3.1. Tensile Properties

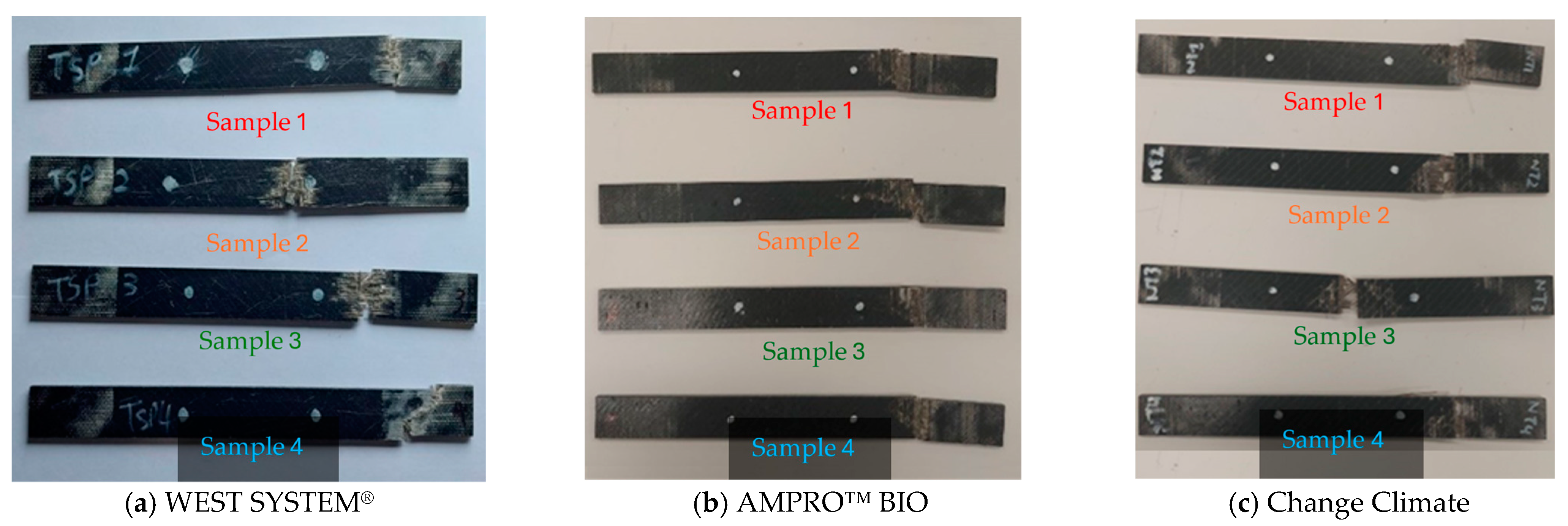

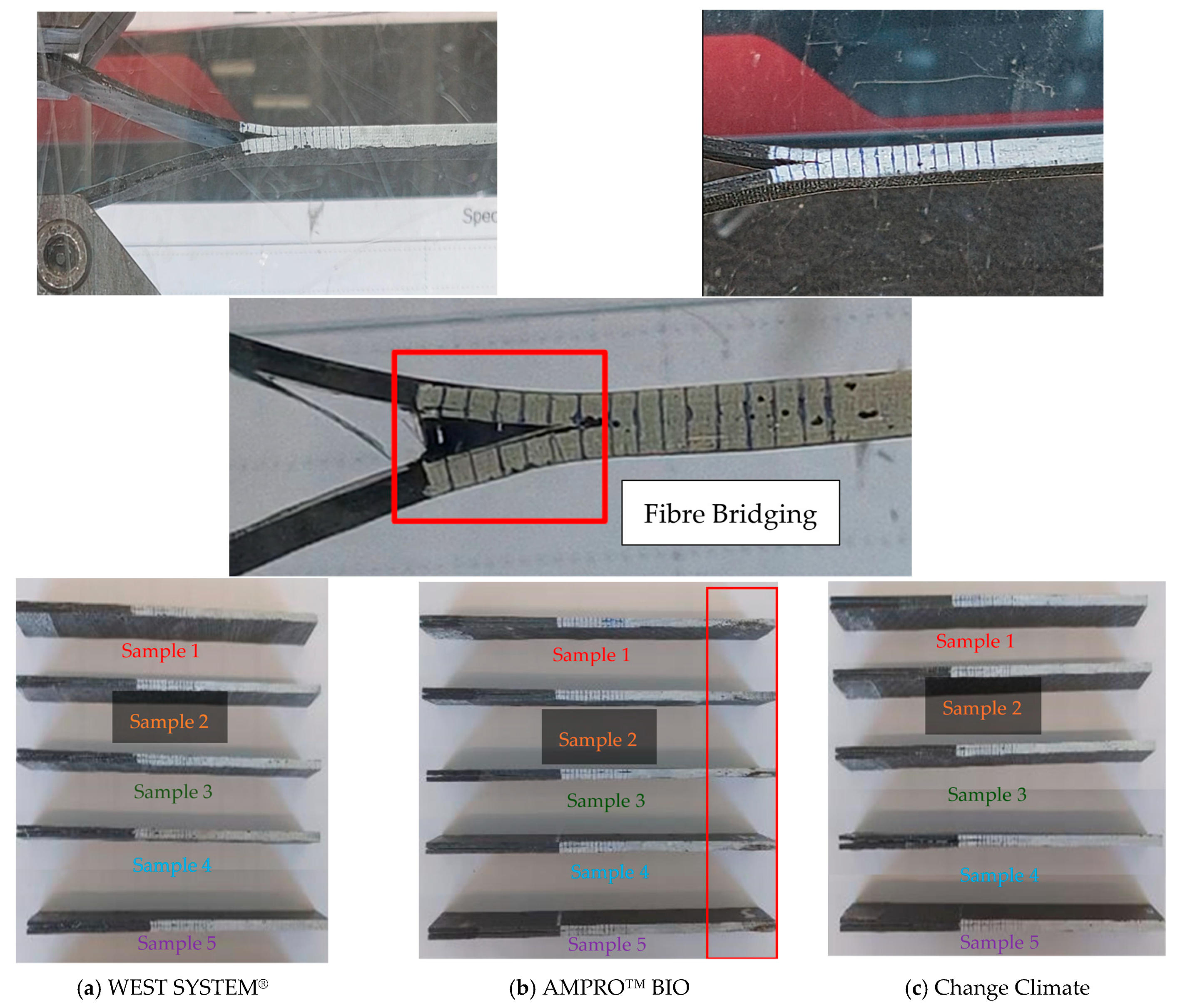

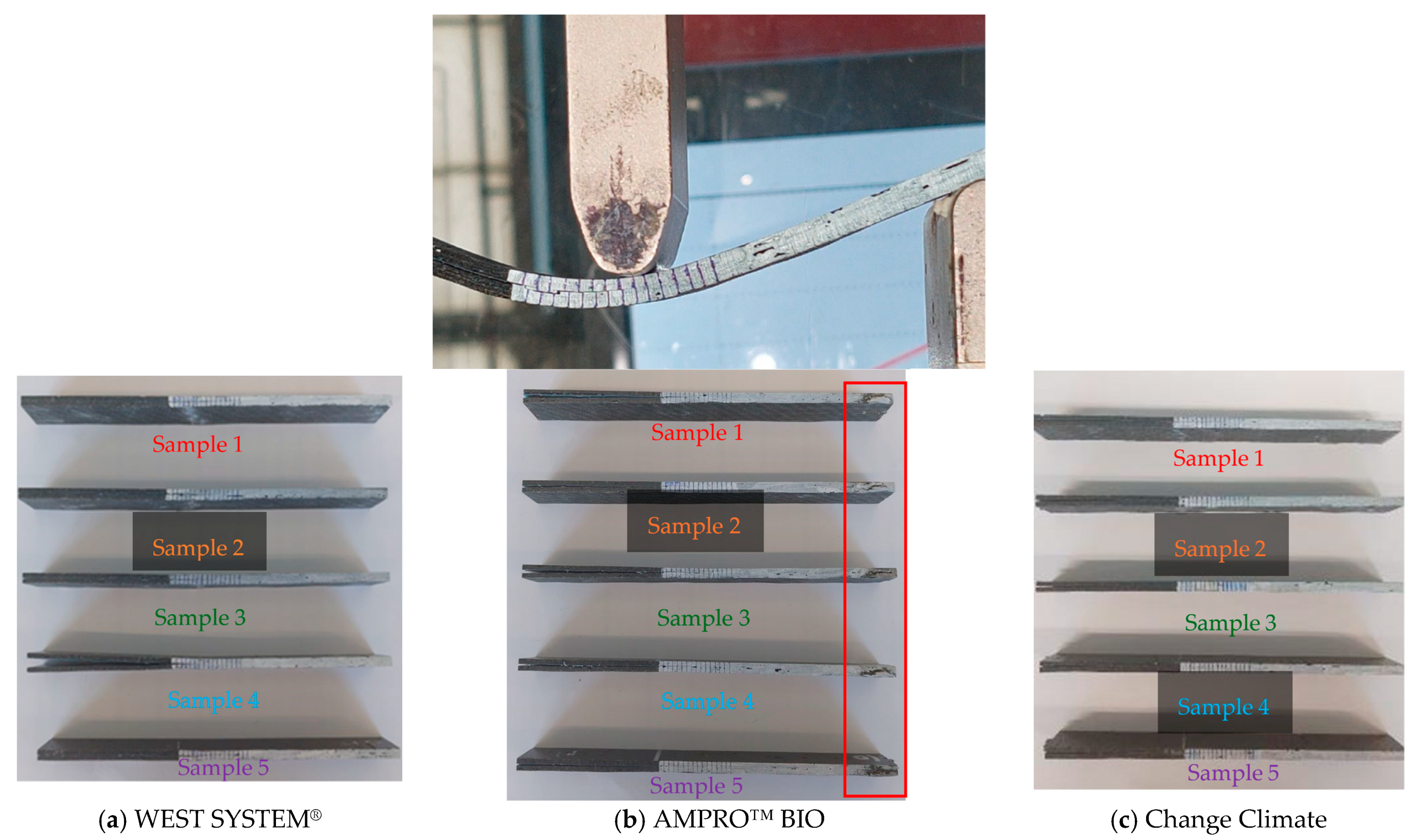

All samples of the uniaxial tension test failed due to fibre failure. The location of fracture can be broadly categorised in two groups.

In all three resin systems, the first failure location is dominant, whereas the second failure location can only be observed twice (one from WEST SYSTEM

® and one from Change Climate), as clearly visible from

Figure 5. However, since the failure was governed by the fibre fracture and not bearing, it did not affect the tensile stress vs. strain behaviour greatly, as observed in

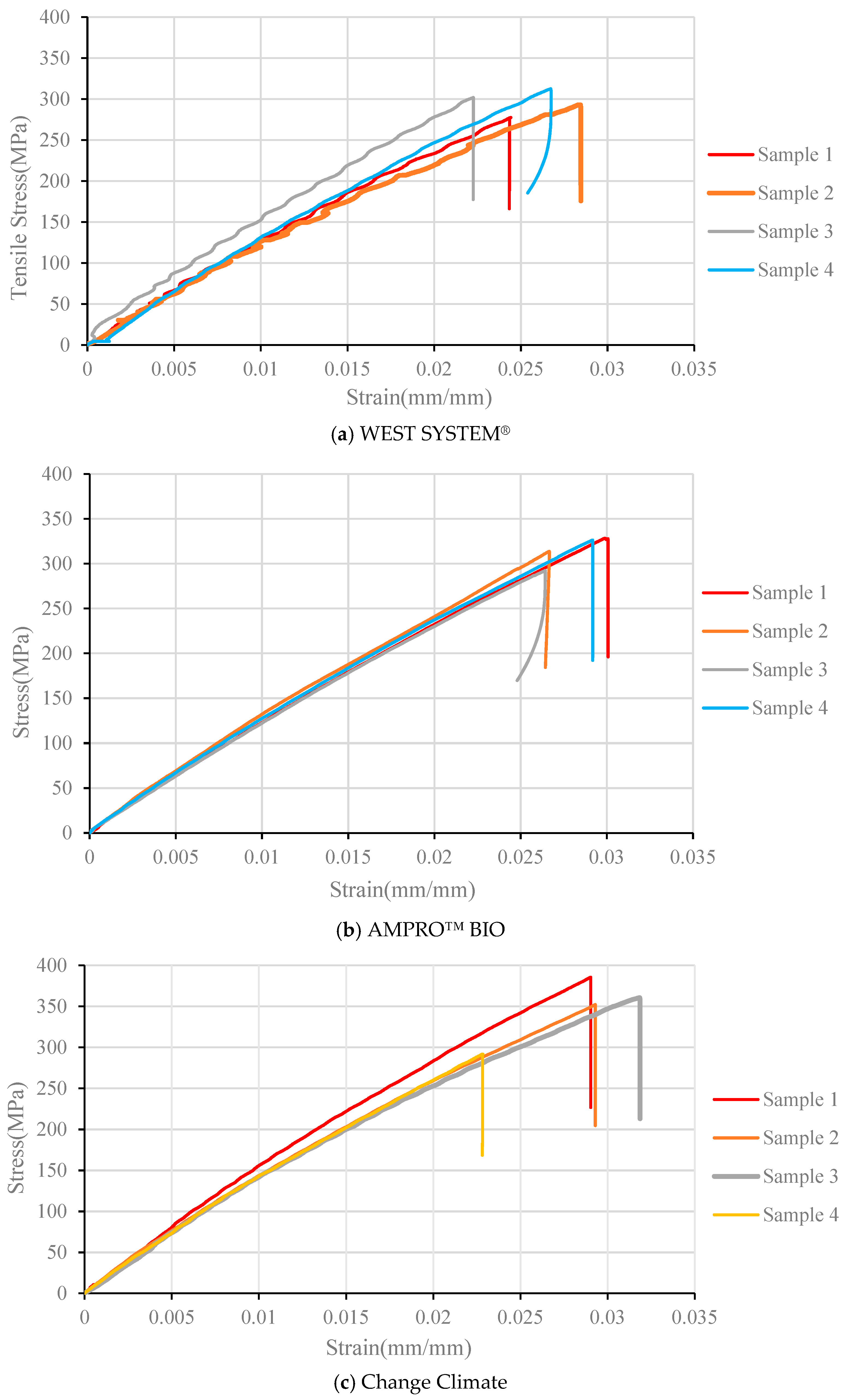

Figure 6.

Figure 6 compares the tensile stress vs. strain plots of all the tensile samples with three different adhesives. The results are consistent in terms of the slope (modulus) of the curves and ultimate tensile strength. Sample 4 in

Figure 6c, made from Change Climate epoxy, was found to have significantly lower (21% lower than the average of the other three samples) tensile strength. This is due to a change in failure mode. As shown in

Figure 5c, visible fibre fracture was not observed in that sample. Local crushing (bearing) at the gripping region is visible which led to lower tensile strength.

While comparing

Figure 6a–c, the bio resins were found to outperform the traditional epoxy slightly in terms of tensile strength. The AMPRO™ BIO-based BFRP laminates attained 6% higher tensile strength compared to its traditional counterparts, while this improvement was 17% for the Change Climate-based BFRP laminates.

Table 3 lists the tensile strength and modulus values of all the samples. It can be noted that the tensile strength of WEST SYSTEM

® (WS), AMPRO™ BIO (AB) and Change Climate (CC) were reported as 50.3, 36.3 and 54 MPa, respectively. Therefore, AMPRO™ BIO actually had lower tensile strength than traditional epoxy, yet it yielded 6% higher tensile strength than the BFRP laminate.

The differences in tensile modulus of the BFRP laminates were less affected by the adhesive, as expected. Both the tensile strength and modulus of FRP laminates are mostly governed by the properties of the fibres, rather than those of the matrix. The AB epoxy had slightly lower modulus, whereas the CC had slightly higher modulus than the traditional epoxy-based BFRP laminates. This trend also follows the differences in tensile modulus of the resin itself, which are 3.2, 1.9 and 4.5 GPa, respectively, for WS, AB and CC.

Considering the rule of mixture and using a Krenchel factor of 0.5 [

41] (since half the fibres were aligned with the loading direction for biaxial FRP), the basalt fibre strength can be found within the range of 1330–1575 MPa for the samples tested in this study.

Chen et al. [

42] conducted a study on the effect of strain rate on static and dynamic properties of BFRP laminates where unidirectional BFRP of 300 gsm and WEST SYSTEM

® 105 (both materials are identical in this study) as epoxy were used to produce 0.7 mm thick laminates using a wet layup process. They reported laminate strength within the range of 268–292 MPa, which is very close to this study (296–347 MPa). This tensile strength of laminate translates to a fibre strength of 1562–1729 MPa, based on the rule of mixture. In another study [

41], using biaxial basalt fibre (220 gsm) and polyester as resin, with a volume fraction of 0.3, the tensile strength and modulus were reported as 291 MPa and 14 GPa, respectively. Ranganathan et al. [

43] obtained a tensile strength and modulus of 377 MPa and 9.7 GPa, respectively, for six-layer uni-directional BFRP with a volume fraction of 0.216. One study [

44] involving carbon fibre and bio resin reported a tensile strength and modulus of 650 MPa and 55 GPa, respectively [31% bio epoxy with a Strength and Young’s modulus of 68.5 MPa and 3000 MPa, respectively]; this higher strength and modulus could be attributed to the higher tensile strength of the epoxy in the study as well as the higher tensile strength that carbon fibre usually possess over basalt fibre [

45].

The fibre strength of BFRP varies significantly, depending on its chemical composition and sizing. The basalt fibre tensile strength was reported within the range of 1850–4800 MPa in [

46]. Chen et al. [

42] conducted a detailed study on the effect of sizing and chemical composition of basalt fibre and reported fibre strength in the range of 1220–2830 depending on the varying chemical composition and sizing.

Most results obtained are comparable to other previous studies involving fibre-reinforced materials.

Table 4 Shows the comparison of the tensile strength and modulus results of this study with the values from the previous study.

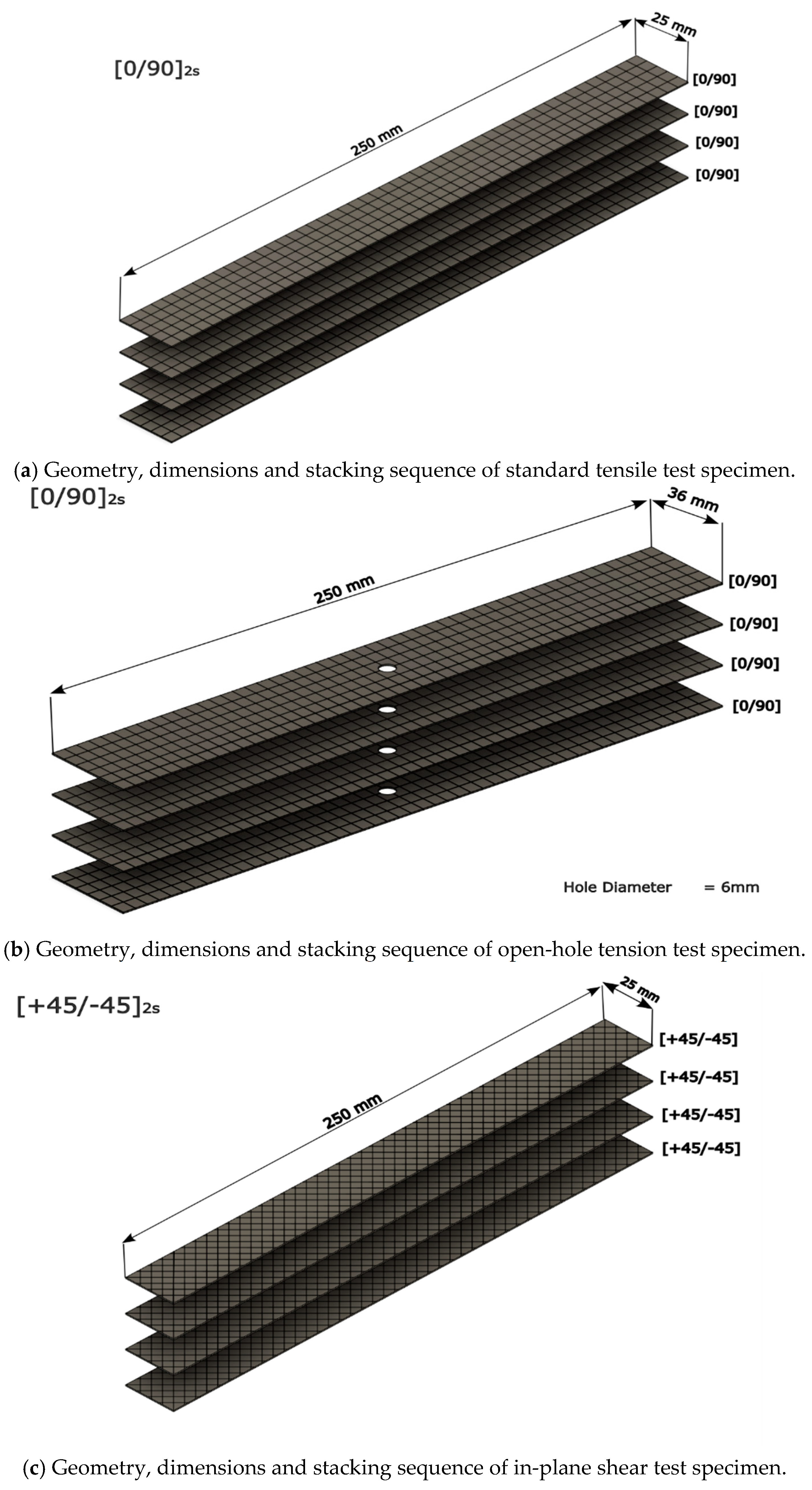

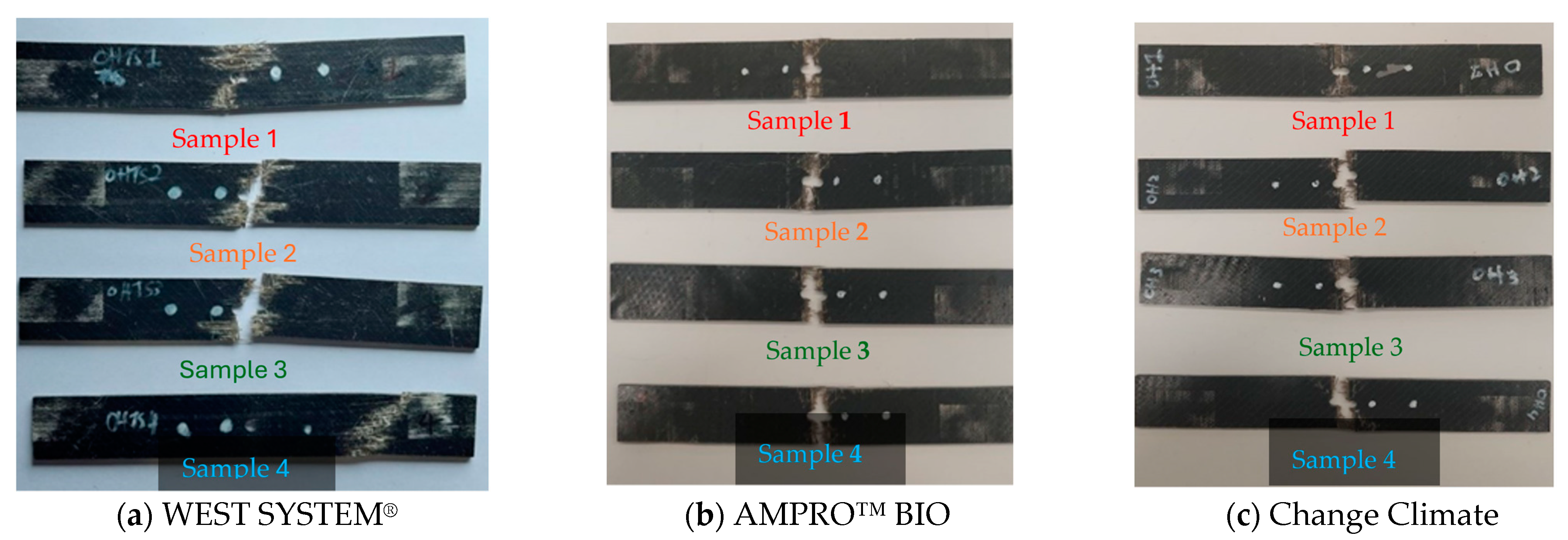

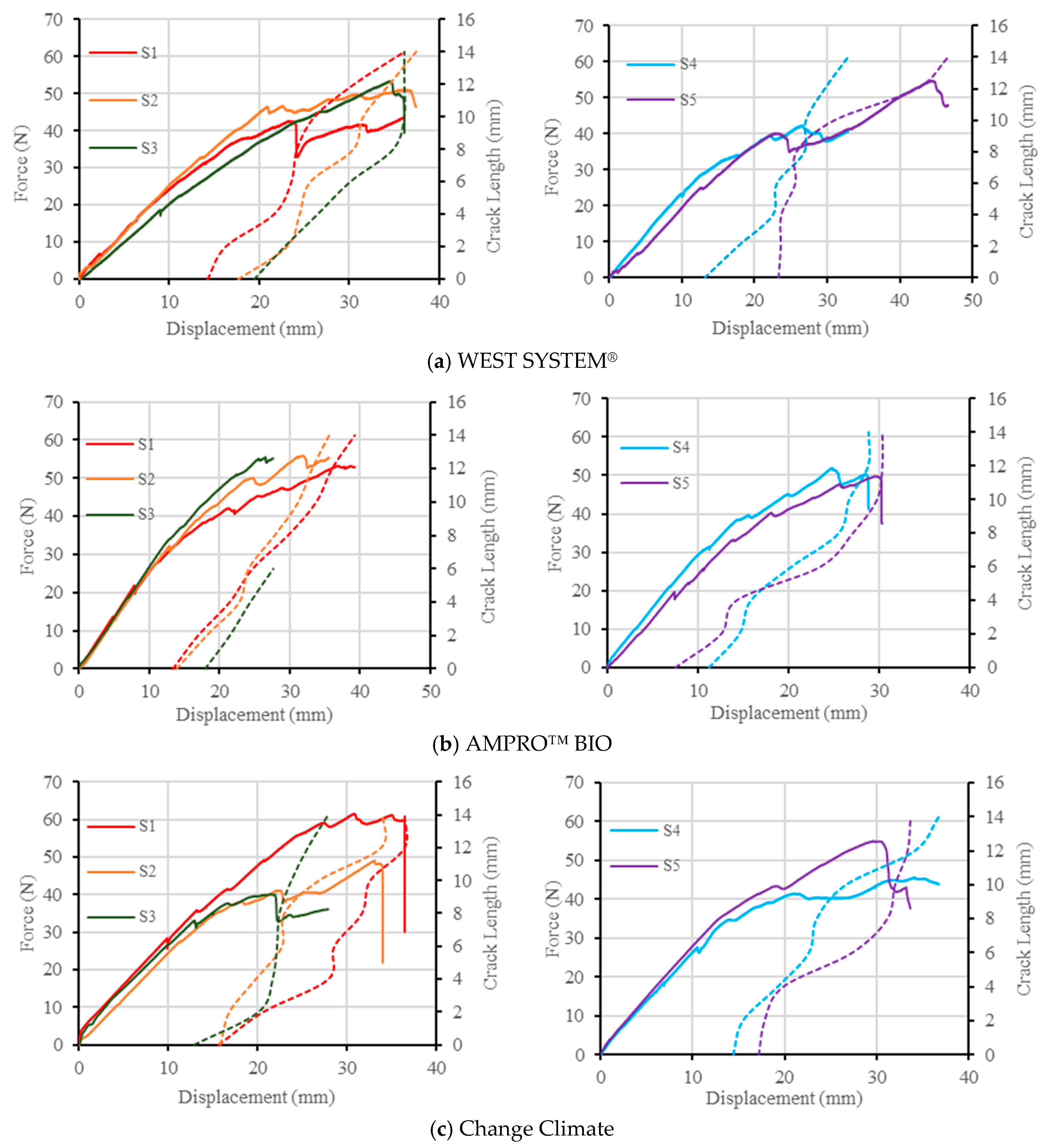

3.2. Open-Hole Tensile Strength

The open-hole tensile strength test was conducted to ensure failure within the desired gauge region within the sample. According to ASTM D5766/D5766M–02a, the only acceptable failure mode is the one that occurs near the hole within the specimen. All, except one, specimens failed near the hole, as illustrated in

Figure 7.

The only sample that failed around the grip was Sample 4 for WEST SYSTEM

®, which can be observed in

Figure 7a. Due to this reason, this specimen is excluded from the graph and calculations.

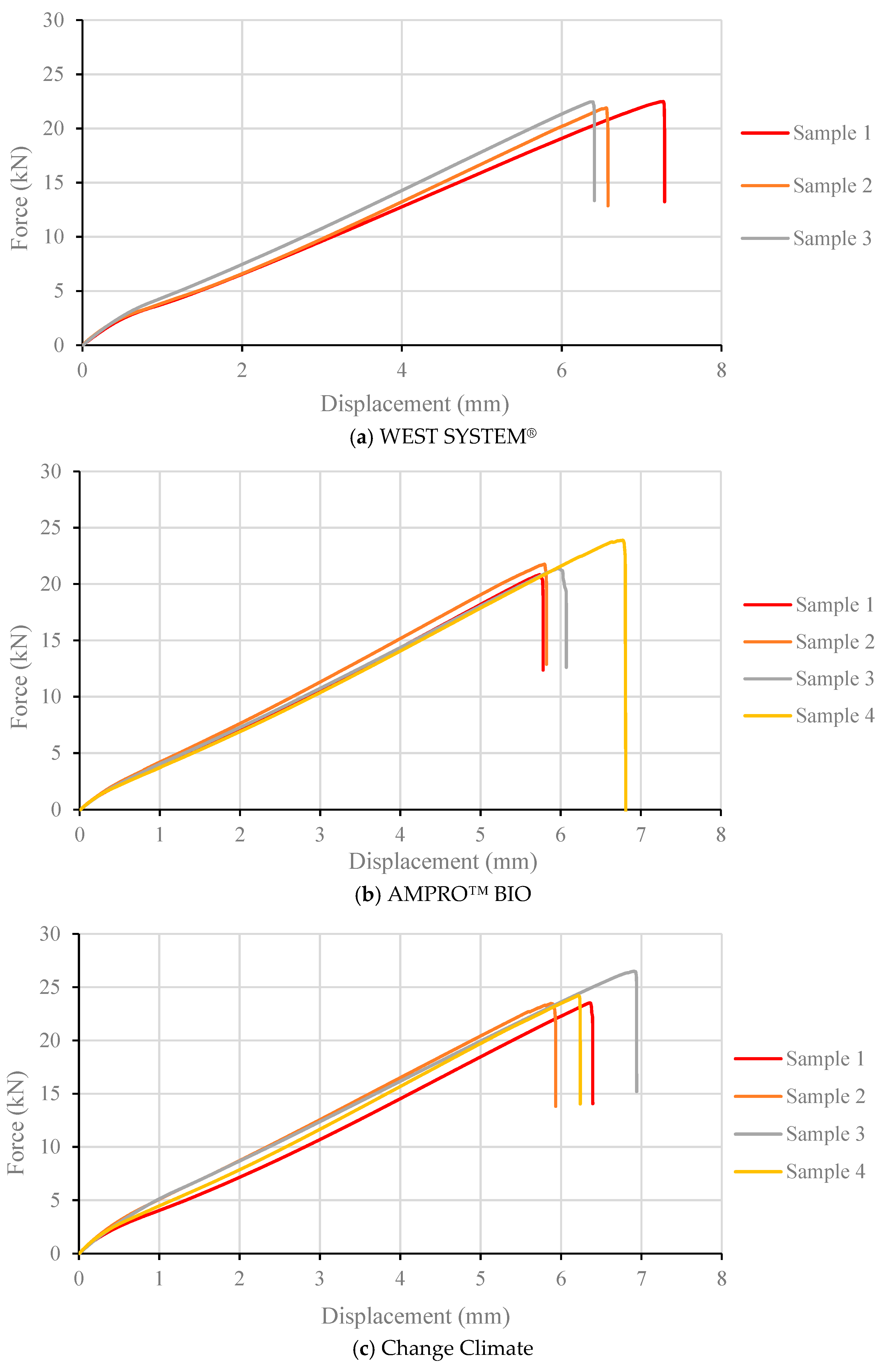

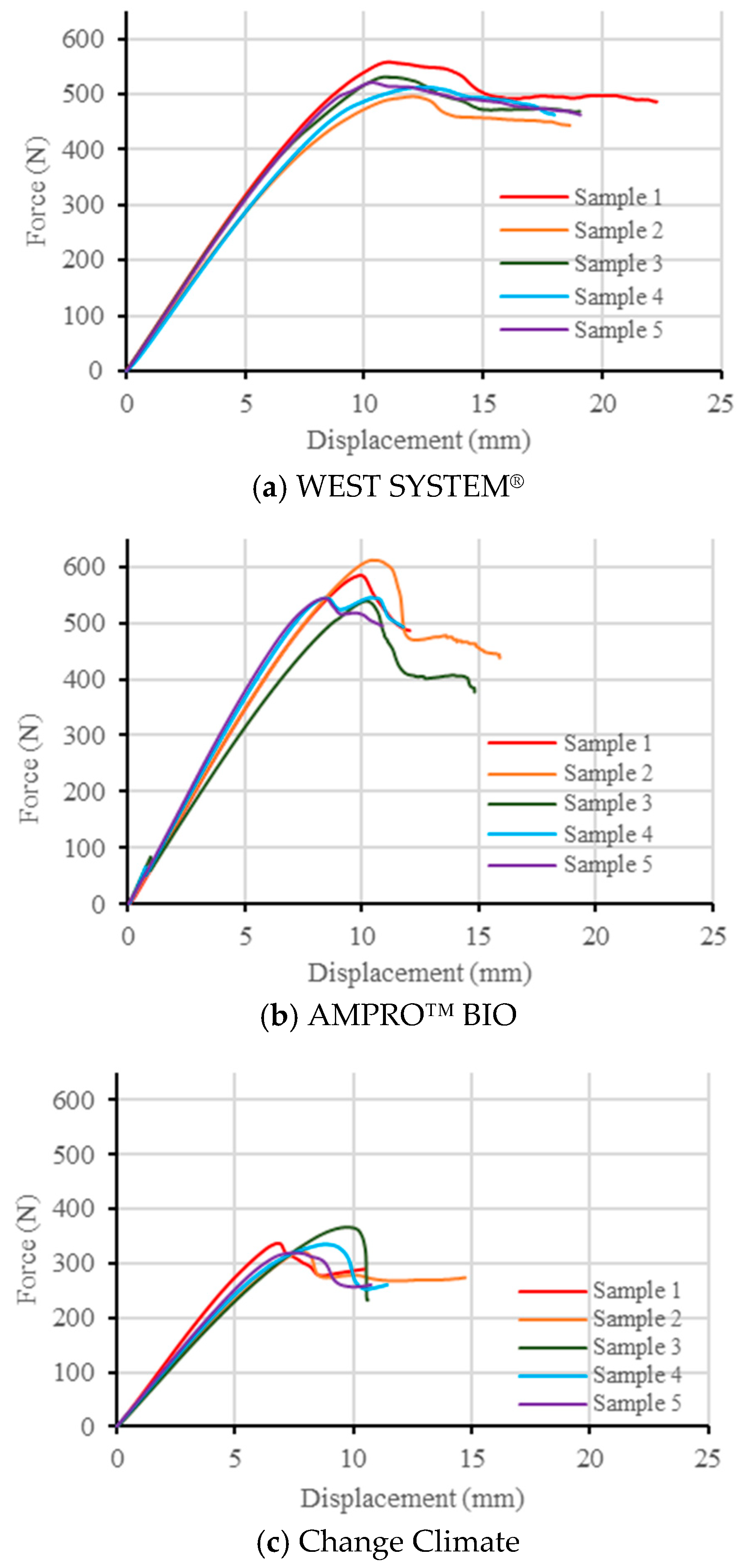

Figure 8 shows the force vs. displacement curves of all the samples made from the three types of adhesives. The consistencies between samples can clearly be observed. The open-hole tensile strength was determined using Equation (1), and the values are listed in

Table 5. CC resin displayed a higher open-hole strength compared to traditional epoxy (by 8%) and AB (by 10%) epoxy. The open-hole strength between traditional and AB resin were similar, with traditional epoxy yielding a slightly higher value. Again, this trend follows the tensile strength of the adhesives’ themselves.

The open-hole-to-pristine-sample-strength ratios are 0.67, 0.62 and 0.62 for WEST SYSTEM

®, AMPRO™ BIO and Change Climate, respectively. Sun et al. [

47] conducted open-hole testing with 6 mm diameter of basalt fibre laminate consisting of one biaxial (0–90) layer using traditional epoxy. They reported a reduction of 44% in the 6 mm-hole-diameter basalt fibre sample compared to the pristine sample. It can be noted that the fibre volume fraction was not mentioned in [

47]. Nevertheless, the reduction in peak strength/load in their work and in the present study is comparable.

Table 6 shows the open-hole strength of this study compared with the studies conducted previously on the topic. Tuo et al. [

48] reported an open-hole strength of 470 MPa for carbon fibre composites made with traditional epoxy [stacking sequence of [45/−45/90/0/−45/0/0/45/−45/0]

s was used; these results seem to indicate a much higher open-hole strength compared to the current study, and this is most likely due to the higher tensile strength that carbon fibre possesses when compared with basalt fibre. Depending on the fibre type, carbon fibre could be twice as strong in tensile strength when compared to basalt fibre [

45]. Another study [

49] which uses glass fibre composites made from vacuum bagging processes reported an open-hole strength of 112.4 MPa [Plain Wolven C glass fibre, 12 layers] which is lower than the results obtained in this study, which correlates with the physical properties of glass fibre, typically placing it below basalt fibres in tensile strength which can change depending on the fibre type used [

45]. Some studies involving open-hole tests made with basalt composites can also be found. One such study, Fernandes et al. [

50], reports an open-hole strength of 274 MPa for a basalt fibre composite made with the compression moulding method [bidirectional (2-D) basalt with a layup of [0 90]

5]. This result is within the range of the values obtained during this study, and the slightly high strength of the previous study could be attributed to the extra layer of basalt present in the laminate.

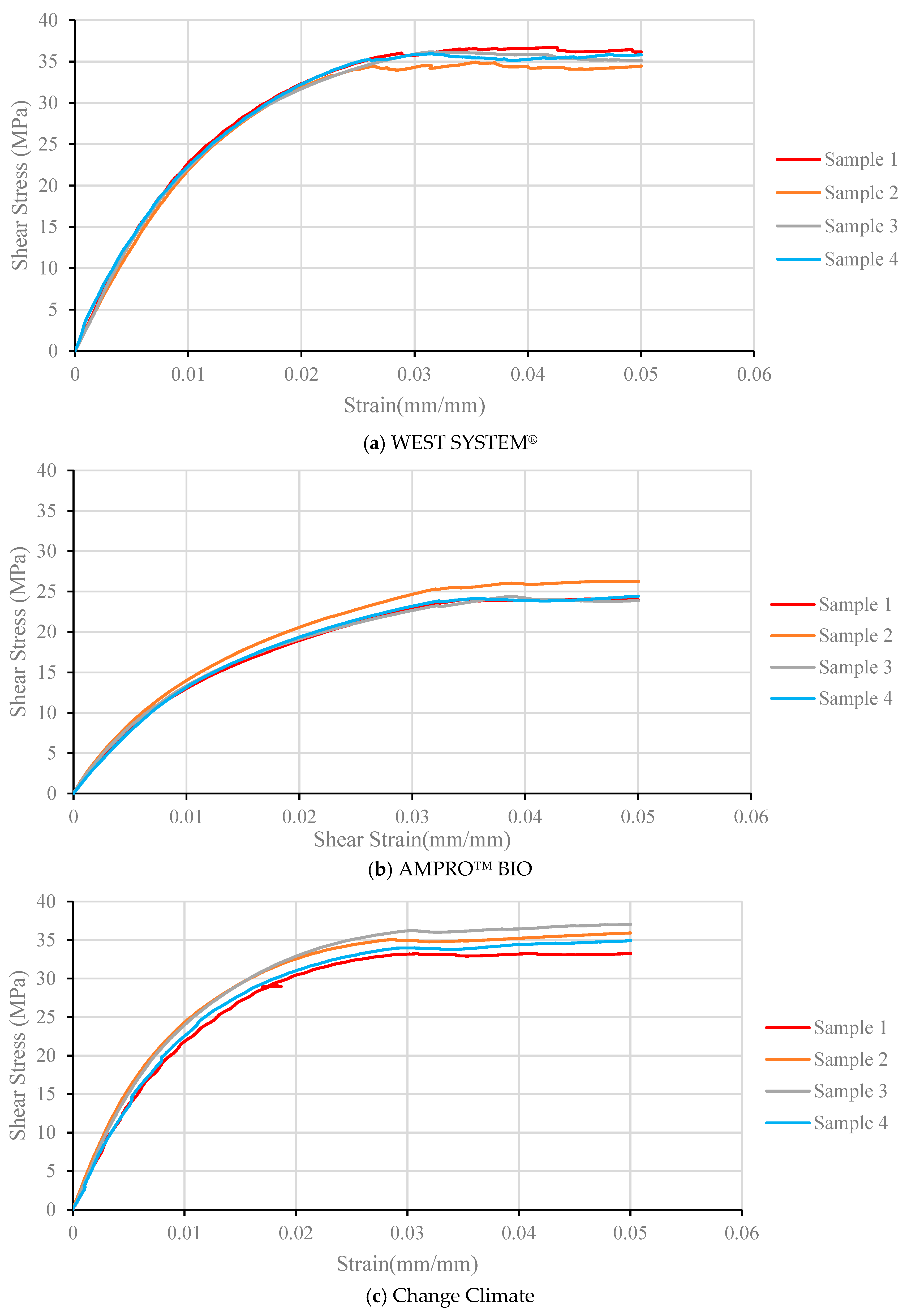

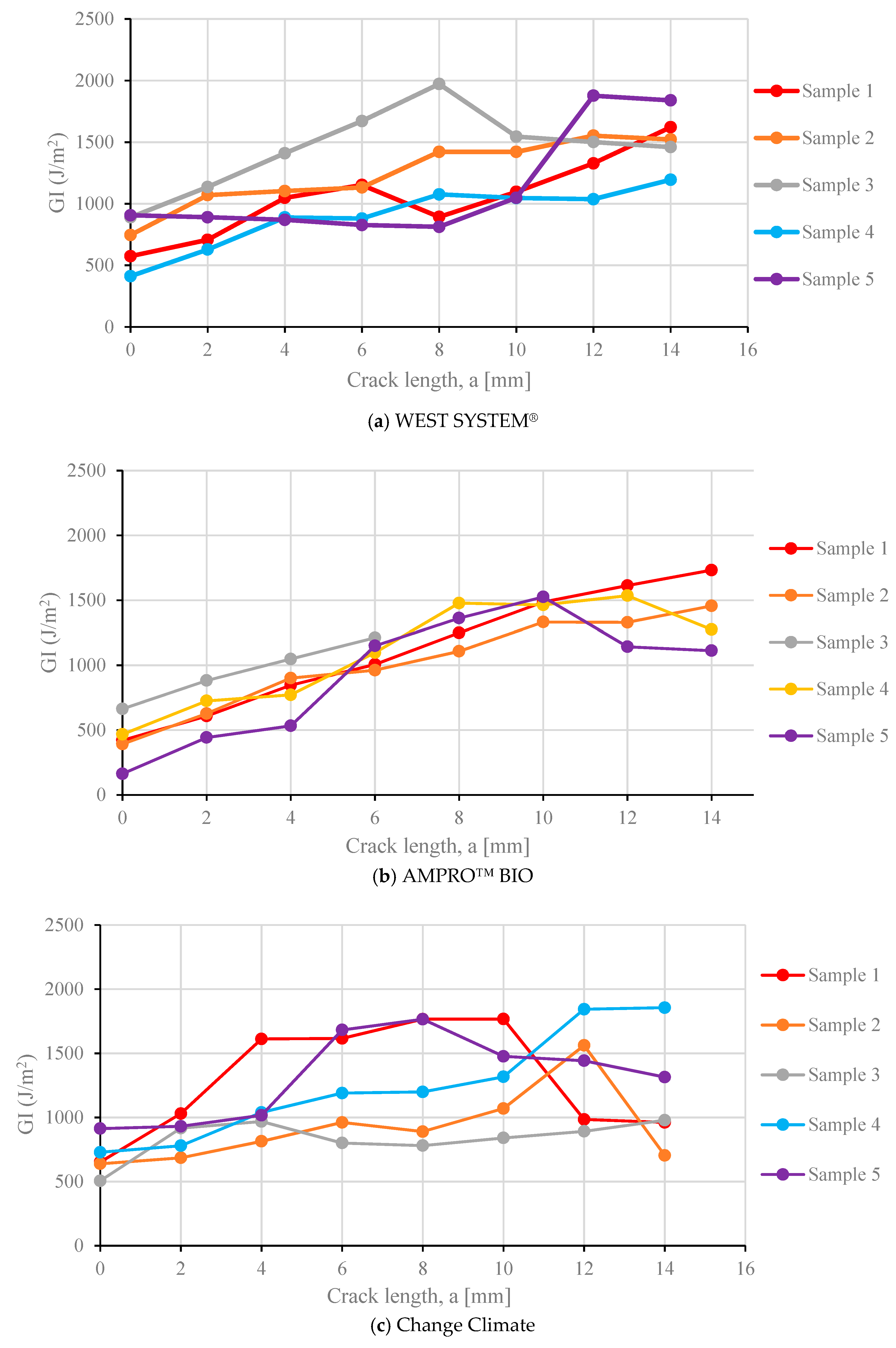

3.3. In-Plane Shear

The in-plane shear properties of the BFRP laminate were determined using tensile tests with the fibres oriented in the ±45 direction. The resin system has significant impact on the shear properties of a laminate, and, hence, this test can directly compare the performance of the traditional vs. bio epoxy on the BFRP laminates. Almost every specimen within the same resin system exhibited similar mechanical properties, as seen in

Figure 9.

The Change Climate epoxy was found to have very comparable in-plane properties with traditional epoxy with less than a 5% difference in terms of both shear strength and modulus (

Table 7). AMPRO™ BIO, in contrast, attained 69% of the shear strength and 58% of the shear modulus of traditional epoxy. As mentioned earlier, the AMPRO™ BIO epoxy has lower mechanical properties compared to WEST SYSTEM

® and Change Climate adhesives.

The in-plane shear strength and modulus of basalt fibre-reinforced epoxies were reported to be 42 MPa and 2.72 GPa, respectively, in [

41]. Although these values are comparable to those in

Table 7, the fibre volume fraction in [

41] was 0.3, and unsaturated polyester was used as the resin. Scalici et al. [

27] reported an in-plane shear strength and modulus of 21.7 MPa and 2.08 GPa, respectively, for basalt fibre of 580 gsm (tensile strength and modulus of 2130 MPa and 93 GPa, respectively) and low viscosity resin (tensile strength and modulus of 60 MPa and 2.7 GPa, respectively). The basalt fibre in this study was continuous basalt fibre yarns, plain woven with low tex weft basalt ties. Scalici et al. implemented the vacuum infusion technique and obtained a volume fraction of 0.57. They reported that they were expecting a shear strength of 54 MPa, according to the rule of mixture. Limited studies of fibre reinforced with bio resin were found. Boursier et al. [

44] tested carbon fibre composites reinforced with bio resins and reported a shear strength of 61 MPa and a shear modulus of 3 GPa [31% bio epoxy with Strength and Young’s modulus of 68.5 MPa and 3000 MPa, respectively; ASTM D5379 was used]; the higher shear strength compared to this study can be attributed to the superior tensile strength properties of the resin used in the study which is higher than any resin used during this study. Overall, the results obtained in this study agree well with limited studies reported in the literature on the in-plane shear properties of basalt fibre.

Table 8 shows the results from other studies with the ones obtained during this study for a better comparison.