The Effects of Combined Treatments of Laser Engraving, Plasma Spraying and Resin Pre-Coating on Improving the Bonding Strength of Titanium Alloy and Carbon Fiber-Reinforced Polymer

Abstract

1. Introduction

2. Preparation and Characterization of Composites

2.1. Major Raw Materials and Manufacturing Equipment

2.2. Preparation of Composite Materials

2.3. Characterization Methods

3. Results and Discussions

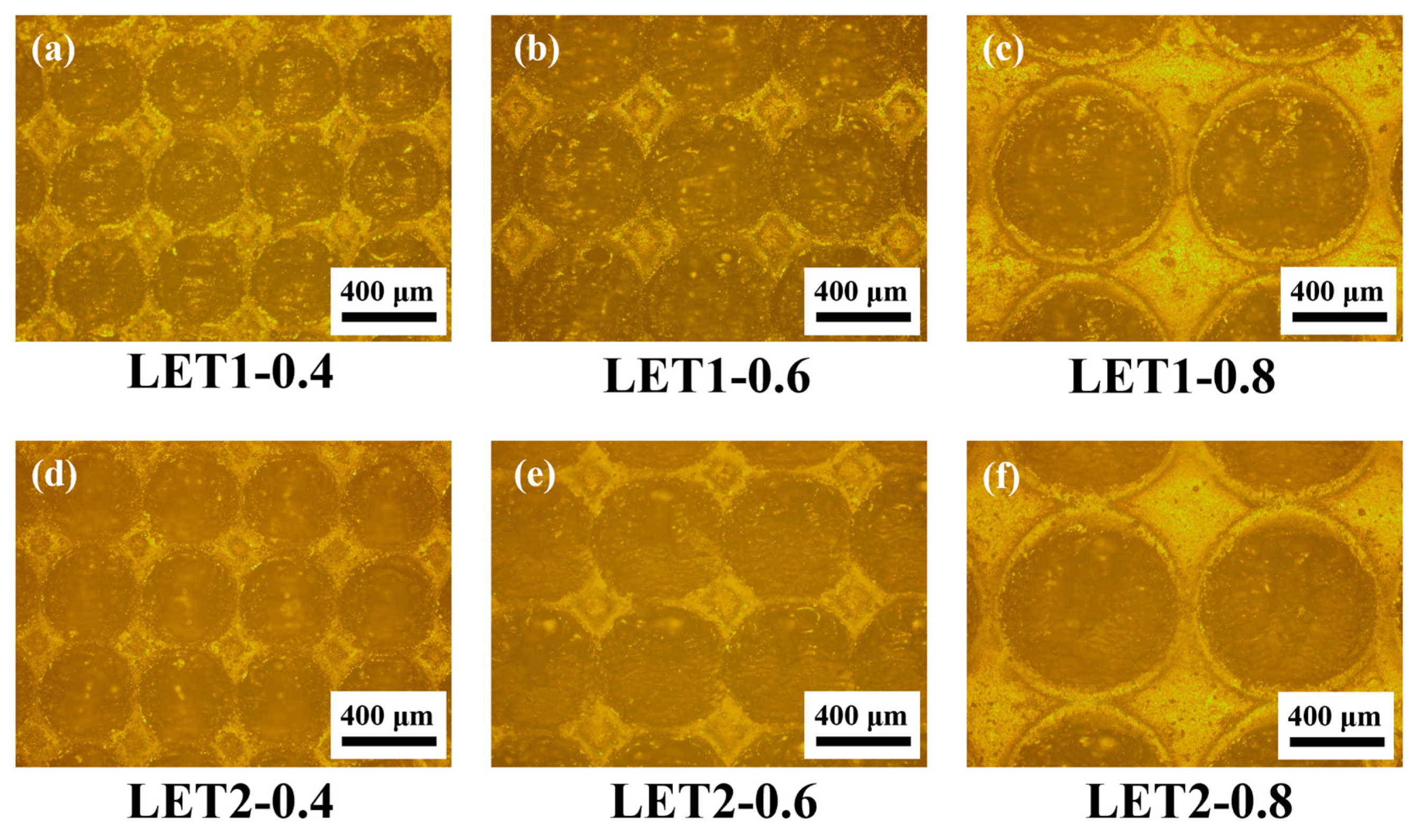

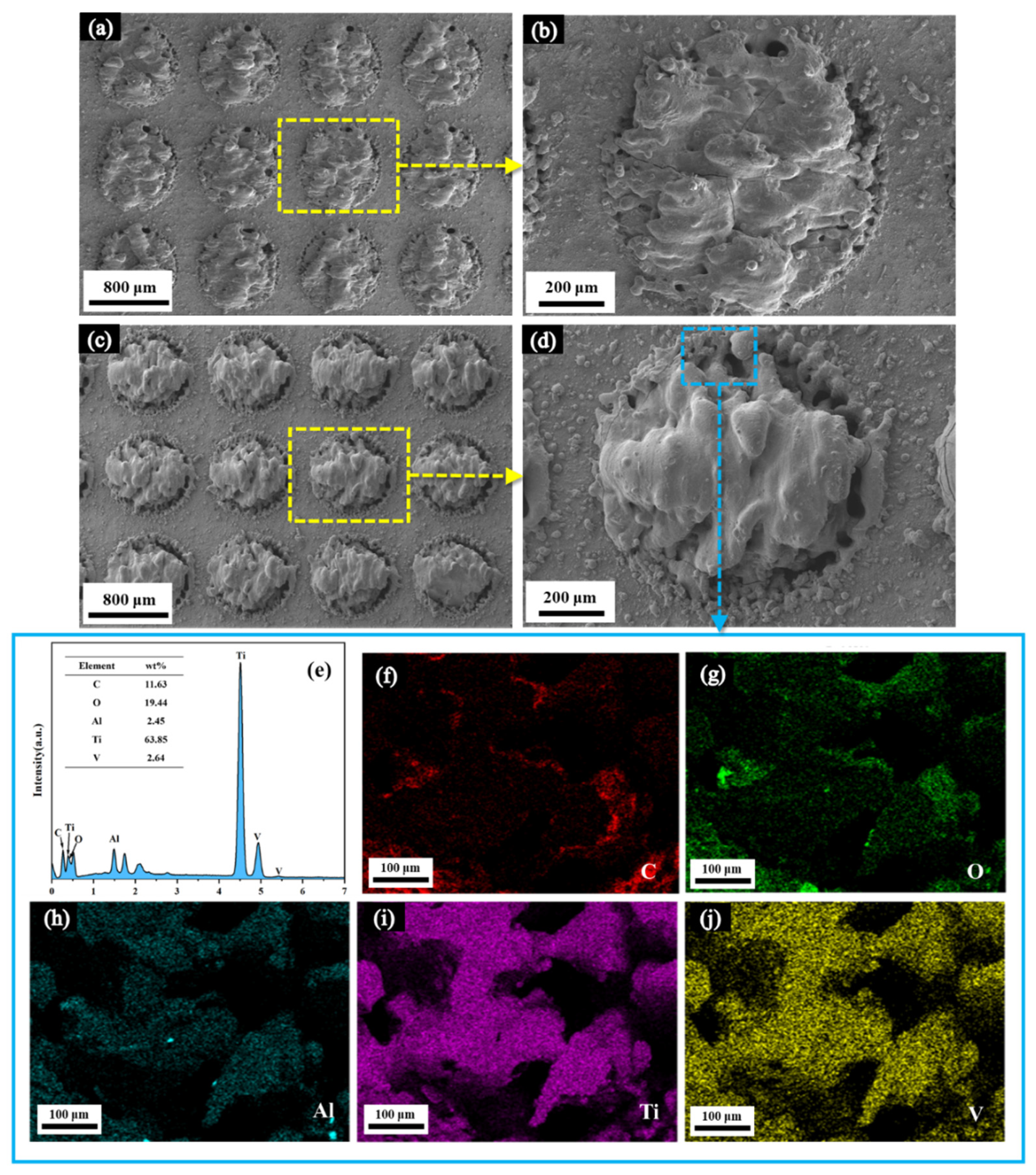

3.1. Surface Morphology of TA Substrates with LET

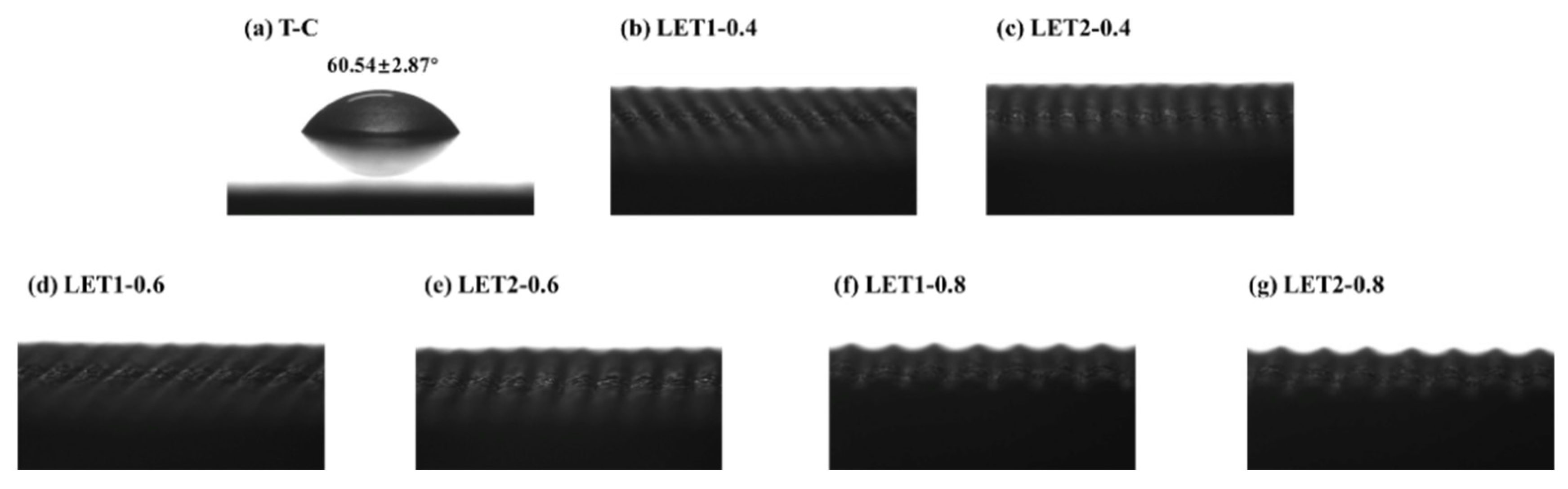

3.2. Contact Angles of TA Surface under Different Conditions

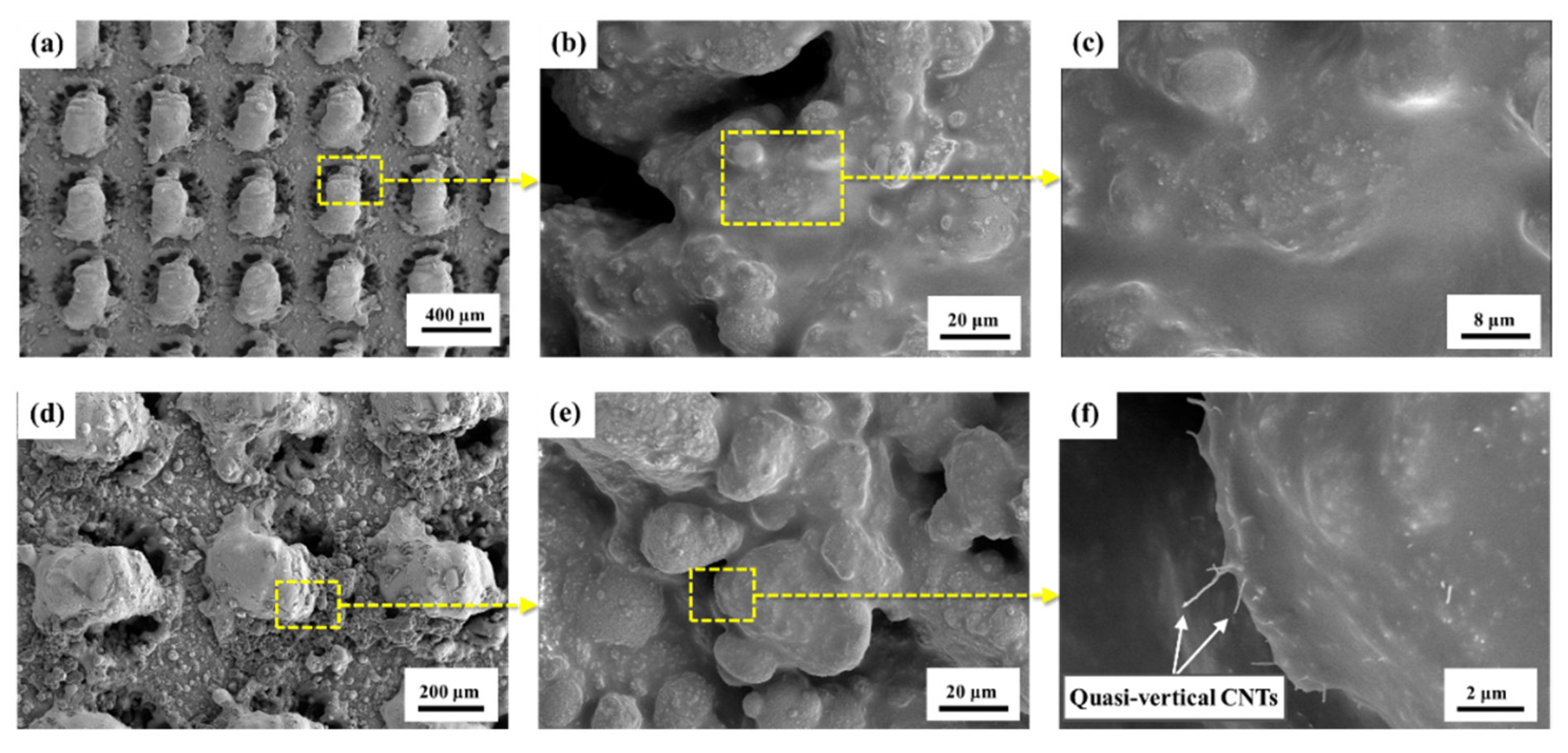

3.3. Surface Microstructure of TA after RPC Treatment

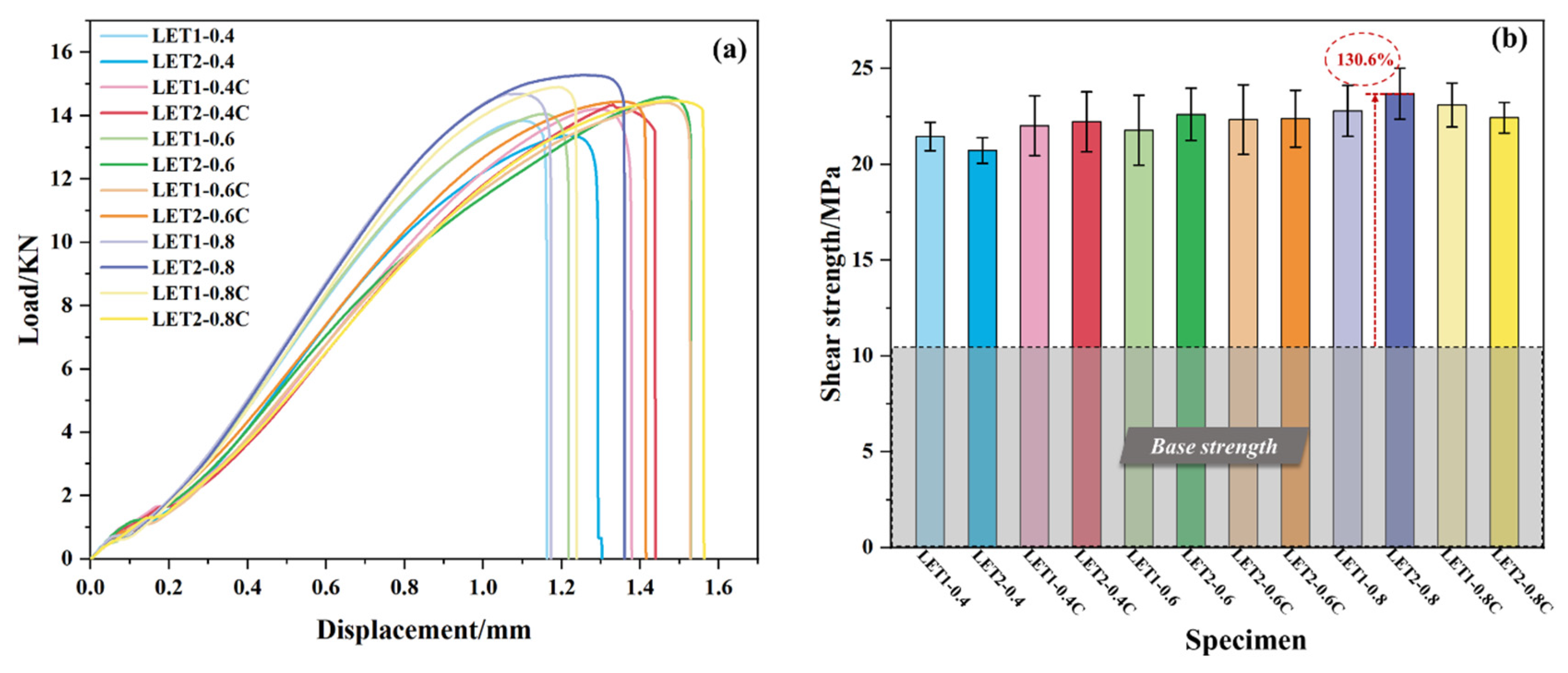

3.4. Bonding Strength Analysis of Specimens of Different Conditions

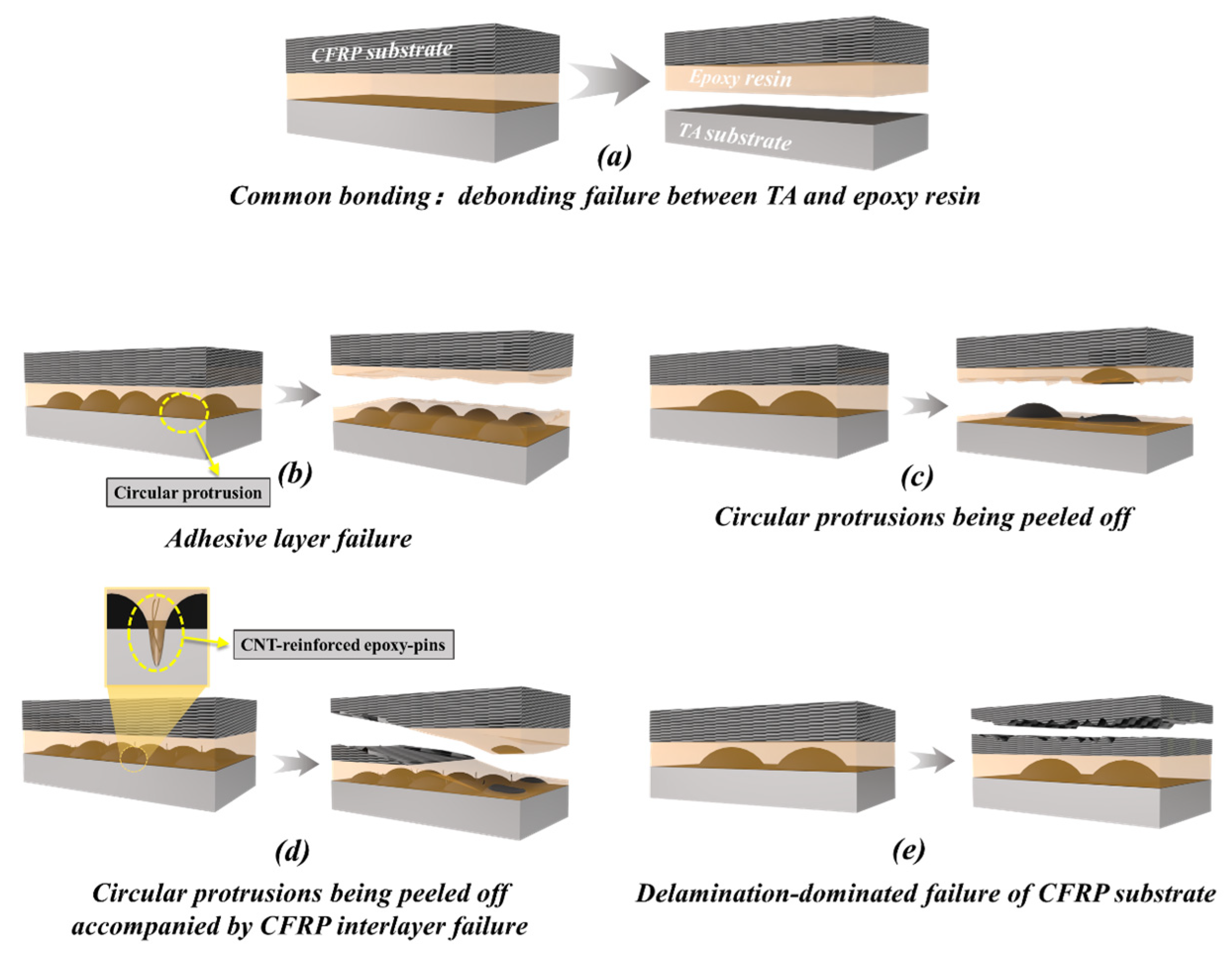

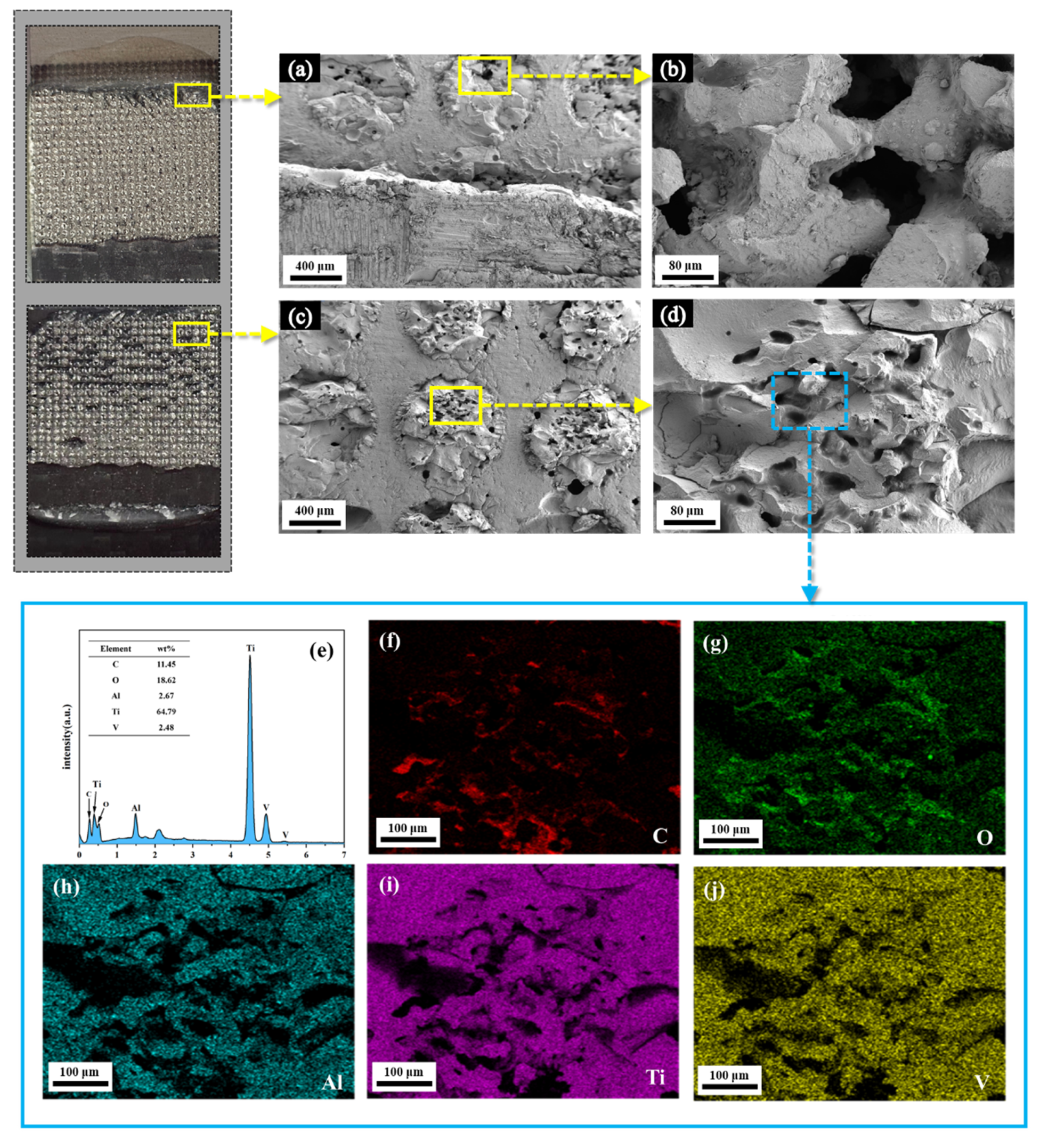

3.5. Failure Mode Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pramanik, A.; Basak, A.; Dong, Y.; Sarker, P.; Uddin, M.; Littlefair, G.; Dixit, A.; Chattopadhyaya, S. Joining of carbon fibre reinforced polymer (CFRP) composites and aluminium alloys—A review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef]

- Backe, S.; Balle, F. A novel short-time concept for fatigue life estimation of carbon (CFRP) and metal/carbon fiber reinforced polymer (MCFRP). Int. J. Fatigue 2018, 116, 317–322. [Google Scholar] [CrossRef]

- Xu, M.-M.; Huang, G.-Y.; Dong, Y.-X.; Feng, S.-S. An experimental investigation into the high velocity penetration resistance of CFRP and CFRP/aluminium laminates. Compos. Struct. 2018, 188, 450–460. [Google Scholar] [CrossRef]

- Zhou, C.; Li, Y.; Zhu, G.; Luo, G.; Zhao, X.; Yu, Q. Tensile and flexural behavior of metal/CFRP hybrid laminated plates. Polym. Compos. 2021, 42, 2882–2897. [Google Scholar] [CrossRef]

- Wang, W.; Chen, X.; Fan, H. Modular technique to construct lightweight CFRP lattice structures. Thin-Wall Struct. 2023, 182, 110259. [Google Scholar] [CrossRef]

- Hosseini, A.; Ghafoori, E.; Motavalli, M.; Nussbaumer, A.; Zhao, X.-L.; Al-Mahaidi, R.; Terrasi, G. Development of prestressed unbonded and bonded CFRP strengthening solutions for tensile metallic members. Eng. Struct. 2019, 181, 550–561. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Chen, C.; Wang, F.J.; Zhang, C.; Wang, Q. Analytical model for delamination of CFRP during drilling of CFRP/metal stacks. Int. J. Adv. Manuf. Technol. 2020, 106, 5099–5109. [Google Scholar] [CrossRef]

- Kolesnikov, B.; Herbeck, L.; Fink, A. CFRP/titanium hybrid material for improving composite bolted joints. Compos. Struct. 2008, 83, 368–380. [Google Scholar] [CrossRef]

- Ke, L.; Li, C.; He, J.; Shen, Q.; Liu, Y.; Jiao, Y. Enhancing fatigue performance of damaged metallic structures by bonded CFRP patches considering temperature effects. Mater. Des. 2020, 192, 108731. [Google Scholar] [CrossRef]

- Camanho, P.; Fink, A.; Obst, A.; Pimenta, S. Hybrid titanium–CFRP laminates for high-performance bolted joints. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1826–1837. [Google Scholar] [CrossRef]

- Guo, K.; Liu, Y.; Gou, G.; Zhang, W.; Gao, W.; Wang, W. Electroplating and brazing joining of 5083 aluminum alloy to CFRP. Int. J. Mod. Phys. B 2019, 33, 1940044. [Google Scholar] [CrossRef]

- Kaiser, I.; Zhang, C.; Tan, K.T. Mechanical behavior and failure mechanisms of CFRP and Titanium tubular adhesive lap joints at extreme temperatures. Compos. Struct. 2022, 290, 115528. [Google Scholar] [CrossRef]

- Raftery, G.M.; Harte, A.M.; Rodd, P.D. Bonding of FRP materials to wood using thin epoxy gluelines. Int. J. Adhes. Adhes. 2009, 29, 580–588. [Google Scholar] [CrossRef]

- Liu, M.; Rohde, B.J.; Krishnamoorti, R.; Robertson, M.L.; Dawood, M. Bond behavior of epoxy resin–polydicyclopentadiene phase separated interpenetrating networks for adhering carbon fiber reinforced polymer to steel. Polym. Eng. Sci. 2020, 60, 104–112. [Google Scholar] [CrossRef]

- Alwash, D.; Kalfat, R.; Du, H.; Al-Mahaidi, R. Development of a new nano modified cement based adhesive for FRP strengthened RC members. Constr. Build. Mater. 2021, 277, 122318. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Sedlaček, M.; Podgornik, B.; Vižintin, J.; Babnik, A.; Možina, J. Surface texturing by pulsed Nd:YAG laser. Tribol. Int. 2009, 42, 1496–1504. [Google Scholar] [CrossRef]

- Min, J.; Wan, H.; Carlson, B.E.; Lin, J.; Sun, C. Application of laser ablation in adhesive bonding of metallic materials: A review. Opt. Laser Technol. 2020, 128, 106188. [Google Scholar] [CrossRef]

- Chen, W.; Lai, W.; Wang, Y.; Wang, K.; Lin, S.; Yen, Y.; Hocheng, H.; Chou, T. Ultrafast Laser Engraving Method to Fabricate Gravure Plate for Printed Metal-Mesh Touch Panel. Micromachines 2015, 6, 1483–1489. [Google Scholar] [CrossRef]

- Nischkauer, W.; Vanhaecke, F.; Limbeck, A. Self-aliquoting micro-grooves in combination with laser ablation-ICP-mass spectrometry for the analysis of challenging liquids: Quantification of lead in whole blood. Anal. Bioanal. Chem. 2016, 408, 5671–5676. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Grossi, V.; Di Ilio, A. Friction assisted joining of aluminum and PVC sheets. J. Manuf. Process 2017, 29, 221–231. [Google Scholar] [CrossRef]

- Wu, L.; Xiao, B.; Nagatsuka, K.; Nakata, K.; Ma, Z. Achieving strong friction lap joints of carbon-fiber reinforced plastic and metals by modifying metal surface structure via laser-processing pretreatment. Compos. Struct. 2020, 242, 112167. [Google Scholar] [CrossRef]

- Xu, Z.; Yip, W.; Dong, Z.; Uddin, M.; Stevens, G. On the laser surface pre-treatment to enhance the surface texture, wettability and adhesion bonding strength of aluminium 7075-T6 laminates. Compos. Interfaces 2024, 31, 123–141. [Google Scholar] [CrossRef]

- Yin, H.; Liu, J.; Xia, H.; Guo, L.; Ao, X.; Luo, J.; Yang, Y. Effect of combination of microstructure and surface treatment on shear strength of precision bonded joints. J. Adhes. 2023, 100, 668–685. [Google Scholar] [CrossRef]

- Wen, L.; Xu, X.; Qin, L. Effect of Low-Temperature Plasma Surface Treatment on Bonding Properties of Single-Lap Joint of Thermosetting Composites. Polymers 2023, 15, 1631. [Google Scholar] [CrossRef] [PubMed]

- Çoban, O.; Akman, E.; Bora M, Ö.; Genc Oztoprak, B.; Demir, A. Laser surface treatment of CFRP composites for a better adhesive bonding owing to the mechanical interlocking mechanism. Polym. Compos. 2019, 40, 3611–3622. [Google Scholar] [CrossRef]

- Palavra, A.; Coelho, B.N.; De Hosson, J.T.M.; Lima, M.S.F.; Carvalho, S.M.; Costa, A.R. Laser surface treatment for enhanced titanium to carbon fiber-reinforced polymer adhesion. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 2917–2924. [Google Scholar] [CrossRef]

- Zuo, S.; Cheng, F.; Yang, G.; Li, J.; Deng, Y.; Gou, G.; Cui, X.; Hu, Y.; Hu, X. An effective micro-arc oxidation (MAO) treatment on aluminum alloy for stronger bonding joint with carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107919. [Google Scholar] [CrossRef]

- Cheng, F.; Xu, Y.; Zhang, J.; Wang, L.; Zhang, H.; Wan, Q.; Li, W.; Wang, L.; Lv, Z. Growing carbon nanotubes in-situ via chemical vapor deposition and resin pre-coating treatment on anodized Ti-6Al-4V titanium substrates for stronger adhesive bonding with carbon fiber composites. Surf. Coat. Technol. 2023, 457, 129296. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, J.; Wang, L.; Cheng, F.; Hu, X. Enhancing adhesive bond strength of CFRP/titanium joints through NaOH anodising and resin pre-coating treatments with optimised anodising conditions. Chin. J. Aeronaut. 2024, 37, 511–523. [Google Scholar] [CrossRef]

- Wang, B.; Ding, G.; Wang, G.; Kang, S. Effects of resin pre-coating on interfacial bond strength and toughness of laminar CFRP with and without short aramid fibre toughening. J. Compos. Mater. 2020, 54, 3883–3893. [Google Scholar] [CrossRef]

- Liu, W.; Xu, H.; Hu, X.; Yuan, B.; Tan, B.; Xu, F. Strengthening and repairing of engineered bamboo-steel epoxy adhesive joints with carbon nanotube on the basis of resin pre-coating method. Eur. J. Wood Wood Prod. 2020, 78, 313–320. [Google Scholar] [CrossRef]

- Cheng, F.; Hu, Y.; Lv, Z.; Chen, G.; Yuan, B.; Hu, X.; Huang, Z. Directing helical CNT into chemically-etched micro-channels on aluminum substrate for strong adhesive bonding with carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105952. [Google Scholar] [CrossRef]

| Materials/Equipment | Special Features and Models | Origins |

|---|---|---|

| Titanium alloy | The compositions of the titanium alloy are 6.06 wt% Al, 4.03 wt% V, 0.15 wt% Fe, 0.17 wt% O, 0.02 wt% C, 0.02 wt% N, 0.015wt% H, and Ti balance (length 101.6 mm, width 25.4 mm, thickness 3.0 mm) | Wuxi Shengtai Technology Co., Ltd., Wuxi, China |

| Carbon fiber composite | 3K twill weave carbon fiber panels (length 101.6 mm, width 25.4 mm, thickness 3.0 mm) | Carbonwiz Technology Co., Ltd., Shenzhen, China |

| Epoxy resin | Bisphenol A epichlorohydrin epoxy resin | Guangdong Advanced Chemical Materials Co., Ltd., Guangzhou, China |

| Hardener | Triethylenetetramine hardener | Guangdong Advanced Chemical Materials Co., Ltd., China |

| Acetone | AR 99.5%, boiling point 56 °C, toxic | Chengdu Kelong Chemical Ltd., Chengdu, China |

| Carbon nanotube | Helical multi-walled carbon nanotube (outer diameter 100–200 nm, length 1–10 μm) | XF Nano, Inc., Nanjing, China |

| Laser engraving machine | JL-F30 | Liaocheng Jiuling Laser Equipment Co., Ltd., Liaocheng, China |

| Plasma cleaning machine | ZH-AP-500X-X | Shenzhen Zhenhua Plasma Intelligent Manufacturing Co., Ltd., Shenzhen, China |

| Electric grinder | DL6391, 120-grit,600-grit, 1000-grit aluminum oxide grinding wheel | Deli Group Co., Ltd., Ningbo, China |

| Specimen Code | TA | CFRP | Specimen Number |

|---|---|---|---|

| T-C | Acetone cleaning | Acetone cleaning | 5 |

| LET1-0.4 a | Laser engraving once + RPC | Grinding + RPC | 5 |

| LET2-0.4 | Laser engraving twice + RPC | Grinding + RPC | 5 |

| LET1-0.4C b | Laser engraving once + RPC (with CNTs) | Grinding + RPC (with CNTs) | 5 |

| LET2-0.4C | Laser engraving twice + RPC (with CNTs) | Grinding + RPC (with CNTs) | 5 |

| LET1-0.6 | Laser engraving once + RPC | Grinding + RPC | 5 |

| LET2-0.6 | Laser engraving twice + RPC | Grinding + RPC | 5 |

| LET1-0.6C | Laser engraving once + RPC (with CNTs) | Grinding + RPC (with CNTs) | 5 |

| LET2-0.6C | Laser engraving twice + RPC (with CNTs) | Grinding + RPC (with CNTs) | 5 |

| LET1-0.8 | Laser engraving once + RPC | Grinding + RPC | 5 |

| LET2-0.8 | Laser engraving twice + RPC | Grinding + RPC | 5 |

| LET1-0.8C | Laser engraving once + RPC (with CNTs) | Grinding + RPC (with CNTs) | 5 |

| LET2-0.8C | Laser engraving twice + RPC (with CNTs) | Grinding + RPC (with CNTs) | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.; Cheng, F.; Zuo, S.; Ji, Y.; Yang, G.; He, J.; Ashfaq, S.; Hu, Y.; Hu, X. The Effects of Combined Treatments of Laser Engraving, Plasma Spraying and Resin Pre-Coating on Improving the Bonding Strength of Titanium Alloy and Carbon Fiber-Reinforced Polymer. Polymers 2024, 16, 2041. https://doi.org/10.3390/polym16142041

Huang W, Cheng F, Zuo S, Ji Y, Yang G, He J, Ashfaq S, Hu Y, Hu X. The Effects of Combined Treatments of Laser Engraving, Plasma Spraying and Resin Pre-Coating on Improving the Bonding Strength of Titanium Alloy and Carbon Fiber-Reinforced Polymer. Polymers. 2024; 16(14):2041. https://doi.org/10.3390/polym16142041

Chicago/Turabian StyleHuang, Wenyi, Fei Cheng, Shihao Zuo, Yi Ji, Guangming Yang, Jiaxin He, Sidra Ashfaq, Yunsen Hu, and Xiaozhi Hu. 2024. "The Effects of Combined Treatments of Laser Engraving, Plasma Spraying and Resin Pre-Coating on Improving the Bonding Strength of Titanium Alloy and Carbon Fiber-Reinforced Polymer" Polymers 16, no. 14: 2041. https://doi.org/10.3390/polym16142041

APA StyleHuang, W., Cheng, F., Zuo, S., Ji, Y., Yang, G., He, J., Ashfaq, S., Hu, Y., & Hu, X. (2024). The Effects of Combined Treatments of Laser Engraving, Plasma Spraying and Resin Pre-Coating on Improving the Bonding Strength of Titanium Alloy and Carbon Fiber-Reinforced Polymer. Polymers, 16(14), 2041. https://doi.org/10.3390/polym16142041