Decay and Termite Resistance of Wood Modified by High-Temperature Vapour-Phase Acetylation (HTVPA), a Simultaneous Acetylation and Heat Treatment Modification Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

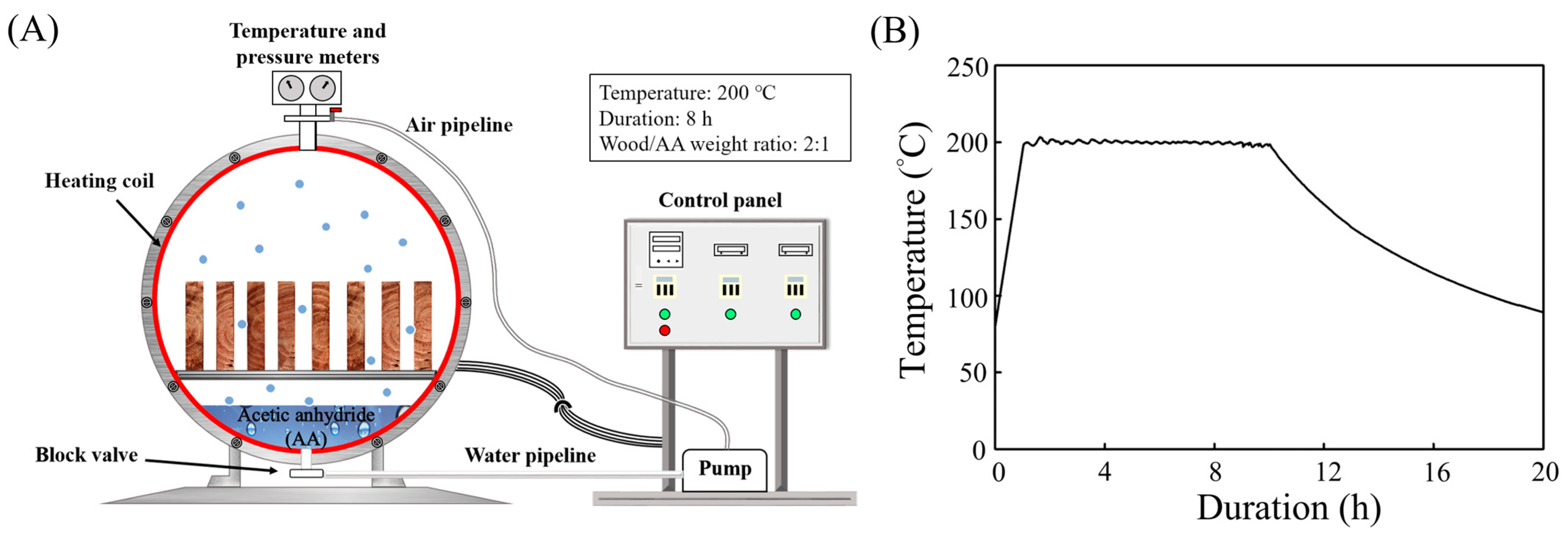

2.2. High-Temperature Vapour-Phase Acetylation (HTVPA) Treatment

2.3. Measurement of Specimen Dimension Changes after HTVPA Treatment

2.4. Density, Equilibrium Moisture Content (EMC), and Moisture Excluding Efficiency (MEE)

2.5. Volumetric Swelling and Anti-Swelling Efficiency (ASE)

2.6. Termite Resistance Test

2.7. Decay Resistance Test

2.8. Analysis of Variance

3. Results and Discussion

3.1. Impacts of Different WPGs on the Physical Properties of HTVPA-Modified Japanese Cedar Wood

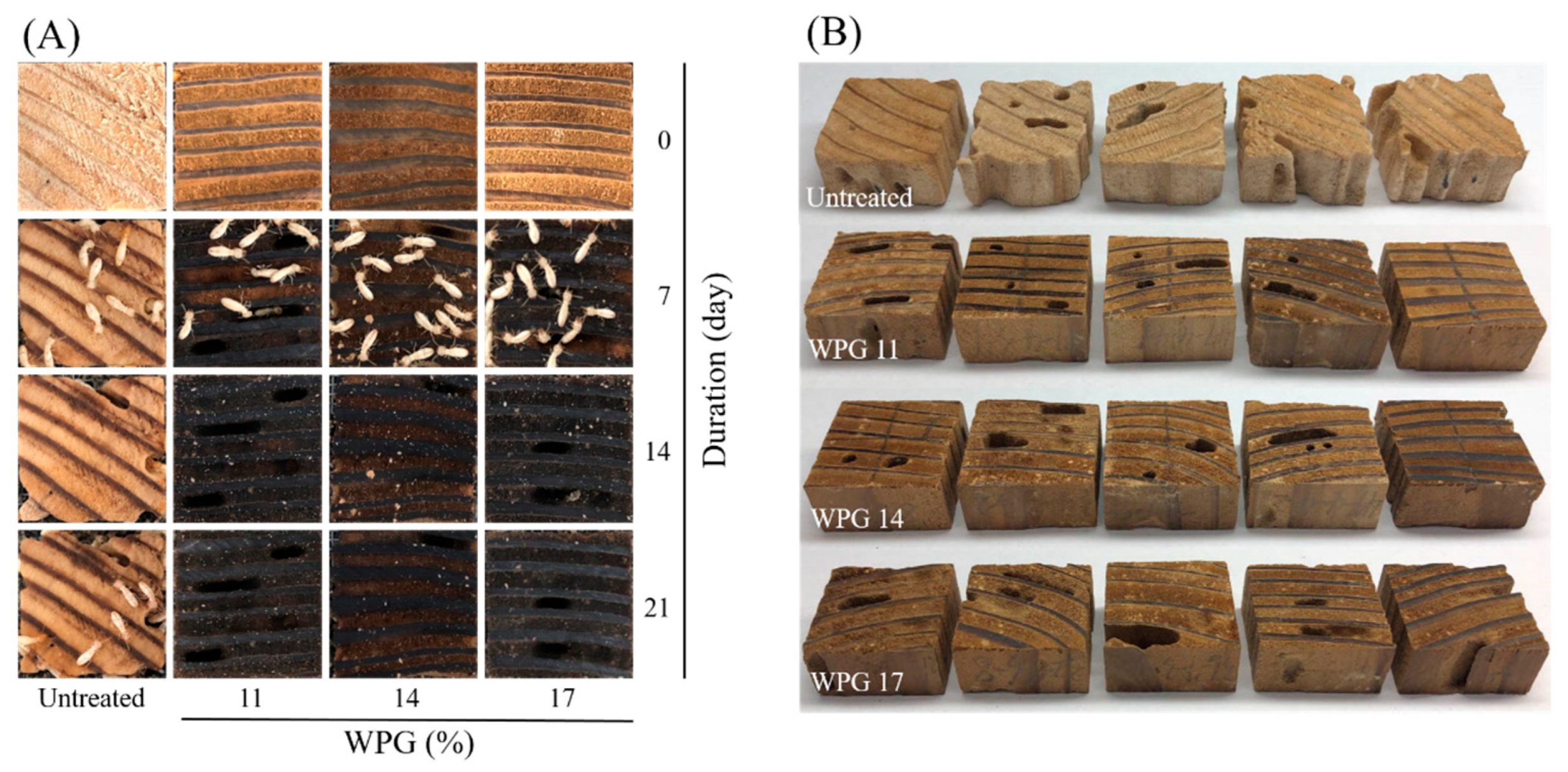

3.2. Impacts of Different WPGs on the Termite Resistance of HTVPA-Modified Japanese Cedar Wood

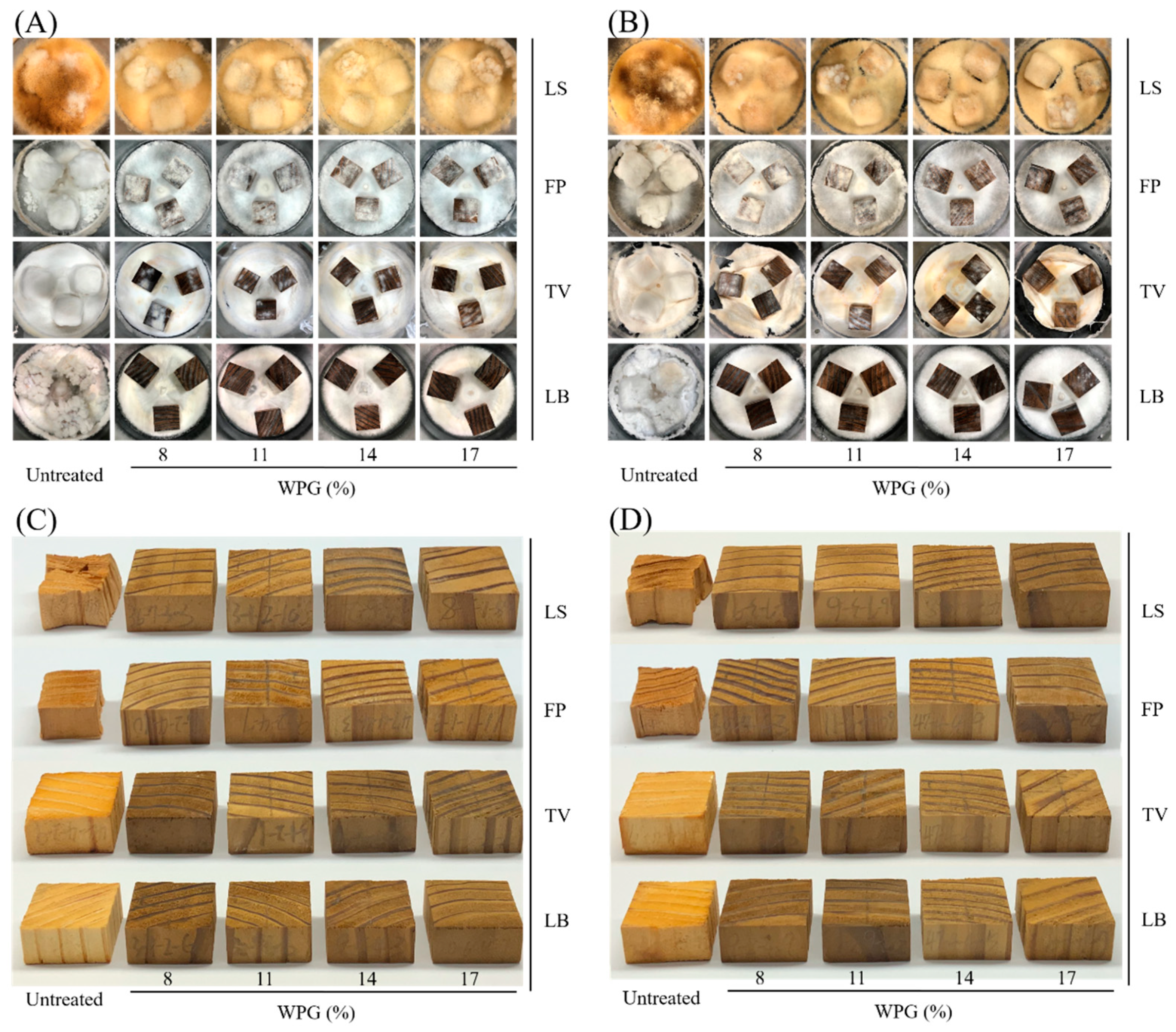

3.3. Impacts of Different WPGs on the Decay Resistance of HTVPA-Modified Japanese Cedar Wood

| Treatment † | MLt (%) | TM (%) | Reference |

|---|---|---|---|

| Untreated | 20.3 A ± 4.7 | 55 B ± 16 | Present study †† |

| HTVPA (WPG 11) | 6.6 B ± 0.3 | 95 A ± 5 | |

| HTVPA (WPG 14) | 7.3 B ± 0.4 | 99 A ± 2 | |

| HTVPA (WPG 17) | 3.2 B ± 0.8 | 100 A ± 0 | |

| ACQ | 0.87 ± 0.15 | 50.8 ± 4.6 | [37] |

| CuAz | 0.89 ± 0.18 | 63.8 ± 7.8 | |

| 210 °C/4 h | 24.7 ± 6.2 | 12.7 ± 3.1 | [36] |

| LPA (WPG 22.8) | 5 | 89 | [35] |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yasuda, Y.; Iki, T.; Takashima, Y.; Takahashi, M.; Hiraoka, Y.; Mishima, K. Genetic gains in wood property can be achieved by indirect selection and nondestructive measurements in full-sib families of Japanese cedar (Cryptomeria japonica. D. Don) plus tree clones. Ann. For. Sci. 2004, 78, 50. [Google Scholar] [CrossRef]

- Wang, S.Y.; Chen, J.H.; Hsu, K.P.; Lin, C.J.; Jane, M.C. Ring characteristics and compressive strength of Japanese cedar trees grown under different silvicultural treatments. Wood Fiber Sci. 2008, 40, 384–391. [Google Scholar]

- Chen, X.H.; Kim, C.S.; Kashiwagi, T.; Tebayashi, S.I.; Horiike, M. Antifeedant against Acusta despesta from the Japanese cedar, Cryptomeria japonica II. Biosci. Biotechnol. Biochem. 2001, 65, 1434–1437. [Google Scholar] [CrossRef]

- Cheng, S.S.; Lin, H.Y.; Chang, S.T. Chemical composition and antifungal activity of essential oil from different tissues of Japanese cedar (Cryptomeria japonica). J. Agric. Food Chem. 2005, 53, 614–619. [Google Scholar] [CrossRef] [PubMed]

- Kofujita, H.; Fujino, Y.; Ota, M.; Takahashi, K. Antifungal diterpenes from the bark of Cryptomeria japonica D. Don. Holzforschung 2006, 60, 20–23. [Google Scholar] [CrossRef]

- Matsushita, Y.; Hwang, Y.; Sugamoto, K.; Matsu, T. Antimicrobial activity of heartwood components of sugi (Cryptomeria japonica) against several fungi and bacteria. J. Wood Sci. 2006, 52, 552–556. [Google Scholar] [CrossRef]

- Cha, J.D.; Kim, J.Y. Essential oil from Cryptomeria japonica induces apoptosis in human oral epidermoid carcinoma cells via mitochondrial stress and activation of caspases. Molecules 2012, 17, 3890–3901. [Google Scholar] [CrossRef]

- Chang, H.T.; Chang, S.T. Bioactivity and characterization of exudates from Cryptomeria japonica bark. Wood Sci. Technol. 2014, 48, 831–840. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Jebrane, M.; Pichavant, F.; Sèbe, G. A comparative study on the acetylation of wood by reaction with vinyl acetate and acetic anhydride. Carbohyd. Polym. 2011, 83, 339–345. [Google Scholar] [CrossRef]

- Mantanis, G.I.; Lykids, C.; Papadopoulos, A.N. Durability of Accoya wood in ground stake testing after 10 years of exposure in Greece. Polymers 2020, 12, 1638. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes, 1st ed.; John Wiley & Sons Ltd: West Sussex, UK, 2006; p. 239. [Google Scholar]

- Imamura, Y.; Nishimoto, K. Some aspects on resistance of acetylated wood against biodeterioration. Wood Res. 1987, 74, 33–44. [Google Scholar]

- Feist, W.C.; Rowell, R.M.; Ellis, W.D. Moisture sorption and accelerated weathering of acetylated and methacrylated aspen. Wood Fiber Sci. 1991, 23, 128–136. [Google Scholar]

- Ohkoshi, M.; Kato, A.; Suzuki, K.; Hayashi, N.; Ishihara, M. Characterization of acetylated wood decayed by brown-rot and white-rot fungi. J. Wood Sci. 1999, 45, 69–75. [Google Scholar] [CrossRef]

- Li, J.Z.; Furuno, T.; Zhou, W.R.; Ren, Q.; Han, X.Z.; Zhao, J.P. Properties of acetylated wood prepared at low temperature in the presence of catalysts. J. Wood Chem. Technol. 2009, 29, 241–250. [Google Scholar] [CrossRef]

- Futemma, Y.; Obataya, E. Non-uniform reaction of solid wood in vapor-phase acetylation. J. Wood Sci. 2012, 58, 336–341. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Mori, M.; Koda, K.; Uraki, Y. Effect of vapor-phase surface acetylation of Japanese cedar wood on fungal degradation and dimensional stability. J. Wood Chem. Technol. 2019, 40, 1–14. [Google Scholar] [CrossRef]

- Wentzel, M.; Rolleri, A.; Pesenti, H.; Militz, H. Chemical analysis and cellulose crystallinity of thermally modified Eucalyptus nitens wood from open and closed reactor systems using FTIR and X-ray crystallography. Eur. J. Wood Wood Prod. 2019, 77, 517–525. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Boonstra, M.; Pizzi, A.; Tekely, P.; Militz, H. Characterisation of thermally modified wood: Molecular reasons for wood performance improvement. Eur. J. Wood Wood Prod. 1998, 56, 149–153. [Google Scholar] [CrossRef]

- Pétrissans, M.; Gérardin, P.; El bakali, I.; Serraj, M. Wettability of heat-treated wood. Holzforschung 2003, 57, 301–307. [Google Scholar] [CrossRef]

- Yildiz, S.; Gezer, E.D.; Yildiz, U.C. Mechanical and chemical behavior of spruce wood modified by heat. Build. Environ. 2006, 41, 1762–1766. [Google Scholar] [CrossRef]

- Kamdem, D.P.; Pizzi, A.; Jermannaud, A. Durability of heat-treated wood. Eur. J. Wood Wood Prod. 2002, 60, 1–6. [Google Scholar] [CrossRef]

- Gosselink, R.J.A.; Krosse, A.M.A.; van der Putten, J.C.; van der Kolk, J.C.; de Klerk-Engels, B.; van Dam, J.E.G. Wood preservation by low-temperature carbonization. Ind. Crop. Prod. 2004, 19, 3–12. [Google Scholar] [CrossRef]

- Kocaefe, D.; Shi, J.L.; Yang, D.Q.; Bouzara, M. Mechanical properties, dimensional stability, and mold resistance of heat-treated jack pine and aspen. For. Prod. J. 2008, 58, 88–93. [Google Scholar]

- Wang, Z.Y.; Hung, K.C.; Xu, J.W.; Liu, J.W.; Wu, Y.H.; Chang, W.S.; Wu, J.H. Physicomechanical properties of Japanese cedar wood modified by high-temperature vapour-phase acetylation (HTVPA), a simultaneous acetylation and heat treatment modification process. J. Ind. Eng. Chem. 2023, 134, 5271–5280. [Google Scholar] [CrossRef]

- CNS 14630; Structural Coniferous Sawn Lumber. Bureau of Standards, Metrology and Inspection: Taipei, Taiwan, 2017.

- CNS 452; Wood—Determination of Moisture Content for Physical and Mechanical Tests. Bureau of Standards, Metrology and Inspection: Taipei, Taiwan, 2013.

- CNS 14927; Wood—Determination of Volumetric Swelling. Bureau of Standards, Metrology and Inspection: Taipei, Taiwan, 2012.

- Islam, M.S.; Hamdan, S.; Rusop, M.; Rahman, M.R.; Ahmed, A.S.; Mohd Idrus, M.A.M. Dimensional stability and water repellent efficiency measurement of chemically modified tropical light hardwood. BioResources 2012, 7, 1221–1231. [Google Scholar] [CrossRef]

- CNS 15756; Wood—Test Methods for Determining Termite Resistance. Bureau of Standards, Metrology and Inspection: Taipei, Taiwan, 2014.

- CNS 6717; Qualitative Standards and Testing Methods of Wood Preservatives. Bureau of Standards, Metrology and Inspection: Taipei, Taiwan, 2011.

- Sun, B.; Chai, Y.; Liu, J.; Militz, H. Acetylation of plantation softwood without catalysts or solvents. Wood Res. 2019, 64, 799–810. [Google Scholar]

- Imamura, Y. My research for wood protection: Unresolved issues. Mokuzai Hozon 2020, 46, 232–241. (In Japanese) [Google Scholar] [CrossRef]

- Nagasawa, Y.; Kodachi, R.; Shibutani, S.; Habu, N. Decay and termite resistance of phthaloylated wood. Mokuzai Hozon 2008, 34, 13–22. (In Japanese) [Google Scholar] [CrossRef]

- Chen, Y.N.; Yang, T.H.; Lee, C.H. Effect of heat-treatment on biological durability of southern pine (Pinus spp.) and Japanese cedar (Cryptomeria japonica) wood. In Proceedings of the 68th Annual Meeting of the Japan Wood Research Society, Kyoto International Conference Center, Kyoto, Japan, 14–16 March 2018. [Google Scholar]

- Lin, L.D.; Chen, Y.F.; Wang, S.Y.; Tsai, M.J. Leachability, metal corrosion, and termite resistance of wood treated with copper-based preservative. Int. Biodeterior. Biodegrad. 2008, 63, 533–538. [Google Scholar] [CrossRef]

- Hosseinpourpia, R.; Mai, C. Mode of action of brown rot decay resistance of thermally modified wood: Resistance to Fenton’s reagent. Holzforschung 2016, 70, 691–697. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Houtman, C.J.; Hirth, K.; Lacher, S.; Lorenz, L.; Thybring, E.E.; Hunt, C.G. The effect of acetylation on iron uptake and diffusion in water saturated wood cell walls and implications for decay. Forests 2020, 11, 1121. [Google Scholar] [CrossRef]

- Lee, H.L.; Shiah, T.C.; Hsu, F.L.; Lin, S.J. Effects of new waterborne wood preservatives on the durability and thermal properties of wood. Taiwan J. For. Sci. 2005, 20, 139–156. [Google Scholar]

- Sakai, H.; Kakutani, T.; Tezuka, D.; Shigeyama, T.; Sugai, Y.; Shintani, T.; Yamaguchi, A. Decay resistance of wood and treated wood to 12 strains of fungi. Mokuzai Hozon 2020, 46, 196–201. (In Japanese) [Google Scholar] [CrossRef]

- Matsunaga, M.; Matsunaga, H.; Ishikawa, A.; Kobayashi, M.; Kanbayashi, T.; Kataoka, Y. Evaluation of decay resistance for acetylated sugi wood produced with supercritical carbon dioxide. Mokuzai Hozon 2020, 46, 20–29. (In Japanese) [Google Scholar] [CrossRef]

| Sample Code | WPG (%) | DC (%) | Density (g/cm3) | EMC (%) | MEE (%) | S65 (%) | ASE65 (%) | |

|---|---|---|---|---|---|---|---|---|

| Tangential | Radial | |||||||

| Untreated | – | – | – | 0.42 A ± 0.08 | 11.84 A ± 0.07 | – | 5.1 A ± 1.4 | – |

| WPG 8 | 7.0–9.0 | 2.9 C ± 0.1 | 1.8 B ± 0.1 | 0.48 A ± 0.05 | 4.02 B ± 0.26 | 66.0 B ± 2.2 | 1.3 B ± 0.1 | 74.6 B ± 2.2 |

| WPG 11 | 10.0–12.0 | 3.6 B ± 0.1 | 2.5 A ± 0.1 | 0.45 A ± 0.07 | 4.02 B ± 0.43 | 66.0 B ± 3.7 | 1.4 B ± 0.3 | 73.3 B ± 5.0 |

| WPG 14 | 13.0–15.0 | 4.4 A ± 0.2 | 2.6 A ± 0.3 | 0.44 A ± 0.06 | 3.82 B ± 0.35 | 67.8 B ± 3.0 | 1.2 B ± 0.2 | 77.2 B ± 4.5 |

| WPG 17 | 16.0–18.0 | 4.6 A ± 0.4 | 2.5 A ± 0.2 | 0.26 B ± 0.004 | 3.28 C ± 0.08 | 72.3 A ± 0.7 | 0.4 C ± 0.1 | 92.7 A ± 1.3 |

| Sample Code | ASE (%) | ||||

|---|---|---|---|---|---|

| Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 | Cycle 5 | |

| WPG 8 | 64.4 Ba ± 4.5 | 65.2 Ba ± 4.4 | 64.8 Ba ± 4.1 | 64.3 Ba ± 4.8 | 64.6 Ba ± 4.5 |

| WPG 11 | 66.3 Ba ± 6.5 | 70.1 Ba ± 6.2 | 66.9 Ba ± 6.5 | 65.5 Ba ± 7.4 | 65.7 Ba ± 7.3 |

| WPG 14 | 71.0 Ba ± 4.1 | 71.6 Ba ± 4.2 | 71.2 Ba ± 4.5 | 71.2 Ba ± 4.7 | 69.7 Ba ± 4.5 |

| WPG 17 | 89.0 Ab ± 1.3 | 90.6 Aa ± 0.8 | 89.2 Aab ± 0.5 | 89.8 Aab ± 0.8 | 87.5 Ac ± 0.5 |

| Sample Code | Periods (Weeks) | Brown Rot | White Rot | ||

|---|---|---|---|---|---|

| LS | FP | LB | TV | ||

| Untreated | 12 | 39.6 A ± 13.4 | 54.5 A ± 4.3 | 16.3 A ± 8.6 | 39.1 A ± 3.1 |

| WPG 8 | 0.9 B ± 0.7 | 0.3 B ± 0.5 | 0.3 B ± 0.1 | 0.1 B ± 0.1 | |

| WPG 11 | 0.7 B ± 0.6 | −0.2 B ± 0.2 | 0.3 B ± 0.1 | 0.2 B ± 0.2 | |

| WPG 14 | 0.2 B ± 0.2 | 0.0 B ± 0.2 | 0.3 B ± 0.2 | 0.1 B ± 0.2 | |

| WPG 17 | 0.3 B ± 0.4 | −0.2 B ± 0.2 | 0.3 B ± 0.1 | 0.1 B ± 0.5 | |

| Untreated | 24 | 48.5 A ± 2.7 | 57.9 A ± 2.2 | 19.7 A ± 14.7 | 39.0 A ± 7.6 |

| WPG 8 | 2.4 B ± 0.6 | −0.3 B ± 0.7 | 0.7 B ± 0.2 | 0.1 B ± 0.2 | |

| WPG 11 | 2.8 B ± 0.6 | −0.2 B ± 0.3 | 0.9 B ± 0.1 | 0.2 B ± 0.5 | |

| WPG 14 | 2.8 B ± 0.6 | −0.1 B ± 0.6 | 0.6 B ± 0.2 | 0.2 B ± 0.3 | |

| WPG 17 | 2.6 B ± 1.6 | −0.5 B ± 0.6 | 0.5 B ± 0.3 | 0.0 B ± 0.2 | |

| Treatment † | MLd (%) | Reference | |

|---|---|---|---|

| Brown Rot (FP) | White Rot (TV) | ||

| Untreated | 54.5 ± 4.3 | 39.1 ± 3.1 | Present study (adapted from Table 4) |

| HTVPA (WPG 8) | 0.3 ± 0.5 | 0.1 ± 0.1 | |

| HTVPA (WPG 11) | −0.2 ± 0.2 | 0.2 ± 0.2 | |

| HTVPA (WPG 14) | 0.0 ± 0.2 | 0.1 ± 0.2 | |

| HTVPA (WPG 17) | −0.2 ± 0.2 | 0.1 ± 0.5 | |

| CCA (WPG 12.8) | 0.25 | – | [40] |

| ACQ (WPG 7–8) | 2 | – | |

| BAAC | −1 | 2 | [41] |

| CuAz | −1 | 2 | |

| AZN | 0 | 2 | |

| AAC | 1 | 2 | |

| 210 °C/4 h | 0.75 ± 0.08 | 0.95 ± 0.13 | [36] |

| VPA (WPG 16) | −0.02 ± 0.11 | 0.33 ± 0.09 | [18] |

| LPA (WPG 20) | −0.44 ± 0.19 | 0.28 ± 1.11 | |

| CO2A (WPG 22) | 1 | – | [42] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.-Y.; Xu, J.-W.; Liu, J.-W.; Hung, K.-C.; Wu, T.-L.; Chang, W.-S.; Wu, J.-H. Decay and Termite Resistance of Wood Modified by High-Temperature Vapour-Phase Acetylation (HTVPA), a Simultaneous Acetylation and Heat Treatment Modification Process. Polymers 2024, 16, 1601. https://doi.org/10.3390/polym16111601

Wang Z-Y, Xu J-W, Liu J-W, Hung K-C, Wu T-L, Chang W-S, Wu J-H. Decay and Termite Resistance of Wood Modified by High-Temperature Vapour-Phase Acetylation (HTVPA), a Simultaneous Acetylation and Heat Treatment Modification Process. Polymers. 2024; 16(11):1601. https://doi.org/10.3390/polym16111601

Chicago/Turabian StyleWang, Zhong-Yao, Jin-Wei Xu, Jian-Wei Liu, Ke-Chang Hung, Tung-Lin Wu, Wen-Shao Chang, and Jyh-Horng Wu. 2024. "Decay and Termite Resistance of Wood Modified by High-Temperature Vapour-Phase Acetylation (HTVPA), a Simultaneous Acetylation and Heat Treatment Modification Process" Polymers 16, no. 11: 1601. https://doi.org/10.3390/polym16111601

APA StyleWang, Z.-Y., Xu, J.-W., Liu, J.-W., Hung, K.-C., Wu, T.-L., Chang, W.-S., & Wu, J.-H. (2024). Decay and Termite Resistance of Wood Modified by High-Temperature Vapour-Phase Acetylation (HTVPA), a Simultaneous Acetylation and Heat Treatment Modification Process. Polymers, 16(11), 1601. https://doi.org/10.3390/polym16111601