Progress in the Preparation and Application of Breathable Membranes

Abstract

1. Introduction

2. Preparation of Breathable Membranes

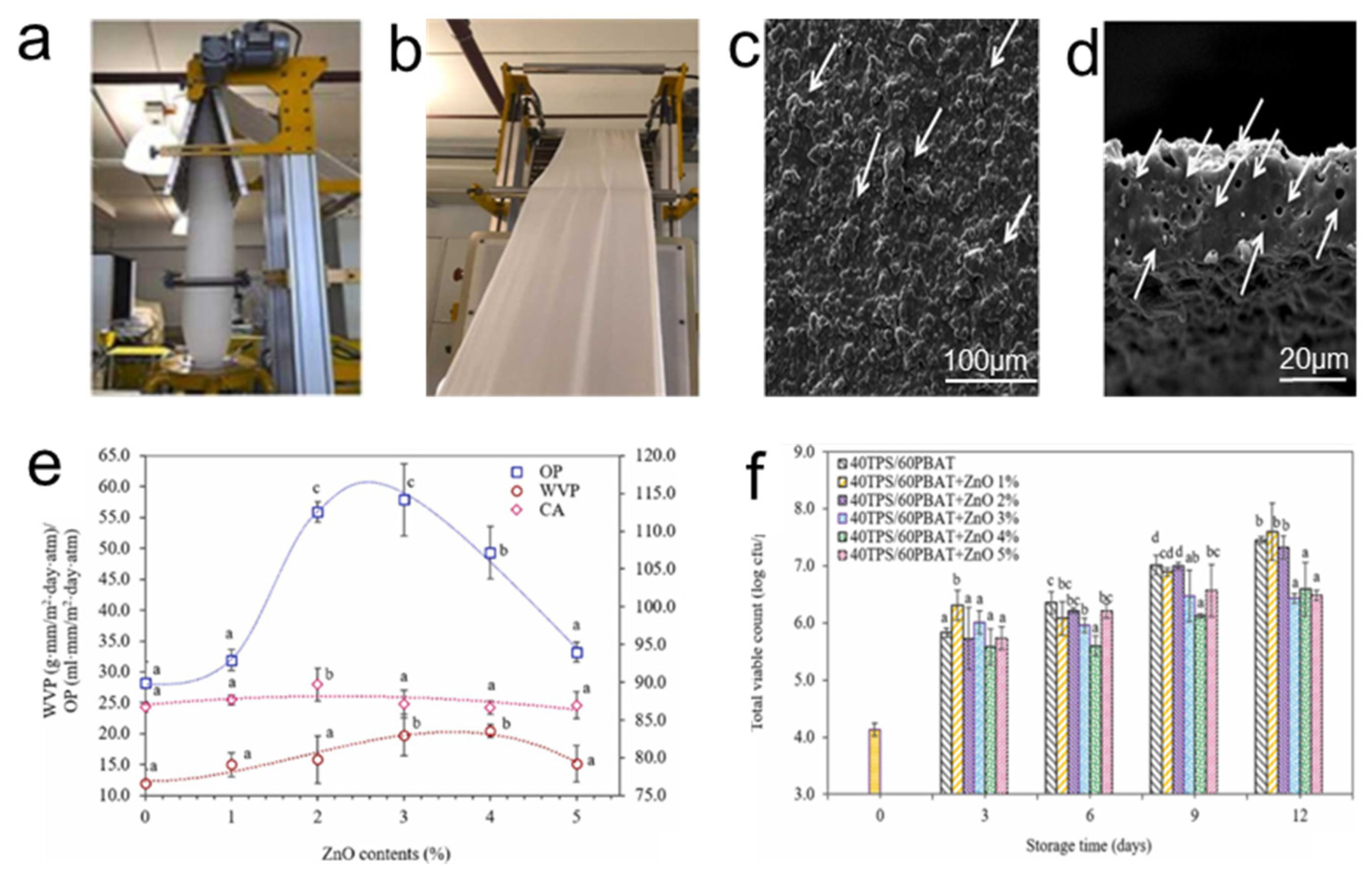

2.1. Blown Film Extrusion

2.2. Cast Film Extrusion

2.3. Phase Separation

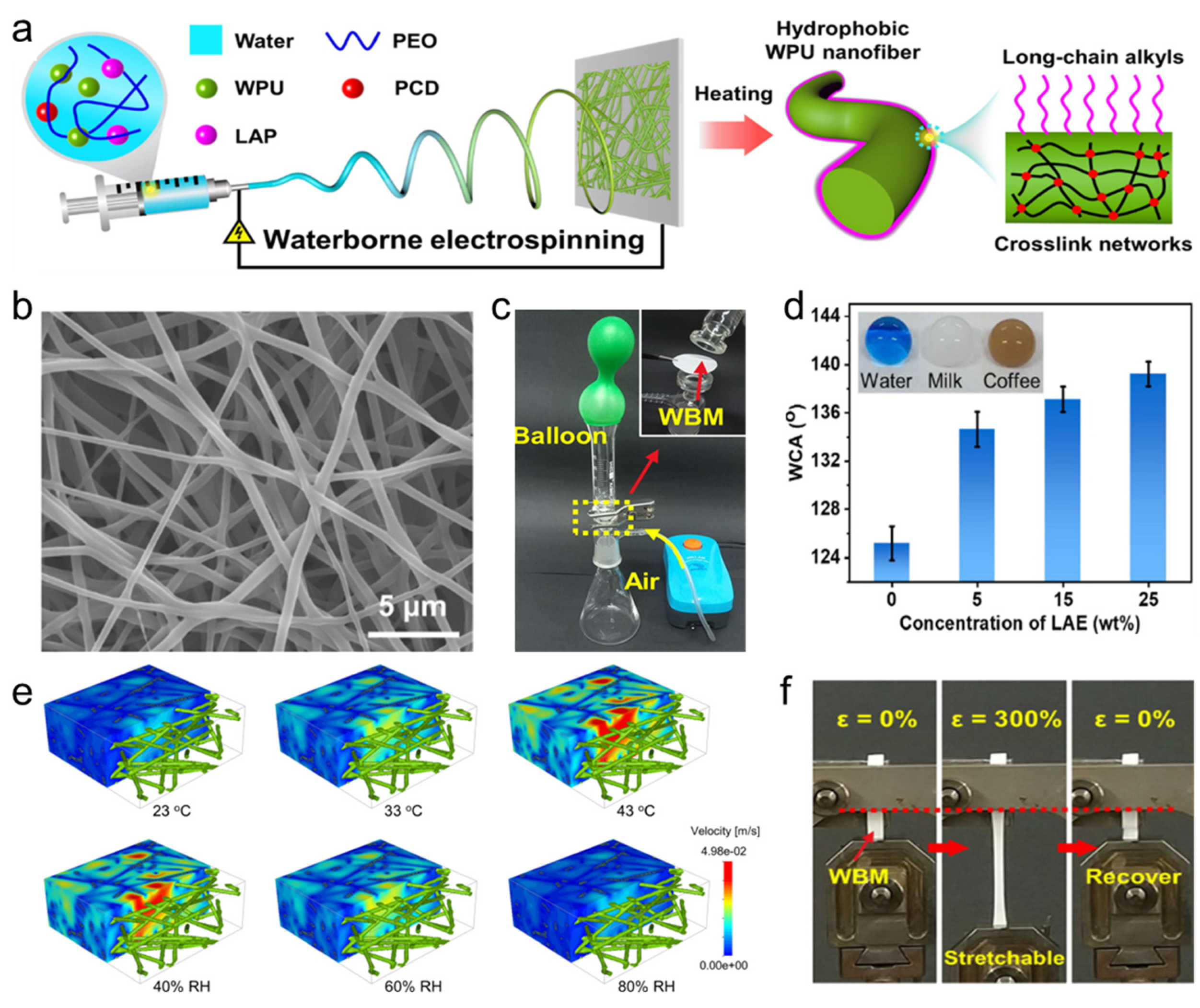

2.4. Electrospinning

3. Applications of Breathable Membranes

3.1. Medical Field

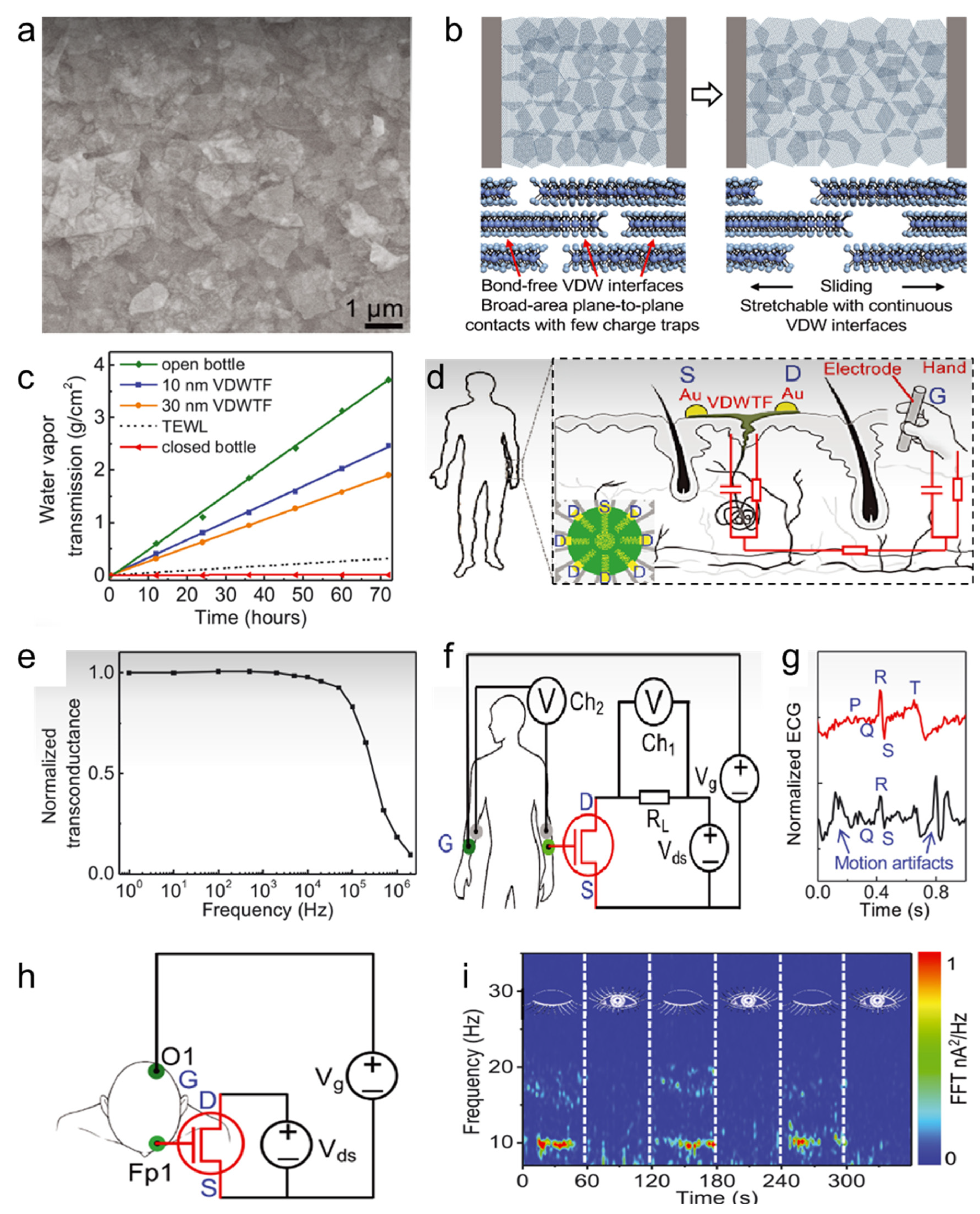

3.2. Electronics Field

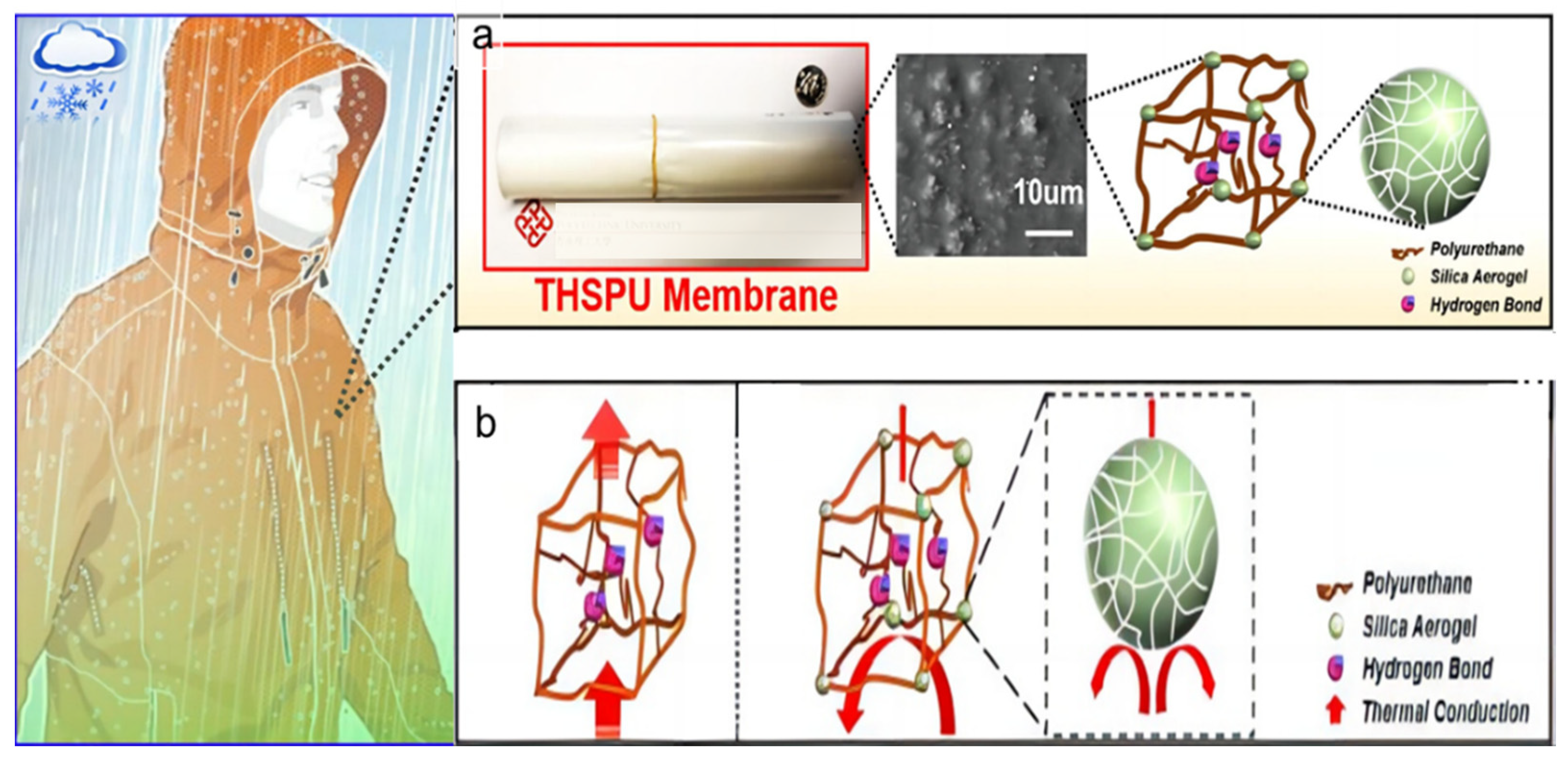

3.3. Textile Field

3.4. Packaging Field

3.5. Energy Field

3.6. Environmental Field

4. Conclusions and Prospects

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ATBC | acetyltributyl citrate |

| Ag-NPs | Ag nanoparticles |

| CVD | chemical vapor deposition |

| FPU | fluorinated polyurethane |

| EPU | ethanol-soluble polyurethane |

| FS | flash-spun nonwoven |

| GTR | gas transmission rate |

| LAP | long-chain alkyl polymers |

| MDO | machine direction orientation |

| MWCNT | multi-walled carbon nanotube |

| NIPS | Nonsolvent-induced phase separation |

| NF-TENG | friction nanogenerators |

| NS | hydrophobic polymer dextrin-nanosponge |

| ODA | 4,4′-oxidianiline |

| PMDA | pyromellitic dianhydride |

| PVDF | polyvinylidene fluoride |

| PI-ENM | electrospun nanofiber membrane |

| PU | polyurethane |

| PAN | polyacrylonitrile |

| PDMS | polydimethylsiloxane |

| PCD | polycarbodiimide |

| PBAT | Polybutylene adipate-co-terephthalate |

| PIM-1 | a polymer of intrinsic microporosity |

| PCL | polycaprolactone |

| PA66 | thermoplastic resin |

| PTFE | polytetrafluoroethylene |

| PVA | polyvinyl alcohol |

| RH | relative humidity |

| SF | film/nonwoven composite |

| SMS | punbond/melt-blown/spunbonded polypropylene |

| SA | silica aerogel |

| SBE-βCD | sodium sulfobutyl ether-β-cyclodextrin |

| TIPS | thermally induced phase separation |

| TPS | thermoplastic starch |

| TVC | total viable count |

| THSPUs | polyurethane-based breathable membranes |

| VDWTF | van der Waals thin-film electronics |

| WVT | water vapor transmission rate |

References

- Yan, Z.; Xu, D.; Lin, Z.; Wang, P.; Cao, B.; Ren, H.; Song, F.; Wan, C.; Wang, L.; Zhou, J.; et al. Highly stretchable van der Waals thin films for adaptable and breathable electronic membranes. Science 2022, 375, 852–859. [Google Scholar] [CrossRef]

- Tehrani-Bagha, A.R. Waterproof breathable layers—A review. Adv. Colloid Interface Sci. 2019, 268, 114–135. [Google Scholar] [CrossRef]

- Gong, X.; Yin, X.; Wang, F.; Liu, X.; Yu, J.; Zhang, S.; Ding, B. Electrospun Nanofibrous Membranes: A Versatile Medium for Waterproof and Breathable Application. Small 2022, 19, 2205067. [Google Scholar] [CrossRef]

- Yu, X.; Wu, X.; Si, Y.; Wang, X.; Yu, J.; Ding, B. Waterproof and Breathable Electrospun Nanofibrous Membranes. Macromol. Rapid. Commun. 2019, 40, e1800931. [Google Scholar] [CrossRef]

- Chang, Y.; Liu, F. Review of Waterproof Breathable Membranes: Preparation, Performance and Applications in the Textile Field. Materials 2023, 16, 5339. [Google Scholar] [CrossRef]

- Karagoz, S.; Kiremitler, N.B.; Sarp, G.; Pekdemir, S.; Salem, S.; Goksu, A.G.; Onses, M.S.; Sozdutmaz, I.; Sahmetlioglu, E.; Ozkara, E.S.; et al. Antibacterial, Antiviral, and Self-Cleaning Mats with Sensing Capabilities Based on Electrospun Nanofibers Decorated with ZnO Nanorods and Ag Nanoparticles for Protective Clothing Applications. ACS Appl. Mater. Interfaces 2021, 13, 5678–5690. [Google Scholar] [CrossRef]

- Li, Y.; Zhong, L.-B.; Zhang, Q.-J.; Guo, C.-Y.; He, B.-Q.; Younas, M.; Zheng, Y.-M. Highly breathable and durable waterproof polyimide electrospun nanofibrous membrane for potential reusable protective clothing application: Preparation, characterization and performance. J. Membr. Sci. 2024, 693, 122354. [Google Scholar] [CrossRef]

- Yue, Y.; Gong, X.; Jiao, W.; Li, Y.; Yin, X.; Si, Y.; Yu, J.; Ding, B. In-situ electrospinning of thymol-loaded polyurethane fibrous membranes for waterproof, breathable, and antibacterial wound dressing application. J. Colloid Interface Sci. 2021, 592, 310–318. [Google Scholar] [PubMed]

- Sun, N.; Wang, G.-G.; Zhao, H.-X.; Cai, Y.-W.; Li, J.-Z.; Li, G.-Z.; Zhang, X.-N.; Wang, B.-L.; Han, J.-C.; Wang, Y.; et al. Waterproof, breathable and washable triboelectric nanogenerator based on electrospun nanofiber films for wearable electronics. Nano Energy 2021, 90, 106639. [Google Scholar] [CrossRef]

- Zhi, C.; Shi, S.; Meng, S.; Wu, H.; Si, Y.; Zhang, K.; Zhang, S.; Hu, J. A biocompatible and antibacterial all-textile structured triboelectric nanogenerator for self-powered tactile sensing. Nano Energy 2023, 115, 108734. [Google Scholar] [CrossRef]

- Zhou, W.; Gong, X.; Li, Y.; Si, Y.; Zhang, S.; Yu, J.; Ding, B. Waterborne electrospinning of fluorine-free stretchable nanofiber membranes with waterproof and breathable capabilities for protective textiles. J. Colloid Interface Sci. 2021, 602, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.; Han, Y.; Hu, J. Robust waterproof and self-adaptive breathable membrane with heat retention property for intelligent protective cloth. Prog. Org. Coat. 2019, 137, 105303. [Google Scholar] [CrossRef]

- Yue, X.; Zhang, T.; Yang, D.; Qiu, F.; Li, Z.; Wei, G.; Qiao, Y. Ag nanoparticles coated cellulose membrane with high infrared reflection, breathability and antibacterial property for human thermal insulation. J. Colloid Interface Sci. 2019, 535, 363–370. [Google Scholar] [CrossRef] [PubMed]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K.; Promsorn, J.; Harnkarnsujarit, N. Blown film extrusion of PBAT/TPS/ZnO nanocomposites for shelf-life extension of meat packaging. Colloids Surf. B 2022, 214, 112472. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Xiao, K.; Zhu, L.; Luo, Q. Preparation and application of equilibrium modified atmosphere packaging membranes with polylactic acid and polymers of intrinsic microporosity. Food Packag. Shelf Life 2023, 37, 101063. [Google Scholar] [CrossRef]

- Abd Al-Ghani, M.M.; Azzam, R.A.; Madkour, T.M. Design and Development of Enhanced Antimicrobial Breathable Biodegradable Polymeric Films for Food Packaging Applications. Polymers 2021, 13, 3527. [Google Scholar] [CrossRef]

- Kim, D.; Seo, J. A review: Breathable films for packaging applications. Trends Food Sci. Technol. 2018, 76, 15–27. [Google Scholar] [CrossRef]

- Wang, J.; Ke, Y.; Chen, X.; Jia, Z. Preparation of Waterproof and Air-Permeable Membrane by Water Surface Spreading Method for Metal-Air Battery. ACS Sustain. Chem. Eng. 2022, 10, 2903–2913. [Google Scholar] [CrossRef]

- Amici, J.; Alidoost, M.; Francia, C.; Bodoardo, S.; Martinez Crespiera, S.; Amantia, D.; Biasizzo, M.; Caldera, F.; Trotta, F. O2 selective membranes based on a dextrin-nanosponge (NS) in a PVDF-HFP polymer matrix for Li–air cells. Chem. Commun. 2016, 52, 13683–13686. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, Y.; Zhang, Q.; Han, Y. Increasing N2200 Charge Transport Mobility to Improve Performance of All Polymer Solar Cells by Forming a Percolation Network Structure. Front. Chem. 2020, 8, 394. [Google Scholar] [CrossRef]

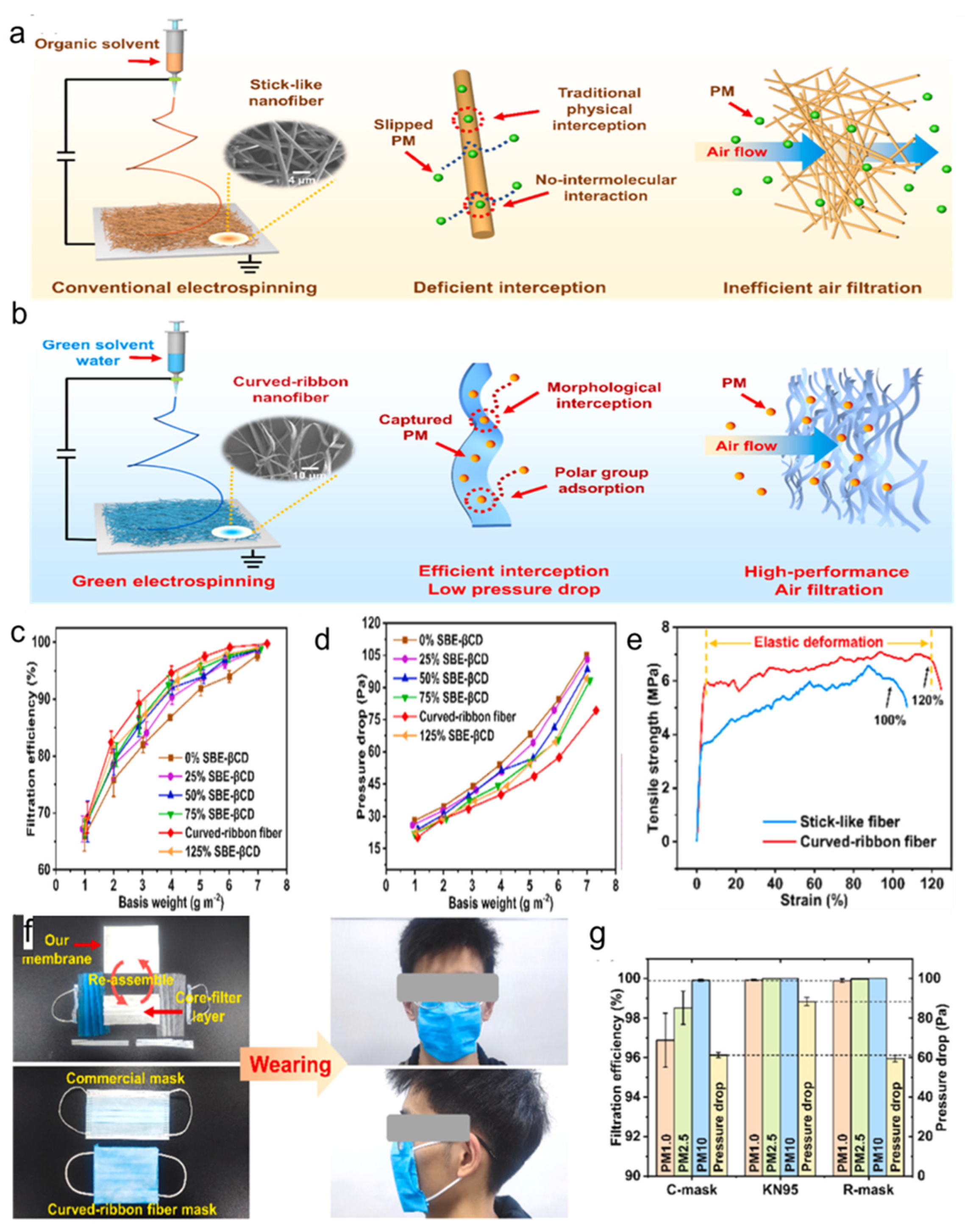

- Deng, Y.; Lu, T.; Zhang, X.; Zeng, Z.; Tao, R.; Qu, Q.; Zhang, Y.; Zhu, M.; Xiong, R.; Huang, C. Multi-hierarchical nanofiber membrane with typical curved-ribbon structure fabricated by green electrospinning for efficient, breathable and sustainable air filtration. J. Membr. Sci. 2022, 660, 120857. [Google Scholar] [CrossRef]

- Cheng, X.; Zhang, Z.; Zhao, L.; Deng, C.; Li, C.; Du, Y.; Zhu, M. Multi-hierarchical nanofibre membranes composited with ordered structure/nano-spiderwebs for air filtration. J. Environ. Chem. Eng. 2023, 11, 110561. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Xu, Y.; He, P.; Si, Y.; Liu, L.; Yu, J.; Ding, B. Multifunctional, Waterproof, and Breathable Nanofibrous Textiles Based on Fluorine-Free, All-Water-Based Coatings. ACS Appl. Mater. Interfaces 2020, 12, 15911–15918. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Gu, H.; Zhang, Q.; Zhao, Y.; Li, N.; Xiong, J. Sandwich-structured composite fibrous membranes with tunable porous structure for waterproof, breathable, and oil-water separation applications. J. Colloid Interface Sci. 2018, 514, 386–395. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yang, F.; Yu, J.; Ding, B. Hydrophobic Fibrous Membranes with Tunable Porous Structure for Equilibrium of Breathable and Waterproof Performance. Adv. Mater. Interfaces 2016, 3, 1600516. [Google Scholar] [CrossRef]

- Zhou, W.; Yu, J.; Zhang, S.; Ding, B. Direct electrospinning of fluorine-free waterproof polyamide/polydimethylsiloxane nanofibrous membranes with highly breathable performance. Compos. Commun. 2022, 35, 101337. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, T.; Li, Y.; Zhao, Z.; Xue, J.; Wang, Q. Fabrication of Breathable Multifunctional On-Skin Electronics Based on Tunable Track-Etched Membranes. ACS Appl. Electron. Mater. 2024, 6, 969–977. [Google Scholar] [CrossRef]

- Zhou, W.; Gong, X.; Li, Y.; Si, Y.; Zhang, S.; Yu, J.; Ding, B. Environmentally friendly waterborne polyurethane nanofibrous membranes by emulsion electrospinning for waterproof and breathable textiles. Chem. Eng. J. 2022, 427, 130925. [Google Scholar] [CrossRef]

- Lim, Y.J.; Goh, K.; Wang, R. The coming of age of water channels for separation membranes: From biological to biomimetic to synthetic. Chem. Soc. Rev. 2022, 51, 4537–4582. [Google Scholar] [CrossRef]

- Mallet, B.; Lamnawar, K.; Maazouz, A. Improvement of blown film extrusion of poly(Lactic Acid): Structure–Processing–Properties relationships. Polym. Eng. Sci. 2013, 54, 840–857. [Google Scholar] [CrossRef]

- Cotto, D.; Duffo, P.; Haudin, J.M. Cast Film Extrusion of Polypropylene Films. Int. Polym. Process. 1989, 4, 103–113. [Google Scholar] [CrossRef]

- Jung, J.T.; Kim, J.F.; Wang, H.H.; Di Nicolo, E.; Drioli, E.; Lee, Y.M. Understanding the non-solvent induced phase separation (NIPS) effect during the fabrication of microporous PVDF membranes via thermally induced phase separation (TIPS). J. Membr. Sci. 2016, 514, 250–263. [Google Scholar] [CrossRef]

- Xue, L.; Zhang, J.; Han, Y. Phase separation induced ordered patterns in thin polymer blend films. Prog. Polym. Sci. 2012, 37, 564–594. [Google Scholar] [CrossRef]

- Peng, J.; Han, Y.; Yang, Y.; Li, B. The influencing factors on the macroporous formation in polymer films by water droplet templating. Polymer 2004, 45, 447–452. [Google Scholar] [CrossRef]

- Wang, Y.; Padua, G.W. Tensile Properties of Extruded Zein Sheets and Extrusion Blown Films. Macromol. Mater. Eng. 2003, 288, 886–893. [Google Scholar] [CrossRef]

- Itabana, B.E.; Pal, A.K.; Mohanty, A.K.; Misra, M. Biodegradable blown film composite from poly (butylene adipate-co-terephthalate) and talc: Effect of uniaxial stretching on mechanical and barrier properties. Food Packag. Shelf Life 2023, 39, 101147. [Google Scholar] [CrossRef]

- Christmann, J.; Gardette, J.-L.; Pichon, G.; Bouchut, B.; Therias, S. Photostabilization of polyethylene by a hindered amine light stabilizer in blooming conditions and impact of MDO processing. Polym. Degrad. Stab. 2021, 191, 109683. [Google Scholar] [CrossRef]

- Hatfield, E.; Tate, R.; Williams, K.; Todd, W. New MDO Medium Molecular Weight High Density Polyethylene Films. J. Plast. Film Sheeting 2002, 18, 117–127. [Google Scholar] [CrossRef]

- Tabatabaei, S.H.; Parent, L.; Cigana, P.; Ajji, A.; Carreau, P.J. Effect of Machine Direction Orientation Conditions On Properties of Hdpe Films. J. Plast. Film Sheeting 2009, 25, 235–249. [Google Scholar] [CrossRef]

- Chatterjee, T.; Patel, R.; Garnett, J.; Paradkar, R.; Ge, S.; Liu, L.; Forziati, K.T.; Shah, N. Machine direction orientation of high density polyethylene (HDPE): Barrier and optical properties. Polymer 2014, 55, 4102–4115. [Google Scholar] [CrossRef]

- Agassant, J.F.; Demay, Y.; Sollogoub, C.; Silagy, D. Cast Film Extrusion. An Overview of Experimental and Theoretical Approaches. Int. Polym. Process. 2005, 20, 136–148. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Park, S.-Y.; Song, H.-S. Lamellar crystalline structure of hard elastic HDPE films and its influence on microporous membrane formation. Polymer 2006, 47, 3540–3547. [Google Scholar] [CrossRef]

- Xu, K.; Zhang, J. Research progress on preparation methods and permeability mechanisms of breathable microporous membranes. China Synth. Resin Plast. 2009, 26, 63–66. [Google Scholar]

- Xiande, C.; Ruijie, X.; Jiayi, X.; Yuanfei, L.; Caihong, L.; Liangbin, L. The study of room-temperature stretching of annealed polypropylene cast film with row-nucleated crystalline structure. Polymer 2016, 94, 31–42. [Google Scholar] [CrossRef]

- Lei, C.; Hu, B.; Xu, R.; Cai, Q.; Shi, W. Influence of room-temperature-stretching technology on the crystalline morphology and microstructure of PVDF hard elastic film. J. Appl. Polym. Sci. 2013, 131, 40077. [Google Scholar] [CrossRef]

- Xie, X.; Yang, X.C.; Yang, Q. The hard elastic structure and stretching porosity of polypropylene cast film. Polym. Mater. Sci. Eng. 2013, 29, 109–112+116. [Google Scholar]

- Duffo, P.; Monasse, B.; Haudin, J.M. Influence of Stretching and Cooling Conditions in Cast Film Extrusion of PP Films. Int. Polym. Process. 1990, 5, 272–283. [Google Scholar] [CrossRef]

- Yu, K.F. Effects of Annealing Conditions on Oriented Lamellar Structures of PP Cast Precursor and Microporous Membrane Formation by Uniaxially Stretching. China Plast. 2015, 29, 84–89. [Google Scholar]

- Yu, Q.; Yang, X.C.; Chen, L. Oriented Lamellar Structure of i-PP/PPR Precursor Film and lts Micropore-Forming Performance by Uniaxially Stretching. J. Chang’an Univ. (Nat. Sci. Ed.) 2016, 28, 1–7. [Google Scholar]

- Zhang, T.-Q.; Jia, Z.-Q.; Peng, W.; Li, S.; Wen, J. Preparation of 4-methyl-1-pentene membranes via non-solvent induced phase separation (NIPS). Eur. Polym. J. 2022, 178, 11148. [Google Scholar] [CrossRef]

- Wang, H.H.; Jung, J.T.; Kim, J.F.; Kim, S.; Drioli, E.; Lee, Y.M. A novel green solvent alternative for polymeric membrane preparation via nonsolvent-induced phase separation (NIPS). J. Membr. Sci. 2019, 574, 44–54. [Google Scholar] [CrossRef]

- Wang, D.-M.; Lai, J.-Y. Recent advances in preparation and morphology control of polymeric membranes formed by nonsolvent induced phase separation. Curr. Opin. Chem. Eng. 2013, 2, 229–237. [Google Scholar] [CrossRef]

- Caneba, G.T.; Soong, D.S. Polymer membrane formation through the thermal-inversion process. 1. Experimental study of membrane structure formation. Macromolecules 1985, 18, 2538–2545. [Google Scholar] [CrossRef]

- Kim, J.F.; Jung, J.T.; Wang, H.H.; Lee, S.Y.; Moore, T.; Sanguineti, A.; Drioli, E.; Lee, Y.M. Microporous PVDF membranes via thermally induced phase separation (TIPS) and stretching methods. J. Membr. Sci. 2016, 509, 94–104. [Google Scholar] [CrossRef]

- Pagliero, M.; Bottino, A.; Comite, A.; Costa, C. Novel hydrophobic PVDF membranes prepared by nonsolvent induced phase separation for membrane distillation. J. Membr. Sci. 2020, 596, 117575. [Google Scholar] [CrossRef]

- Fu, J.; Luan, B.; Pan, C.; Li, B.; Han, Y. Early Stage Interplay of Microphase Separation and Crystallization in Crystalline−Coil Poly(l-lactic acid)-block-polystyrene Thin Films. Macromolecules 2005, 38, 5118–5127. [Google Scholar] [CrossRef]

- Lai, J.-Y.; Lin, F.-C.; Wang, C.-C.; Wang, D.-M. Effect of nonsolvent additives on the porosity and morphology of asymmetric TPX membranes. J. Membr. Sci. 1996, 118, 49–61. [Google Scholar] [CrossRef]

- Tang, Y.; Lin, Y.; Ma, W.; Wang, X. A review on microporous polyvinylidene fluoride membranes fabricated via thermally induced phase separation for MF/UF application. J. Membr. Sci. 2021, 639, 119759. [Google Scholar] [CrossRef]

- Li, P.; Feng, Q.; Chen, L.; Zhao, J.; Lei, F.; Yu, H.; Yi, N.; Gan, F.; Han, S.; Wang, L.; et al. Environmentally Friendly, Durably Waterproof, and Highly Breathable Fibrous Fabrics Prepared by One-Step Fluorine-Free Waterborne Coating. ACS Appl. Mater. Interfaces 2022, 14, 8613–8622. [Google Scholar] [CrossRef]

- Chen, R.; Wan, Y.; Wu, W.; Yang, C.; He, J.-H.; Cheng, J.; Jetter, R.; Ko, F.K.; Chen, Y. A lotus effect-inspired flexible and breathable membrane with hierarchical electrospinning micro/nanofibers and ZnO nanowires. Mater. Des. 2019, 162, 246–248. [Google Scholar] [CrossRef]

- Peng, H.; Pan, M.; Jiang, H.; Huang, W.; Wang, X.; Yang, Q.; Chen, S.; Yan, B. Cobweb-Inspired Quintuple Network Structures toward High-Performance Wearable Electrochromic Devices with Excellent Bending Resistance. ACS Appl. Mater. Interfaces 2022, 14, 42402–42411. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Zhu, W.; Wang, X.; Liu, L.; Yu, J.; Ding, B. Fluorine-Free Waterborne Coating for Environmentally Friendly, Robustly Water-Resistant, and Highly Breathable Fibrous Textiles. ACS Nano 2020, 14, 1045–1054. [Google Scholar] [CrossRef]

- Liu, S.; Jun, S.C.; Zhang, S.; Wang, F.; Yu, J.; Ding, B. Advancements in Electrospun Nanofibrous Membranes for Improved Waterproofing and Breathability. Macromol. Mater. Eng. 2023, 112, 223–234. [Google Scholar] [CrossRef]

- Yu, X.; Li, Y.; Wang, X.; Si, Y.; Yu, J.; Ding, B. Thermoconductive, Moisture-Permeable, and Superhydrophobic Nanofibrous Membranes with Interpenetrated Boron Nitride Network for Personal Cooling Fabrics. ACS Appl. Mater. Interfaces 2020, 12, 32078–32089. [Google Scholar] [CrossRef] [PubMed]

- Sheng, J.; Xu, Y.; Yu, J.; Ding, B. Robust Fluorine-Free Superhydrophobic Amino-Silicone Oil/SiO2 Modification of Electrospun Polyacrylonitrile Membranes for Waterproof-Breathable Application. ACS Appl. Mater. Interfaces 2017, 9, 15139–15147. [Google Scholar] [CrossRef]

- Jiang, G.; Luo, L.; Tan, L.; Wang, J.; Zhang, S.; Zhang, F.; Jin, J. Microsphere-Fiber Interpenetrated Superhydrophobic PVDF Microporous Membranes with Improved Waterproof and Breathable Performance. ACS Appl. Mater. Interfaces 2018, 10, 28210–28218. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Deng, L.; Zhang, T.; Shen, K.; Wang, X. Facile Fabrication of Environmentally Friendly, Waterproof, and Breathable Nanofibrous Membranes with High UV-Resistant Performance by One-Step Electrospinning. Ind. Eng. Chem. Res 2020, 59, 4447–4458. [Google Scholar] [CrossRef]

- Gu, X.; Li, N.; Gu, H.; Xia, X.; Xiong, J. Polydimethylsiloxane-modified polyurethane–poly(ɛ-caprolactone) nanofibrous membranes for waterproof, breathable applications. J. Appl. Polym. Sci. 2018, 135, 46360. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Sheng, J.; Wang, X.; Liu, L.; Yu, J.; Ding, B. Environmentally Friendly and Breathable Fluorinated Polyurethane Fibrous Membranes Exhibiting Robust Waterproof Performance. ACS Appl. Mater. Interfaces 2017, 9, 29302–29310. [Google Scholar] [CrossRef] [PubMed]

- Pant, B.; Park, M.; Park, S.-J. One-Step Synthesis of Silver Nanoparticles Embedded Polyurethane Nano-Fiber/Net Structured Membrane as an Effective Antibacterial Medium. Polymers 2019, 11, 1185. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Sun, H.; Wang, L.; Zhang, J.; Deng, L.; Ma, T. An Optical Fiber Sensor Coated with Electrospinning Polyvinyl Alcohol/Carbon Nanotubes Composite Film. Sensors 2020, 20, 6996. [Google Scholar] [CrossRef]

- Li, G.; Zhu, H.; Ma, Y.; Wang, Y.; Ji, H.; Xie, L. Preparation and performance study of thermal conductive microporous breathable thin films. China Plast. 2022, 36, 14–20. [Google Scholar]

- Kim, J.; Kim, S.S.; Park, M.; Jang, M. Effects of precursor properties on the preparation of polyethylene hollow fiber membranes by stretching. J. Membr. Sci. 2008, 318, 201–209. [Google Scholar] [CrossRef]

- Yu, T.; Mengjie, H.; Yalong, W.; Yanjun, Z.; Rui, Y.; Hu, L.; Chuntai, L.; Changyu, S. Ultra-stretchable, sensitive and breathable electronic skin based on TPU electrospinning fibrous membrane with microcrack structure for human motion monitoring and self-powered application. Chem. Eng. J. 2023, 480, 147899. [Google Scholar]

- Zhao, H.; Wang, Z.; Li, Y.; Yang, M. Single-sided and integrated polyaniline/ poly(vinylidene fluoride) flexible membrane with micro/nanostructures as breathable, nontoxic and fast response wearable humidity sensor. J. Colloid Interface Sci. 2022, 607, 367–377. [Google Scholar] [CrossRef] [PubMed]

- Hoon Hong, S.; Yeon Kim, T.; Cheong, S.; Bae, H.; Hyun Yu, K.; Kwang Hahn, S. Multifunctional breathable electronic devices for smart wearable healthcare applications. Chem. Eng. J. 2023, 476, 146559. [Google Scholar] [CrossRef]

- Luo, J.; Gao, S.; Luo, H.; Wang, L.; Huang, X.; Guo, Z.; Lai, X.; Lin, L.; Li, R.K.Y.; Gao, J. Superhydrophobic and breathable smart MXene-based textile for multifunctional wearable sensing electronics. Chem. Eng. J. 2021, 406, 126898. [Google Scholar] [CrossRef]

- Lou, M.; Abdalla, I.; Zhu, M.; Wei, X.; Yu, J.; Li, Z.; Ding, B. Highly Wearable, Breathable, and Washable Sensing Textile for Human Motion and Pulse Monitoring. ACS Appl. Mater. Interfaces 2020, 12, 19965–19973. [Google Scholar] [CrossRef] [PubMed]

- Ramasamy, S.; Balan, A. Wearable sensors for ECG measurement: A review. Sens. Rev. 2018, 38, 412–419. [Google Scholar] [CrossRef]

- Yao, Y.; Guo, Y.; Li, X.; Yu, J.; Ding, B. Asymmetric Wettable, Waterproof, and Breathable Nanofibrous Membranes for Wound Dressings. ACS Appl. Bio Mater. 2021, 4, 3287–3293. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Q.; Zhang, T.; Hao, M.; Hu, X.; Chen, Z.; Yang, B. Fabrication of breathable superhydrophobic composite fabric with moisture permeability and weak-electric-field bactericidal ability designed for protective clothing applications. Mater. Des. 2024, 237, 112612. [Google Scholar] [CrossRef]

- Sheng, J.; Zhang, M.; Xu, Y.; Yu, J.; Ding, B. Tailoring Water-Resistant and Breathable Performance of Polyacrylonitrile Nanofibrous Membranes Modified by Polydimethylsiloxane. ACS Appl. Mater. Interfaces 2016, 8, 27218–27226. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Wang, C.; Miao, D.; Cheng, N.; Meng, N.; Babar, A.A.; Wang, X.; Ding, B.; Yu, J. A Trilayered Composite Fabric with Directional Water Transport and Resistance to Blood Penetration for Medical Protective Clothing. ACS Appl. Mater. Interfaces 2022, 14, 18944–18953. [Google Scholar] [CrossRef]

- Cai, L.; Xu, L.; Si, Y.; Yu, J.; Ding, B. Autoclavable, Breathable, and Waterproof Membranes Tailored by Ternary Nanofibers for Reusable Medical Protective Applications. ACS Appl. Polym. Mater. 2022, 4, 556–564. [Google Scholar] [CrossRef]

- Wang, B.; Wang, J.; Lou, Y.; Ding, S.; Jin, X.; Liu, F.; Xu, Z.; Ma, J.; Sun, Z.; Li, X. Halloysite nanotubes strengthened electrospinning composite nanofiber membrane for on-skin flexible pressure sensor with high sensitivity, good breathability, and round-the-clock antibacterial activity. Appl. Clay Sci. 2022, 228, 106650. [Google Scholar] [CrossRef]

- Zhen, N.; Wang, X.; Li, X.; Xue, J.; Zhao, Y.; Wu, M.; Zhou, D.; Liu, J.; Guo, J.; Zhang, H. Protein-based natural antibacterial materials and their applications in food preservation. Microb. BioTechnol. 2021, 15, 1324–1338. [Google Scholar] [CrossRef]

- Marković, D.; Zille, A.; Ribeiro, A.I.; Mikučioniene, D.; Simončič, B.; Tomšič, B.; Radetić, M. Antibacterial Bio-Nanocomposite Textile Material Produced from Natural Resources. Nanomaterials 2022, 12, 2539. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Li, J.; Gao, Y.; Tan, H.; Wang, K.; Li, J.; Fu, Q. Synthesis and antibacterial characterization of waterborne polyurethanes with gemini quaternary ammonium salt. Sci. Bull. 2015, 60, 1114–1121. [Google Scholar] [CrossRef]

- Li, T.-T.; Li, J.; Zhang, Y.; Huo, J.-L.; Liu, S.; Shiu, B.-C.; Lin, J.-H.; Lou, C.-W. A study on artemisia argyi oil/sodium alginate/PVA nanofibrous membranes: Micro-structure, breathability, moisture permeability, and antibacterial efficacy. J. Mater. Res. Technol. 2020, 9, 13450–13458. [Google Scholar] [CrossRef]

- Saran, S.; Gurjar, M.; Baronia, A.K.; Lohiya, A.; Azim, A.; Poddar, B.; Rao, N.S. Personal protective equipment during COVID-19 pandemic: A narrative review on technical aspects. Expert. Rev. Med. Devices 2020, 17, 1265–1276. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Joshi, R.; Yasir, M.; Adhikari, A.; Chughtai, A.A.; Heslop, D.; Bull, R.; Willcox, M.; Macintyre, C.R. Graphene- and Nanoparticle-Embedded Antimicrobial and Biocompatible Cotton/Silk Fabrics for Protective Clothing. ACS Appl. Bio Mater. 2021, 4, 6175–6185. [Google Scholar] [CrossRef]

- Na, M.; Yufei, Z.; Yanyan, L.; Cengceng, Z.; Zhaoling, L.; Xianfeng, W.; Jianyong, Y.; Bin, D. Integrated High Barrier and Efficient Moisture-Wicking Multilayer Textile for Medical and Health Protection. Adv. Funct. Mater. 2023, 33, 2305411. [Google Scholar]

- Hale, W.R.; Dohrer, K.K.; Tant, M.R.; Sand, I.D. A diffusion model for water vapor transmission through microporous polyethylene/CaCO3 films. Colloids Surf A 2001, 187, 483–491. [Google Scholar] [CrossRef]

- Hassan, M.A.; Yeom, B.Y.; Wilkie, A.; Pourdeyhimi, B.; Khan, S.A. Fabrication of nanofiber meltblown membranes and their filtration properties. J. Membr. Sci. 2013, 427, 336–344. [Google Scholar] [CrossRef]

- Chen, J.-P.; Chen, S.-C.; Wu, X.-Q.; Ke, X.-X.; Wu, R.-X.; Zheng, Y.-M. Multilevel structured TPU/PS/PA-6 composite membrane for high-efficiency airborne particles capture: Preparation, performance evaluation and mechanism insights. J. Membr. Sci. 2021, 633, 119392. [Google Scholar] [CrossRef]

- Jingjing, W.; Xiaohui, Z.; Fang, W.; Yu, S.; Wen-Bin, Z.; Hui, W. One-step preparation of highly viscoelastic, stretchable, antibacterial, biocompatible, wearable, conductive composite hydrogel with extensive adhesion. Compos. Sci. Technol. 2022, 231, 109793. [Google Scholar]

- Miao, Y.; Tang, Z.; Zhang, Q.; Reheman, A.; Xiao, H.; Zhang, M.; Liu, K.; Huang, L.; Chen, L.; Wu, H. Biocompatible Lignin-Containing Hydrogels with Self-Adhesion, Conductivity, UV Shielding, and Antioxidant Activity as Wearable Sensors. ACS Appl. Polym. Mater. 2022, 4, 1448–1456. [Google Scholar] [CrossRef]

- Tang, Z.; Bian, S.; Wei, J.; Xiao, H.; Zhang, M.; Liu, K.; Huang, L.; Chen, L.; Ni, Y.; Wu, H. Plant-inspired conductive adhesive organohydrogel with extreme environmental tolerance as a wearable dressing for multifunctional sensors. Colloids Surf. B 2022, 215, 112509. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Zhou, X.; Liu, Y.; Fu, Q. Highly Sensitive, Ultrastretchable Strain Sensors Prepared by Pumping Hybrid Fillers of Carbon Nanotubes/Cellulose Nanocrystal into Electrospun Polyurethane Membranes. ACS Appl. Mater. Interfaces 2019, 11, 12968–12977. [Google Scholar] [CrossRef]

- Zhou, X.; Zhu, L.; Fan, L.; Deng, H.; Fu, Q. Fabrication of Highly Stretchable, Washable, Wearable, Water-Repellent Strain Sensors with Multi-Stimuli Sensing Ability. ACS Appl. Mater. Interfaces 2018, 10, 31655–31663. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, S.; Yan, B.; Gu, Y.; Luo, Y.; Yang, F.; Cao, Y. Solution-Processable and Patternable Poly(o-methoxyaniline)-Based Nanocomposite Film for Large-Area Electrochromic Display with Large Optical Modulation and Ultrafast Response Speed. J. Phys. Chem. C 2020, 124, 10898–10906. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, Z.; Wu, C.; Cong, Y.; Zhang, R.; Fu, J. Highly Sensitive Pressure and Strain Sensors Based on Stretchable and Recoverable Ion-Conductive Physically Cross-Linked Double-Network Hydrogels. ACS Appl. Mater. Interfaces 2020, 12, 51969–51977. [Google Scholar] [CrossRef]

- Qian, C.; Li, L.; Gao, M.; Yang, H.; Cai, Z.; Chen, B.; Xiang, Z.; Zhang, Z.; Song, Y. All-printed 3D hierarchically structured cellulose aerogel based triboelectric nanogenerator for multi-functional sensors. Nano Energy 2019, 63, 103885. [Google Scholar] [CrossRef]

- Ye, Q.; Wu, Y.; Qi, Y.; Shi, L.; Huang, S.; Zhang, L.; Li, M.; Li, W.; Zeng, X.; Wo, H.; et al. Effects of liquid metal particles on performance of triboelectric nanogenerator with electrospun polyacrylonitrile fiber films. Nano Energy 2019, 61, 381–388. [Google Scholar] [CrossRef]

- Cao, R.; Wang, J.; Zhao, S.; Yang, W.; Yuan, Z.; Yin, Y.; Du, X.; Li, N.-W.; Zhang, X.; Li, X.; et al. Self-powered nanofiber-based screen-print triboelectric sensors for respiratory monitoring. Nano Res. 2018, 11, 3771–3779. [Google Scholar] [CrossRef]

- Yin, Y.; Wang, J.; Zhao, S.; Fan, W.; Zhang, X.; Zhang, C.; Xing, Y.; Li, C. Stretchable and Tailorable Triboelectric Nanogenerator Constructed by Nanofibrous Membrane for Energy Harvesting and Self-Powered Biomechanical Monitoring. Adv. Mater. Technol. 2018, 3, 1700370. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Liu, L.; Yu, J.; Ding, B. Human Skin-Like, Robust Waterproof, and Highly Breathable Fibrous Membranes with Short Perfluorobutyl Chains for Eco-Friendly Protective Textiles. ACS Appl. Mater. Interfaces 2018, 10, 30887–30894. [Google Scholar] [CrossRef]

- Lomax, G.R. Breathable polyurethane membranes for textile and related industries. J. Mater. Chem. 2007, 17, 2775–2784. [Google Scholar] [CrossRef]

- Gugliuzza, A.; Drioli, E. A review on membrane engineering for innovation in wearable fabrics and protective textiles. J. Membr. Sci. 2013, 446, 350–375. [Google Scholar] [CrossRef]

- Hsu, P.-C.; Song, A.Y.; Catrysse, P.B.; Liu, C.; Peng, Y.; Xie, J.; Fan, S.; Cui, Y. Radiative human body cooling by nanoporous polyethylene textile. Science 2016, 353, 1019–1023. [Google Scholar] [CrossRef]

- Wangprasertkul, J.; Siriwattanapong, R.; Harnkarnsujarit, N. Antifungal packaging of sorbate and benzoate incorporated biodegradable films for fresh noodles. Food Control 2021, 123, 107763. [Google Scholar] [CrossRef]

- Emamifar, A.; Kadivar, M.; Shahedi, M.; Soleimanian-Zad, S. Evaluation of nanocomposite packaging containing Ag and ZnO on shelf life of fresh orange juice. Innov. Food Sci. Emerg. Technol. 2010, 11, 742–748. [Google Scholar] [CrossRef]

- Bumbudsanpharoke, N.; Wongphan, P.; Promhuad, K.; Leelaphiwat, P.; Harnkarnsujarit, N. Morphology and permeability of bio-based poly(butylene adipate-co-terephthalate) (PBAT), poly(butylene succinate) (PBS) and linear low-density polyethylene (LLDPE) blend films control shelf-life of packaged bread. Food Control 2022, 132, 108541. [Google Scholar] [CrossRef]

- Alisiyonak, O.; Lavitskaya, A.; Khoroshko, L.; Kozlovskiy, A.L.; Zdorovets, M.; Korolkov, I.; Yauseichuk, M.; Kaniukov, E.; Shumskaya, A. Breathable Films with Self-Cleaning and Antibacterial Surfaces Based on TiO2-Functionalized PET Membranes. Membranes 2023, 13, 733. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Kim, D.; Song, S.O.; Song, Y.H.; Jang, A. Evaluation of the Microbiological Status of Raw Beef in Korea: Considering the Suitability of Aerobic Plate Count Guidelines. Korean J. Food Sci. Anim. Resour. 2018, 38, 43–51. [Google Scholar] [PubMed]

- Wilson, M.D.; Stanley, R.A.; Eyles, A.; Ross, T. Innovative processes and technologies for modified atmosphere packaging of fresh and fresh-cut fruits and vegetables. Crit. Rev. Food Sci. Nutr 2017, 59, 411–422. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Zhao, X.; Ma, Y.; Guan, H.; Liang, H.; Wang, D. Inhibitory effect of modified atmosphere packaging on Escherichia coli O157:H7 in fresh-cut cucumbers (Cucumis sativus L.) and effectively maintain quality during storage. Food Chem. 2022, 369, 130969. [Google Scholar] [CrossRef]

- Yun, X.; Lu, H.; Zhou, Z.; Yuan, S.; Wang, Y.; Dong, T. Fabrication and design of poly(l-lactic acid) membrane for passive MAP packaging of Brassica chinensis L. J. Food Sci. 2023, 88, 1640–1653. [Google Scholar] [CrossRef] [PubMed]

- Préfol, T.; Gain, O.; Sudre, G.; Gouanvé, F.; Espuche, E. Development of Breathable Pebax®/PEG Films for Optimization of the Shelf-Life of Fresh Agri-Food Products. Membranes 2021, 11, 692. [Google Scholar] [CrossRef]

- Elmehalmey, W.A.; Azzam, R.A.; Hassan, Y.S.; Alkordi, M.H.; Madkour, T.M. Imide-Based Polymers of Intrinsic Microporosity: Probing the Microstructure in Relation to CO2 Sorption Characteristics. ACS Omega 2018, 3, 2757–2764. [Google Scholar] [CrossRef]

- Simona, J.; Dani, D.; Petr, S.; Marcela, N.; Jakub, T.; Bohuslava, T. Edible Films from Carrageenan/Orange Essential Oil/Trehalose—Structure, Optical Properties, and Antimicrobial Activity. Polymers 2021, 13, 332. [Google Scholar] [CrossRef]

- Jang-Soo, L.; Sun Tai, K.; Ruiguo, C.; Nam-Soon, C.; Meilin, L.; Kyu Tae, L.; Jaephil, C. Metal–Air Batteries with High Energy Density: Li–Air versus Zn–Air. Adv. Energy Mater. 2010, 1, 34–50. [Google Scholar]

- Liu, T.; Vivek, J.P.; Zhao, E.W.; Lei, J.; Garcia-Araez, N.; Grey, C.P. Current Challenges and Routes Forward for Nonaqueous Lithium-Air Batteries. Chem. Rev. 2020, 120, 6558–6625. [Google Scholar] [CrossRef]

- Terutsuki, D.; Okuyama, K.; Zhang, H.; Abe, H.; Nishizawa, M. Water-proof anti-drying enzymatic O2 cathode for bioelectric skin patch. J. Power Sources 2022, 546, 231945. [Google Scholar] [CrossRef]

- Song, H.; Xu, S.; Li, Y.; Dai, J.; Gong, A.; Zhu, M.; Zhu, C.; Chen, C.; Chen, Y.; Yao, Y.; et al. Hierarchically Porous, Ultrathick, “Breathable” Wood-Derived Cathode for Lithium-Oxygen Batteries. Adv. Energy Mater. 2018, 8, 1701203. [Google Scholar] [CrossRef]

- Yang, T.; Zhou, K.; Ding, T. Air pollution impacts on public health: Evidence from 110 cities in Yangtze River Economic Belt of China. Sci. Total Environ. 2022, 851, 158125. [Google Scholar] [CrossRef]

- Brauer, M.; Casadei, B.; Harrington, R.A.; Kovacs, R.; Sliwa, K.; Brauer, M.; Davaakhuu, N.; Hadley, M.; Kass, D.; Miller, M.; et al. Taking a Stand Against Air Pollution—The Impact on Cardiovascular Disease: A Joint Opinion from the World Heart Federation, American College of Cardiology, American Heart Association, and the European Society of Cardiology. J. Am. Coll. Cardiol. 2021, 77, 1684–1688. [Google Scholar] [CrossRef]

- Chung, C.Y.; Yang, J.; Yang, X.; He, J. Long-term effects of ambient air pollution on lung cancer and COPD mortalities in China: A systematic review and meta-analysis of cohort studies. Environ. Impact Assess. Rev. 2022, 97, 106865. [Google Scholar] [CrossRef]

- Tian, G.; Huang, Z.; Wang, H.; Cui, C.; Zhang, Y. Polycaprolactone nanofiber membrane modified with halloysite and ZnO for anti-bacterial and air filtration. Appl. Clay Sci. 2022, 223, 106512. [Google Scholar] [CrossRef]

- Deng, Y.; Lu, T.; Cui, J.; Keshari Samal, S.; Xiong, R.; Huang, C. Bio-based electrospun nanofiber as building blocks for a novel eco-friendly air filtration membrane: A review. Sep. Purif. Technol. 2021, 277, 119623. [Google Scholar] [CrossRef]

- Liang, C.; Li, J.; Chen, Y.; Ke, L.; Zhu, J.; Zheng, L.; Li, X.-P.; Zhang, S.; Li, H.; Zhong, G.-J.; et al. Self-Charging, Breathable, and Antibacterial Poly(lactic acid) Nanofibrous Air Filters by Surface Engineering of Ultrasmall Electroactive Nanohybrids. ACS Appl. Mater. Interfaces 2023, 15, 57636–57648. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Liu, Z.; Zhong, L.; Song, C.; Shi, W.; Cui, F.; Wang, W. Breathable and asymmetrically superwettable Janus membrane with robust oil-fouling resistance for durable membrane distillation. J. Membr. Sci. 2018, 563, 602–609. [Google Scholar] [CrossRef]

- Gu, H.; Li, G.; Li, P.; Liu, H.; Chadyagondo, T.T.; Li, N.; Xiong, J. Superhydrophobic and breathable SiO2/polyurethane porous membrane for durable water repellent application and oil-water separation. Appl. Surf. Sci. 2020, 512, 144837. [Google Scholar] [CrossRef]

- Yang, W.; Pan, M.; Zhang, J.; Zhang, L.; Lin, F.; Liu, X.; Huang, C.; Chen, X.Z.; Wang, J.; Yan, B.; et al. A Universal Strategy for Constructing Robust and Antifouling Cellulose Nanocrystal Coating. Adv. Funct. Mater. 2021, 32, 2109989. [Google Scholar] [CrossRef]

- Liu, H.; Cao, C.; Huang, J.; Chen, Z.; Chen, G.; Lai, Y. Progress on particulate matter filtration technology: Basic concepts, advanced materials, and performances. Nanoscale 2020, 12, 437–453. [Google Scholar] [CrossRef]

| Preparation Methods | Polymer State | Pore Formation Mechanism | Impact on the Environment | References |

|---|---|---|---|---|

| Blown film extrusion | Polymer melt | Stretching caused separation between the filled particles and the matrix | Almost no impact | [36] |

| Phase separation | Polymer solution | Nonsolvent-induced phase separation | Organic solvents may pollute the environment | [50] |

| Phase separation | Polymer solution | Thermally induced phase separation | Organic solvents may pollute the environment | [53] |

| Cast film extrusion | Polymer melt | Stretching caused separation between the filled particles and the matrix | Almost no impact | [72] |

| Cast film extrusion | Polymer melt | Stretching caused separation between the crystals and the amorphous polymer | Almost no impact | [42,73] |

| Electrospinning | Polymer solution | Accumulation of fibers | Organic solvents may pollute the environment | [63] |

| Materials | Properties | Applications | References |

|---|---|---|---|

| Ethanol-soluble polyurethane/fluorinated polyurethane/thymol | Antibacterial | Medical | [8] |

| Acid/polyurethane/sodium periodate/dopamine/ethyl orthosilicate | Antibacterial and protective | Medical | [81] |

| Artemisia argyi oil/sodium alginate/polyvinyl alcohol | Antibacterial | Medical | [89] |

| Halloysite nanotubes/silver nanowires/polyurethane | Antibacterial | Medical | [85] |

| PA66/multiwalled carbon nanotubes/polyvinylidene fluoride | Conductivity | Electronics | [9] |

| Carboxylated multi-walled carbon nanotubes/poly(3,4-ethylenedioxythiophene)/poly(styrenesulfonate)/thermoplastic polyurethane | Sensitivity | Electronics | [74] |

| Polyaniline/poly (vinylidene fluoride)/cetyltrimethylammonium bromide | Sensitivity | Electronics | [75] |

| Waterborne polyurethane/polycarbodiimide/long chain alkyl polymer | Hydrophobicity | Textile | [11] |

| Thermoplastic polyurethane/silica | Heat retention | Textile | [12] |

| Silver nanoparticles/Wastepaper cellulose | Antibacterial and thermal insulation | Textile | [13] |

| Poly (butylene adipate-co-terephthalate)/thermoplastic starch/ZnO nanoparticles | Antibacterial and barrier | Packaging | [14] |

| PIM-1/polylactic acid | Antibacterial | Packaging | [15] |

| Poly (lactic acid)/ polycaprolactone/sodium chloride/poly (ethylene oxide) | Antibacterial | Packaging | [16] |

| Low density polyethylene/silver/ZnO | Barrier | Packaging | [112] |

| Polybutylene adipate/polybutylene succinate/linear low-density polyethylene | Antibacterial and barrier | Packaging | [113] |

| Hydrophobic SiO2 /silicalite-1/polydimethylsiloxane | Waterproof and selective | Energy | [18] |

| Poly (vinylidene fluoride-co-hexafluoropropylene)/dextrin-nanosponge | Waterproof and selective | Energy | [19] |

| Sodium sulphobutylether-β-cyclodextrin/polyvinyl alcohol | Filterability and adsorption | Environment | [21] |

| Polyacrylonitrile/nano-spiderweb composite nanofibre | Filterability | Environment | [22] |

| Halloysite nanotubes /ZnO nanoparticles/polycaprolactone | Filterability | Environment | [129] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, T.; Farooq, A.; Weng, W.; Lu, S.; Luo, G.; Zhang, H.; Li, J.; Zhou, X.; Wu, X.; Huang, L.; et al. Progress in the Preparation and Application of Breathable Membranes. Polymers 2024, 16, 1686. https://doi.org/10.3390/polym16121686

Luo T, Farooq A, Weng W, Lu S, Luo G, Zhang H, Li J, Zhou X, Wu X, Huang L, et al. Progress in the Preparation and Application of Breathable Membranes. Polymers. 2024; 16(12):1686. https://doi.org/10.3390/polym16121686

Chicago/Turabian StyleLuo, Tingshuai, Ambar Farooq, Wenwei Weng, Shengchang Lu, Gai Luo, Hui Zhang, Jianguo Li, Xiaxing Zhou, Xiaobiao Wu, Liulian Huang, and et al. 2024. "Progress in the Preparation and Application of Breathable Membranes" Polymers 16, no. 12: 1686. https://doi.org/10.3390/polym16121686

APA StyleLuo, T., Farooq, A., Weng, W., Lu, S., Luo, G., Zhang, H., Li, J., Zhou, X., Wu, X., Huang, L., Chen, L., & Wu, H. (2024). Progress in the Preparation and Application of Breathable Membranes. Polymers, 16(12), 1686. https://doi.org/10.3390/polym16121686