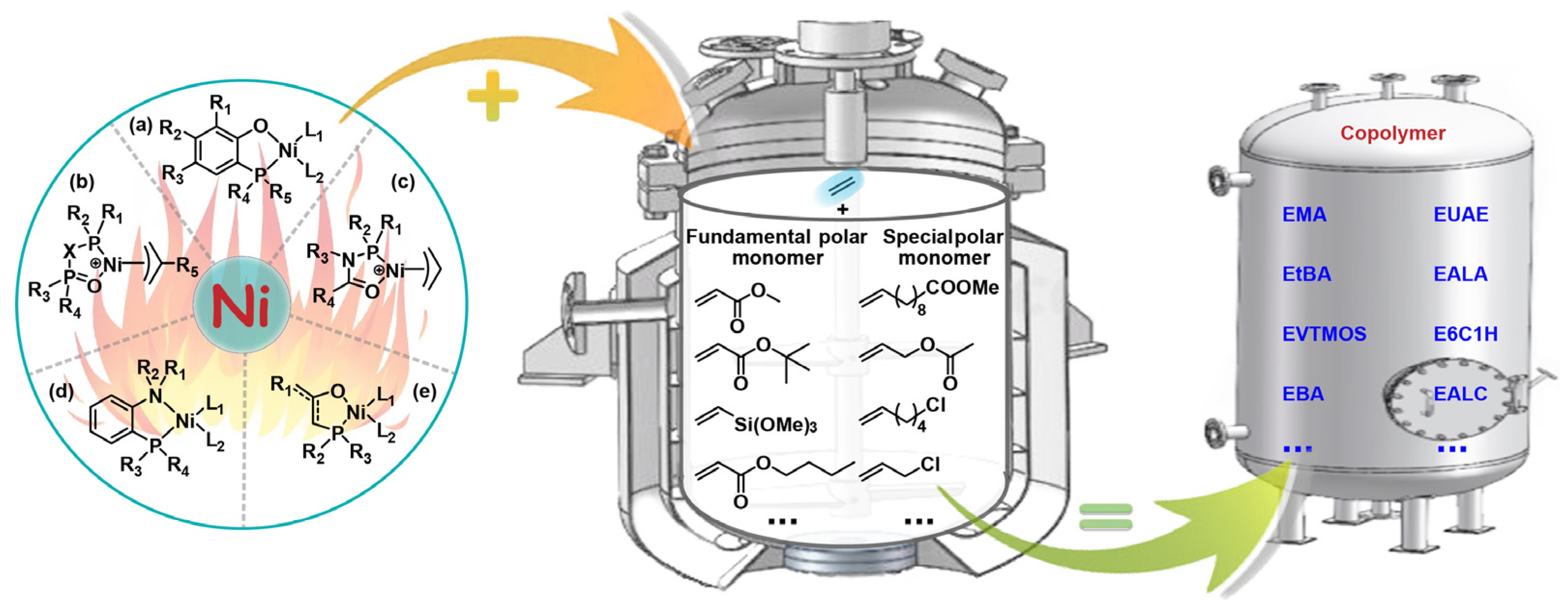

Recent Advances in Nickel Catalysts with Industrial Exploitability for Copolymerization of Ethylene with Polar Monomers

Abstract

1. Introduction

2. Nickel Catalysts for Synthesizing EMA Copolymers

| Entry | Cat. | Tp (°C) | P (atm) | t (min) | Act. (kg mol−1 h−1) | Mn (kg mol−1) | Ɖ | X (mol%) | Tm (°C) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1a | 80 | 8 | 360 | 0.8 | 0.5 | 1.2 | 3.3 | 78.9 | [53] |

| 2 | 1b | 80 | 8 | 360 | 8.3 | 6 | 2.3 | 1.8 | 116.3 | [53] |

| 3 | 1c | 80 | 8 | 360 | 6.7 | 1 | 2.0 | 1.2 | 109.5 | [53] |

| 4 | 2a | 80 | 7.9 | 120 | 7.5 | 24.4 | 2.0 | 1.6 | 124 | [54] |

| 5 | 2b | 80 | 7.9 | 120 | 40 | 17.9 | 2.1 | 1.1 | 126 | [54] |

| 6 | 3 | 80 | 8 | 360 | 0.3 | - a | - a | 4.4 | 95.5 | [55] |

| 7 | 4 | 80 | 27.2 | 120 | 1.8–28.3 | 2.2–5.2 | 1.4–1.8 | 0.66–1.8 | - a | [58] |

| 8 | 4 + Li+ | 80 | 27.2 | 120 | 7.3–81 | 2.5–6.2 | 1.5–1.9 | 0.52–4.5 | - a | [58] |

| 9 | 4 + Na+ | 80 | 27.2 | 120 | 7.1 | 2.9 | 1.1 | 8.1 | - a | [58] |

| 10 | 5 | 80 | 19.7 | 2820 | 0.51 | 1.8 | 2.4 | 0.56 | 124.3 | [60] |

| 11 | 6a | 80 | 8 | 360 | 1.2 | 4.3 | 2.8 | 3.0 | 112.1 | [62] |

| 12 | 6b | 80 | 8 | 360 | 1.4 | 3.9 | 2.7 | 3.7 | 111.7 | [62] |

| 13 | 6c | 80 | 8 | 360 | 2.6 | 4.8 | 2.2 | 2.8 | 110.1 | [62] |

| 14 | 6d | 80 | 8 | 360 | 10.1 | 6.6 | 2.2 | 2.2 | 117.8 | [62] |

| 15 | 6e | 80 | 8 | 360 | 2.9 | 6.2 | 2.4 | 3.1 | 113.9 | [62] |

| 16 | 6f | 80 | 8 | 360 | 5.8 | 9.9 | 2.2 | 2.1 | 123.0 | [62] |

| 17 | 7a | 80 | 7.9–29.6 | 180 | 2–17.5 | 4.2–8.5 | 2.1–2.2 | 2.2–7.0 | 112.8–123.0 | [64] |

| 18 | 7b | 80 | 7.9–29.6 | 180 | 1.2–14.5 | 3.4–7.3 | 2.3–2.8 | 1.8–6.3 | 112.6–122.5 | [64] |

| 19 | 8 | 80 | 7.9 | 180 | 7.7 | 10.1 | 2.8 | 2.5 | 123.9 | [64] |

| 20 | 9 | 80 | 7.9 | 180 | 13.8 | 6.0 | 2.3 | 2.7 | 120.9 | [64] |

| 21 | 10a | 80 | 8 | 30 | 36 | 29 | 1.9 | 1.1 | 123.9 | [70] |

| 22 | 10a-Na | 80 | 8 | 30 | 48 | 36 | 1.8 | 1.5 | 128.6 | [70] |

| 23 | 10a-Na-MgO | 80–140 | 8 | 30 | 96–260 | 56–101 | 2.6 | 0.8–2.5 | 120.9–125.6 | [70] |

| 24 | 10b-Na-MgO | 80 | 8–30 | 30 | 124–456 | 46–147 | 1.8–2.9 | 0.5–2.9 | 123.3–130.8 | [70] |

| 25 | 11 | 80 | 8 | 30 | 80 | 10.6–16.1 | 2.1–2.2 | 2.3–2.4 | 118.8–119.4 | [74] |

| 26 | 12 | 80 | 19.7 | 30 | 22.7 | 19.8 | 1.8 | 15.5 | - a | [75] |

3. Nickel Catalysts for Synthesizing EtBA Copolymers

| Entry | Cat. | Tp (°C) | P (atm) | t (min) | Act. (kg mol−1 h−1) | Mn (kg mol−1) | Ɖ | X (mol%) | Tm (°C) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 13 | 90–100 | 27.2 | 60–75 | 82–661 | 8.7–27 | 2.2–2.4 | 2.15–11.95 | 68.4–110.9 | [76] |

| 2 | 14 | 90–100 | 27.2 | 60 | 205–637 | 3.9–7.2 | 2–2.3 | 0.7–2.0 | 110.6–121.1 | [76] |

| 3 | 13 + Al(OiPr)3 | 90 | 27.2 | 25–58 | 510–1000 | 16.6–22.4 | 2.3–2.4 | 2.2–4.6 | 99–111 | [76] |

| 4 | 11 | 80–150 | 8 | 30 | 40–160 | 6.1–32.8 | 1.7–3.0 | 1.0–3.9 | 115.9–125.8 | [74] |

| 5 | 15a | 90 | 27.2 | 30–60 | 190–490 | 1.2–1.8 | 1.9–2.1 | 1.6–2.8 | 77–113 | [78] |

| 6 | 15b | 90 | 27.2 | 26 | 770 | 1.9 | 3.2 | 1.4 | 114 | [78] |

| 7 | 15c | 90–110 | 27.2 | 6–56.6 | 1160–7700 | 2.7–4.4 | 2.4–2.8 | 0.3–1.4 | 118–125 | [78] |

| 8 | 15d | 90 | 27.2 | 25 | 1090 | 3.3 | 2.1 | 0.7 | 116 | [78] |

| 9 | 15e | 90 | 27.2 | 13–15 | 1340 | 4.6 | 2.2 | 0.5 | 122 | [78] |

| 10 | 15f | 90 | 27.2 | 16–20 | 1850 | 6.6 | 2.3 | 0.6 | 123 | [78] |

| 11 | 15g | 90 | 27.2 | 31–57 | 450–590 | 4.5–6.3 | 2.4–2.5 | 0.6–0.7 | 122–123 | [78] |

| 12 | 16a | 90–110 | 27.2 | 17–60 | 440–1550 | 7.4–30.5 | 2.2–2.4 | 1.5–4.8 | 99–115 | [83] |

| 13 | 16b | 90–130 | 27.2 | 2–31 | 5700–37,000 | 6–16.7 | 2.2–2.6 | 0.3–1.0 | 120–127 | [83] |

| 14 | 17a | 90 | 27.2 | 24–60 | 440–1100 | 25–34 | 2.2–2.3 | 1.6–3.2 | 105–115 | [84] |

| 15 | 17b | 90 | 27.2 | 60 | 120–210 | 15.9–27.4 | 2.3–2.6 | 1.7–3.5 | 104–114 | [84] |

| 16 | 18a | 90–110 | 27.2–29.3 | 2–10 | 2900–24,000 | 2.7–4.8 | 2.2–2.6 | 0.3–1.6 | 112–124 | [84] |

| 17 | 18b | 90 | 27.2 | 5 | 5600 | 5.7 | 2.1 | 0.5 | 122 | [84] |

| 18 | 19 | 90–110 | 27.2 | 60 | 93–240 | 14.3–29.3 | 2.8–3.7 | 1.9–6.1 | 96–115 | [87] |

| 19 | 19 + NaBArF | 90–110 | 27.2 | 26–60 | 410–920 | 5.9–14.1 | 2.4–3.8 | 0.7–1.1 | 109–121 | [87] |

| 20 | 10a-Na-MgO | 80–140 | 8–30 | 30 | 100–1660 | 32–834 | 1.8–3.0 | 1–7.4 | 120.9–133.4 | [70] |

| 21 | 10b-Na-MgO | 80 | 30 | 30 | 1260–4100 | 117–343 | 2.4–4.0 | 0.3–1.2 | 128.2–132.4 | [70] |

| 22 | 10a/21-MgO | 80 | 8–30 | 30 | 160–350 | 0.9–13.3 | 11.5–28.5 | 0.2–1.4 | 125.0–132.1 | [88] |

| 23 | 20/21-MgO | 80 | 8 | 30 | 400 | 1.58 | 34.4 | 0.7 | 129.9 | [88] |

| 24 | 20-MgO/21-MgO | 80 | 8 | 30 | 600 | 1.64 | 34.2 | 0.6 | 118.7/133.9 | [88] |

4. Nickel Catalysts for Synthesizing Copolymers of Ethylene and Other Fundamental Polar Monomers

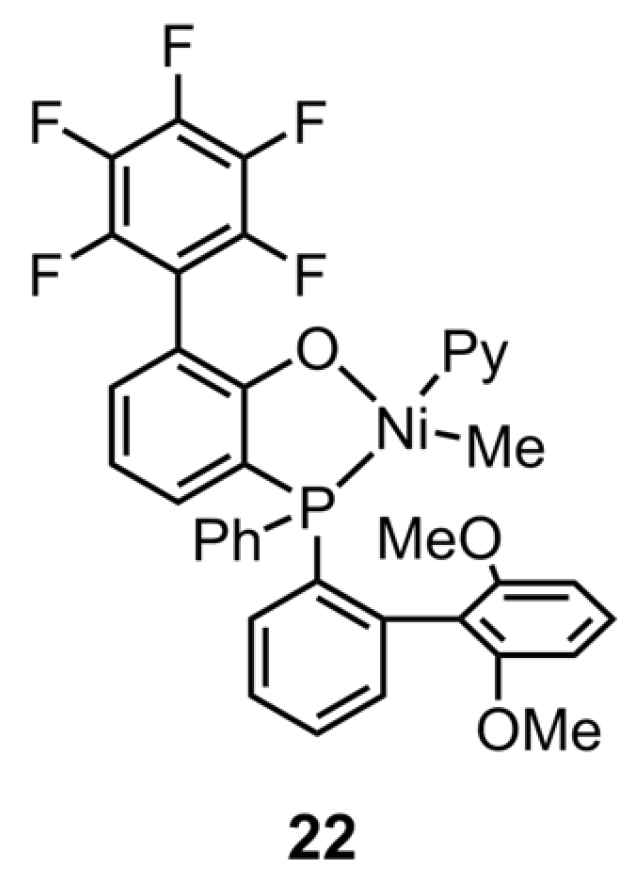

5. Nickel Catalysts for Synthesizing Copolymers of Ethylene and Special Polar Monomers

| Entry | Cat. | Polar Monomer | Tp (°C) | P (atm) | t (min) | Act. (kg mol−1 h−1) | Mn (kg mol−1) | Ɖ | X (mol%) | Tm (°C) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 6d |  | 80 | 8 | 360 | 180 | 5.2 | 2.2 | 2.9 | 112.2 | [62] |

| 2 | 10a-Na-MgO |  | 80–140 | 8 | 30 | 1800–2320 | 47–307 | 2.2–2.9 | 0.6–2.4 | 126.7–130.8 | [70] |

| 3 | 11 |  | 80–150 | 8 | 30 | 680–1440 | 5.5–30.8 | 2.3–2.6 | 0.8–2.0 | 117.5–124.3 | [74] |

| 4 | 20/21-MgO |  | 80–120 | 8–30 | 30 | 660–3920 | 4–8.8 | 3.7–13.3 | 0.5–1.3 | 126.4–132.2 | [88] |

| 5 | 20-MgO/21-MgO |  | 80 | 8 | 30 | 1200 | 2.11 | 34.4 | 0.5 | 125.6/131.1 | [88] |

| 6 | 6d |  | 80 | 8 | 360 | 52 | 8.7 | 1.8 | 1.0 | 123.7 | [62] |

| 7 | 2a |  | 80 | 7.9 | 120 | 1.5 | 13.7 | 1.8 | 1.1 | 125 | [54] |

| 8 | 2b |  | 80 | 7.9 | 120 | 2.0 | 8.7 | 2.6 | 0.7 | 127 | [54] |

| 9 | 5 |  | 80 | 19.7–29.6 | 1440–2820 | 0.02–2.4 | 0.9–35 | 2.6–5.0 | 0.05–0.81 | 118.3–129.1 | [60] |

| 10 | 6b |  | 80 | 8 | 360 | 40 | 5.8 | 2.2 | 1.2 | 109.4 | [62] |

| 11 | 6d |  | 80 | 8 | 360 | 160 | 7.2 | 2.0 | 1.4 | 119.5 | [62] |

| 12 | 10a-Na-MgO |  | 80 | 8 | 30 | 1900 | 268 | 2.1 | 0.7 | 129 | [70] |

| 13 | 2b |  | 80 | 7.9 | 120 | 6.5 | 12.9 | 2.4 | 0.6 | 133 | [54] |

| 14 | 10a-Na-MgO |  | 80 | 8 | 30 | 24 | 38 | 1.8 | 0.3 | 128.2 | [70] |

| 15 | 10a-Na-MgO |  | 80 | 8 | 30 | 2060 | 292 | 2.3 | 0.7 | 129 | [70] |

| 16 | 11 |  | 80–150 | 8 | 30 | 120–520 | 12.8–47.6 | 2.3–2.4 | 0.6–1.2 | 121.1–123.9 | [74] |

| 17 | 10a-Na-MgO |  | 80 | 8 | 30 | 40 | 48 | 2.1 | 0.7 | 128.4 | [70] |

| 18 | 22 | CO/NBE | 100 | 10 | 75 | 53.6–109.6 | 29–43 | 1.7–2.0 | 0.7–1.1 | 97–126 | [101] |

| 19 | 22 | CO | 100 | 10 | 75 | 173 | 65 | 1.6 | 1.3 | 136 | [101] |

6. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Hutley, T.J.; Ouederni, M. Polyolefins-the history and economic impact. In Polyolefin Compounds and Materials: Fundamentals and Industrial Applications; Al-Ali AlMa’adeed, M., Krupa, I., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 13–50. [Google Scholar]

- Chen, C. Designing catalysts for olefin polymerization and copolymerization: Beyond electronic and steric tuning. Nat. Rev. Chem. 2018, 2, 6–14. [Google Scholar] [CrossRef]

- Hustad, P.D. Frontiers in olefin polymerization: Reinventing the world’s most common synthetic polymers. Science 2009, 325, 704–707. [Google Scholar] [CrossRef] [PubMed]

- Sauter, D.W.; Taoufik, M.; Boisson, C. Polyolefins, a success story. Polymers 2017, 9, 185. [Google Scholar] [CrossRef] [PubMed]

- Zou, C.; Chen, C. Polar-functionalized, crosslinkable, self-healing, and photoresponsive polyolefins. Angew. Chem. Int. Ed. 2020, 59, 395–402. [Google Scholar] [CrossRef] [PubMed]

- Baur, M.; Lin, F.; Morgen, T.O.; Odenwald, L.; Mecking, S. Polyethylene materials with in-chain ketones from nonalternating catalytic copolymerization. Science 2021, 374, 604–607. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.; Zou, C.; Chen, C. Material properties of functional polyethylenes from transition-metal-catalyzed ethylene-polar monomer copolymerization. Macromolecules 2022, 55, 1910–1922. [Google Scholar] [CrossRef]

- Tan, C.; Zou, C.; Chen, C. An ionic cluster strategy for performance improvements and product morphology control in metal-catalyzed olefin-polar monomer copolymerization. J. Am. Chem. Soc. 2022, 144, 2245–2254. [Google Scholar] [CrossRef] [PubMed]

- Mu, H.; Zhou, G.; Hu, X.; Jian, Z. Recent advances in nickel mediated copolymerization of olefin with polar monomers. Coord. Chem. Rev. 2021, 435, 213802. [Google Scholar] [CrossRef]

- Tan, C.; Chen, C. Emerging palladium and nickel catalysts for copolymerization of olefins with polar monomers. Angew. Chem. Int. Ed. 2019, 58, 7192–7200. [Google Scholar] [CrossRef]

- Gong, Y.; Li, S.; Gong, Q.; Zhang, S.; Liu, B.; Dai, S. Systematic investigations of ligand steric effects on alpha-diimine nickel catalyzed olefin polymerization and copolymerization. Organometallics 2019, 38, 2919–2926. [Google Scholar] [CrossRef]

- Chen, Z.; Leatherman, M.D.; Daugulis, O.; Brookhart, M. Nickel-catalyzed copolymerization of ethylene and vinyltrialkoxysilanes: Catalytic production of cross-linkable polyethylene and elucidation of the chain-growth mechanism. J. Am. Chem. Soc. 2017, 139, 16013–16022. [Google Scholar] [CrossRef]

- Na, Y.; Chen, C. Catechol-functionalized polyolefins. Angew. Chem. Int. Ed. 2020, 59, 7953–7959. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Cai, W.; Hu, Y.; Chen, C. Improving the flame retardancy of polyethylenes through the palladium-catalyzed incorporation of polar comonomers. Polym. Chem. 2019, 10, 1416–1422. [Google Scholar] [CrossRef]

- Takano, S.; Takeuchi, D.; Osakada, K.; Akamatsu, N.; Shishido, A. Dipalladium catalyst for olefin polymerization: Introduction of acrylate units into the main chain of branched polyethylene. Angew. Chem. Int. Ed. 2014, 53, 9246–9250. [Google Scholar] [CrossRef] [PubMed]

- Ruenzi, T.; Mecking, S. Saturated polar- substituted polyethylene elastomers from insertion polymerization. Adv. Funct. Mater. 2014, 24, 387–395. [Google Scholar] [CrossRef]

- Mazzolini, J.; Boyron, O.; Monteil, V.; Gigmes, D.; Bertin, D.; D’Agosto, F.; Boisson, C. Polyethylene end functionalization using radical-mediated thiol-ene chemistry: Use of polyethylenes containing alkene end functionality. Macromolecules 2011, 44, 3381–3387. [Google Scholar] [CrossRef]

- Boaen, N.K.; Hillmyer, M.A. Post-polymerization functionalization of polyolefins. Chem. Soc. Rev. 2005, 34, 267–275. [Google Scholar] [CrossRef]

- Du, W.; Zheng, H.; Li, Y.; Cheung, C.; Li, D.; Gao, H.; Deng, H.; Gao, H. Neutral tridentate α-sulfonato-β-diimine nickel catalyst for (co)polymerizations of ethylene and acrylates. Macromolecules 2022, 55, 3096–3105. [Google Scholar] [CrossRef]

- Chen, J.; Gao, Y.; Marks, T. Early transition metal catalysis for olefin-polar monomer copolymerization. Angew. Chem. Int. Ed. 2020, 59, 14726–14735. [Google Scholar] [CrossRef]

- Schöbel, A.; Winkenstette, M.; Anselment, T.; Rieger, B. Copolymerization of alkenes and polar monomers by early and late transition metal catalysts. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 779–823. [Google Scholar]

- Nakamura, A.; Ito, S.; Nozaki, K. Coordination-insertion copolymerization of fundamental polar monomers. Chem. Rev. 2009, 109, 5215–5244. [Google Scholar] [CrossRef]

- Imuta, J.; Kashiwa, N.; Toda, Y. Catalytic regioselective introduction of allyl alcohol into the nonpolar polyolefins: Development of one-pot synthesis of hydroxyl-capped polyolefins mediated by a new metallocene IF catalyst. J. Am. Chem. Soc. 2002, 124, 1176–1177. [Google Scholar] [CrossRef] [PubMed]

- Terao, H.; Ishii, S.; Mitani, M.; Tanaka, H.; Fujita, T. Ethylene/polar monomer copolymerization behavior of bis(phenoxy-imine)Ti complexes: Formation of polar monomer copolymers. J. Am. Chem. Soc. 2008, 130, 17636–17637. [Google Scholar] [CrossRef] [PubMed]

- Toda, T.; Nakata, N.; Matsuo, T.; Ishii, A. Synthesis and structures of dialkyl zirconium complexes with an OSSO-type bis(phenolate) ligand bearing a trans-1,2-cyclooctanediylbis(thio) unit. J. Organomet. Chem. 2011, 696, 1258–1261. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, L.; Ren, X.; Guo, F.; Hou, Z. Synthesis of bromine-functionalized polyolefins by scandium-catalyzed copolymerization of 10-bromo-1-decene with ethylene, propylene, and dienes. J. Polym. Sci. 2021, 59, 2324–2333. [Google Scholar] [CrossRef]

- Mu, H.; Pan, L.; Song, D.; Li, Y. Neutral nickel catalysts for olefin homo- and copolymerization: Relationships between catalyst structures and catalytic properties. Chem. Rev. 2015, 115, 12091–12137. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Brookhart, M. Exploring ethylene/polar vinyl monomer copolymerizations using Ni and Pd alpha-diimine catalysts. Accounts. Chem. Res. 2018, 51, 1831–1839. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Waddell, P.M.; Tiedemann, M.A.; Padilla, C.E.; Mei, J.; Chen, L.; Carrow, B.P. Electron-rich metal cations enable synthesis of high molecular weight, linear functional polyethylenes. J. Am. Chem. Soc. 2018, 140, 8841–8850. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Qiu, Z.; Li, D.; Pei, L.; Gao, H. Advance on nickel- and palladium-catalyzed insertion copolymerization of ethylene and acrylate monomers. J. Polym. Sci. 2023, 61, 2987–3021. [Google Scholar] [CrossRef]

- Khan, W.U.; Mazhar, H.; Shehzad, F.; Al-Harthi, M.A. Recent advances in transition metal-based catalysts for ethylene copolymerization with polar comonomer. Chem. Rec. 2023, 23, e202200243. [Google Scholar]

- Rünzi, T.; Fröhlich, D.; Mecking, S. Direct synthesis of ethylene−acrylic acid copolymers by insertion polymerization. J. Am. Chem. Soc. 2010, 132, 17690–17691. [Google Scholar] [CrossRef]

- Daigle, J.-C.; Piche, L.; Claverie, J.P. Preparation of functional polyethylenes by catalytic copolymerization. Macromolecules 2011, 44, 1760–1762. [Google Scholar] [CrossRef]

- Friedberger, T.; Wucher, P.; Mecking, S. Mechanistic insights into polar monomer insertion polymerization from acrylamides. J. Am. Chem. Soc. 2012, 134, 1010–1018. [Google Scholar] [CrossRef] [PubMed]

- Ji, G.; Chen, Z.; Wang, X.; Ning, X.; Xu, C.; Zhang, X.; Tao, W.; Li, J.; Gao, Y.; Shen, Q.; et al. Direct copolymerization of ethylene with protic comonomers enabled by multinuclear Ni catalysts. Nat. Commun. 2021, 12, 6283. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Mu, H.; Jian, Z. Facile access to diverse polyethylenes via neutral salicylaldiminato nickel catalysts. Polym. Chem. 2023, 14, 3196–3202. [Google Scholar] [CrossRef]

- Zheng, H.; Li, Y.; Du, W.; Cheung, C.; Li, D.; Gao, H.; Deng, H.; Gao, H. Unprecedented square-planar α-diimine dibromonickel complexes and their ethylene polymerizations modulated by Ni-phenyl interactions. Macromolecules 2022, 55, 3533–3540. [Google Scholar] [CrossRef]

- Wang, C.; Friedrich, S.; Younkin, T.R.; Li, R.T.; Grubbs, R.H.; Bansleben, D.A.; Day, M.W. Neutral nickel(II)-based catalysts for ethylene polymerization. Organometallics 1998, 17, 3149–3151. [Google Scholar] [CrossRef]

- Younkin, T.R.; Conner, E.F.; Henderson, J.I.; Friedrich, S.K.; Grubbs, R.H.; Bansleben, D.A. Neutral, single-component nickel (II) polyolefin catalysts that tolerate heteroatoms. Science 2000, 287, 460–462. [Google Scholar] [CrossRef] [PubMed]

- Ali, E.M.; Abasaeed, A.E.; Al-Zahrani, S.M. Optimization and control of industrial gas-phase ethylene polymerization reactors. Ind. Eng. Chem. Res. 1998, 37, 3414–3423. [Google Scholar] [CrossRef]

- Zhou, G.; Cui, L.; Mu, H.; Jian, Z. Custom-made polar monomers utilized in nickel and palladium promoted olefin copolymerization. Polym. Chem. 2021, 12, 3878–3892. [Google Scholar] [CrossRef]

- Song, Z.; Wang, S.; Gao, R.; Wang, Y.; Gou, Q.; Zheng, G.; Feng, H.; Fan, G.; Lai, J. Recent advancements in mechanistic studies of palladium- and nickel-catalyzed ethylene copolymerization with polar monomers. Polymers 2023, 15, 4343. [Google Scholar] [CrossRef]

- Nozaki, K.; Kusumoto, S.; Noda, S.; Kochi, T.; Chung, L.W.; Morokuma, K. Why did incorporation of acrylonitrile to a linear polyethylene become possible? Comparison of phosphine-sulfonate ligand with diphosphine and imine-phenolate ligands in the pd-catalyzed ethylene/acrylonitrile copolymerization. J. Am. Chem. Soc. 2010, 132, 16030–16042. [Google Scholar] [CrossRef]

- Rhinehart, J.L.; Brown, L.A.; Long, B.K. A robust Ni(II) alpha-diimine catalyst for high temperature ethylene polymerization. J. Am. Chem. Soc. 2013, 135, 16316–16319. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Gao, R.; Gou, Q.; Lai, J.; Zhang, R.; Li, X.; Guo, Z. Developments in late transition metal catalysts with high thermal stability for ethylene polymerization: A crucial aspect from laboratory to industrialization. Eur. Polym. J. 2022, 181, 111693. [Google Scholar] [CrossRef]

- Mitchell, N.E.; Long, B.K. Recent advances in thermally robust, late transition metal-catalyzed olefin polymerization. Polym. Int. 2019, 68, 14–26. [Google Scholar] [CrossRef]

- Ma, Z.; Yang, W.; Sun, W.-H. Recent progress on transition metal (Fe, Co, Ni, Ti and V) complex catalysts in olefin polymerization with high thermal stability. Chin. J. Chem. 2017, 35, 531–540. [Google Scholar] [CrossRef]

- Tan, C.; Chen, M.; Zou, C.; Chen, C. Potentially practical catalytic systems for olefin-polar monomer coordination copolymerization. CCS Chem. 2024, 6, 882–897. [Google Scholar] [CrossRef]

- Gao, Z.; Wu, Y.; Xu, L.; Hao, H.; Wu, Q.; Xie, H. Preparation and luminescent properties of Eu(III) organic complex and novel transparent ethylene-methyl acrylate copolymer (EMA) films doped with complexes. Opt. Mater. 2018, 85, 193–199. [Google Scholar] [CrossRef]

- Ding, J.; Yue, Z.; Sun, J.; Zhou, J.; Gao, J. Effect of ABS/PMMA/EMA ternary blending sequence on mechanical properties and surface glossiness. J. Polym. Eng. 2016, 36, 625–633. [Google Scholar] [CrossRef]

- Cavodeau, F.; Viretto, A.; Otazaghine, B.; Lopez-Cuesta, J.-M.; Delaite, C. Influence of colemanite on the fire retardancy of ethylene-vinyl acetate and ethylene-methyl acrylate copolymers. Polym. Degrad. Stabil. 2017, 144, 401–410. [Google Scholar] [CrossRef]

- Behzadi, S.; Chi, M.; Pang, W.; Liang, T.; Tan, C. Camphor-based phosphine-carbonyl ligands for Ni catalyzed ethylene oligomerization. New J. Chem. 2020, 44, 1076–1081. [Google Scholar] [CrossRef]

- Cui, L.; Jian, Z. A N-bridged strategy enables hemilabile phosphine-carbonyl palladium and nickel catalysts to mediate ethylene polymerization and copolymerization with polar vinyl monomers. Polym. Chem. 2020, 11, 6187–6193. [Google Scholar] [CrossRef]

- Zhu, N.; Liang, T.; Huang, Y.; Pang, W.; Chen, M.; Tan, C. Influences of ligand backbone substituents on phosphinecarbonylpalladium and -nickel catalysts for ethylene polymerization and copolymerization with polar monomers. Inorg. Chem. 2021, 60, 13080–13090. [Google Scholar] [CrossRef] [PubMed]

- Cui, L.; Chu, Y.-K.; Liu, D.-J.; Han, Y.-F.; Mu, H.-L.; Jian, Z.-B. Enhancement on hemilabile phosphine-amide palladium and nickel catalysts for ethylene (co)polymerization with polar monomers using a cyclizing strategy. Chin. J. Polym. Sci. 2022, 40, 241–247. [Google Scholar] [CrossRef]

- Cai, Z.; Xiao, D.; Do, L.H. Fine-tuning nickel phenoxyimine olefin polymerization catalysts: Performance boosting by alkali cations. J. Am. Chem. Soc. 2015, 137, 15501–15510. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.; Do, L.H. Customizing polyolefin morphology by selective pairing of alkali ions with nickel phenoxyimine-polyethylene glycol catalysts. Organometallics 2017, 36, 4691–4698. [Google Scholar] [CrossRef]

- Tahmouresilerd, B.; Xiao, D.; Do, L.H. Rigidifying cation-tunable nickel catalysts increases activity and polar monomer incorporation in ethylene and methyl acrylate copolymerization. Inorg. Chem. 2021, 60, 19035–19043. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Chen, C. A versatile ligand platform for palladium- and nickel-catalyzed ethylene copolymerization with polar monomers. Angew. Chem. Int. Ed. 2018, 57, 3094–3098. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.; Yasuda, H.; Nozaki, K. Copolymerization of nonpolar olefins and allyl acetate using nickel catalysts bearing a methylene-bridged bisphosphine monoxide ligand. Macromolecules 2020, 53, 2547–2556. [Google Scholar] [CrossRef]

- Hong, C.; Sui, X.; Li, Z.; Pang, W.; Chen, M. Phosphine phosphonic amide nickel catalyzed ethylene polymerization and copolymerization with polar monomers. Dalton Trans. 2018, 47, 8264–8267. [Google Scholar] [CrossRef]

- Zou, C.; Liao, D.; Pang, W.; Chen, M.; Tan, C. Versatile PNPO ligands for palladium and nickel catalyzed ethylene polymerization and copolymerization with polar monomers. J. Catal. 2021, 393, 281–289. [Google Scholar] [CrossRef]

- Brassat, I.; Keim, W.; Killat, S.; Möthrath, M.; Mastrorilli, P.; Nobile, C.F.; Suranna, G.P. Synthesis and catalytic activity of allyl, methallyl and methyl complexes of nickel(II) and palladium(II) with biphosphine monoxide ligands: Oligomerization of ethylene and copolymerization of ethylene and carbon monoxide. J. Mol. Catal. A Chem. 2000, 157, 41–58. [Google Scholar] [CrossRef]

- Xu, M.; Yu, F.; Li, P.; Xu, G.; Zhang, S.; Wang, F. Enhancing chain initiation efficiency in the cationic allyl-nickel catalyzed (co)polymerization of ethylene and methyl acrylate. Inorg. Chem. 2020, 59, 4475–4482. [Google Scholar] [CrossRef]

- Lv, X.; Du, Y.; Du, S.; Xiang, L. Graded preparation and industrial applications of large-ball polyolefin catalyst carriers. Catalysts 2022, 12, 117. [Google Scholar] [CrossRef]

- Atiqullah, M.; Al-Asiri, H.S. Polyolefin catalyst research: A product-driven industrial perspective. Chem. Rec. 2022, 22, e202100321. [Google Scholar] [CrossRef] [PubMed]

- Culver, D.B.; Tafazolian, H.; Conley, M.P. A Bulky Pd (II) α-diimine catalyst supported on sulfated zirconia for the polymerization of ethylene and copolymerization of ethylene and methyl acrylate. Organometallics 2018, 37, 1001–1006. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, Y.; Pan, Y.; Pang, W.; Si, G.; Zou, C. Heterogenization of nickel catalysts with ionic liquid-modified supports for ethylene polymerization and copolymerization. J. Polym. Sci. 2023, 61, 1457–1464. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Cai, Z.; Li, M.; Liu, Z. Influence of silica-supported alkylaluminum on heterogeneous zwitterionic anilinonaphthoquinone nickel and palladium-catalyzed ethylene polymerization and copolymerization with polar monomers. ACS Catal. 2022, 12, 9646–9654. [Google Scholar] [CrossRef]

- Zou, C.; Si, G.; Chen, C. A general strategy for heterogenizing olefin polymerization catalysts and the synthesis of polyolefins and composites. Nat. Commun. 2022, 13, 1954. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.; Do, L.H. Thermally robust heterobimetallic palladium-alkali catalysts for ethylene and alkyl acrylate copolymerization. Organometallics 2018, 37, 3874–3882. [Google Scholar] [CrossRef]

- Xiao, D.; Cai, Z.; Do, L.H. Accelerating ethylene polymerization using secondary metal ions in tetrahydrofuran. Dalton Trans. 2019, 48, 17887–17897. [Google Scholar] [CrossRef]

- Tran, T.V.; Karas, L.J.; Wu, J.I.; Do, L.H. Elucidating secondary metal cation effects on nickel olefin polymerization catalysts. ACS Catal. 2020, 10, 10760–10772. [Google Scholar] [CrossRef]

- Wang, W.; Nie, N.; Xu, M.; Zou, C. Lewis acid modulation in phosphorus phenol nickel catalyzed ethylene polymerization and copolymerization. Polym. Chem. 2023, 14, 4933–4939. [Google Scholar] [CrossRef]

- Cao, L.; Cai, Z.; Li, M. Phosphinobenzenamine nickel catalyzed efficient copolymerization of methyl acrylate with ethylene and norbornene. Macromolecules 2022, 55, 3513–3521. [Google Scholar] [CrossRef]

- Xiong, S.; Shoshani, M.M.; Zhang, X.; Spinney, H.A.; Nett, A.J.; Henderson, B.S.; Miller, T.F.; Agapie, T. Efficient copolymerization of acrylate and ethylene with neutral P, O-chelated nickel catalysts: Mechanistic investigations of monomer insertion and chelate formation. J. Am. Chem. Soc. 2021, 143, 6516–6527. [Google Scholar] [CrossRef] [PubMed]

- Xiong, S.; Shoshani, M.M.; Nett, A.J.; Spinney, H.A.; Henderson, B.S.; Agapie, T. Nickel-based heterometallic catalysts for ethylene-acrylate copolymerization: Interrogating effects of secondary metal additives. Organometallics 2023, 42, 2849–2855. [Google Scholar] [CrossRef]

- Xiong, S.; Hong, A.; Bailey, B.C.; Spinney, H.A.; Senecal, T.D.; Bailey, H.; Agapie, T. Highly active and thermally robust nickel enolate catalysts for the synthesis of ethylene-acrylate copolymers. Angew. Chem. Int. Ed. 2022, 61, e202206637. [Google Scholar] [CrossRef]

- Xiong, S.; Hong, A.; Ghana, P.; Bailey, B.C.; Spinney, H.A.; Bailey, H.; Henderson, B.S.; Marshall, S.; Agapie, T. Acrylate-induced β-H elimination in coordination insertion copolymerizaton catalyzed by nickel. J. Am. Chem. Soc. 2023, 145, 26463–26471. [Google Scholar] [CrossRef] [PubMed]

- Xiong, S.; Ghana, P.; Bailey, B.C.; Spinney, H.A.; Henderson, B.S.; Espinosa, M.R.; Agapie, T. Impact of labile ligands on catalyst initiation and chain propagation in Ni-catalyzed ethylene/acrylate copolymerization. ACS Catal. 2023, 13, 5000–5006. [Google Scholar] [CrossRef]

- Xiong, S.; Spinney, H.A.; Bailey, B.C.; Henderson, B.S.; Tekpor, A.A.; Espinosa, M.R.; Saha, P.; Agapie, T. Switchable synthesis of ethylene/acrylate copolymers by a dinickel catalyst: Evidence for chain growth on both nickel centers and concepts of cation exchange polymerization. ACS Catal. 2024, 14, 5260–5268. [Google Scholar] [CrossRef]

- Keim, W. Oligomerization of ethylene to alpha-olefins: Discovery and development of the Shell Higher Olefin Process (SHOP). Angew. Chem. Int. Ed. 2013, 52, 12492–12496. [Google Scholar] [CrossRef]

- Shoshani, M.M.; Xiong, S.; Lawniczak, J.J.; Zhang, X.; Miller, T.F., III; Agapie, T. Phosphine-phenoxide nickel catalysts for ethylene/acrylate copolymerization: Olefin coordination and complex isomerization studies relevant to the mechanism of catalysis. Organometallics 2022, 41, 2119–2131. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, C.; Mecking, S.; Jian, Z. Ultrahigh branching of main-chain-functionalized polyethylenes by inverted insertion selectivity. Angew. Chem. Int. Ed. 2020, 59, 14296–14302. [Google Scholar] [CrossRef] [PubMed]

- McInnis, J.P.; Delferro, M.; Marks, T.J. Multinuclear group 4 catalysis: Olefin polymerization pathways modified by strong metal–metal cooperative effects. Accounts. Chem. Res. 2014, 47, 2545–2557. [Google Scholar] [CrossRef]

- Yue, Q.; Gao, R.; Song, Z.; Lai, J.; Zhang, R.; Wang, Y.; Gou, Q. Recent advancements in multinuclear early transition metal catalysts for olefin polymerization through cooperative effects. E-Polymers 2024, 24, 20230195. [Google Scholar] [CrossRef]

- Cai, Z.; Xiao, D.; Do, L.H. Cooperative heterobimetallic catalysts in coordination insertion polymerization. Comment. Inorg. Chem. 2019, 39, 27–50. [Google Scholar] [CrossRef]

- Zou, C.; Wang, Q.; Si, G.; Chen, C. A co-anchoring strategy for the synthesis of polar bimodal polyethylene. Nat. Commun. 2023, 14, 1442. [Google Scholar] [CrossRef] [PubMed]

- Jin, Z.; Fan, H.; Li, B.-G.; Zhu, S. Evaluation of octyltetramethyldisiloxane-containing ethylene copolymers as composite lubricant for high-density polyethylene. Macromol. Mater. Eng. 2016, 301, 1494–1502. [Google Scholar] [CrossRef]

- Jin, Z.; Fan, H.; Li, B.-G.; Zhu, S. Synthesis of a novel type of octyltetramethyldisiloxane-containing olefinic macromonomer and its copolymerization with ethylene. Polymer 2016, 83, 20–26. [Google Scholar] [CrossRef]

- Moyano, M.A.; París, R.; Martín-Martínez, J.M. Changes in compatibility, tack and viscoelastic properties of ethylene n-butyl acrylate (EBA) copolymer-pentaerythritol rosin ester blend by adding microcrystalline wax, Fischer-Tropsch wax and mixture of waxes. Int. J. Adhes. Adhes. 2016, 65, 47–53. [Google Scholar] [CrossRef]

- Moyano, M.A.; París, R.; Martín-Martínez, J.M. Assessment of the compatibility in hot melts by using different thermoanalytical methods. Ethylene/n-butyl acrylate (EBA) hot melts containing tackifiers of different nature. J. Therm. Anal. Calorim. 2017, 129, 1495–1503. [Google Scholar] [CrossRef]

- Xu, M.; Chen, C. A disubstituted-norbornene-based comonomer strategy to address polar monomer problem. Sci. Bull. 2021, 66, 1429–1436. [Google Scholar] [CrossRef] [PubMed]

- Bielawski, C.W.; Morita, T.; Grubbs, R.H. Synthesis of ABA triblock copolymers via a tandem ring-opening metathesis polymerization: Atom transfer radical polymerization approach. Macromolecules 2000, 33, 678–680. [Google Scholar] [CrossRef]

- Mai, B.; Liu, R.; Li, Z.; Feng, S.; Wu, Q.; Gao, H.; Liang, G.; Zhu, F. Synthesis and self-assembly in aqueous solution of amphiphilic diblock copolymers containing hyperbranched polyethylene. Polymer 2015, 57, 125–131. [Google Scholar] [CrossRef]

- Gao, H.; Hu, Z.; Guan, Q.; Liu, Y.; Zhu, F.; Wu, Q. Synthesis and thermoreversible gelation of coil-helical polyethylene-block-poly(gamma-benzyl-L-glutamate) diblock copolymer. Polymer 2013, 54, 4923–4929. [Google Scholar] [CrossRef]

- Zhao, Y.; Shi, X.; Gao, H.; Zhang, L.; Zhu, F.; Wu, Q. Thermo- and pH-sensitive polyethylene-based diblock and triblock copolymers: Synthesis and self-assembly in aqueous solution. J. Mater. Chem. 2012, 22, 5737–5745. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, Y.; Wang, D.; Yan, M.; Zhang, J.; Zhang, P.; Ding, T.; Chen, L.; Chen, C. Current technologies for plastic waste treatment: A review. J. Clean. Prod. 2021, 282, 124523. [Google Scholar] [CrossRef]

- Sangroniz, A.; Zhu, J.-B.; Tang, X.; Etxeberria, A.; Chen, E.Y.X.; Sardon, H. Packaging materials with desired mechanical and barrier properties and full chemical recyclability. Nat. Commun. 2019, 10, 3559. [Google Scholar] [CrossRef] [PubMed]

- Roy, P.K.; Hakkarainen, M.; Varrna, I.K.; Albertsson, A.-C. Degradable polyethylene: Fantasy or reality. Environ. Sci. Technol. 2011, 45, 4217–4227. [Google Scholar] [CrossRef]

- De Stefano, F.; Baur, M.; De Rosa, C.; Mecking, S. Keto-polyethylenes with controlled crystallinity and materials properties from catalytic ethylene-CO-norbornene terpolymerization. Macromolecules 2024, 57, 1072–1079. [Google Scholar] [CrossRef]

| Entry | Cat. | Polar Monomer | Tp (°C) | P (atm) | t (min) | Act. (kg mol−1 h−1) | Mn (kg mol−1) | Ɖ | X (mol%) | Tm (°C) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 6b |  | 80 | 8 | 360 | 52 | 4.5 | 2.7 | 4.2 | 103.7 | [62] |

| 2 | 6d |  | 80 | 8 | 360 | 72 | 7.0 | 1.9 | 2.4 | 118.3 | [62] |

| 3 | 10a-Na-MgO |  | 80 | 8 | 30 | 104 | 97 | 2.3 | 0.1 | 130.3 | [70] |

| 4 | 10a-Na-MgO |  | 80 | 8 | 30 | 76 | 62 | 2.3 | 1.5 | 126.5 | [70] |

| 5 | 10a-Na-MgO |  | 80 | 8 | 30 | 60 | 33 | 1.7 | 1.2 | 125.9 | [70] |

| 6 | 1b |  | 80 | 8 | 360 | 0.7 | 1.9 | 2.4 | 2.0 | 114.2 | [53] |

| 7 | 1c |  | 80 | 8 | 360 | 0.4 | 2.5 | 2.4 | 2.6 | 118.3 | [53] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Lai, J.; Gao, R.; Gou, Q.; Li, B.; Zheng, G.; Zhang, R.; Yue, Q.; Song, Z.; Guo, Z. Recent Advances in Nickel Catalysts with Industrial Exploitability for Copolymerization of Ethylene with Polar Monomers. Polymers 2024, 16, 1676. https://doi.org/10.3390/polym16121676

Wang Y, Lai J, Gao R, Gou Q, Li B, Zheng G, Zhang R, Yue Q, Song Z, Guo Z. Recent Advances in Nickel Catalysts with Industrial Exploitability for Copolymerization of Ethylene with Polar Monomers. Polymers. 2024; 16(12):1676. https://doi.org/10.3390/polym16121676

Chicago/Turabian StyleWang, Ying, Jingjing Lai, Rong Gao, Qingqiang Gou, Bingyi Li, Gang Zheng, Randi Zhang, Qiang Yue, Zhihui Song, and Zifang Guo. 2024. "Recent Advances in Nickel Catalysts with Industrial Exploitability for Copolymerization of Ethylene with Polar Monomers" Polymers 16, no. 12: 1676. https://doi.org/10.3390/polym16121676

APA StyleWang, Y., Lai, J., Gao, R., Gou, Q., Li, B., Zheng, G., Zhang, R., Yue, Q., Song, Z., & Guo, Z. (2024). Recent Advances in Nickel Catalysts with Industrial Exploitability for Copolymerization of Ethylene with Polar Monomers. Polymers, 16(12), 1676. https://doi.org/10.3390/polym16121676