High-Temperature Resistance of Anchorage System for Carbon Fiber-Reinforced Polymer Composite Cable—A Review

Abstract

1. Introduction

2. High-Temperature Resistance of Materials in Anchorage System

2.1. Bonding Materials and Fillers

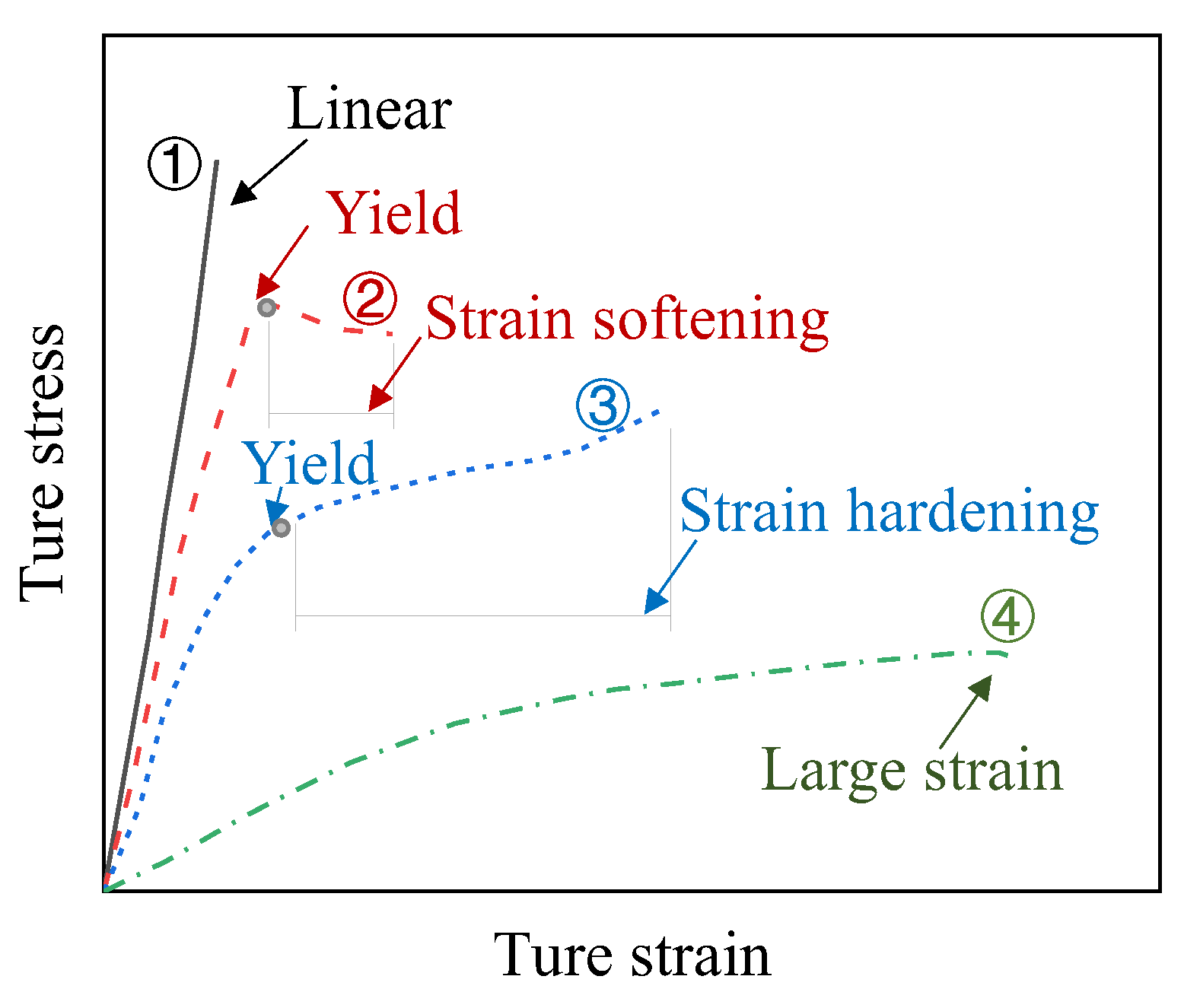

2.1.1. Mechanical Properties of Epoxy Resin at Elevated Temperatures

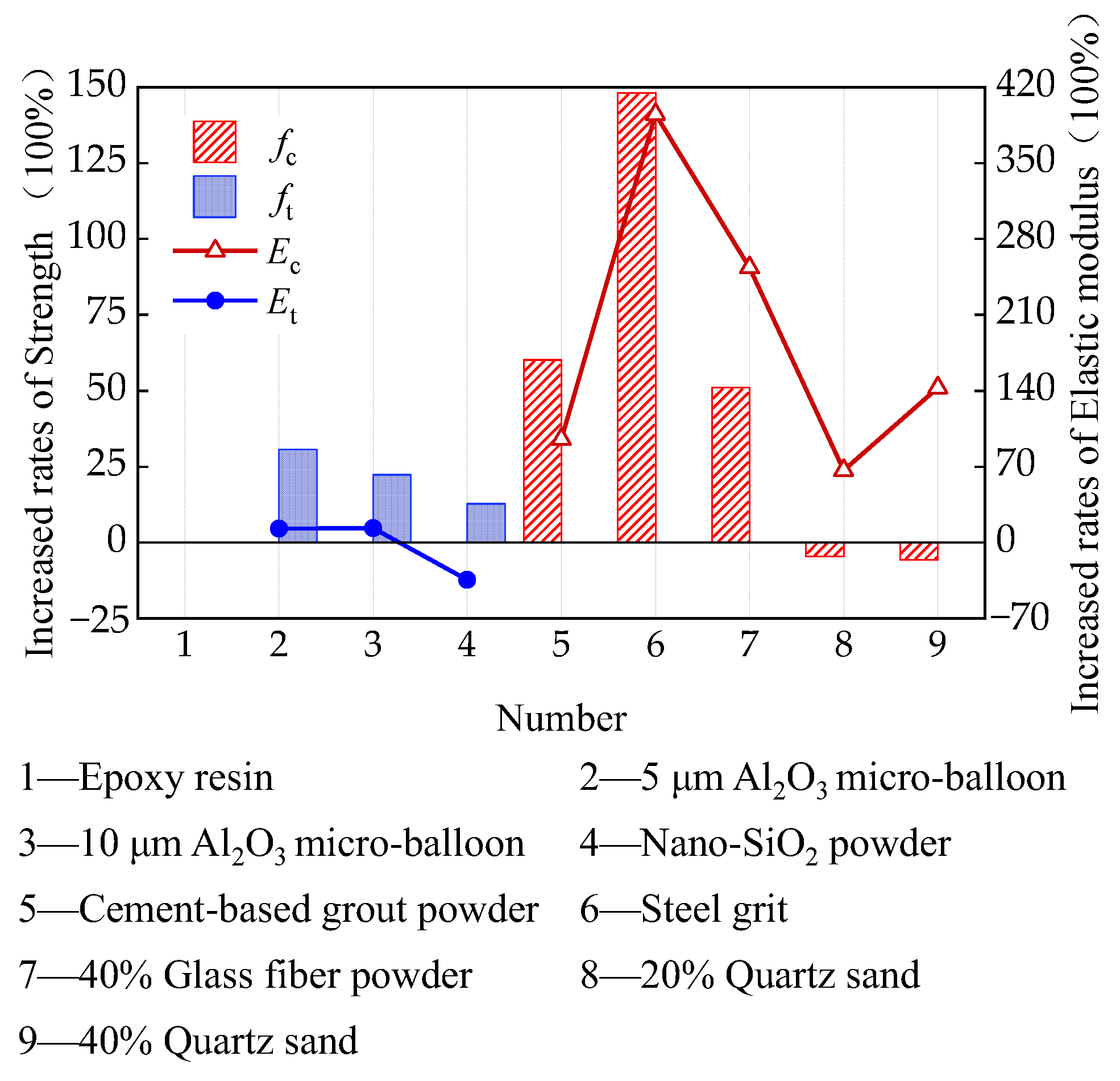

2.1.2. Influence of Fillers on the Performance of Bonding Epoxy Resin

2.1.3. High-Temperature Resistance of Epoxy Resin with Fillers

2.2. CFRP Composites for Cable

2.2.1. Longitudinal Tensile Properties of CFRP Composites at Elevated Temperatures

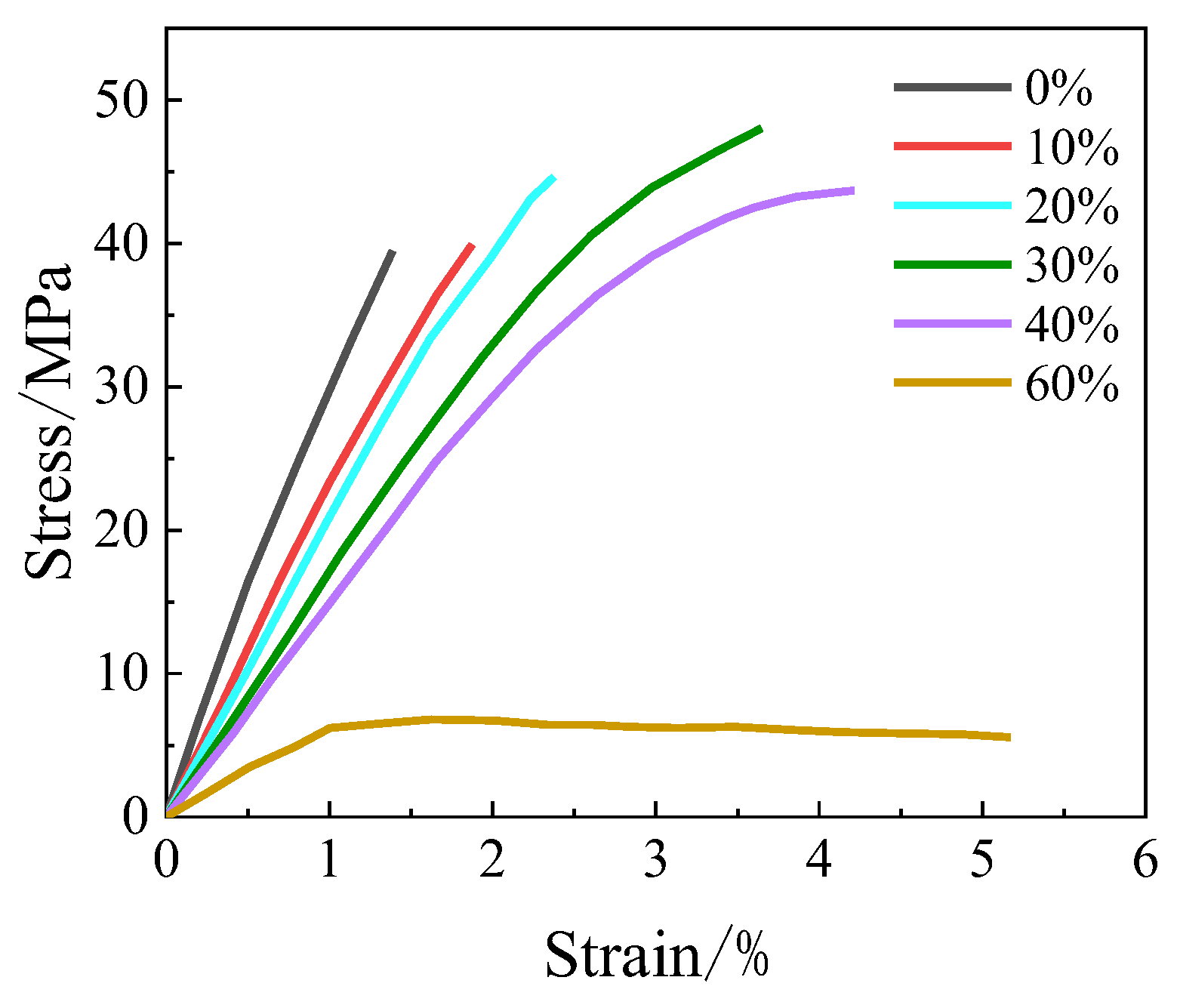

2.2.2. Transverse Compressive Properties of CFRP Composites at Elevated Temperatures

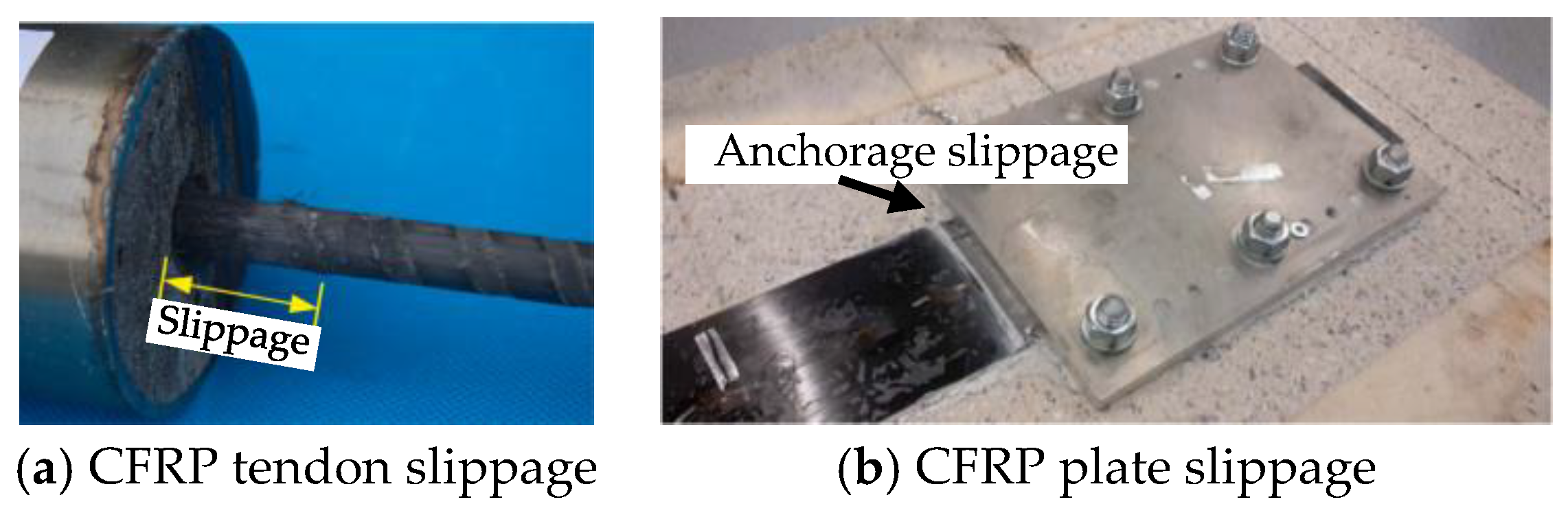

3. High-Temperature Resistance of CFRP Cable Anchorage System

3.1. Temperature Field in Anchorage System

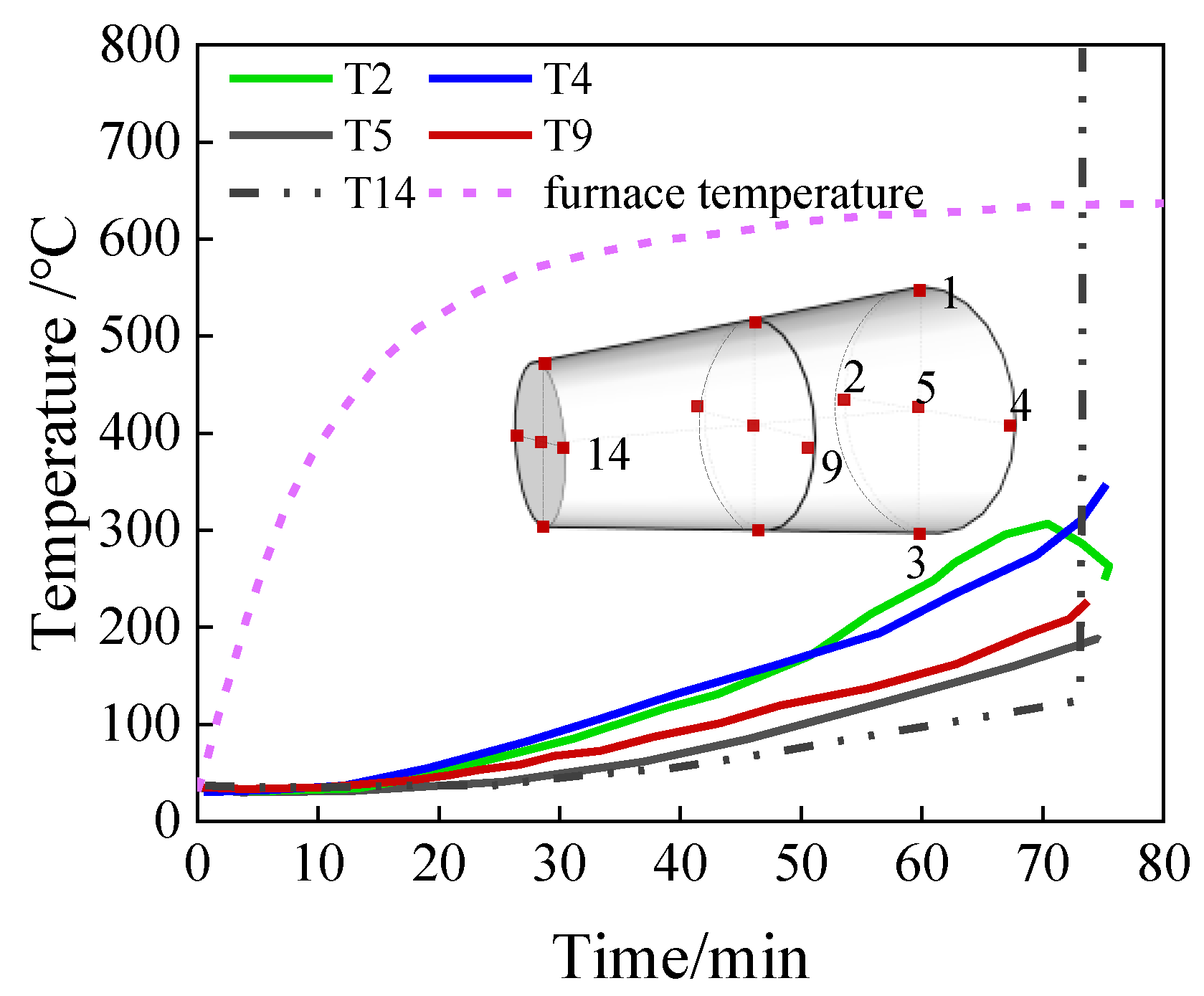

3.1.1. Measurement of Temperature Field

3.1.2. Calculation of Temperature Field

3.2. Analysis of Anchorage Failure at Elevated Temperatures

4. Conclusions

- (1)

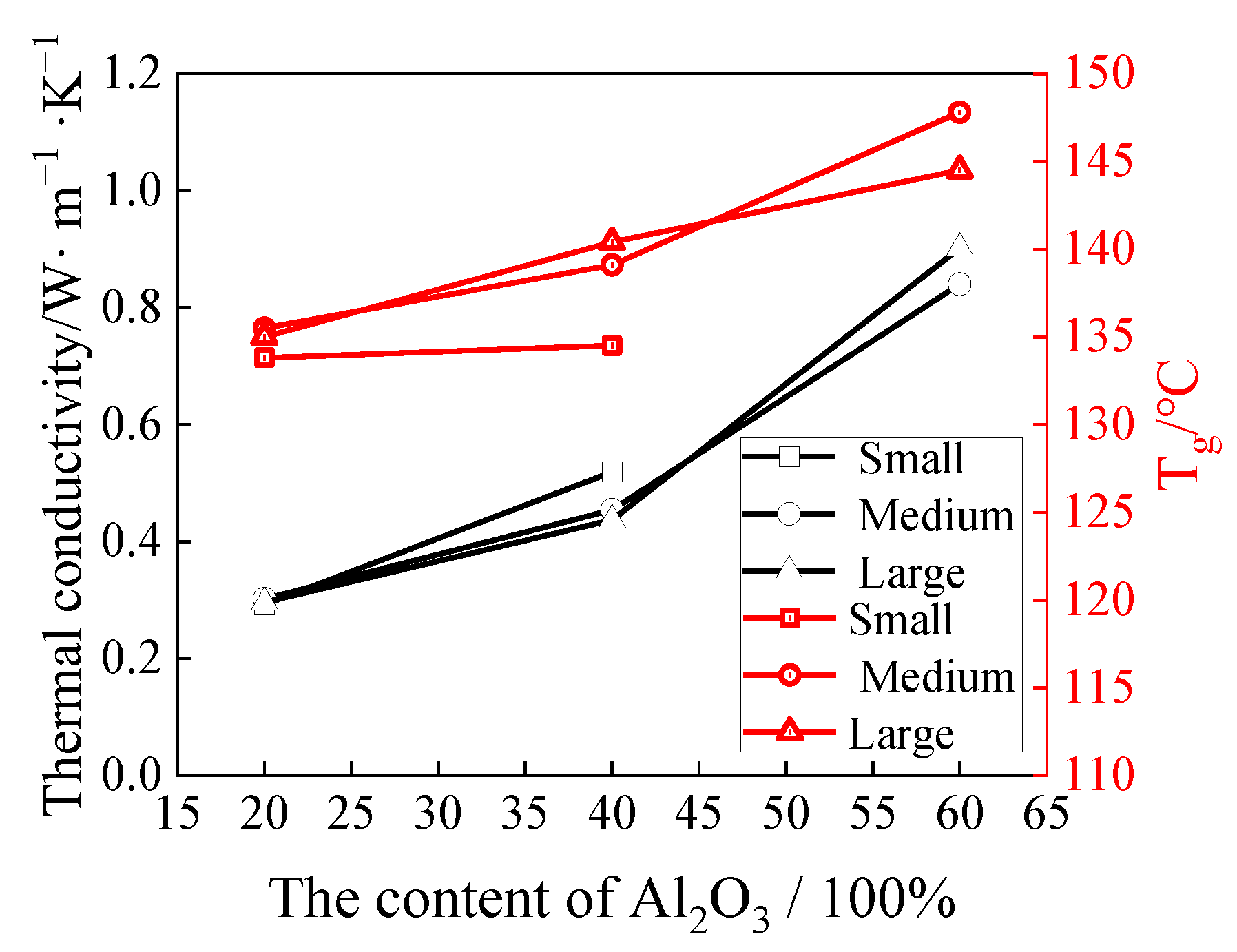

- The degradation of the mechanical properties of the boding epoxy resin at elevated temperatures is dominated by the glass transition temperature. Appropriately added filler contents, such as glass fiber powder, cement-based grout powder, and steel grit, can improve the compressive strength and modulus, while Al2O3 micro-balloon can improve the tensile strength and modulus. Furthermore, adding fillers such as Al2O3 micro-particles and nano-SiO2 powder can also improve the glass transition temperature, and may be beneficial for the high-temperature resistance as well.

- (2)

- The longitudinal tensile properties are relatively insensitive to elevated temperatures within the glass transition temperature of unidirectional CFRP composites. Comparatively, the transverse compressive properties are dominant over the high-temperature resistance of the CFRP cable anchorage systems. It is generally believed that the transverse compression strength of unidirectional CFRP composites at both room and elevated temperatures is dominated by the fiber–resin interfacial bonding strength, but the quantified influencing law lacks experimental validation. The degradation law of the transverse compressive properties with different elevated temperatures is also lacking, especially experimental data.

- (3)

- Traditional thermocouples are unable to measure the temperature field inside the CFRP cable anchorage systems due to technical difficulty such as the arrangement and location fixing of thermocouples. Commercial FEA software can provide an effective approach for the temperature field calculation of the CFRP cable anchorage systems, combined with careful measurement of the thermophysical parameters of the materials. Additionally, new temperature measurement technologies such as optical fiber sensing can be utilized, serving as the experimental validation of the FEA temperature field calculation.

- (4)

- Generally, the softening of the bonding resin at elevated temperatures is critical for the high-temperature resistance of the bonding and bonding–mechanical composite anchorages, while the transverse compression softening of the CFRP composites at elevated temperatures is critical for the high-temperature resistance of the mechanical and bonding–mechanical composite anchorages dominated by mechanical clamping. However, relevant experimental investigation and theoretical analysis is quite insufficient.

- (1)

- Adding fillers may improve both the mechanical properties and the thermal conductivity of the epoxy resin, which has coupling influence on the high-temperature resistance of CFRP cable anchorage systems, which needs quantified investigation to clarify whether it is beneficial or not. Additionally, the temperature-dependent mechanical properties and the constitutive stress–strain relationship of the epoxy resin with fillers also need to be investigated.

- (2)

- Further experimental investigation is still needed to clarify the degradation of the transverse compressive properties of unidirectional CFRP composites at elevated temperatures, as well as establish a temperature-dependent constitutive model. Combination of the RVE analysis and the micro-experimental test data is also needed to clarify the quantified influence of epoxy resin’s mechanical properties and fiber–resin interfacial mechanical properties on the transverse compressive properties of unidirectional CFRP composites.

- (3)

- The failure mechanism and the high-temperature resistance of CFRP cable anchorages at elevated temperatures are quite lacking in research. Further experimental investigation and theoretical analysis is needed, where the FEA thermo-mechanical coupling analysis can be utilized.

- (4)

- The enhancing effect of the confining constraint by anchorage devices on the transverse compression of unidirectional CFRP composites at both room and elevated temperatures also needs attention, as it may be important for analyzing the failure mechanism of CFRP cable anchorages.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Fahmy MF, M.; Guan, S.; Pan, Z.; Zhan, Y.; Zhao, T. Properties and applications of FRP cable on long-span cable-supported bridges: A review. Compos. Part B Eng. 2020, 190, 107934. [Google Scholar] [CrossRef]

- Schmidt, J.W.; Bennitz, A.; Täljsten, B.; Goltermann, P.; Pedersen, H. Mechanical anchorage of FRP tendons—A literature review. Constr. Build. Mater. 2012, 32, 110–121. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, J.; Xu, J.; Han, Q. Anchorage systems of CFRP cables in cable structures—A review. Constr. Build. Mater. 2018, 160, 82–99. [Google Scholar] [CrossRef]

- Duo, Y.; Liu, X.; Yue, Q.; Chen, H. A novel variable curvature clamping anchor for the multilayer CFRP plate cable: Concept, numerical investigation, and design proposals. Structures 2022, 43, 164–177. [Google Scholar] [CrossRef]

- Wang, A.; Liu, X.; Yue, Q. Research progress of carbon fiber reinforced polymer composite cable: Anchorage system and service performance. J. Build. Struct. 2022, 43, 45–54. (In Chinese) [Google Scholar]

- Sadighi, M.; Alderliesten, R. Impact fatigue, multiple and repeated low-velocity impacts on FRP composites: A review. Compos. Struct. 2022, 297, 115962. [Google Scholar] [CrossRef]

- Wang, Z.; Xian, G. Impact performances of fiber reinforced polymer composites and cables: A review. Compos. Struct. 2023, 319, 117128. [Google Scholar] [CrossRef]

- Ahmed, A.; Zillur Rahman, M.; Ou, Y.; Mobasher, B.; Guo, S.; Zhu, D. A review on the tensile behavior of fiber-reinforced polymer composites under varying strain rates and temperatures. Constr. Build. Mater. 2021, 294, 123565. [Google Scholar] [CrossRef]

- Jiang, Z.; Fang, Z.; Fang, C.; Li, Q.; Wang, Z. Mechanical properties under high-temperature and fire resistant limit of carbon fiber reinforced polymer cable. Constr. Build. Mater. 2022, 361, 129586. [Google Scholar] [CrossRef]

- Correia, J.R.; Keller, T.; Garrido, M.; Sa, M.; Firmo, J.; Shahid, M.A.; Machado, M. Mechanical properties of FRP materials at elevated temperature—Definition of a temperature conversion factor for design in service conditions. Constr. Build. Mater. 2023, 367, 130298. [Google Scholar] [CrossRef]

- Manalo, A.; Maranan, G.; Sharma, S.; Sharma, S.; Karunasena, W.; Yu, B. Temperature-sensitive mechanical properties of GFRP composites in longitudinal and transverse directions: A comparative study. Compos. Struct. 2017, 173, 255–267. [Google Scholar] [CrossRef]

- Xu, K.; Chen, W.; Zhu, X.; Liu, L.; Zhao, Z.; Luo, G. Prediction of transverse mechanical performance of UD CFRP composite lamina considering high-temperature properties of epoxy. Mech. Adv. Mater. Struct. 2023, 30, 3351–3364. [Google Scholar] [CrossRef]

- Firmo, J.P.; Roquette, M.G.; Correia, J.R.; Azevedo, A.S. Influence of elevated temperatures on epoxy adhesive used in CFRP strengthening systems for civil engineering applications. Int. J. Adhes. Adhes. 2019, 93, 102333. [Google Scholar] [CrossRef]

- Ke, L.; Li, C.; He, J.; Dong, S.; Chen, C.; Jiao, Y. Effects of elevated temperatures on mechanical behavior of epoxy adhesives and CFRP-steel hybrid joints. Compos. Struct. 2020, 235, 111789. [Google Scholar] [CrossRef]

- Jahani, Y.; Baena, M.; Barris, C.; Perera, R.; Torres, L. Influence of curing, post-curing and testing temperatures on mechanical properties of a structural adhesive. Constr. Build. Mater. 2022, 324, 126698. [Google Scholar] [CrossRef]

- Moussa, O.; Vassilopoulos, A.P.; De Castro, J.; Keller, T. Time-temperature dependence of thermomechanical recovery of cold-curing structural adhesives. Int. J. Adhes. Adhes. 2012, 35, 94–101. [Google Scholar] [CrossRef]

- Khalil, N.Z.; Johanne, M.F.; Ishak, M. Influence of Al2O3 nanoreinforcement on the adhesion and thermomechanical properties for epoxy adhesive. Compos. Part B Eng. 2019, 172, 9–15. [Google Scholar] [CrossRef]

- Han, Q.; Wang, L.; Xu, J. Experimental research on fracture behaviors of damaged CFRP tendons: Fracture mode and failure analysis. Constr. Build. Mater. 2016, 112, 1013–1024. [Google Scholar] [CrossRef]

- Du, Y.; Zhu, Y.; Jiang, J.; Li, G. Transient temperature distribution in pre-tensioned anchors of cable-supported structures under ISO834 fire. Thin-Walled Struct. 2019, 138, 231–242. [Google Scholar] [CrossRef]

- Jiang, Z.; Pi, X.; Fang, Z. Mechanical performance of a bond-type anchorage system for CFRP cable exposed to elevated temperature. Eng. Struct. 2024, 302, 117388. [Google Scholar] [CrossRef]

- Mahieux, C.A.; Reifsnider, K.L. Property modeling across transition temperatures in polymers: A robust stiffness–temperature model. Polymer 2001, 42, 3281–3291. [Google Scholar] [CrossRef]

- Miao, J.; Ge, M.; Wu, Y.; Chou, T.; Wang, H.; Zheng, L.; Wu, L. Eugenol-derived reconfigurable high-performance epoxy resin for self-deployable smart 3D structures. Eur. Polym. J. 2020, 134, 109805. [Google Scholar] [CrossRef]

- Bascom, W.D.; Cottington, R.L. Effect of temperature on the adhesive fracture behavior of an elastomer-epoxy resin. J. Adhes. 1976, 7, 333–346. [Google Scholar] [CrossRef]

- Plecnik, J.M.; Bresler, B.; Cunningham, J.D.; Iding, R. Temperature effects on epoxy adhesives. J. Struct. Div. 1980, 106, 99–113. [Google Scholar] [CrossRef]

- Mei, K.; Sun, S.; Li, B.; Sun, Y.; Jin, G. Experimental investigation on the mechanical properties of a bond-type anchor for carbon fiber reinforced polymer tendons. Compos. Struct. 2018, 201, 193–199. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Peng, Z.; Wu, Z. Optimization of load transfer component for FRP cable anchor system. Compos. Struct. 2022, 282, 115009. [Google Scholar] [CrossRef]

- Feng, B.; Wang, X.; Wu, Z. Static and fatigue behavior of multitendon CFRP cables with integrated anchorages. J. Compos. Constr. 2019, 23, 04019051. [Google Scholar] [CrossRef]

- Wu, J.; Xian, G.; Li, H. A novel anchorage system for CFRP cable: Experimental and numerical investigation. Compos. Struct. 2018, 194, 555–563. [Google Scholar] [CrossRef]

- Bai, D.; He, Y.; Li, T.; Wang, R.; Liu, Z.; Wang, Z.; Jin, H. Effects of particle size and content of alumina filler on mechanical properties of epoxy resin composite materials. J. Xi’an Jiaotong Univ. 2021, 55, 181–188. (In Chinese) [Google Scholar]

- Li, Y.; Li, C.; He, J.; Gao, Y.; Zheng, H. Effect of functionalized nano-SiO2 addition on bond behavior of adhesively bonded CFRP-steel double-lap joint. Constr. Build. Mater. 2020, 244, 118400. [Google Scholar] [CrossRef]

- Daissè, G.; Abali, B.E.; Wan-Wendner, R. Tensile and Shear Creep Behavior of Structural Adhesives: Experiments and Modeling. Appl. Compos. Mater. 2024, 31, 739–764. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, X.; Li, Z.; Xu, S.; Hao, L.; Zhao, J.; Wang, B.; Yang, J.; Ishizaki, K. Enhanced thermal conductivity of epoxy composites by constructing thermal conduction networks via adding hybrid alumina filler. Polym. Compos. 2022, 43, 483–492. [Google Scholar] [CrossRef]

- Li, Y.; Wu, P.; Ma, X.; Ping, L. Property of epoxy resin /carbon fiber /nanometer SiO2 composites subjected to laser action. Eng. Plast. Appl. 2009, 37, 27–29. (In Chinese) [Google Scholar]

- Zhang, X.; Guo, W.; Liang, T. Effects of the properties by filling nano-particles into epoxy resin based underfiller. Polym. Mater. Sci. Eng. 2009, 25, 101–103+110. (In Chinese) [Google Scholar] [CrossRef]

- Ma, J.; Meng, Q.; Zaman, I.; Zhu, S.; Michelmore, A.; Kawashima, N.; Wang, C.H.; Kuan, H.C. Development of polymer composites using modified, high-structural integrity graphene platelets. Compos. Sci. Technol. 2014, 91, 82–90. [Google Scholar] [CrossRef]

- Li, P.; Zheng, Y.; Li, M.; Shi, T.; Li, D.; Zhang, A. Enhanced toughness and glass transition temperature of epoxy nanocomposites filled with solvent-free liquid-like nanocrystal-functionalized graphene oxide. Mater. Des. 2016, 89, 653–659. [Google Scholar] [CrossRef]

- Alim Md, A.; Abdullah, M.Z.; Aziz MS, A. Recent Advances on Thermally Conductive Adhesive in Electronic Packaging: A Review. Polymers 2021, 13, 3337. [Google Scholar] [CrossRef]

- Akhtar, M.W.; Lee, Y.S.; Yoo, D.J.; Kim, J.S. Alumina-graphene hybrid filled epoxy composite: Quantitative validation and enhanced thermal conductivity. Compos. Part B Eng. 2017, 131, 184–195. [Google Scholar] [CrossRef]

- Zeng, C.; Lu, S.; Song, L.; Xiao, X.; Gao, J.; Pan, L.; He, Z.; Yu, J. Enhanced thermal properties in a hybrid graphene–alumina filler for epoxy composites. RSC Adv. 2015, 5, 35773–35782. [Google Scholar] [CrossRef]

- Khotbehsara, M.M.; Manalo, A.; Aravinthan, T. Effect of elevated in-service temperature on the mechanical properties and microstructure of particulate-filled epoxy polymers. Polym. Degrad. Stab. 2019, 170, 108994. [Google Scholar] [CrossRef]

- Yue, C.; Dong, S.; Weng, L. Environmental Resistance and Fatigue Behaviors of Epoxy/Nano-Boron Nitride Thermally Conductive Structural Film Adhesive Toughened by Polyphenoxy. Polymers 2021, 13, 3253. [Google Scholar] [CrossRef]

- Pan, L.; Dang, Z. Study and application of new-type stuffing for chilled cast anchor device. Bridge Constr. 1999, 04, 46–48. (In Chinese) [Google Scholar]

- Sauder, C.; Lamon, J.; Pailler, R. Thermomechanical properties of carbon fibres at high temperatures (up to 2000 °C). Compos. Sci. Technol. 2002, 62, 499–504. [Google Scholar] [CrossRef]

- Xu, J.; Wang, W.; Han, Q. Mechanical properties of pultruded high-temperature-resistant carbon-fiber-reinforced polymer tendons at elevated temperatures. Constr. Build. Mater. 2020, 258, 119526. [Google Scholar] [CrossRef]

- Nguyen, P.L.; Vu, X.H.; Ferrier, E. Elevated temperature behaviour of carbon fibre-reinforced polymer applied by hand lay-up (M-CFRP) under simultaneous thermal and mechanical loadings: Experimental and analytical investigation. Fire Saf. J. 2018, 100, 103–117. [Google Scholar] [CrossRef]

- Mazzuca, P.; Firmo, J.P.; Correia, J.R. Influence of elevated temperatures on the mechanical properties of glass fibre reinforced polymer laminates produced by vacuum infusion. Constr. Build. Mater. 2022, 345, 128340. [Google Scholar] [CrossRef]

- Yu, B.; Kodur, V. Effect of temperature on strength and stiffness properties of near-surface mounted FRP reinforcement. Compos. Part B Eng. 2014, 58, 510–517. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Abu-obeidah, A.; Abdalla, J.A.; Al-Tamimi, A. Temperature effect on the mechanical properties of carbon, glass and carbon-glass FRP laminates. Constr. Build. Mater. 2015, 75, 342–348. [Google Scholar] [CrossRef]

- Li, T.; Zhu, H.; Shen, J.; Keller, T. Thermophysical and thermomechanical properties of basalt-phenolic FRP rebars under high temperature. Constr. Build. Mater. 2022, 342, 127983. [Google Scholar] [CrossRef]

- Wang, Y.C.; Wong PM, H.; Kodur, V. An experimental study of the mechanical properties of fibre reinforced polymer (FRP) and steel reinforcing bars at elevated temperatures. Compos. Struct. 2007, 80, 131–140. [Google Scholar] [CrossRef]

- Hamad RJ, A.; Megat Johari, M.A.; Haddad, R.H. Mechanical properties and bond characteristics of different fiber reinforced polymer rebars at elevated temperatures. Constr. Build. Mater. 2017, 142, 521–535. [Google Scholar] [CrossRef]

- Khaneghahi, M.H.; Najafabadi, E.P.; Shoaei, P.; Oskouei, A. Effect of intumescent paint coating on mechanical properties of FRP bars at elevated temperature. Polym. Test. 2018, 71, 72–86. [Google Scholar] [CrossRef]

- Cao, S.; Wu, Z.; Wang, X. Tensile properties of CFRP and hybrid FRP composites at elevated temperatures. J. Compos. Mater. 2009, 43, 315–330. [Google Scholar]

- Li, Z.; Jiang, Z.; Fang, Z. High-temperature axial tensile property and fire resisting performance of CFRP strand cable. Constr. Build. Mater. 2024, 421, 135746. [Google Scholar] [CrossRef]

- Swolfs, Y.; Verpoest, I.; Gorbatikh, L. A review of input data and modelling assumptions in longitudinal strength models for unidirectional fibre-reinforced composites. Compos. Struct. 2016, 150, 153–172. [Google Scholar] [CrossRef]

- Maierhofer, C.; Röllig, M.; Ehrig, K.; Meinel, D.; Céspedes-Gonzales, G. Validation of flash thermography using computed tomography for characterizing inhomogeneities and defects in CFRP structures. Compos. Part B Eng. 2014, 64, 175–186. [Google Scholar] [CrossRef]

- Swolfs, Y.; Verpoest, I.; Gorbatikh, L. Issues in strength models for unidirectional fibre-reinforced composites related to Weibull distributions, fibre packings and boundary effects. Compos. Sci. Technol. 2015, 114, 42–49. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Romanov, V.; Orlova, S.; Lomov, S.V.; Verpoest, I. Stress concentrations in an impregnated fibre bundle with random fibre packing. Compos. Sci. Technol. 2013, 74, 113–120. [Google Scholar] [CrossRef]

- Zong, Q. Research on Mechanical Behavior of Carbon Fiber Composite Laminates in Thermal Environment. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2020. (In Chinese). [Google Scholar]

- Zhang, Y.; Fang, Z.; Jiang, R. Static Performance of a Long-Span Concrete Cable-Stayed Bridge Subjected to Multiple-Cable Loss during Construction. J. Bridge Eng. 2020, 25, 04020002. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, C.; Yu, Y. Failure response of fiber-epoxy unidirectional laminate under transverse tensile/compressive loading using finite-volume micromechanics. Compos. Part B Eng. 2015, 79, 331–341. [Google Scholar] [CrossRef]

- Huang, F.; Pang, X.; Zhu, F.; Zhang, S.; Fan, Z.; Chen, X. Transverse mechanical properties of unidirectional FRP including resin-rich areas. Comput. Mater. Sci. 2021, 198, 110701. [Google Scholar] [CrossRef]

- Li, R.; Xu, Z.; Zou, X.; Hu, C.; He, X. A frictional cohesive zone model for characterizing transverse compression responses of unidirectional fiber-reinforced polymer composites. Mech. Adv. Mater. Struct. 2023, 30, 2164–2172. [Google Scholar] [CrossRef]

- Flores, M.; Sharits, A.; Wheeler, R.; Sesar, N.; Mollenhauer, D. Experimental analysis of polymer matrix composite microstructures under transverse compression loading. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106859. [Google Scholar] [CrossRef]

- Han, Q.; Wang, L.; Xu, J. Experimental research on mechanical properties of transverse enhanced and high-temperature-resistant CFRP tendons for prestressed structure. Constr. Build. Mater. 2015, 98, 864–874. [Google Scholar] [CrossRef]

- Zhu, M.; Meng, F.; Zhang, H.; Cui, Q. Fire tests on prestressed cable sockets. China J. Highw. Transp. 2020, 33, 111–119. (In Chinese) [Google Scholar]

- Rosa, I.C.; Firmo, J.P.; Correia, J.R. Experimental study of the tensile behaviour of GFRP reinforcing bars at elevated temperatures. Constr. Build. Mater. 2022, 324, 126676. [Google Scholar] [CrossRef]

- Wang, G.; Meng, Y.; Liu, R.; Liu, W. Study on fire resistance of steel cables. J. Builiding Struct. 2022, 11, 1–8. (In Chinese) [Google Scholar]

- Kodur VK, R.; Bhatt, P.P. A numerical approach for modeling response of fiber reinforced polymer strengthened concrete slabs exposed to fire. Compos. Struct. 2018, 187, 226–240. [Google Scholar] [CrossRef]

- Kodur VK, R.; Bhatt, P.P.; Naser, M.Z. High temperature properties of fiber reinforced polymers and fire insulation for fire resistance modeling of strengthened concrete structures. Compos. Part B Eng. 2019, 175, 107104. [Google Scholar] [CrossRef]

- Zhou, F. Study on Structural Behavior of CFRP Tendons under Fire Action. Ph.D. Thesis, Southeast University, Nanjing, China, 2019. (In Chinese). [Google Scholar]

- Liu, Z. Bond Behavior of CFRP Grids Reinforcement at Elevated Temperatures and Fire Resistance of CFRP Grids Strengthened RC Beams. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2019. (In Chinese). [Google Scholar]

- Du, Y.; Li, P.; Huang, L. Study on bonding strength of hot-cast anchors subject to elevated temperature. Structures 2022, 46, 1634–1656. [Google Scholar] [CrossRef]

- Prete, I.D.; Bilotta, A.; Bisby, L.; Nigro, E. Elevated temperature response of RC beams strengthened with NSM FRP bars bonded with cementitious grout. Compos. Struct. 2021, 258, 113182. [Google Scholar] [CrossRef]

- Dong, X.; Zeng, L.; Chu, D.; Sun, X.; Duan, J. Enhanced high temperature properties of overexposed FBG fabricated by femtosecond laser. Measurement 2022, 195, 111118. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, X.; Song, Y.; Dong, M.; Zhu, L. Characterization of a fiber Bragg grating in pure-silica-core and Ge-doped-core optical fiber under high-temperature strain. Meas. Sci. Technol. 2018, 29, 035102. [Google Scholar] [CrossRef]

- Ridge, I.; Hobbs, R. The behaviour of cast rope sockets at elevated temperatures. J. Struct. Fire Eng. 2012, 3, 155–168. [Google Scholar] [CrossRef]

- BS EN 13411-4:2011; Terminations for Steel Wire Ropes—Safety—Part 4: Metal and Resin Socketing. British Standards Institution: Milton Keynes, UK, 2011.

- Correia, L.; Barris, C.; França, P.; Sena-Cruz, J. Effect of temperature on bond behavior of externally bonded FRP laminates with mechanical end anchorage. J. Compos. Constr. 2019, 23, 04019036. [Google Scholar] [CrossRef]

- Liu, W.; Song, J.; Li, X. Research on fire resistance performance and new structure idea for long-span suspension bridge slings. China J. Highw. Transp. 2022, 35, 222–237. (In Chinese) [Google Scholar]

- Tan, H.; Qian, D.; Xu, Y.; Yuan, M.; Zhao, H. Analysis of Vertical Temperature Gradients and Their Effects on Hybrid Girder Cable-Stayed Bridges. Sustainability 2023, 15, 1053. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Qi, L.; Wang, A.; Liu, X.; Yue, Q. High-Temperature Resistance of Anchorage System for Carbon Fiber-Reinforced Polymer Composite Cable—A Review. Polymers 2024, 16, 1960. https://doi.org/10.3390/polym16141960

Liu Q, Qi L, Wang A, Liu X, Yue Q. High-Temperature Resistance of Anchorage System for Carbon Fiber-Reinforced Polymer Composite Cable—A Review. Polymers. 2024; 16(14):1960. https://doi.org/10.3390/polym16141960

Chicago/Turabian StyleLiu, Qian, Ligang Qi, Anni Wang, Xiaogang Liu, and Qingrui Yue. 2024. "High-Temperature Resistance of Anchorage System for Carbon Fiber-Reinforced Polymer Composite Cable—A Review" Polymers 16, no. 14: 1960. https://doi.org/10.3390/polym16141960

APA StyleLiu, Q., Qi, L., Wang, A., Liu, X., & Yue, Q. (2024). High-Temperature Resistance of Anchorage System for Carbon Fiber-Reinforced Polymer Composite Cable—A Review. Polymers, 16(14), 1960. https://doi.org/10.3390/polym16141960