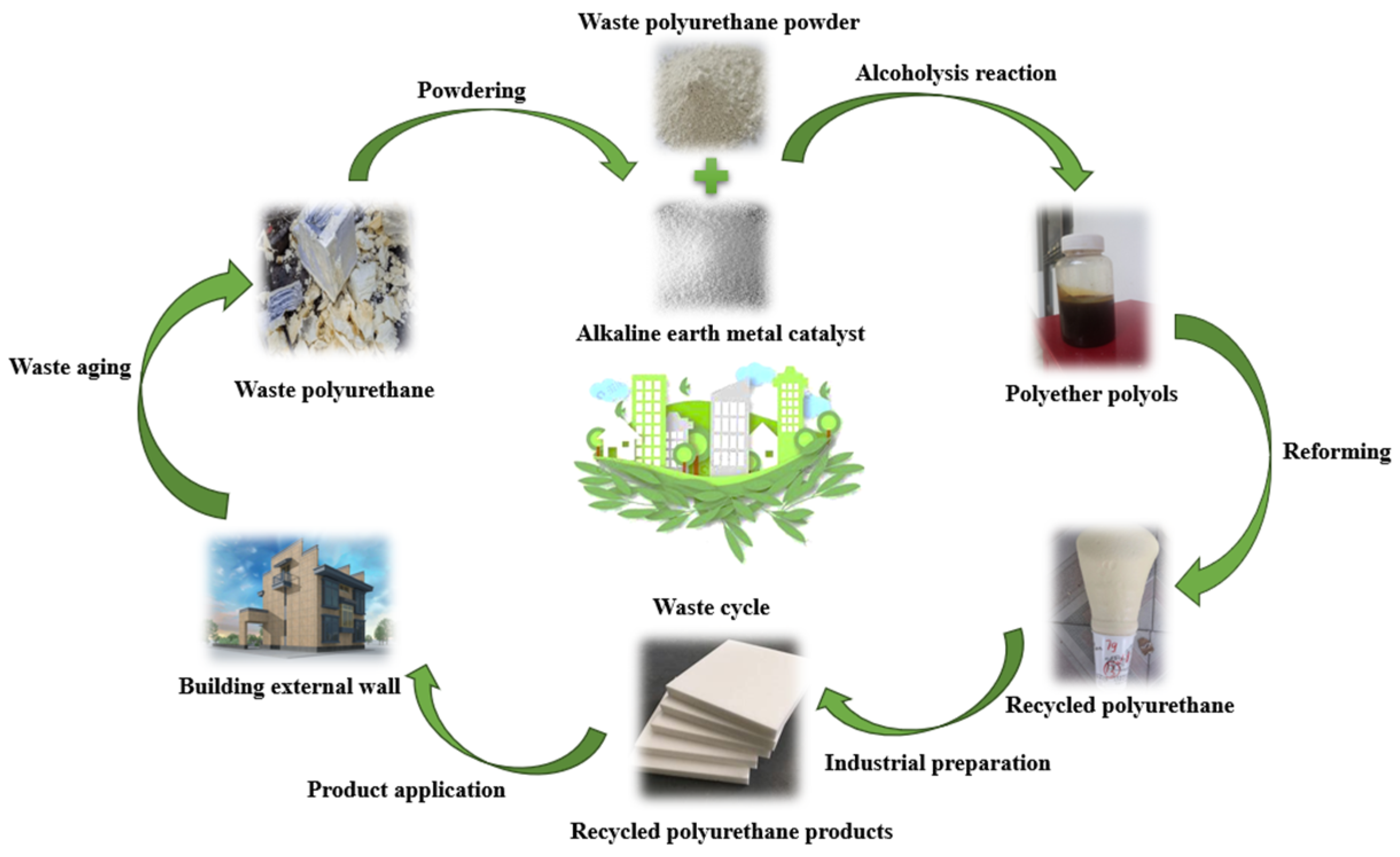

1.3. Energy Saving and Environmental Protection of PU Recycled Insulation Wall

1.4. Evaluation Indicators of Energy Consumption of Recycled Building Materials

1.4.1. Recycled Building Materials, Building Energy Consumption and Energy Saving per Unit Area

1.4.2. Software Simulation of Recycled Building Materials

2. Simulation Analysis of Recycled Building Materials

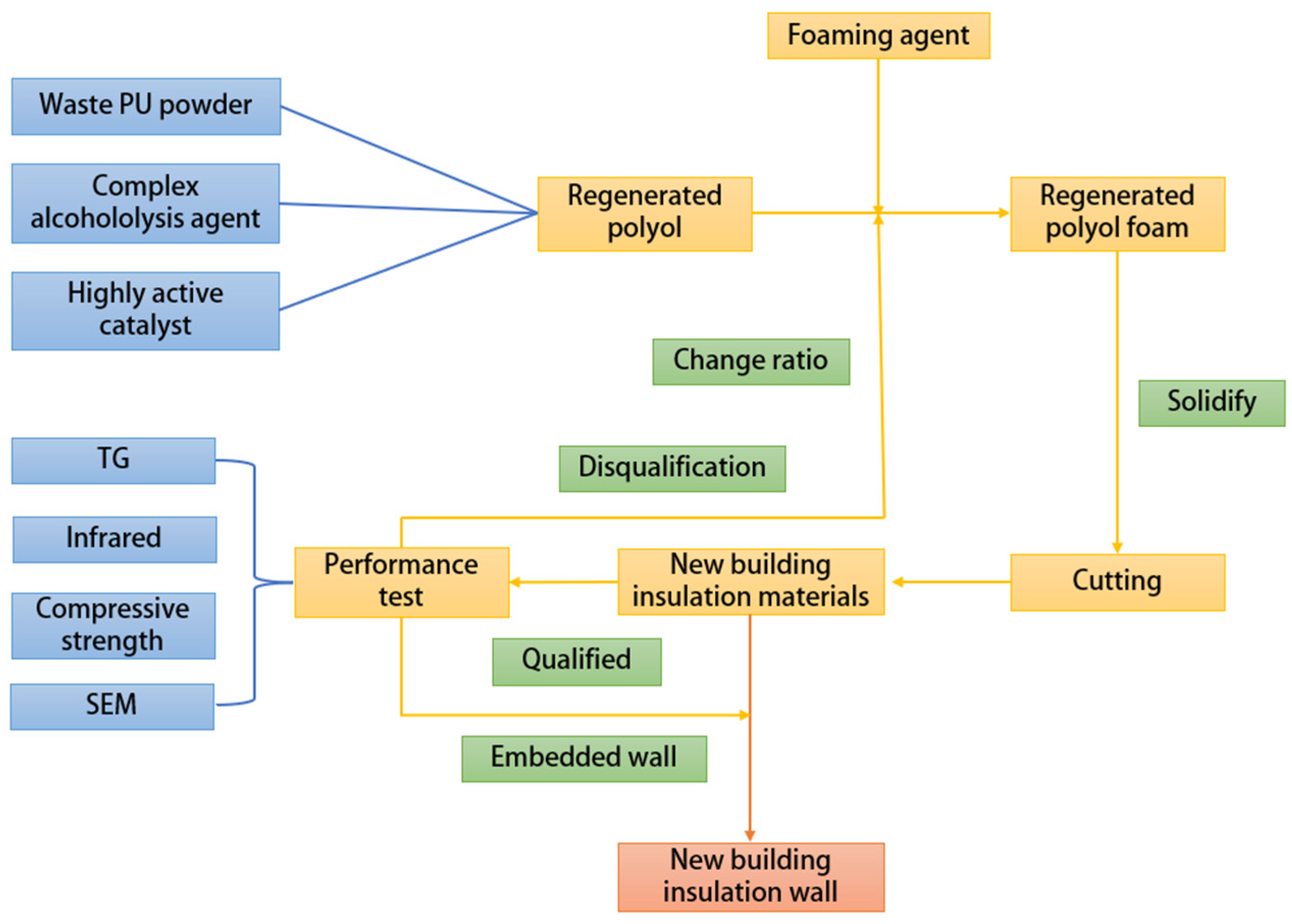

2.1. Preparation of PU Recycled Building Materials and Manufacturing Process of Building Insulation Walls

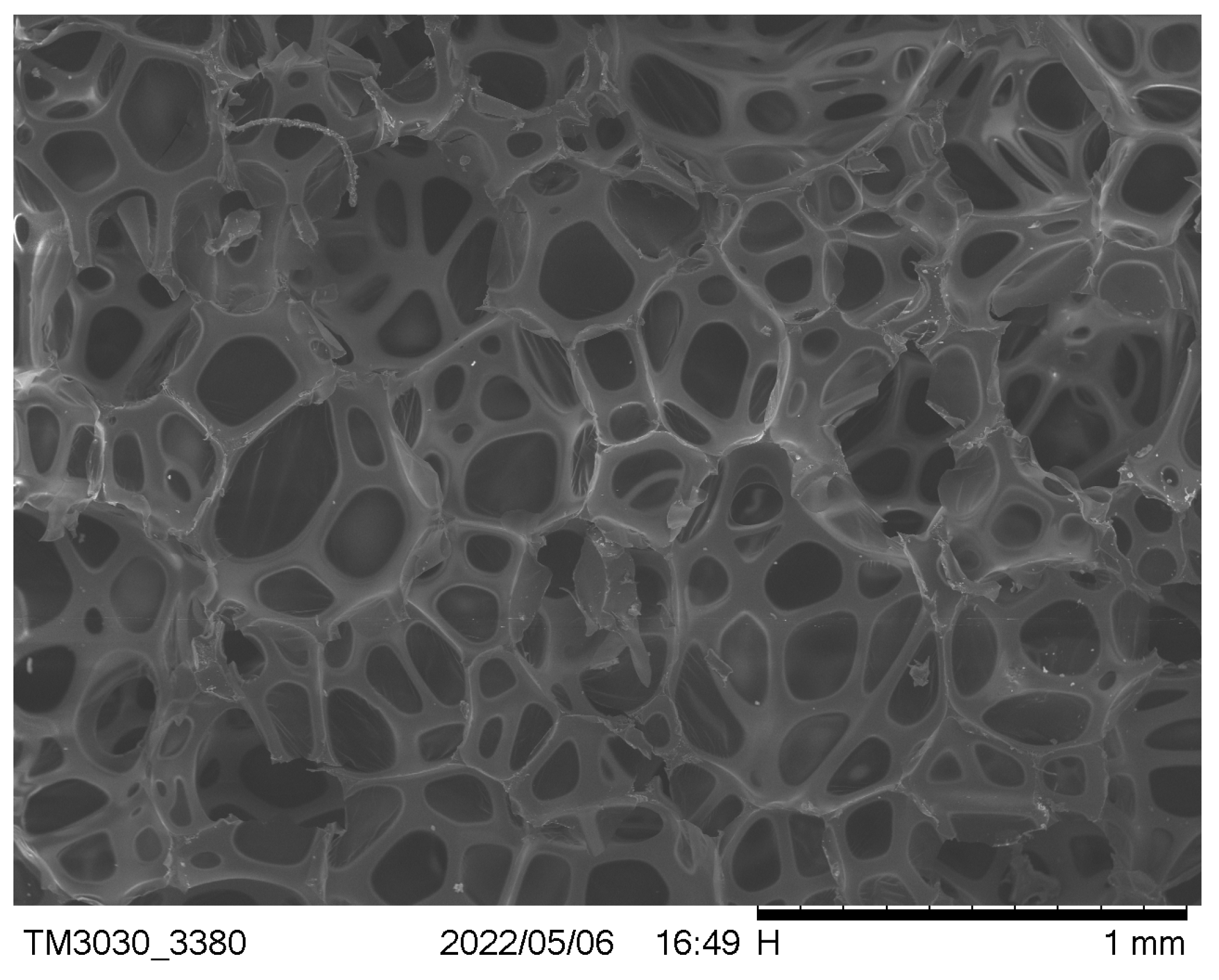

2.1.1. Preparation of PU Recycled Building Materials

2.1.2. Manufacturing Process of Waste PU Recycled Building Insulation Wall

2.2. Project Overview

2.3. Wall Structure and Parameter Setting

- (1)

- Perforated brick wall, painted inside and outside, ordinary brick wall, δ = 280 mm.

- (2)

- Perforated brick wall, painted inside and outside, and the insulation material is aerated concrete, δ = 350 mm.

- (3)

- Perforated brick wall, stucco inside and outside, insulation material is polystyrene board, δ = 350 mm.

- (4)

- Perforated brick wall, painted inside and outside, the insulation material is rock wool, δ = 350 mm.

- (5)

- Perforated brick wall, painted inside and outside, and the insulation material is a new type of building insulation recycled PU material, δ = 350 mm.

3. Result Analysis

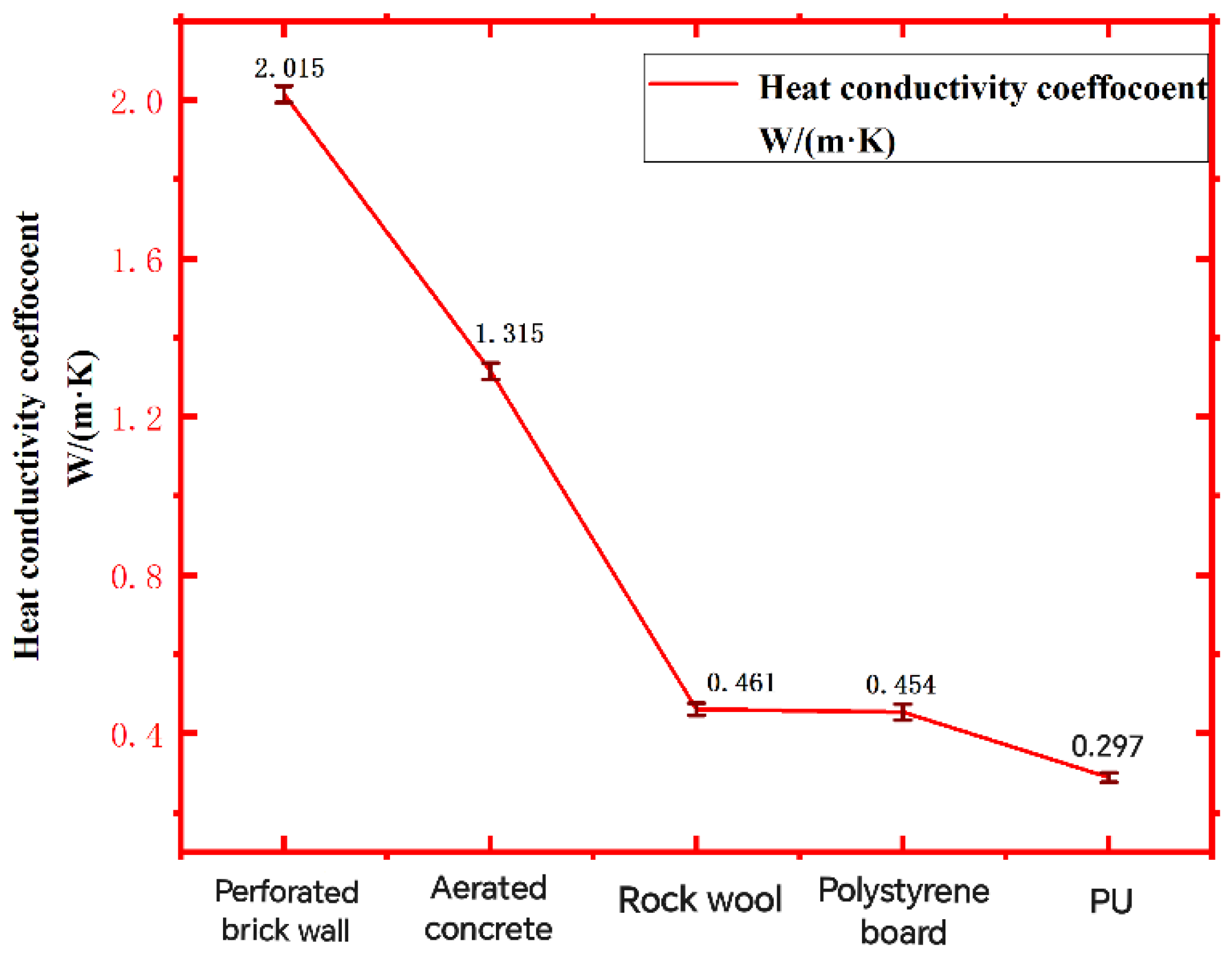

3.1. Comparison of Thermal Conductivity of Different Thermal Insulation Walls

3.2. Analysis of Building Energy Consumption of Recycled PU Materials

- (1)

- The thermal properties of different wall insulation materials are different, which will have different effects on the total energy consumption of the wall [26]. The results also take into account the energy consumption of lighting and equipment, and the energy consumption of the wall with insulation material is reduced. Among them, the recycled PU material wall has the best energy-saving effect; with the traditional wall insulation effect, the recycled PU material wall can save 85.4% of energy consumption per square meter.

- (2)

- The wall load of the wall with insulation materials is significantly reduced compared with the porous brick wall, aerated concrete insulated walls, rock wool insulation wall, polystyrene board insulation wall, and recycled PU material insulation walls, which can save 85.4% per square meter, in turn, 53.33%, 19.43%, and 16.26% energy consumption. It can be seen that the wall with insulation materials has improved the thermal insulation properties of the wall and reduced the energy consumption of the wall, among which the thermal insulation effect of the recycled PU material wall is the best, and the energy saving rate of the wall has reached 85.4%.

3.3. Economic Analysis of Recycled PU Materials

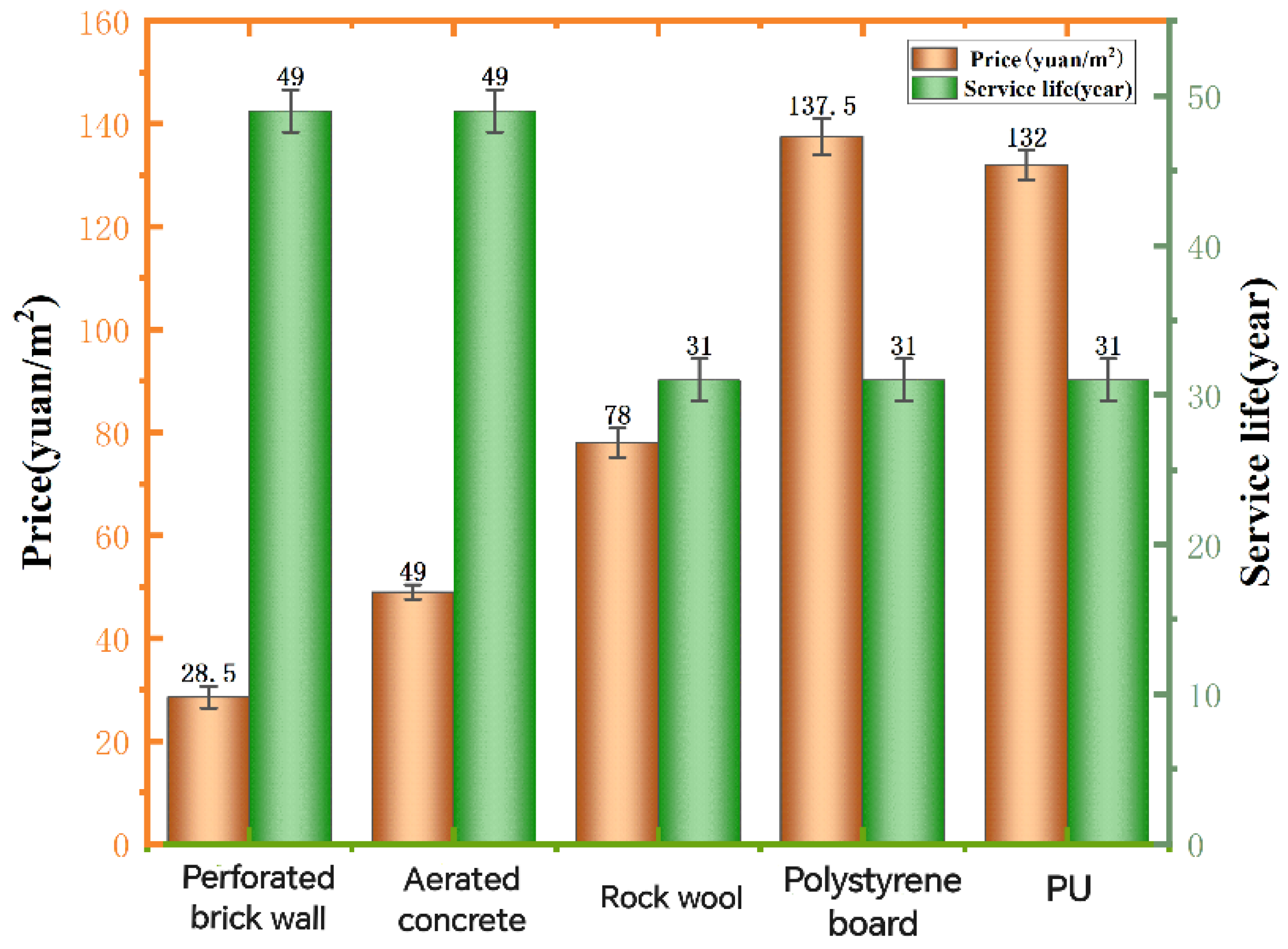

3.3.1. Cost of Recycled PU Materials

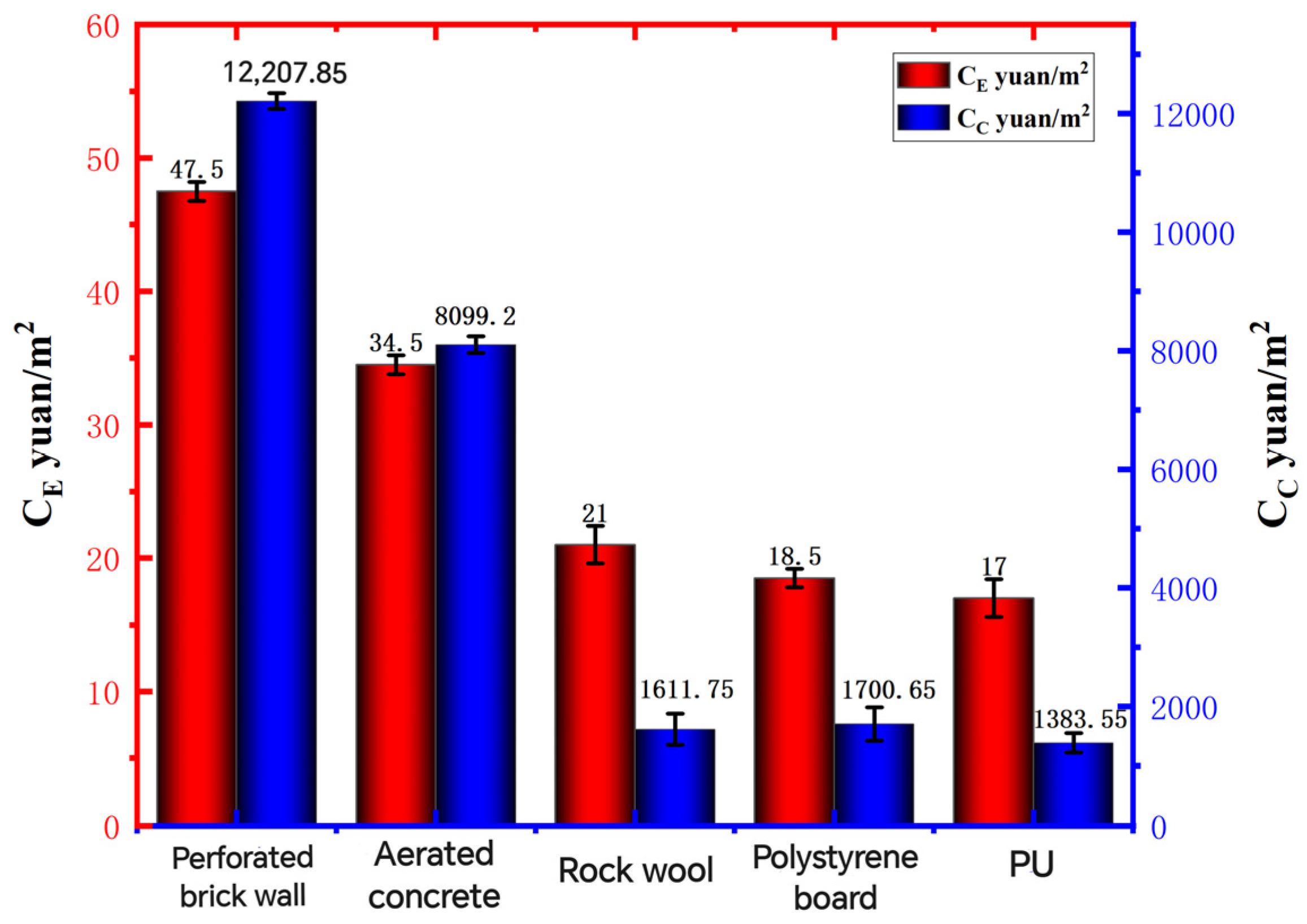

3.3.2. Analysis of Energy-Saving Benefits of Recycled PU Material Insulation Wall

- (1)

- Total Life Cycle Investment Costs

- (2)

- Analysis of environmental benefits

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, B.; Liu, Z.; Wei, H.; Meng, Y.; Hou, Q.; Wang, A.; Zhang, Y.; Han, E.; Hu, S.; Zhou, J. Performance characterization and biocompatibility assessment of silicone polyurethanes for polymer heart valve applications. RSC Adv. 2024, 14, 10858–10873. [Google Scholar] [CrossRef]

- Song, Y.; Zhai, R.; Zhang, J.; Li, J.; Hong, C.; Liu, M.; Wang, Y.; Zhang, J.; Zhou, C. Effect of fluorine atom positions on the properties of waterborne polyurethanes. Prog. Org. Coat. 2024, 189, 108330. [Google Scholar] [CrossRef]

- Stefan, O.; Otilia, V.P. The inclusion of a salicylate derivative in polyurethane structures and its effect on the properties and the stability of polyurethanes exposed to weathering. Soft Mater. 2023, 21, 149–160. [Google Scholar]

- Wu, C.; Ye, G.; Zhao, Y.; Ye, B.; Wang, T.; Wang, L.; Zhang, Z. Experimental and numerical study of in-plane uniaxial compression response of PU foam filled aluminum arrowhead auxetic honeycomb. Rapid Prototyp. J. 2024, 30, 502–512. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Wei, S.; Huang, Y.; Yang, S.; Xue, Y.; Xuan, H.; Yuan, H. A Solvent System Involved Fabricating Electrospun Polyurethane Nanofibers for Biomedical Applications. Polymers 2020, 12, 3038. [Google Scholar] [CrossRef]

- Sophie, W.; Deyvid, P.S.D.; Luc, A. Synthesis of Biobased and Hybrid Polyurethane Xerogels from Bacterial Polyester for Potential Biomedical Applications. Polymers 2021, 13, 4256. [Google Scholar] [CrossRef]

- Bajire, S.K.; Jain, S.; Johnson, R.P.; Shastry, R.P. 6-Methylcoumarin attenuates quorum sensing and biofilm formation in Pseudomonas aeruginosa PAO1 and its applications on solid surface coatings with polyurethane. Appl. Microbiol. Biotechnol. 2021, 105, 8647–8661. [Google Scholar] [CrossRef]

- Choi, B.; Gil, D.; Lee, J.J.; Kim, C. Selective visual staining of polyurethane microplastics by novel colorimetric and near-infrared (NIR) fluorescent dye: Application to environmental water and natural soil samples. J. Hazard. Mater. 2024, 471, 134332. [Google Scholar] [CrossRef]

- Weng, H. Development status and technical progress of polyurethane industry. Chem. Propellants Polym. Mater. 2008, 6, 1–7. [Google Scholar]

- Middlemas, S.; Janney, D.E.; Adkins, C.; Bawane, K. Determining the effects of U/Pu ratio on subsolidus phase transitions in U-Pu-Zr metallic fuel alloys. J. Nucl. Mater. 2024, 591, 154909. [Google Scholar] [CrossRef]

- Han, J. Research on the performance and application of thermal insulation wall materials. Inf. Rec. Mater. 2018, 19, 6–7. [Google Scholar] [CrossRef]

- Hao, Y.; Wu, Z.; Qin, L.; Sun, H.; Ci, T. Experimental study on axial compression performance of new fly ash foam concrete wall. Build. Struct. 2024, 54, 57–61. [Google Scholar] [CrossRef]

- Mao, Q. Practical application of green building wall materials in wall insulation engineering. House Collect. 2024, 11, 67–69. [Google Scholar]

- Fu, K.; Zhang, L.; Zhang, W.; Ma, Q.; Zheng, X.; Chang, C. Sustainable production and evaluation of bio-based flame-retardant PU foam via liquefaction of industrial biomass residues. Ind. Crops Prod. 2024, 210, 118100. [Google Scholar] [CrossRef]

- Li, H.; Hou, L.; Liu, Y.; Yao, Z.; Liang, L.; Tian, D.; Liu, C.; Xue, J.; Zhan, L.; Liu, Y.; et al. Balanced Thermal Insulation, Flame-Retardant and Mechanical Properties of PU Foam Constructed via Cost-Effective EG/APP/SA Ternary Synergistic Modification. Polymers 2024, 16, 330. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, X.; Xiong, X.; Pang, J. Research on acoustic parameter inversion method of glass wool based on impedance model. Acoust. Technol. 2024, 43, 90–97. [Google Scholar] [CrossRef]

- Lang, Z. Application of rock wool board in the construction of external insulation of building exterior wall. Real Estate World 2023, 13, 127–129. [Google Scholar]

- Zhang, C. Key Technology of Mixed Load-bearing Construction of Brick Wall and Concrete Wall Column in Underground Garage; China State Construction Engineering Co., Ltd. Seventh Engineering Bureau: Beijing, China, 2020. [Google Scholar]

- Chen, Y.; Jian, B.; He, M.; He, M. Research on construction technology of high-precision blocks for autoclaved aerated concrete. In Proceedings of the 2023 National Civil Engineering Construction Technology Exchange Conference, Beijing, China, 28 December 2023. [Google Scholar] [CrossRef]

- Wang, F. Analysis on the application of residential construction technology in the context of reducing building energy consumption. House Collect. 2024, 11, 55–57+99. [Google Scholar]

- Chen, Z.; Liu, J.; Chen, Q.; Wei, X.; Song, J. Effect of heat addition on the electrogasdynamic flow and thermodynamic cycle efficiency. Appl. Therm. Eng. 2017, 121, 67–73. [Google Scholar] [CrossRef]

- Kowalczyk, Ł.; Korol, J.; Chmielnicki, B.; Laska, A.; Chuchala, D.; Hejna, A. One More Step towards a Circular Economy for Thermal Insulation Materials—Development of Composites Highly Filled with Waste Polyurethane (PU) Foam for Potential Use in the Building Industry. Materials 2023, 16, 782. [Google Scholar] [CrossRef]

- Migda, W.; Szczepański, M.; Jankowski, R. Increasing the Seismic Resistance of Wood-frame Buildings By Applying Pu Foam As Thermal Insulation. J. Eng. 2019, 63, 480–488. [Google Scholar] [CrossRef]

- Cardoso, T.G.; Neto, C.S.; Vecchia, F. Rigid foam polyurethane (PU) derived from castor oil (Ricinus communis) for thermal insulation in roof systems. Front. Archit. Res. 2012, 1, 348–356. [Google Scholar] [CrossRef]

- Yang, C.G.; Li, Y.J.; Gao, X.; Xu, L. A Review of Vacuum Degradation Research and the Experimental Outgassing Research of the Core Material- Pu foam on Vacuum Insulation Panels. Phys. Procedia 2012, 32, 239–244. [Google Scholar] [CrossRef]

- Wang, S.; Li, H.; Zou, S.; Zhang, G. Experimental Research on a Feasible Rice Husk/geopolymer Foam Building Insulation Material. Energy Build. 2020, 226, 110358. [Google Scholar] [CrossRef]

- Savio, L.; Pennacchio, R.; Patrucco, A.; Manni, V.; Bosia, D. Natural Fibre Insulation Materials: Use of Textile and Agri-food Waste in a Circular Economy Perspective. Mater. Circ. Econ. 2022, 4, 6. [Google Scholar] [CrossRef]

- Javier, C.H.R.; Karin, N.R.; Pablo, J.R.C. Valorization of Wheat Crop Waste in Araucanía, Chile: Development of Prototype of Thermal Insulation Material for Blowing Technique and Geographical Analysis. Buildings 2023, 13, 1152. [Google Scholar] [CrossRef]

- Bunjac, A.; Hure, N.; Kaovačević, M.; Novak, H.; Vašak, M.; Perić, N. Modular Hierarchical Model Predictive Control for Coordinated and Holistic Energy Management of Buildings—Battery Storage Considerations. Eng. Power Bull. Croat. Acad. Eng. 2021, 16, 2–6. [Google Scholar]

- Wu, Y.; Jian, W.; Yang, L.; Zhang, T.; Liu, Y. Effects of Different Surface Heat Transfer Coefficients on Predicted Heating and Cooling Loads towards Sustainable Building Design. Buildings 2021, 11, 609. [Google Scholar] [CrossRef]

- Gyeong, S.B. Plan for the Sustainability of Public Buildings through the Energy Efficiency Certification System: Case Study of Public Sports Facilities, Korea. Buildings 2021, 11, 589. [Google Scholar] [CrossRef]

- Pan, W.; Teng, Y.; Bai, Y.; Yu, C.; Xu, J. A Holistic Framework for Determining the Trade-off between Embodied and Operational Carbon Emissions of High-rise Residential Buildings. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 022014. [Google Scholar] [CrossRef]

- Marzouk, M.; Fattouh, K.M. Modeling investment policies effect on environmental indicators in Egyptian construction sector using system dynamics. Clean. Eng. Technol. 2021, 6, 100368. [Google Scholar] [CrossRef]

- Konior, J. Monitoring of Construction Projects Feasibility by Bank Investment Supervision Approach. Civ. Eng. Archit. 2019, 7, 31–35. [Google Scholar] [CrossRef]

- Zulu, E.; Zulu, S.; Chabala, M.; Musonda, I.; Kavishe, N.; Chileshe, N. Challenges and advocated solutions for environmental protection legislation for building infrastructure projects in developing countries: Evidence from Zambia. Proj. Leadersh. Soc. 2022, 3, 100056. [Google Scholar] [CrossRef]

- Tarek, R.; Mohammed, R. A Step towards Building Environmental Protection Strategy: Game Theory Framework for Al-Abrash River Basin Management. Int. J. Environ. Sci. Dev. 2019, 10, 38–45. [Google Scholar]

- Jianlu, Z. Practical Application of Environmental Protection and Energy Saving in Building Electrical Design. J. Electron. Res. Appl. 2017, 1. [Google Scholar] [CrossRef]

- Verma, R.K.; Ahmed, Z. Surface treatment of the Secretariat Building, Chandigarh, India using selected concrete sealers for protection from environmental deterioration. Curr. Sci. 2016, 111, 1234–1241. [Google Scholar] [CrossRef]

| Summertime | Calculate the dry-bulb temperature outside the air conditioner | 34.2 °C | |||||

| Average outdoor wind speed | 1.5 m/s | ||||||

| Calculate the (dry-bulb) temperature outside the ventilation room | 31.8 °C | ||||||

| Room type | Temperature | Humidity | Lighting power | Device power | Personnel density | ||

| Living quarters | summertime | winter | summertime | winter | 15 W/m2 | 20 W/m2 | 4 person |

| 24 °C | 22 | 60–65% | 40–50% | ||||

| Heat Preservation Materials | Total Energy Consumption (kW·h/m2) | Cooling Energy Consumption (kW·h/m2) | Energy Consumption for Heating (kW·h/m2) | Equipment Energy Consumption (kW·h/m2) | Lighting Energy Consumption (kW·h/m2) |

|---|---|---|---|---|---|

| Ordinary brick walls | 198.2 | 87.7 | 64.8 | 13.9 | 31.8 |

| Aerated concrete | 145.7 | 57.5 | 42.5 | 13.9 | 31.8 |

| Rock wool | 84.4 | 21.1 | 15.6 | 13.9 | 31.8 |

| Polystyrene board | 81.2 | 20.4 | 15.1 | 13.9 | 31.8 |

| Recycled PU board | 68 | 12.8 | 9.5 | 13.9 | 31.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhao, Q.; Gu, X.; Fan, A.; Zhu, S.; Su, Q.; Kang, L.; Feng, L. Research on the Application of New Building Recycled Insulation Materials for Walls. Polymers 2024, 16, 2122. https://doi.org/10.3390/polym16152122

Liu Y, Zhao Q, Gu X, Fan A, Zhu S, Su Q, Kang L, Feng L. Research on the Application of New Building Recycled Insulation Materials for Walls. Polymers. 2024; 16(15):2122. https://doi.org/10.3390/polym16152122

Chicago/Turabian StyleLiu, Yan, Qinglong Zhao, Xiaohua Gu, Anyu Fan, Shangwen Zhu, Qingyong Su, Li Kang, and Lizhi Feng. 2024. "Research on the Application of New Building Recycled Insulation Materials for Walls" Polymers 16, no. 15: 2122. https://doi.org/10.3390/polym16152122

APA StyleLiu, Y., Zhao, Q., Gu, X., Fan, A., Zhu, S., Su, Q., Kang, L., & Feng, L. (2024). Research on the Application of New Building Recycled Insulation Materials for Walls. Polymers, 16(15), 2122. https://doi.org/10.3390/polym16152122