Structural Health Monitoring of Fiber Reinforced Composites Using Integrated a Linear Capacitance Based Sensor

Abstract

1. Introduction

2. Materials and Methods

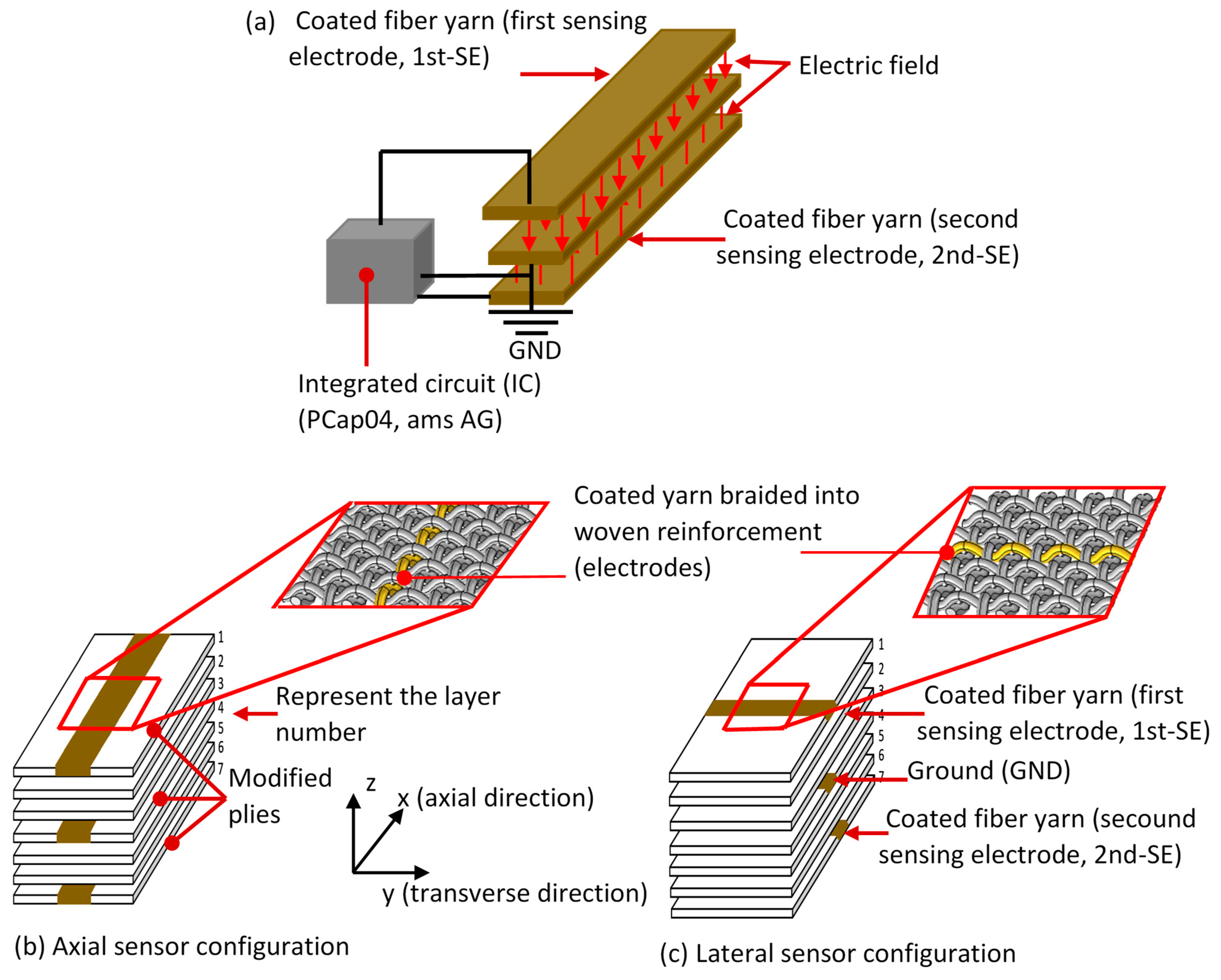

2.1. Working Principle of the Embedded Capacitive Sensor into FRP

- is the incremental change in capacitance value,

- is the initial measured capacitance,

- and are the measured strains in the axial and lateral directions obtained using strain gauge sensors.

2.2. Preparation of Coated Fibres Yarn (Electrodes) for Capacitive Sensing

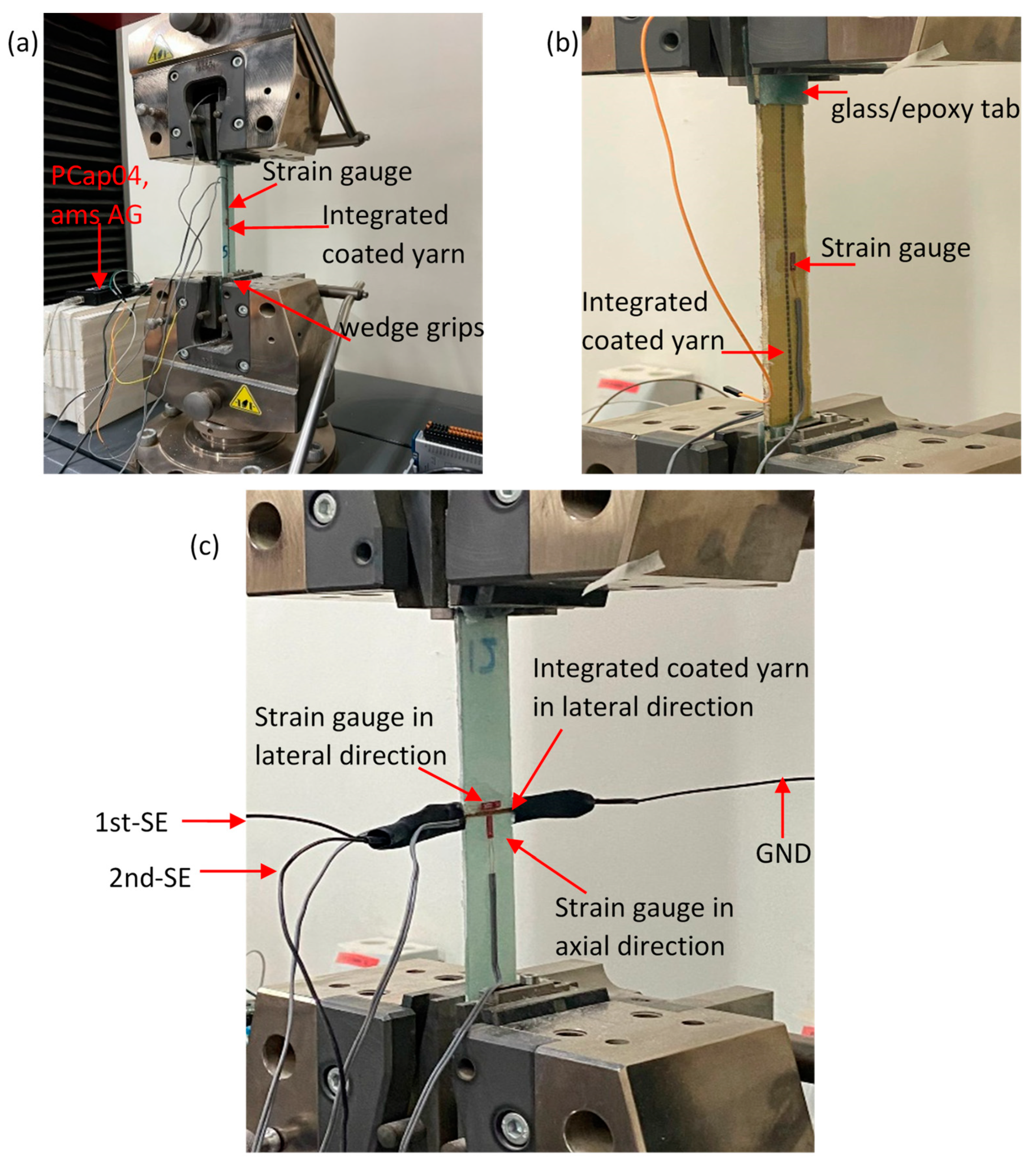

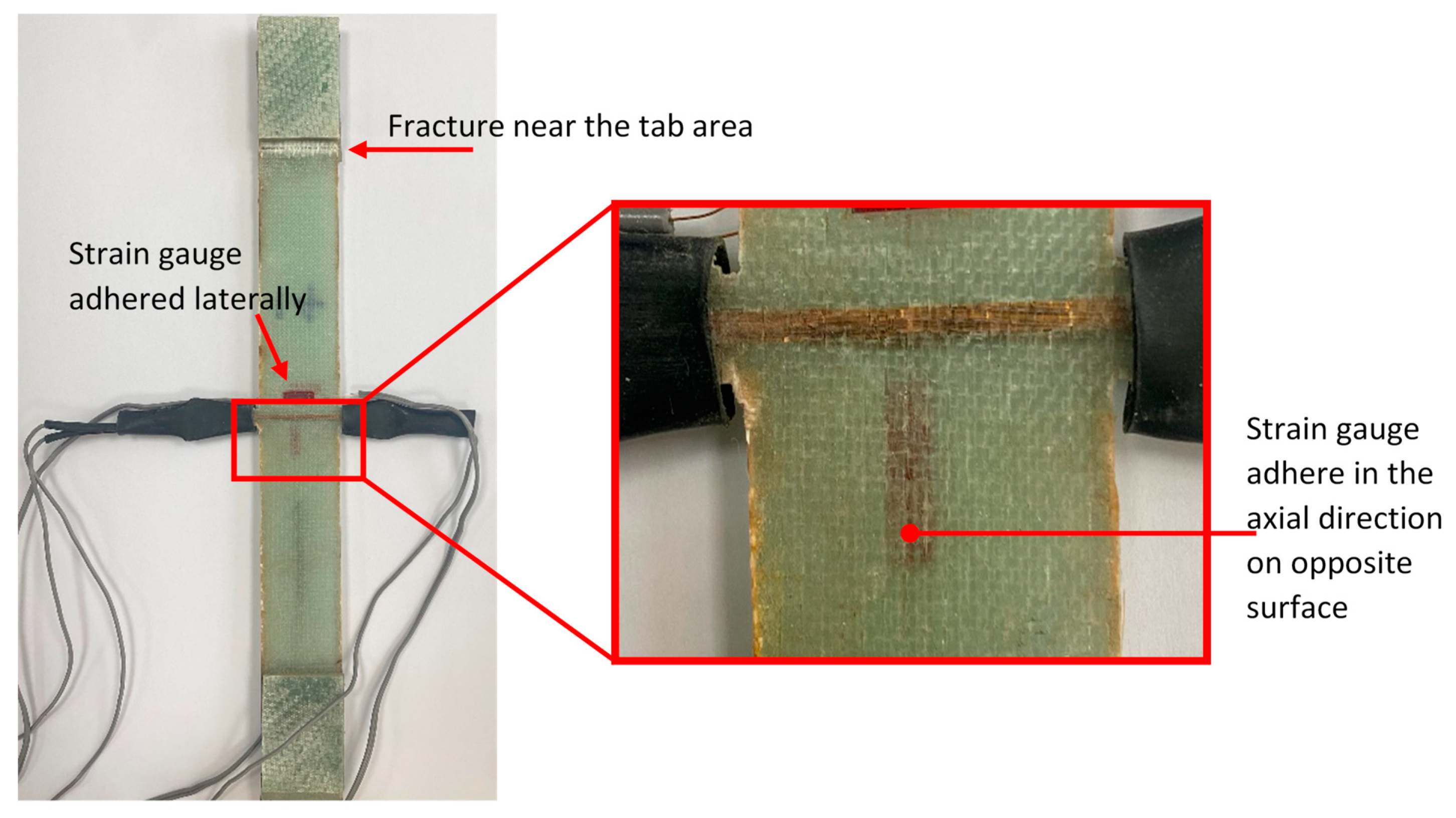

2.3. Experimental Setup

3. Result and Discussion

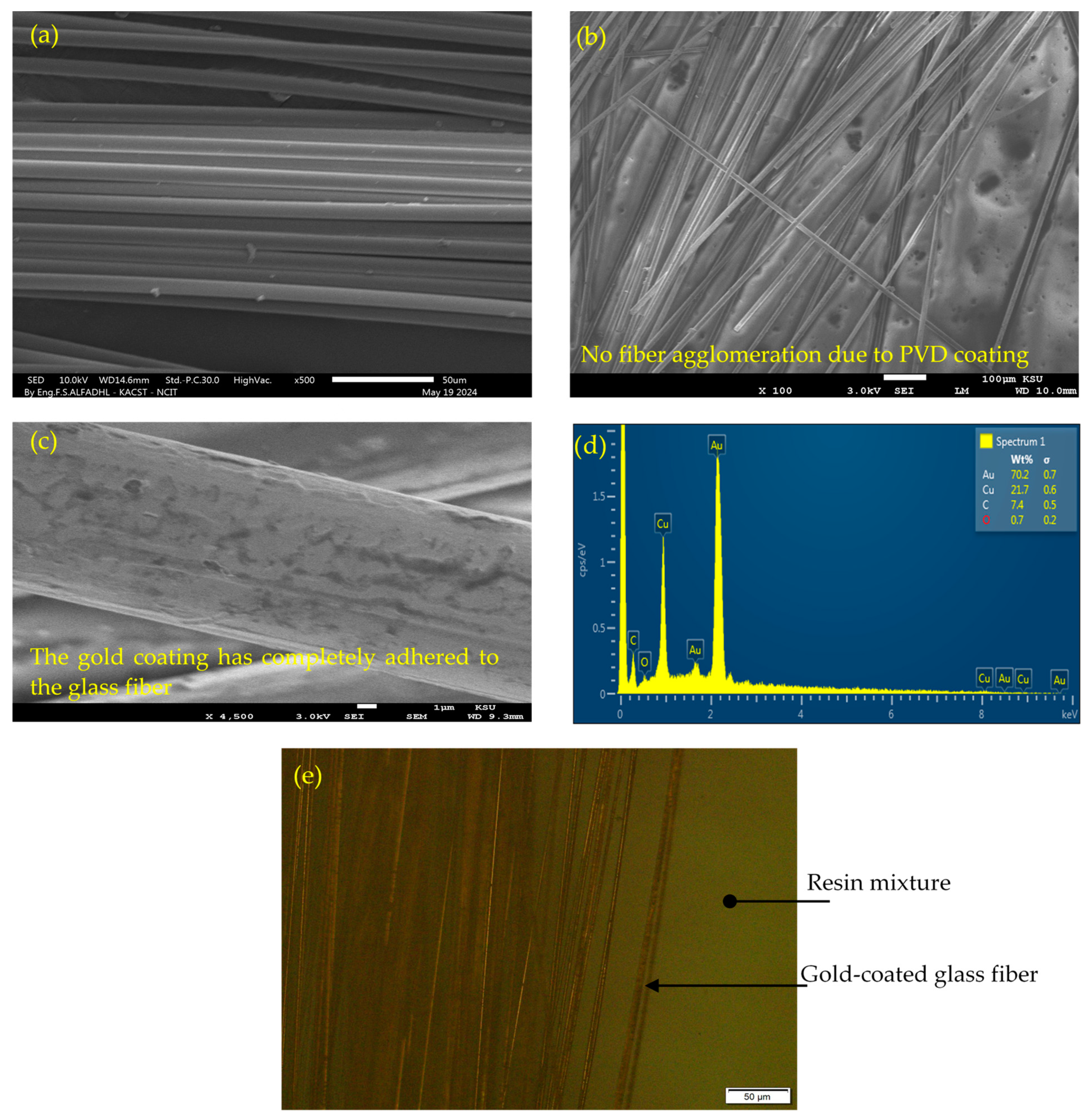

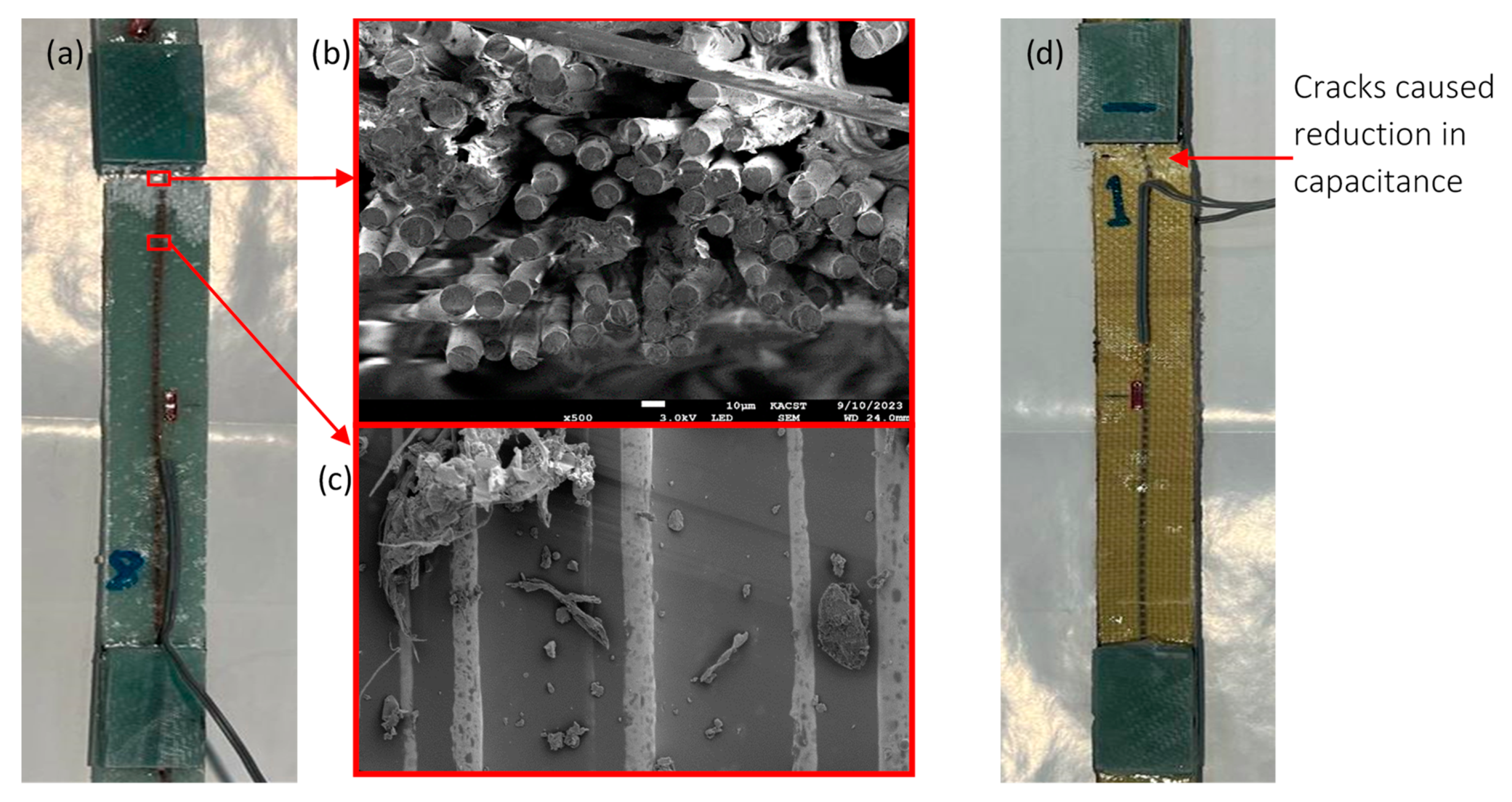

3.1. Surface Morphology and Coating Adhesion

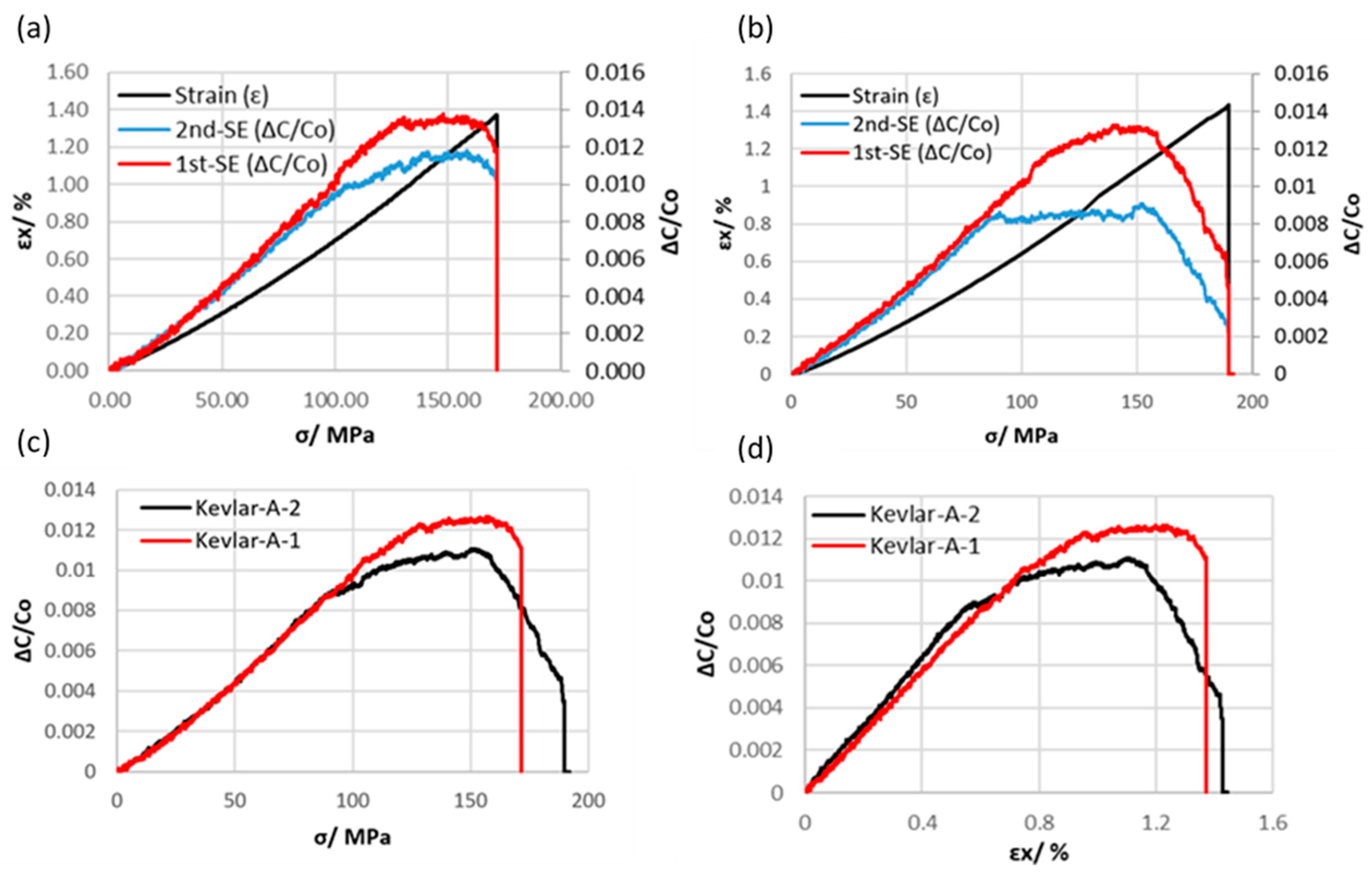

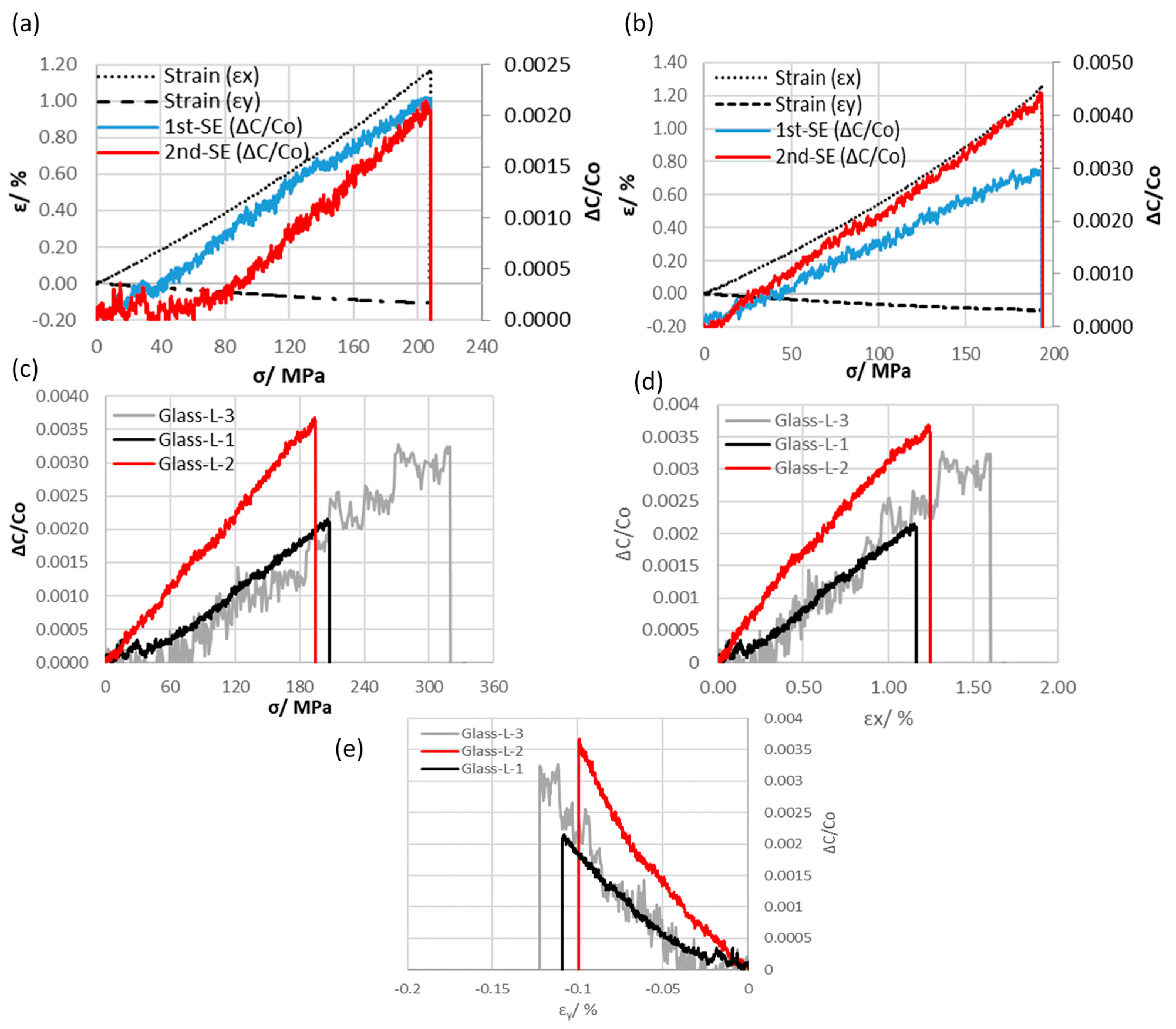

3.2. Sensor Performance in Axial Direction

3.3. Sensor Performance in the Lateral Direction

| Specimen | Young’s Modulus/GPa | Co/pF | Gauge Factor/kx | Gauge Factor/ky | Ultimate | |

|---|---|---|---|---|---|---|

| Stress/MPa | Strain/ɛx (%) | |||||

| Glass-L-1 | 18 | 10.5 | 0.19 | −1.98 | 207.9 | 1.15 |

| Glass-L-2 | 15.4 | 11.8 | 0.32 | −3.03 | 193.4 | 1.26 |

| Glass-L-3 | 19.8 | 11.4 | 0.23 | −2.32 | 316 | 1.6 |

| Average | 18 | 11.23 | 0.25 | −2.44 | 240 | 1.33 |

4. Conclusions and Future Work

- Uniform Coating and Low Resistance: The deposition of nanoparticles (Au) using the PVD technique resulted in a uniform coating along the fiber bundles. The coating exhibited strong adhesion to the fibers and had low resistance, measuring only a few hundred ohms for a 1 m length of fibers. This low resistance is essential for forming effective electrodes.

- Axial Sensor Configuration: The integrated capacitive sensor in the axial direction demonstrated linear sensitivity across a wide range of strains. The average gauge factor was approximately 1 for glass fiber/epoxy composite and 1.5 for Kevlar fiber/epoxy composite. This configuration had the capability to cover the entire composite structure and measure strain along composite layers, making it suitable for detecting onset damage that may occur along the sensor’s path.

- Lateral Sensor Configuration: The lateral sensor configuration, which indirectly sensed axial loads, had an average gauge factor of 0.25. However, in the lateral direction, the gauge factor was estimated to be relatively high at around −2.44. This increased sensitivity in the lateral direction makes it suitable for monitoring small strains, but it was less effective in directly detecting damage.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, T.; Hameed Sultan, M.T.B.; Ariffin, A.H. The challenges of natural fiber in manufacturing, material selection, and technology application: A review. J. Reinf. Plast. Compos. 2018, 37, 770–779. [Google Scholar] [CrossRef]

- Wang, Q.; Tian, Y.; Duongthipthewa, A.; Zhang, J.; Liu, M.; Su, Z.; Zhou, L. An embedded non-intrusive graphene/epoxy broadband nanocomposite sensor co-cured with GFRP for in situ structural health monitoring. Compos. Sci. Technol. 2023, 236, 109995. [Google Scholar] [CrossRef]

- Hassani, S.; Mousavi, M.; Gandomi, A.H. Structural health monitoring in composite structures: A comprehensive review. Sensors 2022, 22, 153. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, M.; Ogino, H.; Burman, M.; Wada, D.; Igawa, H.; Murayama, H. Shape sensing for CFRP and aluminum honeycomb sandwich panel using inverse finite element method with distributed fiber-optic sensors. Compos. Struct. 2023, 308, 116648. [Google Scholar] [CrossRef]

- Ghadarah, N.; Ayre, D. A Review on Acoustic Emission Testing for Structural Health Monitoring of Polymer-Based Composites. Sensors 2023, 23, 6945. [Google Scholar] [CrossRef] [PubMed]

- Laflamme, S.; Ubertini, F. Back-to-basics: Self-sensing materials for nondestructive evaluation. Mater. Eval 2020, 78, 526–536. [Google Scholar]

- Islam, M.H.; Afroj, S.; Uddin, M.A.; Andreeva, D.V.; Novoselov, K.S.; Karim, N. Graphene and CNT-Based Smart Fiber-Reinforced Composites: A Review. Adv. Funct. Mater. 2022, 32, 2205723. [Google Scholar] [CrossRef]

- Ferreira, A.D.B.L.; Nóvoa, P.R.O.; Marques, A.T. Multifunctional Material Systems: A state-of-the-art review. Compos. Struct. 2016, 151, 3–35. [Google Scholar] [CrossRef]

- Gupta, S.; Mahapatra, A.; Angelopoulou, P.; Kearney, L.; Yu, Z.; Naskar, A.K.; Bowland, C.C. A versatile fiber coating process for efficient fabrication of multifunctional composites. In Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation XVII, Long Beach, CA, USA, 12–17 March 2023; p. 19. [Google Scholar] [CrossRef]

- Ferreira, P.M.; Machado, M.A.; Carvalho, M.S.; Vidal, C. Embedded Sensors for Structural Health Monitoring: Methodologies and Applications Review. Sensors 2022, 22, 8320. [Google Scholar] [CrossRef]

- Martins, A.T.; Aboura, Z.; Harizi, W.; Laksimi, A.; Khellil, K. Structural health monitoring for GFRP composite by the piezoresistive response in the tufted reinforcements. Compos. Struct. 2019, 209, 103–111. [Google Scholar] [CrossRef]

- Paleari, L.; Bragaglia, M.; Fabbrocino, F.; Nanni, F. Structural Monitoring of Glass Fiber/Epoxy Laminates by Means of Carbon Nanotubes and Carbon Black Self-Monitoring Plies. Nanomaterials 2021, 11, 1543. [Google Scholar] [CrossRef] [PubMed]

- Pires, M.; Chalivendra, V. In-situ damage sensing in intra-ply glass/carbon laminate composites under interlaminar shear loading. J. Compos. Mater. 2022, 56, 213–222. [Google Scholar] [CrossRef]

- Alsaadi, A.; Meredith, J.; Swait, T.; Curiel-Sosa, J.L.; Jia, Y.; Hayes, S. Structural health monitoring for woven fabric CFRP laminates. Compos. Part B Eng. 2019, 174, 107048. [Google Scholar] [CrossRef]

- Irfan, M.S.; Khan, T.; Hussain, T.; Liao, K.; Umer, R. Carbon coated piezoresistive fiber sensors: From process monitoring to structural health monitoring of composites—A review. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106236. [Google Scholar] [CrossRef]

- Cech, V.; Marek, A.; Knob, A.; Valter, J.; Branecky, M.; Plihal, P.; Vyskocil, J. Continuous surface modification of glass fibers in a roll-to-roll plasma-enhanced CVD reactor for glass fiber/polyester composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 244–253. [Google Scholar] [CrossRef]

- Hao, B.; Ma, P.C. Carbon Nanotubes for Defect Monitoring in Fiber-Reinforced Polymer Composites. In Industrial Applications of Carbon Nanotubes; Elsevier: Amsterdam, The Netherlands, 2017; pp. 71–99. [Google Scholar] [CrossRef]

- Gao, S.L.; Zhuang, R.C.; Zhang, J.; Liu, J.W.; Mäder, E. Class fibers with carbon nanotube networks as multifunctional sensors. Adv. Funct. Mater. 2010, 20, 1885–1893. [Google Scholar] [CrossRef]

- Rodríguez-González, J.A.; Rubio-González, C.; Soto-Cajiga, J.A. Piezoresistive Response of Spray-coated Multiwalled Carbon Nanotube/Glass Fiber/Epoxy Composites under Flexural Loading. Fibers Polym. 2019, 20, 1673–1683. [Google Scholar] [CrossRef]

- Qureshi, Y. Development of a New Generation of Fiber Sensors for Structural Health Monitoring in Composites in Real-Time. Doctoral Dissertation, ENSTA Bretagne-École Nationale Supérieure de Techniques Avancées Bretagne, Brest, France, 2020; pp. 1–268. [Google Scholar]

- Eddib, A.A.; Chung, D.D.L. First report of capacitance-based self-sensing and in-plane electric permittivity of carbon fiber polymer-matrix composite. Carbon 2018, 140, 413–427. [Google Scholar] [CrossRef]

- Chung, D.D.L.; Wang, S. Carbon fiber polymer-matrix structural composite as a semiconductor and concept of optoelectronic and electronic devices made from it. Smart Mater. Struct. 1999, 8, 161. [Google Scholar] [CrossRef]

- O’Brien, D.J.; Baechle, D.M.; Wetzel, E.D. Design and performance of multifunctional structural composite capacitors. J. Compos. Mater. 2011, 45, 2797–2809. [Google Scholar] [CrossRef]

- Yan, J.; Downey, A.; Chen, A.; Laflamme, S.; Hassan, S. Capacitance-based sensor with layered carbon-fiber reinforced polymer and titania-filled epoxy. Compos. Struct. 2019, 227, 111247. [Google Scholar] [CrossRef]

- Nassr, A.A.; Ahmed, W.H.; El-Dakhakhni, W.W. Coplanar capacitance sensors for detecting water intrusion in composite structures. Meas. Sci. Technol. 2008, 19, 75702. [Google Scholar] [CrossRef]

- Shen, Z.; Zhou, H. Mechanical and electrical behavior of carbon fiber structural capacitors: Effects of delamination and interlaminar damage. Compos. Struct. 2017, 166, 38–48. [Google Scholar] [CrossRef]

- Buggisch, C.; Gagani, A.; Fiedler, B. Capacitance measurements on integrated conductors for detection of matrix cracks in GFRP. Funct. Compos. Mater. 2021, 2, 2. [Google Scholar] [CrossRef]

- Buggisch, C.; Gibhardt, D.; Kern, M.; Fiedler, B. Impact damage detection in glass fibre reinforced polymers via electrical capacitance measurements on integrated carbon fibre bundles. Compos. Commun. 2022, 30, 14–17. [Google Scholar] [CrossRef]

- Alblalaihid, K.; Alghamdi, S.A.; Alburayt, A.; Almutairi, S.H.; Alwahid, A.; Abuobaid, M.; Alkhibari, S.; Almutairi, K.S.; Alarifi, I.M. Interlayer Defect Detection in Intra-Ply Hybrid Composite Material (GF/CF) Using a Capacitance-Based Sensor. Sensors 2022, 22, 2966. [Google Scholar] [CrossRef]

- Alblalaihid, K.; Alghamdi, S.A.; Alburayt, A.; Alwahid, A.; Abuobaid, M.; Alshaikh, A.; Alkhibari, S.; Alarifi, I.M. Self-Sensing Hybrid Fibre-Reinforced Polymer for Structural Health Monitoring (SHM). Key Eng. Mater. 2022, 922, 87–93. [Google Scholar] [CrossRef]

- Alblalaihid, K.; Alghamdi, S.A.; Alburayt, A.; Alharbi, A.; Aldoihi, S.; Alwahid, A.; Abuobaid, M.; Alkhibari, S.; Khormi, K.; Almuzini, I. Coating Glass Fibre Yarn with Conductive Materials for Real-Time Structure Sensing. Adv. Sci. Technol. 2023, 133, 25–32. [Google Scholar]

- Baptista, A.; Silva, F.; Porteiro, J.; Míguez, J.; Pinto, G. Sputtering physical vapour deposition (PVD) coatings: A critical review on process improvement andmarket trend demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- JEHN, H.A. Vapor deposition and electrochemical plating: Competition, alternative or combination-or: Which serves best? J. Adv. Sci. 2001, 13, 549–560. [Google Scholar] [CrossRef]

- Andrieux-Ledier, A.; Tremblay, B.; Courty, A. Stability of self-ordered thiol-coated silver nanoparticles: Oxidative environment effects. Langmuir 2013, 29, 13140–13145. [Google Scholar] [CrossRef] [PubMed]

- Nagata, H.; Shinriki, T.; Shima, K.; Tamai, M.; Min Haga, E. Improvement of bonding strength between Au/Ti and SiO2 films by Si layer insertion. J. Vac. Sci. Technol. A Vacuum Surfaces Films 1999, 17, 1018–1023. [Google Scholar] [CrossRef]

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM Int.: West Conshohocken, PA, USA, 2008.

- Yuan, Z.; Wang, Y.; Yang, G.; Tang, A.; Yang, Z.; Li, S.; Li, Y.; Song, D. Evolution of curing residual stresses in composite using multi-scale method. Compos. Part B Eng. 2018, 155, 49–61. [Google Scholar] [CrossRef]

- Holmes, J.; Sommacal, S.; Stachurski, Z.; Das, R.; Compston, P. Digital image and volume correlation with X-ray micro-computed tomography for deformation and damage characterisation of woven fibre-reinforced composites. Compos. Struct. 2022, 279, 114775. [Google Scholar] [CrossRef]

| Sensor Configuration | Type of FRP | Guague Length/mm | Width/mm | Thickness/mm |

|---|---|---|---|---|

| Axial | Glass-A-1 | 170 | 24.92 | 2.08 |

| Glass-A-2 | 170 | 25.03 | 1.99 | |

| Kevlar-A-1 | 170 | 25.76 | 2.90 | |

| Kevlar-A-2 | 170 | 25.67 | 2.68 | |

| Lateral | Glass-L-1 | 170 | 24.85 | 1.94 |

| Glass-L-2 | 170 | 24.76 | 1.74 | |

| Glass-L-3 | 170 | 24.84 | 1.72 |

| Specimen | Young’s Modulus/GPa | Co/pF | Gauge Factor/k | Failure Initiation Characteristics | Ultimate | |||

|---|---|---|---|---|---|---|---|---|

| Stress/MPa | Strain/ɛ (%) | (%) | Stress/MPa | Strain/ɛ (%) | ||||

| Glass-A-1 | 16.8 | 62.4 | 1.04 | 186 | 0.99 | 0.94 | 241.6 | 1.44 |

| Glass-A-2 | 17 | 52 | 1.00 | 231 | 1.38 | 1.11 | 272.18 | 1.60 |

| Average | 17 | 54.2 | 1.02 | 208 | 1.185 | 1.02 | 257 | 1.52 |

| Kevlar-A-1 | 12.4 | 37.1 | 1.45 | 148.9 | 1.15 | 1.25 | 171.5 | 1.39 |

| Kevlar-A-2 | 13.3 | 37.95 | 1.57 | 137.8 | 0.98 | 1.07 | 189.7 | 1.43 |

| Average | 13 | 37.52 | 1.51 | 143.35 | 1.06 | 1.16 | 180.6 | 1.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alblalaihid, K.S.; Aldoihi, S.A.; Alharbi, A.A. Structural Health Monitoring of Fiber Reinforced Composites Using Integrated a Linear Capacitance Based Sensor. Polymers 2024, 16, 1560. https://doi.org/10.3390/polym16111560

Alblalaihid KS, Aldoihi SA, Alharbi AA. Structural Health Monitoring of Fiber Reinforced Composites Using Integrated a Linear Capacitance Based Sensor. Polymers. 2024; 16(11):1560. https://doi.org/10.3390/polym16111560

Chicago/Turabian StyleAlblalaihid, Khalid S., Saad A. Aldoihi, and Abdulaziz A. Alharbi. 2024. "Structural Health Monitoring of Fiber Reinforced Composites Using Integrated a Linear Capacitance Based Sensor" Polymers 16, no. 11: 1560. https://doi.org/10.3390/polym16111560

APA StyleAlblalaihid, K. S., Aldoihi, S. A., & Alharbi, A. A. (2024). Structural Health Monitoring of Fiber Reinforced Composites Using Integrated a Linear Capacitance Based Sensor. Polymers, 16(11), 1560. https://doi.org/10.3390/polym16111560