A Review of EPDM (Ethylene Propylene Diene Monomer) Rubber-Based Nanocomposites: Properties and Progress

Abstract

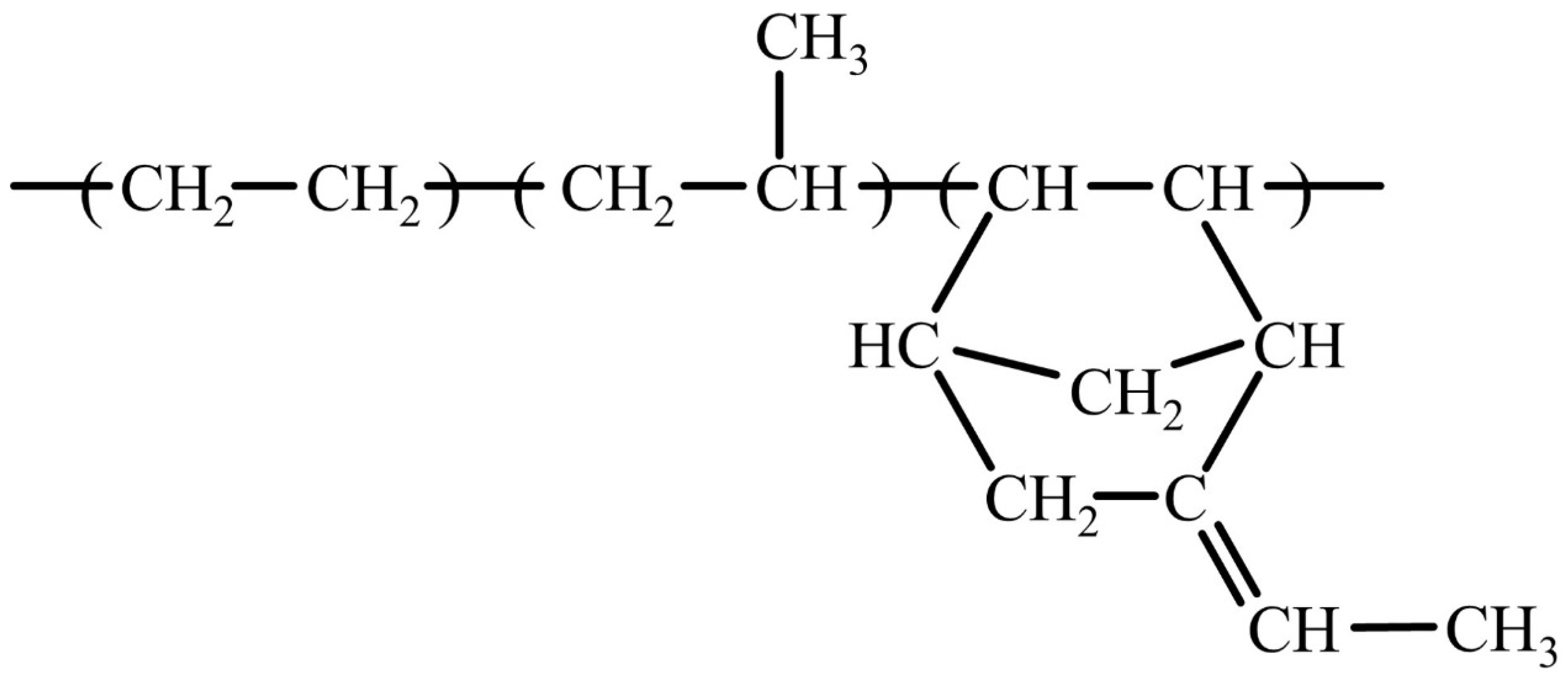

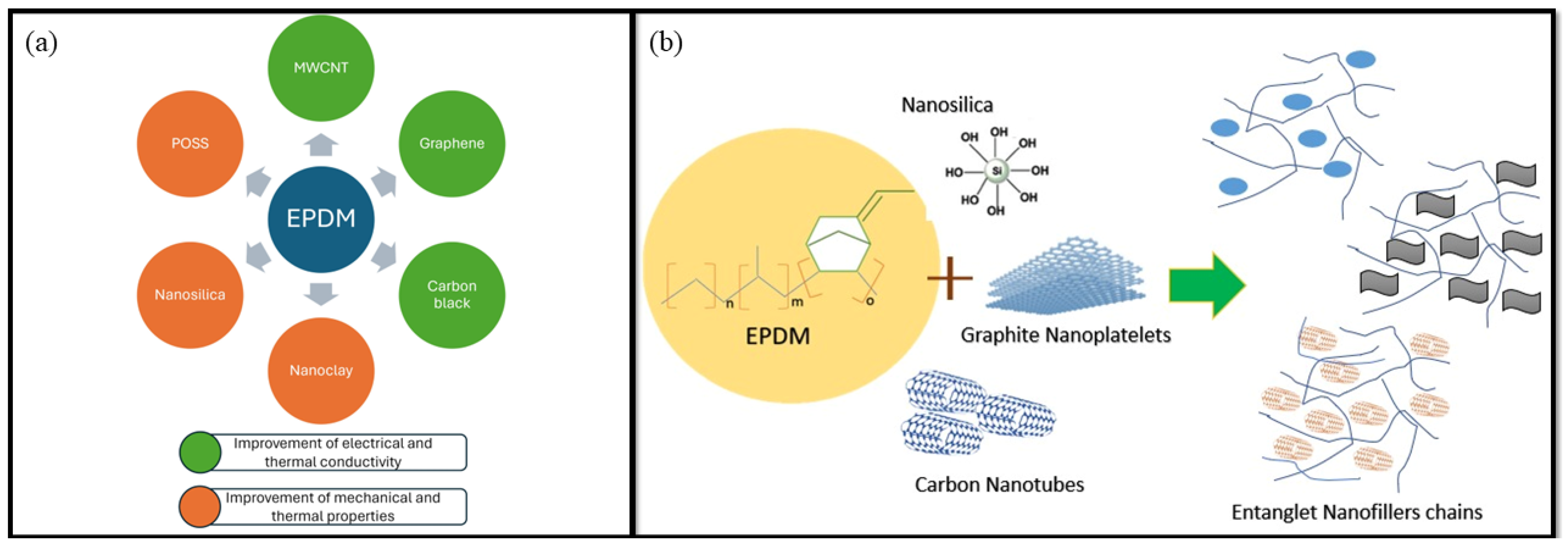

1. Introduction

2. Mechanical Properties

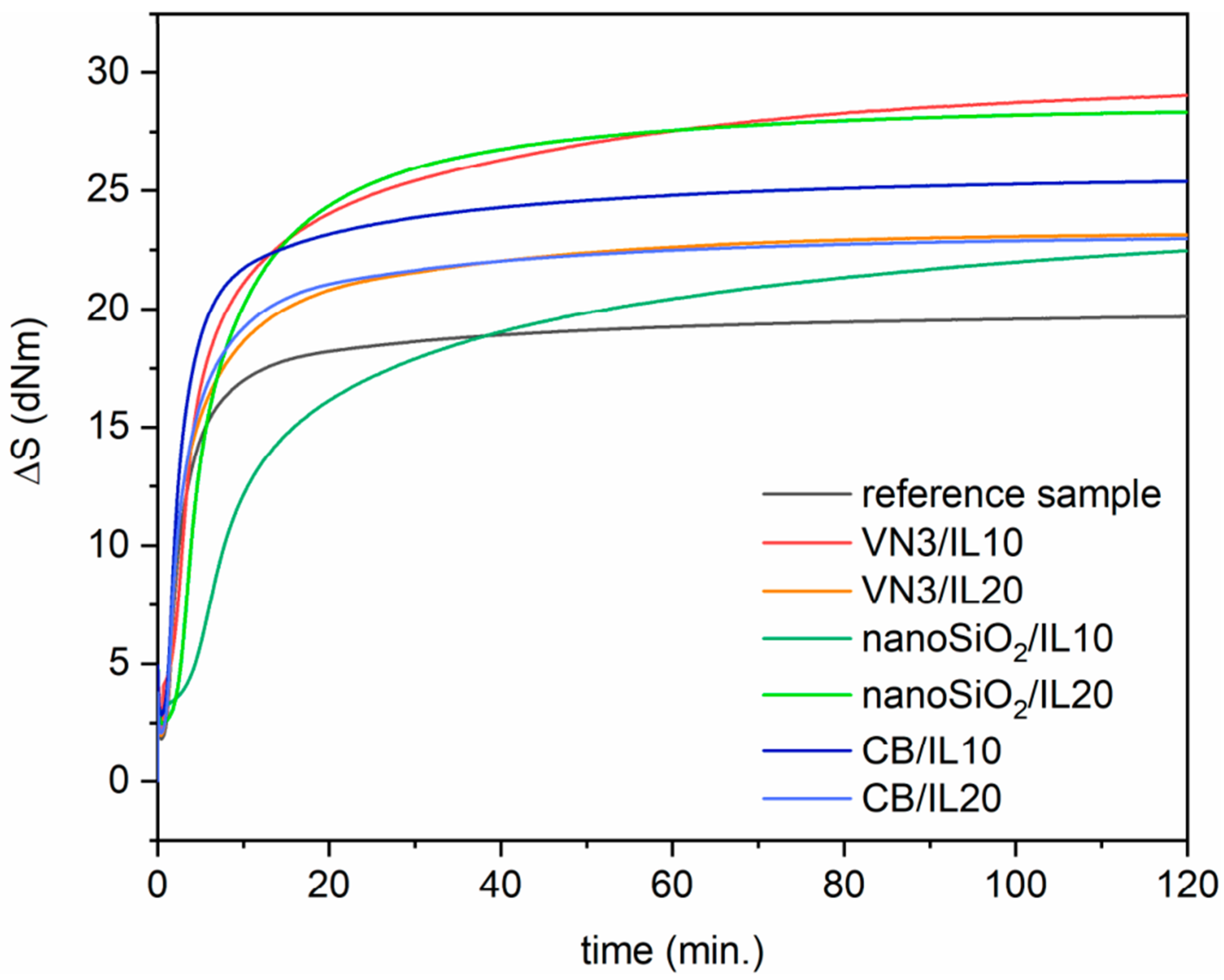

3. Rheological Properties

4. Swelling Properties

5. Thermal Properties

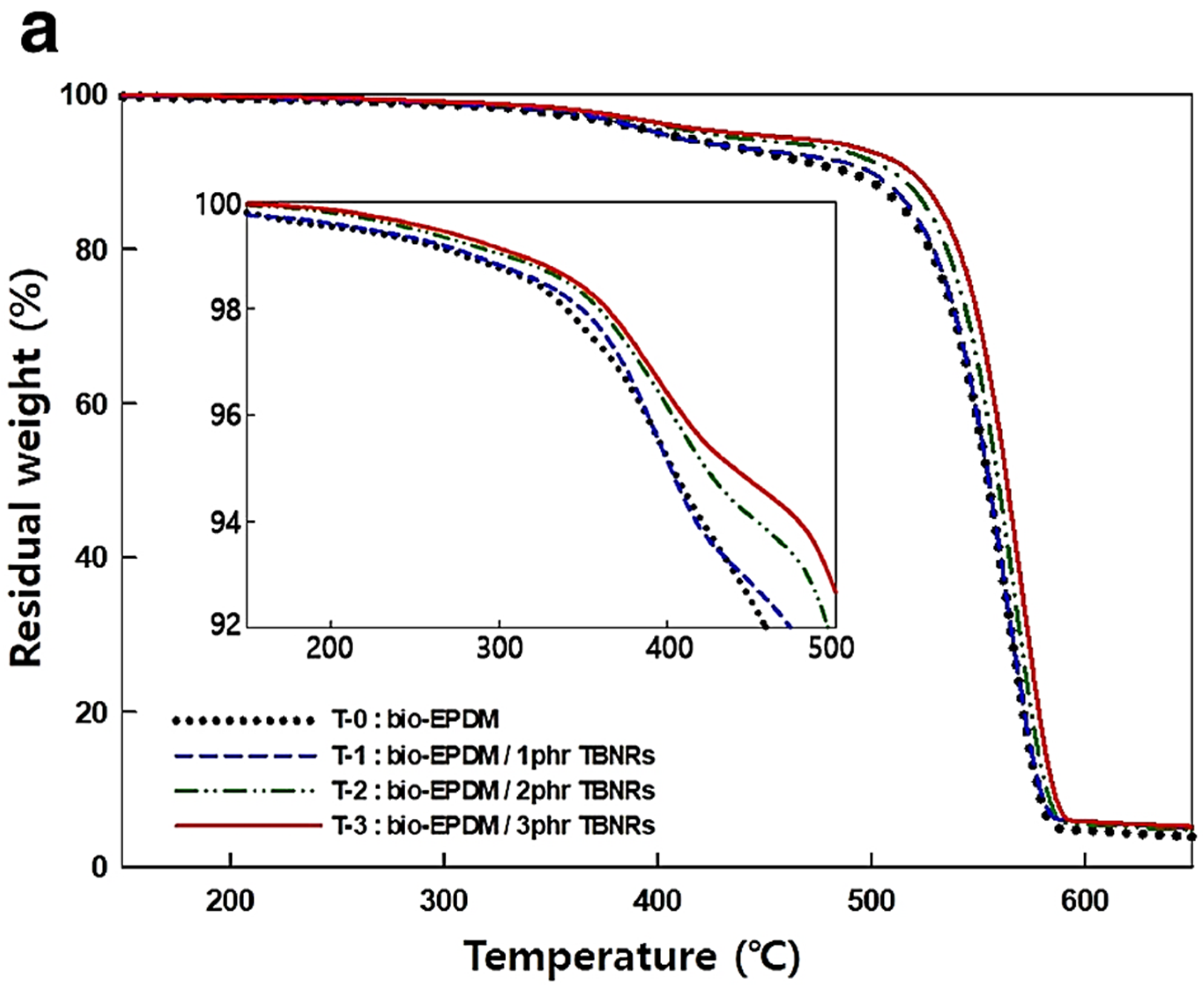

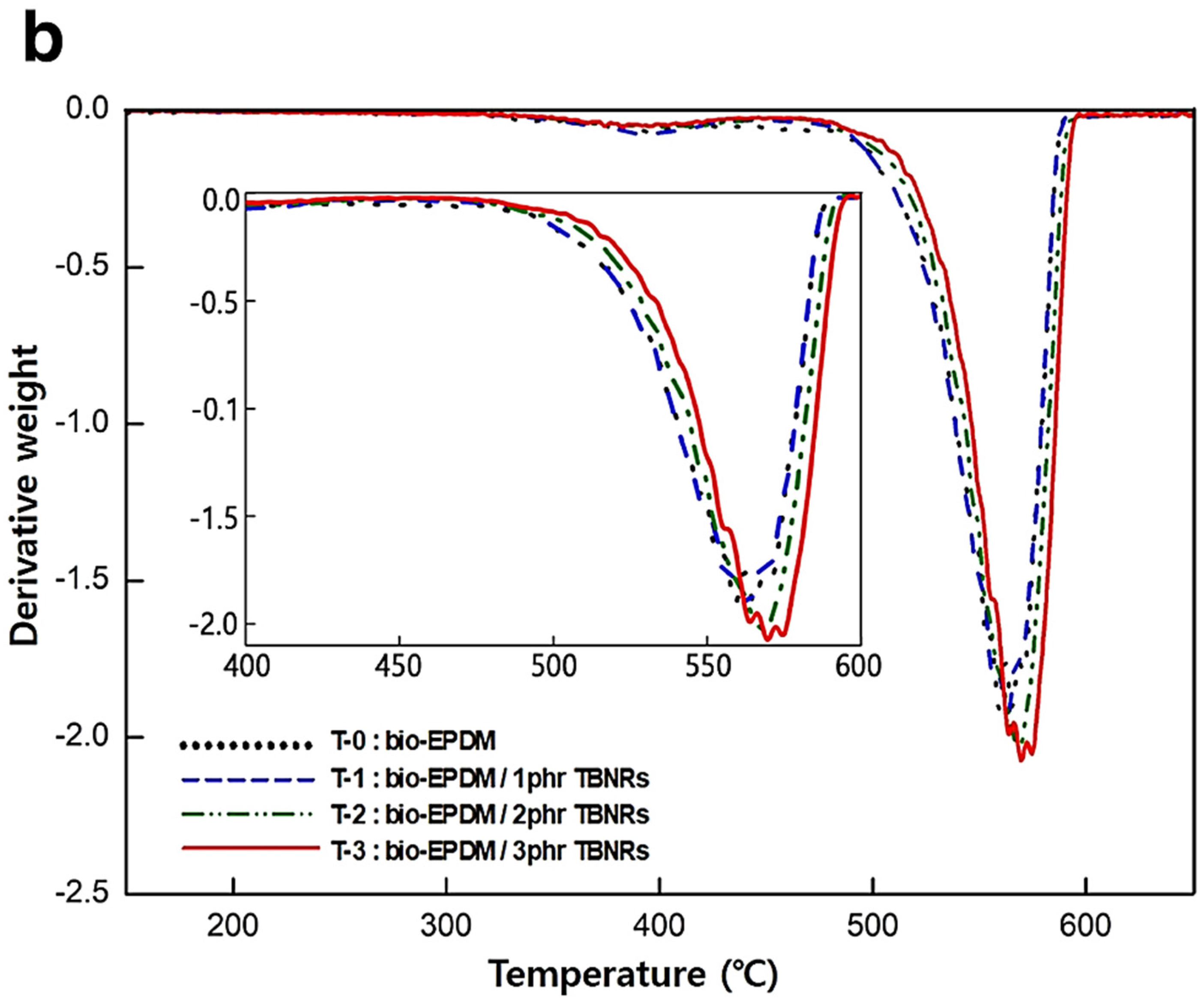

5.1. TGA Analysis

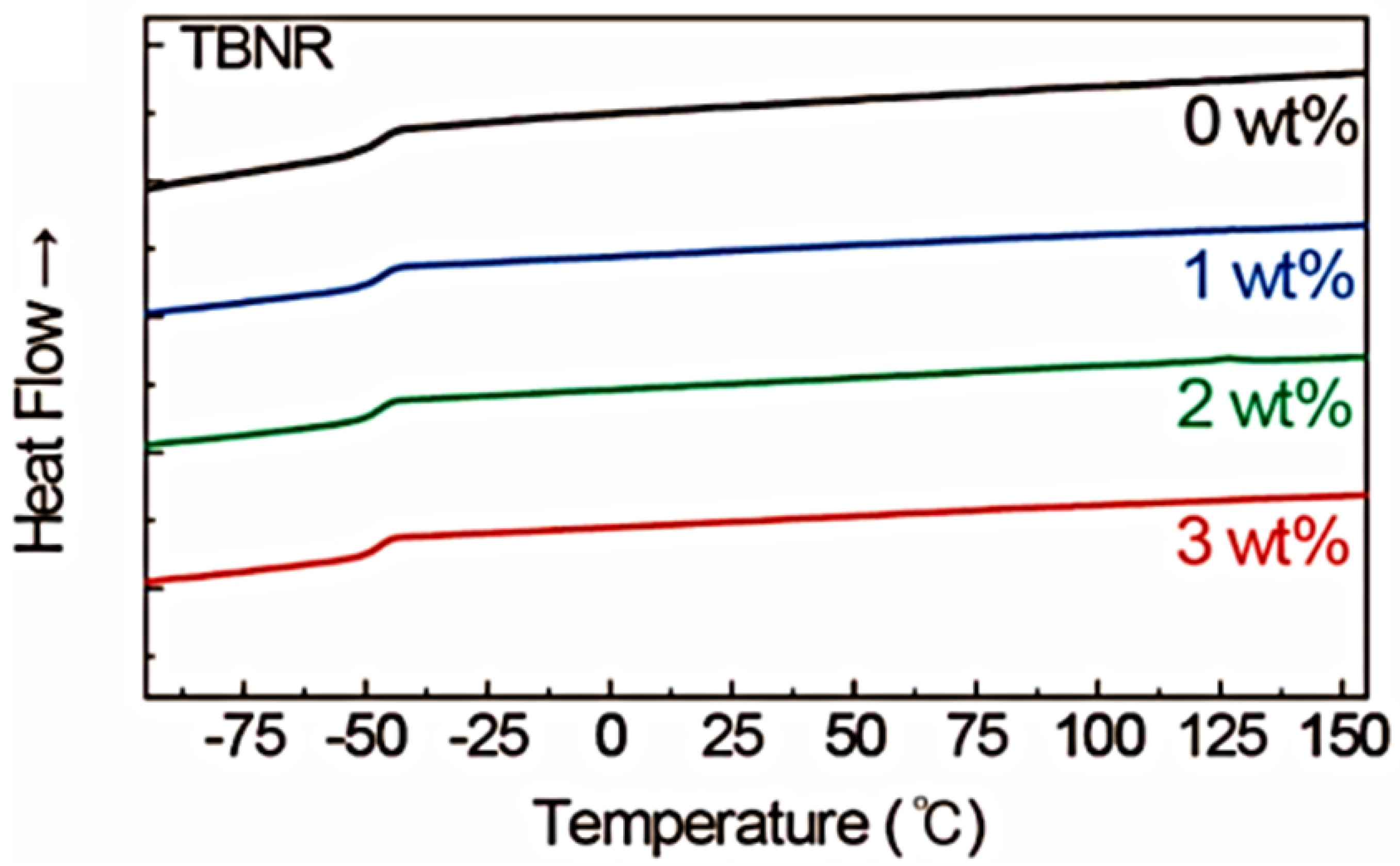

5.2. DSC Analysis

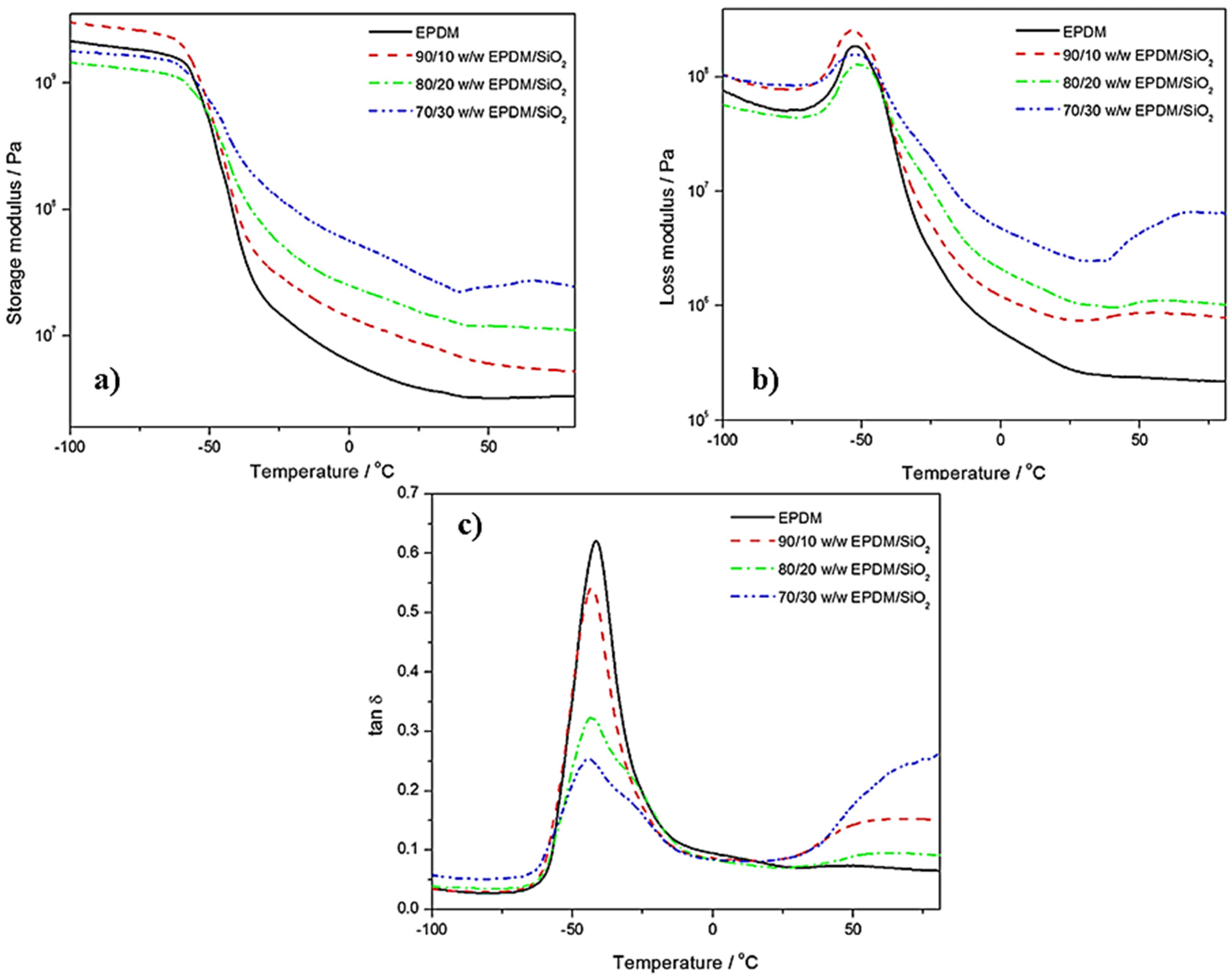

5.3. DMTA Analysis

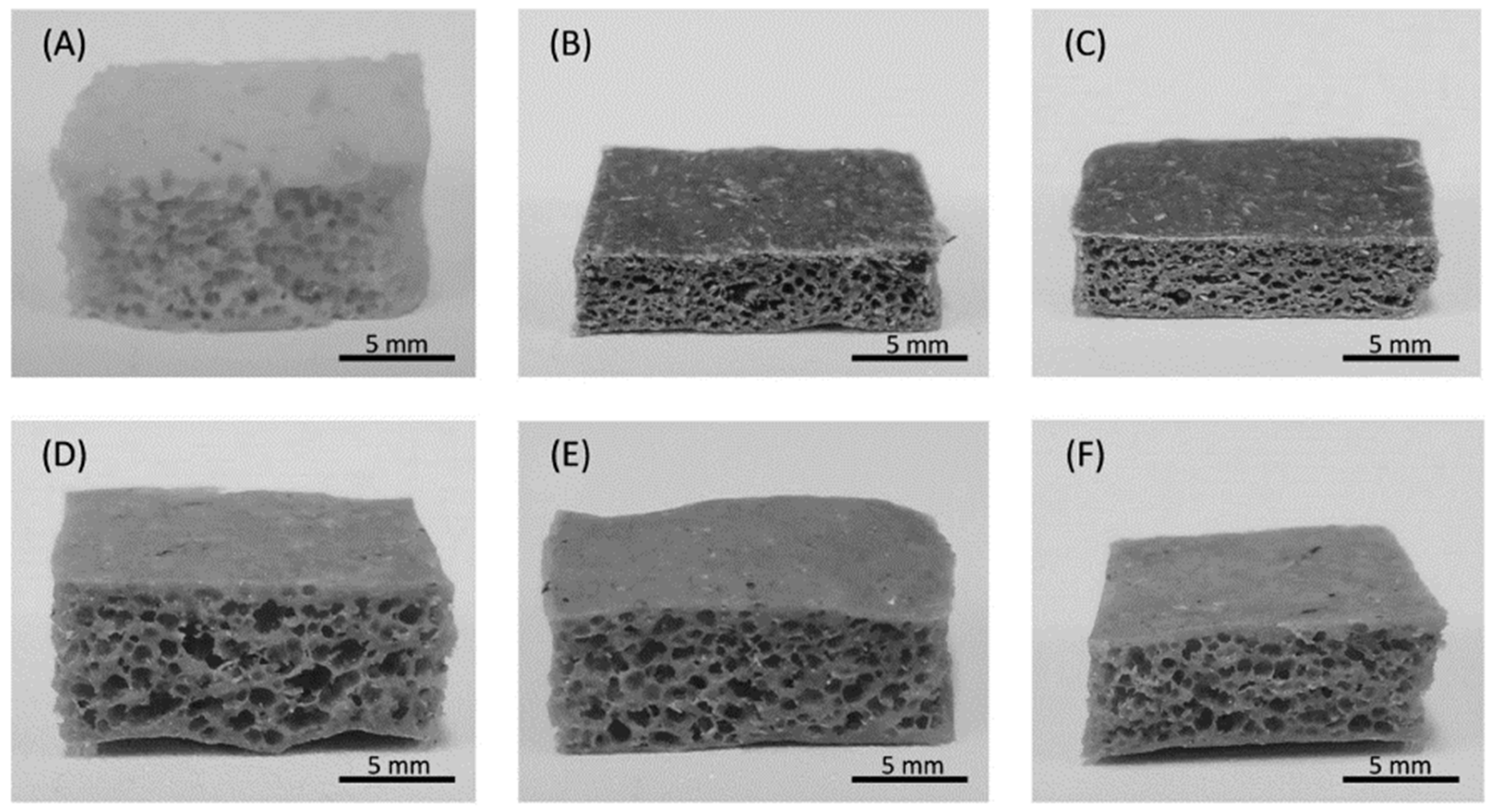

6. Morphological Properties

| Matrices | Nanofiller | Observation | Ref. |

|---|---|---|---|

| EPDM/Silica-SBR | Nanoclay | High loading of nanoclay (10 phr)—formation of clusters with poor dispersion | [2] |

| EPDM | Organoclay | 3 wt.% of fillers to the matrix cause a substantial wettability of elastomer | [35] |

| EPDM | MWCNT | The densities of samples increased as a function of MWCNT content | [28] |

| PP/EPDM | MWCNT | Morphological changes induced by the dynamic vulcanization process | [127] |

| EPDM/MFS | Graphene | The addition of graphene improved the homogeneous dispersion with a decrease in agglomerates. | [123] |

| EPDM/PP | Nanoclay and nanosilica | AFM and SEM show two phases and the uniform distribution of the nanofillers | [125] |

| SAN/EPDM | Organically modified montmorillonite | Micrographs indicate two phases (SAN + EPDM) with different domain sizes and shapes. | [124] |

| PP/EPDM | MWCNT | SEM and TEM show MWCNT aggregates in the matrix | [128] |

7. Thermal Conductivity

8. Electrical Properties

9. EPDM-Based Nanocomposites: Advantages, Disadvantages, and Perspectives

| Matrix | Advantage | Disadvantage | Ref. |

|---|---|---|---|

| EPDM | Increased tensile strength, elastic modulus, wear resistance; superior resistance to heat and oxidation; high mechanical strength and flexibility; cost-effectiveness | Nanoparticle dispersion challenges, increased production costs, environmental concerns | [126,163,164,165,166,167] |

| SBR | Cost-effective; good abrasion resistance; excellent adhesion to fabrics | Heat and ozone resistance are low; oil and solvent resistance is low | [168,169] |

| Natural Rubber | Excellent tensile strength; high elasticity; high resilience | The product has a low resistance to heat, ozone, oils, and solvents | [161,170,171] |

| Silicone Rubber | Heat and cold resistance; good electrical properties; chemically inert | High cost; low tensile strength | [172,173,174] |

| Synthetic Rubbers (General) | Adjustable properties: more excellent resistance to oils, solvents, and weather than natural rubber | It may be less elastic and resilient than natural rubber; some types may be more harmful to the environment. | [154,155] |

| Epoxy- or Polyamide-based Nanocomposites | Mechanical strength and rigidity are high | Comparatively less flexible than elastomeric materials | [147,162] |

| Matrix | Nanofiller | Morphology | Properties | Ref. |

|---|---|---|---|---|

| EPDM-SBR | Nanoclay | A high loading of nanoclay (10 phr) results in the formation of clusters with poor dispersion | As the concentration of nanoclay (4–10 phr) is gradually increased in the EPDM/S-SBR rubber nanocomposites, the 100% modulus of elasticity increases. In the same manner, when nanoclay loading is up to 8 phr, the compression set increases, but as the load increases, the compression set decreases due to the afferent crosslinking density and mobility of the long rubber chains. From abrasion resistance to hardness, nanocomposites showed a gradual increase in both properties. | [2] |

| EPDM | Organoclay | The presence of 3 wt.% of fillers in the matrix makes the elastomer more wettable. | Thermal degradation of pure EPDM was observed using TGA. The maximum degradation temperature (Tmax) at 10% weight loss of the material was 478 °C, indicating high thermal stability when compared to other studies. The onset temperature of degradation (T10%) at 10% weight loss of the material was 401 °C. Antimicrobial tests were conducted on tissue samples coated with 5% by weight of EOC or OC and 20% by weight of a long oil alkyd resin based on soybean oil. It was conducted against three different types of microbes: Staphylococcus aureus (G-ve bacteria), Pseudomonas aeruginosa (G-ve bacteria), and Candida albicans (fungi). LAR resin (fatty acid) with expanded organoclay is likely to serve as an essential component of microbial fatty acids that are a promising target for the development of antimicrobial-resistant tissues in the presence of 20 wt.% LAR resin (fatty acid). | [35] |

| EPDM | MWCNT | Sample density increased with MWCNT content | The development of EPDM/MWCNT foams has achieved superior EMI-specific SE and deformability. The use of EPDM should also ensure properties such as chemical, moisture, and ozone resistance. The developed foam samples exhibit high thermal and electrical conductivities of up to 2.7 × 10−4 S/cm and EMI shielding efficiencies of up to 45 dB, which do not degrade significantly after repeated bending. The EPDM matrix exhibits these properties because of the formation of a three-dimensional interconnected network. | [28] |

| PP/EPDM | MWCNT | Dynamic vulcanization causes morphological changes | Despite a high loading level, the samples have formed a dense, stable conductive network, which is difficult to destroy, resulting in excellent resistance stability. The cyclic loading test revealed no fractures and electrical shots, which indicates strong potential for practical applications. Approximately 0.1% of incident electromagnetic waves could penetrate the material without being reflected or absorbed, primarily as a result of the high density of the MWCNT network and the greater electrical conductivity of the samples compared to TPE without filler, indicating that the TPV elastomer composites may be helpful to as materials for stretchable conductors with electromagnetic radiation shielding capabilities. | [127] |

| EPDM/MFS | Graphene | With the addition of graphene, homogeneous dispersion was improved, and agglomerates were reduced. | EPDM/S/TiO2 samples showed a 30% increase in dielectric strength over vulcanized EPDM rubber samples. The addition of MFS, TiO2, and graphene to EPDM and EPDM/S rubbers resulted in a higher thermal conductivity for all composites. The EPDM composites containing TiO2 had the highest thermal conductivity values. The thermal conductivity of the composites did not appear to be affected by the addition of graphene. | [123] |

| ultra-high molecular weight EPDM (UHMW-EPDM) and PP | Nanoclay and nanosilica | SEM shows the presence of two phases and a uniform distribution of nanofillers | Compared with the other blends, the tensile strength and modulus were 250% higher with the 7 phr nanofiller loading. Nanosilica-added TPVs are superior to nanoclay-added TPVs in terms of mechanical properties, crosslink density, and morphology. | [125] |

| SAN/EPDM | Organically modified montmorillonite | Micrographs indicate two phases (SAN-EPDM) with different domain sizes and shapes. | Incorporating nanoclay and EPDM improved the thermal stability of SAN. Due to the establishment provided by EPDM rubber (known for its high thermal stability) and the improved interaction between SAN and nanoclay, nanocomposite blends demonstrated higher thermal stability than pure SAN. Because the EPDM soft phase has a low modulus, the Young’s modulus of the binary blends was decreased. As long as there is good phase interaction, adding a low-modulus EPDM dispersed phase to a high-modulus matrix (pure SAN) will tend to reduce its modulus. | [124] |

| PP/EPDM | MWCNT | TEM and SEM images show aggregates of MWCNTs | There was a significant difference between the unvulcanized mixtures and the vulcanized TPVs, which had superior tensile strength and deformation resistance. Dynamic vulcanization played a substantial role in determining the fracture toughness of vulcanized samples, although different curing mechanisms contributed to fracture toughness in various ways. | [128] |

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Nazir, M.T.; Phung, B.T.; Sahoo, A.; Yu, S.; Zhang, Y.; Li, S. Surface Discharge Behaviours, Dielectric and Mechanical Properties of EPDM based Nanocomposites containing Nano-BN. Appl. Nanosci. 2019, 9, 1981–1989. [Google Scholar] [CrossRef]

- Malas, A.; Das, C.K. Carbon black–clay hybrid nanocomposites based upon EPDM elastomer. J. Mater. Sci. 2012, 47, 2016–2024. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Kabir, I.; Yuen, A.C.Y.; Yeoh, G.H.; Zhang, Y.; Yu, S.; Li, S. Investigation on Dry Band Arcing Induced Tracking Failure on Nanocomposites of EPDM Matrix. In Proceedings of the 2019 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), Guangzhou, China, 7–10 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 309–312. [Google Scholar]

- Nazir, M.T.; Butt, F.T.; Phung, B.T.; Yeoh, G.H.; Yasin, G.; Akram, S.; Bhutta, M.S.; Hussain, S.; Nguyen, T.A. Simulation and Experimental Investigation on Carbonized Tracking Failure of EPDM/BN-Based Electrical Insulation. Polymers 2020, 12, 582. [Google Scholar] [CrossRef] [PubMed]

- Attia, N.F.; Saleh, B.K. Novel Synthesis of Renewable and Green Flame-Retardant, Antibacterial and Reinforcement Material for Styrene–Butadiene Rubber Nanocomposites. J. Therm. Anal. Calorim. 2020, 139, 1817–1827. [Google Scholar] [CrossRef]

- Ahamad, A.; Kumar, P. Effect of Reinforcing Ability of Halloysite Nanotubes in Styrene-Butadiene Rubber Nanocomposites. Compos. Commun. 2020, 22, 100440. [Google Scholar] [CrossRef]

- Silva, M.J.; Cena, C.R.; Sanches, A.O.; Mattoso, L.H.C.; Malmonge, J.A. DBSA to Improve the Compatibility, Solubility, and Infusibility of Cellulose Nanowhiskers Modified by Polyaniline in Reinforcing a Natural Rubber-Based Nanocomposite. Polym. Bull. 2019, 76, 3517–3533. [Google Scholar] [CrossRef]

- Silva, M.J.; Dias, Y.J.; Zaszczyńska, A.; Kołbuk, D.; Kowalczyk, T.; Sajkiewicz, P.Ł.; Yarin, A.L. Three-phase bio-nanocomposite natural-rubber-based microfibers reinforced with cellulose nanowhiskers and 45S5 bioglass obtained by solution blow spinning. J. Appl. Polym. Sci. 2023, 140, e54661. [Google Scholar] [CrossRef]

- Silva, M.J.; Sanches, A.O.; Cena, C.R.; Nagashima, H.N.; Medeiros, E.S.; Malmonge, J.A. Study of the Electrical Conduction Process in Natural Rubber-Based Conductive Nanocomposites Filled with Cellulose Nanowhiskers Coated by Polyaniline. Polym. Compos. 2020, 42, 1519–1529. [Google Scholar] [CrossRef]

- Stelescu, M.D.; Manaila, E.; Georgescu, M.; Nituica, M. New Materials Based on Ethylene Propylene Diene Terpolymer and Hemp Fibers Obtained by Green Reactive Processing. Materials 2020, 13, 2067. [Google Scholar] [CrossRef]

- Abdel-Aziz, M.M.; Amer, H.A.; Atia, M.K.; Rabie, A.M. Effect of Gamma Radiation on the Physicomechanical Characters of EPDM Rubber/Modified Additives Nanocomposites. J. Vinyl Addit. Technol. 2017, 23, E188–E200. [Google Scholar] [CrossRef]

- Jahed, M.; Naderi, G.; Hamid Reza Ghoreishy, M. Microstructure, Mechanical, and Rheological Properties of Natural Rubber/Ethylene Propylene Diene Monomer Nanocomposites Reinforced by Multi-wall Carbon Nanotubes. Polym. Compos. 2018, 39, E745–E753. [Google Scholar] [CrossRef]

- Ismail, H.; Che Mat, N.S.; Othman, N. Curing Characteristics, Tear, Fatigue, and Aging Properties of Bentonite-filled Ethylene-propylene-diene (EPDM) Rubber Composites. J. Vinyl Addit. Technol. 2018, 24, E77–E84. [Google Scholar] [CrossRef]

- Razak, J.; Mohamad, N.; Mahamood, M.A.; Jaafar, R.; Othman, I.S.; Ismail, M.M.; Tee, L.K.; Junid, R.; Mustafa, Z. On the Preparation of EPDM-g-MAH Compatibilizer via Melt-Blending Method. J. Mech. Eng. Sci. 2019, 13, 5424–5440. [Google Scholar] [CrossRef]

- Valentini, L.; Bittolo Bon, S.; Lopez-Manchado, M.A.; Verdejo, R.; Pappalardo, L.; Bolognini, A.; Alvino, A.; Borsini, S.; Berardo, A.; Pugno, N.M. Synergistic Effect of Graphene Nanoplatelets and Carbon Black in Multifunctional EPDM Nanocomposites. Compos. Sci. Technol. 2016, 128, 123–130. [Google Scholar] [CrossRef]

- Amin, A.; Kandil, H.; Rabia, A.M.; Nashar, D.E.E.; Ismail, M.N. Enhancing the Mechanical and Dielectric Properties of EPDM Filled with Nanosized Rice Husk Powder. Polym. Plast. Technol. Eng. 2018, 57, 1733–1742. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Yuan, Z.; Ye, L. Construction of Sacrificial Bonds and Hybrid Networks in EPDM Rubber towards Mechanical Performance Enhancement. Appl. Surf. Sci. 2019, 484, 616–627. [Google Scholar] [CrossRef]

- Lei, Y.; He, J.; Zhao, Q.; Liu, T. A Nitrile Functionalized Graphene Filled Ethylene Propylene Diene Terpolymer Rubber Composites with Improved Heat Resistance. Compos. B Eng. 2018, 134, 81–90. [Google Scholar] [CrossRef]

- Güngör, A.; Akbay, I.K.; Özdemir, T. EPDM Rubber with Hexagonal Boron Nitride: A Thermal Neutron Shielding Composite. Radiat. Phys. Chem. 2019, 165, 108391. [Google Scholar] [CrossRef]

- Ghoreishi, A.; Koosha, M.; Nasirizadeh, N. Modification of Bitumen by EPDM Blended with Hybrid Nanoparticles: Physical, Thermal, and Rheological Properties. J. Thermoplast. Compos. Mater. 2020, 33, 343–356. [Google Scholar] [CrossRef]

- Restrepo-Zapata, N.C.; Osswald, T.A.; Hernández-Ortiz, J.P. Vulcanization of EPDM Rubber Compounds with and without Blowing Agents: Identification of Reaction Events and TTT-Diagram Using DSC Data. Polym. Eng. Sci. 2015, 55, 2073–2088. [Google Scholar] [CrossRef]

- Khalaf, A.; Helaly, F.; El Sawy, S. Improvement Properties of EPDM Rubber Using Hybrid Chitin/Clay Filler for Industrial Products. Egypt. J. Chem. 2019, 63, 129–143. [Google Scholar] [CrossRef]

- Manaila, E.; Airinei, A.; Stelescu, M.D.; Sonmez, M.; Alexandrescu, L.; Craciun, G.; Pamfil, D.; Fifere, N.; Varganici, C.-D.; Doroftei, F.; et al. Radiation Processing and Characterization of Some Ethylene-Propylene-Diene Terpolymer/Butyl (Halobutyl) Rubber/Nanosilica Composites. Polymers 2020, 12, 2431. [Google Scholar] [CrossRef] [PubMed]

- Craciun, G.; Manaila, E.; Ighigeanu, D.; Stelescu, M.D. A Method to Improve the Characteristics of EPDM Rubber Based Eco-Composites with Electron Beam. Polymers 2020, 12, 215. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Li, C.H. Effect of Carbon Nanotube Content on Properties of Ethylene Propylene Diene Rubber/CaCO3 Carbon Nanotube Composites. Adv. Mat. Res. 2017, 1142, 206–210. [Google Scholar] [CrossRef]

- Guo, M.; Li, J.; Li, K.; Zhu, G.; Hu, B.; Liu, Y.; Ji, J. Carbon Nanotube Reinforced Ablative Material for Thermal Protection System with Superior Resistance to High-Temperature Dense Particle Erosion. Aerosp. Sci. Technol. 2020, 106, 106234. [Google Scholar] [CrossRef]

- Jha*, N.; Mahapatra, S.P. Morphology, Barrier, Mechanical and Electrical Conductivity Properties of Oil-Extended EPDM/MWCNT Nanocomposites. Int. J. Eng. Adv. Technol. 2019, 8, 4116–4121. [Google Scholar] [CrossRef]

- Bizhani, H.; Katbab, A.A.; Lopez-Hernandez, E.; Miranda, J.M.; Verdejo, R. Highly Deformable Porous Electromagnetic Wave Absorber Based on Ethylene–Propylene–Diene Monomer/Multiwall Carbon Nanotube Nanocomposites. Polymers 2020, 12, 858. [Google Scholar] [CrossRef]

- Lu, S.; Bai, Y.; Wang, J.; Chen, D.; Ma, K.; Meng, Q.; Liu, X. Flexible GnPs/EPDM with Excellent Thermal Conductivity and Electromagnetic Interference Shielding Properties. Nano 2019, 14, 1950075. [Google Scholar] [CrossRef]

- Allahbakhsh, A.; Mazinani, S. Influences of Sodium Dodecyl Sulfate on Vulcanization Kinetics and Mechanical Performance of EPDM/Graphene Oxide Nanocomposites. RSC Adv. 2015, 5, 46694–46704. [Google Scholar] [CrossRef]

- Han, S.-W.; Choi, N.-S.; Ryu, S.-R.; Lee, D.-J. Mechanical Property Behavior and Aging Mechanism of Carbon-Black-Filled EPDM Rubber Reinforced by Carbon Nano-Tubes Subjected to Electro-Chemical and Thermal Degradation. J. Mech. Sci. Technol. 2017, 31, 4073–4078. [Google Scholar] [CrossRef]

- Sagar, M.; Nibedita, K.; Manohar, N.; Kumar, K.R.; Suchismita, S.; Pradnyesh, A.; Reddy, A.B.; Sadiku, E.R.; Gupta, U.N.; Lachit, P.; et al. A Potential Utilization of End-of-Life Tyres as Recycled Carbon Black in EPDM Rubber. Waste Manag. 2018, 74, 110–122. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Zhou, X.; Liang, K.; Guo, B.; Li, X.; Wang, Z.; Zhang, L. Mechanically Robust and Recyclable EPDM Rubber Composites by a Green Cross-Linking Strategy. ACS Sustain. Chem. Eng. 2019, 7, 11712–11720. [Google Scholar] [CrossRef]

- Ashok, N.; Balachandran, M. Effect of Nanoclay and Nanosilica on Carbon Black Reinforced EPDM/CIIR Blends for Nuclear Applications. Mater. Res. Express 2020, 6, 125364. [Google Scholar] [CrossRef]

- Moustafa, H.; Lawandy, S.N.; Rabee, M.; Zahran, M.A.H. Effect of Green Modification of Nanoclay on the Adhesion Behavior of EPDM Rubber to Polyester Fabric. Int. J. Adhes. Adhes. 2020, 100, 102617. [Google Scholar] [CrossRef]

- Wasfy, S.A.; Hegazi, E.M.; Abd El-megeed, A.A.; Mahmoud, T.S.; El-Kady, E.Y. Effect of Nanoclay on EPDM Composites under Gamma Irradiation. Arab. J. Nucl. Sci. Appl. 2018, 51, 168–176. [Google Scholar]

- Mokhothu, T.H.; Luyt, A.S.; Messori, M. Preparation and Characterization of EPDM/Silica Composites Prepared through Non-Hydrolytic Sol-Gel Method in the Absence and Presence of a Coupling Agent. Express Polym. Lett. 2014, 8, 809–822. [Google Scholar] [CrossRef]

- George, K.; Mohanty, S.; Biswal, M.; Nayak, S.K. Thermal Insulation Behaviour of Ethylene Propylene Diene Monomer Rubber/Kevlar Fiber Based Hybrid Composites Containing Nanosilica for Solid Rocket Motor Insulation. J. Appl. Polym. Sci. 2021, 138, 49934. [Google Scholar] [CrossRef]

- Zygo, M.; Lipinska, M.; Lu, Z.; Ilcíková, M.; Bockstaller, M.R.; Mosnacek, J.; Pietrasik, J. New Type of Montmorillonite Compatibilizers and Their Influence on Viscoelastic Properties of Ethylene Propylene Diene and Methyl Vinyl Silicone Rubbers Blends. Appl. Clay Sci. 2019, 183, 105359. [Google Scholar] [CrossRef]

- Lee, K.; Chang, Y. Peroxide Vulcanized EPDM Rubber/Polyhedral Oligomeric Silsesquioxane Nanocomposites: Vulcanization Behavior, Mechanical Properties, and Thermal Stability. Polym. Eng. Sci. 2015, 55, 2814–2820. [Google Scholar] [CrossRef]

- Zaharescu, T.; Blanco, I.; Bottino, F.A. Antioxidant Activity Assisted by Modified Particle Surface in POSS/EPDM Hybrids. Appl. Surf. Sci. 2020, 509, 144702. [Google Scholar] [CrossRef]

- Lu, S.; Li, B.; Ma, K.; Wang, S.; Liu, X.; Ma, Z.; Lin, L.; Zhou, G.; Zhang, D. Flexible MXene/EPDM Rubber with Excellent Thermal Conductivity and Electromagnetic Interference Performance. Appl. Phys. A 2020, 126, 513. [Google Scholar] [CrossRef]

- Bizhani, H.; Katbab, A.A.; Lopez-Hernandez, E.; Miranda, J.M.; Lopez-Manchado, M.A.; Verdejo, R. Preparation and Characterization of Highly Elastic Foams with Enhanced Electromagnetic Wave Absorption Based on Ethylene-Propylene-Diene-Monomer Rubber Filled with Barium Titanate/Multiwall Carbon Nanotube Hybrid. Polymers 2020, 12, 2278. [Google Scholar] [CrossRef]

- Lu, S.; Ma, J.; Chen, D.; Du, K.; Ma, K.; Bai, Y.; Lu, Z.; Wang, X. Highly Stretchable and Sensitive Sensor Based on GnPs/EPDM Composites with Excellent Heat Dissipation Performance. Appl. Phys. A 2019, 125, 425. [Google Scholar] [CrossRef]

- Jha, N.; Sarkhel, G.; Mahapatra, S.P. Morphology, Barrier and Electrical Properties of Oil-Extended EPDM/Nanographite Nanocomposites. Mater. Today Proc. 2021, 45, 3850–3856. [Google Scholar] [CrossRef]

- Neelesh, A.; Vidhyashree, S.; Meera, B. The Influence of MWCNT and Hybrid (MWCNT/Nanoclay) Fillers on Performance of EPDM-CIIR Blends in Nuclear Applications: Mechanical, Hydrocarbon Transport, and Gamma-Radiation Aging Characteristicscharacteristics. J. Appl. Polym. Sci. 2020, 137, 49271. [Google Scholar] [CrossRef]

- Ahmed, A.F.; Hoa, S. Development and Analysis of a Hybrid Reinforced Composite Material for Solid Rocket Motor Insulation. In Proceedings of the American Society for Composites 23rd Annual Technical Conference, Memphis, TN, USA, 9–11 September 2008; Volume 1, pp. 131–143. [Google Scholar]

- Ding, Z.; He, F.; Li, Y.; Jiang, Z.; Yan, H.; He, R.; Fan, J.; Zhang, K.; Yang, W. Novel Shape-Stabilized Phase Change Materials Based on Paraffin/EPDM@Graphene with High Thermal Conductivity and Low Leakage Rate. Energy Fuels 2020, 34, 5024–5031. [Google Scholar] [CrossRef]

- Guo, M.; Li, J.; Xi, K.; Liu, Y.; Ji, J.; Ye, C. Effects of Multi-Walled Carbon Nanotubes on Char Residue and Carbothermal Reduction Reaction in Ethylene Propylene Diene Monomer Composites at High Temperature. Compos. Sci. Technol. 2020, 186, 107916. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Zhao, Y. Effect of Dendrimer Modified Montmorillonite on Structure and Properties of EPDM Nanocomposites. Polym. Test. 2017, 62, 41–50. [Google Scholar] [CrossRef]

- Chazeau, L.; Gauthier, C.; Chenal, J.M. Mechanical Properties of Rubber Nanocomposites: How, Why … and Then? In Rubber Nanocomposites; Wiley: Hoboken, NJ, USA, 2010; pp. 291–330. [Google Scholar]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of Particle Size, Particle/Matrix Interface Adhesion and Particle Loading on Mechanical Properties of Particulate–Polymer Composites. Compos. B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Mirjalili, F.; Chuah, L.; Salahi, E. Mechanical and Morphological Properties of Polypropylene/Nano α-Al2O3 Composites. Sci. World J. 2014, 2014, 718765. [Google Scholar] [CrossRef]

- Kallungal, J.; Chazeau, L.; Chenal, J.-M.; Adrien, J.; Maire, E.; Barrès, C.; Cantaloube, B.; Heuillet, P.; Wilde, F.; Moosmann, J.; et al. Crack Propagation in Filled Elastomers: 3D Study of Mechanisms Involving the Filler Agglomerates. Eng. Fract. Mech. 2022, 274, 108771. [Google Scholar] [CrossRef]

- Ragupathy, K.; Prabaharan, G.; Pragadish, N.; Vishvanathperumal, S. Effect of Silica Nanoparticles and Modified Silica Nanoparticles on the Mechanical and Swelling Properties of EPDM/SBR Blend Nanocomposites. Silicon 2023, 15, 6033–6046. [Google Scholar] [CrossRef]

- Lin, C.; Kanstad, T.; Jacobsen, S.; Ji, G. Bonding Property between Fiber and Cementitious Matrix: A Critical Review. Constr. Build. Mater. 2023, 378, 131169. [Google Scholar] [CrossRef]

- Da Silva, A.L.N.; Tavares, M.I.B.; Politano, D.P.; Coutinho, F.M.B.; Rocha, M.C.G. Polymer Blends Based on Polyolefin Elastomer and Polypropylene. J. Appl. Polym. Sci. 1997, 66, 2005–2014. [Google Scholar] [CrossRef]

- Sang, J.S.; Kim, T.; Park, E.-Y.; Park, J.; Eum, Y.; Oh, K.W. Bio-EPDM/Tungsten Oxide Nanocomposite Foam with Improved Thermal Storage and Sea Water Resistance. Fash. Text. 2020, 7, 29. [Google Scholar] [CrossRef]

- Bianchi, M.; Valentini, F.; Fredi, G.; Dorigato, A.; Pegoretti, A. Thermo-Mechanical Behavior of Novel EPDM Foams Containing a Phase Change Material for Thermal Energy Storage Applications. Polymers 2022, 14, 4058. [Google Scholar] [CrossRef] [PubMed]

- Hu, H. Recent Advances of Polymeric Phase Change Composites for Flexible Electronics and Thermal Energy Storage System. Compos. B Eng. 2020, 195, 108094. [Google Scholar] [CrossRef]

- Peng, S.; Fuchs, A.; Wirtz, R.A. Polymeric Phase Change Composites for Thermal Energy Storage. J. Appl. Polym. Sci. 2004, 93, 1240–1251. [Google Scholar] [CrossRef]

- Liu, C.; Xiao, T.; Zhao, J.; Liu, Q.; Sun, W.; Guo, C.; Ali, H.M.; Chen, X.; Rao, Z.; Gu, Y. Polymer Engineering in Phase Change Thermal Storage Materials. Renew. Sustain. Energy Rev. 2023, 188, 113814. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Heat Storage Systems. In Exergy Analysis of Heating, Refrigerating and Air Conditioning; Elsevier: Amsterdam, The Netherlands, 2015; pp. 221–278. [Google Scholar]

- Valentini, F.; Dorigato, A.; Fambri, L.; Bersani, M.; Grigiante, M.; Pegoretti, A. Production and Characterization of Novel EPDM/NBR Panels with Paraffin for Potential Thermal Energy Storage Applications. Therm. Sci. Eng. Prog. 2022, 32, 101309. [Google Scholar] [CrossRef]

- Valentini, F.; Fredi, G.; Dorigato, A. Thermal Energy Storage (TES) for Sustainable Buildings: Addressing the Current Energetic Situation in the EU with TES-Enhanced Buildings. In Natural Energy, Lighting, and Ventilation in Sustainable Buildings; Nazari-Heris, M., Ed.; Springer Nature: Cham, Switzerland, 2024; pp. 191–224. ISBN 978-3-031-41148-9. [Google Scholar]

- Mofijur, M.; Mahlia, T.M.I.; Silitonga, A.S.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Rahman, S.M.A. Phase Change Materials (PCM) for Solar Energy Usages and Storage: An Overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef]

- Li, G.; Zheng, X. Thermal Energy Storage System Integration Forms for a Sustainable Future. Renew. Sustain. Energy Rev. 2016, 62, 736–757. [Google Scholar] [CrossRef]

- Chandrasekaran, C. Rubbers Mostly Used in Process Equipment Lining. In Anticorrosive Rubber Lining; Elsevier: Amsterdam, The Netherlands, 2017; pp. 87–101. [Google Scholar]

- Yang, P.; He, M.; Ren, X.; Zhou, K. Effect of Carbon Nanotube on Space Charge Suppression in PP/EPDM/CNT Nanocomposites. J. Polym. Res. 2020, 27, 132. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, H.a.o.; Li, L.; Zhang, J.; Guo, N.; Zhang, X.H. Study on space charge characteristics of xlpe/o-mmt nanocomposites. Acta Polym. Sin. 2013, 13, 126–133. [Google Scholar] [CrossRef]

- Resner, L.; Lesiak, P.; Taraghi, I.; Kochmanska, A.; Figiel, P.; Piesowicz, E.; Zenker, M.; Paszkiewicz, S. Polymer Hybrid Nanocomposites Based on Homo and Copolymer Xlpe Containing Mineral Nanofillers with Improved Functional Properties Intended for Insulation of Submarine Cables. Polymers 2022, 14, 3444. [Google Scholar] [CrossRef]

- Qingyue, Y.; Xiufeng, L.; Peng, Z.; Peijie, Y.; Youfu, C. Properties of Water Tree Growing in XLPE and Composites. In Proceedings of the 2019 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), Guangzhou, China, 7–10 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 409–412. [Google Scholar]

- Vishvanathperumal, S.; Anand, G. Effect of Nanoclay/Nanosilica on the Mechanical Properties, Abrasion and Swelling Resistance of EPDM/SBR Composites. Silicon 2020, 12, 1925–1941. [Google Scholar] [CrossRef]

- Abdelsalam, A.A.; Mohamed, W.S.; Abd El-Naeem, G.; El-Sabbagh, S.H. Effect of the Silane Coupling Agent on the Physicomechanical Properties of EPDM/SBR/AL2O3 Rubber Blend Nanocomposites. J. Thermoplast. Compos. Mater. 2023, 36, 1811–1832. [Google Scholar] [CrossRef]

- Bahadar, A.; Zwawi, M. Development of SWCNTs-Reinforced EPDM/SBR Matrices for Shock Absorbing Applications Development of SWCNTs-Reinforced EPDM/SBR Matrices for Shock Absorbing Applications. Mater. Res. Express 2020, 7, 025310. [Google Scholar] [CrossRef]

- Deng, F.; Jin, H.; Zhang, L.; He, Y. Higher Tear Strength of EPDM/SBR/TPR Composites Foam Based on Double Foaming System. J. Elastomers Plast. 2021, 53, 373–385. [Google Scholar] [CrossRef]

- Hasanzadeh Kermani, H.; Mottaghitalab, V.; Mokhtary, M.; Alizadeh Dakhel, A. Morphological, Rheological, and Mechanical Properties of Ethylene Propylene Diene Monomer/Carboxylated Styrene-Butadiene Rubber/Multiwall Carbon Nanotube Nanocomposites. Int. J. Polym. Anal. Charact. 2020, 25, 479–498. [Google Scholar] [CrossRef]

- Vayyaprontavida Kaliyathan, A.; Varghese, K.M.; Nair, A.S.; Thomas, S. Rubber–Rubber Blends: A Critical Review. Prog. Rubber Plast. Recycl. Technol. 2020, 36, 196–242. [Google Scholar] [CrossRef]

- Sowińska, A.; Maciejewska, M.; Guo, L.; Delebecq, E. Effect of SILPs on the Vulcanization and Properties of Ethylene-Propylene-Diene Elastomer. Polymers 2020, 12, 1220. [Google Scholar] [CrossRef]

- Vishvanathperumal, S.; Gopalakannan, S. Effects of the Nanoclay and Crosslinking Systems on the Mechanical Properties of Ethylene-Propylene-Diene Monomer/Styrene Butadiene Rubber Blends Nanocomposite. Silicon 2019, 11, 117–135. [Google Scholar] [CrossRef]

- Rostami-Tapeh-esmaeil, E.; Vahidifar, A.; Esmizadeh, E.; Rodrigue, D. Chemistry, Processing, Properties, and Applications of Rubber Foams. Polymers 2021, 13, 1565. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, S.Y.; Chung, K.; Jang, K.S. Phlogopite-Reinforced Natural Rubber (Nr)/Ethylene-Propylene-Diene Monomer Rubber (EPDM) Composites with Aminosilane Compatibilizer. Polymers 2021, 13, 2318. [Google Scholar] [CrossRef] [PubMed]

- Chang, E.; Zhao, J.; Zhao, C.; Li, G.; Lee, P.C.; Park, C.B. Scalable Production of Crosslinked Rubber Nanofibre Networks as Highly Efficient Toughening Agent for Isotactic Polypropylene: Toughening Mechanism of Non-Traditional Anisotropic Rubber Inclusion. Chem. Eng. J. 2022, 438, 134060. [Google Scholar] [CrossRef]

- Azizli, M.J.; Barghamadi, M.; Rezaeeparto, K.; Mokhtary, M.; Parham, S. Compatibility, Mechanical and Rheological Properties of Hybrid Rubber NR/EPDM-g-MA/EPDM/Graphene Oxide Nanocomposites: Theoretical and Experimental Analyses. Compos. Commun. 2020, 22, 100442. [Google Scholar] [CrossRef]

- Burgaz, E.; Goksuzoglu, M. Effects of Magnetic Particles and Carbon Black on Structure and Properties of Magnetorheological Elastomers. Polym. Test. 2020, 81, 106233. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Li, S.; Akram, S.; Mehmood, M.A.; Yeoh, G.H.; Hussain, S. Effect of Micro-Nano Additives on Breakdown, Surface Tracking and Mechanical Performance of Ethylene Propylene Diene Monomer for High Voltage Insulation. J. Mater. Sci. Mater. Electron. 2019, 30, 14061–14071. [Google Scholar] [CrossRef]

- Khademeh Molavi, F.; Soltani, S.; Naderi, G.; Bagheri, R. Effect of Multi-Walled Carbon Nanotube on Mechanical and Rheological Properties of Silane Modified EPDM Rubber. Polyolefins J. 2016, 3, 69–77. [Google Scholar] [CrossRef]

- Zvereva, U.G.; Solomatin, D.V.; Kuznetsova, O.P.; Prut, E.V. Rheological Properties of Ethylene-Propylene-Diene Elastomers. Polym. Sci. Ser. D 2016, 9, 234–237. [Google Scholar] [CrossRef]

- ASTM D-2084-07; Test Standard Methods for Rubber Property-Vulacization Using Oscillating Disk Cure Meter. ASTM International: West Conshohocken, PA, USA, 2007.

- Chen, G.; Gupta, A.; Mekonnen, T.H. Silane-Modified Wood Fiber Filled EPDM Bio-Composites with Improved Thermomechanical Properties. Compos. Part A Appl. Sci. Manuf. 2022, 159, 107029. [Google Scholar] [CrossRef]

- Abdelsalam, A.A.; Araby, S.; El-Sabbagh, S.H.; Abdelmoneim, A.; Hassan, M.A. Effect of Carbon Black Loading on Mechanical and Rheological Properties of Natural Rubber/Styrene-Butadiene Rubber/Nitrile Butadiene Rubber Blends. J. Thermoplast. Compos. Mater. 2021, 34, 490–507. [Google Scholar] [CrossRef]

- Utracki, L.A.; Walsh, D.J.; Weiss, R.A. Multiphase Polymers: Blends and Ionomers; American Chemical Society: Washington, DC, USA, 1989; pp. 1–35. [Google Scholar] [CrossRef]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crosslink Density and Diffusion Mechanisms in Blend Vulcanizates Loaded with Carbon Black and Paraffin Wax. J. Appl. Polym. Sci. 2009, 116, 2658–2667. [Google Scholar] [CrossRef]

- Monakhova, T.V.; Bogaevskaya, T.A.; Shlyapnikov, Y.A. Effect of Polydimethylsiloxane on Oxidation of Isotactic Polypropylene. Polym. Degrad. Stab. 1999, 66, 149–151. [Google Scholar] [CrossRef]

- Robeson, L.M. Applications of Polymer Blends: Emphasis on Recent Advances. Polym. Eng. Sci. 1984, 24, 587–597. [Google Scholar] [CrossRef]

- Stelescu, M.D.; Airinei, A.; Bargan, A.; Fifere, N.; Georgescu, M.; Sonmez, M.; Nituica, M.; Alexandrescu, L.; Stefan, A. Mechanical Properties and Equilibrium Swelling Characteristics of Some Polymer Composites Based on Ethylene Propylene Diene Terpolymer (EPDM) Reinforced with Hemp Fibers. Materials 2022, 15, 6838. [Google Scholar] [CrossRef]

- Ghobashy, M.M.; Mousa, S.A.S.; Siddiq, A.; Nasr, H.M.D.; Nady, N.; Atalla, A.A. Optimal the Mechanical Properties of Bioplastic Blend Based Algae-(Lactic Acid-Starch) Using Gamma Irradiation and Their Possibility to Use as Compostable and Soil Conditioner. Mater. Today Commun. 2023, 34, 105472. [Google Scholar] [CrossRef]

- Zarrinjooy Alvar, M.; Abdeali, G.; Bahramian, A.R. Influence of Graphite Nano Powder on Ethylene Propylene Diene Monomer/Paraffin Wax Phase Change Material Composite: Shape Stability and Thermal Applications. J. Energy Storage 2022, 52, 105065. [Google Scholar] [CrossRef]

- Jiang, X.; Yuan, X.; Guo, X.; Zeng, F.; Wang, H.; Liu, G. Study on the Application of Flory–Huggins Interaction Parameters in Swelling Behavior and Crosslink Density of HNBR/EPDM Blend. Fluid. Phase Equilib. 2023, 563, 113589. [Google Scholar] [CrossRef]

- Salimi, A.; Abbassi-Sourki, F.; Karrabi, M.; Reza Ghoreishy, M.H. Investigation on Viscoelastic Behavior of Virgin EPDM/Reclaimed Rubber Blends Using Generalized Maxwell Model (GMM). Polym. Test. 2021, 93, 106989. [Google Scholar] [CrossRef]

- Evgin, T.; Mičušík, M.; Machata, P.; Peidayesh, H.; Preťo, J.; Omastová, M. Morphological, Mechanical and Gas Penetration Properties of Elastomer Composites with Hybrid Fillers. Polymers 2022, 14, 4043. [Google Scholar] [CrossRef] [PubMed]

- Azaar, K.; Vergnaud, J.M.; Rosca, I.D. Anisotropic Swelling of EPDM Rubber Discs by Absorption of Toluene. Rubber Chem. Technol. 2002, 76, 1031–1044. [Google Scholar] [CrossRef]

- Vishvanathperumal, S.; Anand, G. Effect of Nanosilica on the Mechanical Properties, Compression Set, Morphology, Abrasion and Swelling Resistance of Sulphur Cured EPDM/SBR Composites. Silicon 2022, 14, 3523–3534. [Google Scholar] [CrossRef]

- Darko, C. The Link between Swelling Ratios and Physical Properties of EPDM Rubber Compound Having Different Oil Amounts. J. Polym. Res. 2022, 29, 325. [Google Scholar] [CrossRef]

- Abdelsalam, A.A.; Ward, A.A.; Abdel-Naeem, G.; Mohamed, W.S.; El-Sabbagh, S.H. Effect of Alumina Modified by Silane on the Mechanical, Swelling and Dielectric Properties of Al2O3/EPDM/SBR Blend Composites. Silicon 2023, 15, 3609–3621. [Google Scholar] [CrossRef]

- Prakash, P.C.; Srinivasan, D.; Navaneethakrishnan, V.; Vishvanathperumal, S. Effect of Modified Nanographene Oxide Loading on the Swelling and Compression Set Behavior of EPDM/SBR Nano-Composites. J. Inorg. Organomet. Polym. Mater. 2023, 34, 593–610. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo-Navarrete, F.; Saeb, M.R.; Marin, M.; Formela, K.; Cañavate, J. Evaluation and Rationale of the Performance of Several Elastomeric Composites Incorporating Devulcanized EPDM. Polym. Test. 2023, 121, 107976. [Google Scholar] [CrossRef]

- Simet, C.; Mougin, K.; Moreau, M.; Perche, M.; Vaulot, C.; Ponche, A.; Bally-Le Gall, F. Investigation of Ethylene-Propylene-Diene Monomer (EPDM) Ageing Behaviour in PMDIs Environment by Surface NMR. Polym. Test. 2023, 127, 108171. [Google Scholar] [CrossRef]

- Najibah, M.; Kong, J.; Khalid, H.; Hnát, J.; Park, H.S.; Bouzek, K.; Henkensmeier, D. Pre-Swelling of FAA3 Membranes with Water-Based Ethylene Glycol Solution to Minimize Dimensional Changes after Assembly into a Water Electrolyser: Effect on Properties and Performance. J. Memb. Sci. 2023, 670, 121344. [Google Scholar] [CrossRef]

- Mothé, C.G.; Azevedo, A.D. De Analise Termica de Materiais, 1st ed.; Artliber Editora: São Paulo, Brazil, 2009; ISBN 8588098490. [Google Scholar]

- Mohamad, N.; Yaakub, J.; Ab Maulod, H.E.; Jeefferie, A.R.; Yuhazri, M.Y.; Lau, K.T.; Ahsan, Q.; Shueb, M.I.; Othman, R. Vibrational Damping Behaviors of Graphene Nanoplatelets Reinforced NR/EPDM Nanocomposites. J. Mech. Eng. Sci. 2017, 11, 3274–3287. [Google Scholar] [CrossRef]

- Rana, A.S.; Vamshi, M.K.; Naresh, K.; Velmurugan, R.; Sarathi, R. Mechanical, Thermal, Electrical and Crystallographic Behaviour of EPDM Rubber/Clay Nanocomposites for out-Door Insulation Applications. Adv. Mater. Process. Technol. 2020, 6, 54–74. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, Q.; Liu, T.; Lei, Y.; Chen, C. Preparation and Relaxation Dynamics of Ethylene–Propylene–Diene Rubber/Clay Nanocomposites with Crosslinking Interfacial Design. J. Appl. Polym. Sci. 2018, 135, 45553. [Google Scholar] [CrossRef]

- Guo, M.; Li, J.; Xi, K.; Liu, Y.; Ji, J. Effect of Multi-Walled Carbon Nanotubes on Thermal Stability and Ablation Properties of EPDM Insulation Materials for Solid Rocket Motors. Acta Astronaut. 2019, 159, 508–516. [Google Scholar] [CrossRef]

- Iqbal, S.S.; Iqbal, N.; Jamil, T.; Bashir, A.; Khan, Z.M. Tailoring in Thermomechanical Properties of Ethylene Propylene Diene Monomer Elastomer with Silane Functionalized Multiwalled Carbon Nanotubes. J. Appl. Polym. Sci. 2016, 133, 43221. [Google Scholar] [CrossRef]

- Jeon, B.; Kim, T.; Lee, D.; Shin, T.J.; Oh, K.W.; Park, J. Photothermal Polymer Nanocomposites of Tungsten Bronze Nanorods with Enhanced Tensile Elongation at Low Filler Contents. Polymers 2019, 11, 1740. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; Luyt, A.S.; Messori, M. Reinforcement of EPDM Rubber with in Situ Generated Silica Particles in the Presence of a Coupling Agent via a Sol–Gel Route. Polym. Test. 2014, 33, 97–106. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; Luyt, A.S.; Morselli, D.; Bondioli, F.; Messori, M. Influence of in Situ-Generated Silica Nanoparticles on EPDM Morphology, Thermal, Thermomechanical, and Mechanical Properties. Polym. Compos. 2015, 36, 825–833. [Google Scholar] [CrossRef]

- Basu, D.; Das, A.; Wang, D.-Y.; George, J.J.; Stöckelhuber, K.W.; Boldt, R.; Leuteritz, A.; Heinrich, G. Fire-Safe and Environmentally Friendly Nanocomposites Based on Layered Double Hydroxides and Ethylene Propylene Diene Elastomer. RSC Adv. 2016, 6, 26425–26436. [Google Scholar] [CrossRef]

- Drzeżdżon, J.; Jacewicz, D.; Sielicka, A.; Chmurzyński, L. A Review of New Approaches to Analytical Methods to Determine the Structure and Morphology of Polymers. TrAC Trends Anal. Chem. 2019, 118, 470–476. [Google Scholar] [CrossRef]

- Haghnegahdar, M.; Naderi, G.; Ghoreishy, M.H.R. Fracture Toughness and Deformation Mechanism of Un-Vulcanized and Dynamically Vulcanized Polypropylene/Ethylene Propylene Diene Monomer/Graphene Nanocomposites. Compos. Sci. Technol. 2017, 141, 83–98. [Google Scholar] [CrossRef]

- Hajibabazadeh, S.; Razavi Aghjeh, M.; Palahang, M. Study on the Fracture Toughness and Deformation Micro-Mechanisms of PP/EPDM/SiO2 Ternary Blend-Nanocomposites. J. Compos. Mater. 2020, 54, 591–605. [Google Scholar] [CrossRef]

- Azizi, S.; Momen, G.; Ouellet-Plamondon, C.; David, E. Performance Improvement of EPDM and EPDM/Silicone Rubber Composites Using Modified Fumed Silica, Titanium Dioxide and Graphene Additives. Polym. Test. 2020, 84, 106281. [Google Scholar] [CrossRef]

- Benneghmouche, Z.; Benachour, D. Effect of Organophilic Clay Addition on Properties of SAN/EPDM Blends. Compos. Interfaces 2019, 26, 711–727. [Google Scholar] [CrossRef]

- Bhattacharya, A.B.; Raju, A.T.; Chatterjee, T.; Naskar, K. Development and Characterizations of Ultra-High Molecular Weight EPDM/PP Based TPV Nanocomposites for Automotive Applications. Polym. Compos. 2020, 41, 4950–4962. [Google Scholar] [CrossRef]

- Mohamed Bak, K.; Raj Kumar, G.; Ramasamy, N.; Vijayanandh, R. Experimental and Numerical Studies on the Mechanical Characterization of Epdm/S-Sbr Nano Clay Composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 912, 052016. [Google Scholar] [CrossRef]

- Ma, L.; Yang, W.; Jiang, C. Stretchable Conductors of Multi-Walled Carbon Nanotubes (MWCNTs) Filled Thermoplastic Vulcanizate (TPV) Composites with Enhanced Electromagnetic Interference Shielding Performance. Compos. Sci. Technol. 2020, 195, 108195. [Google Scholar] [CrossRef]

- Khodabandelou, M.; Razavi Aghjeh, M.K.; Khonakdar, H.A.; Mehrabi Mazidi, M. Effect of Localization of Carbon Nanotubes on Fracture Behavior of Un-Vulcanized and Dynamically Vulcanized PP/EPDM/MWCNT Blend-Nanocomposites. Compos. Sci. Technol. 2017, 149, 134–148. [Google Scholar] [CrossRef]

- Haghnegahdar, M.; Naderi, G.; Ghoreishy, M.H.R. Electrical and Thermal Properties of a Thermoplastic Elastomer Nanocomposite Based on Polypropylene/Ethylene Propylene Diene Monomer/Graphene. Soft Mater. 2017, 15, 82–94. [Google Scholar] [CrossRef]

- Kang, S.; Choi, K.; Nam, J.-D.; Choi, H. Magnetorheological Elastomers: Fabrication, Characteristics, and Applications. Materials 2020, 13, 4597. [Google Scholar] [CrossRef]

- Cho, J.K.; Sun, H.; Seo, H.W.; Chung, J.-Y.; Seol, M.; Kim, S.-H.; Kim, R.-S.; Park, I.-K.; Suhr, J.; Park, J.C.; et al. Heat Dissipative Mechanical Damping Properties of EPDM Rubber Composites Including Hybrid Fillers of Aluminium Nitride and Boron Nitride. Soft Matter 2020, 16, 6812–6818. [Google Scholar] [CrossRef] [PubMed]

- Melo, D.S.; Reis, I.C.; Queiroz, J.C.; Cena, C.R.; Nahime, B.O.; Malmonge, J.A.; Silva, M.J. Evaluation of Piezoresistive and Electrical Properties of Conductive Nanocomposite Based on Castor-Oil Polyurethane Filled with MWCNT and Carbon Black. Materials 2023, 16, 3223. [Google Scholar] [CrossRef] [PubMed]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.-J.; Lee, W.R. A Review on Carbon Nanotubes and Graphene as Fillers in Reinforced Polymer Nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Al Sheheri, S.Z.; Al-Amshany, Z.M.; Al Sulami, Q.A.; Tashkandi, N.Y.; Hussein, M.A.; El-Shishtawy, R.M. The Preparation of Carbon Nanofillers and Their Role on the Performance of Variable Polymer Nanocomposites. Des. Monomers Polym. 2019, 22, 8–53. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Sudhakara, P.; Omran, A.A.B.; Singh, J.; Ilyas, R.A. Recent Trends and Developments in Conducting Polymer Nanocomposites for Multifunctional Applications. Polymers 2021, 13, 2898. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Wei, H.; Han, L.; Li, Q. Durability and Electrical Conductivity of Carbon Fiber Cloth/Ethylene Propylene Diene Monomer Rubber Composite for Active Deicing and Snow Melting. Polymers 2019, 11, 2051. [Google Scholar] [CrossRef] [PubMed]

- Peidayesh, H.; Špitalský, Z.; Chodák, I. Electrical Conductivity of Rubber Composites with Varying Crosslink Density under Cyclic Deformation. Polymers 2022, 14, 3640. [Google Scholar] [CrossRef] [PubMed]

- Silva, M.J.D.; Kanda, D.H.F.; Nagashima, H.N. Mechanism of Charge Transport in Castor Oil-Based Polyurethane/Carbon Black Composite (PU/CB). J. Non Cryst. Solids 2012, 358, 270–275. [Google Scholar] [CrossRef][Green Version]

- Rebeque, P.V.; Silva, M.J.; Cena, C.R.; Nagashima, H.N.; Malmonge, J.A.; Kanda, D.H.F. Analysis of the Electrical Conduction in Percolative Nanocomposites Based on Castor-Oil Polyurethane with Carbon Black and Activated Carbon Nanopowder. Polym. Compos. 2019, 40, 7–15. [Google Scholar] [CrossRef]

- Bunde, A.; Dieterich, W. Percolation in Composites. J. Electroceram 2000, 5, 81–92. [Google Scholar] [CrossRef]

- Kirkpatrick, S. Percolation and Conduction. Rev. Mod. Phys. 1973, 45, 574. [Google Scholar] [CrossRef]

- Xue, Q.; Sun, J. Electrical Conductivity and Percolation Behavior of Polymer Nanocomposites. In Polymer Nanocomposites; Springer: Cham, Switzerland, 2016; pp. 51–82. [Google Scholar]

- Kwon, S.; Cho, H.W.; Gwon, G.; Kim, H.; Sung, B.J. Effects of Shape and Flexibility of Conductive Fillers in Nanocomposites on Percolating Network Formation and Electrical Conductivity. Phys. Rev. E 2016, 93, 032501. [Google Scholar] [CrossRef] [PubMed]

- Sanches, A.O.; Kanda, D.H.F.; Malmonge, L.F.; da Silva, M.J.; Sakamoto, W.K.; Malmonge, J.A. Synergistic Effects on Polyurethane/Lead Zirconate Titanate/Carbon Black Three-Phase Composites. Polym. Test. 2017, 60, 253–259. [Google Scholar] [CrossRef]

- Ma, A.; Wang, X.; Chen, Y.; Yu, J.; Zheng, W.; Zhao, Y. Largely Enhanced Thermal Conductivity of Ethylene-Propylene-Diene Monomer Composites by Addition of Graphene Ball. Compos. Commun. 2019, 13, 119–124. [Google Scholar] [CrossRef]

- Balberg, I.; Azulay, D.; Goldstein, Y.; Jedrzejewski, J. Possible Origin of the Smaller-than-Universal Percolation-Conductivity Exponent in the Continuum. Phys. Rev. E 2016, 93, 062132. [Google Scholar] [CrossRef] [PubMed]

- Athawale, A.A.; Joshi, A.M. Electronic Applications of Ethylene Propylene Diene Monomer Rubber and Its Composites; Springer: Cham, Switzerland, 2016; pp. 305–333. [Google Scholar]

- Koca, H.D.; Turgut, A.; Evgin, T.; Ateş, İ.; Chirtoc, M.; Šlouf, M.; Omastová, M. A Comprehensive Study on the Thermal and Electrical Conductivity of EPDM Composites with Hybrid Carbon Fillers. Diam. Relat. Mater. 2023, 139, 110289. [Google Scholar] [CrossRef]

- Chi, Q.; Jiang, L.; Zhang, T.; Zhang, C.; Zhang, Y.; Zhang, Y. Study on Electrical Properties of Donor ZnO Nanoparticles/EPDM Composites. J. Mater. Sci. Mater. Electron. 2021, 32, 26894–26904. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, H.; Dai, C.; Zhang, C.; Zhang, Y.; Chi, Q. Carbon Nanotubes and Hexagonal Boron Nitride Nanosheets Co-filled Ethylene Propylene Diene Monomer Composites: Improved Electrical Property for Cable Accessory Applications. High Volt. 2023, 1–10. [Google Scholar] [CrossRef]

- Ketikis, P.; Ketikis, I.; Klonos, P.; Giannakopoulou, T.; Kyritsis, A.; Trapalis, C.; Tarantili, P. The Effect of MWCNTs on the Properties of Peroxide Vulcanized Ethylene Propylene Diene Monomer (EPDM) Composites. J. Compos. Mater. 2023, 57, 2043–2058. [Google Scholar] [CrossRef]

- ASTM D-1418; Standard Practice for Rubber and Rubber Latices-Nomenclature. ASTM International: West Conshohocken, PA, USA, 2022.

- Grand View Research. Ethylene Propylene Diene Monomer (EPDM) Market Size, Share & Trends Analysis Report by Product (Hoses, Seals & O-Rings), by Application (Building & Construction, Tires & Tubes, Automotive), and Segment Forecasts, 2023–2030; Grand View Research: San Francisco, CA, USA, 2021. [Google Scholar]

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review Article: Polymer-Matrix Nanocomposites, Processing, Manufacturing, and Application: An Overview. J. Compos. Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A Review on Interface Modification and Characterization of Natural Fiber Reinforced Plastic Composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Satterthwaite, K. Plastics Based on Styrene. In Brydson’s Plastics Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 311–328. [Google Scholar]

- Akiba, M. Vulcanization and Crosslinking in Elastomers. Prog. Polym. Sci. 1997, 22, 475–521. [Google Scholar] [CrossRef]

- Maiti, M.; Bhattacharya, M.; Bhowmick, A.K. Elastomer Nanocomposites. Rubber Chem. Technol. 2008, 81, 384–469. [Google Scholar] [CrossRef]

- Li, W.; Huang, Y.D.; Ahmadi, S.J. Preparation and Properties of Ethylene–Propylene–Diene Rubber/Organomontmorillonite Nanocomposites. J. Appl. Polym. Sci. 2004, 94, 440–445. [Google Scholar] [CrossRef]

- Koerner, R.M. Designing with Geosynthetics, 6th ed.; Xlibris Corporation: Bloomington, IL, USA, 2012; Volume 1. [Google Scholar]

- Bokobza, L. Natural Rubber Nanocomposites: A Review. Nanomaterials 2018, 9, 12. [Google Scholar] [CrossRef] [PubMed]

- Camargo, P.H.C.; Satyanarayana, K.G.; Wypych, F. Nanocomposites: Synthesis, Structure, Properties and New Application Opportunities. Mater. Res. 2009, 12, 1–39. [Google Scholar] [CrossRef]

- Acharya, H.; Srivastava, S.K. Mechanical, Thermo-Mechanical, Thermal, and Swelling Properties of EPDM-Organically Modified Mesoporous Silica Nanocomposites. Polym. Compos. 2017, 38, E371–E380. [Google Scholar] [CrossRef]

- Bartosik, D.; Szadkowski, B.; Kuśmierek, M.; Rybiński, P.; Mirkhodzhaev, U.; Marzec, A. Advanced Ethylene-Propylene-Diene (EPDM) Rubber Composites Filled with Raw Silicon Carbide or Hybrid Systems with Different Conventional Fillers. Polymers 2022, 14, 1383. [Google Scholar] [CrossRef]

- Ateia, E.E.; El-Nashar, D.E.; Ramadan, R.; Shokry, M.F. Synthesis and Characterization of EPDM/Ferrite Nanocomposites. J. Inorg. Organomet. Polym. Mater. 2020, 30, 1041–1048. [Google Scholar] [CrossRef]

- George, K.; Biswal, M.; Mohanty, S.; Nayak, S.K.; Panda, B.P. Nanosilica Filled EPDM/Kevlar Fiber Hybrid Nanocomposites: Mechanical and Thermal Properties. Mater. Today Proc. 2020, 41, 983–986. [Google Scholar] [CrossRef]

- Azizli, M.J.; Mokhtary, M.; Khonakdar, H.A.; Goodarzi, V. Hybrid Rubber Nanocomposites Based on XNBR/EPDM: Select the Best Dispersion Type from Different Nanofillers in the Presence of a Compatibilizer. J. Inorg. Organomet. Polym. Mater. 2020, 30, 2533–2550. [Google Scholar] [CrossRef]

- Peddini, S.K.; Bosnyak, C.P.; Henderson, N.M.; Ellison, C.J.; Paul, D.R. Nanocomposites from Styrene–Butadiene Rubber (SBR) and Multiwall Carbon Nanotubes (MWCNT) Part 2: Mechanical Properties. Polymer 2015, 56, 443–451. [Google Scholar] [CrossRef]

- Rajasekar, R.; Pal, K.; Heinrich, G.; Das, A.; Das, C.K. Development of Nitrile Butadiene Rubber–Nanoclay Composites with Epoxidized Natural Rubber as Compatibilizer. Mater. Des. 2009, 30, 3839–3845. [Google Scholar] [CrossRef]

- Santos, R.J.; Agostini, D.L.S.; Cabrera, F.C.; Budemberg, E.R.; Job, A.E. Recycling Leather Waste: Preparing and Studying on the Microstructure, Mechanical, and Rheological Properties of Leather Waste/Rubber Composite. Polym. Compos. 2015, 36, 2275–2281. [Google Scholar] [CrossRef]

- Santos, R.J.; Hiranobe, C.T.; Dognani, G.; Silva, M.J.; Paim, L.L.; Cabrera, F.C.; Torres, G.B.; Job, A.E. Using the Lorenz–Park, Mooney–Rivlin, and Dynamic Mechanical Analysis Relationship on Natural Rubber/Leather Shavings Composites. J. Appl. Polym. Sci. 2021, 139, 51880. [Google Scholar] [CrossRef]

- Mechanics, M.; Li, R.; Sun, L.Z. Dynamic Mechanical Analysis of Silicone Rubber Reinforced with Multi-Walled Carbon Nanotubes. Interact. Multiscale Mech. 2011, 4, 239–245. [Google Scholar] [CrossRef]

- Avila Torrado, M.; Constantinescu, A.; Johlitz, M.; Lion, A. Viscoelastic Behavior of Filled Silicone Elastomers and Influence of Aging in Inert and Hermetic Environment. Contin. Mech. Thermodyn. 2022, 36, 333–350. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.-J.; Park, S.-S. Silicone Rubber Composites Reinforced by Carbon Nanofillers and Their Hybrids for Various Applications: A Review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef]

- Praveen, K.M.; Pillin, I.; Kervoelen, A.; Grohens, Y.; Thomas, S. Investigations on the Effect of Sol-Gel Coated Coir Fiber Reinforcement in PP/EPDM Composites. Eur. Polym. J. 2024, 212, 113081. [Google Scholar] [CrossRef]

- Guo, W.; Zhao, J.; Zhao, F.; Feng, T.; Liu, L. Assessment of Properties of Bamboo Fiber and EPDM Reinforced Polypropylene Microcellular Foam Composites. Polymer 2024, 304, 127142. [Google Scholar] [CrossRef]

- Scaglia, F.; Mazzini, A.; Perretta, C.; Regattieri, G.; Marchetti, G. Industrial EP(D)M Rubber Production Process: A First-Principle Data-Driven Modelling Approach. Chem. Eng. Trans. 2023, 100, 163–168. [Google Scholar] [CrossRef]

- Kulkarni, S.D.; Manjunatha, B.; Chandrasekhar, U.; Siddesh, G.K.; Lenin, H.; Arul, S.J. Effect of Curing Temperature and Time on Mechanical Properties of Vinyl Polymer Material for Sealing Applications in Industry Using Machine Learning Techniques. Adv. Polym. Technol. 2023, 2023, 9964610. [Google Scholar] [CrossRef]

- Correia, S.L.; Palaoro, D.; Segadães, A.M. Property Optimisation of EPDM Rubber Composites Using Mathematical and Statistical Strategies. Adv. Mater. Sci. Eng. 2017, 2017, 2730830. [Google Scholar] [CrossRef]

- Song, L.-F.; Bai, N.; Shi, Y.; Wang, Y.-X.; Song, L.-X.; Liu, L.-Z. Effects of Ethylene-Propylene-Diene Monomers (EPDMs) with Different Moony Viscosity on Crystallization Behavior, Structure, and Mechanical Properties of Thermoplastic Vulcanizates (TPVs). Polymers 2023, 15, 642. [Google Scholar] [CrossRef]

- Hosseinpour, A.; Katbab, A.A.; Ohadi, A. Improving the Sound Absorption of a Highly Deformable Nanocomposite Foam Based on Ethylene-Propylene-Diene-Monomer (EPDM) Infused with Multi-Walled Carbon Nanotubes (MWCNTs) to Absorb Low-Frequency Waves. Eur. Polym. J. 2022, 178, 111522. [Google Scholar] [CrossRef]

- Chen, G.; Gupta, A.; Mekonnen, T.H. Effects of Wood Fiber Loading, Silane Modification and Crosslinking on the Thermomechanical Properties and Thermal Conductivity of EPDM Biocomposite Foams. Ind. Crops Prod. 2023, 200, 116911. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Wan, L.; Wang, L.; Li, K. A Lightweight Rubber Foaming Insulation Reinforced by Carbon Nanotubes and Carbon Fibers for Solid Rocket Motors. Acta Astronaut. 2023, 208, 270–280. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Chai, J.; Chang, E.; Wang, S.; Zhang, A.; Park, C.B. Polylactic Acid/UV-Crosslinked in-Situ Ethylene-Propylene-Diene Terpolymer Nanofibril Composites with Outstanding Mechanical and Foaming Performance. Chem. Eng. J. 2022, 447, 137509. [Google Scholar] [CrossRef]

- Sang, J.S.; Park, E.-Y.; Lim, S.-W.; Park, S.; Oh, K.W. Performance of Bio-Ethylene Propylene Diene Monomer (Bio-EPDM) Foam with Mixed Chemical and Encapsulated Blowing Agents. Fash. Text. 2019, 6, 21. [Google Scholar] [CrossRef]

- Kouhi, F.; Vahidifar, A.; Naderi, G.; Esmizadeh, E. Tire-Derived Reclaimed Rubber as a Secondary Raw Material for Rubber Foams: In the Framework of Circular Economy Strategy. J. Polym. Res. 2023, 30, 97. [Google Scholar] [CrossRef]

- Buchen, S.; Kröger, N.H.; Reppel, T.; Weinberg, K. Time-Dependent Modeling and Experimental Characterization of Foamed EPDM Rubber. Contin. Mech. Thermodyn. 2021, 33, 1747–1764. [Google Scholar] [CrossRef]

- Bhuyan, C.; Konwar, A.; Bora, P.; Rajguru, P.; Hazarika, S. Cellulose Nanofiber-Poly(Ethylene Terephthalate) Nanocomposite Membrane from Waste Materials for Treatment of Petroleum Industry Wastewater. J. Hazard. Mater. 2023, 442, 129955. [Google Scholar] [CrossRef] [PubMed]

- Shahrim, N.A.; Abounahia, N.M.; El-Sayed, A.M.A.; Saleem, H.; Zaidi, S.J. An Overview on the Progress in Produced Water Desalination by Membrane-Based Technology. J. Water Process Eng. 2023, 51, 103479. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, N.L.; Hiranobe, C.T.; Cardim, H.P.; Dognani, G.; Sanchez, J.C.; Carvalho, J.A.J.; Torres, G.B.; Paim, L.L.; Pinto, L.F.; Cardim, G.P.; et al. A Review of EPDM (Ethylene Propylene Diene Monomer) Rubber-Based Nanocomposites: Properties and Progress. Polymers 2024, 16, 1720. https://doi.org/10.3390/polym16121720

Costa NL, Hiranobe CT, Cardim HP, Dognani G, Sanchez JC, Carvalho JAJ, Torres GB, Paim LL, Pinto LF, Cardim GP, et al. A Review of EPDM (Ethylene Propylene Diene Monomer) Rubber-Based Nanocomposites: Properties and Progress. Polymers. 2024; 16(12):1720. https://doi.org/10.3390/polym16121720

Chicago/Turabian StyleCosta, Naiara Lima, Carlos Toshiyuki Hiranobe, Henrique Pina Cardim, Guilherme Dognani, Juan Camilo Sanchez, Jaime Alberto Jaramillo Carvalho, Giovanni Barrera Torres, Leonardo Lataro Paim, Leandro Ferreira Pinto, Guilherme Pina Cardim, and et al. 2024. "A Review of EPDM (Ethylene Propylene Diene Monomer) Rubber-Based Nanocomposites: Properties and Progress" Polymers 16, no. 12: 1720. https://doi.org/10.3390/polym16121720

APA StyleCosta, N. L., Hiranobe, C. T., Cardim, H. P., Dognani, G., Sanchez, J. C., Carvalho, J. A. J., Torres, G. B., Paim, L. L., Pinto, L. F., Cardim, G. P., Cabrera, F. C., dos Santos, R. J., & Silva, M. J. (2024). A Review of EPDM (Ethylene Propylene Diene Monomer) Rubber-Based Nanocomposites: Properties and Progress. Polymers, 16(12), 1720. https://doi.org/10.3390/polym16121720