Remaining Oil Distribution Law and Development Potential Analysis after Polymer Flooding Based on Reservoir Architecture in Daqing Oilfield, China

Abstract

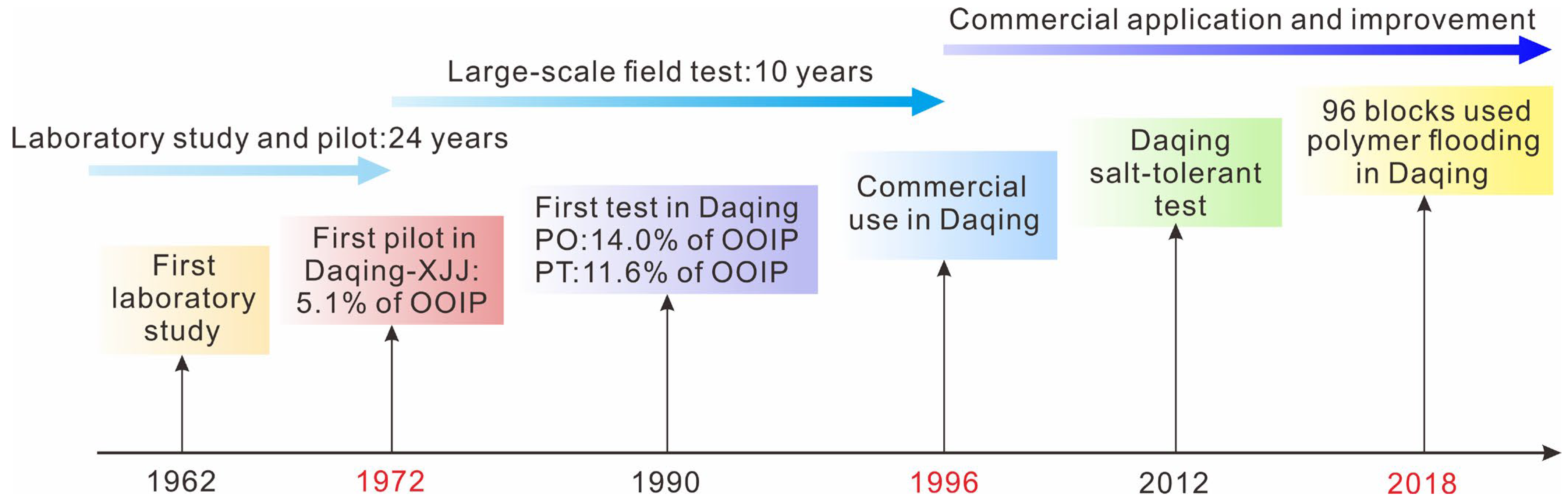

1. Introduction

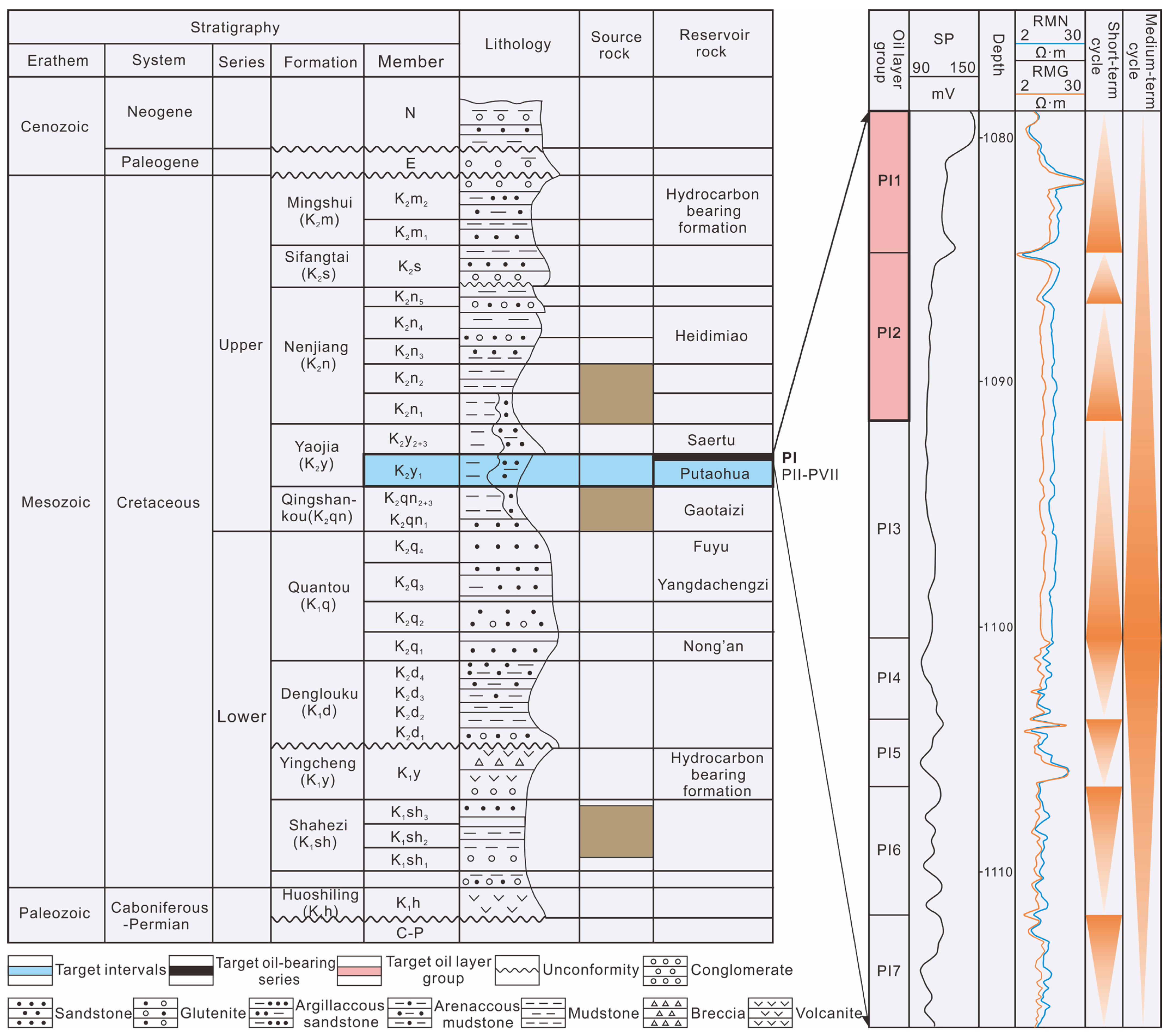

2. Reservoirs Setting

3. Characterization Methods of Reservoir Architecture

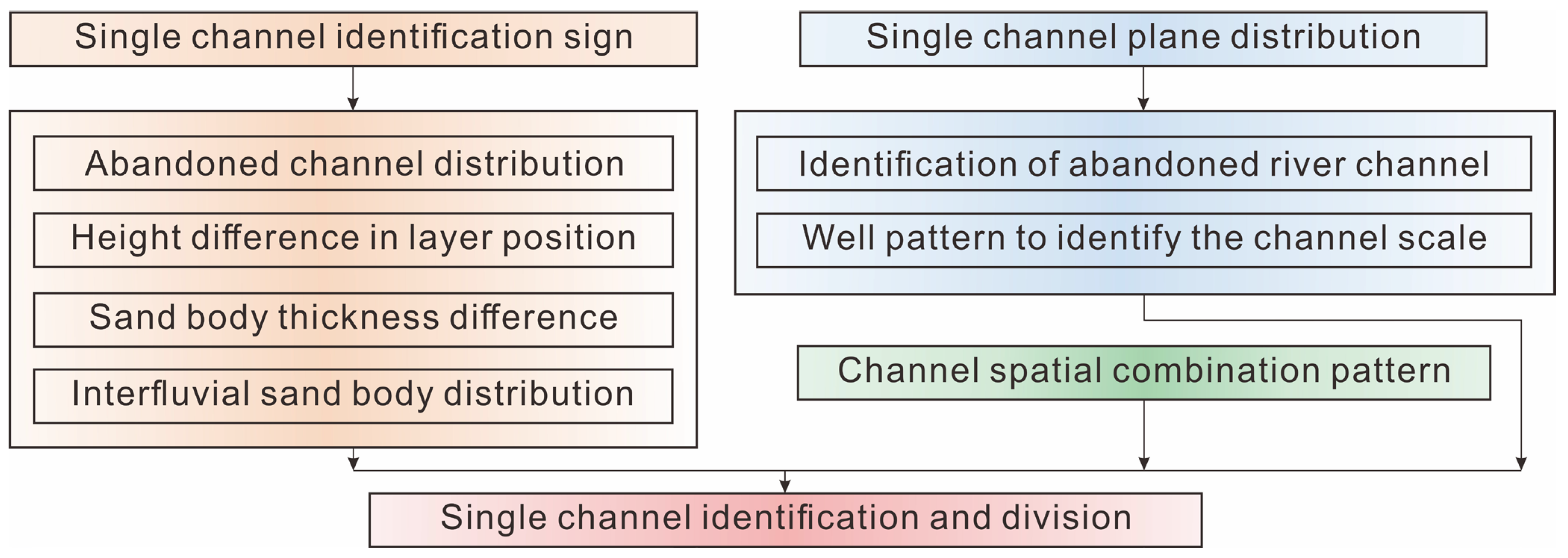

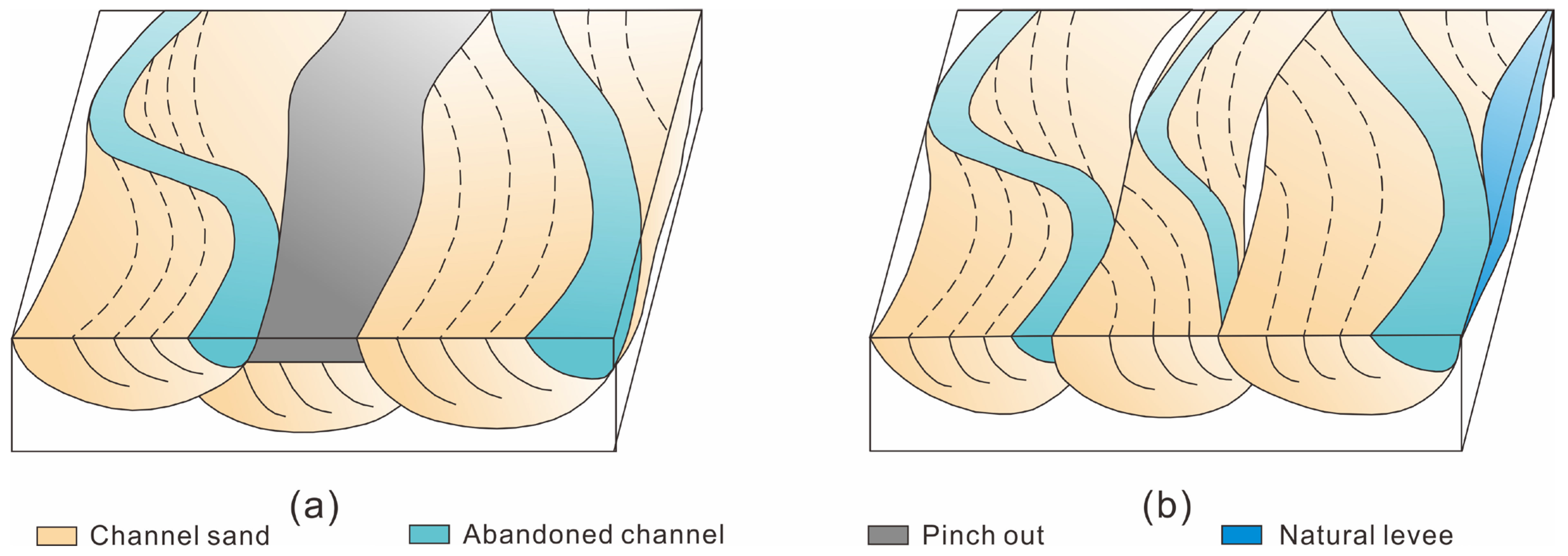

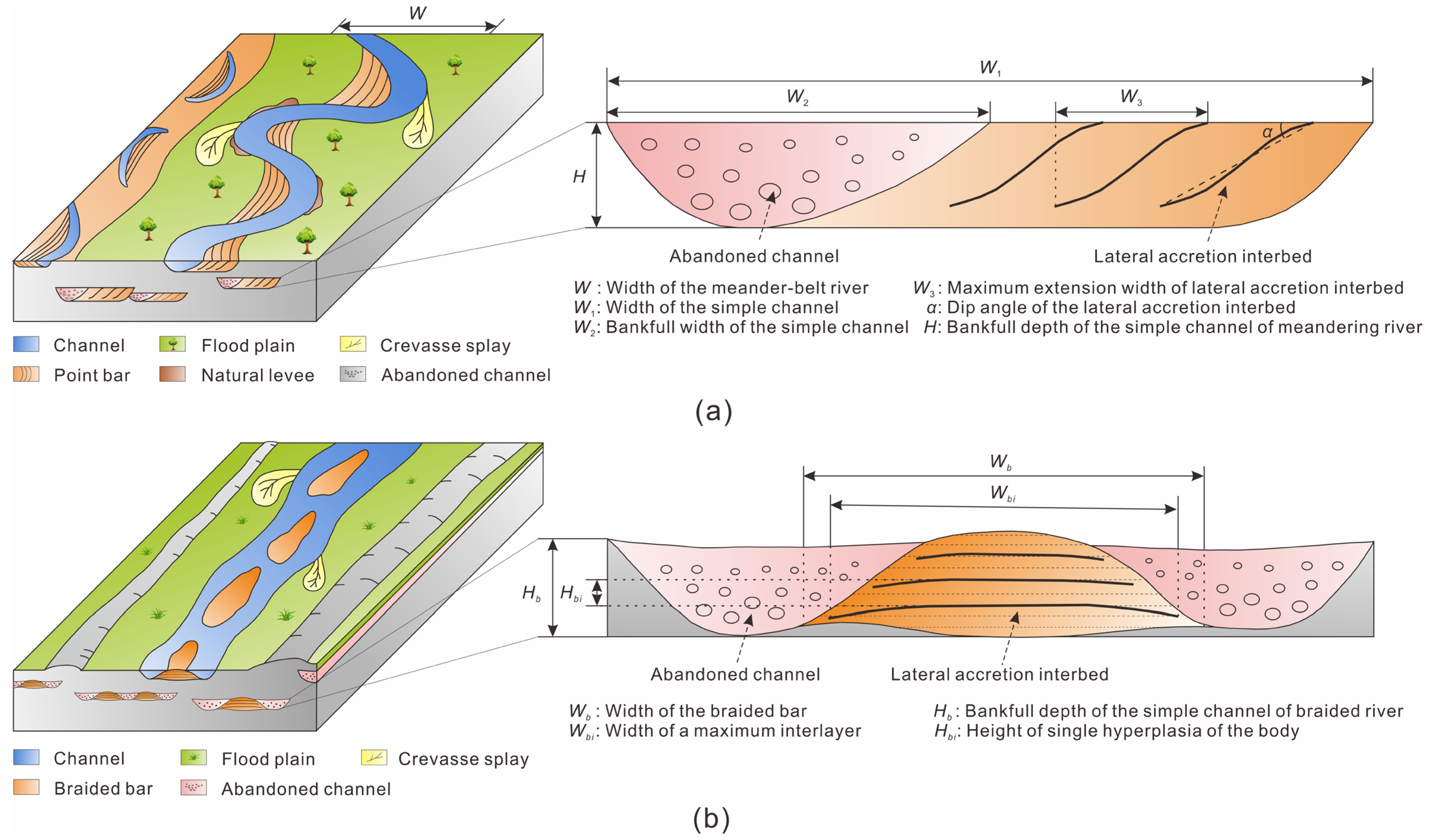

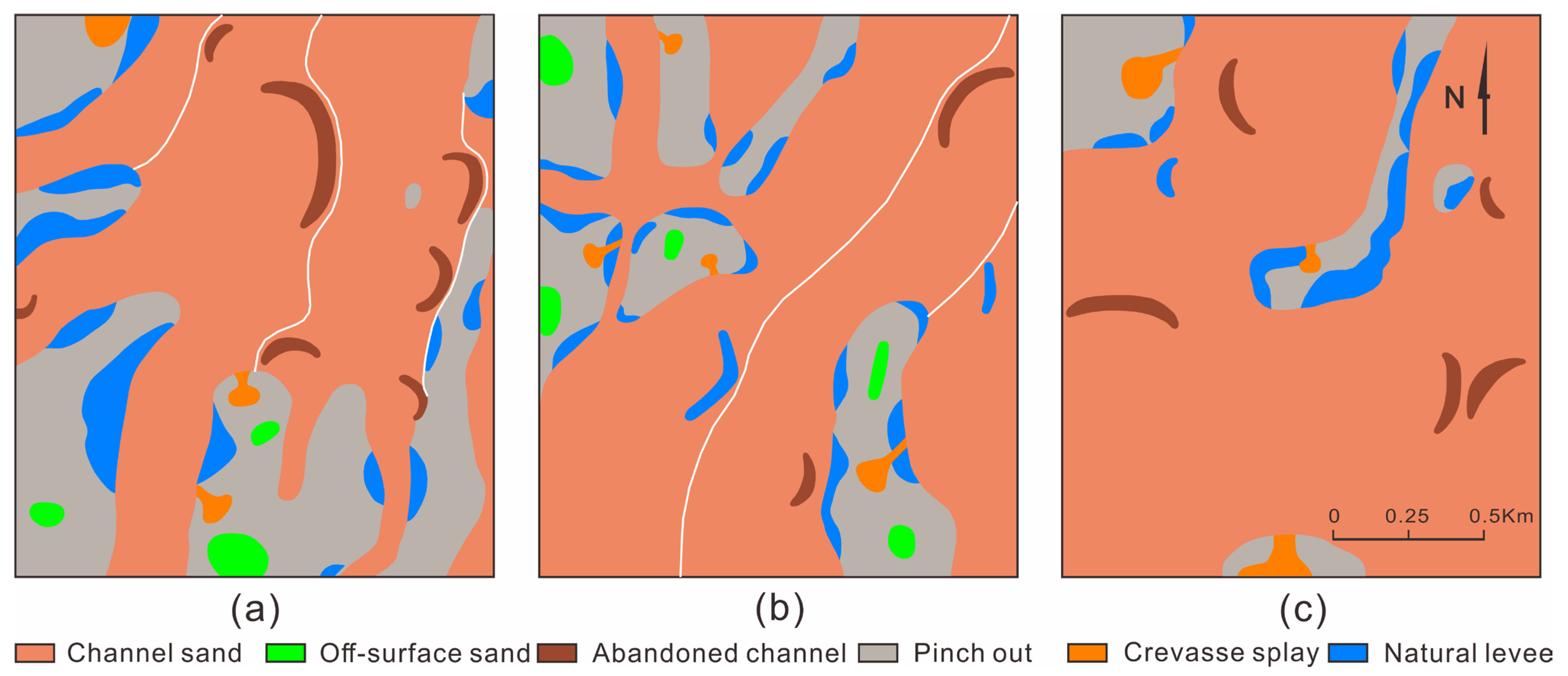

3.1. Single-Channel Division and Internal Architecture

3.2. Internal Architecture of Point Bar and Braided Bar

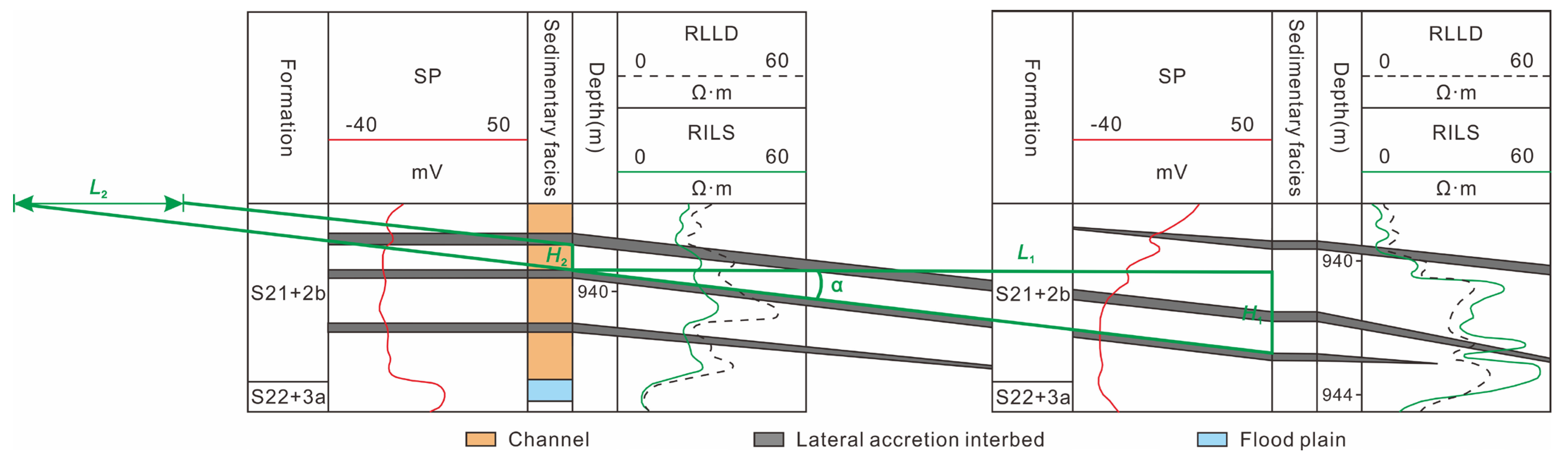

3.2.1. Internal Architecture of Point Bar

3.2.2. Internal Architecture Braided Bar

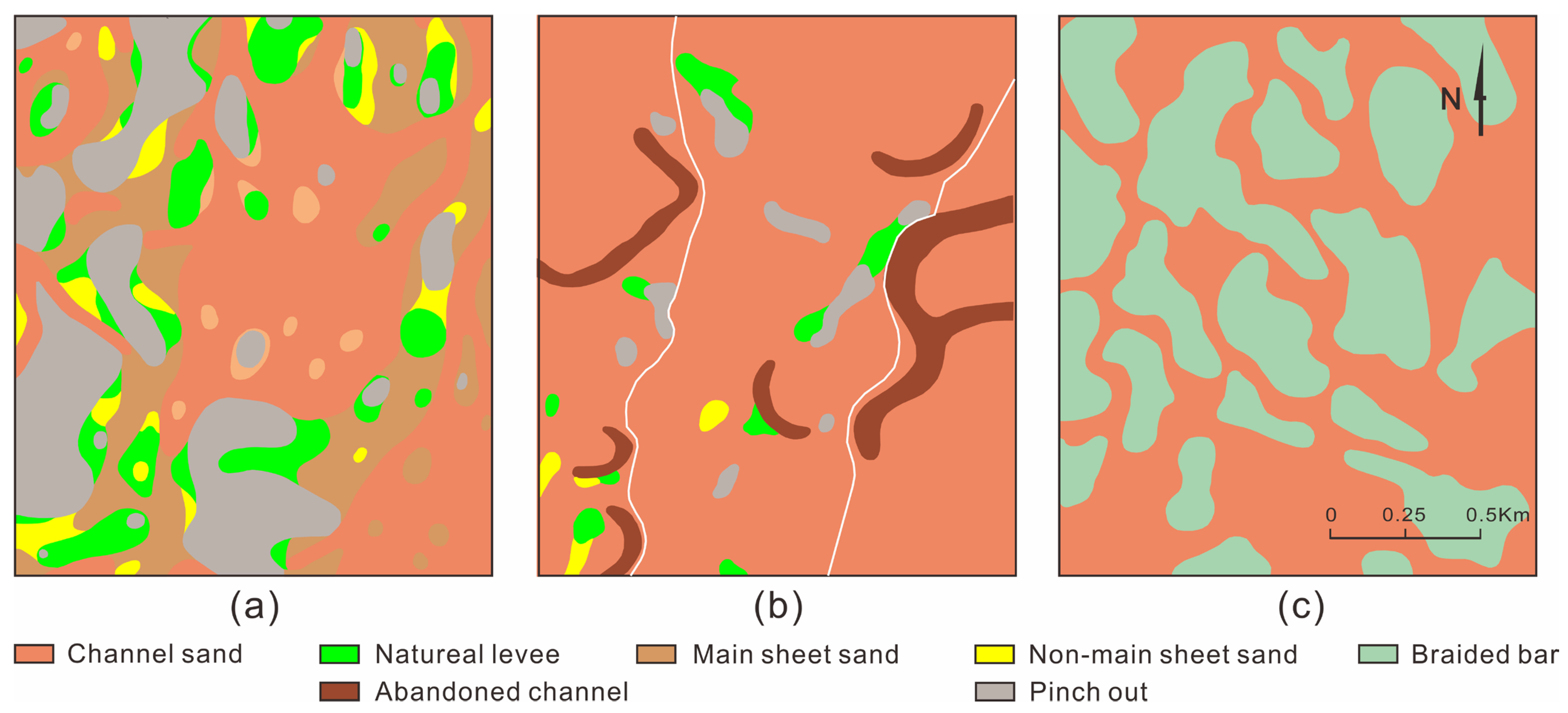

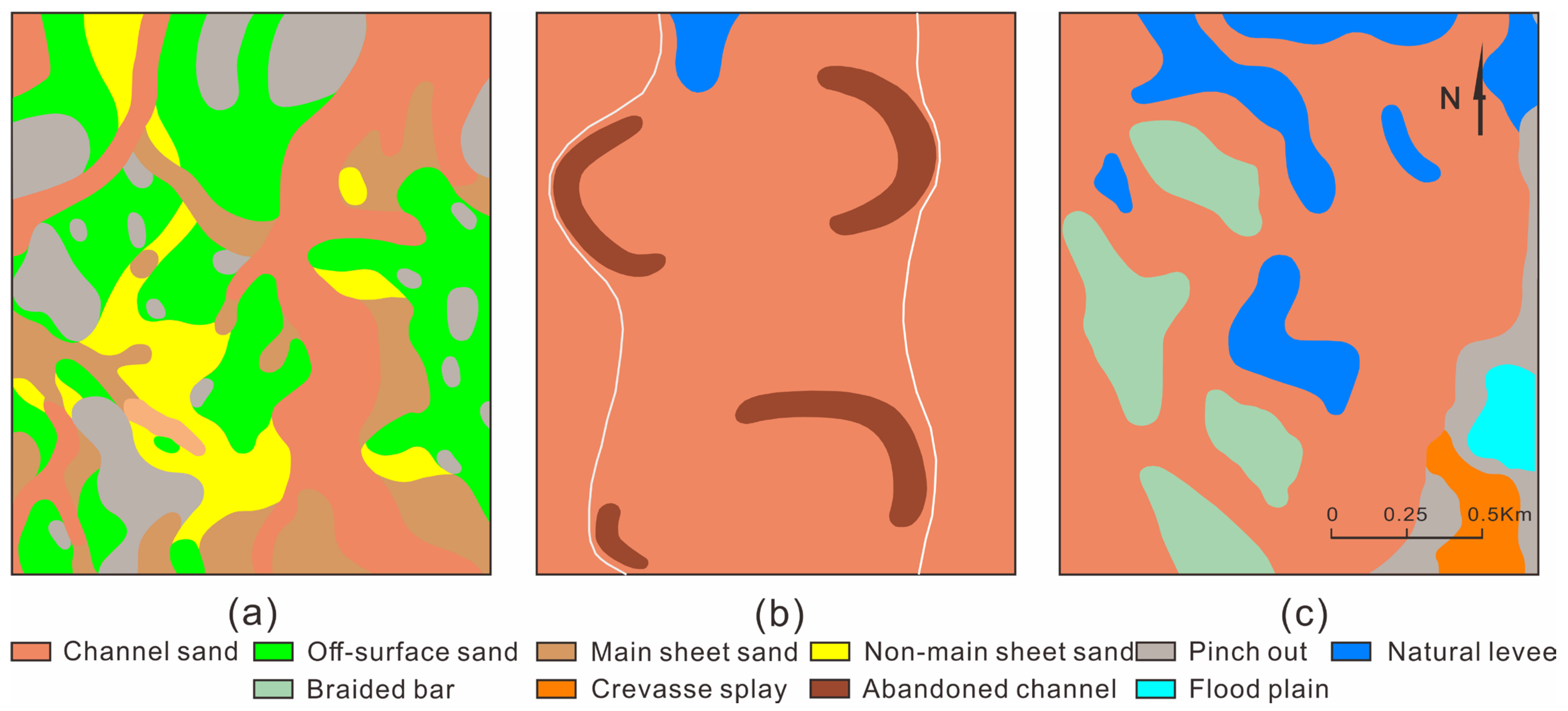

3.2.3. Geological Modeling of Reservoir Architecture

4. Results and Discussion

4.1. Quantitative Distribution of Reservoir Architecture Elements

4.1.1. BB Reservoir

4.1.2. BE Reservoir

4.1.3. NS Reservoir

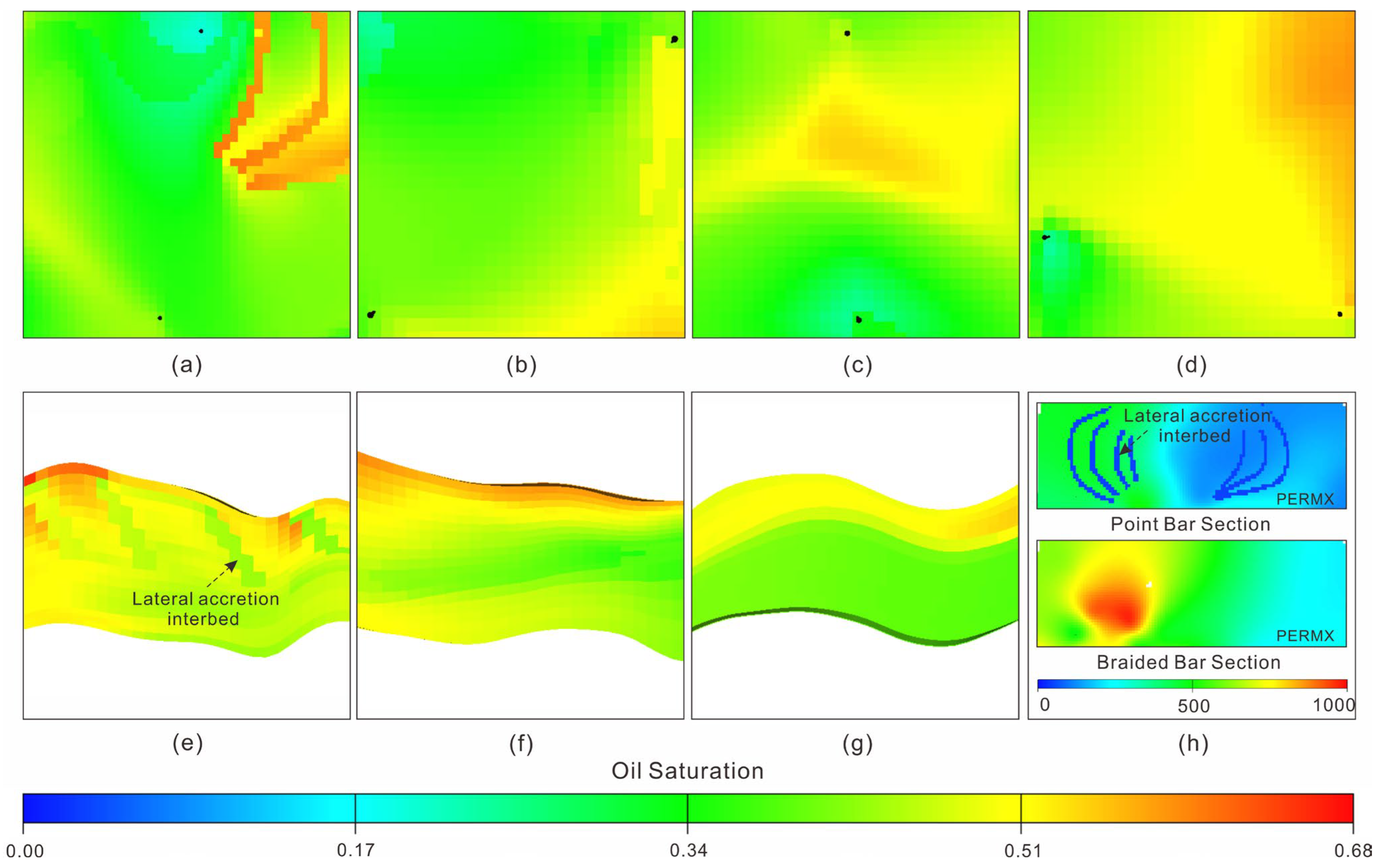

4.2. Influence of Reservoir Architecture on Remaining Oil

4.3. Remaining Oil Distribution Law

4.4. Development Potential Analysis

5. Conclusions

- (1)

- We quantitatively characterized the architectural elements of fluvial sedimentary reservoirs, and their variation was found. In the sedimentary process from north to south in Daqing Oilfield, the simple channel width becomes narrower, and the thickness of the meandering river decreases. The point bar sand body’s width becomes larger, the thickness decreases, and the dip angle of the interlayer inside the point bar sand body becomes smaller. The braided bar sand body’s scale becomes larger, the thickness decreases, and the number of braided bar sand bodies decreases in braided rivers.

- (2)

- Sand bodies are connected between the upper and lower single layers in the area where there is no interlayer present in the braided river sand body. Polymer flooding is affected by gravity and rhythm and replaces the lower high-permeability oil layer; the remaining oil is rich in the upper oil layer. In the area with poor occlusion and connectivity of the abandoned channel in the single-channel sand body of the meandering river, the remaining oil is located at the edge of channel after polymer flooding.

- (3)

- According to the detailed dissection results of the reservoir architecture, four remaining planar oil distribution types (abandoned channel occlusion type, interfluvial sand body occlusion type, interwell retention type and well pattern uncontrollable type) and three remaining vertical oil distribution types (in-layer interlayer occlusion type, rhythm type and gravity type) were classified. For the remaining oil distribution types, the proportion of the gravity type was more than 30% in the braided river sand body, and the proportion of the occlusion type was more than 40% in the meandering river sand body.

- (4)

- After polymer flooding, Daqing Oilfield still has about 40% OOIP, and the remaining oil reserves have high development potential. The development measures of remaining oil in Daqing Oilfield from north to south should transform from the method of expanding the sweep volume to the method of improving the displacement efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, S.Y.; Gao, H.Y.; Jiang, H.F. A Study of Infill Pattern in the Later Period at High Water Cut Stage to the Main Reservoir in the Central Portion of the Saertu Pool. SPE Adv. Technol. Ser. 1997, 5, 56–60. [Google Scholar]

- Zhu, L.H.; Du, Q.L.; Jiang, X.Y.; Guo, J.H.; Wei, L.Y. Characteristics and Strategies of Three Major Contradictions for Continental Facies Multi-Layered Sandstone Reservoir at Ultra-High Water Cut Stage. Acta Pet. Sin. 2015, 36, 210–215. [Google Scholar]

- Luo, D.W.; Weng, D.W.; Luo, J.; Zhang, J.J.; Li, Y.L. Achievements and Future Work of Oil and Gas Production Engineering of CNPC. Pet. Explor. Dev. 2019, 46, 139–144. [Google Scholar]

- Amirian, E.; Dejam, M.; Chen, Z.X. Performance Forecasting for Polymer Flooding in Heavy Oil Reservoirs. Fuel 2018, 216, 83–100. [Google Scholar] [CrossRef]

- Guo, H.; Song, K.P.; Liu, S.P.; Zhao, F.X.; Wang, Z.B.; Xu, Y.; Liu, J.B.; Tang, E.G.; Yang, Z.P. Recent Advances in Polymer Flooding in China: Lessons Learned and Continuing Development. SPE J. 2021, 26, 2038–2052. [Google Scholar] [CrossRef]

- Song, K.P.; Tao, J.W.; Lyu, X.Q.; Xu, Y.; Liu, S.P.; Wang, Z.B.; Liu, H.F.; Zhang, Y.X.; Fu, H.T.; Meng, E.; et al. Recent Advances in Polymer Flooding in China. Molecules 2022, 27, 6978. [Google Scholar] [CrossRef] [PubMed]

- Seright, R.; Wang, D.M. Polymer Flooding: Current Status and Future Directions. Pet. Sci. 2023, 216, 83–100. [Google Scholar] [CrossRef]

- Li, Y. Simulation Study on Propulsion Trajectory of Polymer Blockage in Oil Reservoir. J. China Univ. Pet. (Nat. Sci. Ed.) 2019, 32, 56–61. [Google Scholar]

- Sun, L.D.; Wu, X.L.; Zhou, W.F.; Li, X.J.; Han, P.H. Technologies of Enhancing Oil Recovery by Chemical Flooding in Daqing Oilfield. Pet. Explor. Dev. 2013, 45, 636–644. [Google Scholar] [CrossRef]

- Koh, H.; Lee, V.B.; Pope, G.A. Experimental Investigation of the Effect of Polymers on Residual Oil Saturation. SPE J. 2017, 23, 1–17. [Google Scholar] [CrossRef]

- Denney, D. Study of Remaining-Oil Distribution after Polymer Injection. J. Pet. Technol. 2011, 63, 46–48. [Google Scholar] [CrossRef]

- Yang, Y.F.; Liu, T.; Iglauer, S.; Hejazi, H.; Yao, J. Quantitative Statistical Evaluation of Micro Residual Oil after Polymer Flooding Based on X-ray Micro Computed-Tomography Scanning. Energy Fuels 2020, 34, 10762–10772. [Google Scholar] [CrossRef]

- Qi, P.P.; Daniel, H.E.; Koh, H.; Balhoff, M.T. Reduction of Residual Oil Saturation in Sandstone Cores by Use of Viscoelastic Polymers. SPE J. 2020, 22, 447–458. [Google Scholar] [CrossRef]

- Bai, Z.Q.; Wu, S.H.; Fu, Z.G. The Distribution of Microcosmic Remaining Oils after Polymer Flooding in Daqing Oilfield. Acta Pet. Sin. 2013, 34, 924–930. [Google Scholar]

- Gao, S.; Chen, S.M.; Pu, H.; Gong, L.; Ma, S.Z.; Luo, Q.Y.; Wang, X.X.; Gao, A.; Zhang, B.C. Fine Characterization of Large Composite Channel Sand body Architecture and Its Control on Remaining Oil Distribution: A Case Study of Alkaline-surfactant-polymer (ASP) Flooding Test Area in Xingshugang Oilfield, China. J. Pet. Sci. Eng. 2019, 175, 363–374. [Google Scholar] [CrossRef]

- Deng, M.; Shao, Y.B.; Zhao, Y.B.; Liao, H.; Deng, Q. Reservoir Architecture and Remaining Oil Distribution of Channel bar: A Case from Lower Minghuazhen Formation in Bohai a Oilfield. Lithol. Reserv. 2020, 32, 154–162. [Google Scholar]

- Meng, Y.J.; Zhao, Y.C.; Xiong, S.; Liu, H.P.; Li, Y.L. Study on Reservoir Architecture and Reservoir Units of Fluvial Deposits of Dongying Formation in Yuke Oilfield. Earth Sci. 2021, 46, 2481–2490. [Google Scholar]

- Allen, J.R.L. The plan Shape of Current Ripples in Relation to Flow Condition. Sedimentary 1977, 24, 53–62. [Google Scholar] [CrossRef]

- Allen, J.R.L. Studies in Fluviatile Sedimentation: Baras, Bar Complexes and Sandstone Sheets (Low Sinuosity Braided Streams) in the Brownstones (L. Devonian), Welsh Borders. Sediment. Geol. 1983, 33, 237–293. [Google Scholar] [CrossRef]

- Miall, A.D. Architectural-element Analysis: A New Method of Facies Analysis Applied to Fluvial Deposites. Earth Sci. Rev. 1985, 22, 261–308. [Google Scholar]

- Miall, A.D. Reservoir Heterogeneities in Fluvial Sandstone: Lessons from Outcrop Studies. AAPG Bull. 1988, 72, 682–697. [Google Scholar]

- Weber, K.J.; Geuns, L.C.V. Framework for Constructing Clastic Reservoir Simulation Models. J. Pet. Technol. 1900, 42, 1248–1253. [Google Scholar] [CrossRef]

- Xue, P.H. Introduction to Reservoir Model of River Point Bar Facies; Petroleum Industry Press: Beijing, China, 1991; pp. 1–20. [Google Scholar]

- Deptuck, M.E.; Steffens, G.S.; Barton, M. Architecture and Evolution of Upper Fan Channel-belts on the Niger Delta Slope and in the Arabian Sea. Mar. Pet. Geol. 2003, 20, 649–676. [Google Scholar] [CrossRef]

- Yue, D.L.; Wu, S.H.; Liu, J.M. An Accurate Method for Anatomizing Architecture of Subsurface Reservoirin Point Bar of Meandering River. Acta Pet. Sin. 2007, 28, 99–103. [Google Scholar]

- Ma, S.Z.; Sun, Y.; Fan, G.J.; Hao, Y.L. The Method for Studying Thin Interbed Architecture of Burial Meandering Channel Sandbody. Acta Sedimentol. Sin. 2008, 26, 632–638. [Google Scholar]

- Matthew, D.J.; Gary, J.H.; Richard, P.S. Three-dimensional Modeling of a Shoreface-shelf Parasequence Reservoir Analog: Part 2. Geologic Controls on Fluid Flow and Hydrocarbon Recovery. AAPG Bull. 2009, 93, 1155–1181. [Google Scholar]

- Zhou, X.M.; Gao, X.J.; Tian, C.B.; Wang, X.M.; Chen, J.Y. Quantitative Description of Internal Architecture in Point Bar of Meandering River. Nat. Gas Geosci. 2010, 21, 421–426. [Google Scholar]

- Zhou, Y.B.; Wu, S.H.; Yue, D.L.; Du, Q.L.; Zhong, X.X. Controlling Factor Analysis and Identification Method of Lateral Accretion Shale Beddings Angle in Point Bar. J. China Univ. Pet. 2009, 33, 7–10. [Google Scholar]

- Wang, Y.; Chen, S.Y. Meandering River Sand Body Architecture and Heterogeneity: A Case Study of Permian Meandering River Outcrop in Palougou, Baode, Shanxi Province. Pet. Explor. Dev. 2016, 43, 230–240. [Google Scholar] [CrossRef]

- Li, S.M.; He, H.; Hao, R.L.; Chen, H.Q.; Bie, H.Y.; Liu, P.C. Depositional Regimes and Reservoir Architecture Characterization of Alluvial Fans of Karamay Oilfield in Junggar Basin, Western China. J. Pet. Sci. Eng. 2020, 186, 106730. [Google Scholar] [CrossRef]

- Ovie, B.O. Sequence Stratigraphic Controls on Reservoir Characterization and Architectural analysis: A Case Study of Tovo Field, Coastal Swamp Depobelt, Niger Delta Basin, Nigeria. Mar. Pet. Geol. 2020, 121, 104579. [Google Scholar]

- Zhu, X.M.; Zeng, H.L.; Li, S.L.; Dong, Y.L.; Zhu, S.F.; Zhao, D.N.; Huang, W. Sedimentary Characteristics and Seismic Geomorphologic Responses of a Shallow-water Delta in the Qingshankou Formation from the Songliao Basin, China. Mar. Pet. Geol. 2017, 79, 131–148. [Google Scholar] [CrossRef]

- Shan, J.F.; Lin, Z.P.; Chen, L.; Zhang, B.; Fang, S.X.; Yan, X.; Fang, W.; Xie, L.L.; Liu, B.; Zhang, L. Reconstruction of Meandering Paleo-channels Using Dense Well Data, Daqing Oil Field, Songliao Basin, China. Pet. Sci. 2018, 15, 722–743. [Google Scholar] [CrossRef]

- Ji, Z.; Meng, Q.A.; Wan, C.B.; Ge, W.C.; Yang, H.; Zhang, Y.L.; Dong, Y.; Jin, X. Early Cretaceous Adakitic Lavas and A-type Rhyolites in the Songliao Basin, NE China: Implications for the Mechanism of Lithospheric Extension. Gondwana Res. 2019, 71, 28–48. [Google Scholar] [CrossRef]

- Wang, S.Y.; Cheng, Y.H.; Zeng, L.; Miao, P.S.; Jin, R.S.; Zhang, T.F.; Li, C.H.; Zhang, X.W. Thermal Imprints of Cenozoic Tectonic Evolution in the Songliao Basin, NE China: Evidence from Apatite Fission-track (AFT) of CCSD-SK1 Borehole. J. Asian Earth Sci. 2020, 195, 104353. [Google Scholar] [CrossRef]

- Feng, Y.L.; Zou, C.N.; Li, J.Z.; Lin, C.S.; Wang, H.J.; Jiang, S.; Yang, Z.; Zhang, S.; Fu, X.L. Sediment Gravity-flow Deposits in Late Cretaceous Songliao Postrift Downwarped Lacustrine Basin, Northeastern China. Mar. Pet. Geol. 2021, 134, 105378. [Google Scholar] [CrossRef]

- Li, Z.D.; Pang, H.; Xu, J.Z.; Li, Z.; Zhang, H.X.; Liu, Y.K. Case Study of Sandbody Architecture and Quantitative Parameters of the Farsource Sandy Braided River: Saertu Oilfield, Daqing, China. J. Pet. Sci. Eng. 2019, 181, 106249. [Google Scholar] [CrossRef]

- Wang, D.Q.; Yin, D.Y.; Zhou, Y.Z. Fine Classification of Ultra-low Permeability Reservoirs around the Placanticline of Daqing Oilfield (PR of China). J. Pet. Sci. Eng. 2019, 174, 1042–1052. [Google Scholar]

- Seright, R.S. How Much Polymer Should Be Injected During a Polymer Flood? Review of Previous and Current Practices. SPE J. 2016, 22, 1–18. [Google Scholar] [CrossRef]

- Deng, Q.J.; Hu, M.Y.; Su, S.; Chen, W.; Shen, J.; Kane, O.L.; Cai, Q.S.; Hu, Z.G. Factors Controlling Reservoir Quality of a Retreating Delta-front in Shallow-water Lacustrine in the Songliao Basin, Northeast China. J. Pet. Sci. Eng. 2022, 216, 110773. [Google Scholar] [CrossRef]

- Mo, W.L.; Wu, C.D.; Su, N.; Zhang, S.; Wang, M.Z. Seismic Imaging of the Sedimentary System of the Upper Cretaceous Nenjiang Formation in the Northern Songliao Basin. J. Earth Sci. 2019, 30, 788–798. [Google Scholar] [CrossRef]

- Li, H.S.; He, W.T.; Chen, F.J.; Kong, D.M. Superheavy Pyrite in the Upper Cretaceous Mudstone of the Songliao Basin, NE China and Its Implication for Paleolimnological Environments. J. Asian Earth Sci. 2020, 189, 104156. [Google Scholar]

- Zhang, P.H.; Fang, H.; Zhong, Q.; Zhang, X.B.; Yuan, Y.Z.; Liu, J.X. Structural Features and Tectonic Evolution of the Nenjiang–Balihan Fault in the Western Margin of the Songliao Basin, NE China, Inferred from 2D Inversion of Magnetotelluric Data. J. Asian Earth Sci. 2021, 206, 104628. [Google Scholar] [CrossRef]

- Xue, X.Y.; Liu, Z.B.; Jiang, Z.X.; Zhang, J.G.; Yang, T.J. Static Connectivity of Fluvial Reservoirs and Their Temporal Evolution: An Example from Densely Drilled Dubsurface Data in the Sanzhao Sag, Songliao Basin. Mar. Pet. Geol. 2021, 134, 105327. [Google Scholar] [CrossRef]

- Liu, C.Y.; Shan, X.L.; Yi, J.; Shi, Y.Q.; Ventura, G.D. Volcanism at the End of Continental Rifting: The Cretaceous Syn-Rift to Ppost-Rift Transition in the Songliao Basin (NE China). Gondwana Res. 2022, 111, 174–188. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Guo, T.; Zeng, Z.; Fu, Q.L.; Pu, J.B. Dynamic Evolution of the Mesozoic-Cenozoic Basins in Northeastern China. Earth Sci. Front. 2015, 22, 88–96. [Google Scholar]

- Li, J.Y.; Liu, J.F.; Qu, J.F.; Zheng, G.R.; Zhao, S. Major Geological Features and Crustal Tectonic Framework of Northeast China. Acta Petrol. Sin. 2019, 35, 2989–3006. [Google Scholar]

- Chen, X.; Xu, S.Y.; Li, S.M.; He, H.; Han, Y.M.; Qu, X.Y. Identification of Architectural Elements Based on SVM with PCA: A Case Study of Sandy Braided River Reservoir in the Lamadian Oilfield, Songliao Basin, NE China. J. Pet. Sci. Eng. 2021, 198, 108247. [Google Scholar] [CrossRef]

- Pan, S.X.; Liu, H.Q.; Zavala, C.; Liu, C.Y.; Liang, S.J. Sublacustrine Hyperpycnal Channel Fan System in a Large Depression Basin: A Case Study of Nen 1 Member, Cretaceous Nenjiang Formation in the Songliao Basin, NE China. Pet. Explor. Dev. 2017, 44, 860–868. [Google Scholar] [CrossRef]

- Huang, L.; Tong, H.M.; Yang, D.H.; Fan, J.Y.; Huang, H.T. A New Model for the Formation and Evolation of Middle Shallow Faults in the Daqing Placanticline, Songliao Basin. Acta Geol. Sin. 2019, 93, 597–604. [Google Scholar]

- Zhuo, H.C.; Lin, C.M.; Li, Y.L.; Feng, Z.Q.; Zhang, S. Characteristics of Sedimentary Facies and Sequence Boundary in Upper Cretaceous Qingshankou Yaojia Formation of Northern Songliao Basin. Acta Sedimentol. Sin. 2007, 25, 29–37. [Google Scholar]

- Shi, L.Z.; Wang, Z.Z.; Zhang, G.; Zhang, Y.S.; Xing, E.Y. Distribution and Formation of Tight Oil in Qijia area, Songliao Basin, NE China. Pet. Explor. Dev. 2015, 42, 48–55. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.H.; Hou, J.G.; Liu, J.M. Progress and Prospects of Reservoir Development Geology. Pet. Explor. Dev. 2017, 44, 603–604. [Google Scholar] [CrossRef]

- Liang, H.W.; Zhao, X.Q.; Mu, L.X.; Fan, Z.F.; Zhao, L.; Wu, S.H. Channel Sandstone Architecture Characterization by Seismic Simulation. J. Earth Sci. 2019, 4, 799–808. [Google Scholar] [CrossRef]

- Yu, X.C.; Liu, C.L.; Wang, C.L.; Li, F.; Wang, J.Y. Eolian Deposits of the Northern Margin of the South China (Jianghan Basin): Reconstruction of the Late Cretaceous East Asian landscape in central China. Mar. Pet. Geol. 2020, 117, 104390. [Google Scholar] [CrossRef]

- Sun, Z.F.; Lin, C.Y.; Du, D.X.; Jiang, S.; Yan, K.; Jiao, H.Y. Quantitative Architectural Characteristics of Deep-Lake Turbidites: Taking Block 146 of Shinan Oilfield in Dongying Depression in China as an Example. Mar. Pet. Geol. 2020, 112, 104046. [Google Scholar] [CrossRef]

- Zhao, Y.G.; Li, L.; Shi, L.Q.; Wang, Z.J.; Yang, L.Y.; Wang, Z.W. Sand Body Microfacies Types and Single Sand Body Division in Sandy Braided River Reservoirs: A Case Study from Yan10 Member in the H303-6 Well Area, Southwestern Ordos Basin, China. In Proceedings of the International Field Exploration and Development Conference, Chengdu, China, 23–25 September 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 2306–2319. [Google Scholar]

- Niu, B.; Bao, Z.D.; Yu, D.F.; Zhang, C.; Long, M.; Su, J.C.; Gao, X.J.; Zhang, L.; Zang, D.S.; Li, M.; et al. Hierarchical Modeling Method Based on Multilevel Architecture Surface Restriction and Its Application in Point-bar Internal Architecture of a Complex Meandering River. J. Pet. Sci. Eng. 2021, 205, 108808. [Google Scholar] [CrossRef]

- Zheng, X.B.; Zhu, H.T.; Liu, Q.H. Seismic Geomorphology Applied to Sediment Dispersal Patterns and an Analysis of the Stages of Channel-lobe Systems in the Yinggehai Basin, Northern South China Sea. Mar. Pet. Geol. 2022, 139, 105602. [Google Scholar] [CrossRef]

- Lorenz, J.C.; Heinze, D.M.; Clark, J.A. Determination of Width of Meander-belt Sandstone Reservoirs from Vertical down Hole Data Mesaverde Group Piceance Greek Basin Colorado. AAPG Bull. 1985, 69, 710–721. [Google Scholar]

- Wu, S.H.; Yue, D.L.; Liu, J.M.; Shu, Q.L.; Fan, Z.; Li, Y.P. Hierarchy Modeling of Subsurface Palaeochannel Reservoir Architecture. Sci. China Ser. D Earth Sci. 2008, 51, 126–137. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, X.J.; Zhou, X.M. Reservoir Architecture Characterization and Remaining Oil Distribution of Meandering. J. China Univ. Pet. 2019, 43, 13–22. [Google Scholar]

- Usman, M.; Siddiqui, N.A.; Zhang, S.Q.; Mathew, M.J.; Zhang, Y.X.; Jamil, M.; Liu, X.L.; Ahmed, N. 3D Geo-cellular Static Virtual Outcrop Model and Its Implications for Reservoir Petro-Physical Characteristics and Heterogeneities. Pet. Sci. 2021, 18, 1357–1369. [Google Scholar] [CrossRef]

- Yan, B.Q.; Zhang, X.L.; Yu, L.M.; Zhang, D.; Jiang, G.P.; Yang, Y.F.; Sun, Y.; Han, X.L.; Xu, Y.N. Point Bar Configuration and Residual Oil Analysis Based on Core and Dense Well Pattern. Pet. Explor. Dev. 2014, 41, 654–662. [Google Scholar] [CrossRef]

- Leeder, M.R. Fluviatile Fining upwards Cycles and the Magnitude of Paleochannels. Geol. Mag. 1973, 110, 265–276. [Google Scholar] [CrossRef]

- Sun, Z.F.; Lin, C.Y.; Zhu, P.; Chen, J.Y. Analysis and Modeling of Fluvial-reservoir Petrophysical Heterogeneity Based on Sealed Coring Wells and Their Test Data, Guantao Formation, Shengli Oilfield. J. Pet. Sci. Eng. 2018, 162, 785–800. [Google Scholar] [CrossRef]

- Li, J.; Lin, C.Y.; Zhang, X.G.; Dong, C.L.; Wei, Y.N.; Ning, W.Y.; Han, C.C.; Guo, W. Multiscale Modeling of Meandering Fluvial Reservoir Architecture Based on Multiple-Point Geostatistics: A Case Study of the Minghuazhen Formation, Yangerzhuang Oilfield, Bohai Bay Basin, China. Geofluids. 2021, 2021, 1717195. [Google Scholar] [CrossRef]

- He, Y.H.; Song, B.Q.; Zhang, C.S. A Study of Braided River Sand Deposit in Changywan, Daqing through Physicalsimulation Experiments. Earth Sci. Front. 2021, 19, 41–48. [Google Scholar]

- Kelly, S. Scaling and Hierarchy in Braided Rivers and Their Deposits: Examples and Implications for Reservoir Modeling; International Association of Sedimentologists: Gent, Belgium, 2006; Volume 36, pp. 75–106. [Google Scholar]

- Lynds, R.; Hajek, E. Conceptual Model for Predicting Mudstone Dimensions in Sandy Braided River Reservoirs. AAPG Bull. 2006, 90, 1273–1288. [Google Scholar] [CrossRef]

- Liu, J.S.; Yang, H.M.; Wu, X.F.; Liu, Y. The In Situ Stress Field and Microscale Controlling Factors in the Ordos Basin, Central China. Int. J. Rock Mech. Min. Sci. 2020, 135, 104482. [Google Scholar] [CrossRef]

- Yong, H.; He, W.X.; Guo, B.C. Combining Sedimentary forward Modeling with Sequential Gauss Simulation for Fine Prediction of Tight Sandstone Reservoir. Mar. Pet. Geol. 2020, 112, 104044. [Google Scholar] [CrossRef]

- Yu, D.S. Study on Meandering River Sand Body Configuration and 3D Geological Modeling in Sartu Oilfield. In Proceedings of the International Field Exploration and Development Conference, Qingdao, China, 20–22 October 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 2457–2462. [Google Scholar]

- Zhang, X.; Huang, Z.Q.; Lei, Q.H.; Yao, J.; Gong, L.; Sun, S.Y.; Li, Y. Connectivity, Permeability and Flow Channelization in Fractured Karst Reservoirs: A Numerical Investigation Based on a Two-dimensional Discrete Fracture-cave Network Model. Adv. Water Resour. 2022, 161, 104142. [Google Scholar] [CrossRef]

- Imseeh, W.H.; Alshibli, K.A. 3D Finite Element Modelling of Force Transmission and Particle Fracture of Sand. Comput. Geotech. 2018, 94, 184–195. [Google Scholar] [CrossRef]

- Parquer, M.; Yan, N.; Colomberac, L.; Mountney, N.P.; Collon, P.; Caumonb, G. Combined Inverse and Forward Numerical Modelling for Reconstruction of Channel Evolution and Facies Distributions in Fluvial Meander-belt Deposits. Mar. Pet. Geol. 2020, 117, 104409. [Google Scholar] [CrossRef]

- Liu, D.H.; Sun, J. The Control Theory and Application for Well Pattern Optimization of Heterogeneous Sandstone Reservoirs; Springer Geology; Springer: Berlin/Heidelberg, Germany, 2017; pp. 334–363. [Google Scholar]

- Avansi, G.D.; Maschio, C.; Schiozer, D.J. Simultaneous History-Matching Approach by Use of Reservoir—Characterization and Reservoir—Simulation Studies. SPE Res. Eval. Eng. 2016, 19, 694–712. [Google Scholar] [CrossRef]

- Wu, Z.B.; Liu, H.Q. Investigation of Hot-water Flooding after Steam Injection to Improve Oil Recovery in Thin Heavy-oil Reservoir. J. Pet. Explor. Prod. Technol. 2019, 9, 1547–1554. [Google Scholar] [CrossRef]

- Zhu, W.Y.; Zou, C.J.; Wang, J.L.; Liu, W.C.; Wang, J.Q. A New Three-dimensional Effective Water-flooding Unit Model for Potential Tapping of Remained Oil in the Reservoirs with Rhythmic Conditions. J. Pet. Explor. Prod. Technol. 2021, 11, 1375–1391. [Google Scholar] [CrossRef]

- Lin, F.F.J.; Besserer, G.J.; Pitts, M.J. Laboratory Evaluation of Crosslinked Polymer and Alkaline-Polymer-Surfactant Flood. J. Can. Pet. Technol. 1987, 26, 54–65. [Google Scholar] [CrossRef]

| Architecture Interface Level | Architecture Units | Time Scale (a) | Examples of Sedimentation | Reservoir Correlation Unit Classification |

|---|---|---|---|---|

| Level 0 | Lamina | 10−6 | Small-scale ripple mark | / |

| Level 1 | Microforms | 10−5–10−4 | Large-scale ripple mark | / |

| Level 2 | Mesoforms | 10−2–10−1 | Dunes | / |

| Level 3 | Macroforms accreted terrace | 100–101 | Lateral accretion body | / |

| Level 4 | Macroforms | 102–103 | Point bar, natural levee, crevasse splay | Single layer (sedimentary unit) |

| Level 5 | River channel | 103–104 | Single channel | Single layer |

| Level 6 | River channel zone | 104–105 | Composite channel | Sands group |

| Level 7 | Large sedimentary system | 105–106 | Level 4 cycle (Milankovitch) | Oil layer group |

| Level 8 | Basin-fill complex | 106–107 | Level 3 cycle (Milankovitch) | Oil-bearing series |

| Reservoirs | Sedimentary Unit | Width of Simple Channel Sand Body (m) | Width of Point Bar Sand Body (m) | Thickness of Point Bar Sand Body (m) | Dip Angle of Lateral Accretion Interbed (°) |

|---|---|---|---|---|---|

| BB Reservoir | PI21 | 700–1200 | 100–150 | 6–8 | 4 |

| BE Reservoir | PI21 | 600–1000 | 150–350 | 5.5–7 | 5 |

| NS Reservoir | PI1b | 300–500 | 350–400 | 4–5 | 5 |

| PI2b | 350–400 | 400–600 | 5–6 | 7 | |

| PI2c | 400–500 | 400–500 | 4–6 | 5 |

| Type | High Displacement Efficiency (HDE) | Medium Displacement Efficiency (MDE) | Low Displacement Efficiency (LDE) | No Displacement Efficiency (NDE) |

|---|---|---|---|---|

| value (%) | >55 | 35–55 | 15–35 | <15 |

| Types | Distribution Type of Remaining Oil | Characteristics of Remaining Oil Distribution after Polymer Flooding |

|---|---|---|

| Planar | Abandoned channel occlusion type | Blocked by the abandoned channel, the remaining oil is rich at the edge of abandoned channel [15]. |

| Interfluvial sand body occlusion type | The displacement fluid advances along the channel center, and the remaining oil is rich at the edge of the channel sand body [30]. | |

| Interwell retention type | In the well pattern, the displacement fluid advances along both sides of main flow line, and the remaining oil is rich at the diverting flow line [80]. | |

| Well pattern uncontrollable type | The reservoir sand body is widely distributed, and remaining oil uncontrolled by the well pattern is formed at its edge or extension area, with poor physical properties [15]. | |

| Vertical | In-layer interlayer occlusion type | In the meandering river sand body, the remaining oil is rich in lateral accretion interbeds due to the occlusion of the lateral accretion interbed [15]. |

| Rhythm type | The rhythm distribution of thick reservoirs is complex, and the remaining oil is rich under the action of positive rhythm, reverse rhythm and compound rhythm [81]. | |

| Gravity type | Due to the influence of gravity, the degree of water flooding in the lower part of the thick reservoir is much higher than that in the upper part, and the remaining oil is rich in the upper part [82]. |

| Reservior | Sand Body Type | Injection–Production Imperfect Type (%) | Occlusion Type (%) | Rhythm Type (%) | Gravity Type (%) | |||

|---|---|---|---|---|---|---|---|---|

| Interwell Retention Type | Well Pattern Uncontrolled Type | Abandoned/Braided Channel | Interfluvial Sand Body | In-layer Interlayer | ||||

| BB Reservior | Meandering river | 3.0 | 6.0 | 22.0 | 11.0 | 13.0 | 21.6 | 23.4 |

| Braided river | 6.0 | 7.0 | 20.0 | 6.0 | 2.0 | 28.3 | 30.7 | |

| BE Reservior | Meandering river | 6.0 | 8.0 | 10.0 | 15.0 | 19.0 | 16.8 | 25.2 |

| Braided river | 11.0 | 9.0 | 12.0 | 10.0 | 3.0 | 22.0 | 33.0 | |

| NS Reservior | Meandering river | 2.0 | 6.0 | 13.0 | 14.0 | 18.0 | 9.4 | 37.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, H.; Bai, Z.; Guo, H.; Yang, K.; Guo, C.; Liu, M.; Liang, L.; Song, K. Remaining Oil Distribution Law and Development Potential Analysis after Polymer Flooding Based on Reservoir Architecture in Daqing Oilfield, China. Polymers 2023, 15, 2137. https://doi.org/10.3390/polym15092137

Fu H, Bai Z, Guo H, Yang K, Guo C, Liu M, Liang L, Song K. Remaining Oil Distribution Law and Development Potential Analysis after Polymer Flooding Based on Reservoir Architecture in Daqing Oilfield, China. Polymers. 2023; 15(9):2137. https://doi.org/10.3390/polym15092137

Chicago/Turabian StyleFu, Hongtao, Zhenqiang Bai, Hu Guo, Kena Yang, Chunping Guo, Mingxi Liu, Lihao Liang, and Kaoping Song. 2023. "Remaining Oil Distribution Law and Development Potential Analysis after Polymer Flooding Based on Reservoir Architecture in Daqing Oilfield, China" Polymers 15, no. 9: 2137. https://doi.org/10.3390/polym15092137

APA StyleFu, H., Bai, Z., Guo, H., Yang, K., Guo, C., Liu, M., Liang, L., & Song, K. (2023). Remaining Oil Distribution Law and Development Potential Analysis after Polymer Flooding Based on Reservoir Architecture in Daqing Oilfield, China. Polymers, 15(9), 2137. https://doi.org/10.3390/polym15092137