Preparation of UV Topcoat Microcapsules and Their Effect on the Properties of UV Topcoat Paint Film

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials, Equipment, and Instruments

2.2. Preparation Method of UV Topcoat Microcapsules

2.3. Preparation Method of UV Topcoat Paint Film

2.4. Testing and Characterization

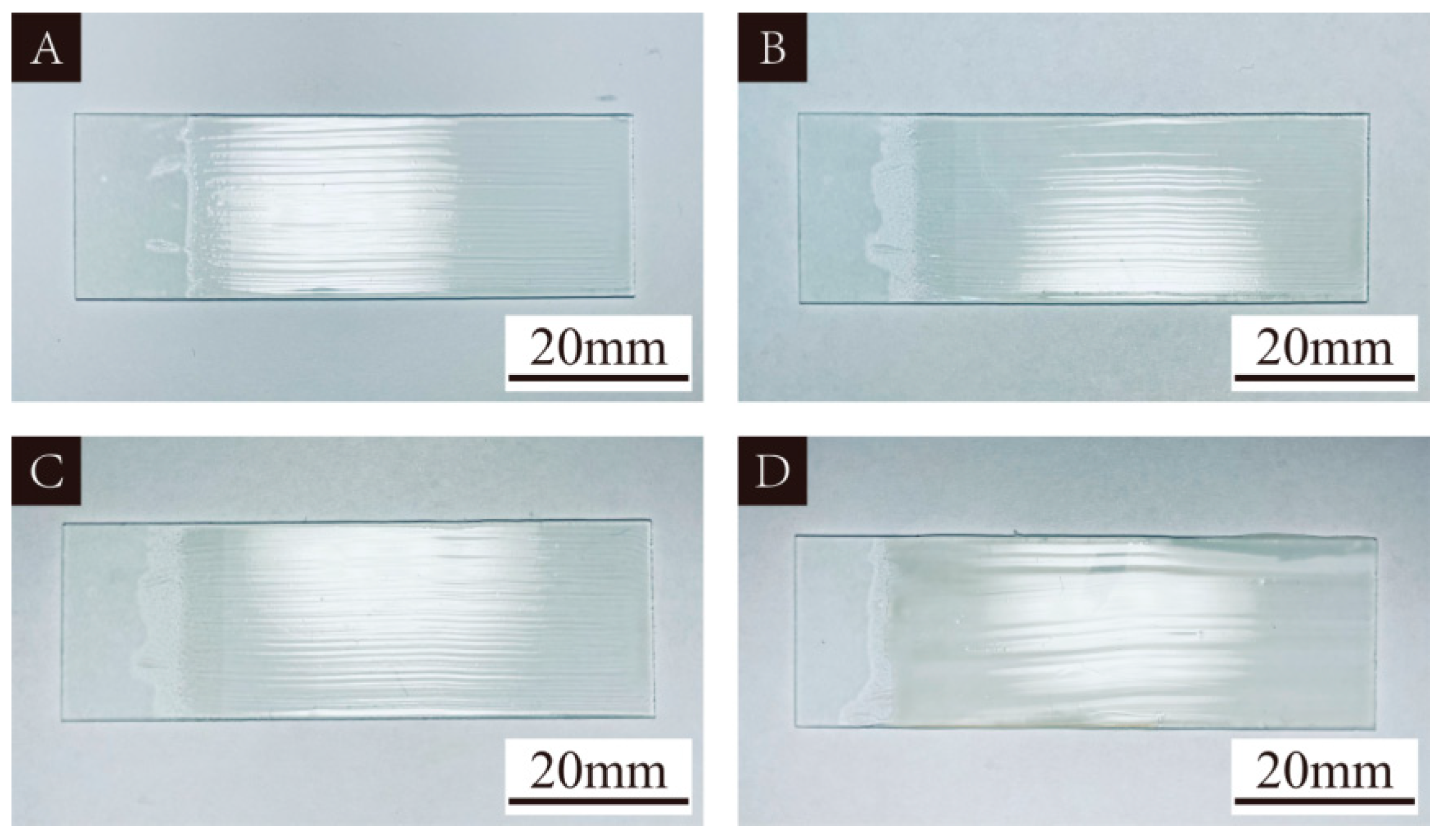

2.4.1. UV Topcoat Natural Light Curing Test

2.4.2. Yield Rate and Encapsulation Rate Testing

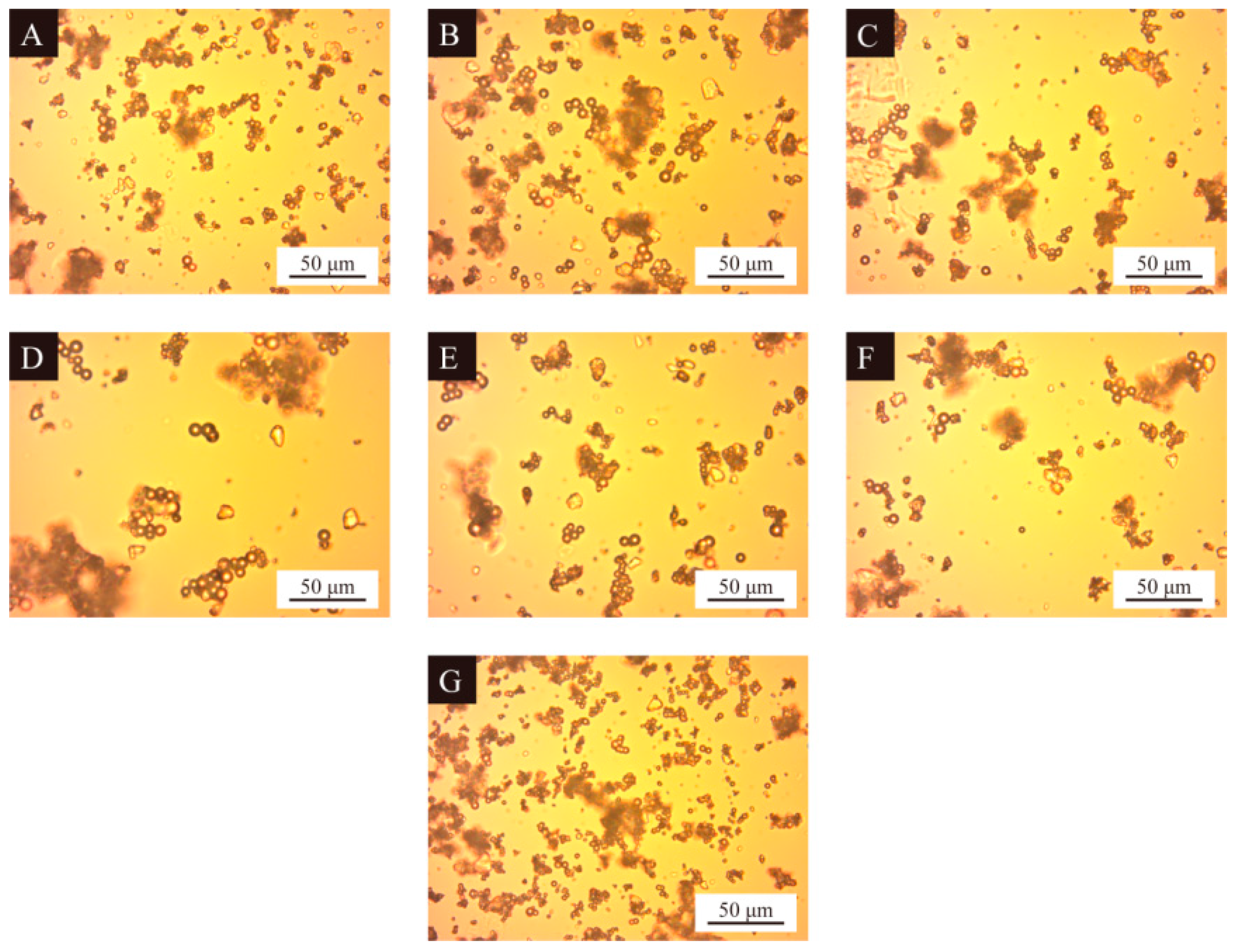

2.4.3. Microscopic Characterization

2.4.4. Chemical Composition

2.4.5. Optical Properties

2.4.6. Tensile and Roughness Testing

2.4.7. Self-Healing Performance Testing

3. Results and Discussion

3.1. Analysis of UV Topcoat Natural Light Curing Results

3.2. Analysis of the UV Topcoat Microcapsules

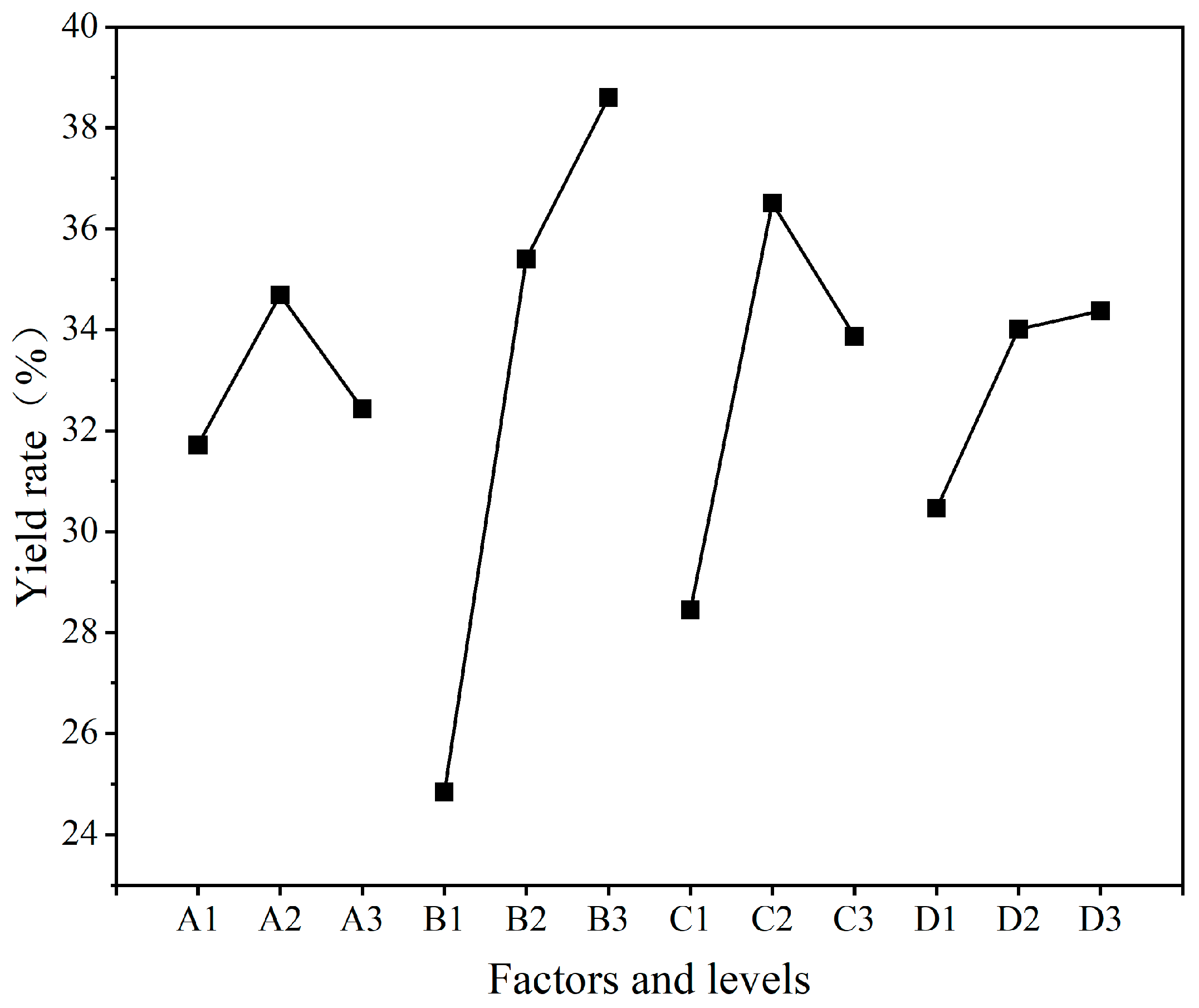

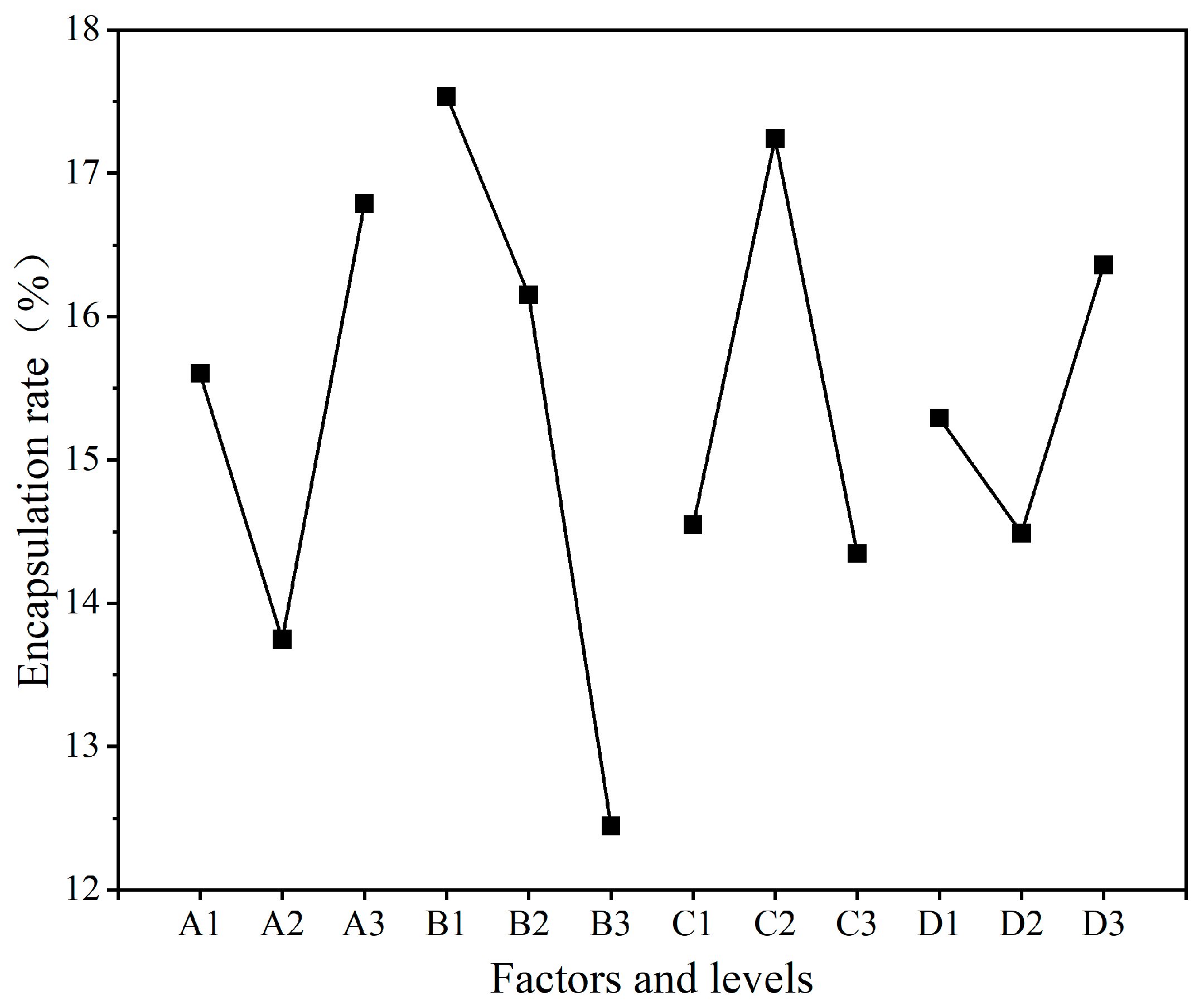

3.2.1. Analysis of UV Topcoat Microcapsule Yield Rate and Encapsulation Rate

3.2.2. Microscopic Morphology Analysis of UV Topcoat Microcapsules

3.2.3. Analysis of Chemical Composition

3.3. Analysis of UV Topcoat Paint Film Performance

3.3.1. Analysis of UV Topcoat Paint Film Morphology

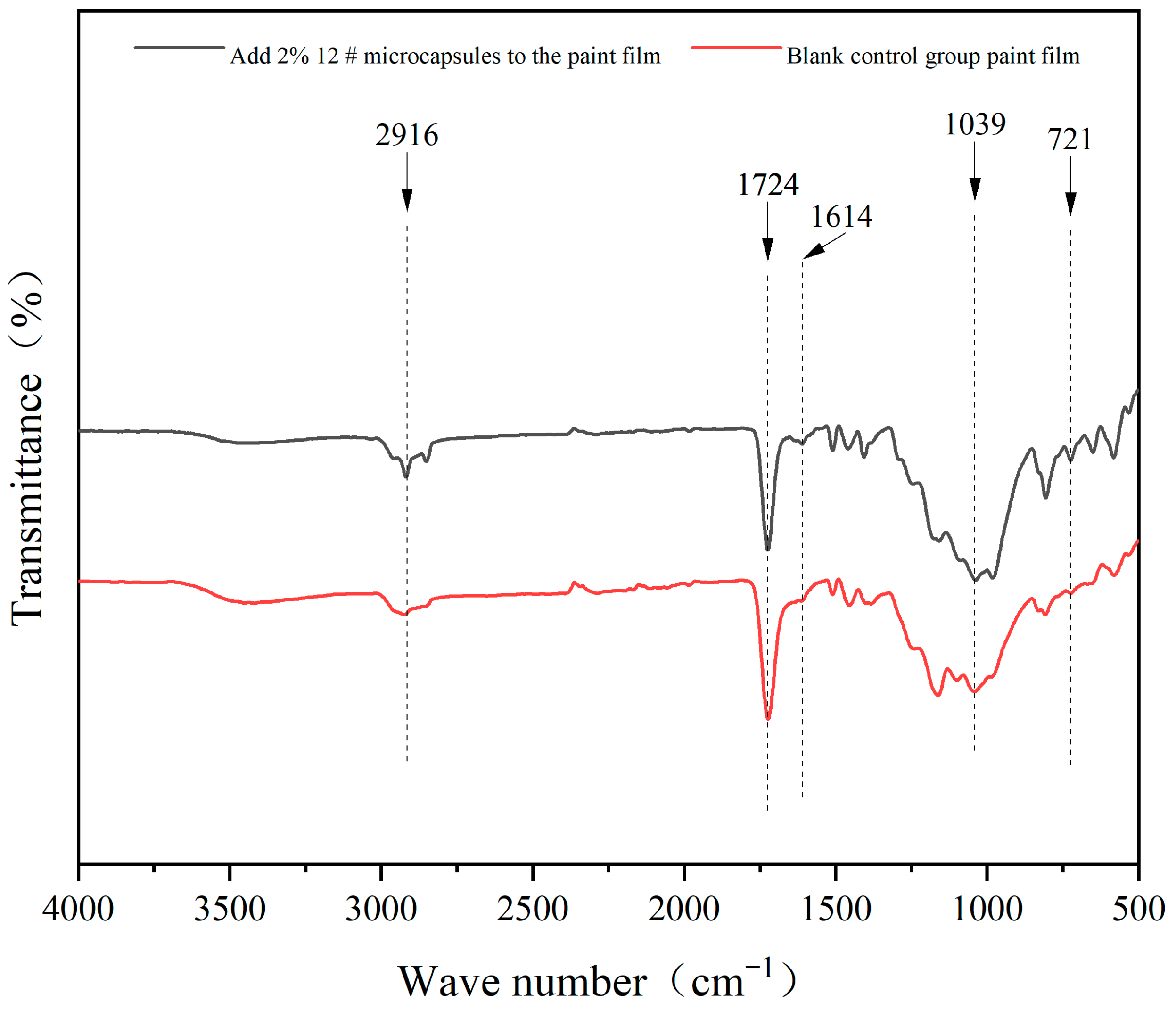

3.3.2. Chemical Composition Analysis of UV Topcoat Paint Film

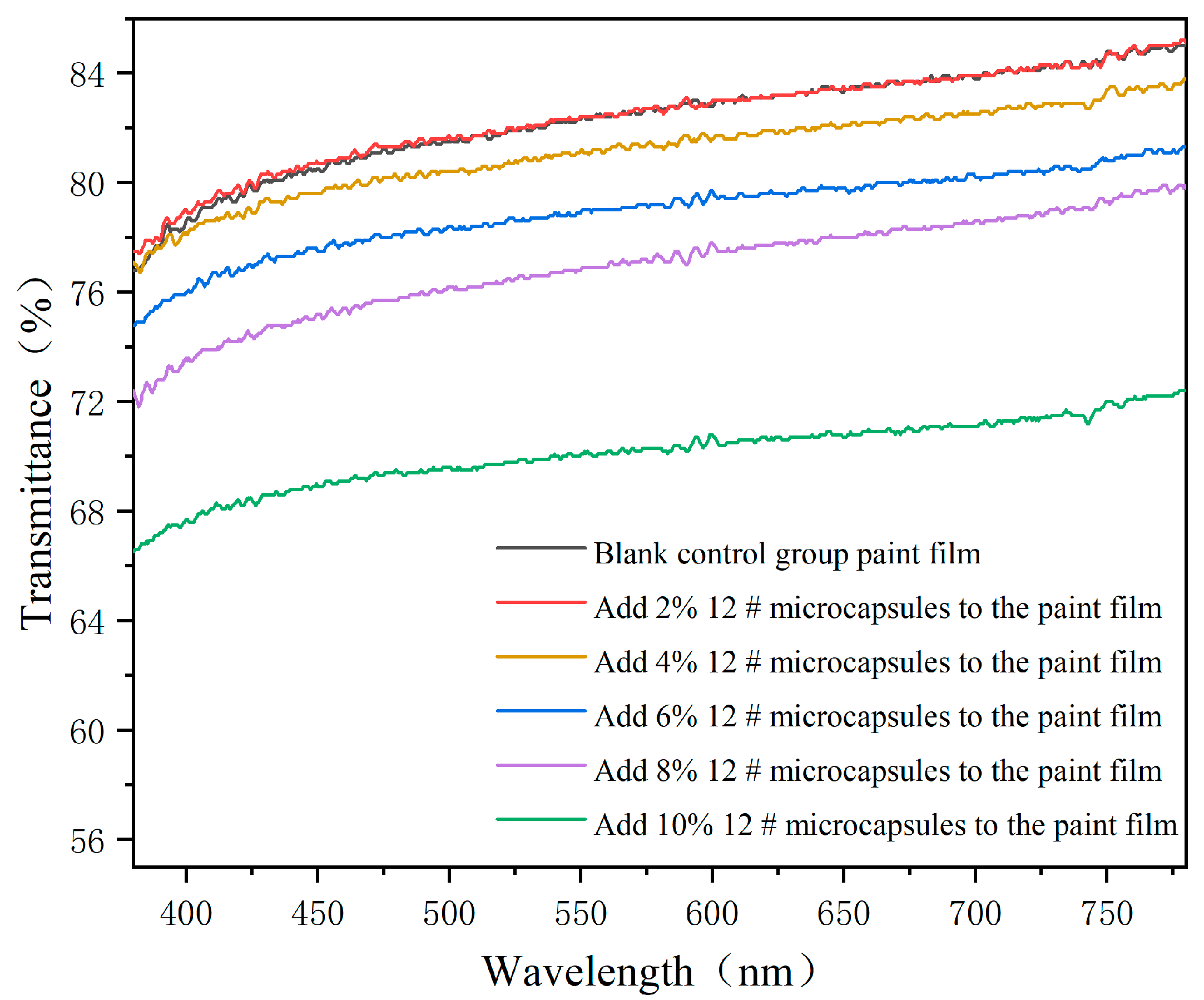

3.3.3. Analysis of Optical Properties of UV Topcoat Paint Films

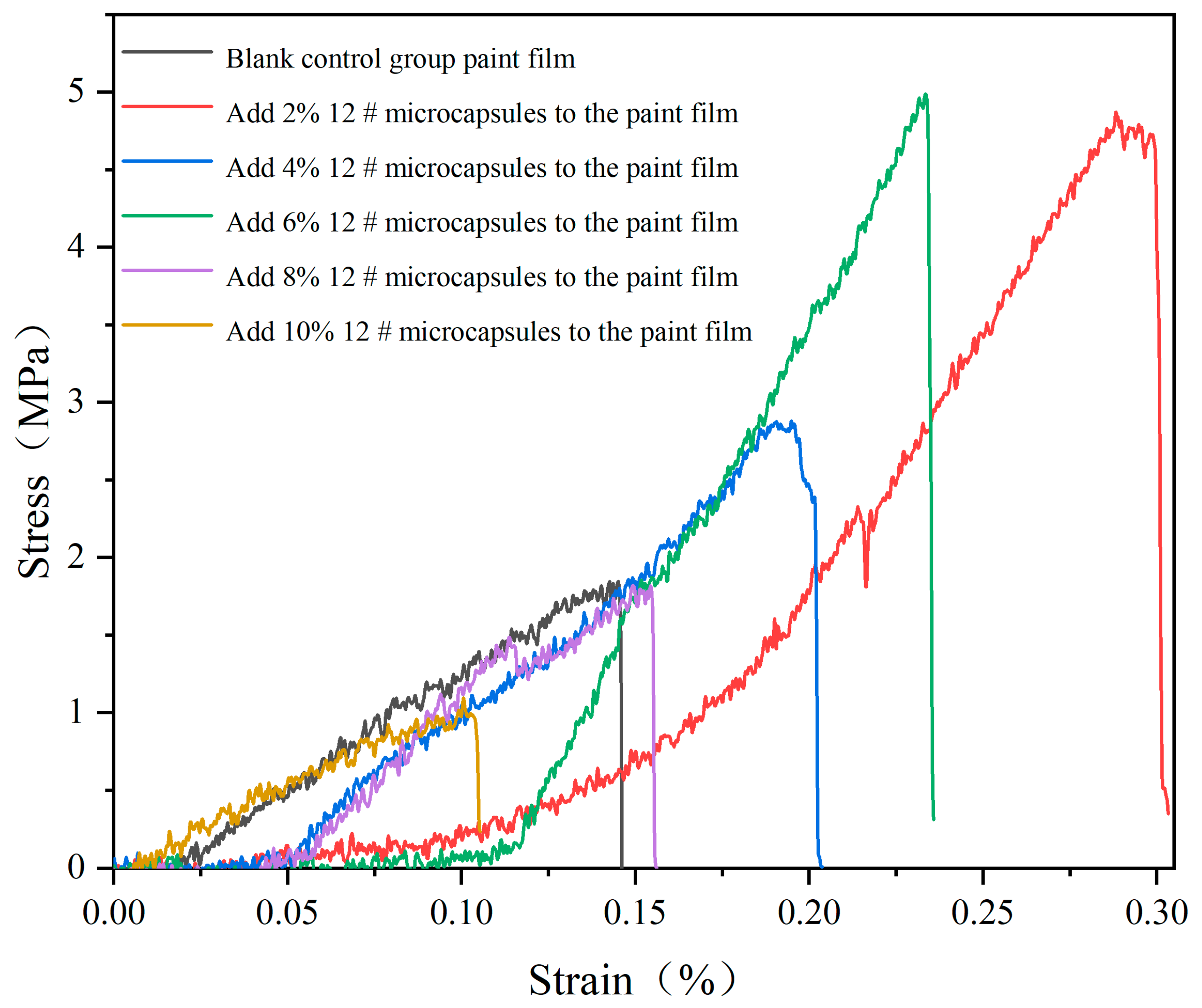

3.3.4. Analysis of Tensile Resistance and Roughness of UV Topcoat Paint Film

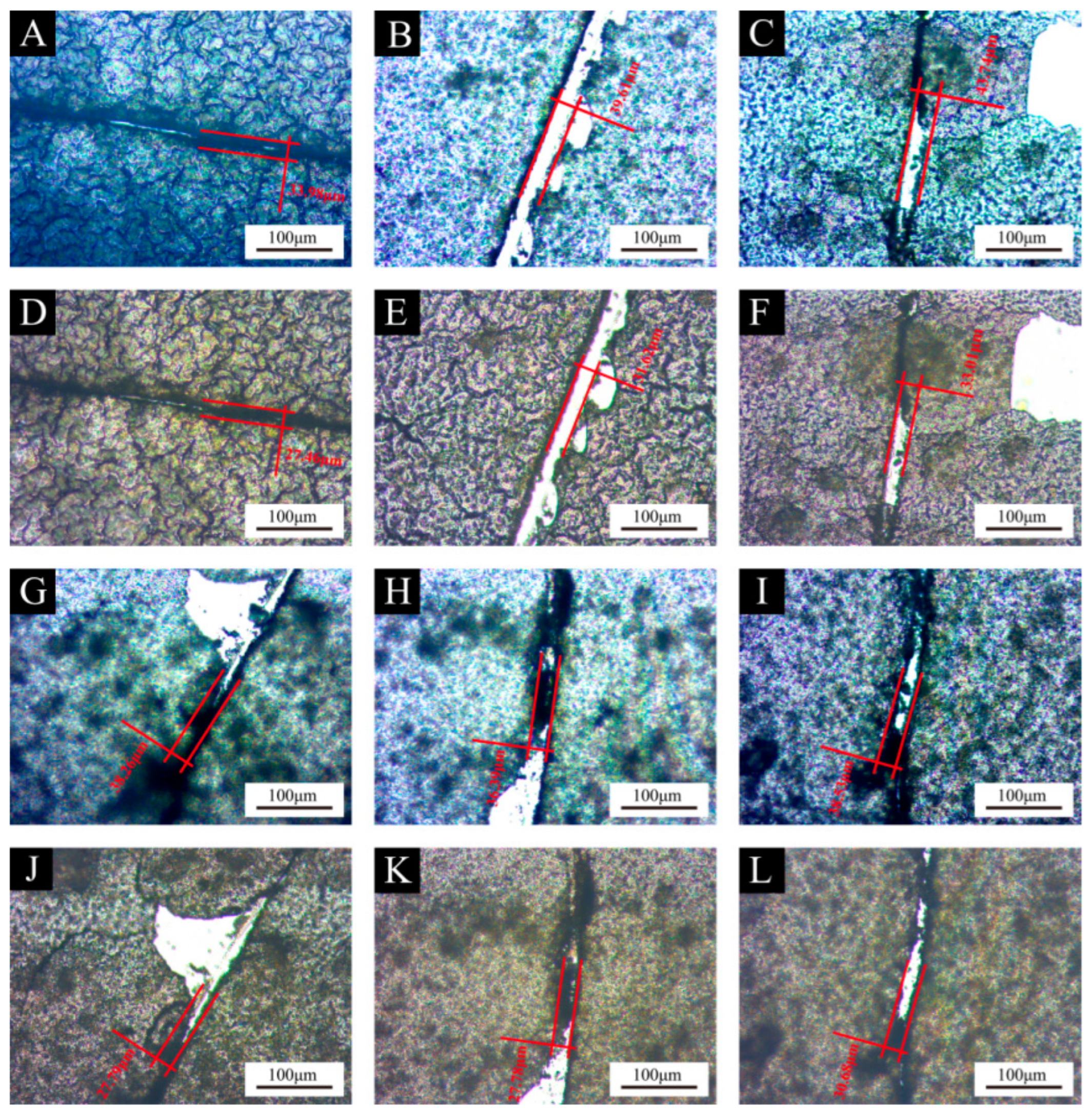

3.3.5. Analysis of Self-Healing Performance of UV Topcoat Paint Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Liu, R.; Luo, J. Enhancing weathering resistance of UV-curable coatings by using TiO2 particles as filler. Prog. Org. Coat. 2023, 169, 106936. [Google Scholar] [CrossRef]

- Zhao, Z.N.; Niu, Y.T.; Chen, F.Y. Development and Finishing Technology of Waterborne UV Lacquer-Coated Wooden Flooring. Bioresources 2021, 16, 1101–1114. [Google Scholar] [CrossRef]

- Choi, J.H.; Kim, H.J. Three hardness test methods and their relationship on UV-curable epoxy acrylate coatings for wooden flooring systems. J. Ind. Eng. Chem. 2006, 12, 412–417. [Google Scholar]

- Marrot, L.; Zouari, M.; Schwarzkopf, M.; DeVallance, D.B. Sustainable biocarbon/tung oil coatings with hydrophobic and UV-shielding properties for outdoor wood substrates. Prog. Org. Coat. 2023, 177, 107428. [Google Scholar] [CrossRef]

- Cataldi, A.; Corcione, C.E.; Frigione, M.; Pegoretti, A. Photocurable resin/nanocellulose composite coatings for wood protection. Prog. Org. Coat. 2017, 106, 128–136. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, W.; Kasal, A.; Erdil, Y.Z. The State of the Art of Biomechanics Applied in Ergonomic Furniture Design. Appl. Sci. 2023, 13, 12120. [Google Scholar] [CrossRef]

- Hu, W.G.; Liu, Y.; Konukcu, A.C. Study on withdrawal load resistance of screw in wood-based materials: Experimental and numerical. Wood Mater. Sci. Eng. 2023, 18, 334–343. [Google Scholar] [CrossRef]

- Hu, W.; Fu, W.; Zhao, Y. Optimal design of the traditional Chinese wood furniture joint based on experimental and numerical method. Wood. Res. 2024, 69, 50–59. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of Paint Process on the Performance of Modified Poplar Wood Antique. Coatings 2021, 11, 1174. [Google Scholar] [CrossRef]

- Jiang, S.P.; Lin, Z.Y.; Tang, C.; Hao, W.F. Preparation and Mechanical Properties of Microcapsule-Based Self-Healing Cementitious Composites. Materials 2010, 14, 4866. [Google Scholar] [CrossRef]

- Wang, H.P.; Rong, M.Z.; Zhang, M.Q. Self-Healing Polymers and Polymer-Based Composites Containing Microcapsules. Prog. Chem. 2010, 22, 2397–2407. [Google Scholar]

- Ma, Y.X.; Liu, J.T.; Zhang, Y.R.; Ge, Y.; Wu, R.; Song, X.H.; Zhang, P.; Wu, J. Mechanical behavior and self-healing mechanism of polyurea-based double-walled microcapsule/epoxy composite films. Prog. Org. Coat. 2020, 157, 106283. [Google Scholar] [CrossRef]

- Hao, W.F.; Hao, H.; Kanwal, H.; Jiang, S.P. Evaluation of Self-Healing Efficiency of Microcapsule-Based Self-Healing Cementitious Composites Based on Acoustic Emission. J. Renew. Mater. 2023, 11, 1687–1697. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of Polyurethane Non-Transparent Coating Process on Coating Performance Applied on Modified Poplar. Coatings 2022, 12, 39. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, J. Effect of growth rings on acoustic emission characteristic signals of southern yellow pine wood cracked in mode I. Constr. Build. Mater. 2022, 329, 127092. [Google Scholar] [CrossRef]

- Chen, B.; Yu, X.; Hu, W. Experimental and numerical studies on the cantilevered leg joint and its reinforced version commonly used in modern wood furniture. Bioresources 2022, 17, 3952–3964. [Google Scholar] [CrossRef]

- Yan, X.X.; Zhao, W.T.; Wang, L. Mechanism of Thermochromic and Self-Repairing of Waterborne Wood Coatings by Synergistic Action of Waterborne Acrylic Microcapsules and Fluorane Microcapsules. Polymers 2022, 14, 56. [Google Scholar] [CrossRef]

- Yan, X.X.; Li, W.B.; Han, Y.; Yin, T.Y. Preparation of melamine/rice husk powder coated shellac microcapsules and effect of different rice husk powder content in wall material on properties of wood waterborne primer. Polymers 2022, 14, 72. [Google Scholar] [CrossRef]

- Li, P.H.; Lu, Z.; Ma, K.X.; Zou, G.F.; Chang, L.; Guo, W.C.; Tian, K.S.; Li, X.A.; Wang, H.Y. UV-triggered self-healing SiO2/PDA hybrid microcapsules with both enhanced UV-shielding ability and improved compatibility for epoxy resin coating. Prog. Org. Coat. 2021, 163, 106636. [Google Scholar] [CrossRef]

- Li, P.H.; Guo, W.C.; Lu, Z.; Tian, J.F.; Li, X.A.; Wang, H.Y. UV-responsive single-microcapsule self-healing material with enhanced UV-shielding SiO2/ZnO hybrid shell for potential application in space coatings. Prog. Org. Coat. 2021, 151, 106046. [Google Scholar] [CrossRef]

- Cong, Y.; Chen, K.L.; Zhou, S.X.; Wu, L.M. Synthesis of pH and UV dual-responsive microcapsules with high loading capacity and their application in self-healing hydrophobic coatings. J. Mater. Chem. A 2015, 3, 19093–19099. [Google Scholar] [CrossRef]

- Yuan, H.Z.; Li, G.X.; Yang, L.J.; Yan, X.J.; Yang, D.B. Development of melamine-formaldehyde resin microcapsules with low formaldehyde emission suited for seed treatment. Colloid. Surf. B 2015, 128, 149–154. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.Y.; Sui, J.Y.; Li, Z.X.; Song, L.N.; Yang, L.N.; Wang, N.; Zhao, J. Preparation and characterization of halogen-free flame retardant MCA core-shell microcapsules coated with melamine or acrylic acid resin. Polimery 2021, 66, 245–252. [Google Scholar] [CrossRef]

- Gao, G.B.; Qian, C.X.; Gao, M.J. Preparation and characterization of hexadecane microcapsule with polyurea-melamine formaldehyde resin shell materials. Chin. Chem. Lett. 2010, 21, 533–537. [Google Scholar] [CrossRef]

- Yan, X.F.; Wang, Y.; Liu, H.H.; Li, R.H.; Qian, C.Q. Synthesis and Characterization of Melamine-Formaldehyde Microcapsules Containing Pyraclostrobin by In situ Polymerization. Polym. Sci. Ser. B 2019, 60, 798–805. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Shu, P.; Deng, J.; Chen, S.K.; Li, X.N. Preparation and properties of ammonium polyphosphate microcapsules for coal spontaneous combustion prevention. Int. J. Coal Prep. Util. 2021, 42, 3090–3102. [Google Scholar] [CrossRef]

- Chen, B.; Xia, H.; Hu, W. The design and evaluation of the three-dimensional corner joints used in wooden furniture frames: Experimental and numerical. Bioresources 2022, 17, 2143–2156. [Google Scholar] [CrossRef]

- Wang, H.P.; Li, M.Q.; Guo, C.; Hu, S.Q. Microencapsulation of diglycidyl 1,2-cyclohexanedicarboxylate by in situ polymerization: Preparation and characterization. E-Polymers 2015, 15, 377–383. [Google Scholar] [CrossRef]

- Cao, F.Y.; Yang, B. Supercooling suppression of microencapsulated phase change materials by optimizing shell composition and structure. Appl. Energy 2014, 113, 1512–1518. [Google Scholar] [CrossRef]

- Chai, Y.Q.; Zhao, T.B.; Gao, X.; Zhang, J.J. Low cracking ratio of paraffin microcapsules shelled by hydroxyl terminated polydimethylsiloxane modified melamine-formaldehyde resin. Colloids Surf. A 2018, 538, 86–93. [Google Scholar] [CrossRef]

- Li, W.B.; Yan, X.X. Effects of Shellac Self-Repairing and Carbonyl Iron Powder Microcapsules on the Properties of Dulux Waterborne Coatings on Wood. Polymers 2022, 15, 2016. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Yan, X.X. Influence of HLB Value of Emulsifier on the Properties of Microcapsules and self-healing performance of Waterborne Coatings. Polymers 2022, 14, 1304. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Wan, H. Comparative study on weathering durability properties of phenol formaldehyde resin modified sweetgum and southern pine specimens. Maderas. Cienc. Y Tecnol. 2022, 24, 17. [Google Scholar] [CrossRef]

- Hu, W.; Liu, Y.; Li, S. Characterizing mode I fracture behaviors of wood using compact tension in selected system crack propagation. Forests 2021, 12, 1369. [Google Scholar] [CrossRef]

- Han, Y.; Yan, X.X.; Tao, Y. Effect of transparent, purple, and yellow shellac microcapsules on properties of the coating on Paraberlinia bifoliolata surface. Polymers 2022, 14, 3304. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Yan, X.X.; Tao, Y. Effect of transparent, purple, and yellow shellac microcapsules on the optical properties and self-healing performance of waterborne coatings. Coatings 2022, 12, 1056. [Google Scholar] [CrossRef]

- Gao, J.; Wang, R.; Zhang, Z.M.; Song, D.D.; Li, X.G. Effect of membrane structure of waterborne coatings on the transport process of corrosive medium. Prog. Org. Coat. 2018, 124, 8–15. [Google Scholar] [CrossRef]

- Zhao, Z.P.; Meng, F.C.; Tang, J.R.; Liu, H.S.; Liu, H.Y.; Yang, L.N.; Wang, J.N.; Xiong, T.Y. A novel method of fabricating an antibacterial aluminum-matrix composite coating doped graphene/silver-nanoparticles. Mater. Lett. 2019, 245, 211–214. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Influence of the Bottom Color Modification and Material Color Modification Process on the Performance of Modified Poplar. Coatings 2021, 11, 660. [Google Scholar] [CrossRef]

- Weng, M.; Zhu, Y.; Mao, W.; Zhou, J.; Xu, W. Nano-Silica/Urea-Formaldehyde Resin-Modified Fast-Growing Lumber Performance Study. Forests 2023, 14, 1440. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, J. Bolt-Bearing Yield Strength of Three-Layered Cross-Laminated Timber Treated with Phenol Formaldehyde Resin. Forests 2020, 11, 551. [Google Scholar] [CrossRef]

- Bolimowski, P.A.; Kozera, R.; Boczkowska, A. Poly (urea-formaldehyde) microcapsules—Synthesis and influence of stirring speed on capsules size. Polimery 2018, 63, 339–346. [Google Scholar] [CrossRef]

- Hu, W.; Liu, N. Comparisons of finite element models used to predict bending strength of mortise-and-tenon joints. Bioresources 2020, 15, 5801–5811. [Google Scholar] [CrossRef]

- Liu, C.; Xu, W. Effect of Coating Process on Properties of Two-Component Waterborne Polyurethane Coatings for Wood. Coatings 2022, 12, 1857. [Google Scholar] [CrossRef]

- Wang, C.; Yu, J.; Jiang, M.; Li, J. Effect of selective enhancement on the bending performance of fused deposition methods 3D-printed PLA models. Bioresources 2024, 19, 2660–2669. [Google Scholar] [CrossRef]

- Ullah, H.; Qureshi, K.S.; Khan, U.; Zaffar, M.; Yang, Y.J.; Rabat, N.E.; Khan, M.I.; Saqib, S.; Mukhtar, A.; Ullah, S.; et al. Self-healing epoxy coating synthesis by embedment of metal 2-methyl imidazole and acetylacetonate complexes with microcapsules. Chemosphere 2021, 285, 131492. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zhou, Z. Optical properties and lampshade design applications of PLA 3D printing materials. Bioresources 2023, 18, 1545–1553. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.; Ding, K.; Jiang, M. Immersion polishing post-treatment of PLA 3D printed formed parts on its surface and mechanical performance. Bioresources 2023, 18, 7995–8006. [Google Scholar] [CrossRef]

- Zotiadis, C.; Patrikalos, I.; Loukaidou, V.; Korres, D.M.; Karantonis, A.; Vouyiouka, S. Self-healing coatings based on poly (urea-formaldehyde) microcapsules: In situ polymerization, capsule properties and application. Prog. Org. Coat. 2021, 161, 106475. [Google Scholar] [CrossRef]

- Luo, Z.; Xu, W.; Wu, S. Performances of Green Velvet Material (PLON) Used in Upholstered Furniture. Bioresources 2023, 18, 5108–5119. [Google Scholar] [CrossRef]

- Luo, Y.; Xu, W. Optimization of Panel Furniture Plates Rework Based on Intelligent Manufacturing. Bioresources 2023, 18, 5198–5208. [Google Scholar] [CrossRef]

- Wang, C.; Yu, J.; Jiang, M.H.; Li, J.Y. Effect of slicing parameters on the light transmittance of 3D-printed polyethylene terephthalate glycol products. Bioresources 2024, 19, 500–509. [Google Scholar] [CrossRef]

| Experimental Materials | Molecular Mass (g/mol) | CAS | Producer |

|---|---|---|---|

| 37% formaldehyde | 30.03 | 50-00-0 | Shandong Xinjiuchenghuagong Technology Co., Ltd., Jinan, China |

| Melamine | 126.12 | 108-78-1 | Jiangning District Wanjuyi Experimental Equipment Firm, Nanjing, China |

| Triethanolamine | 149.19 | 102-71-6 | Nanjing Houxin Biotechnology Co., Ltd., Nanjing, China |

| Span-20 | 346.459 | 133-39-2 | Nanjing Houxin Biotechnology Co., Ltd., Nanjing, China |

| Triton X-100 | 646.85 | 9002-93-1 | Shandong Yousuo Chemical Technology Co., Ltd., Linyi, China |

| Absolute ethanol | 46.07 | 64-17-5 | Wuxi Jingke Chemical Co., Ltd., Wuxi, China |

| UV topcoat | - | - | Jiangsu Himonia Technology Co., Ltd., Zhenjiang, China |

| Citric acid monohydrate | 210.139 | 5949-29-1 | Jinan Xiaoshi Chemical Co., Ltd., Jinan, China |

| Paint film preparation mold | - | - | Dongguan Xinchen Industrial Investment Co., Ltd., Dongguan, China |

| Experimental Instruments | Model | Manufacturer |

|---|---|---|

| Water bath | LC-OB-5L | Hunan Yunyihui E-commerce Co., Ltd., Changsha, China |

| Scanning electron microscope | OLS3000 | Jiangdong Jiecheng Electronic Components Store, Ningbo, China |

| Powder tablet press | HY-12 | Tianjin Tianguang Optical Instrument Co., Ltd., Tianjin, China |

| Infrared spectrometer | Cary630 | Shenyang Jasco Trading Co., Ltd., Shenyang, China |

| Color difference instrument | 3nhYS3010 | Shenzhen threenh Technology Co., Ltd., Shenzhen, China |

| Glossmeter | 3nhYG60S | Shenzhen threenh Technology Co., Ltd., Shenzhen, China |

| Ultraviolet spectrophotometer | U-3900 | Hitachi High-Tech Co., Ltd., Beijing, China |

| Universal mechanical testing machine | 5000N | Zhejiang Wanxiong Instrument Manufacturing Co., Ltd., Ningbo, China |

| Coating roughness tester | SJ-411 | Dongguan Asktools Co., Ltd., Dongguan, China |

| Single-lamp curing machine | 620# | Huzhou Tongxu Machinery Equipment Co., Ltd., Huzhou, China |

| Level | Factor A mwall material:mcore material | Factor B HLB Value of Emulsifier | Factor C Temperature (°C) | Factor D Time (h) |

|---|---|---|---|---|

| 1 | 1:0.6 | 8.60 | 50 | 1.0 |

| 2 | 1:0.7 | 10.04 | 60 | 2.0 |

| 3 | 1:0.8 | 13.40 | 70 | 3.0 |

| Sample (#) | Factor A mwall material:mcore material | Factor B HLB Value of Emulsifier | Factor C Temperature (°C) | Factor D Time (h) |

|---|---|---|---|---|

| 1 | 1:0.6 | 8.60 | 50 | 1.0 |

| 2 | 1:0.6 | 10.04 | 60 | 2.0 |

| 3 | 1:0.6 | 13.40 | 70 | 3.0 |

| 4 | 1:0.7 | 8.60 | 60 | 3.0 |

| 5 | 1:0.7 | 10.04 | 70 | 1.0 |

| 6 | 1:0.7 | 13.40 | 50 | 2.0 |

| 7 | 1:0.8 | 8.60 | 70 | 2.0 |

| 8 | 1:0.8 | 10.04 | 50 | 3.0 |

| 9 | 1:0.8 | 13.40 | 60 | 1.0 |

| Sample (#) | Triton X-100 (g) | Span 20 (g) | Ethanol (mL) | UV Topcoat (g) | Formaldehyde (g) | Melamine (g) | Deionized Water (mL) |

|---|---|---|---|---|---|---|---|

| 1 | 0.00 | 0.30 | 78.90 | 8.80 | 18.02 | 8.00 | 40.00 |

| 2 | 0.08 | 0.22 | 78.90 | 8.80 | 18.02 | 8.00 | 40.00 |

| 3 | 0.30 | 0.00 | 78.90 | 8.80 | 18.02 | 8.00 | 40.00 |

| 4 | 0.00 | 0.30 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| 5 | 0.08 | 0.22 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| 6 | 0.30 | 0.00 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| 7 | 0.00 | 0.30 | 78.90 | 8.80 | 13.52 | 6.00 | 30.00 |

| 8 | 0.08 | 0.22 | 78.90 | 8.80 | 13.52 | 6.00 | 30.00 |

| 9 | 0.30 | 0.00 | 78.90 | 8.80 | 13.52 | 6.00 | 30.00 |

| Sample (#) | Triton X-100 (g) | Span 20 (g) | Ethanol (mL) | UV Topcoat (g) | Formaldehyde (g) | Melamine (g) | Deionized Water (mL) |

|---|---|---|---|---|---|---|---|

| 10 | 0.00 | 0.30 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| 11 | 0.05 | 0.25 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| 12 | 0.08 | 0.22 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| 13 | 0.15 | 0.15 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| 14 | 0.20 | 0.10 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| 15 | 0.25 | 0.05 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| 16 | 0.30 | 0.00 | 78.90 | 8.80 | 15.44 | 6.86 | 35.00 |

| Amount of UV Topcoat Microcapsules (%) | Mass of UV Topcoat Microcapsules (g) | Mass of UV Topcoat (g) |

|---|---|---|

| 0 | 0 | 1.50 |

| 2.0 | 0.03 | 1.47 |

| 4.0 | 0.06 | 1.44 |

| 6.0 | 0.09 | 1.41 |

| 8.0 | 0.12 | 1.38 |

| 10.0 | 0.15 | 1.35 |

| Sample (#) | Factor A mwall material:mcore material | Factor B HLB Value of Emulsifier | Factor C Temperature (°C) | Factor D Time (h) | P (%) |

|---|---|---|---|---|---|

| 1 | 1:0.6 | 8.60 | 50 | 1.0 | 16.63 |

| 2 | 1:0.6 | 10.04 | 60 | 2.0 | 38.80 |

| 3 | 1:0.6 | 13.40 | 70 | 3.0 | 39.72 |

| 4 | 1:0.7 | 8.60 | 60 | 3.0 | 31.58 |

| 5 | 1:0.7 | 10.04 | 70 | 1.0 | 35.59 |

| 6 | 1:0.7 | 13.40 | 50 | 2.0 | 36.91 |

| 7 | 1:0.8 | 8.60 | 70 | 2.0 | 26.31 |

| 8 | 1:0.8 | 10.04 | 50 | 3.0 | 31.81 |

| 9 | 1:0.8 | 13.40 | 60 | 1.0 | 39.16 |

| Mean value 1 | 31.717 | 24.840 | 28.450 | 30.460 | |

| Mean value 2 | 34.693 | 35.400 | 36.513 | 34.007 | |

| Mean value 3 | 32.427 | 38.597 | 33.873 | 34.370 | |

| Range | 2.976 | 13.4057 | 8.063 | 3.910 | |

| Order of influencing factors | B > C > D > A | ||||

| Optimal level | A2 | B3 | C2 | D3 | |

| Optimal scheme | A2B3C2D3 | ||||

| Sources of Variation | Quadratic Sum | Free Degree | F-Ratio | F-Critical Value | Significance |

|---|---|---|---|---|---|

| Factor A | 14.502 | 2 | 0.128 | 4.460 | |

| Factor B | 310.978 | 2 | 2.735 | 4.460 | |

| Factor C | 101.399 | 2 | 0.892 | 4.460 | |

| Factor D | 27.999 | 2 | 0.246 | 4.460 | |

| Error | 454.88 | 8 |

| Sample (#) | Factor A mwall material:mcore material | Factor B HLB Value of Emulsifier | Factor C Temperature (°C) | Factor D Time (h) | Pc (%) |

|---|---|---|---|---|---|

| 1 | 1:0.6 | 8.60 | 50 | 1.0 | 16.84 |

| 2 | 1:0.6 | 10.04 | 60 | 2.0 | 17.35 |

| 3 | 1:0.6 | 13.40 | 70 | 3.0 | 12.62 |

| 4 | 1:0.7 | 8.60 | 60 | 3.0 | 18.75 |

| 5 | 1:0.7 | 10.04 | 70 | 1.0 | 13.40 |

| 6 | 1:0.7 | 13.40 | 50 | 2.0 | 9.09 |

| 7 | 1:0.8 | 8.60 | 70 | 2.0 | 17.02 |

| 8 | 1:0.8 | 10.04 | 50 | 3.0 | 17.71 |

| 9 | 1:0.8 | 13.40 | 60 | 1.0 | 15.63 |

| Mean value 1 | 15.603 | 17.537 | 14.547 | 15.290 | |

| Mean value 2 | 13.4047 | 16.153 | 17.243 | 14.487 | |

| Mean value 3 | 16.787 | 12.447 | 14.347 | 16.360 | |

| Range | 3.040 | 5.090 | 2.896 | 1.873 | |

| Order of influencing factors | B > A > C > D | ||||

| Optimal level | A3 | B1 | C2 | D3 | |

| Optimal scheme | A3B1C2D3 | ||||

| Sources of Variation | Quadratic Sum | Free Degree | F-Ratio | F-Critical Value | Significance |

|---|---|---|---|---|---|

| Factor A | 14.089 | 2 | 0.735 | 4.460 | |

| Factor B | 41.561 | 2 | 2.169 | 4.460 | |

| Factor C | 15.703 | 2 | 0.819 | 4.460 | |

| Factor D | 5.300 | 2 | 0.277 | 4.460 | |

| Error | 76.65 | 8 |

| Sample (#) | Factor B HLB Value of Emulsifier | P (%) | Pc (%) |

|---|---|---|---|

| 10 | 8.60 | 31.70 | 18.70 |

| 11 | 9.32 | 30.84 | 17.80 |

| 12 | 10.04 | 35.34 | 19.40 |

| 13 | 10.88 | 31.48 | 18.20 |

| 14 | 11.72 | 30.42 | 19.30 |

| 15 | 12.56 | 29.32 | 18.80 |

| 16 | 13.40 | 30.96 | 14.00 |

| Amount of 12# UV Topcoat Microcapsules (%) | L | a | b | ΔE |

|---|---|---|---|---|

| 0 | 76.53 | 0.50 | 1.43 | - |

| 2.0 | 76.47 | 0.53 | 2.00 | 0.34 |

| 4.0 | 74.93 | 0.23 | 2.57 | 0.71 |

| 6.0 | 75.20 | 0.27 | 2.73 | 1.84 |

| 8.0 | 75.10 | 0.23 | 2.97 | 1.78 |

| 10.0 | 76.53 | 0.50 | 1.43 | 2.03 |

| Amount of 12# UV Topcoat Microcapsules (%) | Glossiness at 20° (GU) | Glossiness at 60° (GU) | Glossiness at 85° (GU) |

|---|---|---|---|

| 0 | 1.17 | 5.00 | 3.60 |

| 2.0 | 0.87 | 5.07 | 2.83 |

| 4.0 | 1.27 | 5.13 | 5.67 |

| 6.0 | 0.90 | 3.90 | 3.17 |

| 8.0 | 1.00 | 3.80 | 7.27 |

| 10.0 | 0.87 | 3.53 | 7.73 |

| Amount of 12# UV Topcoat Microcapsules (%) | Elongation at Break (%) |

|---|---|

| 0 | 0.66 |

| 2.0 | 1.22 |

| 4.0 | 1.50 |

| 6.0 | 1.14 |

| 8.0 | 0.62 |

| 10.0 | 0.41 |

| Amount of 12# UV Topcoat Microcapsules (%) | Ra (μm) |

|---|---|

| 0 | 0.369 |

| 2.0 | 1.590 |

| 4.0 | 1.631 |

| 6.0 | 2.598 |

| 8.0 | 2.698 |

| 10.0 | 3.706 |

| Amount of 12# UV Topcoat Microcapsules (%) | Scratch Width (μm) | Self-Healing Rate (%) | |

|---|---|---|---|

| After Scratching | One Week Later | ||

| 0 | 33.98 | 27.46 | 19.19 |

| 2.0 | 39.61 | 31.62 | 20.16 |

| 4.0 | 43.74 | 33.01 | 24.53 |

| 6.0 | 38.26 | 27.97 | 26.89 |

| 8.0 | 36.39 | 27.78 | 23.67 |

| 10.0 | 38.53 | 30.68 | 20.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Y.; Yan, X. Preparation of UV Topcoat Microcapsules and Their Effect on the Properties of UV Topcoat Paint Film. Polymers 2024, 16, 1410. https://doi.org/10.3390/polym16101410

Xia Y, Yan X. Preparation of UV Topcoat Microcapsules and Their Effect on the Properties of UV Topcoat Paint Film. Polymers. 2024; 16(10):1410. https://doi.org/10.3390/polym16101410

Chicago/Turabian StyleXia, Yongxin, and Xiaoxing Yan. 2024. "Preparation of UV Topcoat Microcapsules and Their Effect on the Properties of UV Topcoat Paint Film" Polymers 16, no. 10: 1410. https://doi.org/10.3390/polym16101410

APA StyleXia, Y., & Yan, X. (2024). Preparation of UV Topcoat Microcapsules and Their Effect on the Properties of UV Topcoat Paint Film. Polymers, 16(10), 1410. https://doi.org/10.3390/polym16101410