Process Characterizations of Ultrasonic Extruded Weld-Riveting of AZ31B Magnesium Alloy to Carbon Fiber-Reinforced PA66

Abstract

1. Introduction

2. Experimental Procedures

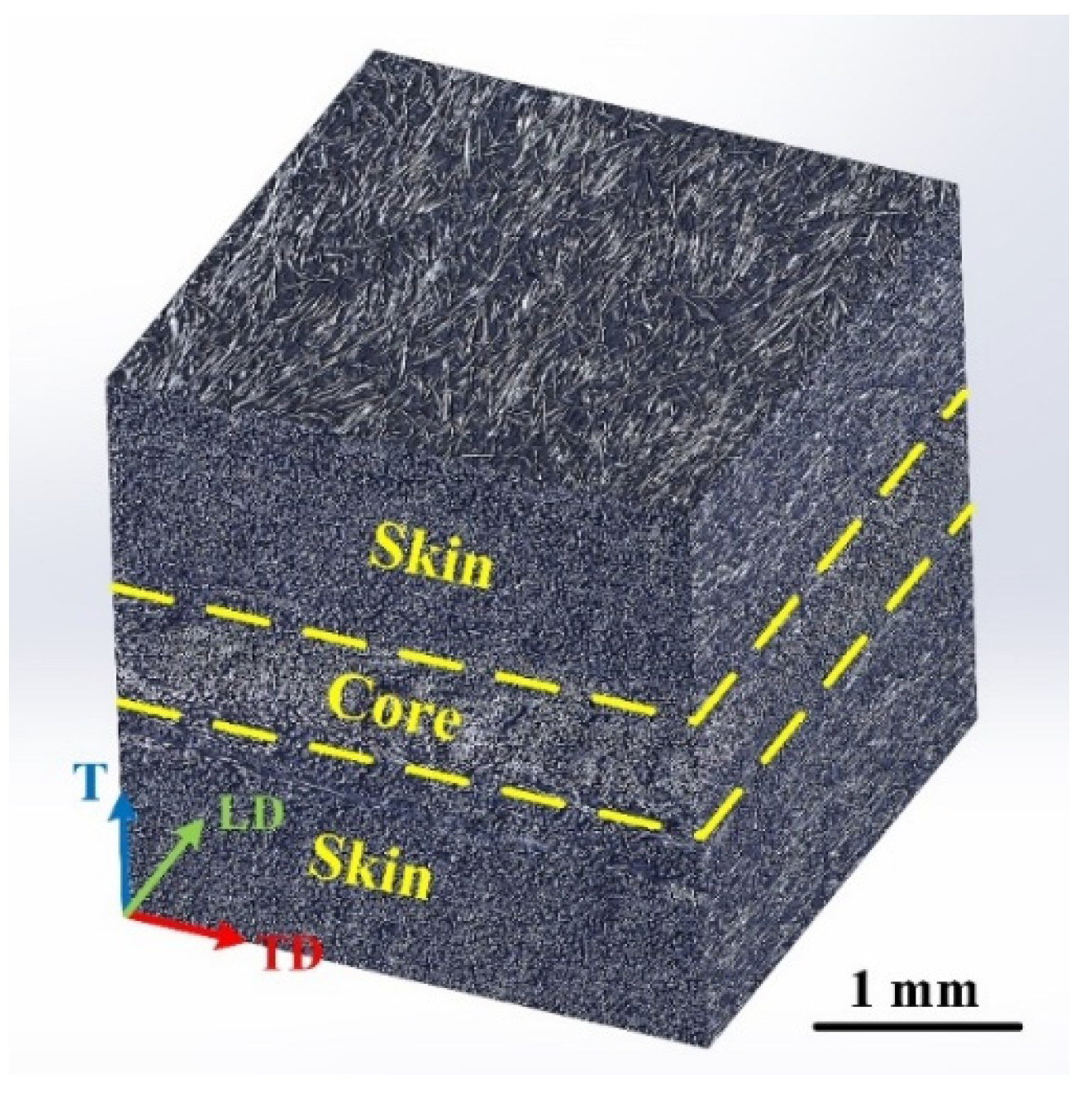

2.1. Materials

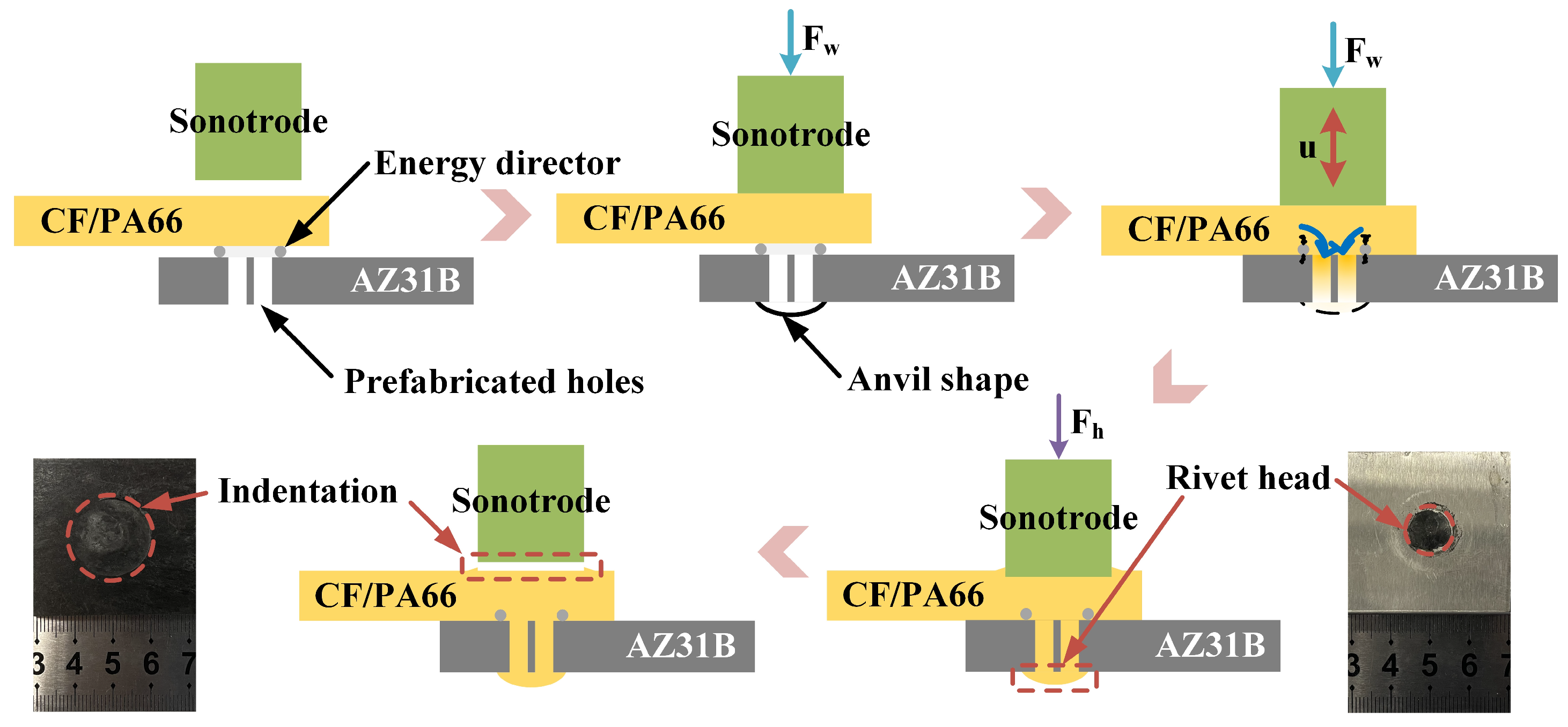

2.2. Ultrasonic Extruded Weld-Riveting

2.3. Tensile Shear Test and Microstructural Observation

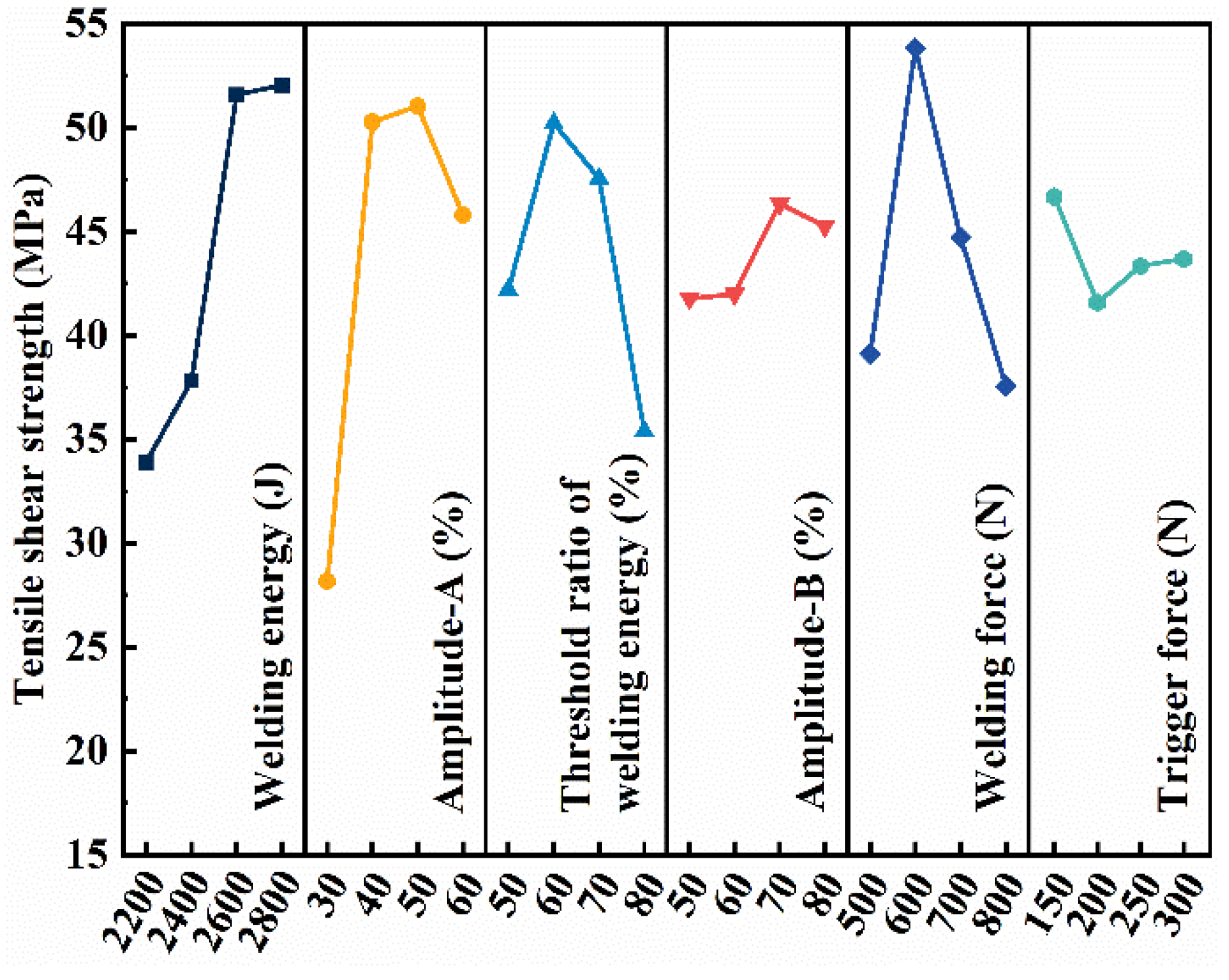

3. Results and Discussion

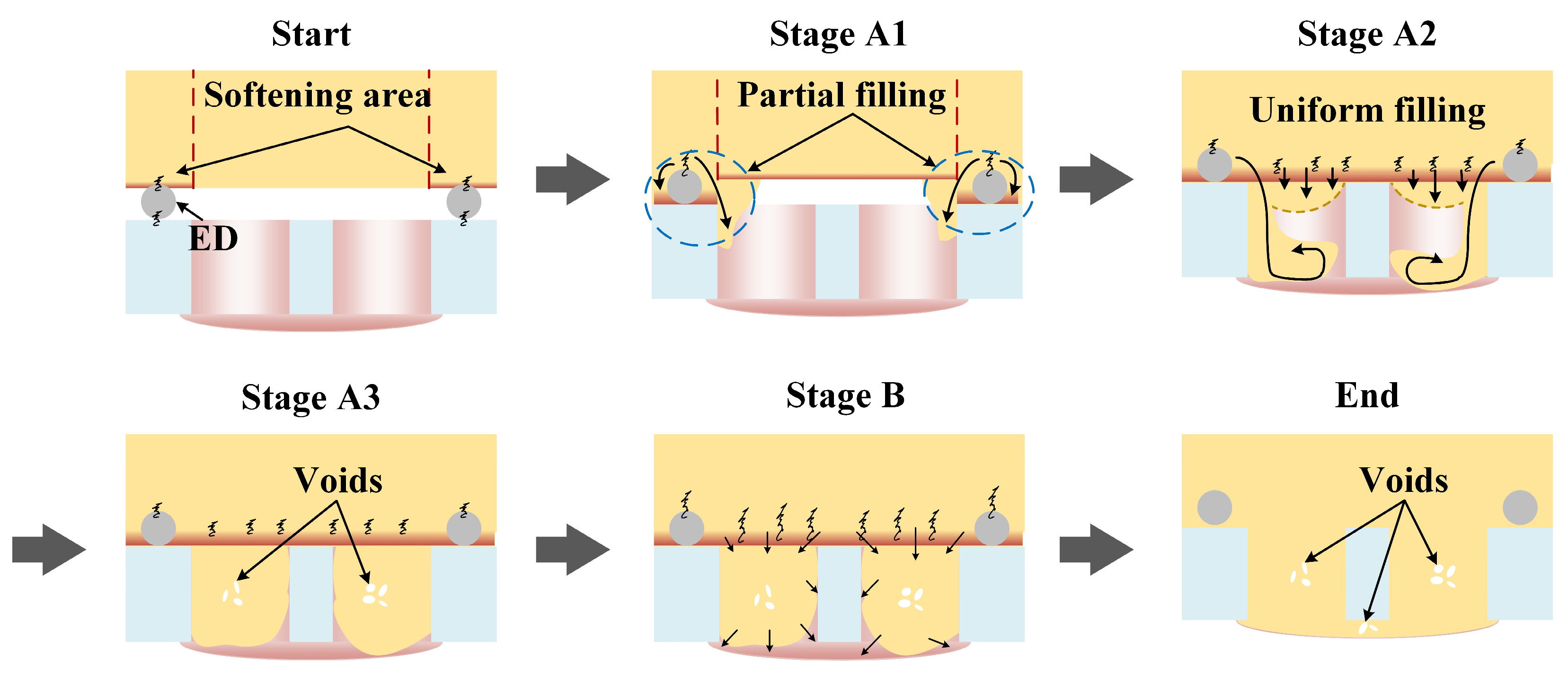

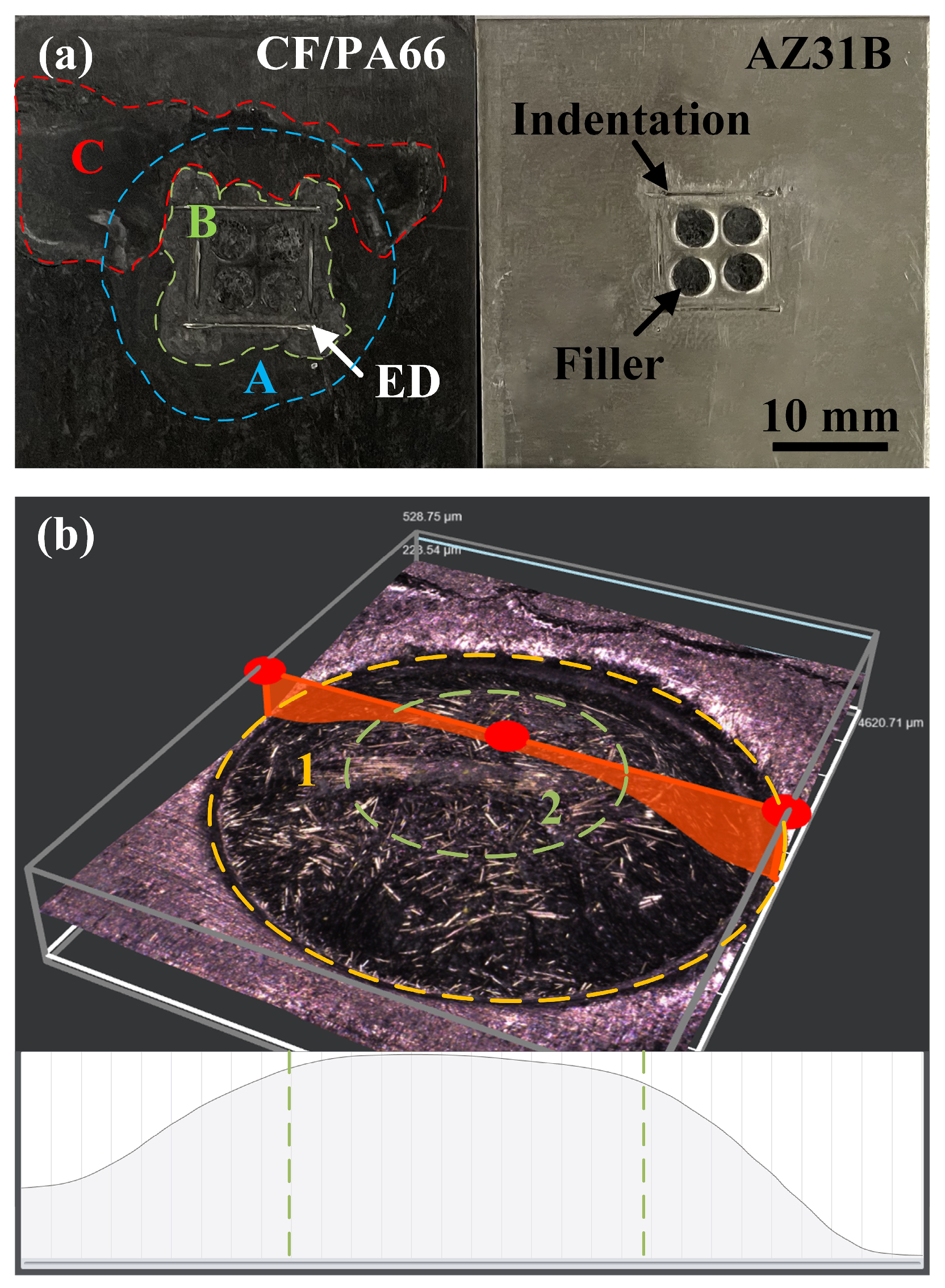

3.1. Weld Quality

3.2. Cross-Sections of Joints

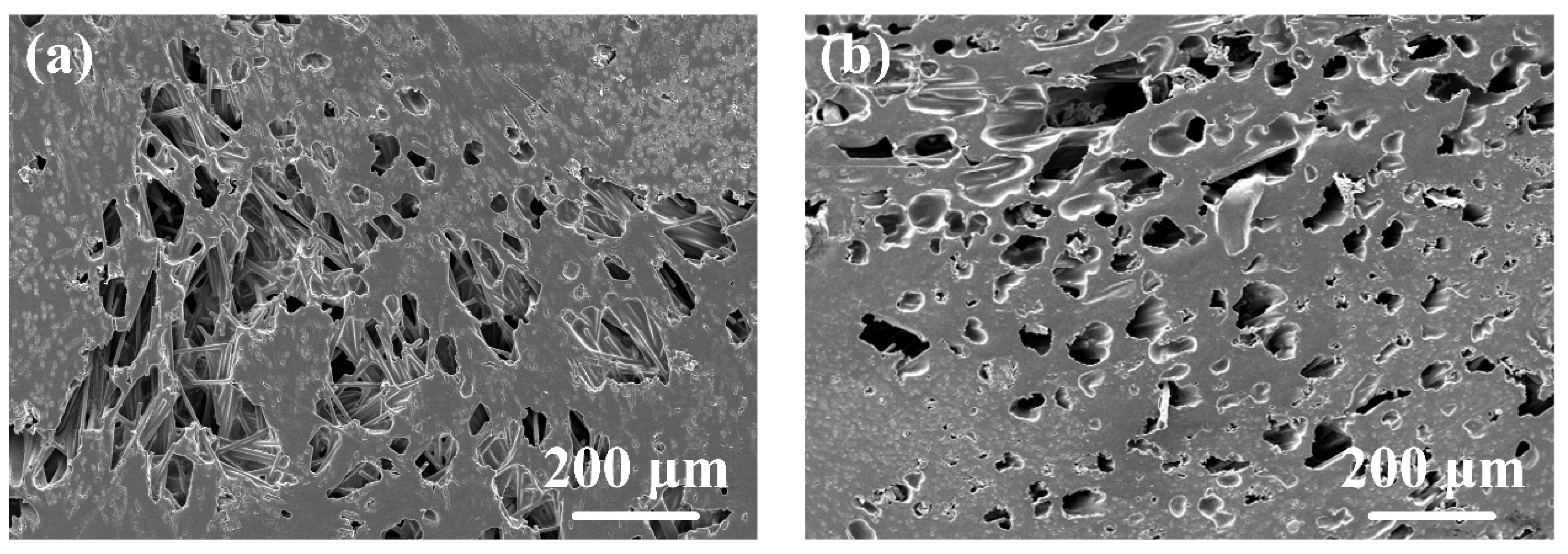

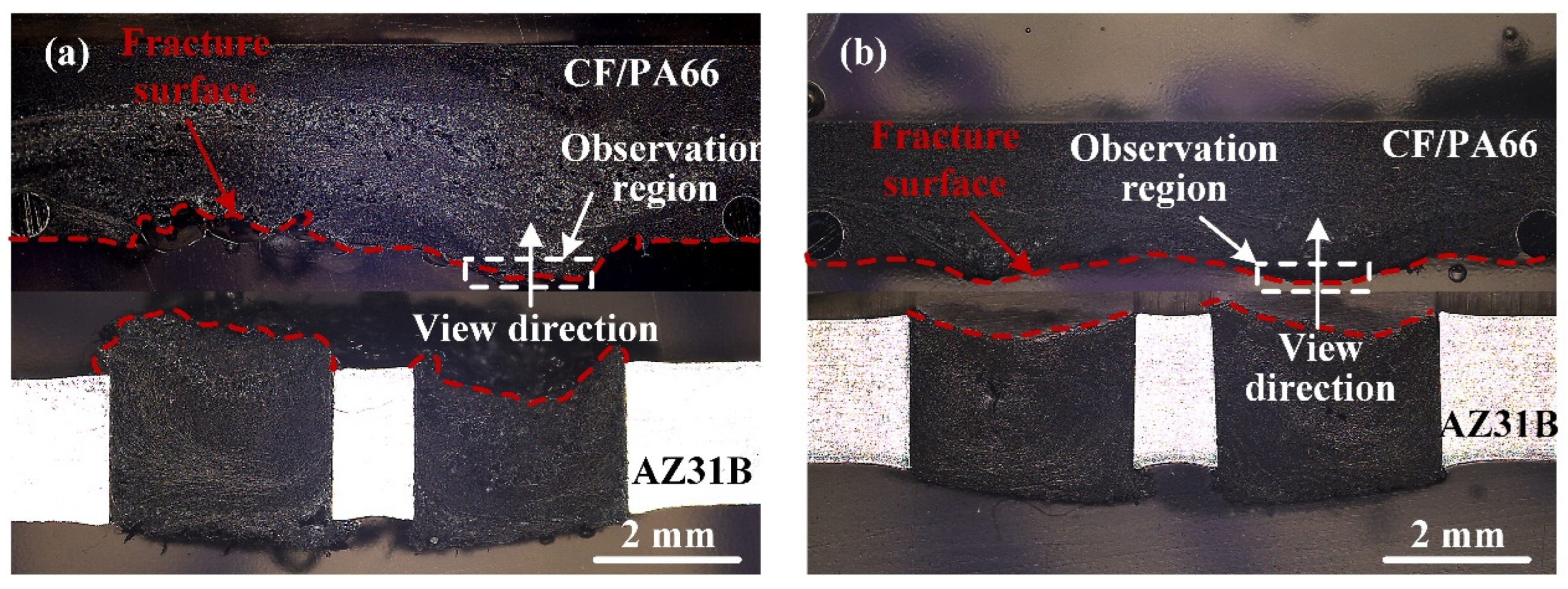

3.3. Fractography

4. Conclusions

- (1)

- Welding energy and amplitude-A have greater impact on joint strength. A stepped amplitude strategy could promote the flow of molten resin and facilitate better joint appearance. The maximum tensile shear strength is about 56.5 ± 6.2 MPa with the optimal parameters (welding energy 2800 J, amplitude-A 50%, threshold ratio of welding energy 60%, amplitude-B 70%, welding force 600 N and trigger force 200 N).

- (2)

- Two flow patterns of molten resin are observed. One is when the molten resin flows along the sidewall of the holes and refluxes when it reaches the bottom of the holes, and the other is when the molten resin flows into the hole uniformly in an arc shape.

- (3)

- Insufficient (welding energy < 2600 J or amplitude-A < 50%) or excessive (welding energy > 2800 J or amplitude-A > 50%) heat input will introduce porous areas inside the joint, causing the joints fracture along the porous areas. With optimal welding parameters, the joints fail through fiber–matrix debonding.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, B.; Chen, Q.; Yang, J. Advances in joining technology of carbon fiber-reinforced thermoplastic composite materials and aluminum alloys. Int. J. Adv. Manuf. Technol. 2020, 110, 2631–2649. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M.; Takahashi, J. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.; Zitoune, R.; Morel, C.; Ferrero, J.F.; Vieille, B. Joining of AA5052 to CF/PEEK by friction lap welding. Int. J. Adv. Manuf. Technol. 2024, 132, 1137–1150. [Google Scholar] [CrossRef]

- Lambiase, F.; Yanala, P.B.; Leone, C.; Paoletti, A. Repairing aluminum-PEEK hybrid metal-polymer joints made by thermo-mechanical joining. J. Manuf. Process 2023, 93, 1–14. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Liu, Z.; Yang, Y.; Li, Y.; Luo, Z. Ultrasonic welding of metal to fiber-reinforced thermoplastic composites: A review. J. Manuf. Process 2023, 85, 702–712. [Google Scholar] [CrossRef]

- Bi, X.; Wang, Z.; Xu, M.; Li, X. Femtosecond laser fabricated micro/nano interfacial structures to strengthen CFRPEEK/A6061-T6 FLJ hybrid joints. Compos. B Eng. 2022, 231, 109540. [Google Scholar] [CrossRef]

- Kumar, R.K.; Omkumar, M. Investigation of ultrasonic welding of carbon fiber reinforced thermoplastic to an aluminum alloy using a interfacial coating. Mater. Manuf. Process. 2021, 36, 1323–1331. [Google Scholar] [CrossRef]

- Sarantinos, N.; Kostopoulos, V.; Di-Vita, G.; Campoli, G.; Bricout, L. Micro-pins: The next step in composite-composite and metal-composite joining. CEAS Space J. 2019, 11, 351–358. [Google Scholar] [CrossRef]

- Tan, C.; Su, J.; Liu, Y.; Feng, Z.; Song, X.; Wang, X.; Chen, B. Enhanced interfacial bonding strength of laser bonded titanium alloy/CFRTP joint via hydrogen bonds interaction. Compos. B Eng. 2022, 239, 109966. [Google Scholar] [CrossRef]

- Kim, S.G.; Suzuki, A.; Takata, N.; Kobashi, M. Effect of hot-press thermal history on joint strength of A5052/Polyamide-6 hybrid structure via a porous layer. J. Mater. Process. Technol. 2020, 276, 116388. [Google Scholar] [CrossRef]

- Lim, Y.C.; Jun, J.; Leonard, D.N.; Li, Y.; Chen, J.; Brady, M.P.; Feng, Z. Study of galvanic corrosion and mechanical joint properties of AZ31B and carbon-fiber-reinforced polymer joined by friction self-piercing riveting. J. Magnes. Alloys 2022, 10, 400–410. [Google Scholar] [CrossRef]

- Li, Y.; Hu, S.; Shriver, D.; Wang, K.; Banu, M.; Arinez, J.F. Ultrasonic Welding of Dissimilar Sheet Materials. U.S. Patent US11027498B2, 29 May 2018. [Google Scholar]

- Zhou, H.; Li, Y.; Liu, W.; Luo, Y.; Ao, S.; Luo, Z. Effect of Process Parameters on Joint Performance in Hot Pressure Welding of 6061 Aluminum Alloy to CF/PA66. Materials 2024, 17, 329. [Google Scholar] [CrossRef]

- Lv, Z.; Liang, Y.; Jia, M.; Wang, J.; Zhang, X. Analysis of Factors Affecting Magnetic Memory Time of CaCO3 Solutions Based on Orthogonal Experiment. Sens. Mater. 2020, 32, 1139–1350. [Google Scholar] [CrossRef]

- Li, W.; Wang, D.; Cheng, P.; Liu, X.; Zhang, P. Springback simulation analysis of angle shape forming of springs based on orthogonal experiment method. IOP Conf. Ser. J. Phys. Conf. Ser. 2019, 1303, 012149. [Google Scholar] [CrossRef]

- Kawakami, K.; Yasuda, K. Ultrasonic joining of carbon fiber reinforced thermoplastic and magnesium alloy. In Proceedings of the 2019 IEEE CPMT Symposium Japan (ICSJ), Kyoto, Japan, 18–20 November 2019; pp. 135–137. [Google Scholar]

- Liu, Y.; Su, J.; Ma, G.; Han, X.; Tan, C.; Wu, L.; Chen, B.; Song, X. Effect of the laser texturing width on hot-pressing joining of AZ31B and CFRTP. Opt. Laser Technol. 2021, 143, 107350. [Google Scholar] [CrossRef]

- Arkhurst, B.M.; Lee, M.; Kim, J.H. Effect of resin matrix on the strength of an AZ31 Mg alloy-CFRP joint made by the hot metal pressing technique. Compos. Struct. 2018, 201, 303–314. [Google Scholar] [CrossRef]

- Arkhurst, B.M.; Kim, J.H.; Lee, M.Y. Hot metal pressing joining of carbon fiber reinforced plastic to AZ31 Mg alloy and the effect of the oxide surface layer on joint strength. Appl. Surf. Sci. 2019, 477, 241–256. [Google Scholar] [CrossRef]

- Arkhurst, B.M.; Seol, J.B.; Seoung, Y.; Lee, M.Y.; Kim, J.H. Interfacial structure and bonding mechanism of AZ31/carbon-fiber-reinforced plastic composites fabricated by thermal laser joining. Compos. B Eng. 2019, 167, 71–82. [Google Scholar] [CrossRef]

- Wahba, M.; Kawahito, Y.; Katayama, S. Laser direct joining of AZ91D thixomolded Mg alloy and amorphous polyethylene terephthalate. J. Mater. Process. Technol. 2011, 211, 1166–1174. [Google Scholar] [CrossRef]

- Tan, C.; Liu, Y.; Liu, F.; Su, J.; Zhang, Z.; Zhang, X.; Song, K.; Chen, B.; Song, X. Effect of laser power on laser joining of carbon fiber reinforced plastic to AZ31B Mg alloy. Opt. Laser Technol. 2022, 145, 107449. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, C.; Zhang, Z.; Su, J.; Song, X.; Chen, B.; Xia, H.; Wu, T. Surface pre-oxidation for enhancing laser assisted joining between carbon fiber reinforced thermoplastic composites and AZ31B Mg alloy. J. Mater. Process. Technol. 2023, 312, 117871. [Google Scholar] [CrossRef]

- Wang, H.; Li, N.; Liu, L. Investigation of the Joining Technology of FRP/AZ31B Magnesium Alloy by Welding and Riveting Hybrid Bonding Method. Materials 2019, 12, 2167. [Google Scholar] [CrossRef]

- Wang, H.; Dong, Y.; Hu, Z.; Liu, L. The research on laser welding-riveting hybrid bonding of titanium alloy and carbon fiber reinforced composites. Opt. Laser Technol. 2022, 155, 108405. [Google Scholar] [CrossRef]

- Wang, H.; Huang, B.; Li, J.; Li, N.; Liu, L. Welding and Riveting Hybrid Bonding of 6061 Al and Carbon Fiber Reinforced Composites. Polymers 2022, 14, 99. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Z.; Dong, Y.; Chen, S.; Liu, L. Research on the hybrid joining process and failure mode of laser welding and riveting on QP980 steel/CFRP. J. Manuf. Process 2023, 90, 310–320. [Google Scholar] [CrossRef]

- Liu, F.C.; Nakata, K.; Liao, J.; Hirota, S.; Fukui, H. Reducing bubbles in friction lap welded joint of magnesium alloy and polyamide. Sci. Technol. Weld. Join. 2014, 19, 578–587. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Xie, Y.; Li, J.; Guan, M.; Wan, L.; Dong, Z.; Cao, J. Friction self-riveting welding between polymer matrix composites and metals. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105624. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Feed temperature (°C) | 80 |

| Zone 1 temperature (°C) | 290 |

| Zone 2 temperature (°C) | 300 |

| Zone 3 temperature (°C) | 310 |

| Nozzle temperature (°C) | 300 |

| Tool temperature (°C) | 100 |

| Hold-on pressure (bar) | 550 |

| Dynamic pressure (bar) | 40 |

| Screw speed (m/min) | 7 |

| Materials | Glass Transition Temperature (°C) | Melting Point (°C) | Density (g/cm3) | Tensile Modulus (GPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|---|

| AZ31B | --- | 650 | 1.78 | 45 | 260 | 9 |

| CF/PA66 | 85 | 260 | 1.34 | 29.5 | 335 | 1.4 |

| Parameters | Levels | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Welding energy (J) | 2200 | 2400 | 2600 | 2800 |

| Amplitude-A (%) | 30 | 40 | 50 | 60 |

| Threshold ratio of welding energy (%) | 50 | 60 | 70 | 80 |

| Amplitude-B (%) | 50 | 60 | 70 | 80 |

| Welding force (N) | 500 | 600 | 700 | 800 |

| Trigger force (N) | 150 | 200 | 250 | 300 |

| Welding Energy (J) | Amplitude-A (%) | Threshold Ratio of Welding Energy (%) | Amplitude-B (%) | Welding Force (N) | Trigger Force (N) | |

|---|---|---|---|---|---|---|

| Mechanical property | 2800 | 50 | 60 | 70 | 600 | 150 |

| Filling performance | 2200 | 60 | 50 | 70 | 600 | 200 |

| Balanced | 2800 | 50 | 60 | 70 | 600 | 200 |

| Methods | Materials | Pre-Treatment/Post-Treatment | Tensile Shear Strength/Force | Ref. |

|---|---|---|---|---|

| Ultrasonic welding | AZX612/CF-PA6 | Plasma electrolytic oxidation treatment of Mgalloy surface and preheating before welding/None | 5.7 MPa | [16] |

| Hot-pressing joining | AZ31B/CF-PEEK | Laser texturing of mg alloy surface/None | 5.4 MPa * | [17] |

| Hot-pressing joining | AZ31/CF-TPU(CF/PA66) | Alcohol cleaning of workpiece surface/Annealing | 4.6 MPa * for AZ31/CF-TPU; 6.9 MPa * for AZ31/CF/PA66 | [18] |

| Hot-pressing joining | AZ31/CF-TPU | None/Annealing | 4.6 MPa * | [19] |

| Laser welding | AZ31/PU | Alcohol cleaning of workpiece surface/Annealing | 4 MPa * | [20] |

| Laser welding | AZ91D/PET | Laser melting treatment of Mg alloy surface/None | 8.7 MPa | [21] |

| Laser welding | AZ31B/CF-PEEK | Polishing the oxide layer on the AZ31B surface with abrasive papers and ultrasonic cleaning of the workpieces/None | 9 MPa | [22] |

| Laser welding | AZ31/CF/PA66 | Micro-arc oxidation treatment/None | 13.3 MPa | [23] |

| Laser-TIG welding–riveting | AZ31B/CF-PEEK | Punching, specially designed rivet | 1.4 kN | [24] |

| Laser welding–riveting | TC4/CF-PEEK | Punching, specially designed rivet | 8.5 kN | [25] |

| Laser welding–riveting | AA6061/CF-PEEK | Punching, specially designed rivet | 4.7 kN | [26] |

| Laser welding–riveting | DP980/CF-PEEK | Punching, specially designed rivet | 10 kN | [27] |

| Friction welding | AZ31B/PA6 | Gritting the Mg alloy surface with #800 sandpaper/None | 5.8 MPa * | [28] |

| Friction self-riveting welding | AA2060/GF-PPS | Prefabricated holes in Al sheet/None | 27 MPa | [29] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Lu, G.; Yang, Y.; Ao, S.; Wang, K.; Li, Y. Process Characterizations of Ultrasonic Extruded Weld-Riveting of AZ31B Magnesium Alloy to Carbon Fiber-Reinforced PA66. Polymers 2024, 16, 1749. https://doi.org/10.3390/polym16121749

Liu Z, Lu G, Yang Y, Ao S, Wang K, Li Y. Process Characterizations of Ultrasonic Extruded Weld-Riveting of AZ31B Magnesium Alloy to Carbon Fiber-Reinforced PA66. Polymers. 2024; 16(12):1749. https://doi.org/10.3390/polym16121749

Chicago/Turabian StyleLiu, Zeguang, Guanxiong Lu, Yuanduo Yang, Sansan Ao, Kaifeng Wang, and Yang Li. 2024. "Process Characterizations of Ultrasonic Extruded Weld-Riveting of AZ31B Magnesium Alloy to Carbon Fiber-Reinforced PA66" Polymers 16, no. 12: 1749. https://doi.org/10.3390/polym16121749

APA StyleLiu, Z., Lu, G., Yang, Y., Ao, S., Wang, K., & Li, Y. (2024). Process Characterizations of Ultrasonic Extruded Weld-Riveting of AZ31B Magnesium Alloy to Carbon Fiber-Reinforced PA66. Polymers, 16(12), 1749. https://doi.org/10.3390/polym16121749