Influences of Fiber Volume Content on the Mechanical Properties of 2D Plain Carbon-Fiber Woven Composite Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Testing Methods

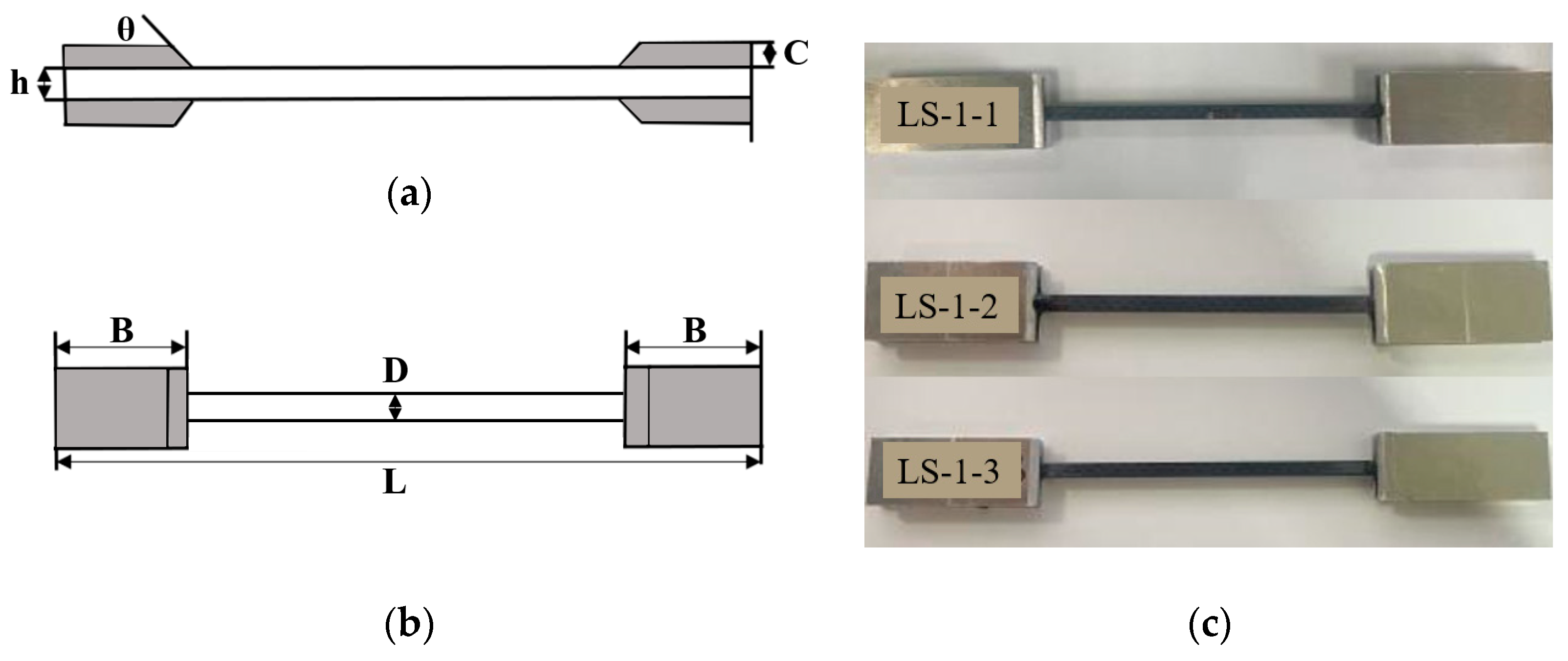

2.2.1. Tensile Test

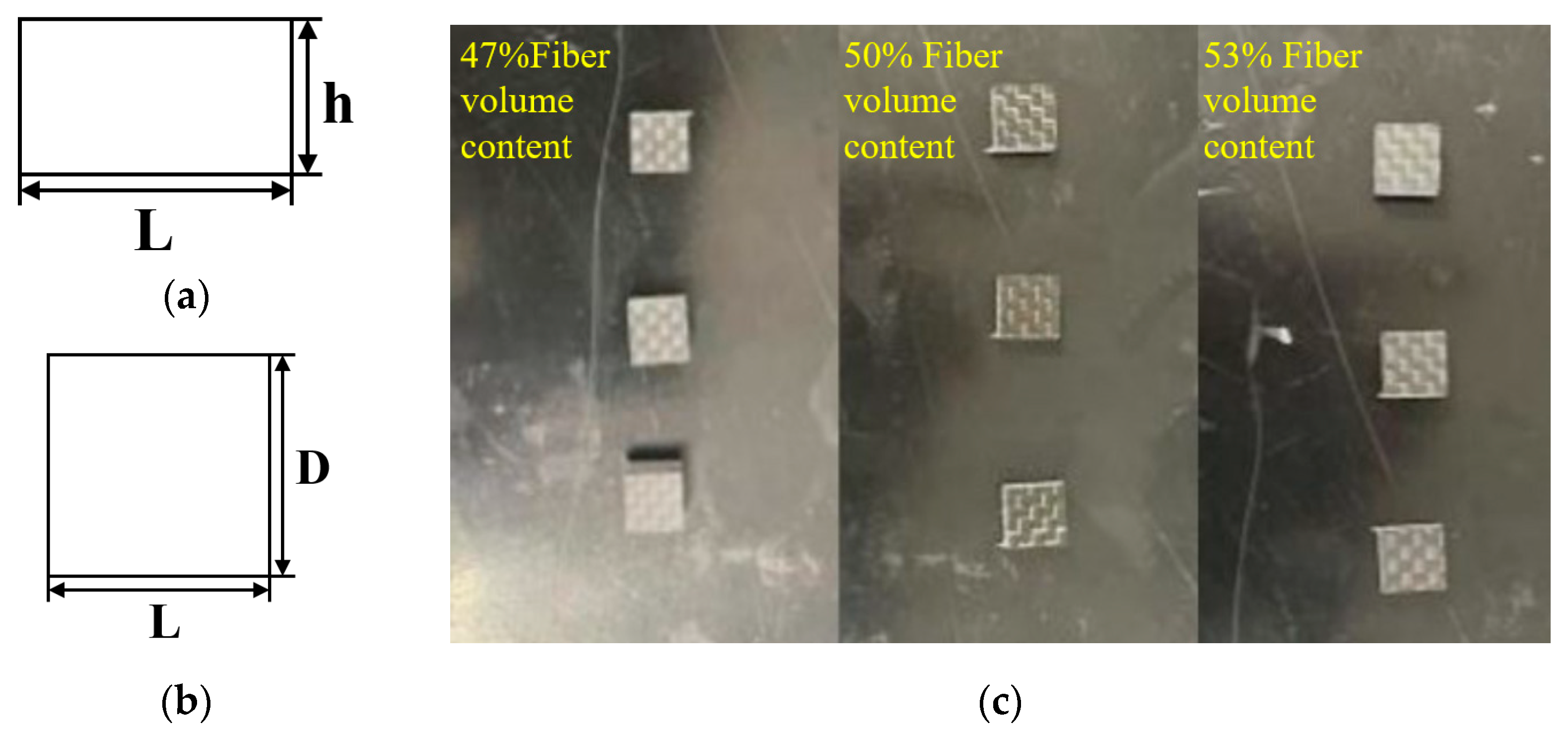

2.2.2. Compression Test

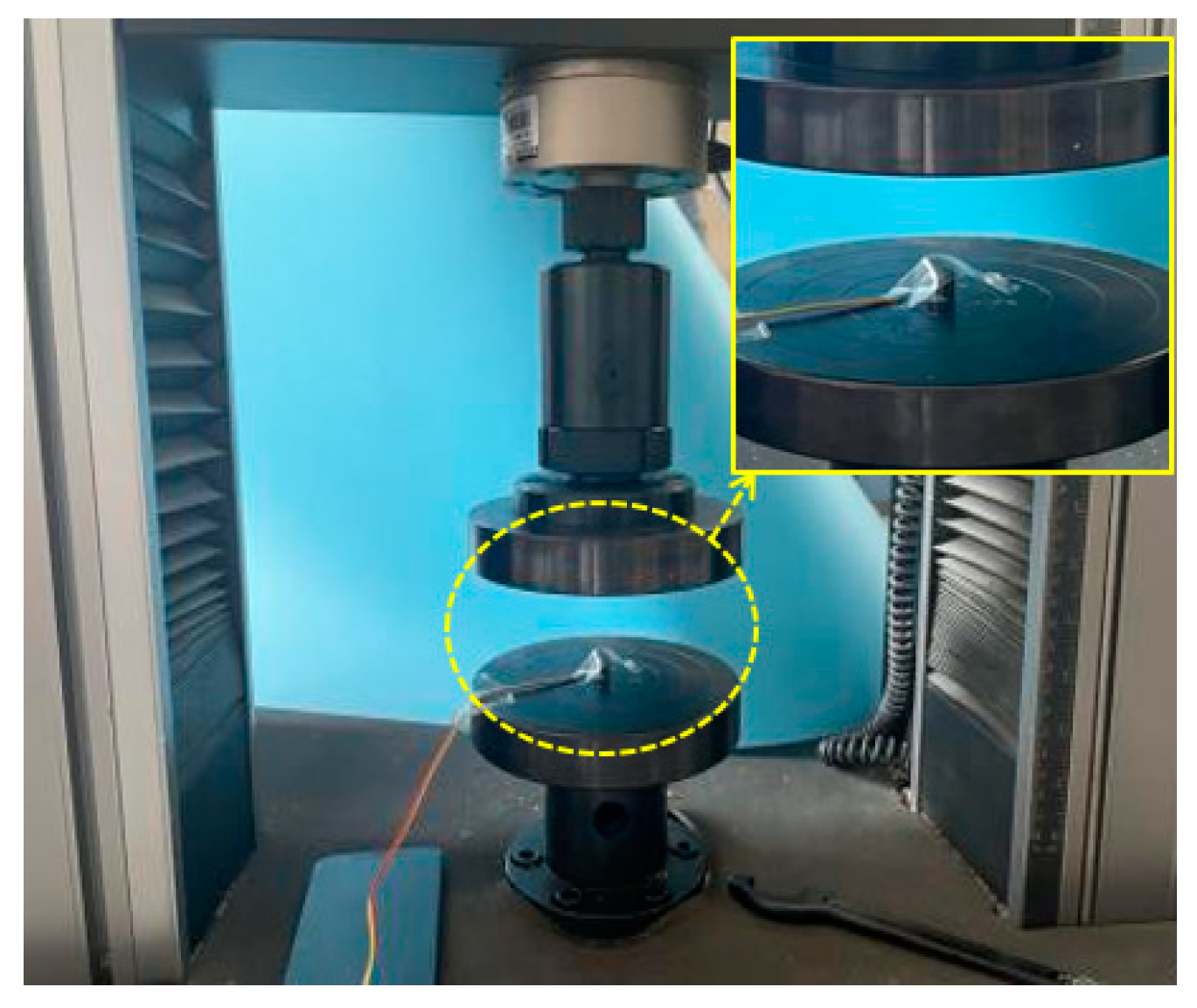

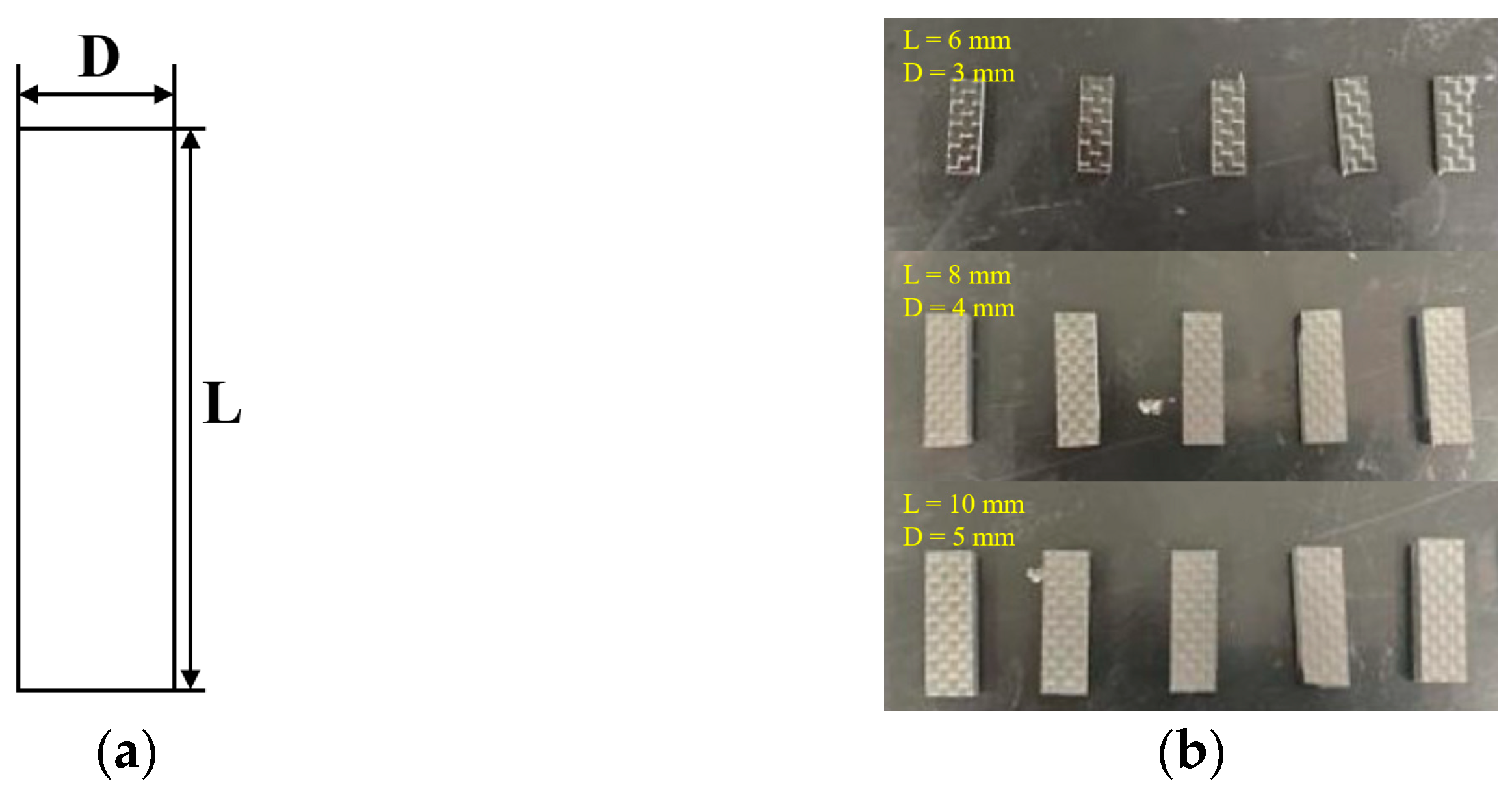

2.2.3. Shear Test

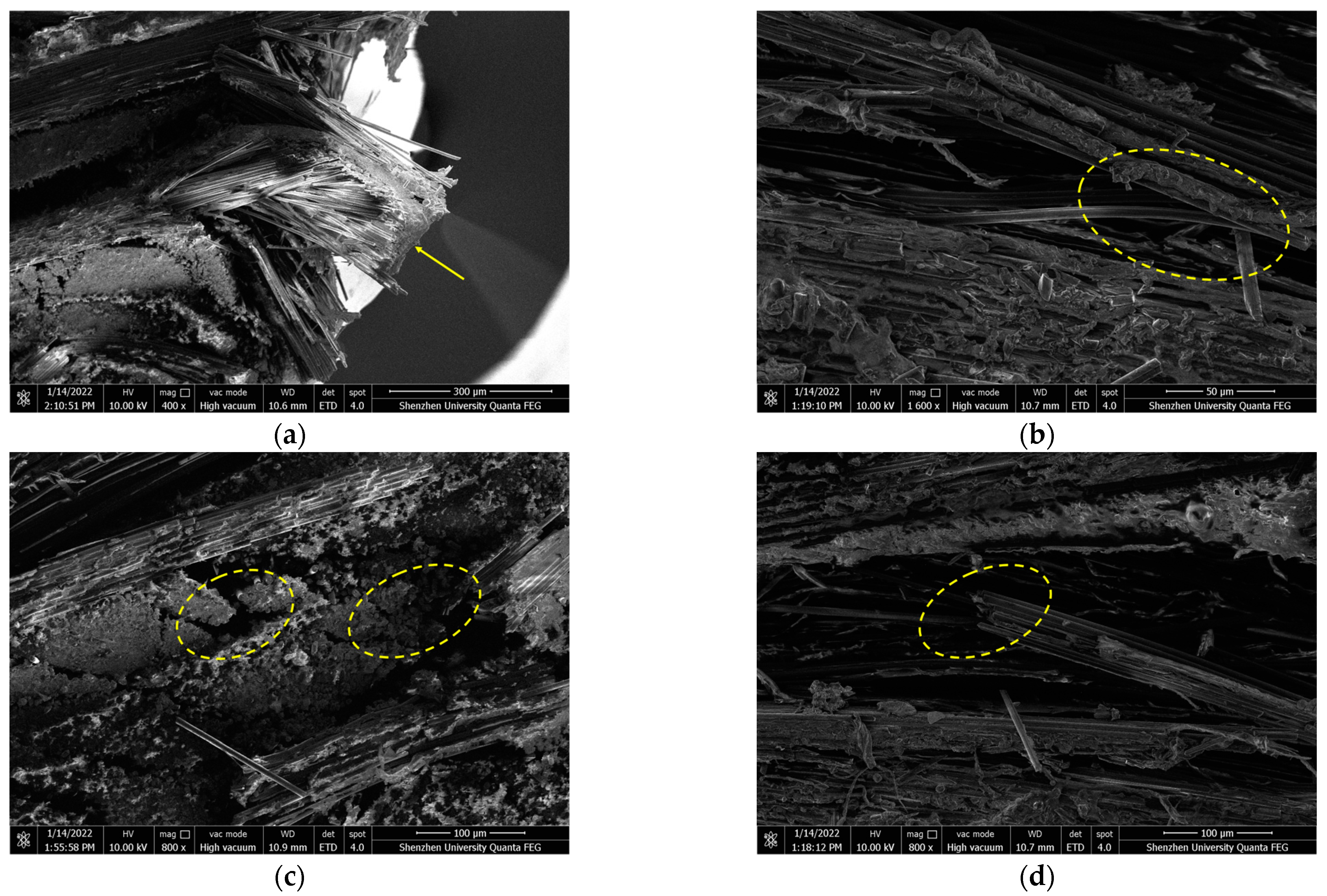

2.3. Scanning Electron Microscope (SEM)

3. Results and Discussion

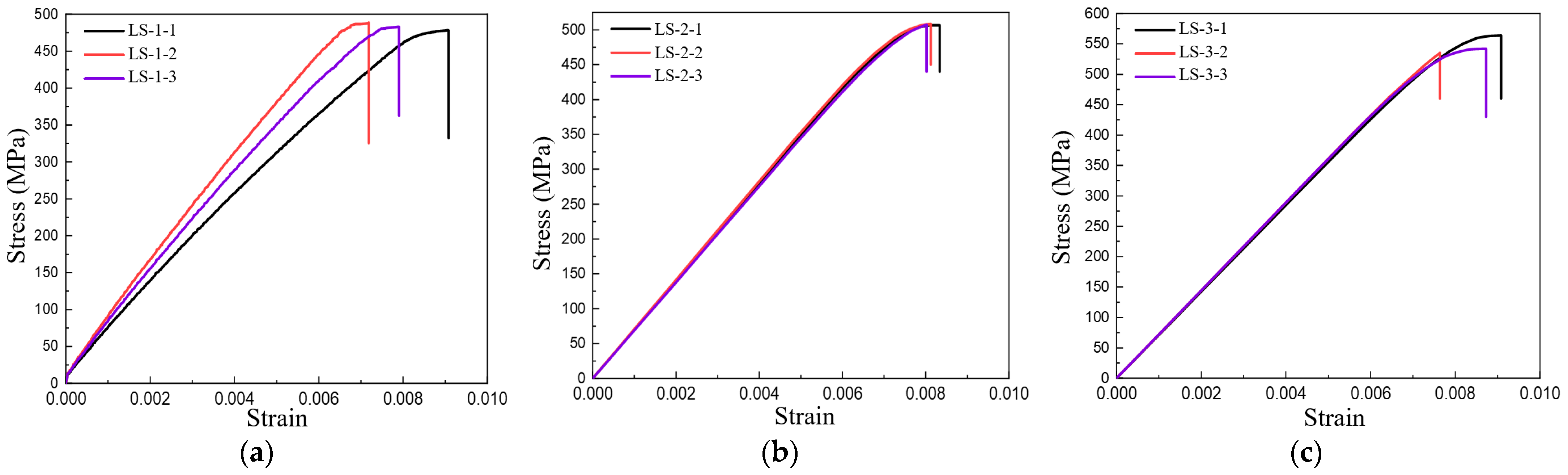

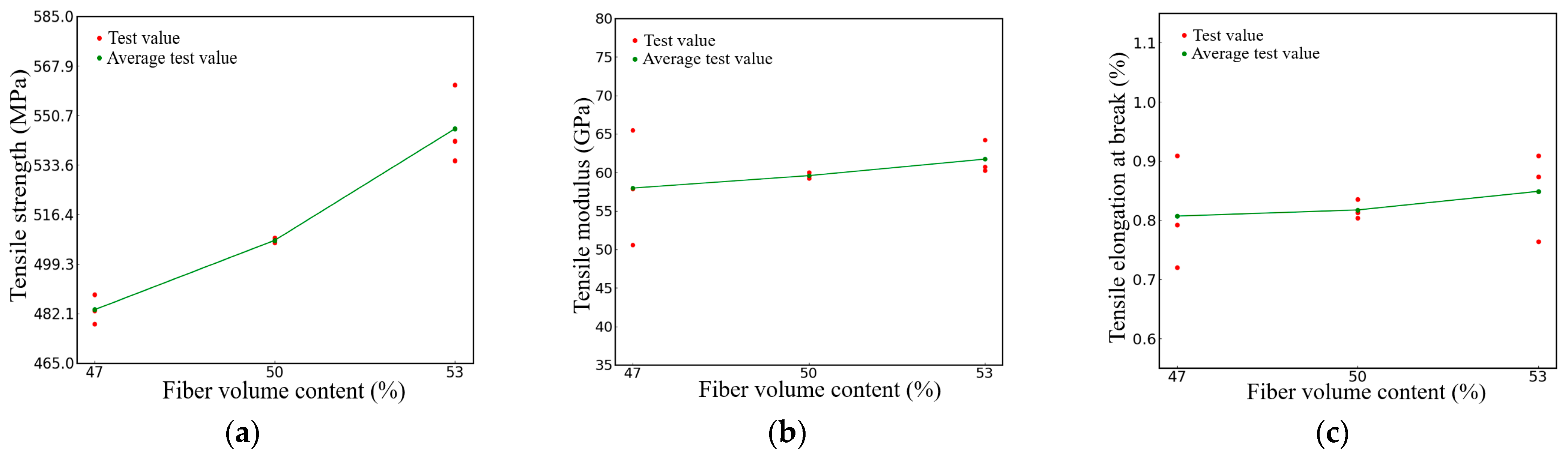

3.1. Tensile Test

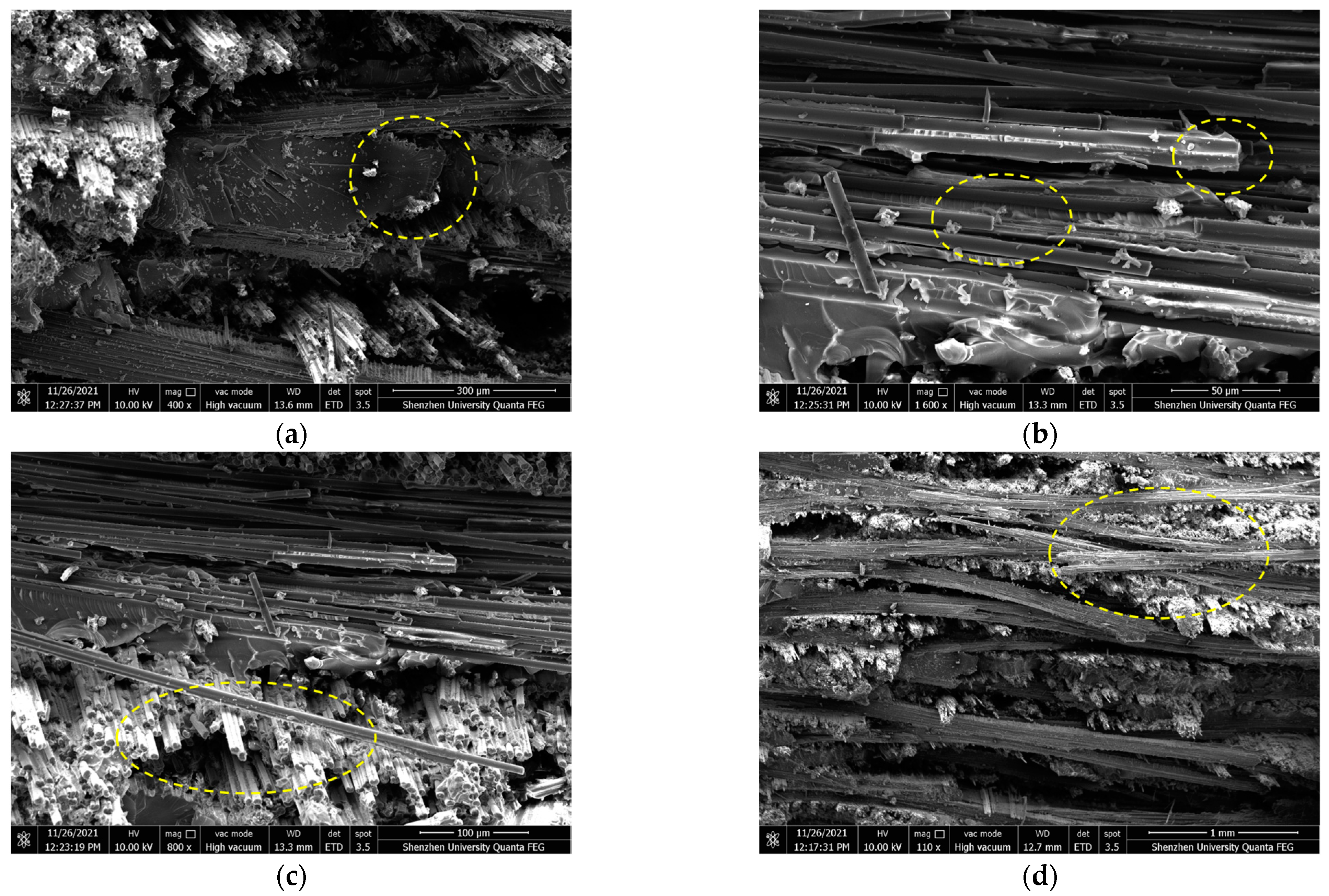

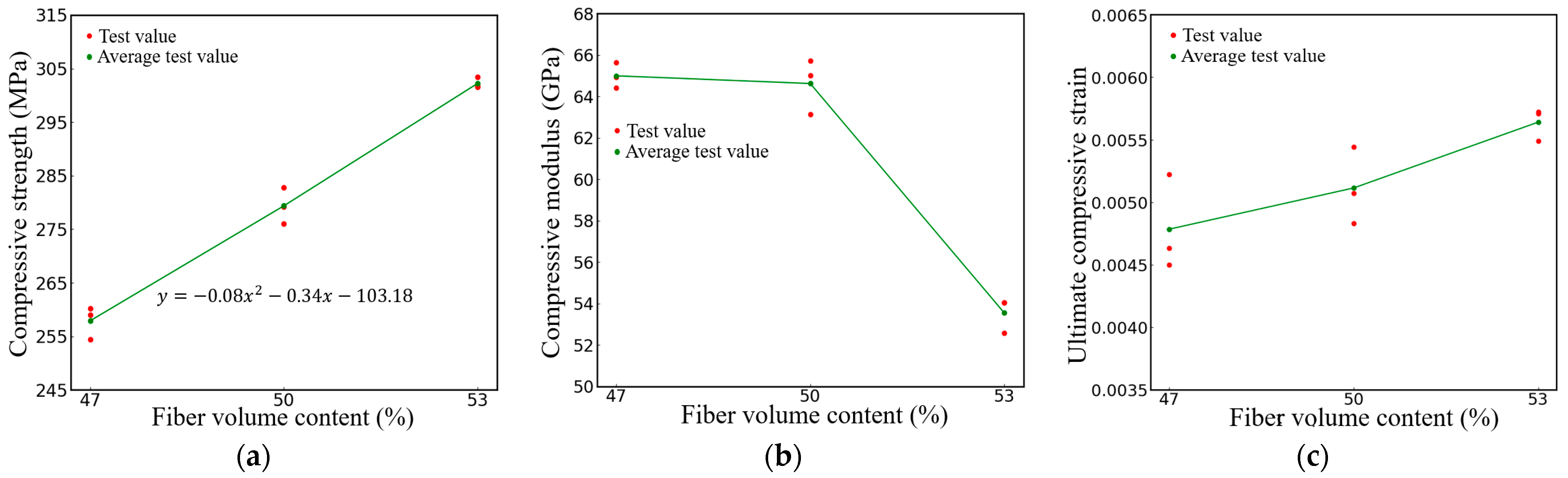

3.2. Compression Test

3.3. Short-Beam Shear Test

4. Conclusions

- (1)

- The tensile strength of 2D woven composites increases approximately linearly with the increase in fiber volume content. The average tensile strengths of specimens with fiber volume contents of 47%, 50% and 53% were 483 MPa, 507 MPa and 546 MPa, respectively. The change of longitudinal tensile elastic modulus with fiber volume content is relatively small. The tensile elastic moduli corresponding to 47%, 50% and 53% fiber volume contents were 58 GPa, 59.6 GPa and 61.7 GPa, respectively. The ultimate tensile strain of two-dimensional woven composites was relatively discrete, with the average value ranging from 0.82% to 0.85%.

- (2)

- The ultimate compressive strength of the two-dimensional woven composites increased almost linearly with the increase in fiber volume content. The average ultimate compressive strength and average compressive modulus of the 2D woven composites with 47% fiber volume content were 258 MPa and 65 GPa, respectively. The average ultimate compressive strength of 2D woven composites with 50% fiber volume content was 279 MPa, and the corresponding compressive modulus was 64.6 GPa. The average ultimate compressive strength of the two-dimensional woven composite with 53% fiber volume content was 302 MPa, and the corresponding average compressive modulus was 53.6 GPa.

- (3)

- The shear strength of the 2D woven composites increased slightly at lower fiber volume contents and increased significantly at higher fiber volume contents. The average value of the shear strength of specimens with 47%, 50% and 53% fiber volume contents were 64.5 MPa, 66.1 MPa and 91.7 MPa, respectively. The shear strain energy of the specimens with 53% fiber volume content was 64.9 MJ/m3, which is 46.6% higher than that of the 50% fiber volume content specimen at 44.3 MJ/m3, and 273% higher than that of the 47% fiber volume content specimen at 17.4 MJ/m3.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ramli, N.; Norkhairunnisa, M.; Ando, Y.; Abdan, K.; Leman, Z. Advanced Polymer Composite for Aerospace Engineering Applications. In Advanced Composites in Aerospace Engineering Applications; Mazlan, N., Sapuan, S.M., Ilyas, R.A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–21. ISBN 978-3-030-88192-4. [Google Scholar]

- Zhong, S.; Nsengiyumva, W. Introduction and Background of Fiber-Reinforced Composite Materials. In Nondestructive Testing and Evaluation of Fiber-Reinforced Composite Structures; Zhong, S., Nsengiyumva, W., Eds.; Springer Nature: Singapore, 2022; pp. 1–59. ISBN 978-981-19084-8-4. [Google Scholar]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Reddy, S.S.P.; Suresh, R.; Hanamantraygouda, M.B.; Shivakumar, B.P. Use of Composite Materials and Hybrid Composites in Wind Turbine Blades. Mater. Today Proc. 2021, 46, 2827–2830. [Google Scholar] [CrossRef]

- Bak, C.; Zahle, F.; Bitsche, R.; Kim, T.; Yde, A.; Henriksen, L.C.; Hansen, M.H.; Blasques, J.P.A.A.; Gaunaa, M.; Natarajan, A. The DTU 10-MW Reference Wind Turbine. In Proceedings of the Danish Wind Power Research 2013, Trinity, Denmark, 27–28 May 2013. [Google Scholar]

- Gaertner, E.; Rinker, J.; Sethuraman, L.; Zahle, F.; Anderson, B.; Barter, G.E.; Abbas, N.J.; Meng, F.; Bortolotti, P.; Skrzypinski, W. IEA Wind TCP Task 37: Definition of the IEA 15-Megawatt Offshore Reference Wind Turbine; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2020. [Google Scholar]

- Ashuri, T.; Martins, J.R.R.A.; Zaaijer, M.B.; van Kuik, G.a.M.; van Bussel, G.J.W. Aeroservoelastic Design Definition of a 20 MW Common Research Wind Turbine Model. Wind Energy 2016, 19, 2071–2087. [Google Scholar] [CrossRef]

- Asian, S.; Ertek, G.; Haksoz, C.; Pakter, S.; Ulun, S. Wind Turbine Accidents: A Data Mining Study. IEEE Syst. J. 2017, 11, 1567–1578. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed]

- Ekoi, E.J.; Dickson, A.N.; Dowling, D.P. Investigating the Fatigue and Mechanical Behaviour of 3D Printed Woven and Nonwoven Continuous Carbon Fibre Reinforced Polymer (CFRP) Composites. Compos. Part B Eng. 2021, 212, 108704. [Google Scholar] [CrossRef]

- Zhang, Y.-Y.; Sun, Z.; Li, Y.-Q.; Huang, P.; Chen, Q.; Fu, S.-Y. Tensile Creep Behavior of Short-Carbon-Fiber Reinforced Polyetherimide Composites. Compos. Part B Eng. 2021, 212, 108717. [Google Scholar] [CrossRef]

- Kang, J.W. The Strain Evaluation of the Notch tip Area for the CFRP/GFRP Hybrid Laminate Plate using the SENT Specimen. J. Korean Soc. Saf. 2014, 29, 15–21. [Google Scholar] [CrossRef][Green Version]

- Balokas, G.; Theotokoglou, E.E. Cross-Section Analysis of Wind Turbine Blades: Comparison of Failure between Glass and Carbon Fiber. Adv. Compos. Mater. 2018, 27, 561–574. [Google Scholar] [CrossRef]

- Mou, S.; Wen, J.; Xu, J.; Li, C.; Song, Q. Application Progress of Carbon Fiber in Wind Turbine Blades. China Textile Lead. 2022, 5, 44–50. [Google Scholar] [CrossRef]

- Teng, H.; Li, S.; Cao, Z.; Li, S.; Li, C.; Ko, T.J. Carbon Fiber Composites for Large-Scale Wind Turbine Blades: Applicability Study and Comprehensive Evaluation in China. J. Mar. Sci. Eng. 2023, 11, 624. [Google Scholar] [CrossRef]

- Pothan, L.A.; Potschke, P.; Habler, R.; Thomas, S. The Static and Dynamic Mechanical Properties of Banana and Glass Fiber Woven Fabric-Reinforced Polyester Composite. J. Compos. Mater. 2005, 39, 1007–1025. [Google Scholar] [CrossRef]

- Xu, J.; Lomov, S.V.; Verpoest, I.; Daggumati, S.; Van Paepegem, W.; Degrieck, J. A Comparative Study of Twill Weave Reinforced Composites under Tension–Tension Fatigue Loading: Experiments and Meso-Modelling. Compos. Struct. 2016, 135, 306–315. [Google Scholar] [CrossRef]

- Unterweger, C.; Mayrhofer, T.; Piana, F.; Duchoslav, J.; Stifter, D.; Poitzsch, C.; Fürst, C. Impact of Fiber Length and Fiber Content on the Mechanical Properties and Electrical Conductivity of Short Carbon Fiber Reinforced Polypropylene Composites. Compos. Sci. Technol. 2020, 188, 107998. [Google Scholar] [CrossRef]

- Adeniyi, A.; Abdulkareem, S.; Ndagi, M.; Abdulkareem, M.; Ighalo, J. Effect of Fiber Content on the Physical and Mechanical Properties of Plantain Fiber Reinforced Polystyrene Composite. Adv. Mater. Process. Technol. 2022, 8, 4244–4256. [Google Scholar] [CrossRef]

- Walter, T.R.; Subhash, G.; Sankar, B.V.; Yen, C.F. Monotonic and Cyclic Short Beam Shear Response of 3D Woven Composites. Compos. Sci. Technol. 2010, 70, 2190–2197. [Google Scholar] [CrossRef]

- Aiman, D.P.C.; Yahya, M.F.; Salleh, J. Impact Properties of 2D and 3D Woven Composites: A Review. AIP Conf. Proc. 2016, 1774, 020002. [Google Scholar] [CrossRef]

- Böhm, R.; Hornig, A.; Luft, J.; Becker, M.; Koch, I.; Grüber, B.; Hufenbach, W. Experimental Investigation of the Strain Rate Dependent Behaviour of 2D Biaxially and Triaxially Reinforced Braided Composites. Appl. Compos. Mater. 2014, 21, 285–299. [Google Scholar] [CrossRef]

- Wehrkamp-Richter, T.; De Carvalho, N.V.; Pinho, S.T. Predicting the Non-Linear Mechanical Response of Triaxial Braided Composites. Compos. Part A Appl. Sci. Manuf. 2018, 114, 117–135. [Google Scholar] [CrossRef]

- Gautam, M.; Sivakumar, S.; Barnett, A.; Barbour, S.; Ogin, S.L.; Potluri, P. On the Behaviour of Flattened Tubular Bi-Axial and Tri-Axial Braided Composites in Tension. Compos. Struct. 2021, 261, 113325. [Google Scholar] [CrossRef]

- Bak, C.; Zahle, F.; Bitsche, R.; Kim, T.; Yde, A.; Henriksen, L.C.; Natarajan, A.; Hansen, M. Dtu Wind Energy Report-i-0092; DTU Wind Energy: Roskilde, Denmark, 2013. [Google Scholar]

- GB/T 1447-2005; Fiber-Reinforced Plastics Composites—Determination of Tensile Properties. China Building Materials Federation: Beijing, China, 2005.

- GB/T5258-2008; Fiber-Reinforced Plastic Composites—Determination of Compressive Properties in the In-Plane Direction. China Building Materials Federation: Beijing, China, 2008.

- Fan, Z.; Santare, M.H.; Advani, S.G. Interlaminar Shear Strength of Glass Fiber Reinforced Epoxy Composites Enhanced with Multi-Walled Carbon Nanotubes. Compos. Part A Appl. Sci. Manuf. 2008, 39, 540–554. [Google Scholar] [CrossRef]

- Aslan, Z. Apparent Interlaminar Shear Strength Measurement by Four Point Short Beam Test. Adv. Compos. Lett. 2015, 24, 096369351502400203. [Google Scholar] [CrossRef]

- Hu, B.; Wu, Y.-F. Effect of Shear Span-to-Depth Ratio on Shear Strength Components of RC Beams. Eng. Struct. 2018, 168, 770–783. [Google Scholar] [CrossRef]

- Zhang, F.; Xu, J.; Esther, B.; Lu, H.; Fang, H.; Liu, W. Effect of Shear Span-to-Depth Ratio on the Mechanical Behavior of Composite Sandwich Beams with GFRP Ribs and Balsa Wood Core Materials. Thin-Walled Struct. 2020, 154, 106799. [Google Scholar] [CrossRef]

- ASTM D2344/D2344M-22; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- Zehnder, A.T. Griffith Theory of Fracture. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.-W., Eds.; Springer: Boston, MA, USA, 2013; pp. 1570–1573. ISBN 978-0-387-92897-5. [Google Scholar]

- Zhang, D.; Liu, X.; Gu, Y.; Sun, M.; Yu, S.; Zhang, Y.; Qian, K. Effects of Off-Axis Angle on Shear Progressive Damage of 3D Woven Composites with X-Ray Micro-Computed Tomography. Compos. Part A Appl. Sci. Manuf. 2018, 115, 311–320. [Google Scholar] [CrossRef]

| Number of Fiber Layers | Fiber Monolayer Thickness (mm) | Fiber Volume Content (%) | Material Size (Length × Width × Thickness/mm) |

|---|---|---|---|

| 15 | 0.125 | 47% | 200 × 126 × 4 |

| 20 | 0.125 | 50% | 200 × 126 × 5 |

| 25 | 0.125 | 53% | 200 × 126 × 6 |

| Fiber Volume Content (%) | L (mm) | D (mm) | h (mm) | C (mm) | B (mm) | θ (°) |

|---|---|---|---|---|---|---|

| 47 | 200 | 5 ± 0.5 | 4 | 2.5 | 50 | 45 |

| 50 | 200 | 5 ± 0.5 | 5 | 2.5 | 50 | 45 |

| 53 | 200 | 5 ± 0.5 | 6 | 2.5 | 50 | 45 |

| Fiber Volume Content (%) | L (mm) | D (mm) | h (mm) |

|---|---|---|---|

| 47 | 10 ± 0.5 | 10 ± 0.5 | 4 |

| 50 | 10 ± 0.5 | 10 ± 0.5 | 5 |

| 53 | 10 ± 0.5 | 10 ± 0.5 | 6 |

| Fiber Volume Content (%) | L (mm) | D (mm) |

|---|---|---|

| 47 | 6 ± 0.5 | 3 |

| 50 | 8 ± 0.5 | 4 |

| 53 | 10 ± 0.5 | 5 |

| Resolution Ratio | Accelerating Voltage | Magnification |

|---|---|---|

| 1.0 nm@30 kV, 3.0 nm@1 kV | 200 V~30 kV | 14–1,000,000× |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, J.; Saeed, N.; Huang, X.; Tian, W.; Li, L.; Song, J. Influences of Fiber Volume Content on the Mechanical Properties of 2D Plain Carbon-Fiber Woven Composite Materials. Polymers 2024, 16, 108. https://doi.org/10.3390/polym16010108

Gong J, Saeed N, Huang X, Tian W, Li L, Song J. Influences of Fiber Volume Content on the Mechanical Properties of 2D Plain Carbon-Fiber Woven Composite Materials. Polymers. 2024; 16(1):108. https://doi.org/10.3390/polym16010108

Chicago/Turabian StyleGong, Jingliang, Nouman Saeed, Xigui Huang, Weiwei Tian, Lixiao Li, and Jian Song. 2024. "Influences of Fiber Volume Content on the Mechanical Properties of 2D Plain Carbon-Fiber Woven Composite Materials" Polymers 16, no. 1: 108. https://doi.org/10.3390/polym16010108

APA StyleGong, J., Saeed, N., Huang, X., Tian, W., Li, L., & Song, J. (2024). Influences of Fiber Volume Content on the Mechanical Properties of 2D Plain Carbon-Fiber Woven Composite Materials. Polymers, 16(1), 108. https://doi.org/10.3390/polym16010108