Nucleation, Development and Healing of Micro-Cracks in Shape Memory Polyurethane Subjected to Subsequent Tension Cycles

Abstract

1. Introduction

2. Materials and Methods

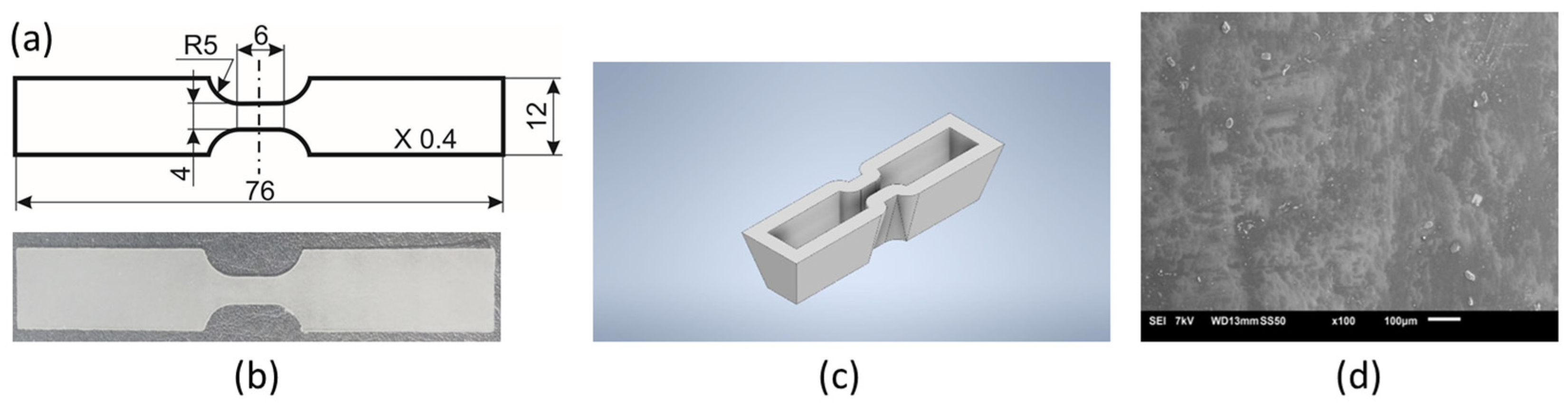

2.1. Materials and Specimens

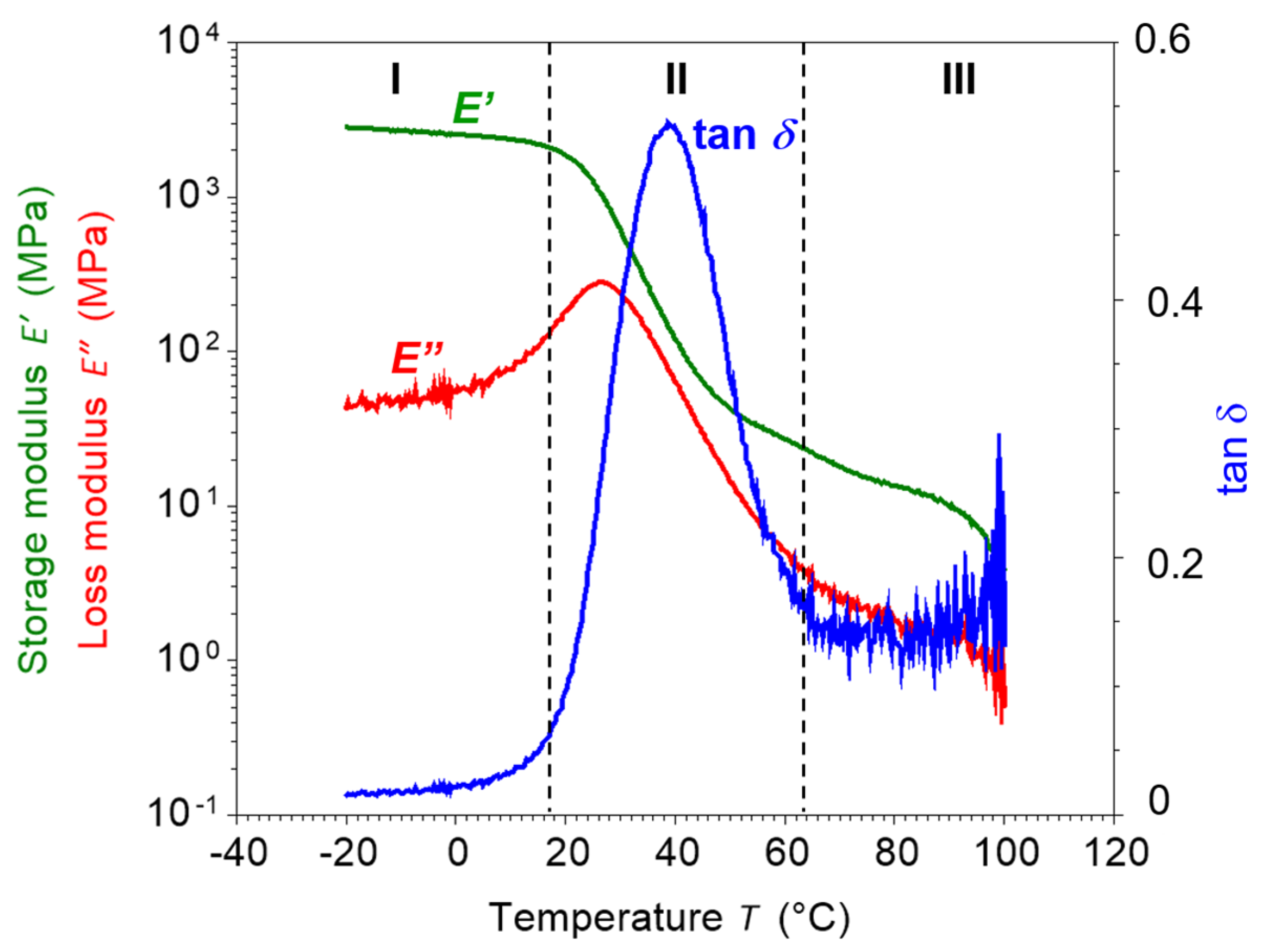

2.2. Dynamic Mechanical Analysis (DMA)

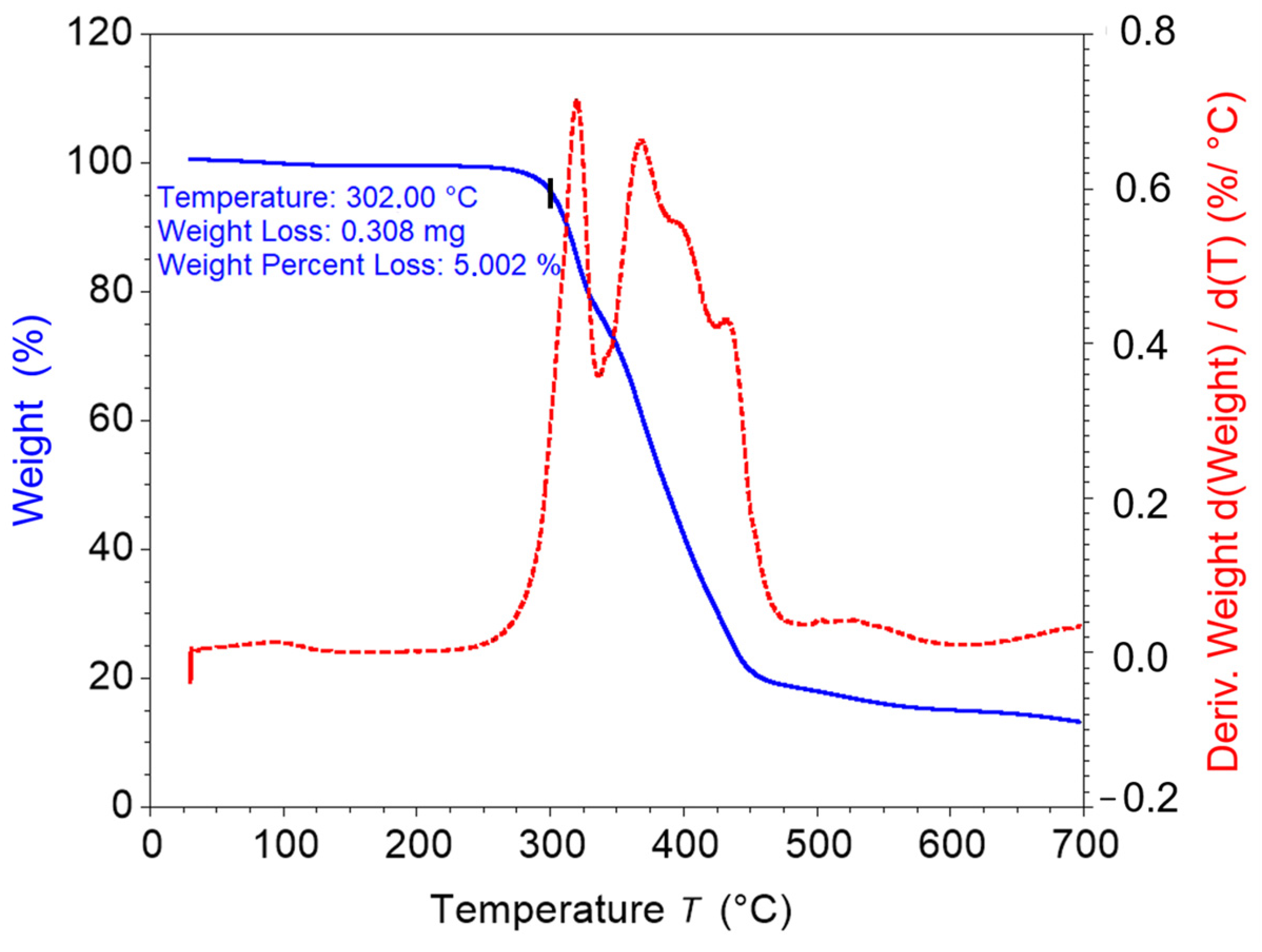

2.3. Thermogravimetric Analysis (TGA)

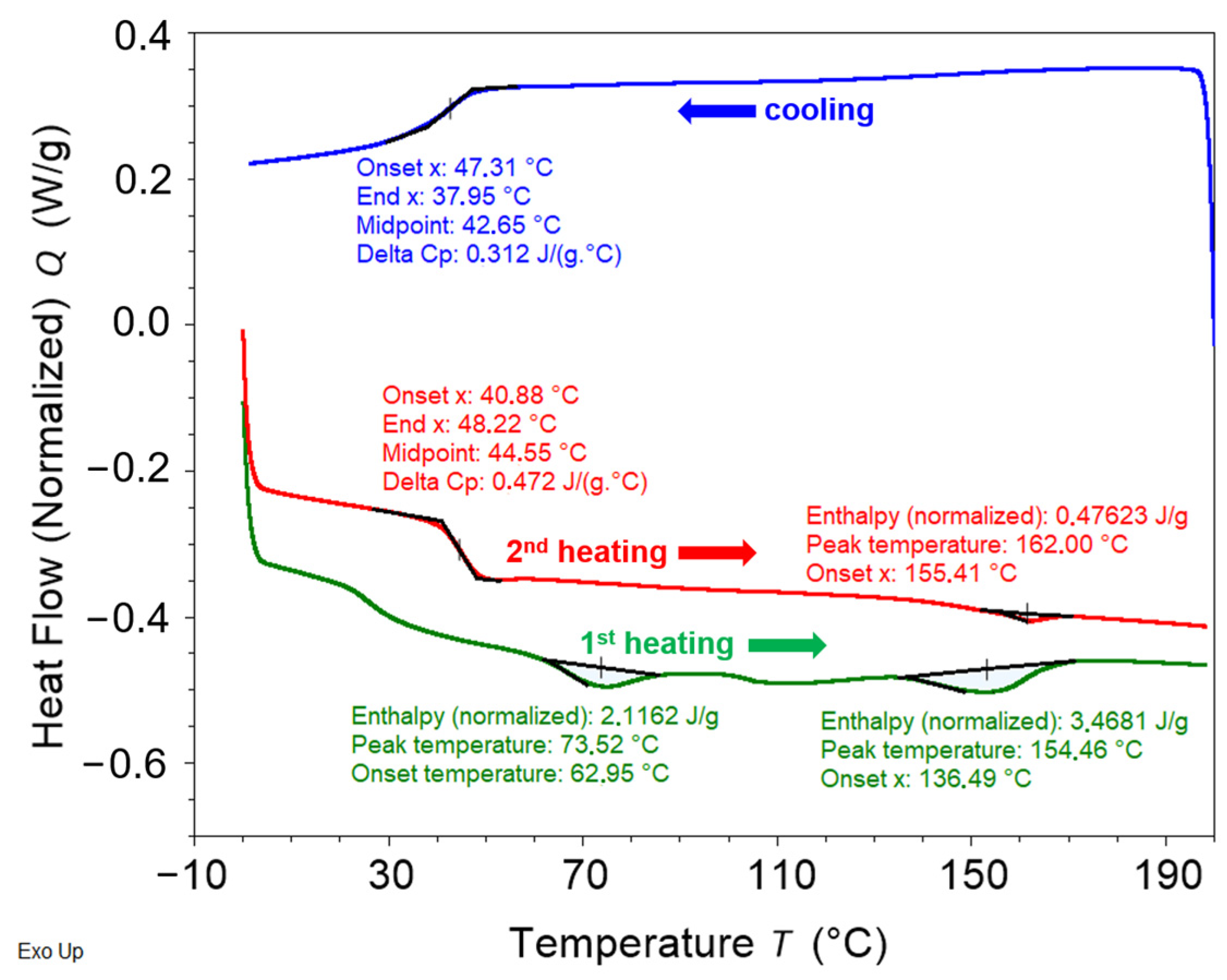

2.4. Differential Scanning Calorimetry (DSC)

2.5. Investigation of Mechanical Properties

2.6. Investigation of Shape Memory Properties in the Thermomechanical Loading Program

2.7. Scanning Electron Microscopy (SEM)

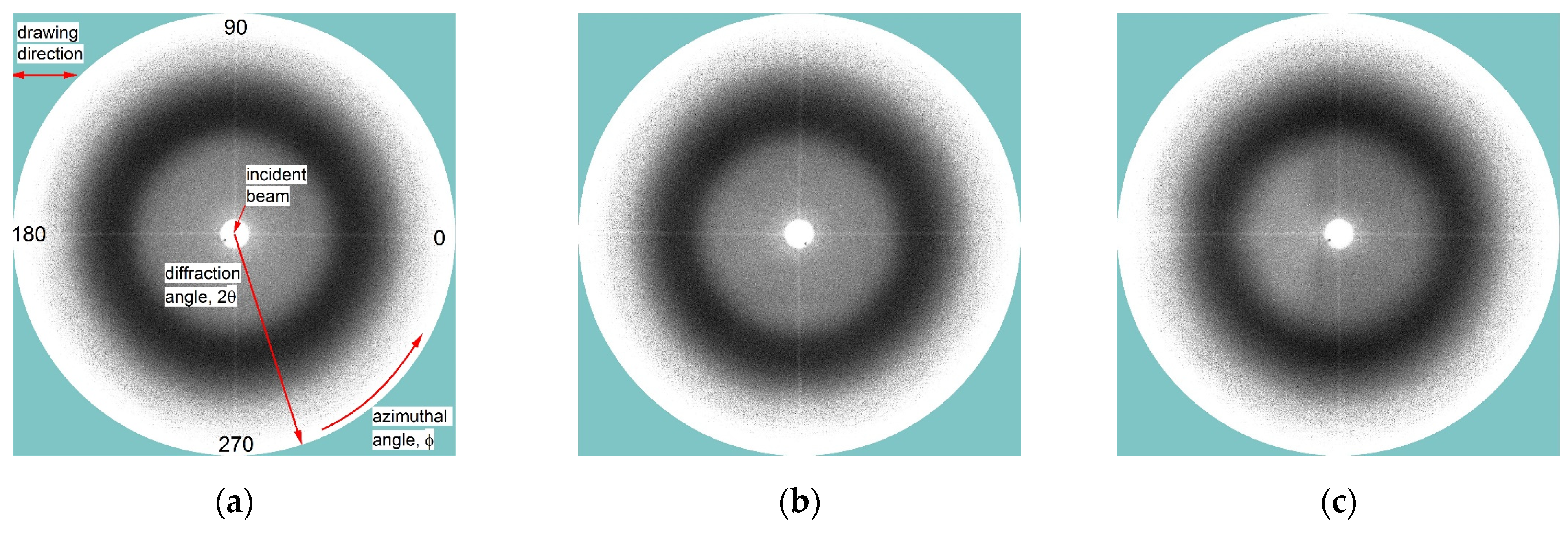

2.8. Wide-Angle X-ray Scattering (WAXS)

3. Results and Discussion

3.1. Structural and Thermal Characterization Results

3.1.1. Dynamic Mechanical Analysis Results

3.1.2. Thermogravimetric Analysis Results

3.1.3. Differential Scanning Calorimetry (DSC) Results

3.2. Results and Analysis of Mechanical Characteristics of the PU–SMP with Tg = 45 °C

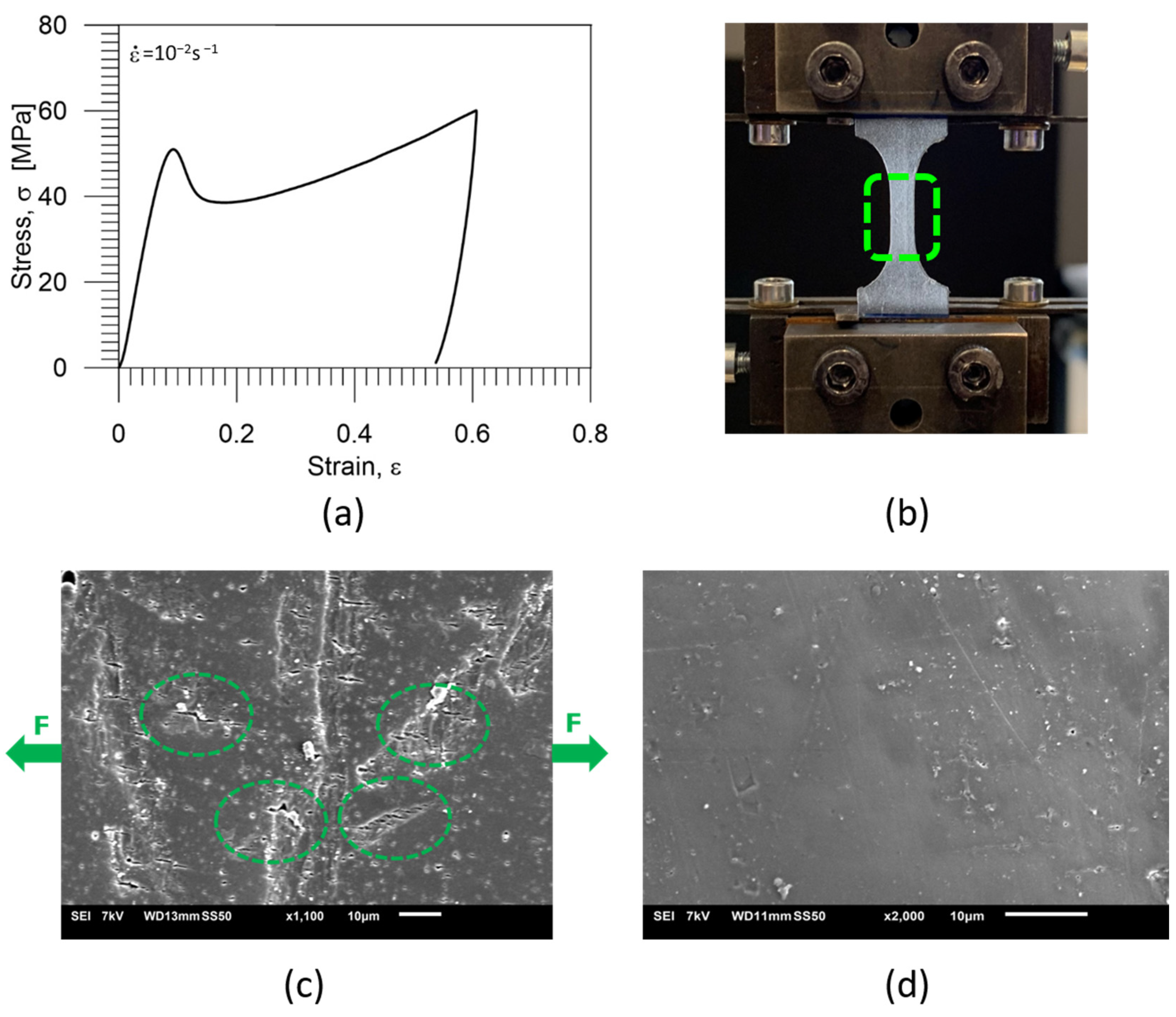

3.2.1. Mechanical Behavior of PU–SMP during Tension until Rupture

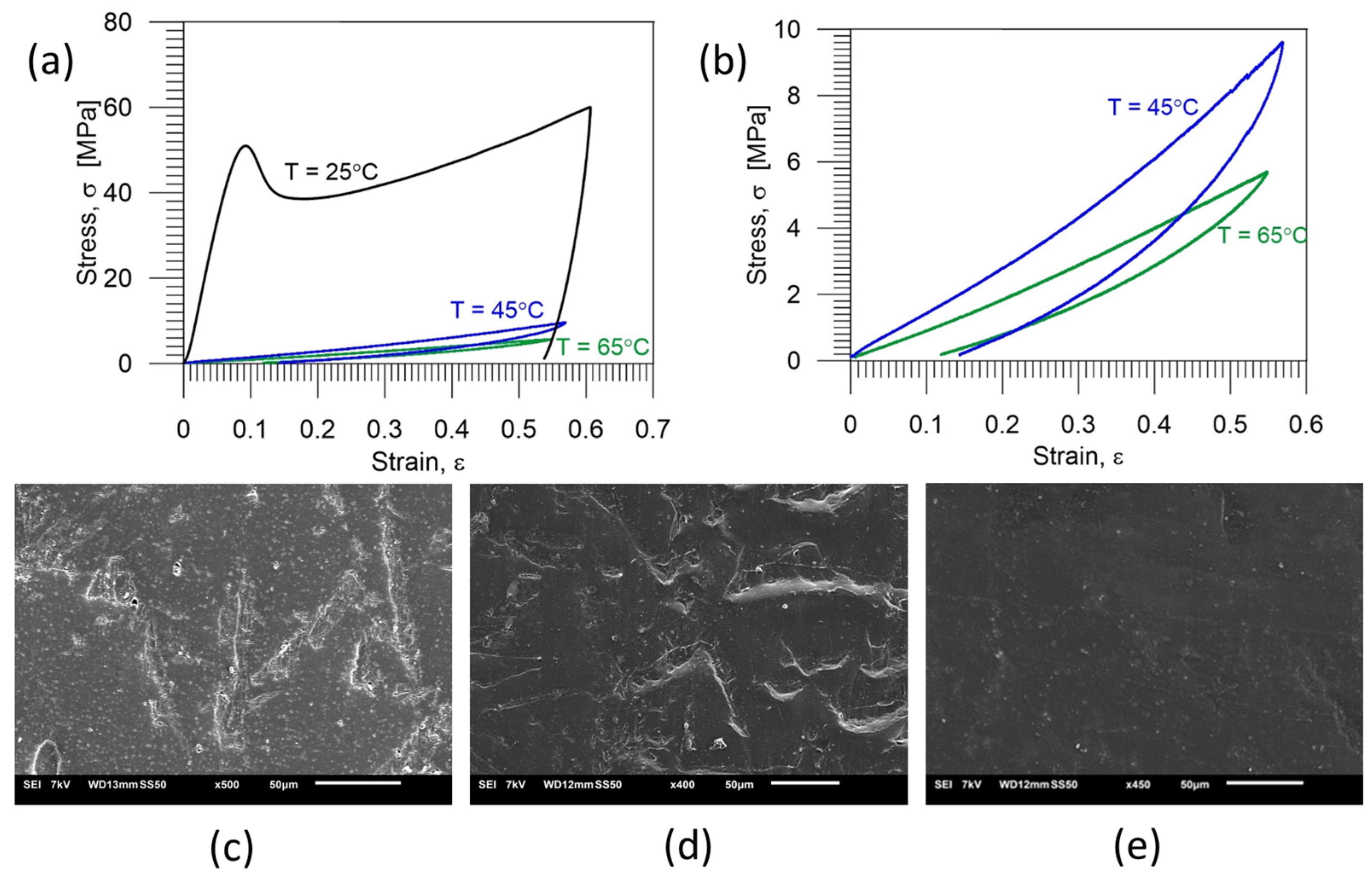

3.2.2. Mechanical Characteristics of the PU-SMP with Tg = 45 °C Subjected to Tension at Various Temperatures in the Strain Range of 60%

3.3. Investigation of PU-SMP Shape Memory Properties

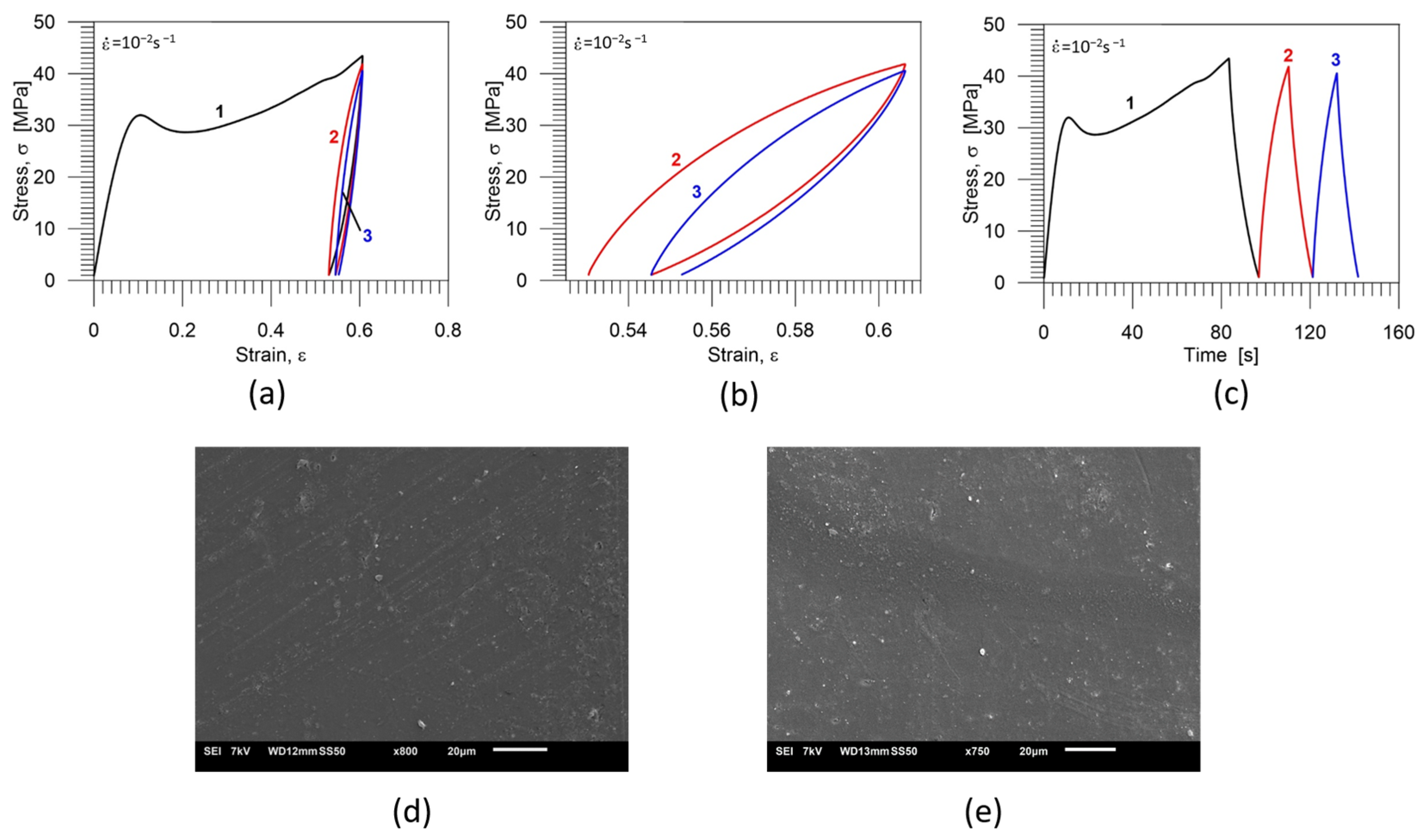

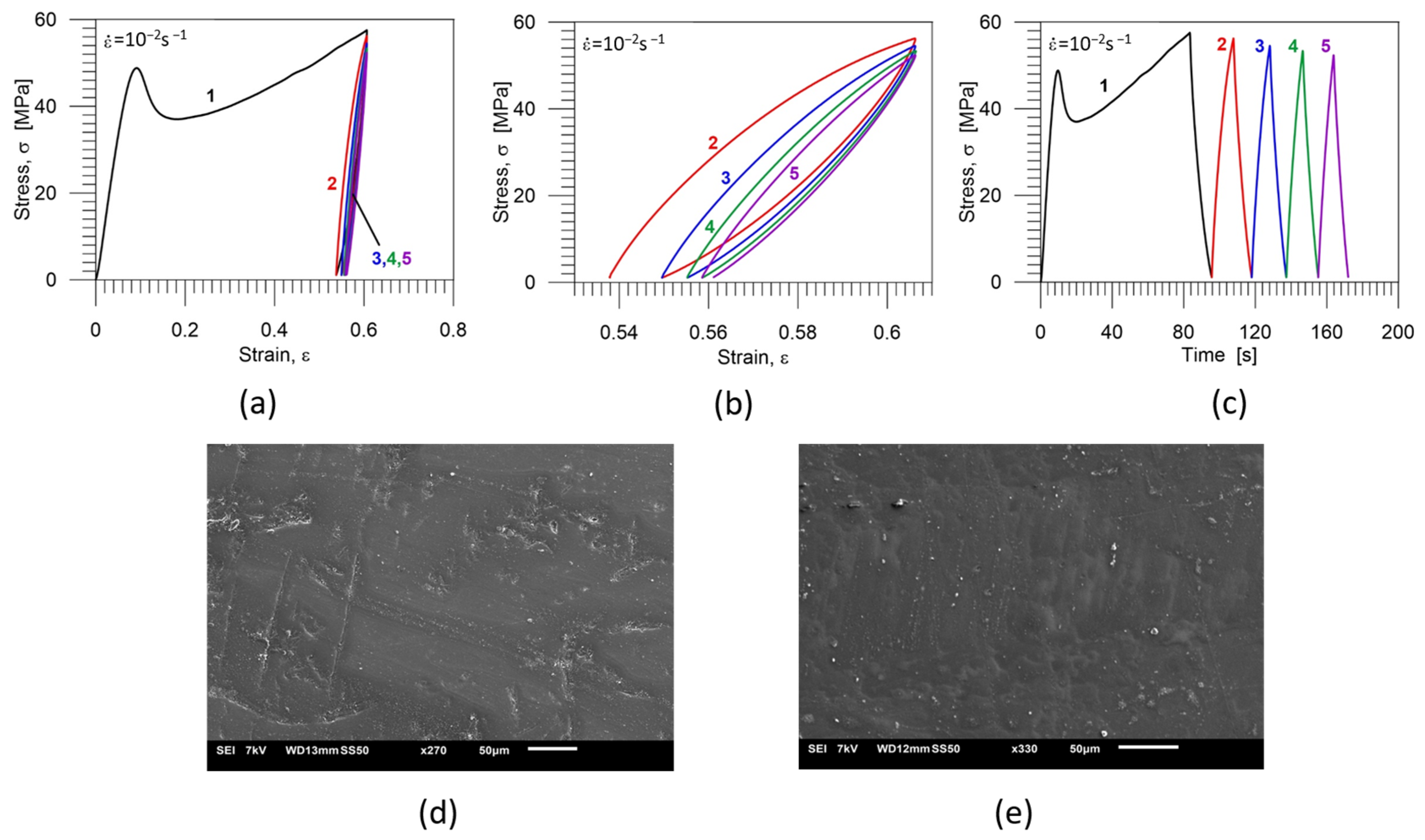

3.4. Cyclic Loading—Mechanical and SEM Results

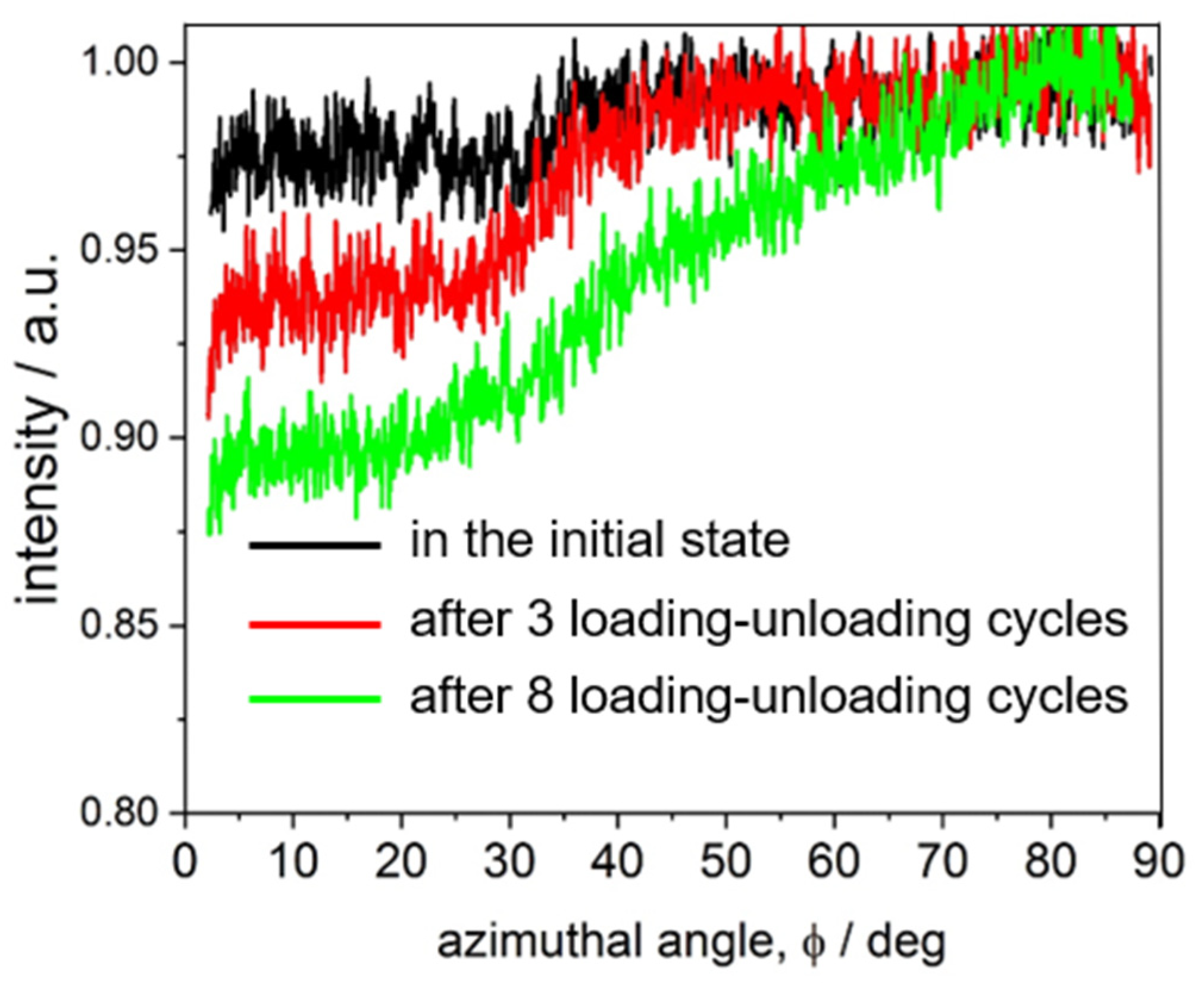

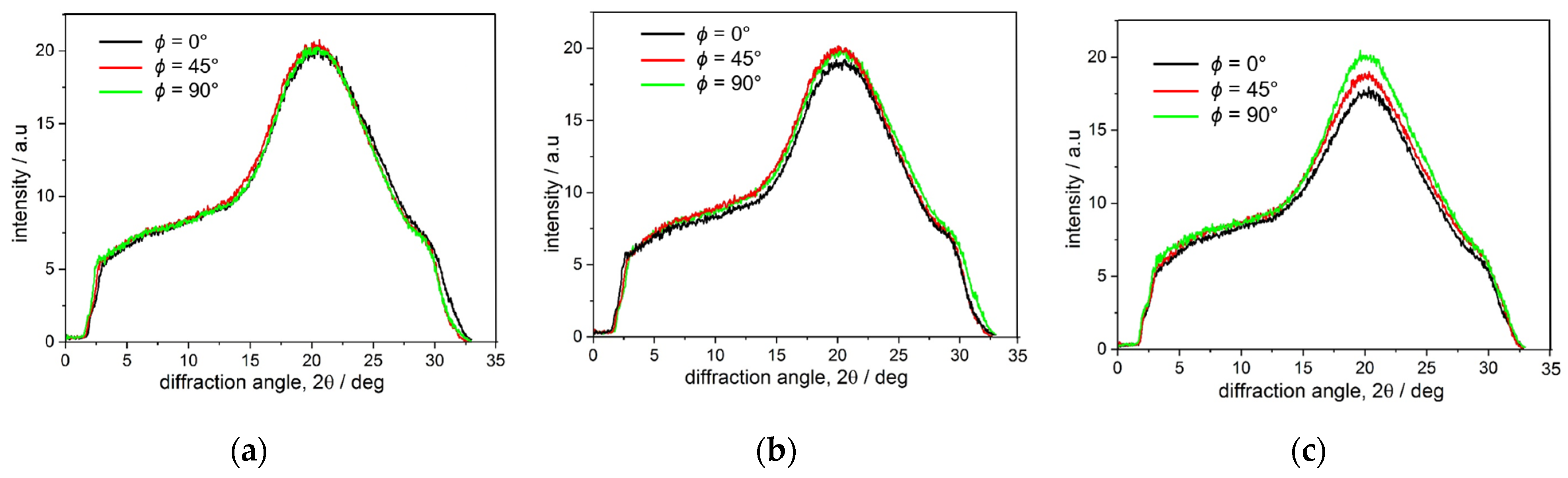

Cyclic Loading—Mechanical and Wide-Angle X-ray Scattering Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lendlein, A.; Kelch, S. Shape-memory polymers. Angew. Chem. Int. Ed. 2002, 41, 2034–2057. Available online: https://onlinelibrary.wiley.com/doi/10.1002/1521-3773(20020617)41:12%3C2034::AID-ANIE2034%3E3.0.CO;2-M (accessed on 12 June 2002). [CrossRef]

- Hager, M.D.; Bode, S.; Weber, C.; Schubert, U.S. Shape memory polymers: Past, present and future developments. Prog. Polym. Sci. 2015, 49, 3–33. [Google Scholar] [CrossRef]

- Zhao, W.; Li, N.; Liu, L.; Leng, J.; Liu, Y. Mechanical behaviors and applications of shape memory polymer and its composites. Appl. Phys. Rev. 2023, 10, 011306. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Filippova, O.V.; Tcherdyntsev, V.V.; Telyshev, D.V. Shape Memory Polymers as Smart Materials: A Review. Polymers 2022, 14, 3511. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Pahlavani, M.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Shape memory performance assessment of FDM 3D printed PLA-TPU composites by Box-Behnken response surface methodology. Int. J. Adv. Manuf. Technol. 2023, 127, 935–950. [Google Scholar] [CrossRef]

- Tobushi, H.; Hayashi, S.; Hoshio, K.; Ejiri, Y. Shape recovery and irrecoverable strain control in polyurethane shape-memory polymer. Sci. Technol. Adv. Mater. 2008, 9, 015009. [Google Scholar] [CrossRef]

- Salaeh, S.; Nobnop, S.; Thongnuanchan, B.; Das, A.; Wießner, S. Thermo-responsive programmable shape memory polymer based on amidation cured natural rubber grafted with poly(methyl methacrylate). Polymer 2022, 262, 125444. [Google Scholar] [CrossRef]

- Staszczak, M.; Nabavian Kalat, M.; Golasiński, K.M.; Urbański, L.; Takeda, K.; Matsui, R.; Pieczyska, E.A. Characterization of polyurethane shape memory polymer and determination of shape fixity and shape recovery in subsequent thermomechanical cycles. Polymers 2022, 14, 4775. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, D.; Luo, X.; Zhou, J.; Zheng, J.; Lai, C. Preparation and characterization of thermo-responsive shape memory polycaprolactone/poly(ethylene-co-octene) blends for 4D printing. Polym. Eng. Sci. 2023, 63, 2828–2840. [Google Scholar] [CrossRef]

- Jiang, H.Y.; Kelch, S.; Lendlein, A. Polymers move in response to light. Adv. Mater. 2006, 18, 1471–1476. [Google Scholar] [CrossRef]

- Lendlein, A.; Jiang, H.Y.; Jünger, O.; Langer, R. Light-induced shape-memory polymers. Nature 2005, 434, 879–882. [Google Scholar] [CrossRef] [PubMed]

- Herath, M.; Epaarachchi, J.; Islam, M.; Fang, L.; Leng, J. Light activated shape memory polymers and composites: A review. Eur. Polym. J. 2020, 136, 109912. [Google Scholar] [CrossRef]

- Chen, S.; Hu, J.; Yuen, C.; Chan, L. Novel moisture-sensitive shape memory polyurethanes containing pyridine moieties. Polymer 2009, 50, 4424–4428. [Google Scholar] [CrossRef]

- Ge, Y.; Wang, H.; Xue, J.; Jiang, J.; Liu, Z.; Liu, Z.; Li, G.; Zhao, Y. Programmable Humidity-Responsive Actuation of Polymer Films Enabled by Combining Shape Memory Property and Surface-Tunable Hygroscopicity. ACS Appl. Mater. Interfaces 2021, 13, 38773–38782. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Wu, Y.; Wu, J.; Yang, P.; Zhang, Y.; Zhao, W.; Zhang, X.; Cui, Z.; Fu, P.; Pang, X.; et al. Electro-induced two-way shape memory thermoplastic polyamide elastomer/carbon nanotubes composites. J. Mater. Res. Technol. 2024, 29, 2062–2071. [Google Scholar] [CrossRef]

- Ze, Q.; Kuang, X.; Wu, S.; Wong, J.; Montgomery, S.M.; Zhang, R.; Kovitz, J.M.; Yang, F.; Qi, H.J.; Zhao, R. Magnetic shape memory polymers with integrated multifunctional shape manipulation. Adv. Mater. 2019, 32, 1906657. [Google Scholar] [CrossRef]

- van Vilsteren, S.J.M.; Yarmand, H.; Ghodrat, S. Review of Magnetic Shape Memory Polymers and Magnetic Soft Materials. Magnetochemistry 2021, 7, 123. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. 4D printing of porous PLA-TPU structures: Effect of applied deformation, loading mode and infill pattern on the shape memory performance. Phys. Scr. 2024, 99, 025013. [Google Scholar] [CrossRef]

- Liu, Y.; Du, H.; Liu, L.; Leng, J. Shape memory polymers and their composites in aerospace applications: A review. Smart Mater. Struct. 2014, 23, 023001. [Google Scholar] [CrossRef]

- Jape, S.; Garza, M.; Ruff, J.; Espinal, F.; Sessions, D.; Huff, G.; Lagoudas, D.C.; Peraza Hernandez, E.A.; Hart, D.J. Self-foldable origami reflector antenna enabled by shape memory polymer actuation. Smart Mater. Struct. 2020, 29, 115011. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A review of shape memory polymers and composites: Mechanisms, materials, and applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef]

- Azzawi, W.A. Development and performance evaluation of a morphing wing design using shape memory polymer and composite corrugated structure. Aust. J. Mech. Eng. 2024, 22, 12–26. [Google Scholar] [CrossRef]

- Nabavian Kalat, M.; Staszczak, M.; Urbański, L.; Fernandez, C.; Vega, C.; Cristea, M.; Ionita, D.; Lantada, A.; Pieczyska, E.A. Investigating a shape memory epoxy resin and its application to engineering shape-morphing devices empowered through kinematic chains and compliant joints. Mater. Des. 2023, 233, 112263. [Google Scholar] [CrossRef]

- Pfau, M.R.; Grunlan, M.A. Smart scaffolds: Shape memory polymers (SMPs) in tissue engineering. J. Mater. Chem. B 2021, 9, 4287–4297. [Google Scholar] [CrossRef]

- Suzuki, Y.; Hu, Q.; Batchelor, B.; Voit, W.; Ecker, M. Thermo/hydration responsive shape memory polymers with enhanced hydrophilicity for biomedical applications. Smart Mater. Struct. 2023, 32, 015006. [Google Scholar] [CrossRef]

- Pieczyska, E.A.; Staszczak, M.; Maj, M.; Kowalczyk-Gajewska, K.; Golasiński, K.; Cristea, M.; Tobushi, H.; Hayashi, S. Investigation of thermomechanical couplings, strain localization and shape memory properties in a shape memory polymer subjected to loading at various strain rates. Smart Mater. Struct. 2016, 25, 085002. [Google Scholar] [CrossRef]

- Hayashi, S.; Kondo, S.; Kapadia, P.; Ushioda, E. Room-temperature-functional shape-memory polymers. Plast. Eng. 1995, 51, 29–31. [Google Scholar]

- Huang, W.M.; Yang, B.; Fu, Y.Q. Polyurethane Shape Memory Polymers, 1st ed.; CRC Press: Bosa Raton, FL, USA; Taylor & Francis: Abingdon, UK, 2012. [Google Scholar]

- Pieczyska, E.A.; Kowalczyk-Gajewska, K.; Maj, M.; Staszczak, M.; Tobushi, H. Thermomechanical investigation of TiNi shape memory alloy and PU shape memory polymer subjected to cyclic loading. Procedia Eng. 2014, 74, 287–292. [Google Scholar] [CrossRef]

- Mondal, S. Temperature responsive shape memory polyurethanes. Polym.-Plast. Technol. Mater. 2021, 60, 1491–1518. [Google Scholar] [CrossRef]

- Staszczak, M.; Urbański, L.; Cristea, M.; Ionita, D.; Pieczyska, E.A. Investigation of Shape Memory Polyurethane Properties in Cold Programming Process Towards Its Applications. Polymers 2024, 16, 219. [Google Scholar] [CrossRef]

- Sanaka, R.; Sahu, S.K. Experimental investigation into mechanical, thermal, and shape memory behavior of thermoresponsive PU/MXene shape memory polymer nanocomposite. Heliyon 2024, 10, e24014. [Google Scholar] [CrossRef] [PubMed]

- Pieczyska, E.A.; Maj, M.; Kowalczyk-Gajewska, K.; Staszczak, M.; Gradys, A.; Majewski, M.; Cristea, M.; Tobushi, H.; Hayashi, S. Thermomechanical properties of polyurethane shape memory polymer–experiment and modelling. Smart Mater. Struct. 2015, 24, 045043. [Google Scholar] [CrossRef]

- Pieczyska, E.A.; Staszczak, M.; Kowalczyk-Gajewska, K.; Maj, M.; Golasiński, K.; Golba, S.; Tobushi, H.; Hayashi, S. Experimental and numerical investigation of yielding phenomena in a shape memory polymer subjected to cyclic tension at various strain rates. Polym. Test. 2017, 60, 333–342. [Google Scholar] [CrossRef]

- Qi, H.J.; Boyce, M.C. Stress–strain behavior of thermoplastic polyurethanes. Mech. Mater. 2005, 37, 817–839. [Google Scholar] [CrossRef]

- Scetta, G.; Ju, J.; Selles, N.; Heuillet, P.; Ciccotti, M.; Creton, C. Strain induced strengthening of soft thermoplastic polyurethanes under cyclic deformation. J. Polym. Sci. 2021, 59, 685–696. [Google Scholar] [CrossRef]

- Thakur, S.; Jahid, M.A.; Hu, J.L. Mechanically strong shape memory polyurethane for water vapour permeable membranes. Polym. Int. 2018, 67, 1386–1392. [Google Scholar] [CrossRef]

- Guan, X.; Xia, H.; Ni, Q.-Q. Shape memory polyurethane-based electrospun yarns for thermo-responsive actuation. J. Appl. Polym. Sci. 2021, 138, 50565. [Google Scholar] [CrossRef]

- Zeng, B.; Li, Y.; Wang, L.; Zheng, Y.; Shen, J.; Guo, S. Body temperature-triggered shape-memory effect via toughening sustainable poly(propylene carbonate) with thermoplastic polyurethane: Toward potential application of biomedical stents. ACS Sustainable Chem. Eng. 2020, 8, 1538–1547. [Google Scholar] [CrossRef]

- Pringpromsuk, S.; Xia, H.; Ni, Q.-Q. Multifunctional stimuli-responsive shape memory polyurethane gels for soft actuators. Sens. Actuators A Phys. 2020, 313, 112207. [Google Scholar] [CrossRef]

- Awaja, F.; Zhang, S.; Tripathi, M.; Nikiforov, A.; Pugno, N. Cracks, microcracks and fracture in polymer structures: Formation, detection, autonomic repair. Prog. Mater. Sci. 2016, 83, 536–573. [Google Scholar] [CrossRef]

- Almutairi, M.D.; He, F.; Alshammari, Y.L.; Alnahdi, S.S.; Khan, M.A. Analysis of the Self-Healing Capability of Thermoplastic Elastomer Capsules in a Polymeric Beam Structure Based on Strain Energy Release Behaviour during Crack Growth. Polymers 2023, 15, 3384. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Li, G. Advances in healing-on-demand polymers and polymer composites. Prog. Polym. Sci. 2016, 57, 32–63. [Google Scholar] [CrossRef]

- Caruso, M.M.; Davis, D.A.; Shen, Q.; Odom, S.A.; Sottos, N.R.; White, S.R.; Moore, J.S. Mechanically-Induced Chemical Changes in Polymeric Materials. Chem. Rev. 2009, 109, 5755–5798. [Google Scholar] [CrossRef] [PubMed]

- Hayes, S.A.; Jones, F.R.; Marshiya, K.; Zhang, W. A self-healing thermosetting composite material. Compos. A Appl. Sci. Manuf. 2007, 38, 1116–1120. [Google Scholar] [CrossRef]

- Boiko, Y.M. On the molecular mechanism of self-healing of glassy polymers. Colloid Polym. Sci. 2016, 294, 1237–1242. [Google Scholar] [CrossRef]

- Irzhak, V.I.; Uflyand, I.E.; Dzhardimalieva, G.I. Self-Healing of Polymers and Polymer Composites. Polymers 2022, 14, 5404. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wudl, F.; Mal, A.K.; Shen, H.; Nutt, S.R. New thermally remendable highly cross-linked polymeric materials. Macromolecules 2003, 36, 1802–1807. [Google Scholar] [CrossRef]

- Kim, S.-M.; Jeon, H.; Shin, S.-H.; Park, S.-A.; Jegal, J.; Hwang, S.Y.; Oh, D.X.; Park, J. Superior Toughness and Fast Self-Healing at Room Temperature Engineered by Transparent Elastomers. Adv. Mater. 2018, 30, 1870001. [Google Scholar] [CrossRef]

- Deng, X.-Y.; Xie, H.; Du, L.; Fan, C.-J.; Cheng, C.-Y.; Yang, K.-K.; Wang, Y.-Z. Polyurethane Networks Based on Disulfide Bonds: From Tunable Multi-Shape Memory Effects to Simultaneous Self-Healing. Sci. China Mater. 2019, 62, 437–447. [Google Scholar] [CrossRef]

- Li, G.; Ajisafe, O.; Meng, H. Effect of strain hardening of shape memory polymer fibers on healing efficiency of thermosetting polymer composites. Polymer 2013, 54, 920–928. [Google Scholar] [CrossRef]

- Ayres, E.; Orefice, R.L.; Yoshida, M.I. Phase morphology of hydrolysable polyurethanes derived from aqueous dispersions. Eur. Polym. J. 2007, 43, 3510–3521. [Google Scholar] [CrossRef]

- Chen, S.; Yuan, H.; Zhuo, H.; Chen, S.; Yang, H.; Ge, Z.; Liu, J. Development of liquid-crystalline shape-memory polyurethane composites based on polyurethane with semi-crystalline reversible phase and hexadecyloxybenzoic acid for self-healing applications. J. Mater. Chem. C 2014, 2, 4203–4212. [Google Scholar] [CrossRef]

- Kim, B.K.; Lee, S.J.; Xu, M. Polyurethanes having shape memory effects. Polymer 1996, 37, 5781–5793. [Google Scholar] [CrossRef]

- Xie, F.; Zhang, T.; Bryant, P.; Kurusingal, V.; Colwell, J.M.; Laycock, B. Degradation and stabilization of polyurethane elastomers. Prog. Polym. Sci. 2019, 90, 211–268. [Google Scholar] [CrossRef]

- Król, P. Synthesis methods, chemical structures and phase structures of linear polyurethanes. Properties and applications of linear polyurethanes in polyurethane elastomers, copolymers and ionomers. Prog. Mat. Sci. 2007, 52, 915–1015. [Google Scholar] [CrossRef]

- Pawlak, A.; Galeski, A.; Rozanski, A. Cavitation during deformation of semicrystalline polymers. Prog. Polym. Sci. 2014, 39, 921–958. [Google Scholar] [CrossRef]

- Tobushi, H.; Hashimoto, T.; Ito, N.; Hayashi, S.; Yamada, E. Shape fixity and shape recovery in a film of shape memory polymer of polyurethane series. J. Intell. Mater. Syst. Struct. 1998, 9, 127–136. [Google Scholar] [CrossRef]

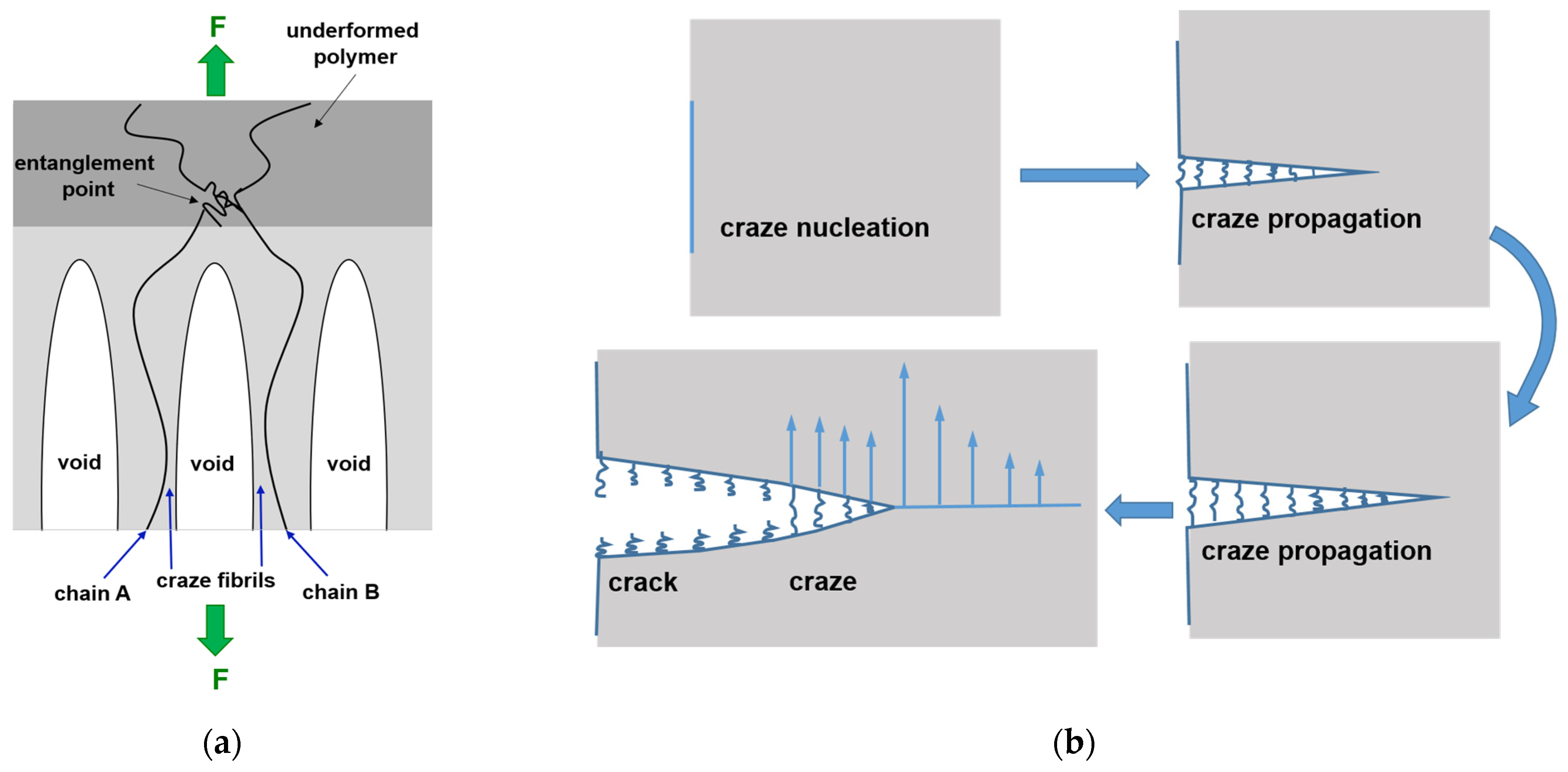

- Donald, A.M. Crazing. In The Physics of Glassy Polymers, 2nd ed.; Haward, R.N., Young, R.J., Eds.; Chapman & Hall: London, UK, 1997; pp. 295–341. [Google Scholar]

- Alexander, L.E. X-ray Diffraction Methods in Polymer Science; Wiley-Interscience: New York, NY, USA, 1969. [Google Scholar]

- Alhazov, D.; Gradys, A.; Sajkiewicz, P.; Arinstein, A.; Zussman, E. Thermo-mechanical behaviour of electrospun thermo-plastic polyurethane nanofibers. Eur. Polym. J. 2013, 49, 3851–3856. [Google Scholar] [CrossRef]

| E′g, MPa | E′r, MPa | E′g/E′r | Tg as tan δ Peak, °C |

|---|---|---|---|

| 2550.0 | 25.6 | 99.6 | 38.8 |

| Loading Temperature, °C | Young’s Modulus, MPa | Yield Strength, MPa | Stress at Maximum Strain, MPa |

|---|---|---|---|

| 25 | 718.81 | 50.73 | 58.97 |

| 45 | 13.35 | - | 9.59 |

| 65 | 8.94 | - | 5.67 |

| Specimen | Shape Fixity Rf, % | Shape Recovery Rr, % |

|---|---|---|

| 1 | 98.75 | 93.34 |

| 2 | 98.62 | 91.64 |

| 3 | 98.63 | 90.96 |

| 4 | 98.64 | 92.32 |

| Average | 98.63 ± 0.01 | 92.06 ± 1.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Staszczak, M.; Urbański, L.; Gradys, A.; Cristea, M.; Pieczyska, E.A. Nucleation, Development and Healing of Micro-Cracks in Shape Memory Polyurethane Subjected to Subsequent Tension Cycles. Polymers 2024, 16, 1930. https://doi.org/10.3390/polym16131930

Staszczak M, Urbański L, Gradys A, Cristea M, Pieczyska EA. Nucleation, Development and Healing of Micro-Cracks in Shape Memory Polyurethane Subjected to Subsequent Tension Cycles. Polymers. 2024; 16(13):1930. https://doi.org/10.3390/polym16131930

Chicago/Turabian StyleStaszczak, Maria, Leszek Urbański, Arkadiusz Gradys, Mariana Cristea, and Elżbieta Alicja Pieczyska. 2024. "Nucleation, Development and Healing of Micro-Cracks in Shape Memory Polyurethane Subjected to Subsequent Tension Cycles" Polymers 16, no. 13: 1930. https://doi.org/10.3390/polym16131930

APA StyleStaszczak, M., Urbański, L., Gradys, A., Cristea, M., & Pieczyska, E. A. (2024). Nucleation, Development and Healing of Micro-Cracks in Shape Memory Polyurethane Subjected to Subsequent Tension Cycles. Polymers, 16(13), 1930. https://doi.org/10.3390/polym16131930