Influence of Thermal Aging on Space Charge Characteristics and Electrical Conduction Behavior of Cross-Linked Polyethylene Cable Insulation

Abstract

1. Introduction

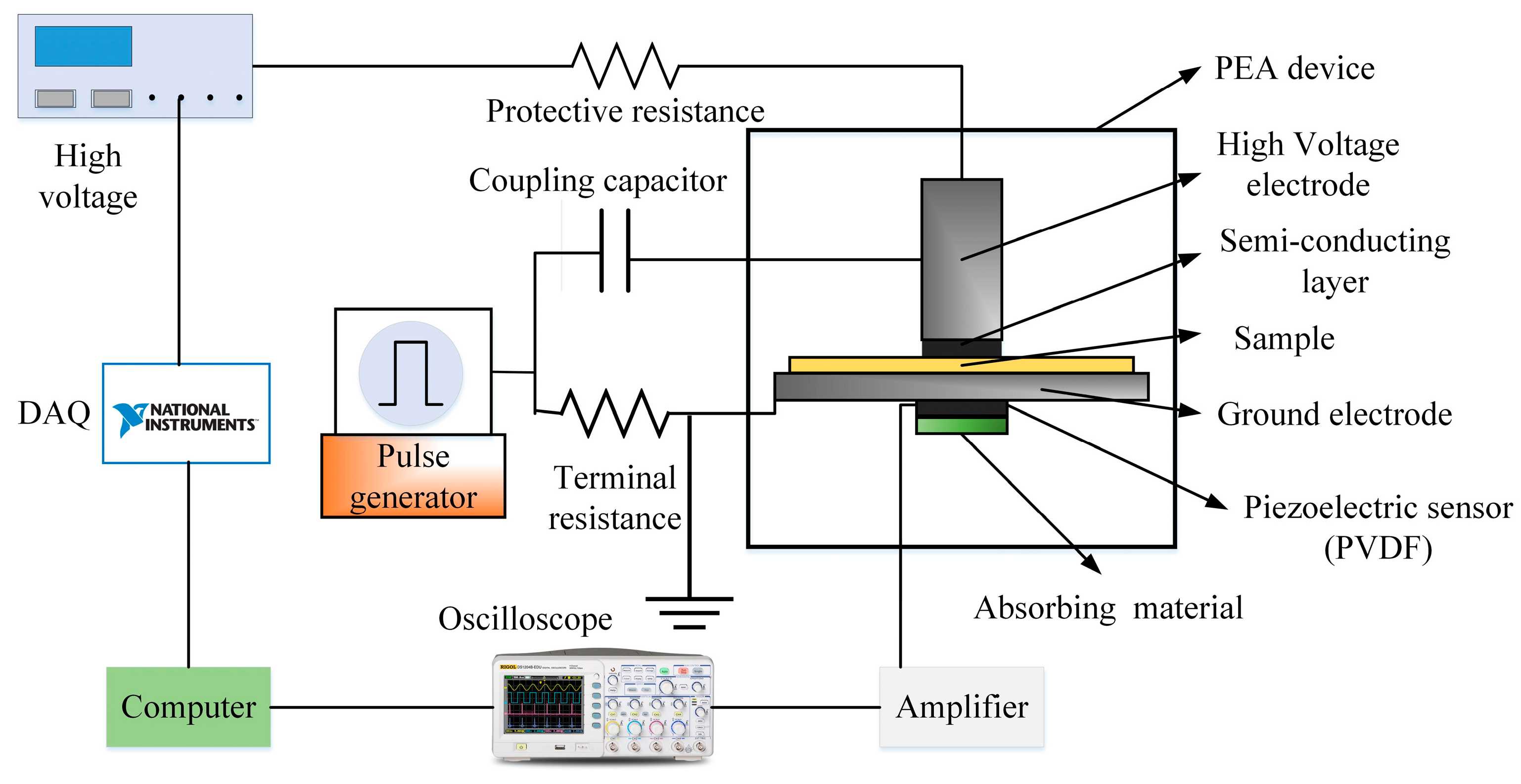

2. Materials and Methods

2.1. Sample Preparation

2.2. Thermal Aging Experimental Setup

2.3. Characterization of Materials

3. Results and Discussions

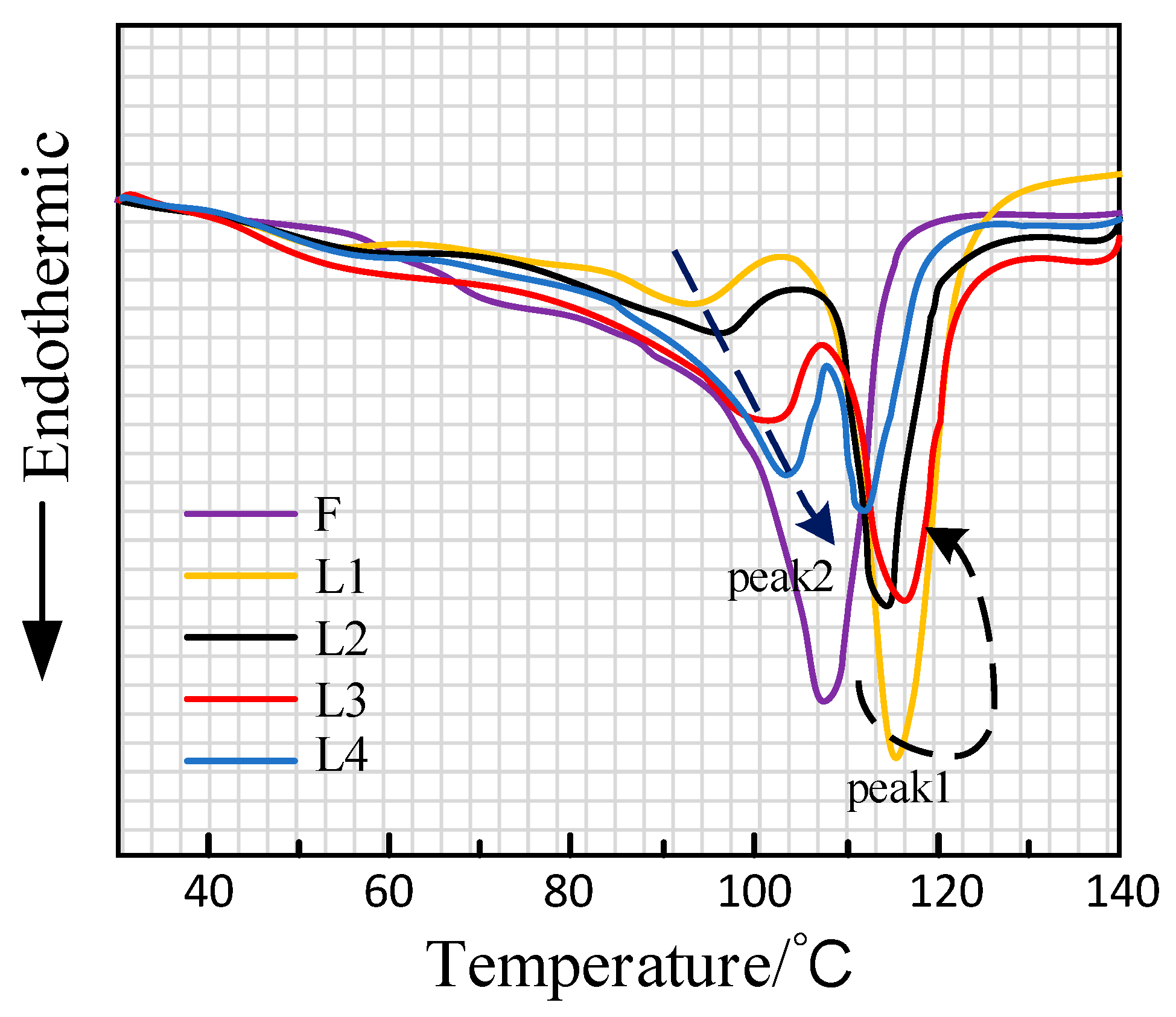

3.1. DSC and SEM Analysis

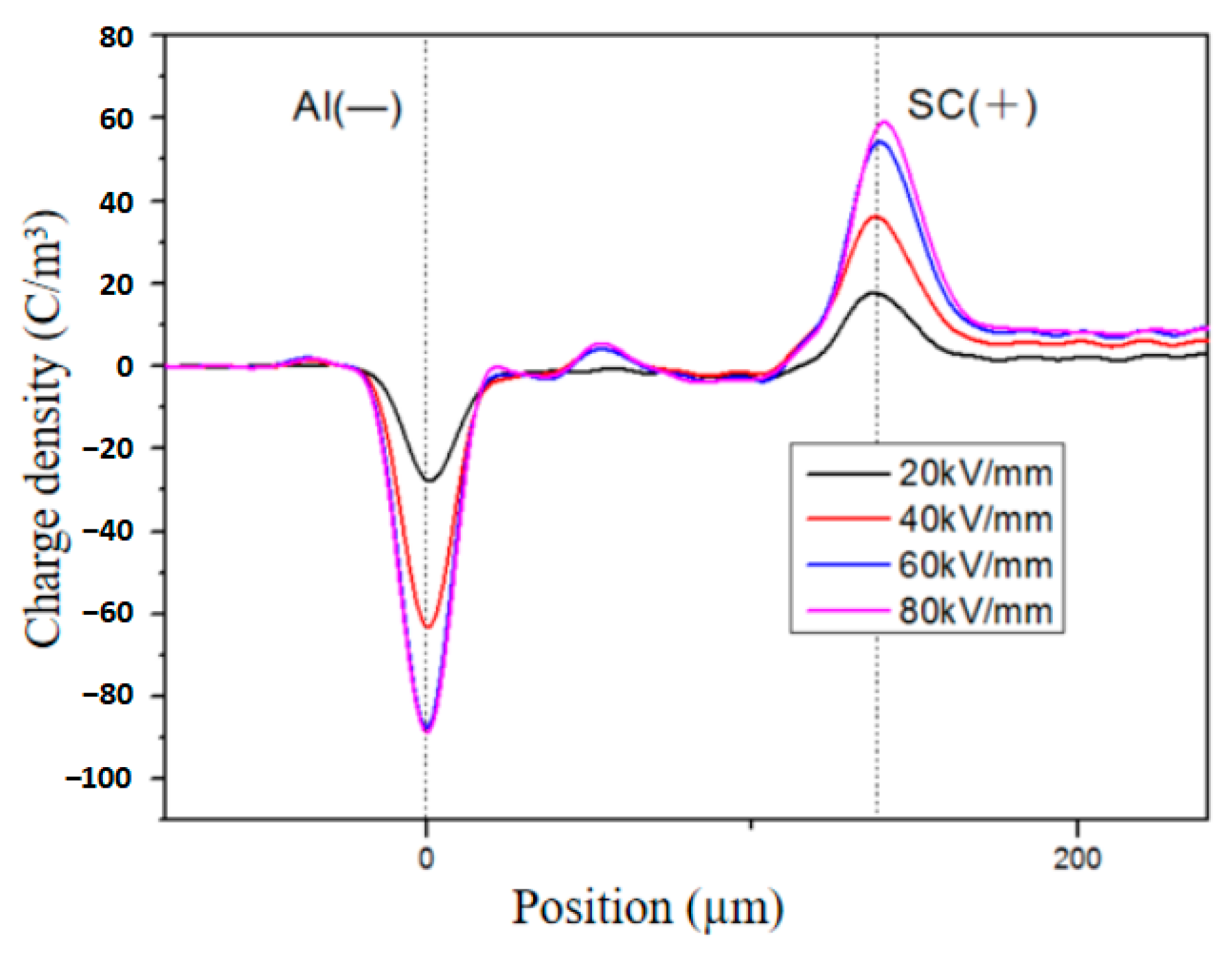

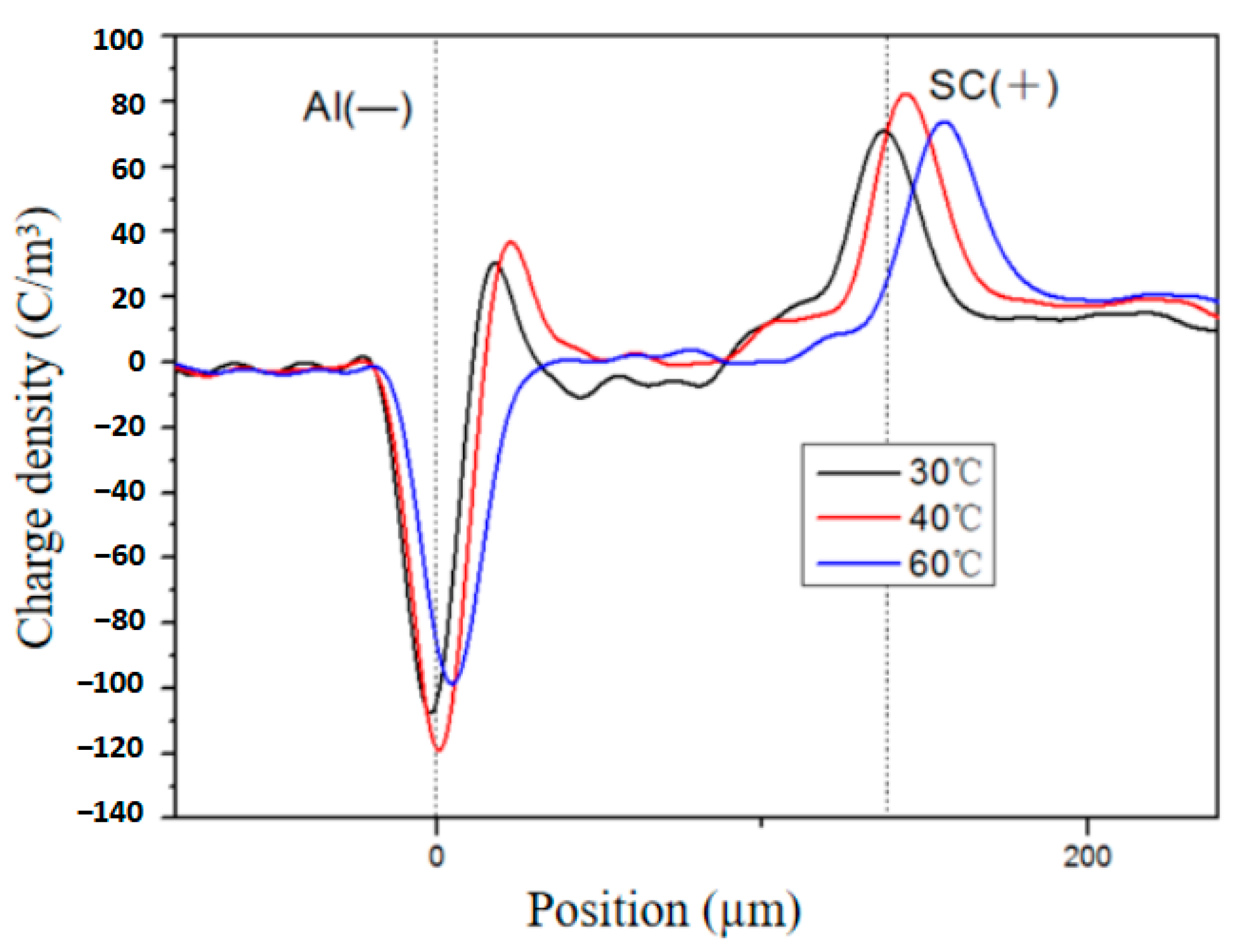

3.2. Space Charge Distribution Characteristics

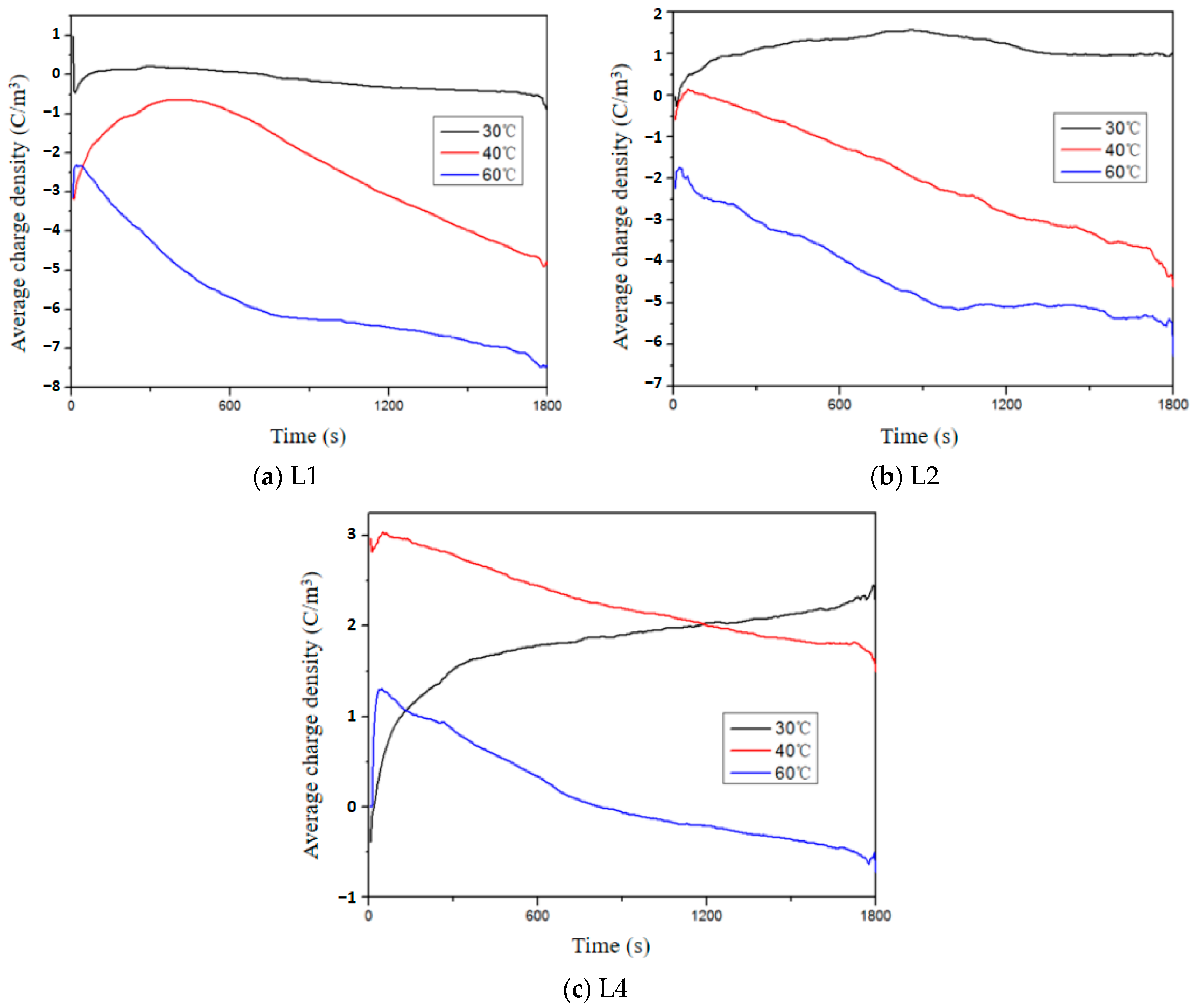

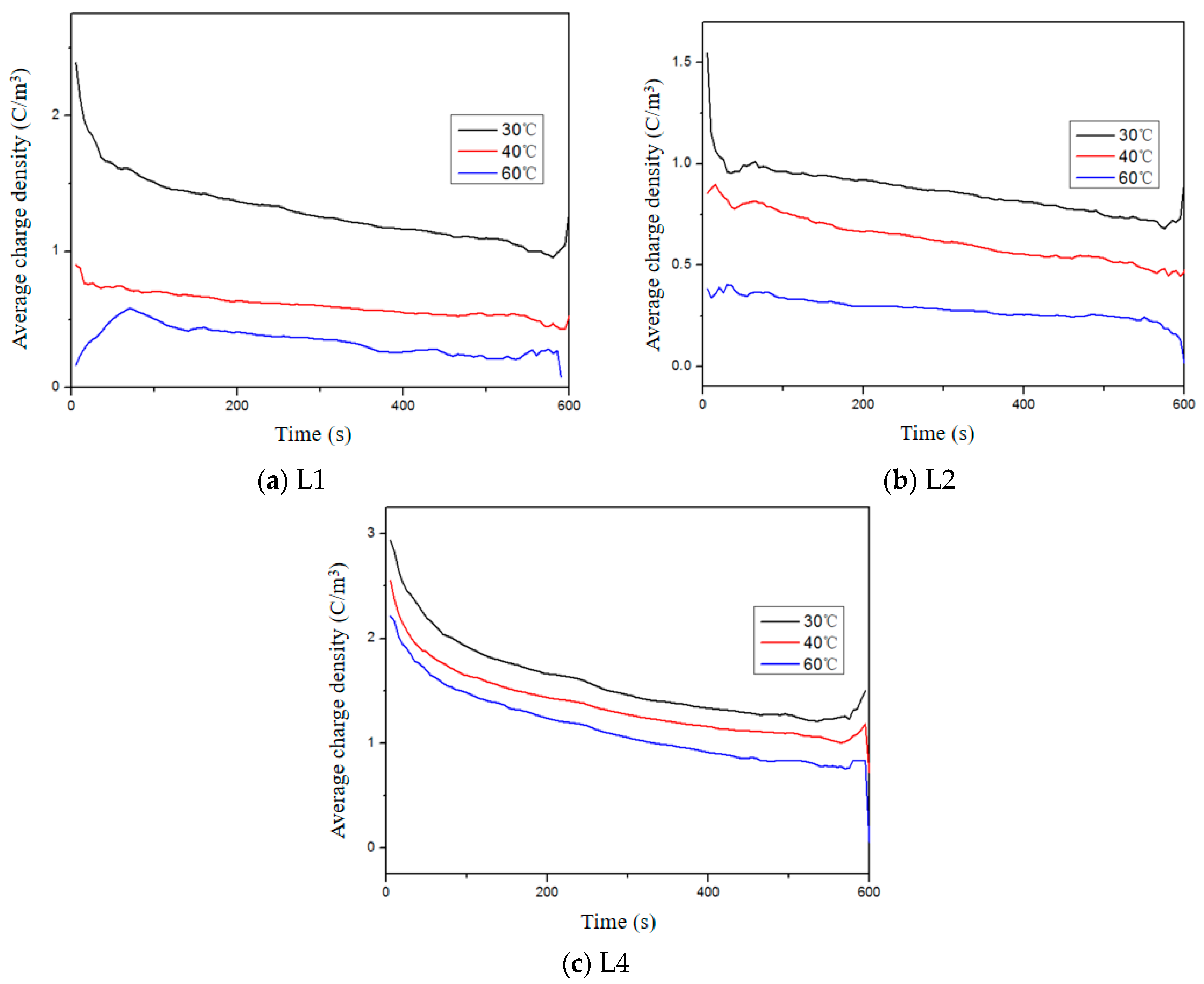

3.3. Space Charge Accumulation and Dissipation Characteristics of Thermally Aged XLPE

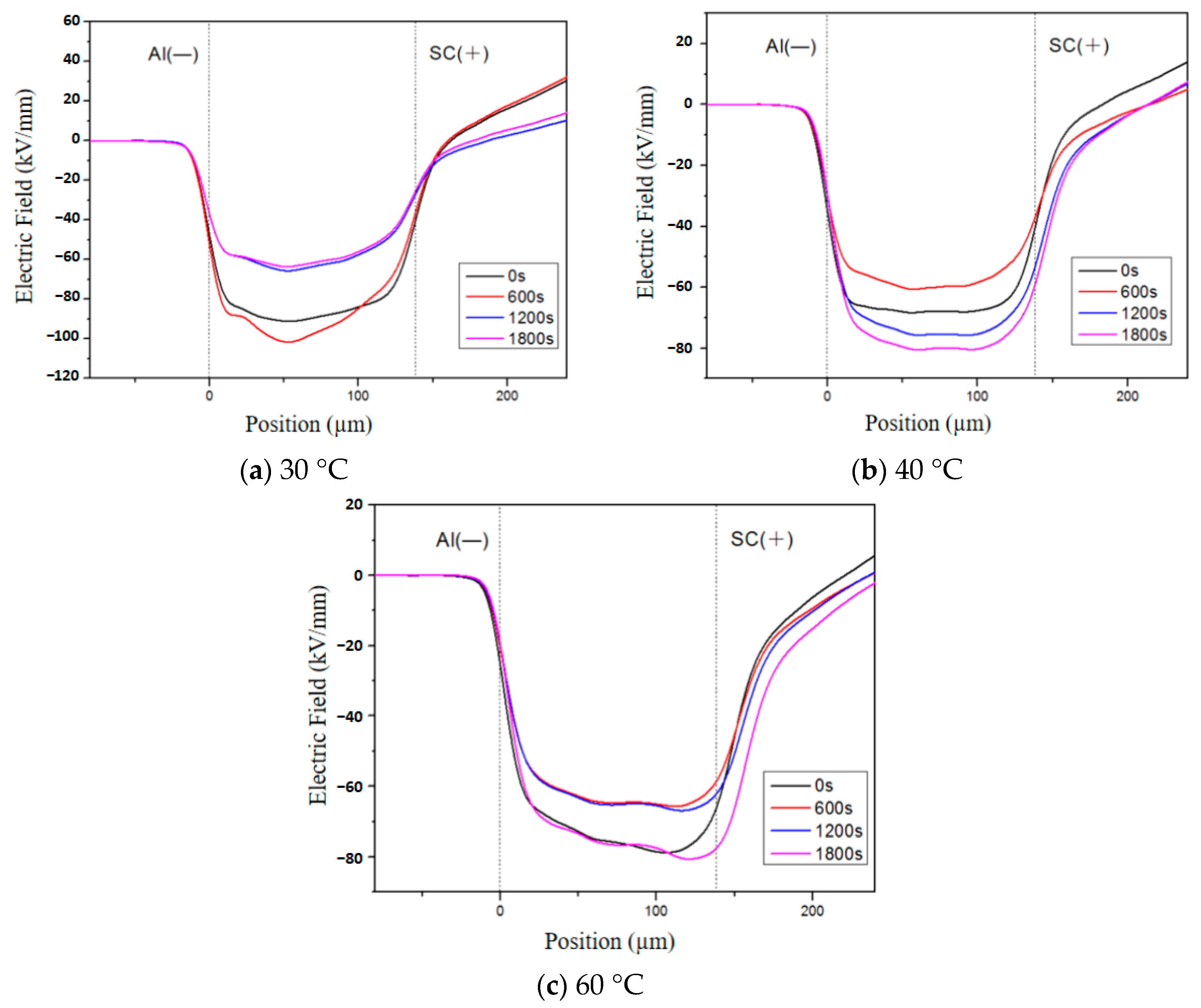

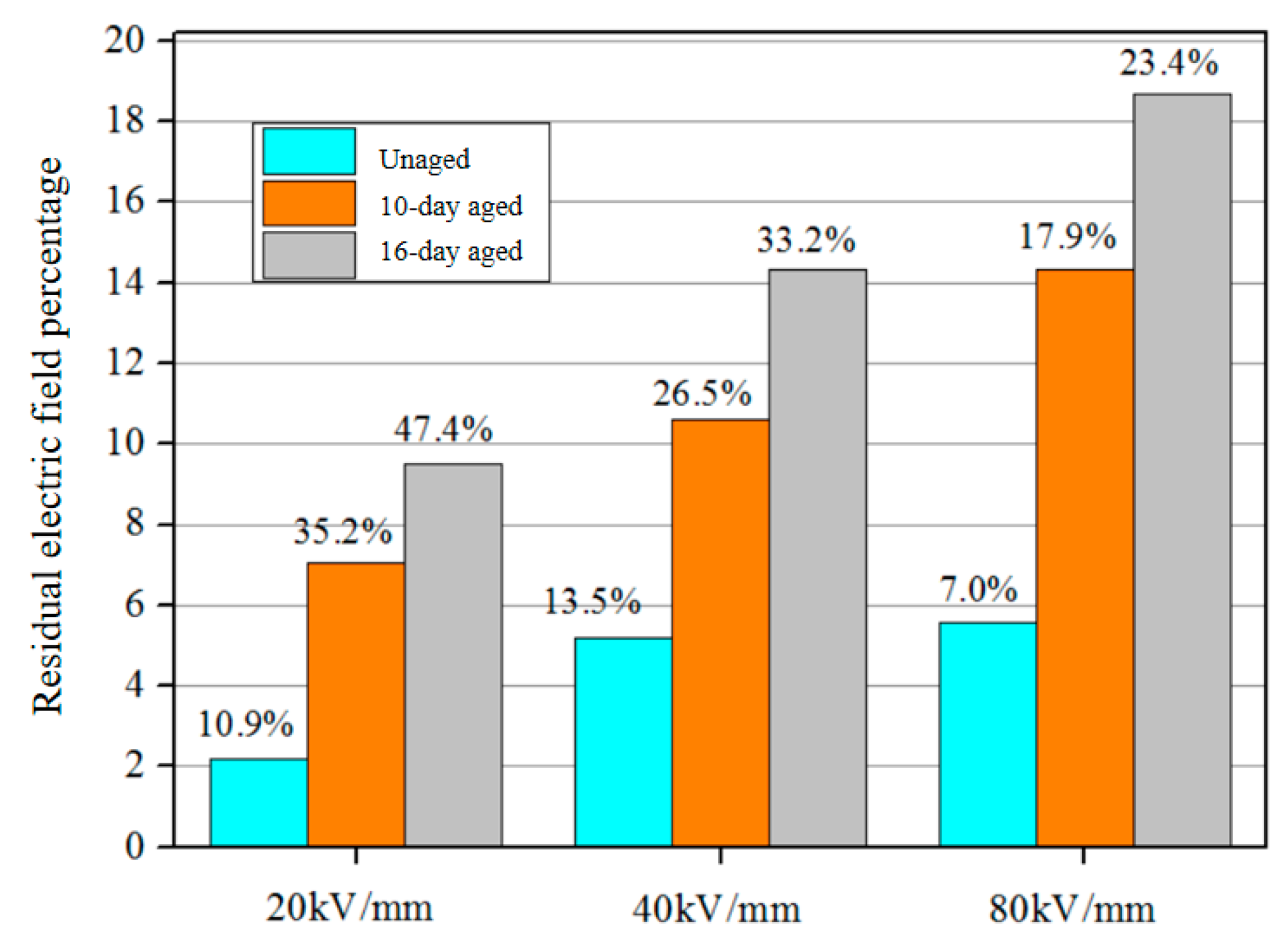

3.4. Electric Field Distribution Characteristics of Thermally Aged XLPE

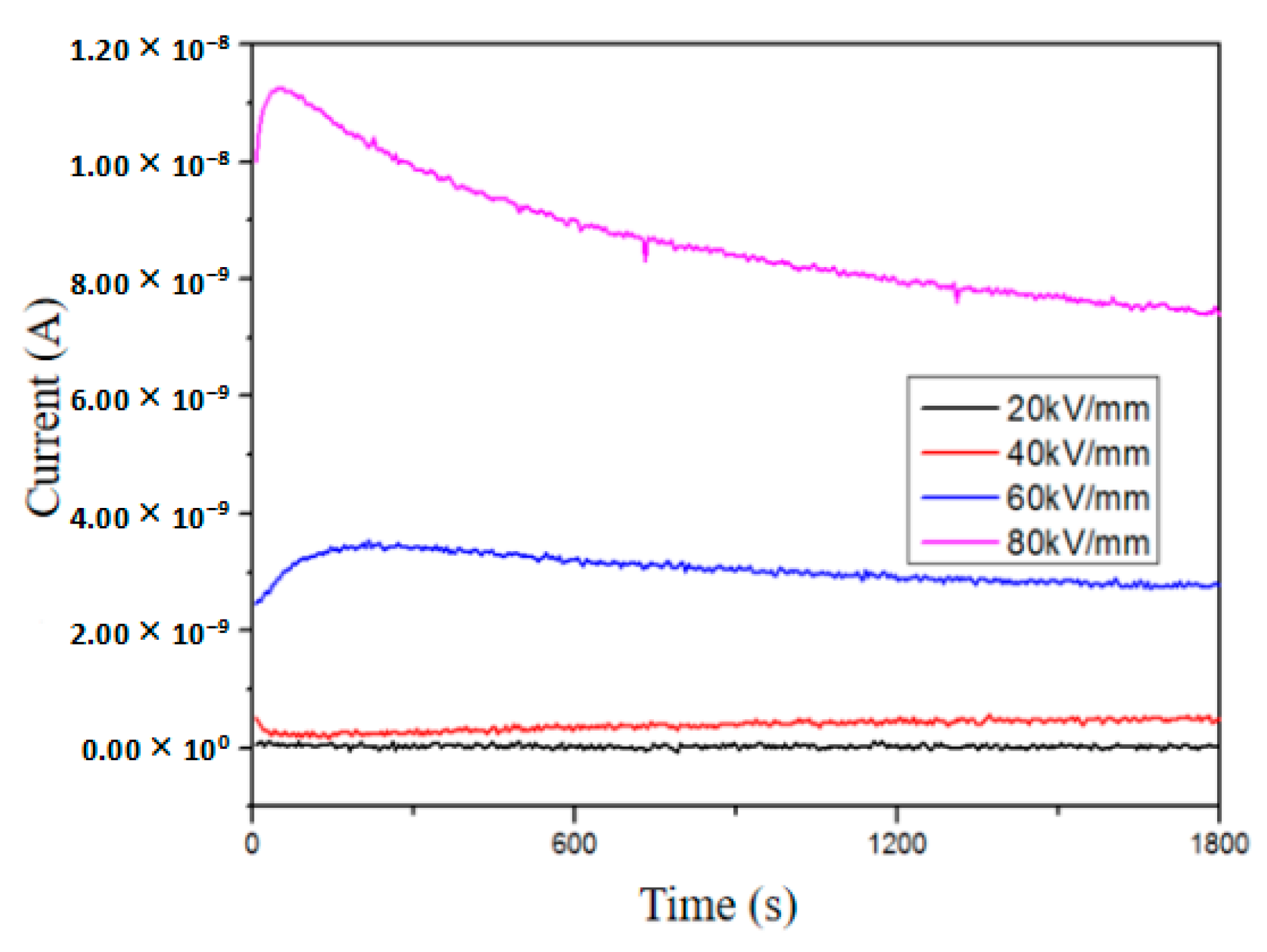

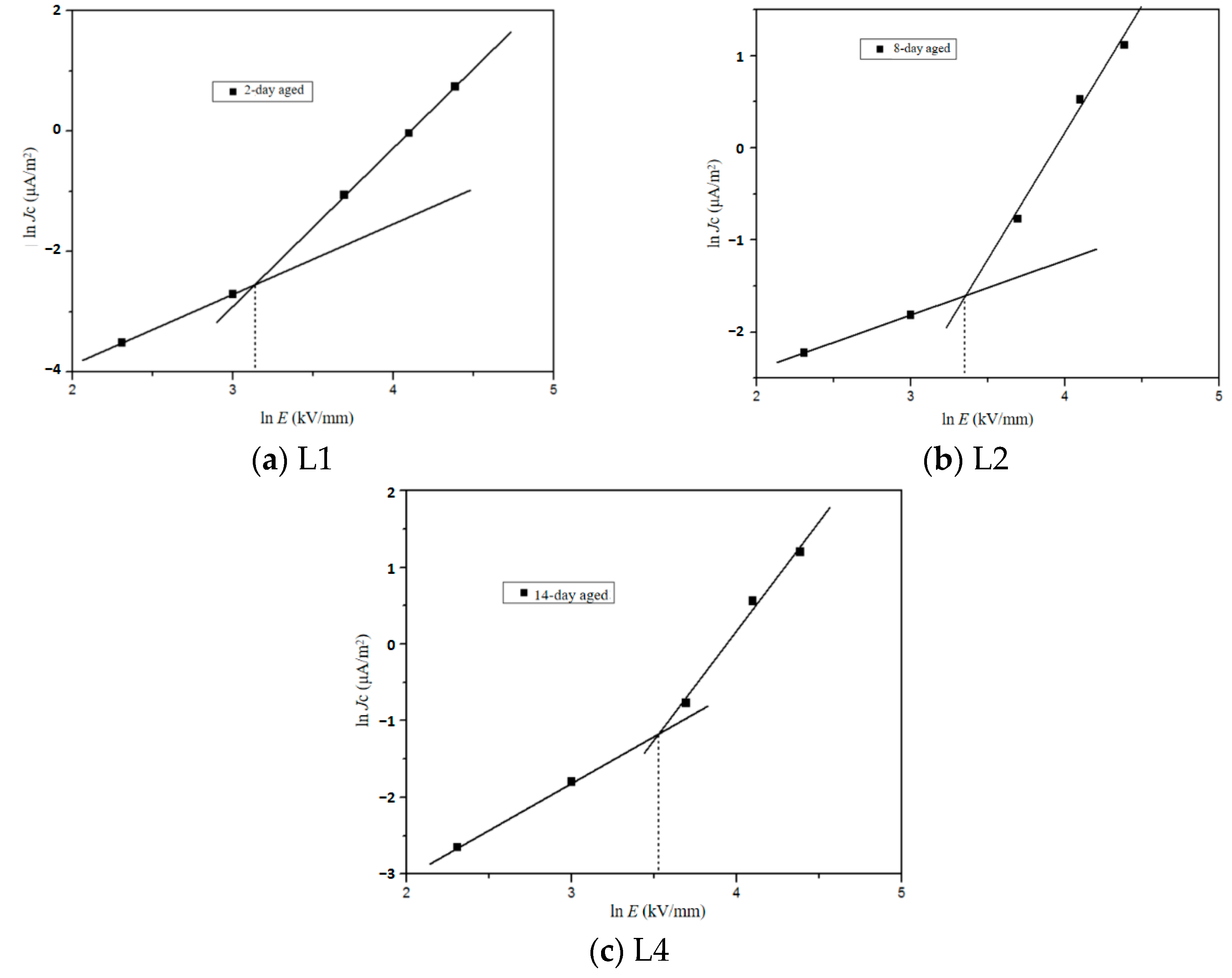

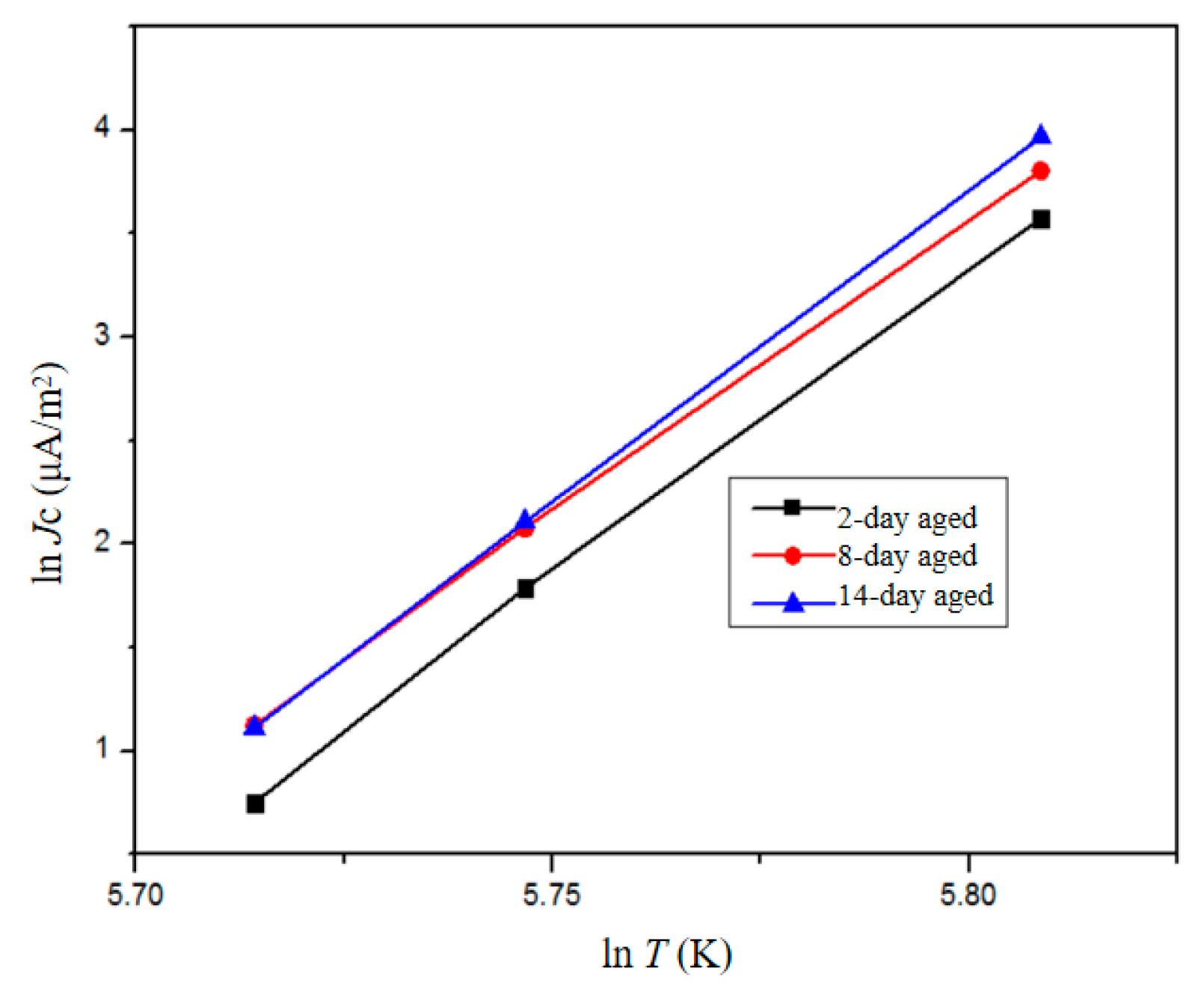

3.5. Electrical Conduction Current Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, G.; Hao, M.; Xu, Z.; Vaughan, A.; Cao, J.; Wang, H. Review of High Voltage Direct Current Cables. CSEE J. Power Energy Syst. 2015, 1, 9–21. [Google Scholar] [CrossRef]

- Du, B.X.; Han, C.; Li, J.; Li, Z. Effect of Voltage Stabilizers on the Space Charge Behavior of XLPE for HVDC Cable Application. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 34–42. [Google Scholar] [CrossRef]

- Adnan, M.; Abdul-Malek, Z.; Lau, K.Y.; Tahir, M. Polypropylene-Based Nanocomposites for HVDC Cable Insulation. IET Nanodielect. 2021, 4, 84–97. [Google Scholar] [CrossRef]

- Fothergill, J.C.; Dodd, S.J.; Dissado, L.A.; Liu, T.; Nilsson, U.H. The Measurement of Very Low Conductivity and Dielectric Loss in XLPE Cables: A Possible Method to Detect Degradation Due to Thermal Aging. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1544–1553. [Google Scholar] [CrossRef]

- Fikri, M.; Abdul-Malek, Z. Partial Discharge Diagnosis and Remaining Useful Lifetime in XLPE Extruded Power Cables under DC Voltage: A Review. Electr. Eng. 2023, 105, 4195–4212. [Google Scholar] [CrossRef]

- Chandrasekar, S.; Purushotham, S.; Montanari, G.C. Investigation of Electrical Tree Growth Characteristics in XLPE Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 558–564. [Google Scholar] [CrossRef]

- Li, J.; Zhao, X.; Yin, G.; Li, S.; Zhao, J.; Ouyang, B. The Effect of Accelerated Water Tree Ageing on the Properties of XLPE Cable Insulation. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1562–1569. [Google Scholar] [CrossRef]

- Rouillon, C.; Bussiere, P.-O.; Desnoux, E.; Collin, S.; Vial, C.; Therias, S.; Gardette, J.-L. Is Carbonyl Index a Quantitative Probe to Monitor Polypropylene Photodegradation? Polym. Degrad. Stab. 2016, 128, 200–208. [Google Scholar] [CrossRef]

- Zuo, P.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Effect of Thermal Aging on Crystallization Behaviors and Dynamic Mechanical Properties of Glass Fiber Reinforced Polyphenylene Sulfide (PPS/GF) Composites. J. Polym. Res. 2020, 27, 77. [Google Scholar] [CrossRef]

- Vyazovkin, S. Activation Energies and Temperature Dependencies of the Rates of Crystallization and Melting of Polymers. Polymers 2020, 12, 1070. [Google Scholar] [CrossRef]

- Meng, F.-B.; Chen, X.; Dai, C.; Zhang, M.; Paramane, A.; Zheng, L.; Tanaka, Y. Effect of Thermal Ageing on Physico-Chemical and Electrical Properties of EHVDC XLPE Cable Insulation. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1012–1019. [Google Scholar] [CrossRef]

- Montanari, G.C. Bringing an Insulation to Failure: The Role of Space Charge. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 339–364. [Google Scholar] [CrossRef]

- Dissado, L.A.; Mazzanti, G.; Montanari, G.C. Proposal of a Space-Charge Life Model for Electrical Polymeric Insulation Aged under AC Voltage. In Proceedings of the Conference Record of the 1998 IEEE International Symposium on Electrical Insulation (Cat. No.98CH36239), Arlington, VA, USA, 7–10 June 1998; Volume 2, pp. 595–598. [Google Scholar]

- Dissado, L.A.; Mazzanti, G.; Montanari, G.C. The Role of Trapped Space Charges in the Electrical Aging of Insulating Materials. IEEE Trans. Dielectr. Electr. Insul. 1997, 4, 496–506. [Google Scholar] [CrossRef]

- Lewis, T.J.; Llewellyn, J.P.; van der Sluijs, M.J.; Freestone, J.; Hampton, R.N. A New Model for Electrical Ageing and Breakdown in Dielectrics. In Proceedings of the Seventh International Conference on Dielectric Materials, Measurements and Applications (Conf. Publ. No. 430), Bath, UK, 23–26 September 1996; pp. 220–224. [Google Scholar]

- Parpal, J.-L.; Crine, J.-P.; Dang, C. Electrical Aging of Extruded Dielectric Cables. A Physical Model. IEEE Trans. Dielectr. Electr. Insul. 1997, 4, 197–209. [Google Scholar] [CrossRef]

- Zhang, Y.; Hou, Z.; Wu, K.; Wang, S.; Li, J.; Li, S. Influence of Oxygen Diffusion on Thermal Ageing of Cross-Linked Polyethylene Cable Insulation. Materials 2020, 13, 2056. [Google Scholar] [CrossRef]

- Huang, B.; Wang, W.; Li, S.; Li, X. Study on Dynamic Charge Characteristics of Thermal Aging XLPE Based on Direct Current Integral Charge Technique. J. Electr. Eng. 2021, 16, 25–32. [Google Scholar]

- Dissado, L.; Mazzanti, G.; Montanari, G.C. A New Thermo-Electrical Life Model Based on Space-Charge Trapping. In Proceedings of the Conference Record of the 1996 IEEE International Symposium on Electrical Insulation, Arlington, VA, USA, 7–10 June 1998; pp. 642–645. [Google Scholar]

- Miceli, M.; Carvelli, V.; Drissi-Habti, M. Modelling Electro-Mechanical Behaviour of an XLPE Insulation Layer for Hi-Voltage Composite Power Cables: Effect of Voids on Onset of Coalescence. Energies 2023, 16, 4620. [Google Scholar] [CrossRef]

- Zhang, Q.; Drissi-Habti, M. Electric Cable Insulator Damage Monitoring by Lasso Regression. Machines 2024, 12, 50. [Google Scholar] [CrossRef]

- Wang, W.; Lv, J.; Feng, Y.; Li, X.; Li, S. Intelligent Model Prediction of Fluctuant Increase of Maximum Electric Field in XLPE Insulation Using Long Short-Term Memory Network Algorithm. High Volt. 2022, 2, 12242. [Google Scholar] [CrossRef]

- Wang, W.; Li, S.; Tanaka, Y.; Takada, T. Interfacial Charge Dynamics of Cross-Linked Polyethylene/Ethylene-Propylene-Diene Dual Dielectric Polymer as Revealed by Energy Band Structure. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1755–1762. [Google Scholar] [CrossRef]

- Hu, L.; Wang, W.; Yu, S.; Ma, D.; Lv, J.; Zhong, Y.; Li, S.; Tanaka, Y.; Takada, T. Interface Charge Characteristics in Polymer Dielectric Contacts: Analysis of Acoustic Approach and Probe Microscopy. Adv. Mater. Interfaces 2023, 10, 2300087. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, Y.; Mo, Y.; Zhou, Z.; Sha, Y.; Lu, Z.; Cheng, Z. Dielectric Property and Charge Evolution Behavior in Thermally Aged Polyimide Films. Polym. Degrad. Stab. 2018, 156, 292–300. [Google Scholar] [CrossRef]

- Xu, R.R.; Du, B.X.; Xiao, M.; Li, J.; Liu, H.L.; Ran, Z.Y.; Xing, J.W. Dielectric Properties Dependent on Crystalline Morphology of PP Film for HVDC Capacitors Application. Polymer 2021, 213, 123204. [Google Scholar] [CrossRef]

- Liu, P.; Xie, Z.; Pang, X.; Xu, T.; Zhang, S.; Morshuis, P.H.F.; Li, H.; Peng, Z. Space Charge Behavior in Epoxy-Based Dielectrics: Progress and Perspective. Adv. Electron. Mater. 2022, 8, 2200259. [Google Scholar] [CrossRef]

- Ren, H.; Li, Q.; Tanaka, Y.; Miyake, H.; Gao, H.; Wang, Z. Frequency and Temperature-Dependent Space Charge Characteristics of a Solid Polymer under Unipolar Electrical Stresses of Different Waveforms. Polymers 2021, 13, 3401. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Wu, K.; Peng, Z.R.; Cheng, Y.H.; Tu, D.M. Space Charge Measurement in LPDE Films under Temperature Gradient and DC Stress. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1796–1805. [Google Scholar] [CrossRef]

- Gao, J.; Wu, K.; Xie, Z.; Li, J.; Li, S. Constructing Interfacial Barrier from Tribo-Positive Shell Microcapsules to Suppress Space Charge in Thermochromic Phase Change Composites for Smart Electronics. Compos. Sci. Technol. 2023, 244, 110291. [Google Scholar] [CrossRef]

- Zhou, G.; Yin, Y.; Zhu, X.; Wu, J. Space Charge Behavior in Oil-Impregnated Paper Insulation Under Sinusoidal Electric Field with Wide Frequency Range. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 127–136. [Google Scholar] [CrossRef]

- Li, S.; Xie, D.; Lei, Q. Understanding Insulation Failure of Nanodielectrics: Tailoring Carrier Energy. High Volt. 2020, 5, 643–649. [Google Scholar] [CrossRef]

- Li, H.; Chang, B.S.; Kim, H.; Xie, Z.; Lainé, A.; Ma, L.; Xu, T.; Yang, C.; Kwon, J.; Shelton, S.W.; et al. High-Performing Polysulfate Dielectrics for Electrostatic Energy Storage under Harsh Conditions. Joule 2023, 7, 95–111. [Google Scholar] [CrossRef]

- Gao, J.; Yang, K.; Wu, K.; Li, J.; Yin, G.; Chen, T. Anomalous Temperature-Dependent Dielectric Performance of Thermochromic RTV Composite: Role of Phase Transition. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 485–492. [Google Scholar] [CrossRef]

- Kao, K.C. Dielectric Phenomena in Solids; Elsevier: Amsterdam, The Netherlands, 2004; ISBN 0-08-047016-5. [Google Scholar]

- Montanari, G.C.; Mazzanti, G.; Palmieri, F.; Motori, A.; Perego, G.; Serra, S. Space-Charge Trapping and Conduction in LDPE, HDPE and XLPE. J. Phys. D 2001, 34, 2902. [Google Scholar] [CrossRef]

| Sample Conditions | Numbers |

|---|---|

| Unaged XLPE | F |

| Aged for 4 days | L1 |

| Aged for 10 days | L2 |

| Aged for 12 days | L3 |

| Aged for 14 days | L4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Li, R.; Hu, L.; Wang, W. Influence of Thermal Aging on Space Charge Characteristics and Electrical Conduction Behavior of Cross-Linked Polyethylene Cable Insulation. Polymers 2024, 16, 1600. https://doi.org/10.3390/polym16111600

Yang J, Li R, Hu L, Wang W. Influence of Thermal Aging on Space Charge Characteristics and Electrical Conduction Behavior of Cross-Linked Polyethylene Cable Insulation. Polymers. 2024; 16(11):1600. https://doi.org/10.3390/polym16111600

Chicago/Turabian StyleYang, Jie, Ruizhe Li, Leiyu Hu, and Weiwang Wang. 2024. "Influence of Thermal Aging on Space Charge Characteristics and Electrical Conduction Behavior of Cross-Linked Polyethylene Cable Insulation" Polymers 16, no. 11: 1600. https://doi.org/10.3390/polym16111600

APA StyleYang, J., Li, R., Hu, L., & Wang, W. (2024). Influence of Thermal Aging on Space Charge Characteristics and Electrical Conduction Behavior of Cross-Linked Polyethylene Cable Insulation. Polymers, 16(11), 1600. https://doi.org/10.3390/polym16111600