Toughness Evolution of Flax-Fiber-Reinforced Composites under Repeated Salt Fog–Dry Aging Cycles

Abstract

1. Introduction

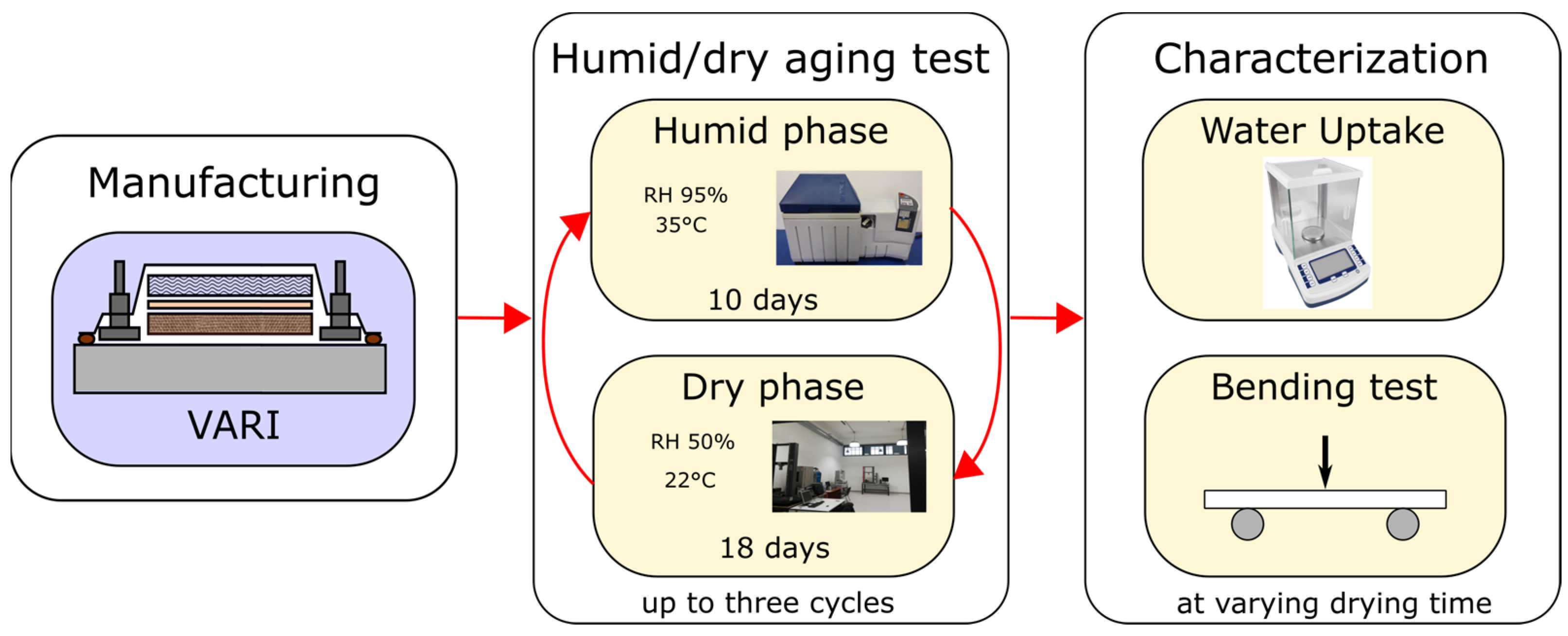

2. Experimental

2.1. Materials and Methods

2.2. Salt Fog/Dry Aging Phases

2.3. Water Changes

2.4. Quasi-Static Three-Point Bending Tests

3. Results and Discussion

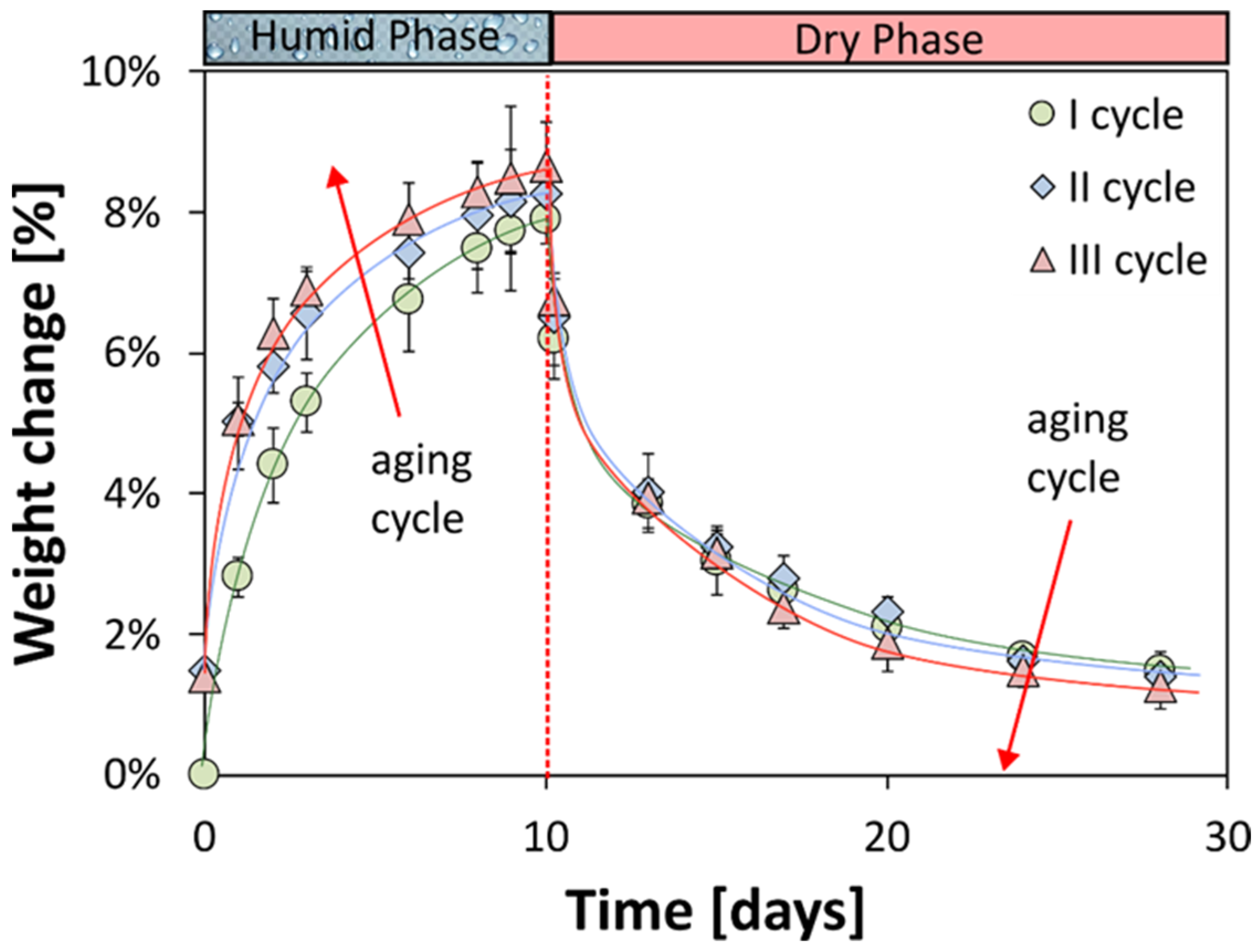

3.1. Water Uptake Measurements

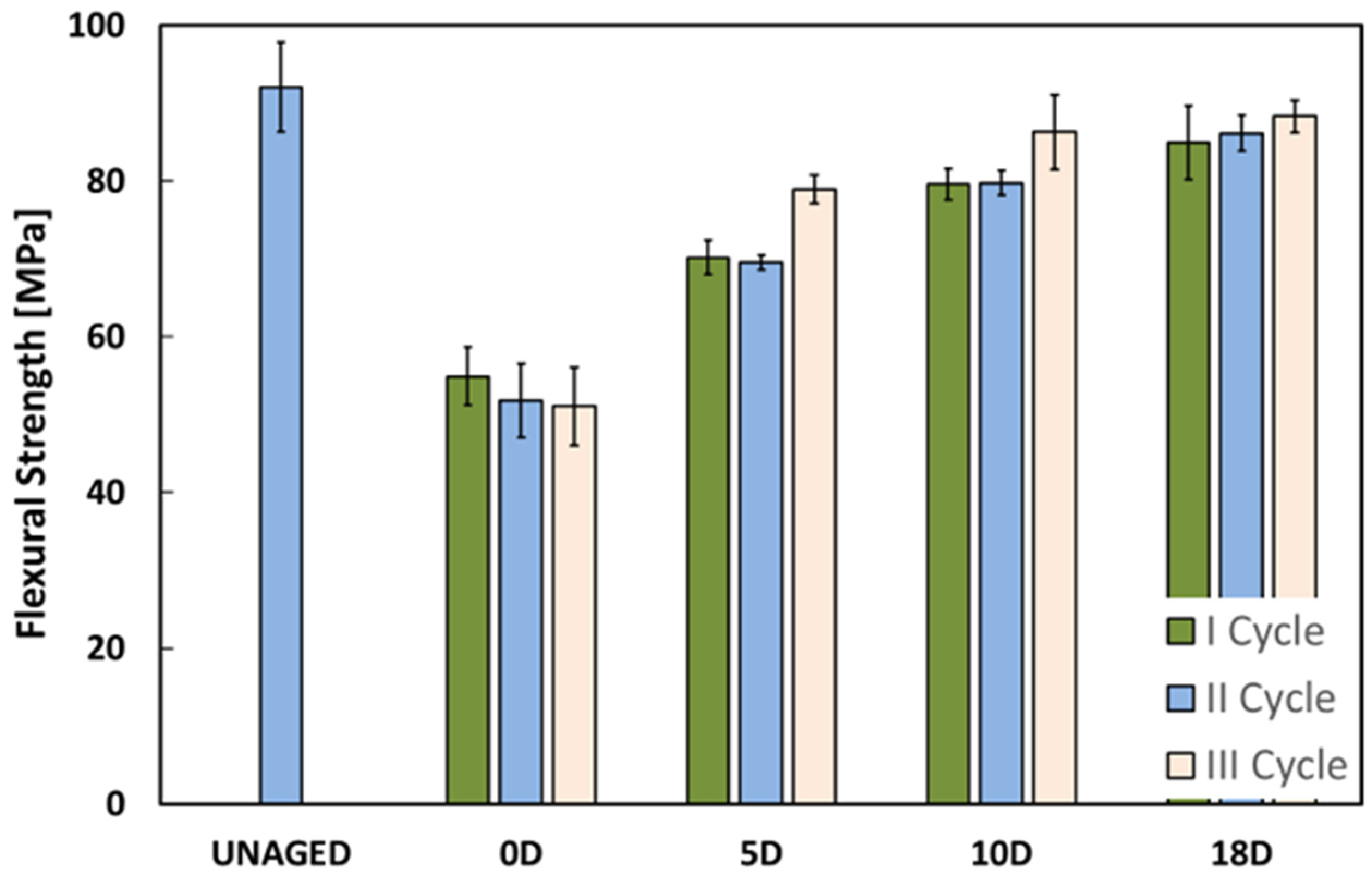

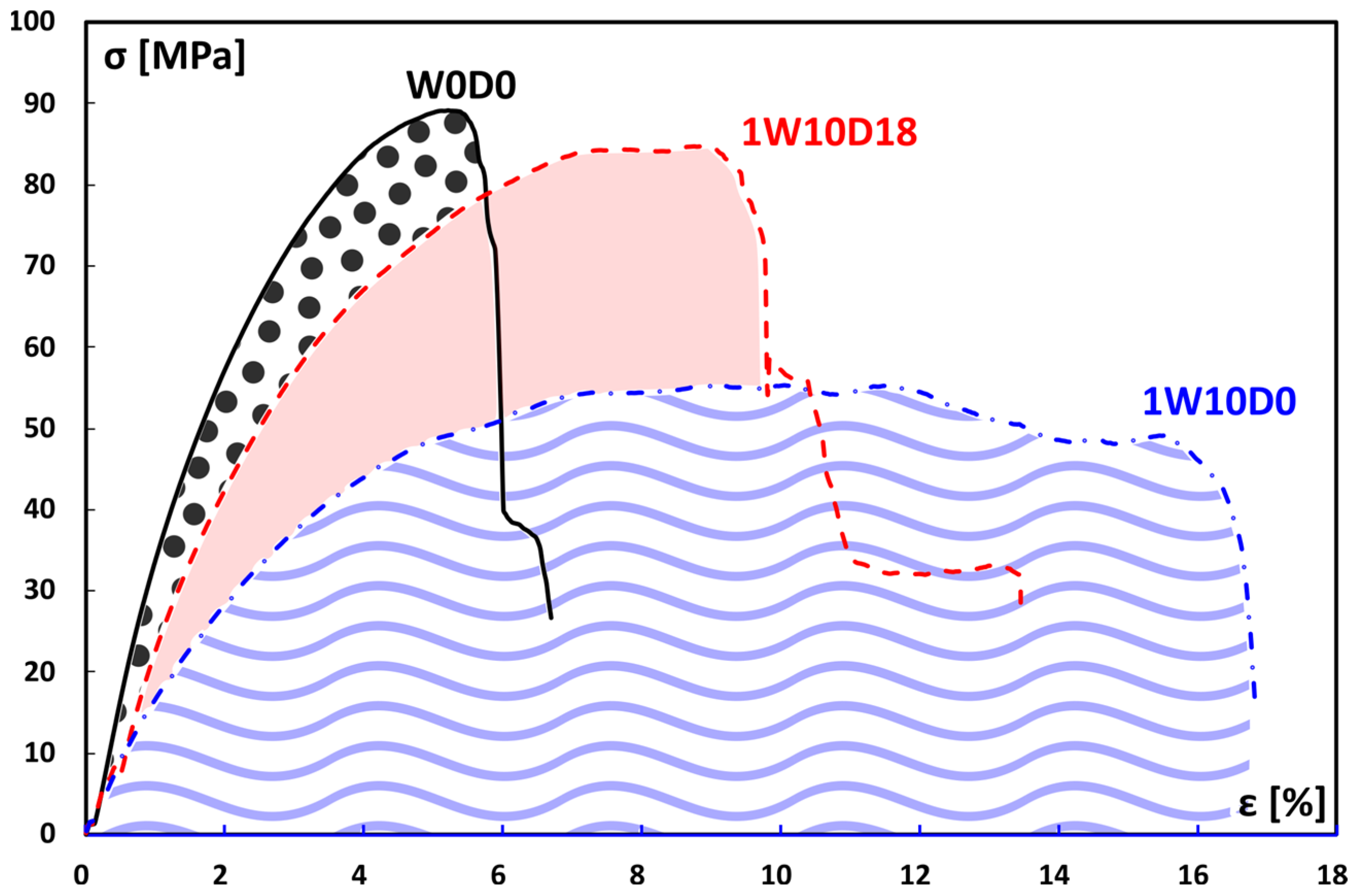

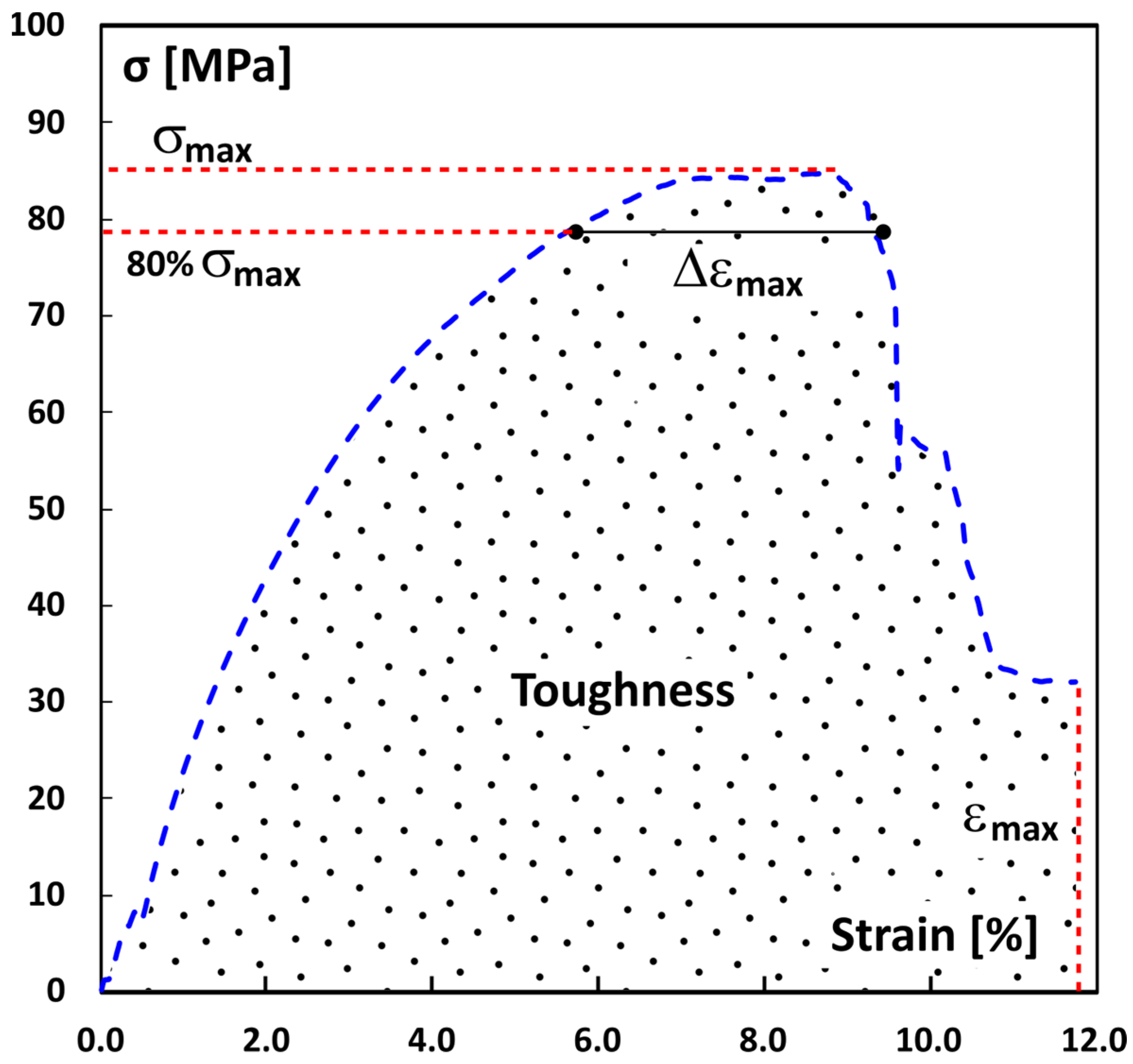

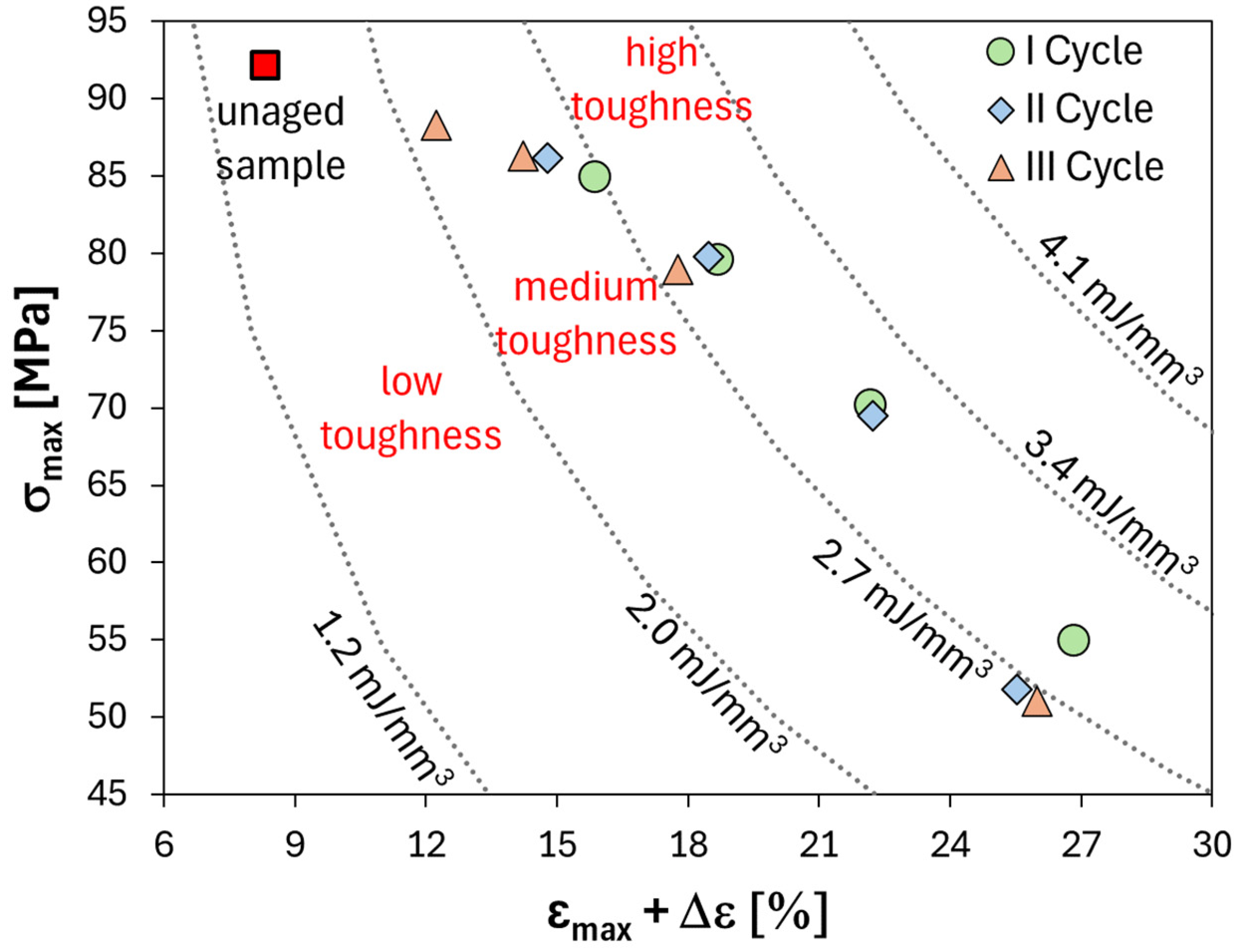

3.2. Three-Point Bending Tests

4. Conclusions

- FFRCs undergo weight fluctuations, gaining weight during humid phases and losing weight during dry phases of each cycle. The cyclical moisture uptake weakens the material over time. The maximum weight gain increases with the number of aging cycles, reaching 8.65% in the final cycle (i.e., the third). There is a slight decrease in residual weight observed at the end of each dry phase as the number of aging cycles increases, reaching 1.25% in the third cycle. The observed ability of the material to release most of the absorbed water during drying suggests that water uptake is primarily due to physical adsorption. However, some irreversible changes likely occur within the material during humid phases.

- FFRCs exhibit an increase in density with increasing exposure time in the salt fog chamber because water molecules can fill voids within the composite structure. This increase in density is followed by a decrease during the drying phase as water evaporates. Consequently, repeated exposure to humid and dry conditions accelerates the creation of defects and voids within the composite, potentially triggering permanent degradation processes.

- The composite’s toughness is very sensitive to the humid–dry cycles. It increases due to a slight reduction on the peak stress and a large increase in the deformation at break after exposure to humid environments. Interestingly, after drying, the composite exposed to three cycles (3W10D18) showed a permanently higher toughness than the unaged composite, likely due to a larger strain at break.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sinha, S.; Devnani, G.L. Natural Fiber Composites. Processing, Characterization, Applications, and Advancements; CRC Press: Boca Raton, FL, USA, 2022; ISBN 9781003201724. [Google Scholar]

- Skosana, S.J.; Khoathane, C.; Malwela, T. Driving towards sustainability: A review of natural fiber reinforced polymer composites for eco-friendly automotive light-weighting. J. Thermoplast. Compos. Mater. 2024, 08927057241254324. [Google Scholar] [CrossRef]

- Mohammed, M.; Jawad, A.J.M.; Mohammed, A.M.; Oleiwi, J.K.; Adam, T.; Osman, A.F.; Dahham, O.S.; Betar, B.O.; Gopinath, S.C.B.; Jaafar, M. Challenges and advancement in water absorption of natural fiber-reinforced polymer composites. Polym. Test. 2023, 124, 108083. [Google Scholar] [CrossRef]

- Nurhania, N.; Syarifuddin, S.; Armynah, B.; Tahir, D. Fiber-reinforced polymer composite: Higher performance with renewable and eco-friendly plant-based fibers. Polym. Renew. Resour. 2023, 14, 215–233. [Google Scholar] [CrossRef]

- Samal, A.; Kumar, S.; Mural, P.K.S.; Bhargava, M.; Das, S.N.; Katiyar, J.K. A critical review of different properties of natural fibre-reinforced composites. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 09544089231202915. [Google Scholar] [CrossRef]

- Musthaq, M.A.; Dhakal, H.N.; Zhang, Z.; Barouni, A.; Zahari, R. The Effect of Various Environmental Conditions on the Impact Damage Behaviour of Natural-Fibre-Reinforced Composites (NFRCs)—A Critical Review. Polymers 2023, 15, 1229. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, M.A.S.; Rabbi, M.S.; Dewanjee, S. Low-velocity impact response of natural fiber reinforced composites: A comprehensive review on influential parameters. Compos. Part C Open Access 2023, 12, 100422. [Google Scholar] [CrossRef]

- Abdollahiparsa, H.; Shahmirzaloo, A.; Teuffel, P.; Blok, R. A review of recent developments in structural applications of natural fiber-Reinforced composites (NFRCs). Compos. Adv. Mater. 2023, 32, 26349833221147540. [Google Scholar] [CrossRef]

- Doddamani, S.; Kulkarni, S.M.; Joladarashi, S.; T S, M.K.; Gurjar, A.K. Analysis of light weight natural fiber composites against ballistic impact: A review. Int. J. Lightweight Mater. Manuf. 2023, 6, 450–468. [Google Scholar] [CrossRef]

- Alshahrani, H.; Sebaey, T.A.; Awd Allah, M.M.; Abd El-baky, M.A. Jute-basalt reinforced epoxy hybrid composites for lightweight structural automotive applications. J. Compos. Mater. 2023, 57, 1315–1330. [Google Scholar] [CrossRef]

- Mohammed, M.; Oleiwi, J.K.; Mohammed, A.M.; Jawad, A.J.M.; Osman, A.F.; Adam, T.; Betar, B.O.; Gopinath, S.C.B.; Dahham, O.S.; Jaafar, M. Comprehensive insights on mechanical attributes of natural-synthetic fibres in polymer composites. J. Mater. Res. Technol. 2023, 25, 4960–4988. [Google Scholar] [CrossRef]

- Mylsamy, B.; Shanmugam, S.K.M.; Aruchamy, K.; Palanisamy, S.; Nagarajan, R.; Ayrilmis, N. A review on natural fiber composites: Polymer matrices, fiber surface treatments, fabrication methods, properties, and applications. Polym. Eng. Sci. 2024, 64, 2345–2373. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Miranda, R.; Badagliacco, D.; Sanfilippo, C.; Palamara, D.; Valenza, A.; Proverbio, E. Assessment of performance degradation of hybrid flax-glass fiber reinforced epoxy composites during a salt spray fog/dry aging cycle. Compos. Part B Eng. 2022, 238, 109897. [Google Scholar] [CrossRef]

- Lu, M.M.; van Vuure, A.W. Long-term moisture cycling performance and unexpected strengthening of non-dry flax fibre composites. Ind. Crops Prod. 2023, 195, 116486. [Google Scholar] [CrossRef]

- Kim, H.J.; Seo, D.W. Effect of water absorption fatigue on mechanical properties of sisal textile-reinforced composites. Int. J. Fatigue 2006, 28, 1307–1314. [Google Scholar] [CrossRef]

- Van Schoors, L.; Cadu, T.; Moscardelli, S.; Divet, L.; Fontaine, S.; Sicot, O. Why cyclic hygrothermal ageing modifies the transverse mechanical properties of a unidirectional epoxy-flax fibres composite? Ind. Crops Prod. 2021, 164, 113341. [Google Scholar] [CrossRef]

- Cadu, T.; Van Schoors, L.; Sicot, O.; Moscardelli, S.; Divet, L.; Fontaine, S. Cyclic hygrothermal ageing of flax fibers’ bundles and unidirectional flax/epoxy composite. Are bio-based reinforced composites so sensitive? Ind. Crops Prod. 2019, 141, 111730. [Google Scholar] [CrossRef]

- Mak, K.; Fam, A. The effect of wet-dry cycles on tensile properties of unidirectional flax fiber reinforced polymers. Compos. Part B Eng. 2020, 183, 107645. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Miranda, R.; Badagliacco, D.; Sanfilippo, C.; Palamara, D.; Valenza, A.; Proverbio, E. Performances recovery of flax fiber reinforced composites after salt-fog aging test. J. Compos. Sci. 2022, 6, 264. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Miranda, R.; Badagliacco, D.; Sanfilippo, C.; Palamara, D.; Valenza, A.; Proverbio, E. On the response of flax fiber reinforced composites under salt-fog/dry conditions: Reversible and irreversible performances degradation. Compos. Part B Eng. 2022, 230, 109535. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Sanfilippo, C.; Proverbio, E.; Valenza, A. Effect of repeated salt fog-dry cycles on the performances reversibility of flax fiber reinforced composites. Polym. Test. 2024, 135, 108472. [Google Scholar] [CrossRef]

- ASTM B 117; Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International: Conshohocken, PA, USA, 2019.

- ISO 291; Plastics–Standard Atmospheres for Conditioning and Testing. ISO: Geneva, Switzerland, 2008.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D570; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 2016.

- Fraga, A.N.; Frullloni, E.; De La Osa, O.; Kenny, J.M.; Vázquez, A. Relationship between water absorption and dielectric behaviour of natural fibre composite materials. Polym. Test. 2006, 25, 181–187. [Google Scholar] [CrossRef]

- Zhou, J.; Lucas, J.P. Hygrothermal effects of epoxy resin. Part I: The nature of water in epoxy. Polymer 1999, 40, 5505–5512. [Google Scholar] [CrossRef]

- Karad, S.K.; Attwood, D.; Jones, F.R. Moisture absorption by cyanate ester modified epoxy resin matrices. Part V: Effect of resin structure. Compos. Part A Appl. Sci. Manuf. 2005, 36, 764–771. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Öchsner, A.; Islam, M.; Francucci, G. Flax fiber and its composites: An overview of water and moisture absorption impact on their performance. J. Reinf. Plast. Compos. 2019, 38, 323–339. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; El Mahi, A.; Poilâne, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax-fibres and glass-fibres. Mater. Des. 2011, 32, 788–795. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Khanlou, H.M.; Hall, W.; Öchsner, A.; Francucci, G. Environmental effects on the durability and the mechanical performance of flax fiber/bio-epoxy composites. Compos. Part B Eng. 2019, 171, 284–293. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.A.; Peijs, T. Effects of environmental conditions on mechanical and physical properties of flax fibers. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1105–1115. [Google Scholar] [CrossRef]

- Mercier, J.; Bunsell, A.; Castaing, P.; Renard, J. Characterisation and modelling of aging of composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 428–438. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Piperopoulos, E.; Badagliacco, D.; Palamara, D.; Valenza, A.; Proverbio, E. In situ monitoring of moisture uptake of flax fiber reinforced composites under humid/dry conditions. J. Appl. Polym. Sci. 2022, 139, 51969. [Google Scholar] [CrossRef]

- Aquino, E.M.F.; Sarmento, L.P.S.; Oliveira, W.; Silva, R.V. Moisture effect on degradation of jute/glass hybrid composites. J. Reinf. Plast. Compos. 2007, 26, 219–233. [Google Scholar] [CrossRef]

- Radkar, S.S.; Amiri, A.; Ulven, C.A. Tensile behavior and diffusion of moisture through flax fibers by desorption method. Sustainability 2019, 11, 3558. [Google Scholar] [CrossRef]

- Sodoke, F.K.; Toubal, L.; Laperrière, L. Wetting/drying cyclic effects on mechanical and physicochemical properties of quasi-isotopic flax/epoxy composites. Polym. Degrad. Stab. 2019, 161, 121–130. [Google Scholar] [CrossRef]

- Akil, H.M.; Cheng, L.W.; Mohd Ishak, Z.A.; Abu Bakar, A.; Abd Rahman, M.A. Water absorption study on pultruded jute fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2009, 69, 1942–1948. [Google Scholar] [CrossRef]

- Wang, M.; Xu, X.; Ji, J.; Yang, Y.; Shen, J.; Ye, M. The hygrothermal aging process and mechanism of the novolac epoxy resin. Compos. Part B Eng. 2016, 107, 1–8. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Scalici, T.; Valenza, A. Evolution of the bearing failure map of pinned flax composite laminates aged in marine environment. Compos. Part B Eng. 2020, 187, 107864. [Google Scholar] [CrossRef]

- Muñoz, E.; García-Manrique, J.A. Water absorption behaviour and its effect on the mechanical properties of flax fibre reinforced bioepoxy composites. Int. J. Polym. Sci. 2015, 2015, 390275. [Google Scholar] [CrossRef]

- Haghighatnia, T.; Abbasian, A.; Morshedian, J. Hemp fiber reinforced thermoplastic polyurethane composite: An investigation in mechanical properties. Ind. Crops Prod. 2017, 108, 853–863. [Google Scholar] [CrossRef]

- Sheinbaum, M.; Sheinbaum, L.; Weizman, O.; Dodiuk, H.; Kenig, S. Toughening and enhancing mechanical and thermal properties of adhesives and glass-fiber reinforced epoxy composites by brominated epoxy. Compos. Part B Eng. 2019, 165, 604–612. [Google Scholar] [CrossRef]

- Javanshour, F.; Prapavesis, A.; Pärnänen, T.; Orell, O.; Lessa Belone, M.C.; Layek, R.K.; Kanerva, M.; Kallio, P.; Van Vuure, A.W.; Sarlin, E. Modulating impact resistance of flax epoxy composites with thermoplastic interfacial toughening. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106628. [Google Scholar] [CrossRef]

| I Cycle | II Cycle | III Cycle | ||||

|---|---|---|---|---|---|---|

| Exposure Time [Days] | Density [g/cm3] | Void Content [%] | Density [g/cm3] | Void Content [%] | Density [g/cm3] | Void Content [%] |

| Humid phase | ||||||

| 0 | 1.132 ± 0.007 | 5.99 ± 0.5 | 1.128 ± 0.013 | 5.97 ± 0.72 | 1.125 ± 0.013 | 6.30 ± 0.49 |

| 1 | 1.16 ± 0.009 | 3.11 ± 0.44 | 1.165 ± 0.009 | 2.30 ± 0.52 | 1.16 ± 0.008 | 2.65 ± 0.62 |

| 2 | 1.174 ± 0.011 | 1.62 ± 0.48 | 1.171 ± 0.014 | 1.67 ± 0.69 | 1.169 ± 0.012 | 1.74 ± 0.69 |

| 3 | 1.181 ± 0.009 | 0.91 ± 0.55 | 1.176 ± 0.007 | 1.07 ± 0.48 | 1.17 ± 0.009 | 1.50 ± 0.38 |

| 6 | 1.186 ± 0.015 | 0.22 ± 0.68 | 1.177 ± 0.009 | 0.87 ± 0.46 | 1.166 ± 0.008 | 1.66 ± 0.29 |

| 8 | 1.187 ± 0.007 | 0.02 ± 0.55 | 1.176 ± 0.009 | 0.79 ± 0.52 | 1.161 ± 0.011 | 2.08 ± 0.45 |

| 9 | 1.186 ± 0.009 | 0.04 ± 0.55 | 1.176 ± 0.011 | 0.82 ± 0.42 | 1.158 ± 0.016 | 2.29 ± 0.88 |

| 10 | 1.184 ± 0.011 | 0.16 ± 0.58 | 1.174 ± 0.013 | 0.96 ± 0.65 | 1.155 ± 0.014 | 2.52 ± 0.71 |

| Dry phase | ||||||

| 10.25 | 1.166 ± 0.009 | 2.01 ± 0.44 | 1.155 ± 0.007 | 2.85 ± 0.42 | 1.135 ± 0.013 | 4.51 ± 0.52 |

| 13 | 1.142 ± 0.011 | 4.38 ± 0.48 | 1.132 ± 0.013 | 5.20 ± 0.59 | 1.11 ± 0.018 | 7.07 ± 0.68 |

| 15 | 1.135 ± 0.009 | 5.13 ± 0.55 | 1.127 ± 0.012 | 5.81 ± 0.58 | 1.105 ± 0.009 | 7.60 ± 0.61 |

| 17 | 1.132 ± 0.008 | 5.48 ± 0.58 | 1.124 ± 0.011 | 6.08 ± 0.49 | 1.101 ± 0.010 | 8.13 ± 0.56 |

| 20 | 1.129 ± 0.007 | 5.84 ± 0.55 | 1.124 ± 0.006 | 6.23 ± 0.52 | 1.101 ± 0.009 | 8.22 ± 0.45 |

| 24 | 1.127 ± 0.009 | 6.03 ± 0.55 | 1.122 ± 0.013 | 6.51 ± 0.65 | 1.104 ± 0.009 | 8.00 ± 0.48 |

| 28 | 1.128 ± 0.011 | 5.97 ± 0.58 | 1.125 ± 0.009 | 6.30 ± 0.32 | 1.109 ± 0.014 | 7.61 ± 0.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calabrese, L.; Sanfilippo, C.; Valenza, A.; Proverbio, E.; Fiore, V. Toughness Evolution of Flax-Fiber-Reinforced Composites under Repeated Salt Fog–Dry Aging Cycles. Polymers 2024, 16, 1926. https://doi.org/10.3390/polym16131926

Calabrese L, Sanfilippo C, Valenza A, Proverbio E, Fiore V. Toughness Evolution of Flax-Fiber-Reinforced Composites under Repeated Salt Fog–Dry Aging Cycles. Polymers. 2024; 16(13):1926. https://doi.org/10.3390/polym16131926

Chicago/Turabian StyleCalabrese, Luigi, Carmelo Sanfilippo, Antonino Valenza, Edoardo Proverbio, and Vincenzo Fiore. 2024. "Toughness Evolution of Flax-Fiber-Reinforced Composites under Repeated Salt Fog–Dry Aging Cycles" Polymers 16, no. 13: 1926. https://doi.org/10.3390/polym16131926

APA StyleCalabrese, L., Sanfilippo, C., Valenza, A., Proverbio, E., & Fiore, V. (2024). Toughness Evolution of Flax-Fiber-Reinforced Composites under Repeated Salt Fog–Dry Aging Cycles. Polymers, 16(13), 1926. https://doi.org/10.3390/polym16131926