Machine Learning in the Analysis of the Mechanical Shredding Process of Polymer Recyclates

Abstract

1. Introduction

- ▪

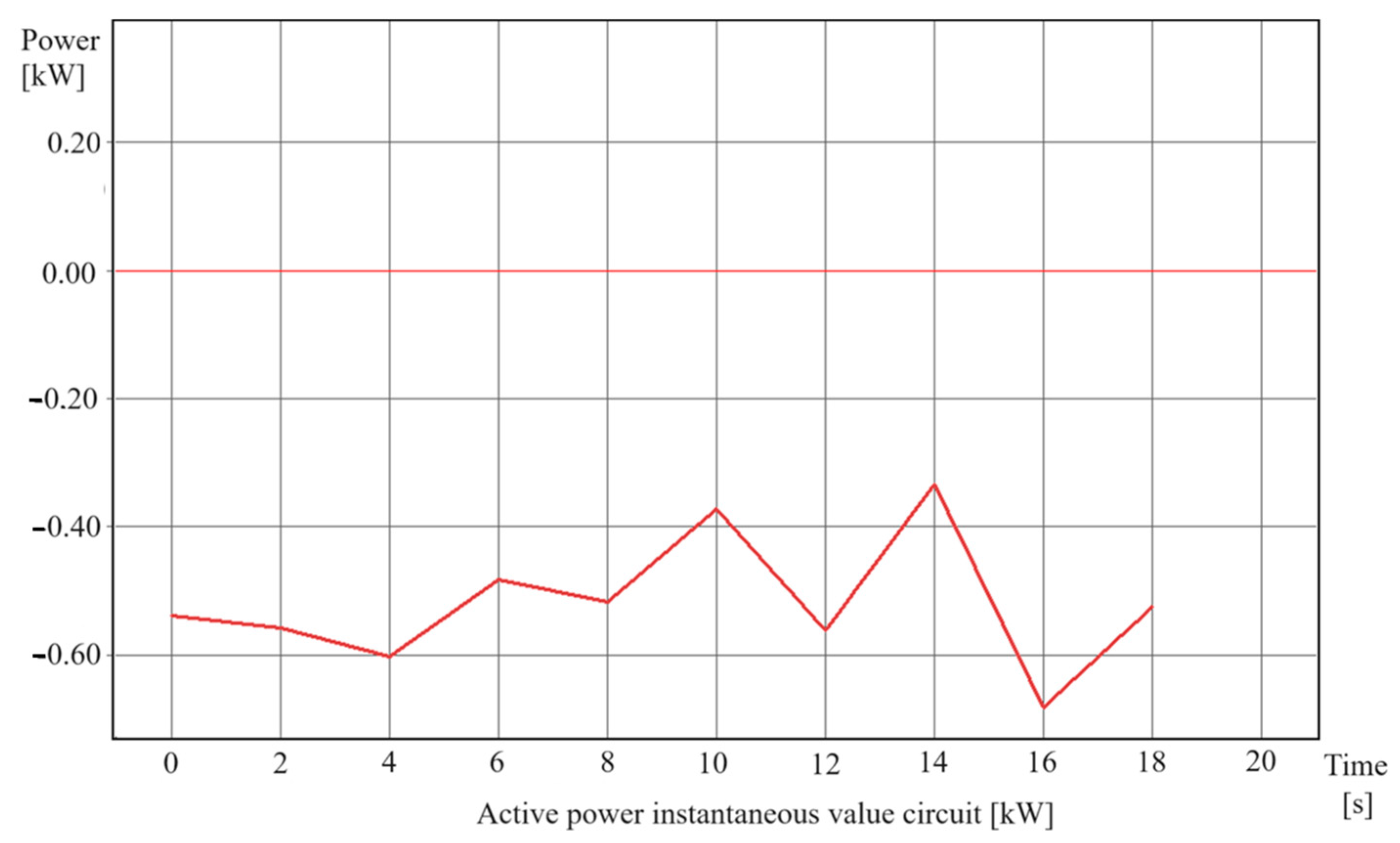

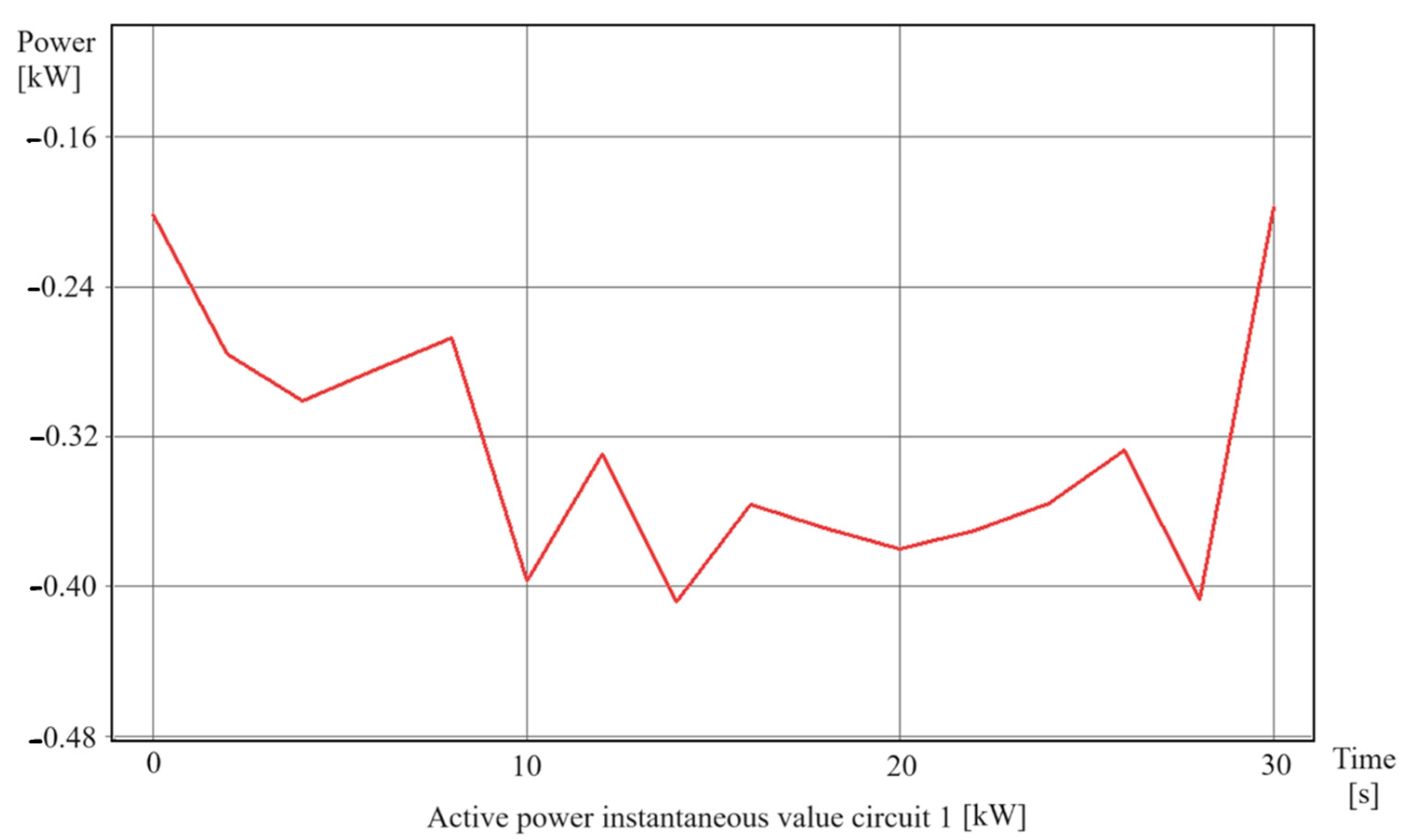

- Data collection: data can be collected both from sensors installed in the shredding equipment to monitor parameters such as temperature, pressure, motor power, and particle size distribution, as well as collected historical data on input materials and shredding conditions.

- ▪

- Data pre-processing: pre-processing techniques such as normalization, outlier removal, and feature engineering are used to improve the quality of the dataset.

- ▪

- Model training: various machine learning algorithms can be used to develop models that capture the relationship between input parameters (e.g., material properties, shredder settings) and output variables (e.g., particle size distribution, energy consumption). Supervised learning algorithms, such as regression, decision trees, random forests, or gradient enhancement, can be used to predict shredder outputs based on input parameters. Alternatively, unsupervised learning techniques such as clustering can help identify patterns in the data without labeled results.

- ▪

- Feature selection and dimensionality reduction: techniques such as principal component analysis (PCA) or feature selection algorithms can help reduce the dimensionality of the data while retaining relevant information, improving model performance, and reducing computational complexity.

- ▪

- Model validation and evaluation: e.g., cross-validation, in which the dataset is split into multiple subsets for training and testing, and evaluation metrics tailored to the specific goals of the fragmentation process analysis, such as mean absolute error or coefficient of determination, can be used to assess model performance.

- ▪

- Model implementation and monitoring: real-time implementation of models in shredding processes can provide insights and recommendations for optimizing operations. Continuous monitoring of model performance and periodic updates based on new data can help maintain model accuracy and relevance over time.

- ▪

- Optimization and control: ML models can be integrated with control systems to optimize shredding parameters in real time, aiming to achieve desired outcomes such as specific particle size distributions or energy efficiency targets. Reinforcement learning techniques can be used to iteratively adjust control parameters based on feedback [43,44,45,46,47,48,49,50].

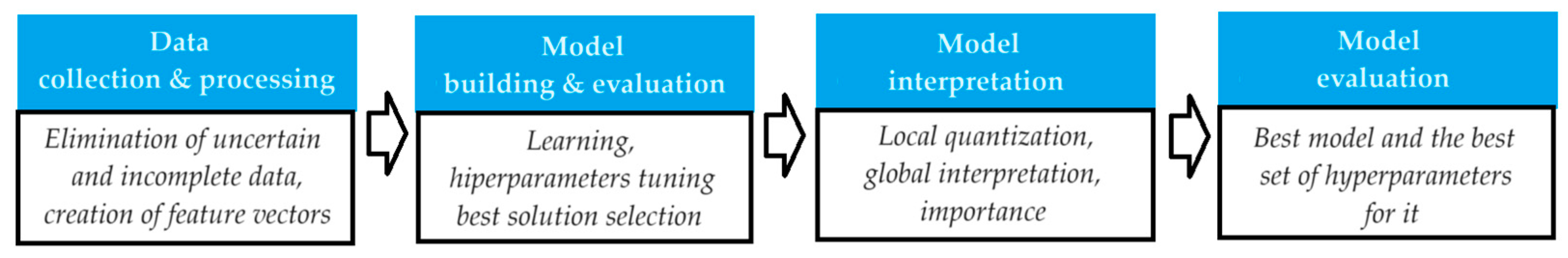

2. Materials and Methods

2.1. Data Set

- ▪

- Tensile strength: 37 MPa;

- ▪

- Tensile: 6%;

- ▪

- Modulus of elasticity: 4 GPa;

- ▪

- Density: 1.3 g/cm3;

- ▪

- Melting point: 173 °C;

- ▪

- ▪

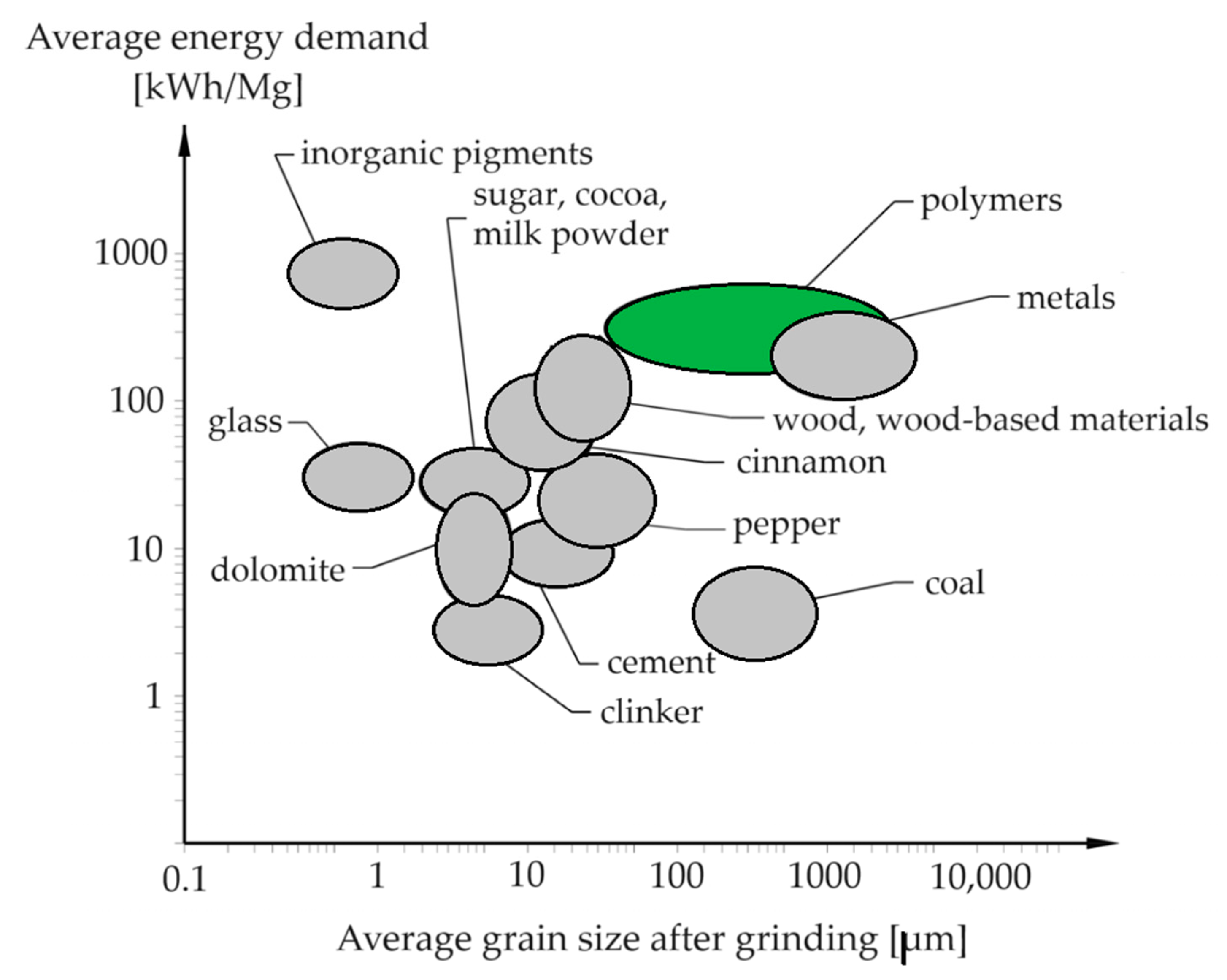

- energy efficiency indices (Figure 2),

- ▪

- improvement of shredding product quality.

- ▪

- Physical indicators defining the geometric features and physical properties of the grained material include dimensions, shapes of grains, distribution of grain sets, dimensions of control grains, external top or bottom grains, medium grains, percentage of the mass of the control grain, specific surface—kinetic, specific surface—static, pycnometric density, microhardness, compressive strength, tensile strength, brittle fracture strength, hygroscopicity, adsorption and absorption capacity, pyrophoricity, color, gloss, total pore volume, averagesize and distribution of pores, shape of pores, angle of internal friction, angle of static, and kinetic friction against metal, etc.;

- ▪

- Chemical indicators describing the share of the basic component and other ingredients, the share of phase impurities (solid, liquid, and gas), the occurrence of oxide coatings, corrosion resistance, chemical activity, electro-chemical, catalytic ability, and toxicity, etc.

2.2. Computational Methods

3. Results

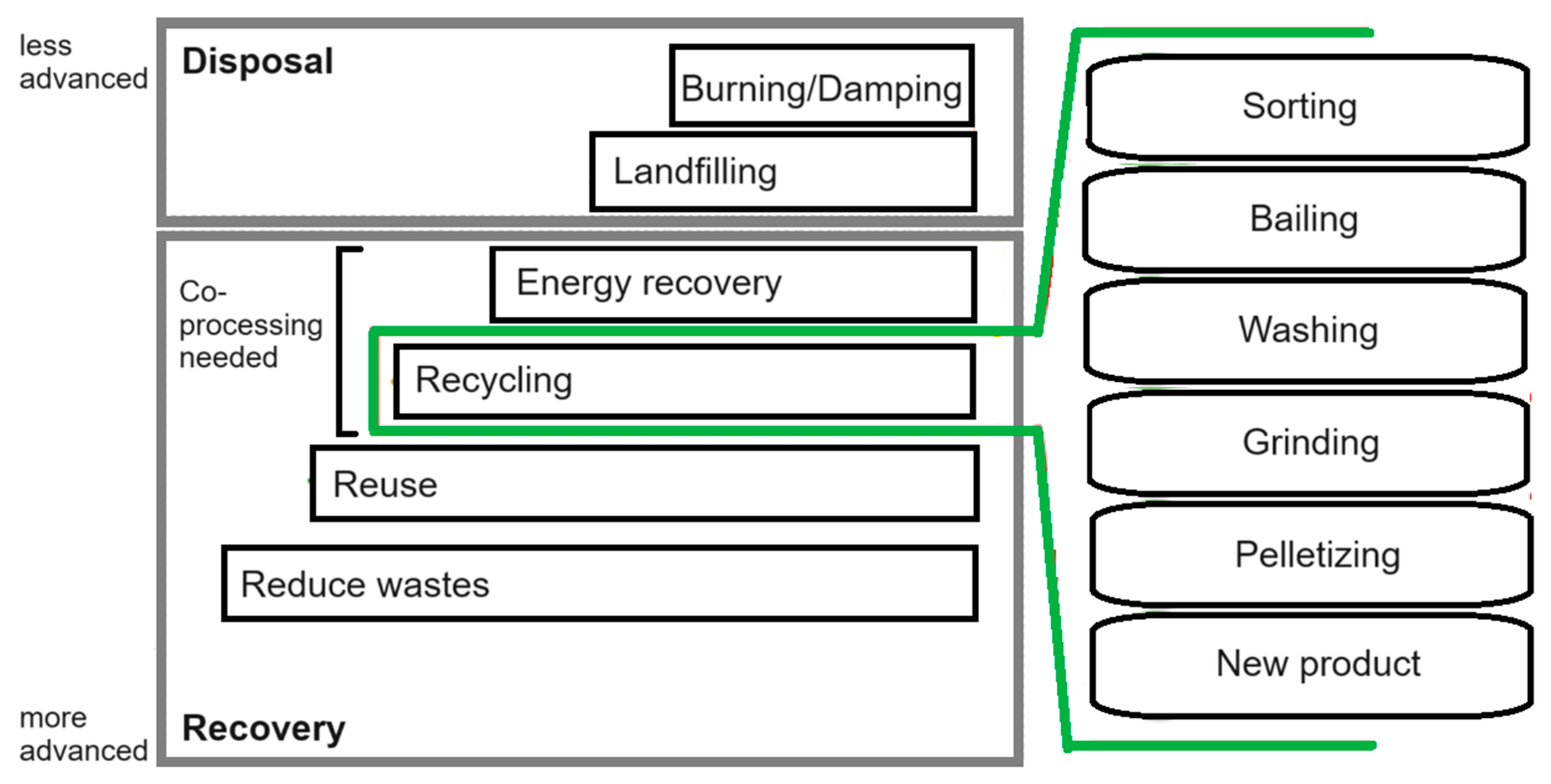

4. Discussion

- ▪

- reuse in unchanged form;

- ▪

- recycling (material and/or energy);

- ▪

- disposal (landfilling or incineration).

- ▪

- preparatory operations (crushing, separating);

- ▪

- dedicated installations and technologies AI/ML;

- ▪

- designing products and services in terms of the possibility of life cycle analysis and recycling,

- ▪

- selection of resource-efficient production processes,

- ▪

- use of renewable materials,

- ▪

- reducing energy consumption during use,

- ▪

- open innovation process for current and potential/future stakeholders,

- ▪

- increased acceptance and chances of implementation.

- ▪

- waste upcycling, creating networks and active knowledge transfer via digital technologies, including ML/AI (Table 3),

- ▪

- analysis and development of solutions within an integrated and coherent circular economy,

- ▪

- testing and evaluation of innovations in a real environment, including in small and medium-sized enterprises.

- ▪

- The most promising raw materials include:

- ▪

- paper and wood dust,

- ▪

- sand,

- ▪

- harvest residues [20].

| Factors | |

|---|---|

| Internal | External |

| Material: size, shape, density, strength, hardness (ML-based material assessment and preparation) | Environment: Temperature, humidity, pressure (ML-based environment compensation) |

| Machine: design, number of cutting edges, shape of cutting edges, movement direction (ML-based machine adjustment) | |

| Process: duration, cutting velocity, number of cutting contacts (ML-based process optimization) | |

- ▪

- improving the efficiency of waste disposal from electrical and electronic products introduced to the market every year,

- ▪

- recovery of the content of key metals contained in the above-mentioned products (including mixtures of fine particles from WEEE grinding).

- ▪

- high variability of materials used in the production of electrical and electronic equipment,

- ▪

4.1. Discussion of the Results Obtained

- ▪

- the accuracy of the description of the polymer feature vector/matrix,

- ▪

- the matching of the best ML algorithm (including the transition to deep learning—DL).

4.2. Limitations of Current Studies

- ▪

- Data quality and quantity: In some cases, obtaining sufficient and high-quality data on the mechanical shredding process, including variables such as material properties, shredder settings, and process results, can be challenging. Limited or biased data can lead to inaccurate models and unreliable predictions.

- ▪

- Complexity of the shredding process: Mechanical shredding processes for polymer recyclates can be very complex and involve various physical and chemical interactions. ML models can struggle to capture the full complexity of these processes, especially if important factors are not well understood or difficult to measure.

- ▪

- Interpretability: Many ML/DL models are often considered black boxes, meaning that their inner workings are not easily interpretable by humans. In industries where interpretability is critical to decision-making, such as manufacturing, this lack of transparency can be a significant limitation.

- ▪

- Generalization: ML models trained on specific data sets may have difficulty generalizing to new or unfamiliar data. Changes in materials, equipment, and operating conditions can lead to model degradation or failure if not properly accounted for during training.

- ▪

- Over- and under-fitting: ML models are prone to over-fitting (capturing noise in the training data) or under-fitting (not capturing underlying patterns). Balancing model complexity and generalizability is essential to mitigate these issues.

- ▪

- Concerns about bias: ML models may inadvertently perpetuate biases present in the data used for training, which can lead to unfair or environmentally unsustainable recommendations/decisions.

- ▪

- Dynamic nature of ML processes: they may exhibit dynamic behavior, with parameters changing over time or in response to external factors; for the above reasons, static machine learning models may struggle to adapt to such dynamic environments without continuous retraining or adaptive mechanisms.

- ▪

4.3. Directions for Further Research

- ▪

- Data augmentation and simulation: Developing techniques to augment limited shredding process data through simulation or synthetic data generation. This may include creating realistic virtual environments to simulate shredding processes or generating synthetic data using physics-based models to supplement experimental data.

- ▪

- Multi-scale modeling: Exploring multi-scale modeling methods that can capture interactions between different length and time scales in the shredding process. This may include the integration of machine learning with computational fluid dynamics (CFD) or finite element analysis (FEA) to model macroscopic grinding behavior together with microscopic material properties.

- ▪

- Dynamic and adaptive models: Developing machine learning models that can dynamically adapt to changes in the conditions of the grinding process in real time. This may include the use of techniques such as online learning or reinforcement learning to continuously update models based on incoming data and feedback from shredding equipment.

- ▪

- Interpretable ML: This may include, for example, the development of model-independent interpretation techniques or the incorporation of domain knowledge constraints into model training to improve model transparency and reliability.

- ▪

- Quantification and uncertainty propagation: This may include Bayesian methods, ensemble learning, or probabilistic modeling approaches to provide uncertainty estimates along with model predictions.

- ▪

- Transfer learning and domain adaptation: Exploring transfer learning and domain adaptation techniques to exploit knowledge from related domains or processes where data may be more abundant; this includes pre-training models on similar tasks or domains before tuning them to chunk process data to improve model performance with limited data.

- ▪

- Integration of ML models into real-time or near real-time process control systems: Adaptive process optimization, which may include the development of control strategies based on ML models or hybrid control architectures that combine machine learning models with traditional control algorithms.

- ▪

- Industry/social implications: Exploring the environmental impact of ML model-based process optimization, addressing bias and fairness in decision-making, and ensuring transparency and accountability in model implementation.

- ▪

- Joint research initiatives: Fostering collaboration between researchers (from different disciplines: mechanical engineering, computer science, materials engineering), economic stakeholders, and regulators to establish common datasets (and rules for organizing and sharing them), practice patterns (including data processing and imaging) and best practices for the application of ML in grinding process analysis. This could facilitate knowledge sharing, accelerate research progress, and ensure the relevance and applicability of research findings to real-world challenges [61,62,63,64,65,66,67,68,69].

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Oti, J.; Adeleke, B.O.; Rathnayake, M.; Kinuthia, J.M.; Ekwulo, E. Strength and Durability Characterization of Structural Concrete Made of Recycled Plastic. Materials 2024, 17, 1841. [Google Scholar] [CrossRef]

- Jia, Y.; Chen, D.; Xu, S.; Hu, Y.; Yuan, G.; Zhang, R.; Yu, W. Mechanical strengths changes of combustible municipal solid waste component Turing their early pyrolysis stage and mechanizm analysis. Waste Manag. Res. 2024, 734242X231219629. [Google Scholar] [CrossRef]

- Ruffino, B.; Zanetti, M. Is the assimilation to a solid recovered fuel a viable solution for automobile shredder residues’ management? Environ. Res. 2024, 247, 118131. [Google Scholar] [CrossRef]

- Dohmen, J.; Lessau, M.; Schmitz, M.; Kalff, J.C. Recycling of Disposable Surgical Instruments—Is It Worth It? Zentralbl Chir. 2023, 148, 329–336. [Google Scholar] [CrossRef]

- Stapleton, M.J.; Ansari, A.J.; Ahmed, A.; Hai, F.I. Evaluating the generation of micro plastics from an unlikely source: The unintentional consequence of the current plastic recycling process. Sci. Total Environ. 2023, 902, 166090. [Google Scholar] [CrossRef] [PubMed]

- Ozawa, K. Identification of overlapping plastic sheets using short-wavelength infrared hyperspectral imaging. Opt. Express. 2023, 31, 12328–12338. [Google Scholar] [CrossRef]

- Alatawi, R.A.S.; Bukhari, A.A.H.; Al-Sayed, H.M.A.; Alenazi, D.A.K.; Alnawmasi, J.S.; Abomuti, M.A. Production of biologically active non-woven textiles from recycled polyethyleneterephthalate. Luminescence 2023, 38, 350–359. [Google Scholar] [CrossRef]

- Hejna, A.; Kosmela, P.; Olszewski, A.; Zedler, Ł.; Formela, K.; Skórczewska, K.; Piasecki, A.; Marć, M.; Barczewski, R.; Barczewski, M. Management of Grodnu tire rubber waste by incorporation into polyurethane-based composite foams. Environ. Sci. Pollut. Res. Int. 2024, 31, 17591–17616. [Google Scholar] [CrossRef] [PubMed]

- O’Rourke, K.; Wurzer, C.; Murray, J.; Doyle, A.; Doyle, K.; Griffin, C.; Christensen, B.; Brádaigh, C.M.Ó.; Ray, D. Diverted from Landfill: Reuse of Single-Use Plastic Packaging Waste. Polymers 2022, 14, 5485. [Google Scholar] [CrossRef]

- Rojas-Valencia, M.N.; Rivas-Torres, B.I.; Fernández-Rojas, D.Y.; Gómez-Soberón, J.M. Recovery of Mixtures of ConstructionWaste, PET and Sugar cane Bagasse for the Manufacture of Partition Blocks. Materials 2022, 15, 6836. [Google Scholar] [CrossRef]

- Akhras, M.H.; Freudenthaler, P.J.; Straka, K.; Fischer, J. From Bottle Caps to Frisbee—A Case Study on Mechanical Recycling of Plastic Waste towards a Circular Economy. Polymers 2023, 15, 2685. [Google Scholar] [CrossRef] [PubMed]

- Nagengast, N.; Bay, C.; Döpper, F.; Schmidt, H.-W.; Neuber, C. Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures. Polymers 2023, 15, 2291. [Google Scholar] [CrossRef] [PubMed]

- Bergaliyeva, S.; Sales, D.L.; Delgado, F.J.; Bolegenova, S.; Molina, S.I. Manufacture and Characterization of Polylactic Acid Filaments Recycled from Real Waste for 3D Printing. Polymers 2023, 15, 2165. [Google Scholar] [CrossRef] [PubMed]

- Zegardło, B.; Maraveas, C.; Kaleszko, S.; Bombik, A. Composites Containing Felt Wastes from the Automotive Industry. Appl. Sci. 2023, 13, 2375. [Google Scholar] [CrossRef]

- Saccani, A.; Fiorini, M.; Manzi, S. Recycling of Wastes Deriving from the Production of Epoxy-Carbon Fiber Composites in the Production of Polymer Composites. Appl. Sci. 2022, 12, 4287. [Google Scholar] [CrossRef]

- Lyskawinski, W.; Baranski, M.; Jedryczka, C.; Mikolajewicz, J.; Regulski, R.; Sedziak, D.; Netter, K.; Rybarczyk, D.; Czarnecka-Komorowska, D.; Barczewski, M. Tribo-Electrostatic Separation Analysis of a Beneficial Solution in the Recycling of Mixed Poly(Ethylene Terephthalate) and High-Density Polyethylene. Energies 2021, 14, 1755. [Google Scholar] [CrossRef]

- Candiani, G.; Picone, N.; Pompilio, L.; Pepe, M.; Colledani, M. Characterization of Fine Metal Particles Derived from Shredded WEEE Usinga Hyperspectral Image System: Preliminary Results. Sensors 2017, 17, 1117. [Google Scholar] [CrossRef] [PubMed]

- Ortego, A.; Iglesias-Émbil, M.; Valero, A.; Gimeno-Fabra, M.; Monné, C.; Moreno, F. Disassemblability Assessment of Car Parts: Lessons Learned froman Ecodesign Perspective. Sustainability 2024, 16, 2311. [Google Scholar] [CrossRef]

- Paz, F.A.G.; Heibeck, M.; Parvez, A.M.; Torrubia, J.; van den Boogaart, K.G.; Raatz, S. Recovery of Materials from Refrigerator: A Study Focused on Product Distribution, Recyclability and LCA Evaluation. Sustainability 2024, 16, 1082. [Google Scholar] [CrossRef]

- Berkemeier, A.; Kühnel, L.; Dürigen, D.; Hoffmann, H.; Zeidler, H.; Bullinger, A.C.; Wagenführ, A. SAMSax—An Innovative Living Lab for the Advancement of a Circular Economy through Additive Manufacturing Technologies. Sustainability 2024, 16, 823. [Google Scholar] [CrossRef]

- Ragab, A.; Elazhary, R.; Schmauder, S.; Ramzy, A. Plastic Waste Valorization for Fused Deposition Modeling Feedstock: A Case Study on Recycled Polyethylene Terephthalate/High-Density Polyethylene Sustainability. Sustainability 2023, 15, 13291. [Google Scholar] [CrossRef]

- Chmielowski, K.; Halecki, W.; Masłoń, A.; Bąk, Ł.; Kalenik, M.; Spychała, M.; Niedziółka, A.; Łaciak, M.; Roman, M.; Mazurkiewicz, J. Use of Shredded Recycled Plastic as Filter Bed Packing in a Vertical Flow Filter for Onsite Wastewater TreatmentPlants: Preliminary Findings. Sustainability 2023, 15, 1883. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of All plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, F.A.C.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Rejeski, D.; Zhao, F.; Huang, Y. Research Leeds and recommendations on environment al implications of additive manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef]

- Dostatni, E.; Rojek, I.; Hamrol, A. The Use of Machine Learning Method in Concurrent Ecodesign of Products and Technological Processes. In Advances in Manufacturing. Lecture Notes in Mechanical Engineering; Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M., Eds.; Springer: Cham, Switzerland, 2018; pp. 321–330. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Rojek, I.; Dostatni, E.; Hamrol, A. Ecodesign of Technological Processes with the Use of Decision Trees Method. In International Joint Conference SOCO’17-CISIS’17-ICEUTE’17 2017, Advances in Intelligent Systems and Computing; Pérez García, H., Alfonso-Cendón, J., Sánchez González, L., Quintián, H., Corchado, E., Eds.; Springer: Cham, Switzerland, 2018; Volume 649, pp. 318–327. [Google Scholar] [CrossRef]

- Herianto;Atsani, S.I.; Mastrisiswadi, H. Recycled Polypropylene Filament for 3D Printer: Extrusion Process Parameter Optimization. IOP Conf. Ser. Mater. Sci. Eng. 2020, 722, 012022. [Google Scholar] [CrossRef]

- Šenitková, I.; Bednárová, P. Lifecycleassessment. JP J. Heat. Mass. Transf. 2015, 11, 29–42. [Google Scholar] [CrossRef]

- Filimonau, V. Life cycle assessment. Routledge Handb. Tour. Sustain. 2015, 6, 209–220. [Google Scholar]

- Rojek, I. Models for Better Environmental Intelligent Management within Water Supply Systems. Water Resour. Manag. 2014, 28, 3875–3890. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2016, 25, 136–145. [Google Scholar] [CrossRef]

- Rojek, I. Neural networks as performance improvement models in intelligent CAPP systems. Control Cybern. 2010, 39, 55–68. [Google Scholar]

- Bakır, A.A.; Atik, R.; Özerinç, S. Effect of Fusem deposition modeling process parameters on the mechanical properties of recycled polyethylene terephthalate parts. J. Appl. Polym. Sci. 2020, 138, 49709. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A. Sustainable Additive Manufacturing: Mechanical Response of High-Density Polyethylene over Multiple Recycling Processes. Recycling 2021, 6, 4. [Google Scholar] [CrossRef]

- Rojek, I. Classifier models in intelligent CAPP systems. In Man-Machine Interactions, Advances in Intelligent and Soft Computing; Cyran, K.A., Kozielski, S., Peters, J.F., Stanczyk, U., Wakulicz-Deja, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 311–319. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2018, 25, 122–130. [Google Scholar] [CrossRef]

- Jarukumjorn, K.; Chareunkvun, S. Compatibilization of Recycled HighDensity Polyethylene (Hdpe)/Polyethylene Terephtha-Late (Pet) Blends. J. Sci. Technol. 2006, 14, 1–8. Available online: http://sutir.sut.ac.th:8080/jspui/handle/123456789/2150 (accessed on 20 April 2024).

- Yousfi, M.; Lepretre, S.; Soulestin, J.; Vergnes, B.; Lacrampe, M.-F.; Krawczak, P. Processing-induced degradation of nanoclay organic modifier in melt-mixed PET/PE blends Turing twin skrew extrusion at industrial scale: Effect on morphology and mechanical behavior. J. Appl. Polym. Sci. 2013, 131, 39712. [Google Scholar] [CrossRef]

- Polline, M.; Mutua, J.M.; Mbuya, T.O.; Ernest, K. Recipe Development and Mechanical Characterization of Carbon Fibre Reinforced Recycled Polypropylene 3D Printing Filament. Open J. Compos. Mater. 2021, 11, 47–61. [Google Scholar] [CrossRef]

- Leong, J.J.A.; Koay, S.C.; Chan, M.Y.; Choo, H.L.; Tshai, K.Y.; Ong, T.K. Composite Filament Made fromPost-used Styrofoam and Corn Husk Fiber for Fuse Deposition Modeling. J. Nat. Fibers 2021, 19, 7033–7048. [Google Scholar] [CrossRef]

- Milosevic, M.; Stoof, D.; Pickering, K.L. Characterizing the Mechanical Properties of Fused Deposition Modelling Natural Fiber Recycled Polypropylene Composites. J. Compos. Sci. 2017, 1, 7. [Google Scholar] [CrossRef]

- Chatham, C.A.; Zawaski, C.E.; Bobbitt, D.C.; Moore, R.B.; Long, T.E.; Williams, C.B. Semi-Crystalline Polymer Blends for Material Extrusion Additive Manufacturing Printability: A Case Study withPoly(ethylene terephthalate) and Polypropylene. Macromol. Mater. Eng. 2019, 304, 1800764. [Google Scholar] [CrossRef]

- Bauer, W.; Kawala-Janik, A. Implementation of bi-fractional filtering on the Arduino Uno hard ware platform. Lect. Notes Electr. Eng. 2017, 407, 419–428. [Google Scholar] [CrossRef]

- Kawala-Janik, A.; Bauer, W.; Zolubak, M.; Baranowski, J. Early-stage pilot study on using fractional-order calculus-based filtering for the purpose of analysis of electroencephalography signals. Stud. Log. Gramm. Rhetor. 2016, 47, 103–111. [Google Scholar] [CrossRef]

- Flizikowski, J.; Piasecka, I.; Kruszelnicka, W.; Tomporowski, A.; Mroziński, A. Destruction assessment of wind power plastics blade. Polimery 2018, 63, 381–386. [Google Scholar] [CrossRef]

- Wojcik, G.M.; Kaminski, W.A. Self-organised criticality as a function of connections’ number in the model of the rat somatosensory cortex. In Computational Science, Proceedings of the ICCS 2008: 8th International Conference, Kraków, Poland, 23–25 June 2008; Proceedings, Part I 8; Springer: Berlin/Heidelberg, Germany, 2008; pp. 620–629. [Google Scholar] [CrossRef]

- Grzesiak, K.; Piotrowski, Z.; Kelner, J.M. A wireless covert channel based on dirty constellation with chase drift. Electronics 2021, 10, 647. [Google Scholar] [CrossRef]

- Sieczkowski, K.; Sondej, T.; Dobrowolski, A.; Olszewski, R. Autocorrelation algorithm for determining a pulse wave delay. In Proceedings of the 2016 Signal Processing: Algorithms, Architectures, Arrangements, and Applications (SPA), Poznan, Poland, 21–23 September 2016; pp. 321–326. [Google Scholar] [CrossRef]

- Lima, G.M.R.; Mukherjee, A.; Picchioni, F.; Bose, R.K. Characterization of Biodegradable Polymers for Porous Structure: Further Steps toward Sustainable Plastics. Polymers 2024, 16, 1147. [Google Scholar] [CrossRef] [PubMed]

- Bogard, F.; Bach, T.; Bogard, V.; Beaumont, F.; Murer, S.; Bliard, C.; Polidori, G. Mechanical Properties of a PLA/Nettle Agro-Composite with 10% Oriented Fibers. Appl. Sci. 2022, 12, 9835. [Google Scholar] [CrossRef]

- Chung, T.-J.; Park, J.-W.; Lee, H.-J.; Kwon, H.-J.; Kim, H.-J.; Lee, Y.-K.; Tai Yin Tze, W. The Improvement of Mechanical Properties, Thermal Stability, and Water Absorption Resistance of an Eco-Friendly PLA/Kenaf Biocomposite Using Acetylation. Appl. Sci. 2018, 8, 376. [Google Scholar] [CrossRef]

- Flizikowski, J.; Kruszelnicka, W.; Macko, M. The Development of Efficient Contaminated Polymer Materials Shredding in Recycling Processes. Polymers 2021, 13, 713. [Google Scholar] [CrossRef]

- Murawski, K.; Sondej, T.; Rozanowski, K.; Macander, M.; Macander, L. The contactless active optical sensor for vehicle driverfatigue detection. In Proceedings of the SENSORS, 2013 IEEE, Baltimore, MD, USA, 3–6 November 2013. [Google Scholar] [CrossRef]

- Ratner, S.; Gomonov, K.; Revinova, S.; Lazanyuk, I. Eco-Design of Energy Production Systems: The Problem of Renewable Energy Capacity Recycling. Appl. Sci. 2020, 10, 4339. [Google Scholar] [CrossRef]

- Grigore, M.E. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Piasecka, I.; Tomporowski, A.; Flizikowski, J.; Kruszelnicka, W.; Kasner, R.; Mroziński, A. Life Cycle Analysis of Ecological Impacts of an Offshore and a Land-Based Wind Power Plant. Appl. Sci. 2019, 9, 231. [Google Scholar] [CrossRef]

- Piasecka, I.; Bałdowska-Witos, P.; Piotrowska, K.; Tomporowski, A. Eco-Energetical Life Cycle Assessment of Materials and Components of Photovoltaic Power Plant. Energies 2020, 13, 1385. [Google Scholar] [CrossRef]

- Bałdowska-Witos, P.; Kruszelnicka, W.; Kasner, R.; Tomporowski, A.; Flizikowski, J.; Kłos, Z.; Piotrowska, K.; Markowska, K. Application of LCA Method for Assessment of Environmental Impacts of a Polylactide (PLA) Bottle Shaping. Polymers 2020, 12, 388. [Google Scholar] [CrossRef] [PubMed]

- Piotrowska, K.; Kruszelnicka, W.; Bałdowska-Witos, P.; Kasner, R.; Rudnicki, J.; Tomporowski, A.; Flizikowski, J.; Opielak, M. Assessment of the Environmental Impact of a Car Tire through out Its Lifecycle Using the LCA Method. Materials 2019, 12, 4177. [Google Scholar] [CrossRef] [PubMed]

- Hocine, L.; MouniaSamira, K. Optimal PV Panel’s End-Life Assessment Based on the Supervision of Their Own Aging Evolution and Waste Management Forecasting. Sol. Energy 2019, 191, 227–234. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Spencer, N. Waste Prevention and Technologies. Eur. Energy Environ. Law Rev. 2017, 26, 66–80. [Google Scholar] [CrossRef]

- Benabderrahmane, A.; Zeghloul, T.; Aksa, W.; Tilmatine, A.; Medles, K.; Dascalescu, L. Shredding as Simultaneous Size-Reduction and Tribo-Charging Operation for Improved Performance of an Electrostatic Separation Processfor Granular Plastic Wastes. Part. Sci. Technol. 2019, 38, 827–834. [Google Scholar] [CrossRef]

- Thi, B.N.V.; Vu-Khanh, T.; Lara, J. Effect of Friction on Cut Resistance of Polymers. J. Thermoplast. Compos. Mater. 2005, 18, 23–35. [Google Scholar] [CrossRef]

- Pires, A.; Martinho, G.; Rodrigues, S.; Gomes, M.I. Prevention and Reuse: Waste Hierarchy Steps Before Waste Collection. In Sustainable Solid Waste Collection and Management; Pires, A., Martinho, G., Rodrigues, S., Gomes, M.I., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 13–23. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef]

- Mahmood, A.; Abdullah, M.I.; Nazar, M.F. Quantum Chemical Designing of Novel Organic Non-Linear Optical Compounds. Bull. Korean Chem. Soc. 2014, 35, 1391–1396. [Google Scholar] [CrossRef]

- Mahmood, A.; Abdullah, M.I.; Ud-Din Khan, S. Enhancement of nonlinear optical (NLO) properties of indigo through modification of auxiliary donor, donor and akceptor. Spectrochim. Acta Part A: Mol. Biomol. Spectrosc. 2015, 139, 425–430. [Google Scholar] [CrossRef] [PubMed]

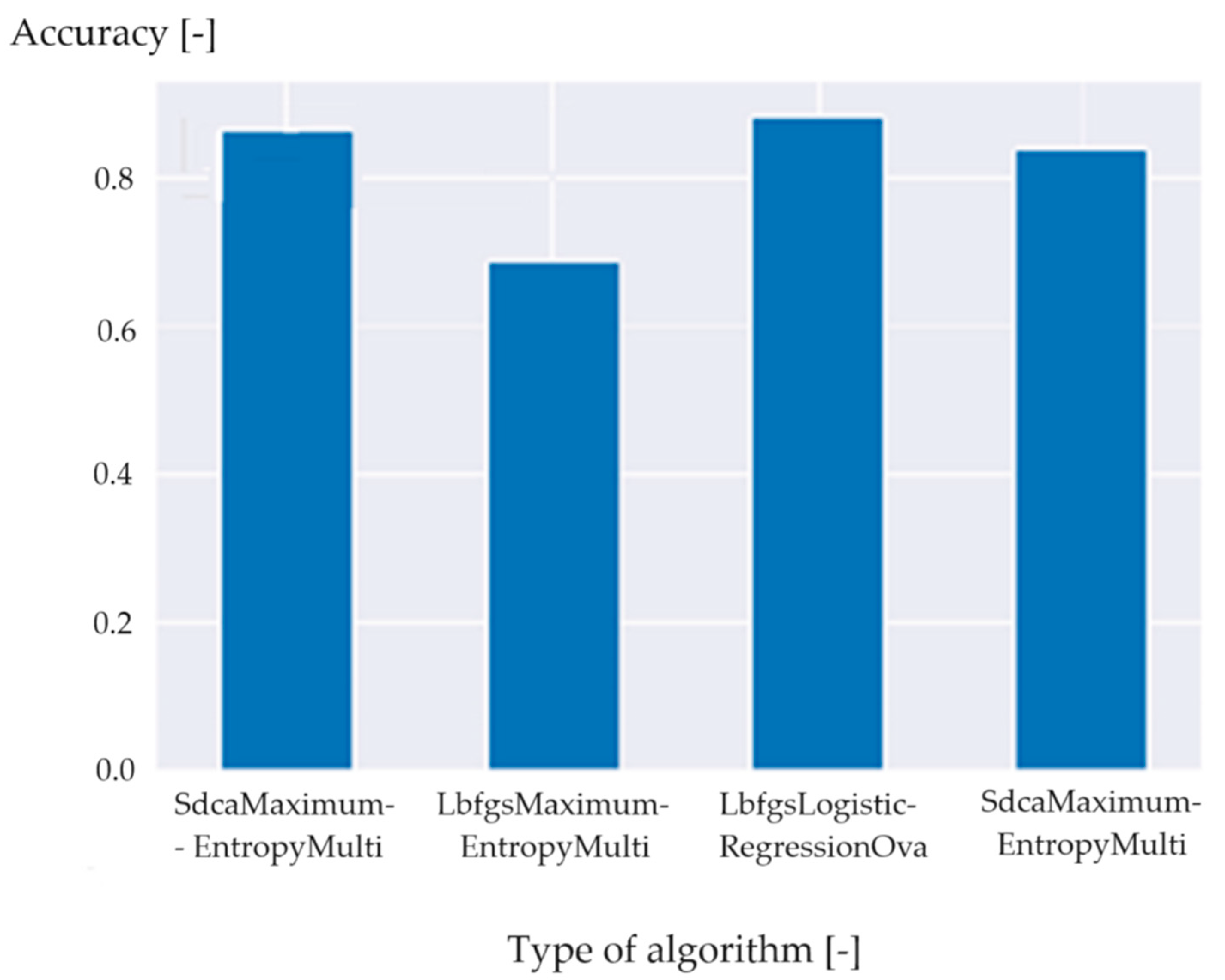

| Algorithm | MicroAccuracy | MacroAccuracy | Duration (Related) |

|---|---|---|---|

| SdcaMaximumEntropyMulti | 0.5167 | 0.5500 | 4.0 |

| FastTreeOva | 0.0900 | 0.0750 | 4.9 |

| SdcaMaximumEntropyMulti | 0.0900 | 0.0750 | 18,6 |

| LbfgsMaximumEntropyMulti | 0.6600 | 0.7083 | 1,2 |

| SdcaLogisticRegressionOva | 0.1033 | 0.1083 | 21.6 |

| LbfgsLogisticRegressionOva | 0.6600 | 0.7083 | 2.0 |

| FastForestOva | 0.6000 | 0.6000 | 8.4 |

| LightGbmMulti | 0.6712 | 0.6933 | 1.9 |

| FastTreeOva | 0.0900 | 0.0750 | 8.2 |

| SdcaMaximumEntropyMulti | 0.8667 | 0.8667 | 2.2 |

| LbfgsMaximumEntropyMulti | 0.6600 | 0.7083 | 1.1 |

| SdcaMaximumEntropyMulti | 0.8667 | 0.8667 | 2.2 |

| SdcaLogisticRegressionOva | 0.0333 | 0.0333 | 13.3 |

| LbfgsLogisticRegressionOva | 0.9000 | 0.9000 | 2.4 |

| LbfgsMaximumEntropyMulti | 0.7600 | 0.7600 | 1.2 |

| Algorithm | MicroAccuracy | MacroAccuracy |

|---|---|---|

| LbfgsLogisticRegressionOva | 0.9213 | 0.9333 |

| SdcaMaximumEntropyMulti | 0.8799 | 0.8912 |

| SdcaMaximumEntropyMulti | 0.8667 | 0.8667 |

| LbfgsMaximumEntropyMulti | 0.6979 | 0.7238 |

| LbfgsLogisticRegressionOva | 0.6801 | 0.7182 |

| Strengths | Weaknesses |

| IoT support 24/7 monitoring ML-based analysis and prediction Warnings and alerts Multipurpose use Automatization of data collection Relatively low cost per device/machine Intuitive use Individualized use | Limited number and quality of data sets to begin Lack of historical data sets Introduction requires educated specialists |

| Opportunities | Threats |

| Reduced workload toward optimization Early diagnosis Preventive intervention Easier testing Novel diagnostic methods Novel factors taken into consideration within processes Possibility of standardization Quick further development Part of bigger systems | Non-acceptance of AI/ML |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojek, I.; Macko, M.; Mikołajewski, D. Machine Learning in the Analysis of the Mechanical Shredding Process of Polymer Recyclates. Polymers 2024, 16, 1852. https://doi.org/10.3390/polym16131852

Rojek I, Macko M, Mikołajewski D. Machine Learning in the Analysis of the Mechanical Shredding Process of Polymer Recyclates. Polymers. 2024; 16(13):1852. https://doi.org/10.3390/polym16131852

Chicago/Turabian StyleRojek, Izabela, Marek Macko, and Dariusz Mikołajewski. 2024. "Machine Learning in the Analysis of the Mechanical Shredding Process of Polymer Recyclates" Polymers 16, no. 13: 1852. https://doi.org/10.3390/polym16131852

APA StyleRojek, I., Macko, M., & Mikołajewski, D. (2024). Machine Learning in the Analysis of the Mechanical Shredding Process of Polymer Recyclates. Polymers, 16(13), 1852. https://doi.org/10.3390/polym16131852