Combining Thermal Effect and Mobility Control Mechanism to Reduce Water Cut in a Sandstone Reservoir in Kazakhstan

Abstract

1. Introduction

2. Methodology

2.1. Brines

2.2. Crude Oil

2.3. Rock Samples

2.4. Chemicals

2.5. Polymer

2.6. Surfactant

2.7. Surfactant-Polymer Solution

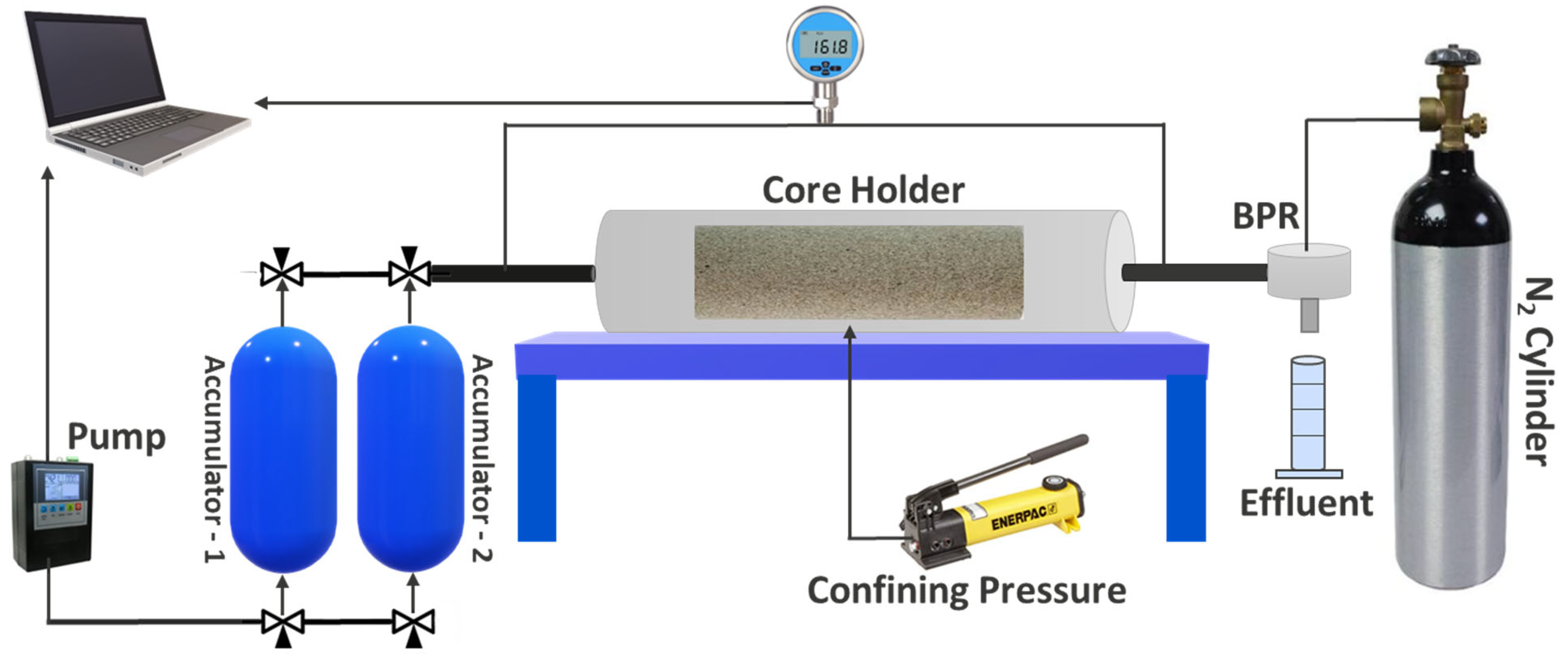

2.8. Oil Displacement Tests

- FW was injected into the saturated core at varying flow rates, and the absolute permeability of the sample was calculated. The CFS system was prepared in accordance with the reservoir specifications at a temperature of 63 °C and a 1500 psi confining pressure to account for overburden pressure. The back pressure was maintained at 300 psi during the entire test except for polymer flooding. The back pressure at the time of polymer injection was set as equal to the atmospheric pressure to prevent polymer degradation in the outlet lines.

- Injection of crude oil was then initiated at 0.5 cc/min, which was then increased in increments of 0.5 cc/min whenever the water cut in the produced fluid fell below 0.1% at a particular flow rate. This was intended to minimize capillary end effects and to establish the initial water saturation (Swi) in the system. The criteria to switch the injection rate was a water cut of less than 0.1% in the produced fluid and a stable and consistent pressure drop across the core. Equation (3) was used to calculate Swi using the volume of the produced water in the effluents.where Vw is the amount of water produced in the effluents.

- Later, SW was injected into the core to obtain oil recovery through water flooding. Seawater flooding was conducted at 0.5 cc/min until the oil cut in the produced fluid was negligible and a stabilized pressure difference was established. The flow rate was then raised in increments of 0.5 cc/min to reduce capillary end effects and to ensure residual oil saturation by seawater injection (Sorw). The produced oil volume during the SW injection stage was utilized to estimate the oil recovery with Equation (4).where is the volume of oil originally in place (OOIP) and is the oil volume recovered during water flooding.

- Subsequently, the designed chemical fluid at a specified strength was prepared in seawater, and injection was started at 0.5 cc/min. A similar criterion was set to change the injection rate to a higher value. The oil production obtained during this step was employed to determine the additional oil recovery through chemical injection. For thermal flooding methods, the CFS system was set at a temperature of 85 °C before injection.

- The resistance factor (RF), residual resistance factor (RRF), and capillary number (Nc) were obtained using Equations (5)–(7), respectively.where is the pressure drop encountered in polymer injection, is the pressure drop observed in water flooding, is the pressure drop established during seawater postflush, K denotes absolute permeability, is the pressure gradient across the sample in a particular chemical injection phase, and σ is the oil–water IFT.

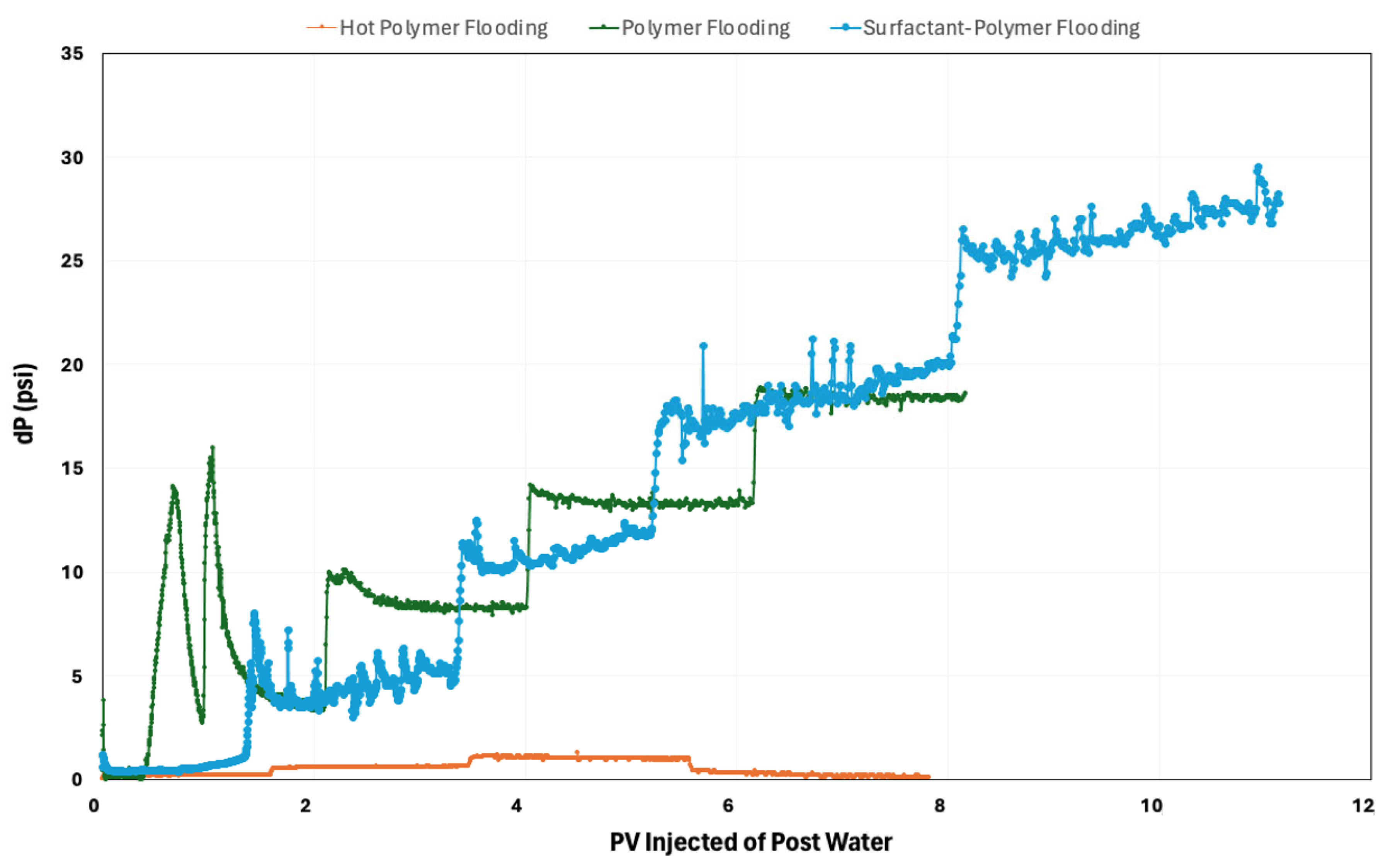

- Lastly, a seawater postflush was conducted to estimate RRF and to move the adsorbed chemicals out.

3. Results

3.1. Chemical Screening

3.2. Oil Displacement Tests

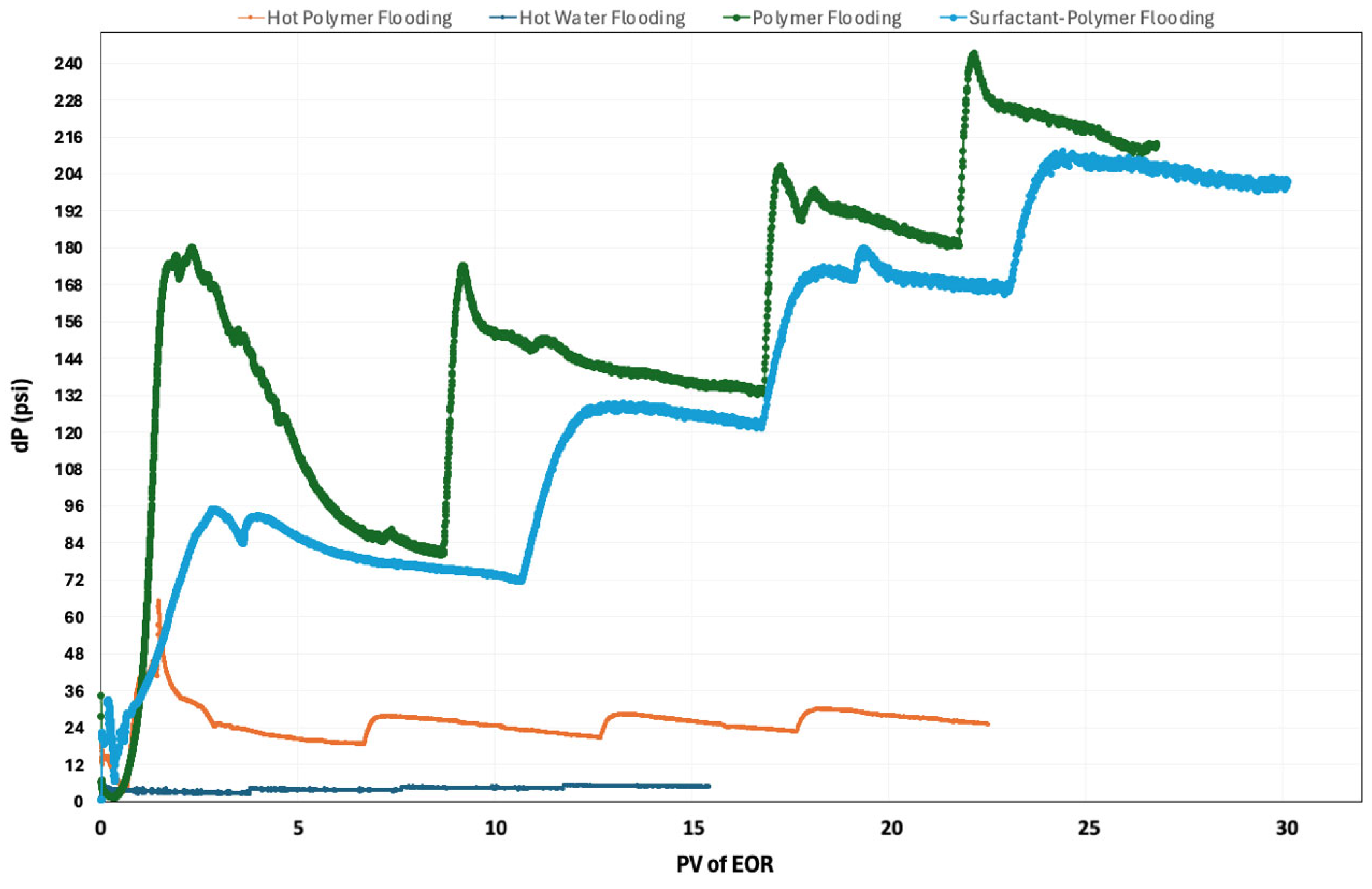

3.3. Polymer Flooding

3.4. Hot Water Flooding

3.5. Hot Polymer Flooding

3.6. Combined Surfactant–Polymer (SP) Flooding

3.7. Evaluation of Oil Recovery Performance of Various EOR Approaches

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yerniyazov, D.; Yesmukhambet, M.; Kenes, R.; Bukayev, A.; Shakeel, M.; Pourafshary, P.; Musharova, D. Polymer Screening for Efficient Water Cut Reduction in a Sandstone Oilfield in Kazakhstan. Polymers 2023, 15, 1969. [Google Scholar] [CrossRef] [PubMed]

- Shuhong, J.; Changbing, T.; Chengfang, S.H.I.; Jigen, Y.E.; Zhang, Z.; Xiujuan, F.U. New Understanding on Water-Oil Displacement Efficiency in a High Water-Cut Stage. Pet. Explor. Dev. 2012, 39, 362–370. [Google Scholar]

- Chang, H.L. Polymer Flooding Technology Yesterday, Today, and Tomorrow. J. Pet. Technol. 1978, 30, 1113–1128. [Google Scholar] [CrossRef]

- Speight, J.G. Enhanced Recovery Methods for Heavy Oil and Tar Sands; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 0127999884. [Google Scholar]

- Sun, X.; Bai, B. Chemical Enhanced Oil Recovery. In Recovery Improvement; Elsevier: Amsterdam, The Netherlands, 2023; pp. 185–279. [Google Scholar]

- Ezeh, O.; Ikiensikimama, S.S.; Akaranta, O. Critical Review of Polymer Flooding in Daqing Field and Pelican Field: Case Studies of the World’s Largest Polymer Flooding in Light and Heavy Oil Reservoirs, Respectively. J. Eng. Res. Rep. 2021, 21, 25–40. [Google Scholar] [CrossRef]

- Druetta, P.; Picchioni, F. Surfactant Flooding: The Influence of the Physical Properties on the Recovery Efficiency. Petroleum 2020, 6, 149–162. [Google Scholar] [CrossRef]

- Anto, R.; Bhui, U.K. Surfactant Flooding for Enhanced Oil Recovery–Insights on Oil Solubilization through Optical Spectroscopic Approach. J. Pet. Sci. Eng. 2022, 208, 109803. [Google Scholar] [CrossRef]

- Wei, J.; Chen, Y.; Zhou, X.; Wang, L.; Fu, P.; Yakushev, V.S.; Khaidina, M.P.; Zhang, D.; Shi, X.; Zhou, R. Experimental Studies of Surfactant-Polymer Flooding: An Application Case Investigation. Int. J. Hydrogen Energy 2022, 47, 32876–32892. [Google Scholar] [CrossRef]

- Wei, J.; Zhou, X.; Shi, X.; Gong, P.; Chen, Y.; Wang, Y.; Fu, P.; Yakushev, V.S.; Khaidina, M.P.; Zhang, D.; et al. Remaining Oil Distribution and Recovery Performances with Waterflooding and Surfactant-Polymer Flooding: An Experimental Investigation. Int. J. Hydrogen Energy 2023, 48, 8430–8439. [Google Scholar] [CrossRef]

- Gao, C.; Shi, J.; Zhao, F. Successful Polymer Flooding and Surfactant-Polymer Flooding Projects at Shengli Oilfield from 1992 to 2012. J. Pet. Explor. Prod. Technol. 2014, 4, 1–8. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, X. Enhancing Heavy-Oil Recovery by Using Middle Carbon Alcohol-Enhanced Hot Polymer Flooding. J. Pet. Sci. Eng. 2017, 149, 193–202. [Google Scholar] [CrossRef]

- Okasha, T.M.; Menouar, H.K.; Abu-Khamsin, S.A. Oil Recovery from Tarmat Reservoirs Using Hot Water and Solvent Flooding. J. Can. Pet. Technol. 1998, 37, PETSOC-98-04-03. [Google Scholar] [CrossRef]

- Duval, K.; Gutiérrez, D.; Petrakos, D.; Ollier, P.; Johannson, D. Successful Application of Hot-Water Circulation in the Pelican Lake Field: Results and Analyses of the E29 Hot-Water-Injection Pilot. J. Can. Pet. Technol. 2015, 54, 361–371. [Google Scholar] [CrossRef]

- Isehunwa, S.O.; Olanisebe, O. Interfacial Tension of Crude Oil-Brine Systems in the Niger Delta; University of Ibadan Institutional Repository: Ibadan, Nigeria, 2012. [Google Scholar]

- Okasha, T. Investigation of the Effect of Temperature and Pressure on Interfacial Tension and Wettability. In Proceedings of the International Symposium of the Society of Core Analysts, Trondheim, Norway, 27–30 August 2018; pp. 27–30. [Google Scholar]

- Rego, F.B.; Botechia, V.E.; Schiozer, D.J. Heavy Oil Recovery by Polymer Flooding and Hot Water Injection Using Numerical Simulation. J. Pet. Sci. Eng. 2017, 153, 187–196. [Google Scholar] [CrossRef]

- Bealessio, B.A.; Alonso, N.A.B.; Mendes, N.J.; Sande, A.V.; Hascakir, B. A Review of Enhanced Oil Recovery (EOR) Methods Applied in Kazakhstan. Petroleum 2021, 7, 1–9. [Google Scholar] [CrossRef]

- Akhmetzhan, S.; Churikova, L.; Kalesheva, G.; Ainah Mukambetkaliyeva, A. A Review Study on an Integrated Method for Solving Problems Associated with the Re-Development of Waterflooded Fields. Geomate J. 2023, 25, 85–92. [Google Scholar] [CrossRef]

- Imanbayev, B.; Kushekov, R.; Sagyndikov, M.; Shyrakbayev, D. Feasibility Study of a Polymer Flood for the Uzen Brownfield Conditions. In Proceedings of the SPE Annual Caspian Technical Conference, Nur-Sultan, Kazakhstan, 15–17 November 2022; OnePetro: Richardson, TX, USA, 2022. [Google Scholar]

- Bedrikovetsky, P. Improved Waterflooding in Reservoirs of Highly Paraffinic Oils. In Proceedings of the Latin American and Caribbean Petroleum Engineering Conference, Rio de Janeiro, Brazil, 30 August–3 September 1997; p. SPE-39083-MS. [Google Scholar]

- Sagyndikov, M.S.; Kushekov, R.M.; Seright, R.S. Review of Important Aspects and Performances of Polymer Flooding versus ASP Flooding; Bulletin of the University of Karaganda–Chemistry: Karaganda, Kazakhstan, 2022. [Google Scholar]

- Navaie, F.; Esmaeilnezhad, E.; Choi, H.-J. Effect of Rheological Properties of Polymer Solution on Polymer Flooding Characteristics. Polymers 2022, 14, 5555. [Google Scholar] [CrossRef] [PubMed]

- Dauyltayeva, A.; Mukhtarov, A.; Sagandykova, D.; Shakeel, M.; Pourafshary, P.; Musharova, D. Screening of Chemicals to Enhance Oil Recovery in a Mature Sandstone Oilfield in Kazakhstan: Overcoming Challenges of High Residual Oil. Appl. Sci. 2023, 13, 10307. [Google Scholar] [CrossRef]

- Shakeel, M.; Sagandykova, D.; Mukhtarov, A.; Dauyltayeva, A.; Maratbekkyzy, L.; Pourafshary, P.; Musharova, D. Maximizing Oil Recovery: Innovative Chemical EOR Solutions for Residual Oil Mobilization in Kazakhstan’s Waterflooded Sandstone Oilfield. Heliyon 2024, 10, e28915. [Google Scholar] [CrossRef] [PubMed]

- Massarweh, O.; Abushaikha, A.S. The Use of Surfactants in Enhanced Oil Recovery: A Review of Recent Advances. Energy Rep. 2020, 6, 3150–3178. [Google Scholar] [CrossRef]

- Sagir, M.; Mushtaq, M.; Tahir, M.S.; Tahir, M.B.; Shaik, A.R. Surfactants for Enhanced Oil Recovery Applications; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 3030187845. [Google Scholar]

- Kang, W.; Wang, D. Emulsification Characteristic and De-Emulsifiers Action for Alkaline/Surfactant/Polymer Flooding. In Proceedings of the SPE International Improved Oil Recovery Conference in Asia Pacific, Kuala Lumpur, Malaysia, 8–9 October 2001; SPE: Kuala Lumpur, Malaysia, 2001; p. SPE-72138. [Google Scholar]

- Igwilo, K.C.; Ogbudu, R.E.; Okolie, S.T.A.; Ohia Princewill, O.N. Experimental Analysis of Chemical De-Emulsification Using Polymerization and Sulfonation Methods on Niger Delta Crude Oil. Int. J. Pet. Gas Eng. Res. 2017, 1, 1–8. [Google Scholar]

| Ions | Ionic Strength (ppm) | |

|---|---|---|

| Seawater | Formation Water | |

| Na+ | 3514 | 18,900 |

| Ca2+ | 401 | 3310 |

| Mg2+ | 791 | 973 |

| Cl− | 6027 | 36,160 |

| (SO4)2− | 3140 | 76 |

| HCO3− | 255 | 390 |

| K+ | 88 | 277 |

| CO32− | 36 | 390 |

| Total | 14,248.7 | 60,083.0 |

| Test | Sample ID | Length (cm) | Diameter (cm) | PV (cm3) | Porosity (%) | Permeability (md) |

|---|---|---|---|---|---|---|

| Polymer Flooding (PF) | 1 | 5.55 | 3.79 | 15.2 | 24.3 | 323.1 |

| Hot Polymer (Hot PF) Flooding | 2 | 5.59 | 3.78 | 16.5 | 26.2 | 441.6 |

| Combined Surfactant–Polymer (SP) Flooding | 3 | 5.43 | 3.79 | 14.7 | 24.1 | 314.5 |

| Hot Water (Hot WF) Flooding | 4 | 5.55 | 3.76 | 14.8 | 24.0 | 352.3 |

| Experiment ID/Name | Injection Sequence/Design | Remarks |

|---|---|---|

| Polymer Flooding (PF) | SW → Polymer → SW-Postflush | ASP3 polymer chosen on the basis of preliminary screening was utilized at an optimal concentration of 2500 ppm at a reservoir temperature of 63 °C. |

| Hot Water (Hot WF) Flooding | SW → Hot SW | Injection of SW at reservoir temperature of 63 °C, followed by injection of SW at a higher temperature of 85 °C. |

| Hot Polymer (Hot PF) Flooding | SW → Hot Polymer → SW-Postflush | ASP3 polymer chosen on the basis of preliminary screening was utilized at an optimal concentration of 2500 ppm and a temperature higher than the reservoir temperature of 85 °C. |

| Combined Surfactant–Polymer (SP) Flooding | SW → Surfactant–Polymer → SW-Postflush | A hybrid mixture of 1.5 wt% 2S/2A at a 30/70 mixing ratio and 2500 ppm ASP3 polymer was utilized. |

| Test Type | Flooding Stage | Recovery Factor | Incremental RF | |

|---|---|---|---|---|

| (%OOIP) | (%OOIP) | (%ROIC) | ||

| Polymer Flooding | SW | 42.8 | - | - |

| Polymer | 90.9 | 48.2 | 84.1 | |

| Hot Polymer Flooding | SW | 42.9 | - | |

| Hot Polymer | 95.6 | 52.7 | 92.3 | |

| Hot Water Flooding | SW | 43.1 | - | |

| Hot SW | 63.4 | 20.3 | 35.6 | |

| Combined SP Flooding | SW | 41.8 | - | |

| Surfactant–Polymer | 95.5 | 53.8 | 92.3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sagandykova, D.; Shakeel, M.; Pourafshary, P. Combining Thermal Effect and Mobility Control Mechanism to Reduce Water Cut in a Sandstone Reservoir in Kazakhstan. Polymers 2024, 16, 1651. https://doi.org/10.3390/polym16121651

Sagandykova D, Shakeel M, Pourafshary P. Combining Thermal Effect and Mobility Control Mechanism to Reduce Water Cut in a Sandstone Reservoir in Kazakhstan. Polymers. 2024; 16(12):1651. https://doi.org/10.3390/polym16121651

Chicago/Turabian StyleSagandykova, Dilyara, Mariam Shakeel, and Peyman Pourafshary. 2024. "Combining Thermal Effect and Mobility Control Mechanism to Reduce Water Cut in a Sandstone Reservoir in Kazakhstan" Polymers 16, no. 12: 1651. https://doi.org/10.3390/polym16121651

APA StyleSagandykova, D., Shakeel, M., & Pourafshary, P. (2024). Combining Thermal Effect and Mobility Control Mechanism to Reduce Water Cut in a Sandstone Reservoir in Kazakhstan. Polymers, 16(12), 1651. https://doi.org/10.3390/polym16121651