Influence of the Carbon Fiber Length Distribution in Polymer Matrix Composites for Large Format Additive Manufacturing via Fused Granular Fabrication

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing of Standard Specimens

2.3. Characterization of the Feedstock Material

2.4. Characterization of the 3D-Printed Composites

3. Results and Discussion

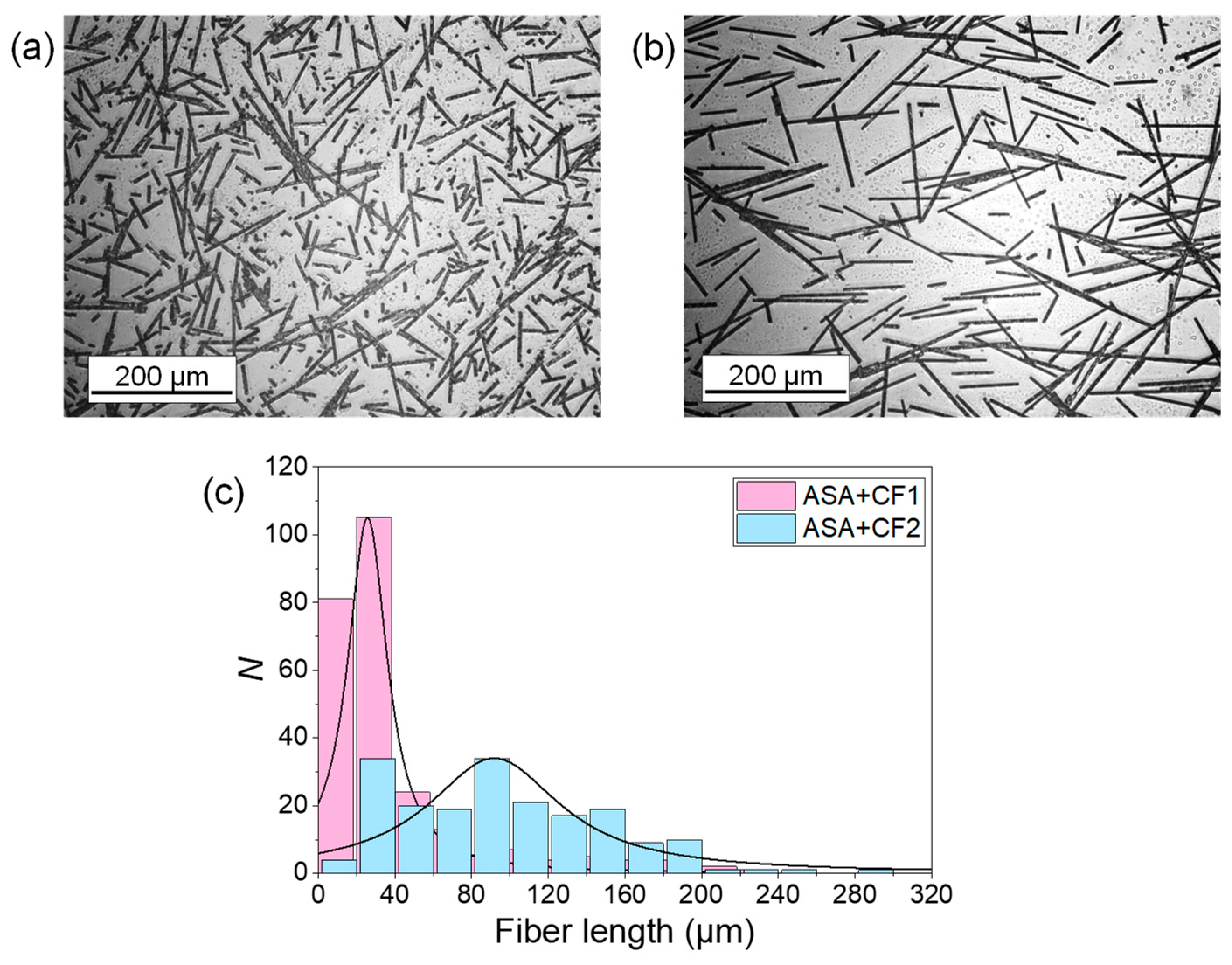

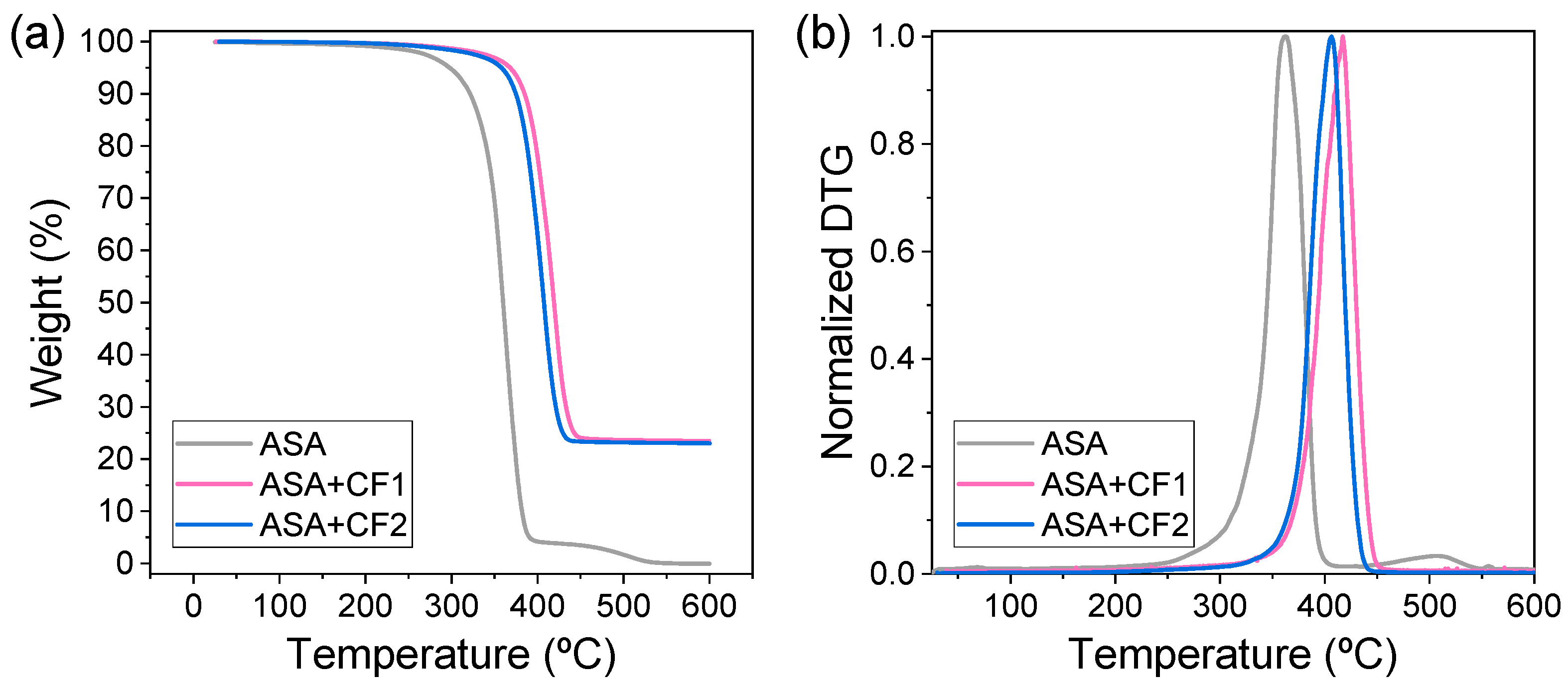

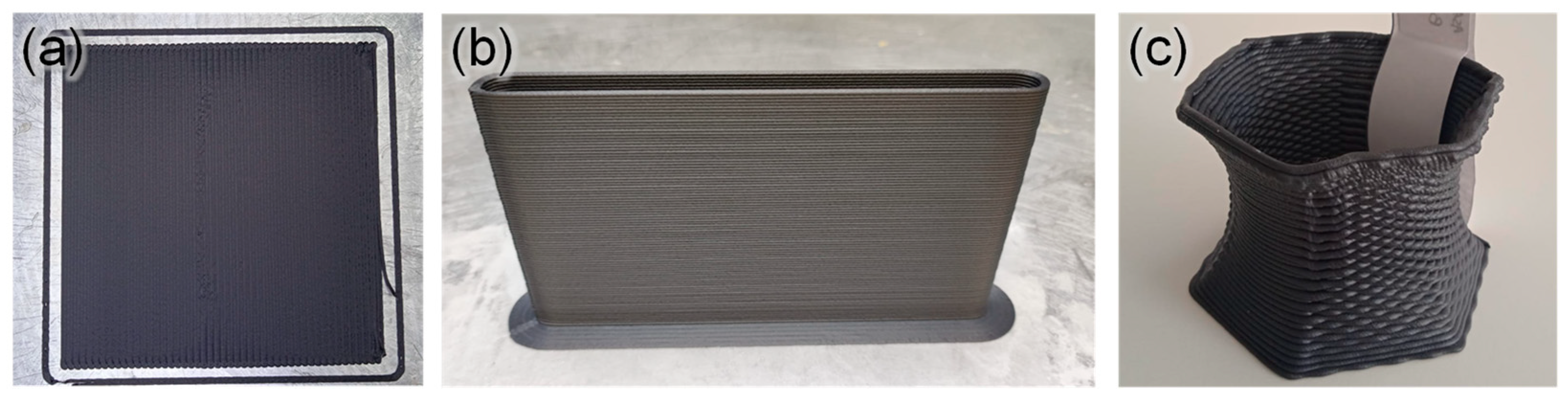

3.1. Analysis of the Feedstock Material and Their Suitability for FGF-LFAM

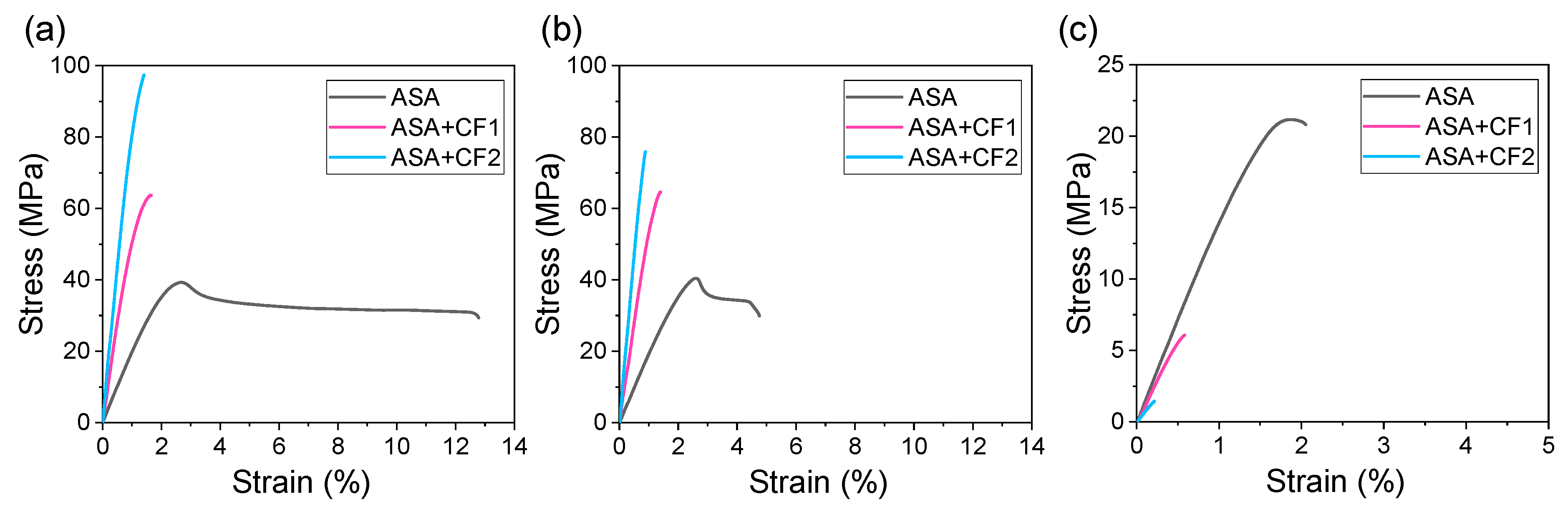

3.2. Influence of the CF Length Distribution in the Mechanical Properties of the Composites Manufactured by FGF-LFAM

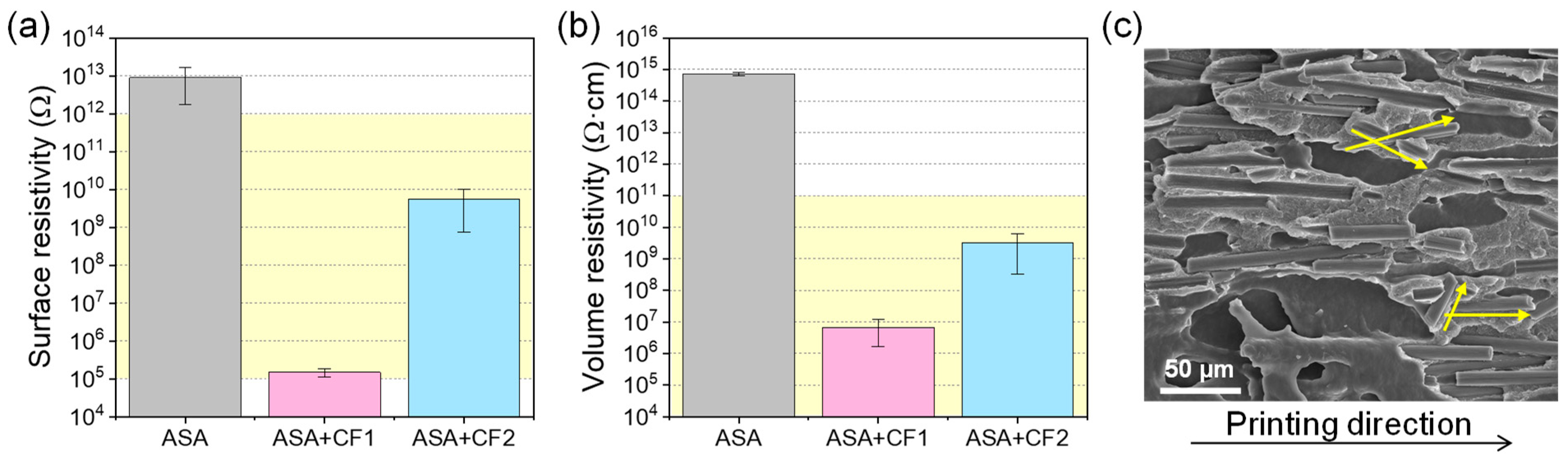

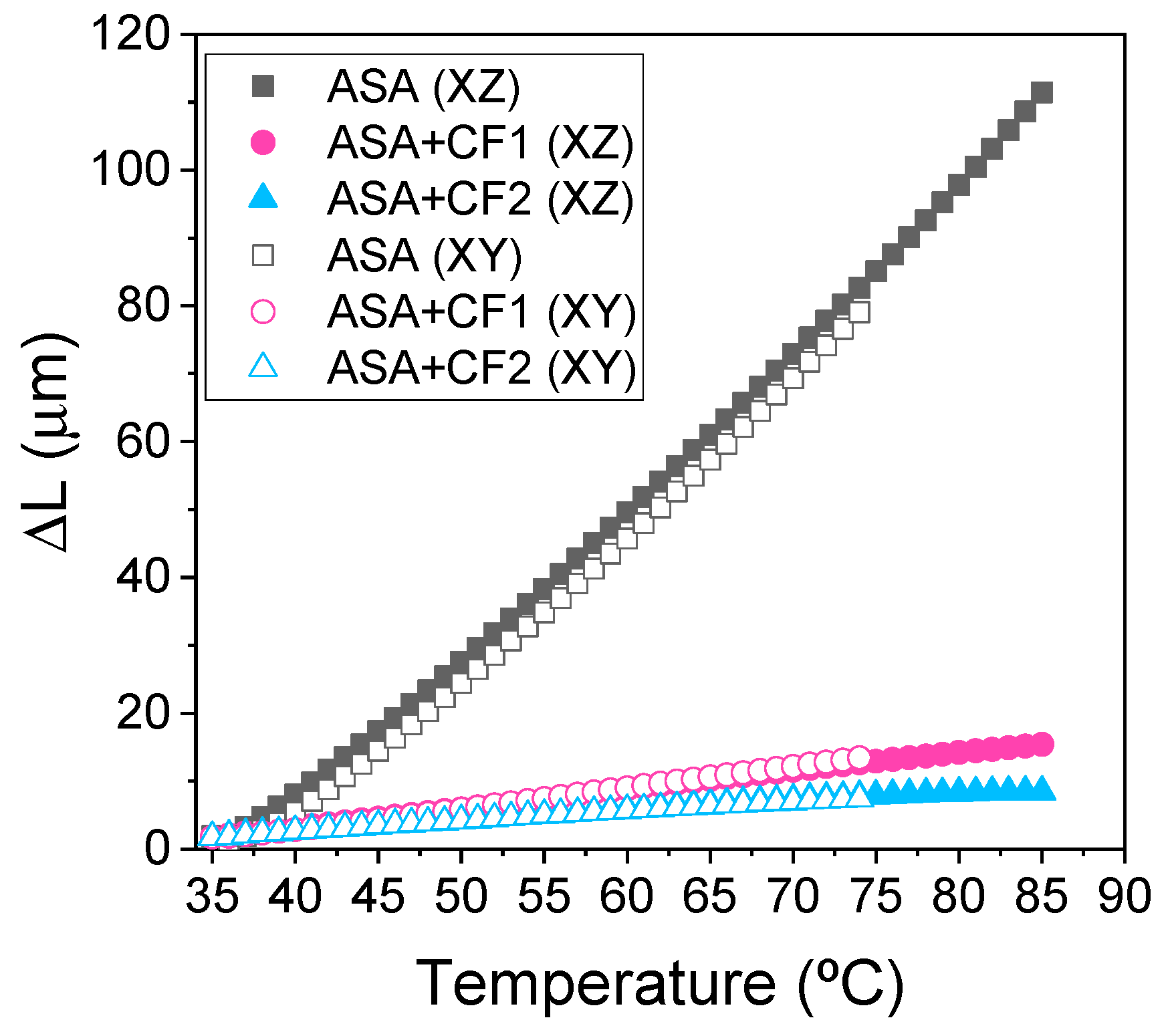

3.3. Influence of the CF Length Distribution in the Functional Properties of the Composites Manufactured via FGF-LFAM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Nieto, D.M.; López, V.C.; Molina, S.I. Large-format polymeric pellet-based additive manufacturing for the naval industry. Addit. Manuf. 2018, 23, 79–85. [Google Scholar] [CrossRef]

- Carter, W.T.; Graham, M.E.; Hayden, C.J.; Jeong, Y.; Mamrak, J.; McCarthy, B.S.; Monaghan, W.F.; Nieters, E.J.; Ostroverkhov, V.; Roychowdhury, S.; et al. A large format DMLM system using a continuously rotating powder bed. Addit. Manuf. 2020, 31, 100983. [Google Scholar] [CrossRef]

- Sweet, G.A.W.; Donaldson, I.W.; Schade, C.T.; Amegadzie, M.Y.; Bishop, D.P. Laser free-form fabrication of dual phase DP600 steel using water atomized feedstock powder. Addit. Manuf. 2021, 47, 102357. [Google Scholar] [CrossRef]

- Chesser, P.; Post, B.; Roschli, A.; Carnal, C.; Lind, R.; Borish, M.; Love, L. Extrusion control for high quality printing on Big Area Additive Manufacturing (BAAM) systems. Addit. Manuf. 2019, 28, 445–455. [Google Scholar] [CrossRef]

- Vicente, C.M.S.; Sardinha, M.; Reis, L.; Ribeiro, A.; Leite, M. Large-format additive manufacturing of polymer extrusion-based deposition systems: Review and applications. Prog. Addit. Manuf. 2023, 8, 1257–1280. [Google Scholar] [CrossRef]

- Pignatelli, F.; Percoco, G. An application- and market-oriented review on large format additive manufacturing, focusing on polymer pellet-based 3D printing. Prog. Addit. Manuf. 2022, 7, 1363–1377. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Hamim, S.U.; Akbari, M.K.; Fakhrhoseini, S.M.; Khayyam, H.; Pakseresht, A.H.; Ghasali, E.; Zabet, M.; Munir, K.S.; Jia, S.; et al. Carbon fiber reinforced metal matrix composites: Fabrication processes and properties. Compos. Part A Appl. Sci. Manuf. 2017, 92, 70–96. [Google Scholar] [CrossRef]

- Yao, S.S.; Jin, F.L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G.P. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Compos. B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Billah, K.M.M.; Lorenzana, F.A.R.; Martinez, N.L.; Wicker, R.B.; Espalin, D. Thermomechanical characterization of short carbon fiber and short glass fiber-reinforced ABS used in large format additive manufacturing. Addit. Manuf. 2020, 35, 101299. [Google Scholar] [CrossRef]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Sapkota, J.; Schuschnigg, S.; Holzer, C. Effect of the printing bed temperature on the adhesion of parts produced by fused filament fabrication. Plast. Rubber Compos. 2017, 47, 17–24. [Google Scholar] [CrossRef]

- De León, A.S.; Domínguez-Calvo, A.; Molina, S.I. Materials with enhanced adhesive properties based on acrylonitrile-butadiene-styrene (ABS)/thermoplastic polyurethane (TPU) blends for fused filament fabrication (FFF). Mater. Des. 2019, 182, 108044. [Google Scholar] [CrossRef]

- Pascual-González, C.; Iragi, M.; Fernández, A.; Fernández-Blázquez, J.P.; Aretxabaleta, L.; Lopes, C.S. An approach to analyse the factors behind the micromechanical response of 3D-printed composites. Compos. B Eng. 2020, 186, 107820. [Google Scholar] [CrossRef]

- Love, L.J.; Kunc, V.; Rios, O.; Duty, C.E.; Elliott, A.M.; Post, B.K.; Smith, R.J.; Blue, C.A. The importance of carbon fiber to polymer additive manufacturing. J. Mater. Res. 2014, 29, 1893–1898. [Google Scholar] [CrossRef]

- Barera, G.; Pegoretti, A. Screw Extrusion Additive Manufacturing of Carbon Fiber Reinforced PA6 Tools. J. Mater. Eng. Perform. 2023, 32, 9579–9597. [Google Scholar] [CrossRef]

- Hassen, A.A.; Dinwiddie, R.B.; Kim, S.; Tekinap, H.L.; Kumar, V.; Lindahl, J.; Yeole, P.; Duty, C.; Vaidya, U.; Wang, H.; et al. Anisotropic thermal behavior of extrusion-based large scale additively manufactured carbon-fiber reinforced thermoplastic structures. Polym. Compos. 2022, 43, 3678–3690. [Google Scholar] [CrossRef]

- Hassan, A.; Hornsby, P.R.; Folkes, M.J. Structure–property relationship of injection-molded carbon fibre-reinforced polyamide 6,6 composites: The effect of compounding routes. Polym. Test. 2003, 22, 185–189. [Google Scholar] [CrossRef]

- Krajangsawasdi, N.; Blok, L.G.; Hamerton, I.; Longana, M.L.; Woods, B.K.S.; Ivanov, D.S. Fused Deposition Modelling of Fibre Reinforced Polymer Composites: A Parametric Review. J. Compos. Sci. 2021, 5, 29. [Google Scholar] [CrossRef]

- Lee, H.; Cho, D. Effects of A, B, and S components on fiber length distribution, mechanical, and impact properties of carbon fiber/ABS composites produced by different processing methods. J. Appl. Polym. Sci. 2021, 138, 50674. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Friedrich, K. Effect of fiber length on the wear resistance of short carbon fiber reinforced epoxy composites. Compos. Sci. Technol. 2007, 67, 222–230. [Google Scholar] [CrossRef]

- Yi, G.; Li, J.; Henderson, L.C.; Lei, W.; Du, L.; Zhao, S. Enhancing Thermal Conductivity of Polyvinylidene Fluoride Composites by Carbon Fiber: Length Effect of the Filler. Polymers 2022, 14, 4599. [Google Scholar] [CrossRef]

- Liang, X.; Ling, L.; Lu, C.; Liu, L. Resistivity of carbon fibers/ABS resin composites. Mater. Lett. 2000, 43, 144–147. [Google Scholar] [CrossRef]

- Starý, Z.; Krückel, J.; Weck, C.; Schubert, D.W. Rheology and conductivity of carbon fibre composites with defined fibre lengths. Compos. Sci. Technol. 2013, 85, 58–64. [Google Scholar] [CrossRef]

- Unterweger, C.; Mayrhofer, T.; Piana, F.; Duchoslav, J.; Stifter, D.; Poitzsch, C.; Fürst, C. Impact of fiber length and fiber content on the mechanical properties and electrical conductivity of short carbon fiber reinforced polypropylene composites. Compos. Sci. Technol. 2020, 188, 107998. [Google Scholar] [CrossRef]

- ISO 17295:2023; Additive manufacturing: General principles—Part positioning, coordinates and orientation. ISO: Geneva, Switzerland, 2023.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM D257-14(2021)e1; Standard Test Methods for DC Resistance or Conductance of Insulating Materials. ASTM: West Conshohocken, PA, USA, 2014.

- Zhang, J.W.J.Z.J.; Wang, B. Compatibilizer Assistant SCF/ABS Composites with Improved Mechanical Properties Prepared by Fused Deposition Modeling. Polym. Plast. Technol. Eng. 2018, 57, 1576–1584. [Google Scholar] [CrossRef]

- Wang, S.; Capoen, L.; D’hooge, D.R.; Cardon, L. Can the melt flow index be used to predict the success of fused deposition modelling of commercial poly(lactic acid) filaments into 3D printed materials? Plast. Rubber Compos. 2017, 47, 9–16. [Google Scholar] [CrossRef]

- Sánchez, D.M.; de la Mata, M.; Delgado, F.J.; Casal, V.; Molina, S.I. Development of carbon fiber acrylonitrile styrene acrylate composite for large format additive manufacturing. Mater. Des. 2020, 191, 108577. [Google Scholar] [CrossRef]

- Pintos, P.B.; de León, A.S.; Molina, S.I. Large format additive manufacturing of polyethylene terephthalate (PET) by material extrusion. Addit. Manuf. 2024, 79, 103908. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Duty, C.E.; Kunc, V.; Compton, B.; Post, B.; Erdman, D.; Smith, R.; Lind, R.; Lloyd, P.; Love, L. Structure and mechanical behavior of Big Area Additive Manufacturing (BAAM) materials. Rapid Prototyp. J. 2017, 23, 181–189. [Google Scholar] [CrossRef]

- Kishore, V.; Ajinjeru, C.; Nycz, A.; Post, B.; Lindahl, J.; Kunc, V.; Duty, C. Infrared preheating to improve interlayer strength of big area additive manufacturing (BAAM) components. Addit. Manuf. 2017, 14, 7–12. [Google Scholar] [CrossRef]

- Moreno-Sanchez, D.; de León, A.S.; Nieto, D.M.; Delgado, F.J.; Molina, S.I. Basalt Fiber Composites with Reduced Thermal Expansion for Additive Manufacturing. Polymers 2022, 14, 3216. [Google Scholar] [CrossRef] [PubMed]

- Türk, D.-A.; Brenni, F.; Zogg, M.; Meboldt, M. Mechanical characterization of 3D printed polymers for fiber reinforced polymers processing. Mater. Des. 2017, 118, 256–265. [Google Scholar] [CrossRef]

- Shanmugam, V.; Rajendran, D.J.J.; Babu, K.; Rajendran, S.; Veerasimman, A.; Marimuthu, U.; Singh, S.; Das, O.; Neisiany, R.E.; Hedenqvist, M.S.; et al. The mechanical testing and performance analysis of polymer-fibre composites prepared through the additive manufacturing. Polym. Test. 2021, 93, 106925. [Google Scholar] [CrossRef]

- Fu, S.Y.; Lauke, B.; Mäder, E.; Yue, C.Y.; Hu, X. Tensile properties of short-glass-fiber- and short-carbon-fiber-reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- LBlok, G.; Longana, M.L.; Woods, B.K.S. Fabrication and Characterisation of Aligned Discontinuous Carbon Fibre Reinforced Thermoplastics as Feedstock Material for Fused Filament Fabrication. Materials 2020, 13, 4671. [Google Scholar] [CrossRef]

- Narkis, M.; Lidor, G.; Vaxman, A.; Zuri, L. New injection moldable electrostatic dissipative (ESD) composites based on very low carbon black loadings. J. Electrostat. 1999, 47, 201–214. [Google Scholar] [CrossRef]

- Rival, G.; Dantras, É.; Paulmier, T. Ageing of PEEK/Carbon Fibre composite under electronic irradiations: Influence on mechanical behaviour and charge transport. Compos. Part A Appl. Sci. Manuf. 2022, 154, 106769. [Google Scholar] [CrossRef]

- Love, L.J.; Duty, C.E.; Post, B.K.; Lind, R.F.; Lloyd, P.D.; Kunc, V.; Peter, W.H.; Blue, C.A. Breaking Barriers in Polymer Additive Manufacturing; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2015; pp. 1–17. [Google Scholar]

| MFR (g/10 min) | |

|---|---|

| ASA | 44.3 ± 2.0 |

| ASA+CF1 | 20.5 ± 1.9 |

| ASA+CF2 | 10.3 ± 0.4 |

| Young’s Modulus (MPa) | |||

|---|---|---|---|

| IM | FGF_XY | FGF_XZ | |

| ASA | 2070 ± 40 | 1960 ± 120 | 1500 ± 50 |

| ASA+CF1 | 5800 ± 400 | 5670 ± 430 | 1270 ± 60 |

| ASA+CF2 | 8600 ± 380 | 9450 ± 400 | 700 ± 80 |

| Tensile Strength (MPa) | |||

|---|---|---|---|

| IM | FGF_XY | FGF_XZ | |

| ASA | 39.3 ± 0.1 | 39.9 ± 0.6 | 21.2 ± 0.7 |

| ASA+CF1 | 64.5 ± 2.7 | 65.4 ± 2.7 | 6.5 ± 1.1 |

| ASA+CF2 | 95.2 ± 4.1 | 74.8 ± 4.3 | 1.2 ± 0.3 |

| Elongation at Break (%) | |||

|---|---|---|---|

| IM | FGF_XY | FGF_XZ | |

| ASA | 13.5 ± 4.1 | 4.6 ± 0.7 | 2.1 ± 0.3 |

| ASA+CF1 | 1.7 ± 0.1 | 1.4 ± 0.1 | 0.59 ± 0.08 |

| ASA+CF2 | 1.4 ± 0.1 | 0.9 ± 0.1 | 0.21 ± 0.03 |

| CTE (µm/m·°C) | ||

|---|---|---|

| FGF_XY | FGF_XZ | |

| ASA | 75.5 ± 0.7 | 70.3 ± 0.6 |

| ASA+CF1 | 12.1 ± 0.2 | 13.5± 0.9 |

| ASA+CF2 | 7.4 ± 0.1 | 7.0 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burgos Pintos, P.; Moreno Sánchez, D.; Delgado, F.J.; Sanz de León, A.; Molina, S.I. Influence of the Carbon Fiber Length Distribution in Polymer Matrix Composites for Large Format Additive Manufacturing via Fused Granular Fabrication. Polymers 2024, 16, 60. https://doi.org/10.3390/polym16010060

Burgos Pintos P, Moreno Sánchez D, Delgado FJ, Sanz de León A, Molina SI. Influence of the Carbon Fiber Length Distribution in Polymer Matrix Composites for Large Format Additive Manufacturing via Fused Granular Fabrication. Polymers. 2024; 16(1):60. https://doi.org/10.3390/polym16010060

Chicago/Turabian StyleBurgos Pintos, Pedro, Daniel Moreno Sánchez, Francisco J. Delgado, Alberto Sanz de León, and Sergio I. Molina. 2024. "Influence of the Carbon Fiber Length Distribution in Polymer Matrix Composites for Large Format Additive Manufacturing via Fused Granular Fabrication" Polymers 16, no. 1: 60. https://doi.org/10.3390/polym16010060

APA StyleBurgos Pintos, P., Moreno Sánchez, D., Delgado, F. J., Sanz de León, A., & Molina, S. I. (2024). Influence of the Carbon Fiber Length Distribution in Polymer Matrix Composites for Large Format Additive Manufacturing via Fused Granular Fabrication. Polymers, 16(1), 60. https://doi.org/10.3390/polym16010060