Effect of Shock-Variable Environmental Temperature and Humidity Conditions on 3D-Printed Polymers for Tensile Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Printing Procedures

2.2. Shock-Variable Environmental Condition Process

2.3. Material Examination

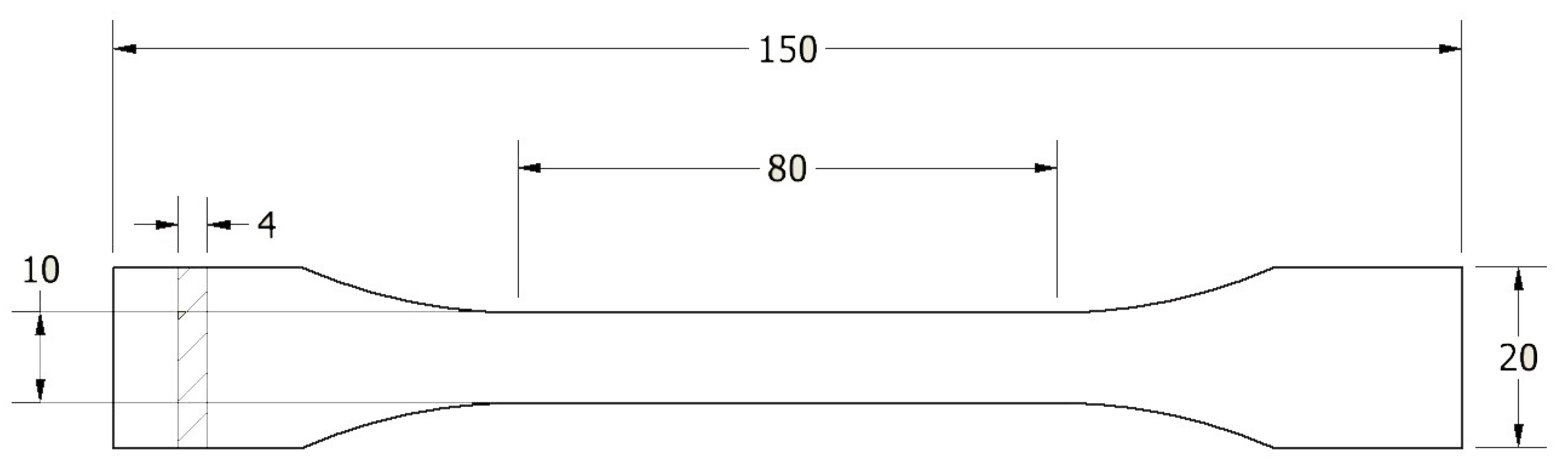

2.3.1. Mechanical Testing

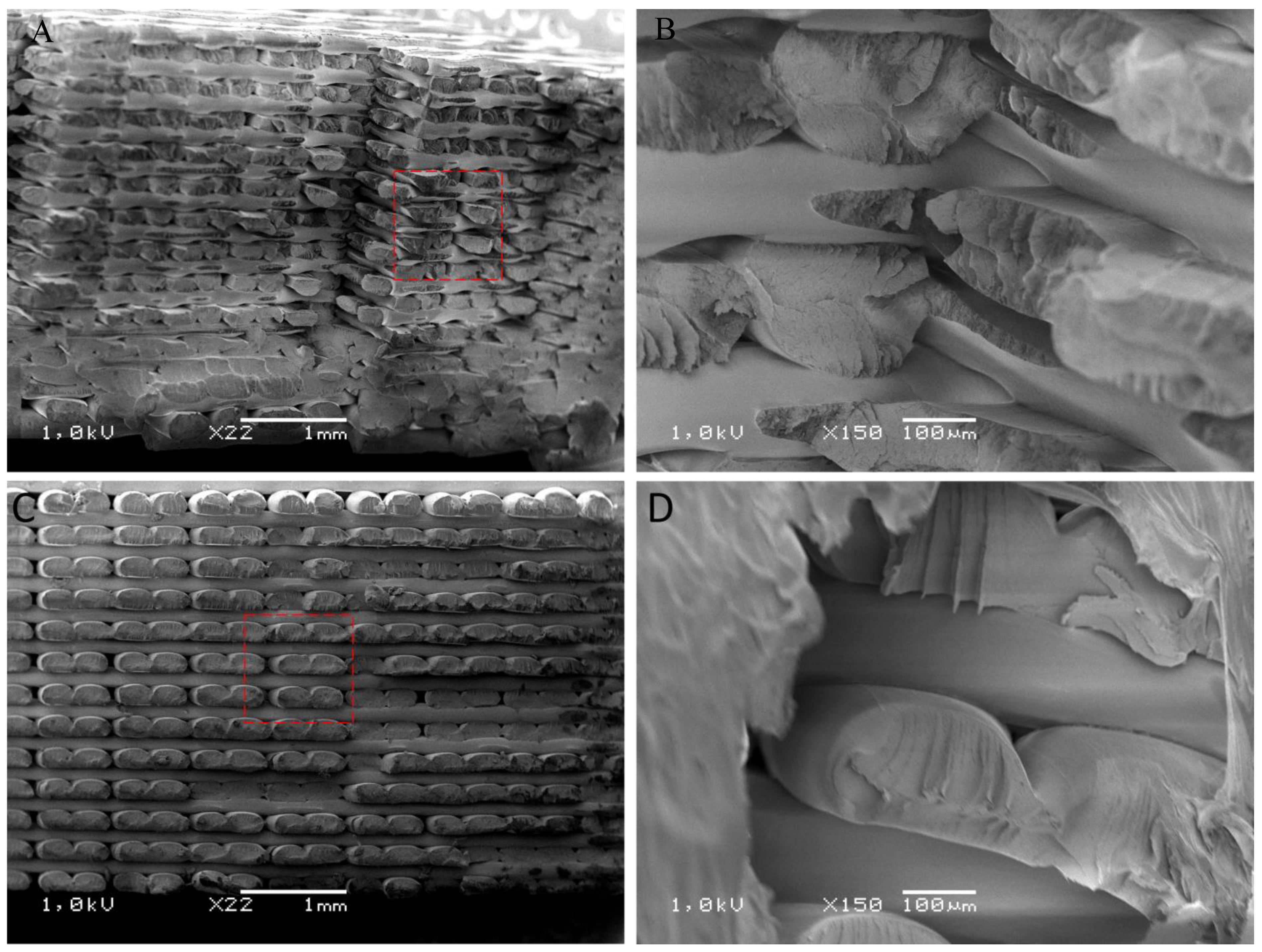

2.3.2. Assessment of Print Structure by Scanning Microscopy

2.3.3. Evaluation of Thermal Stability of Prints

2.3.4. Statistical Analysis

3. Results

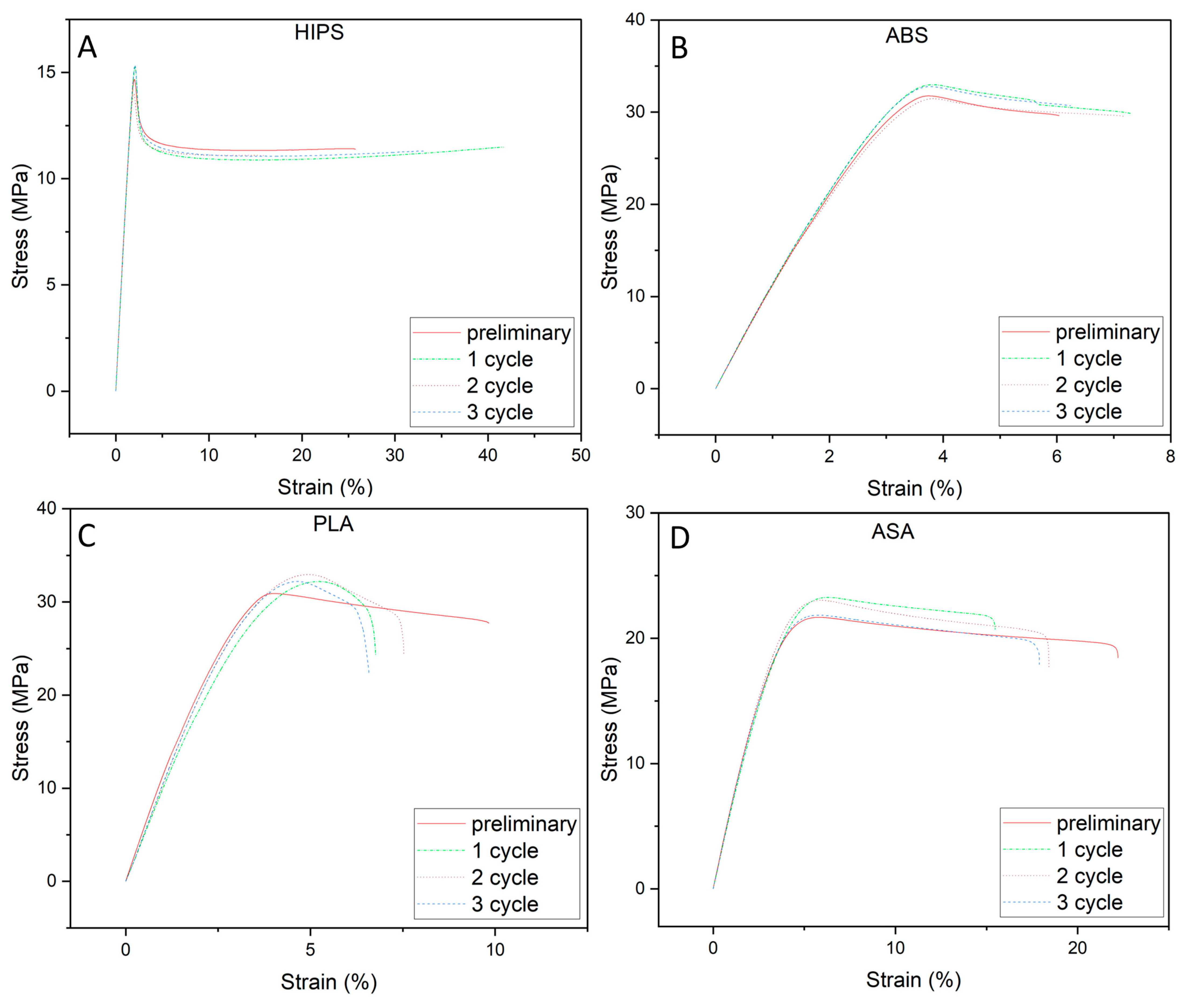

3.1. Results of Tensile Test

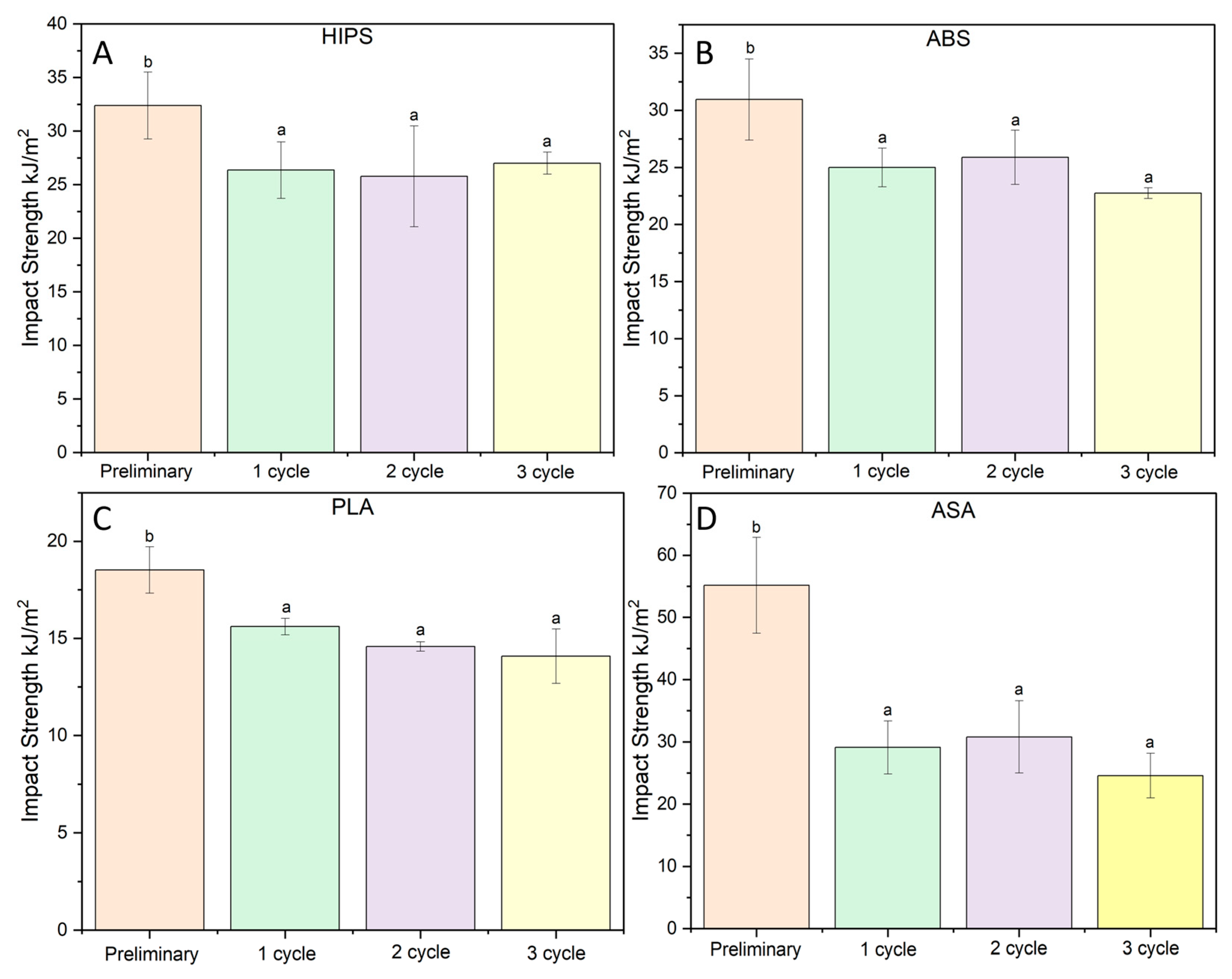

3.2. Charpy Impact Test

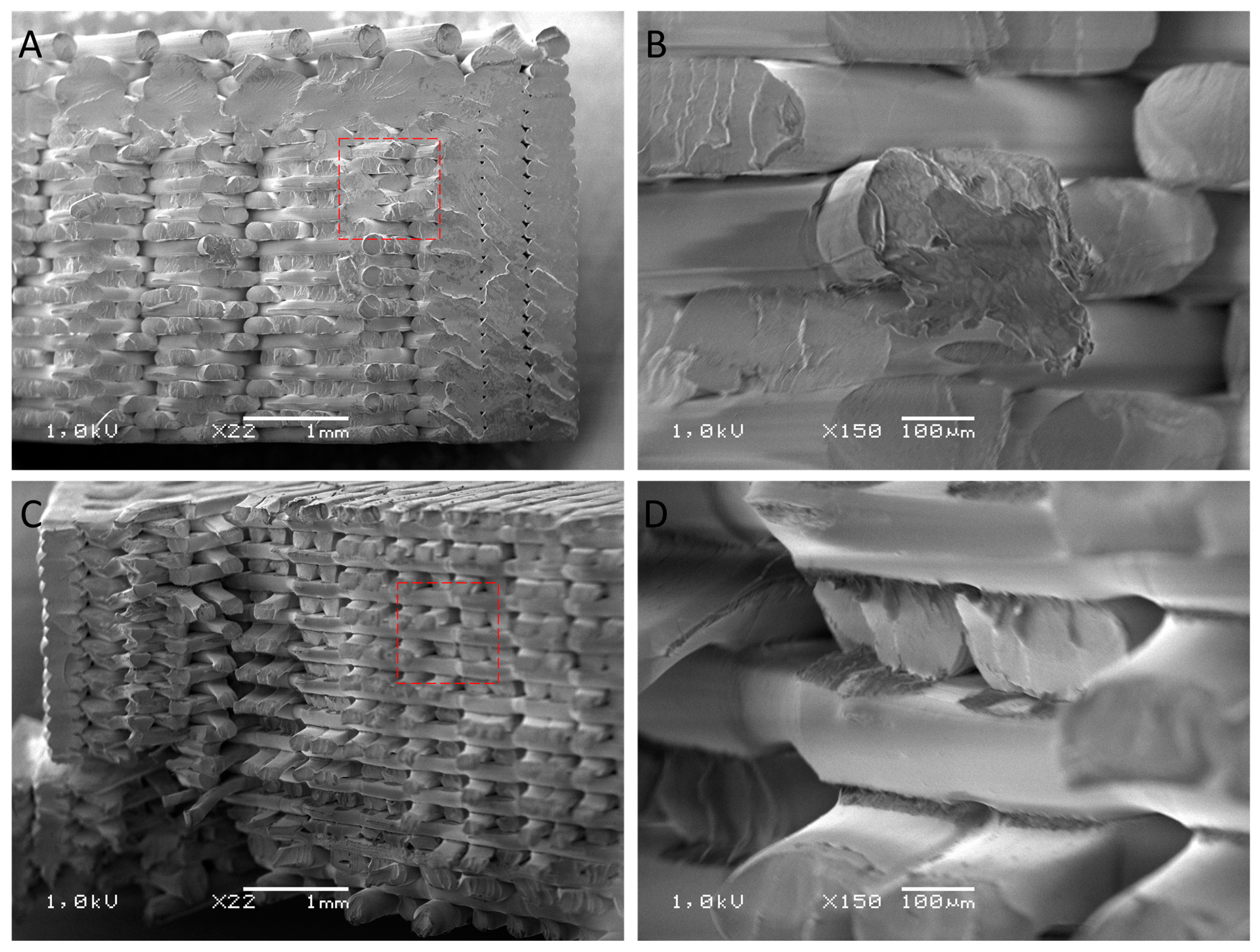

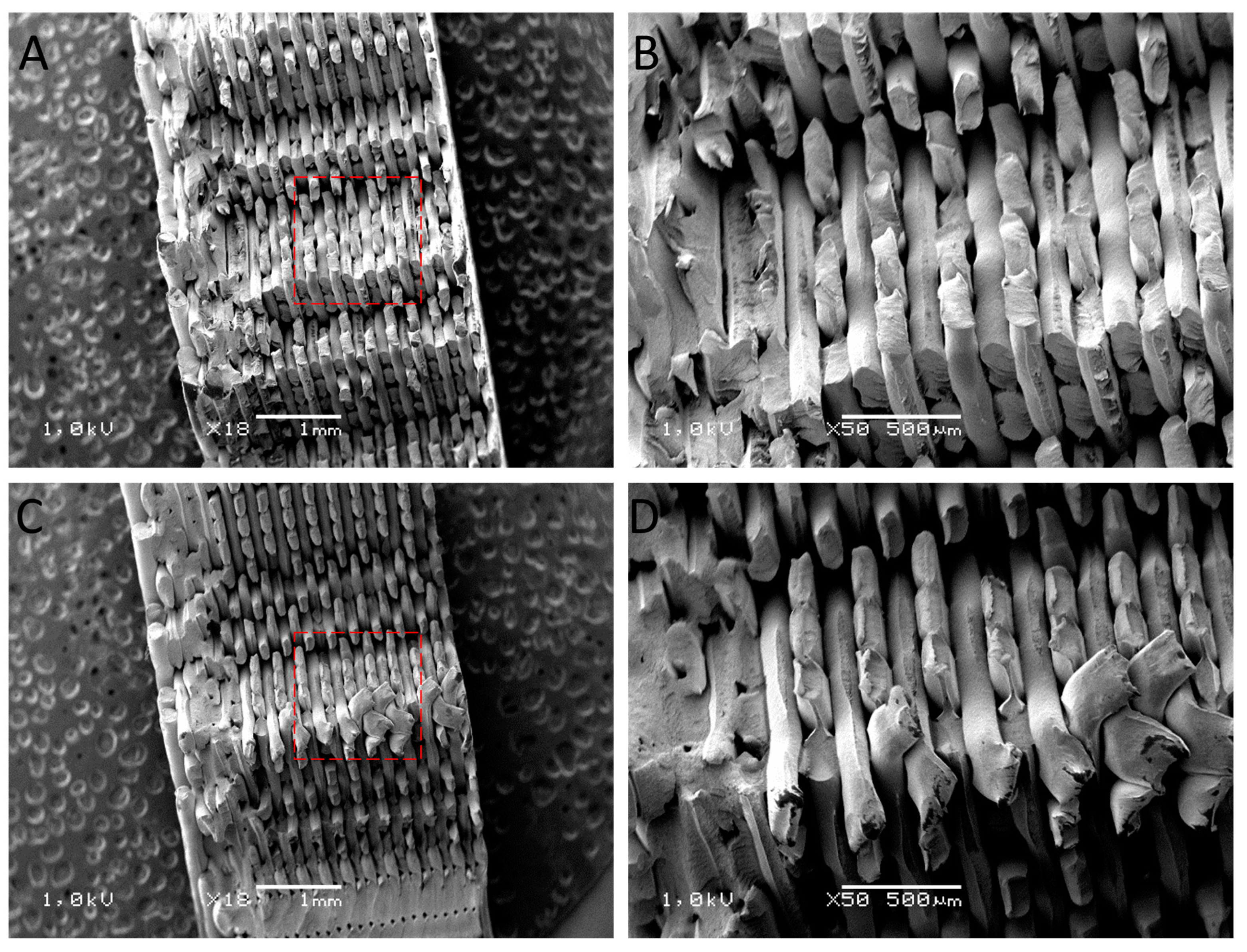

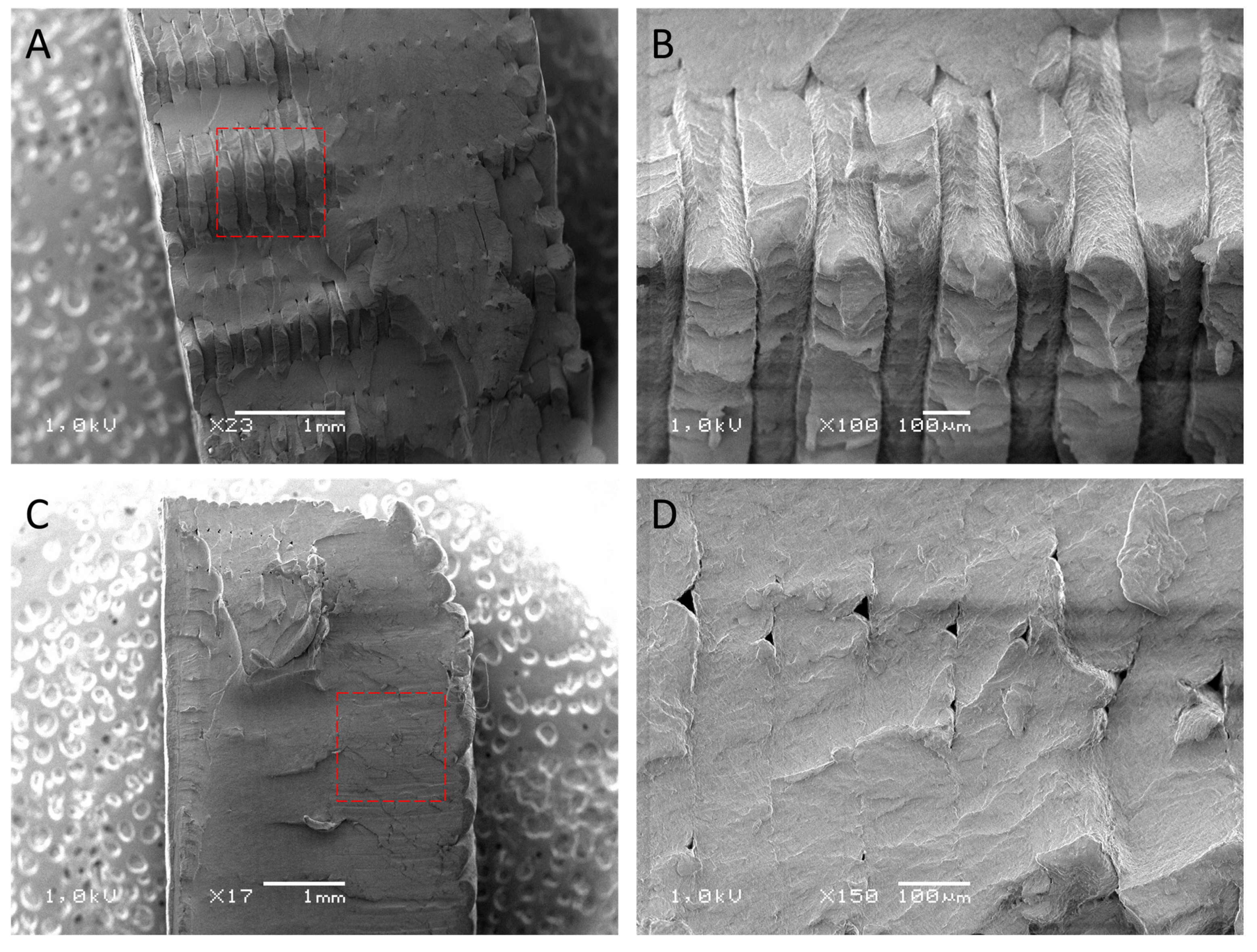

3.3. Evaluation of the Surface Structure of Samples Using the Scanning Electron Microscope

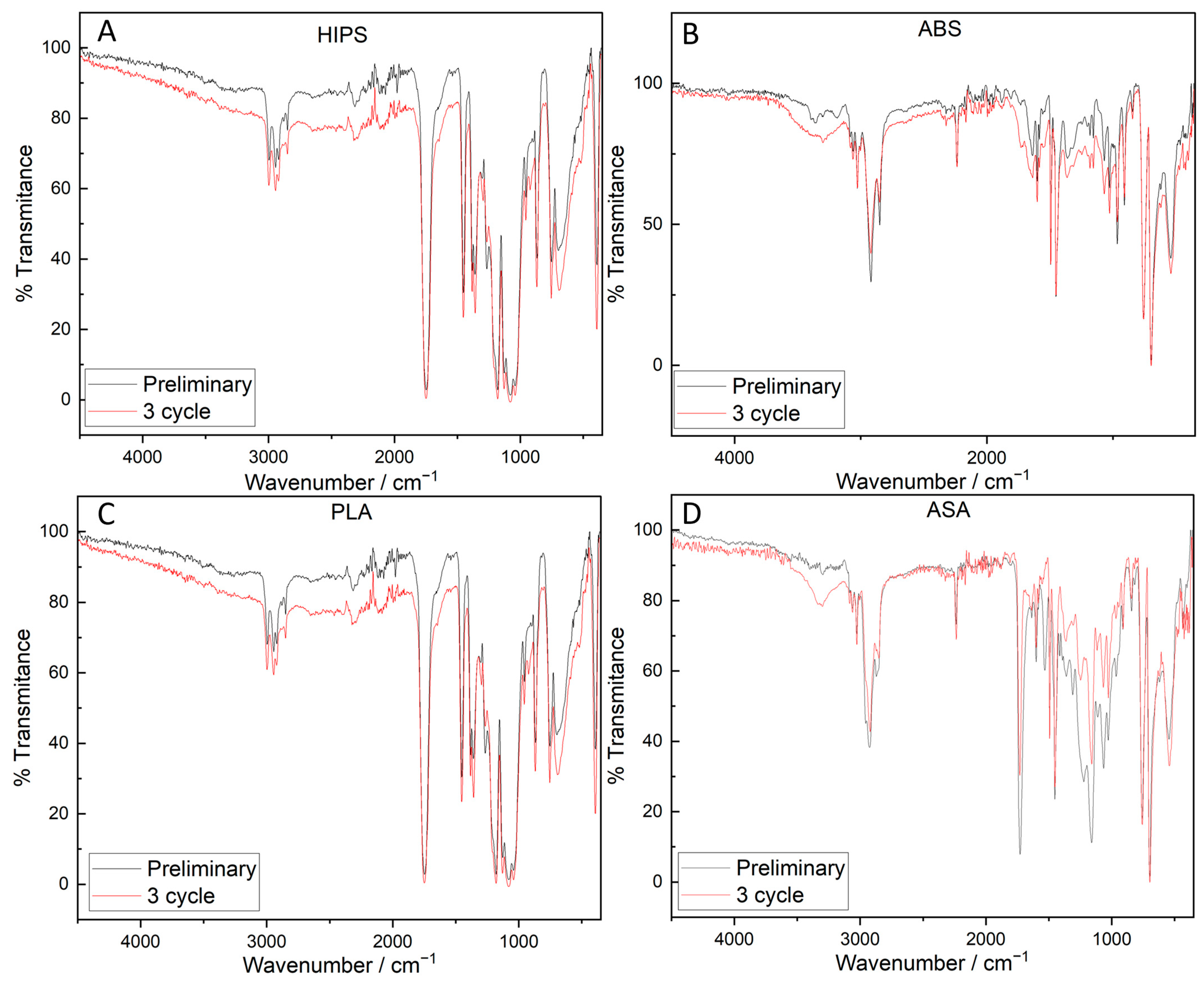

3.4. Analysis of FTIR Results

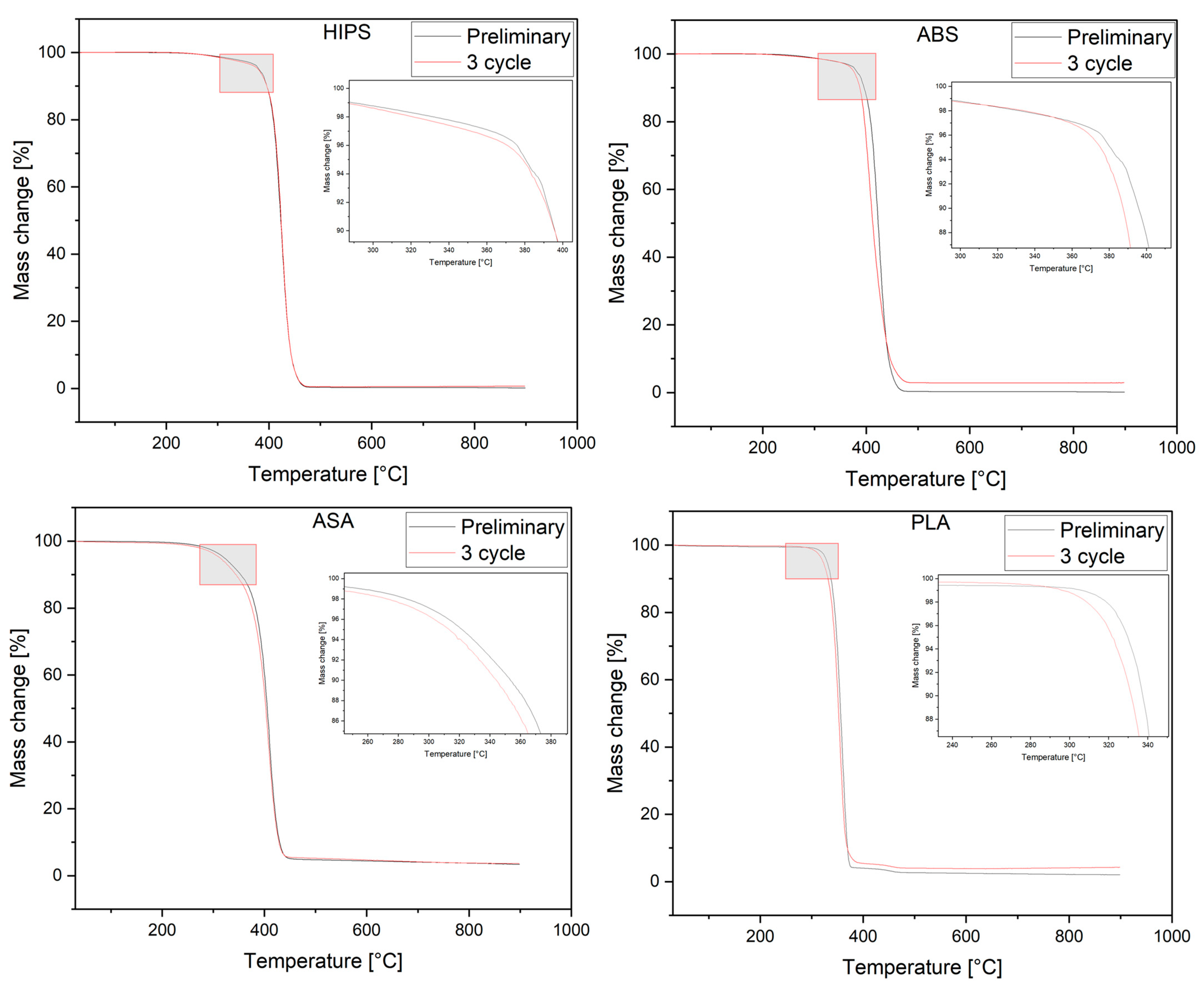

3.5. Analysis of TGA Results

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Haq, M.I.U. 3D printing—A review of processes, materials and applications in industry 4.0. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Quanjin, M.; Rejab, M.R.M.; Idris, M.S.; Kumar, N.M.; Abdullah, M.H.; Reddy, G.R. Recent 3D and 4D intelligent printing technologies: A comparative review and future perspective. Procedia Comput. Sci. 2020, 167, 1210–1219. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Afshar, A.; Wood, R. Development of Weather-Resistant 3D Printed Structures by Multi-Material Additive Manufacturing. J. Compos. Sci. 2020, 4, 94. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Piscitelli, F.; Prota, A.; Lavorgna, M.; Mensitieri, G.; Manfredi, G. Improved mechanical properties of CFRP laminates at elevated temperatures and freeze–thaw cycling. Constr. Build. Mater. 2012, 31, 273–283. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Effects of the Accelerated Freeze-Thaw Cycling on Physical and Mechanical Properties of Wood Flour-Recycled Thermoplastic Composites. Polym. Compos. 2009, 31, 185–194. [Google Scholar] [CrossRef]

- Pérez, J.; Vilas, J.; Laza, J.M.; Arnaiz, S.; Mijangos, F.; Bilbao, E.; León, L.M. Effect of Reprocessing and Accelerated Weathering on ABS Properties. J. Polym. Environ. 2010, 18, 71–78. [Google Scholar] [CrossRef]

- Reza Khosravani, M.; Zolfagharian, A.; Jennings, M.; Reinicke, T. Structural performance of 3D-printed composites under various loads and environmental conditions. Sci. Polym. Test. 2020, 91, 106770. [Google Scholar] [CrossRef]

- Dong, J.; Mei, C.; Han, J.; Lee, S.; Wu, Q. 3D printed poly(lactic acid) composites with grafted cellulose nanofibers: Effect of nanofiber and post-fabrication annealing treatment on composite flexural properties. Addit. Manuf. 2019, 28, 621–628. [Google Scholar] [CrossRef]

- Jayanth, N.; Jaswanthraj, K.; Sandeep, S.; Mallaya, N.H.; Siddharth, S.R. Effect of heat treatment on mechanical properties of 3D printed PLA. J. Mech. Behav. Biomed. Mater. 2021, 123, 104764. [Google Scholar] [CrossRef]

- Grzelak, K.; Łaszcz, J.; Polkowski, J.; Mastalski, P.; Kluczynski, J.; Łuszczek, J.; Torzewski, J.; Szachogłuchowicz, I.; Szymaniuk, R. Additive Manufacturing of Plastics Used for Protection against COVID-19—The Influence of Chemical Disinfection by Alcohol on the Properties of ABS and PETG Polymers. Materials 2021, 14, 4823. [Google Scholar] [CrossRef]

- Aldeen, N.A.; Owaid, B. Effect of ultraviolet and temperature on mechanical properties of three dimension printed materials. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2020; Volume 2213, p. 020184. [Google Scholar]

- Andersen, E.; Mikkelsen, R.; Kristiansen, S.; Hinge, M. Real-time ageing of polyesters with varying diols. Mater. Chem. Phys. 2021, 261, 124240. [Google Scholar] [CrossRef]

- Solarski, S.; Ferreira, M.; Devaux, E. Ageing of polylactide and polylactide nanocomposite filaments. Polym. Degrad. Stab. 2008, 93, 707–713. [Google Scholar] [CrossRef]

- Yildirim, F.F.; Hicyilmaz, A.S.; Yildirim, K. The effects of the weathering methods on the properties of the ABS, ASA and PMMA polymers. Polym. Test. 2022, 107, 107484. [Google Scholar] [CrossRef]

- Paz, E.; Jiménez, M.; Romero, L.; del Mar Espinosa, M.; Domínguez, M. Characterization of the resistance to abrasive chemical, agents of test specimens of thermoplastic elastomeric polyurethane composite materials produced by additive manufacturing. Appl. Polym. Sci. 2020, 138, 50791. [Google Scholar] [CrossRef]

- Krishna Upadhyay, R.; Kumar Mishra, A.; Kumar, A. Mechanical Degradation of 3D Printed PLA in Simulated Marina Environment. Surf. Interfaces 2020, 21, 100778. [Google Scholar] [CrossRef]

- Ambrus, S.; Soporan, R.A.; Kazamer, N.; Pascal, D.T.; Muntean, R.; Dume, A.I.; Mărginean, G.M.; Serban, V.A. Characterizationand mechanical properties of fused deposited PLA material. Mater. Today Proceeding 2021, 45, 4356–4363. [Google Scholar] [CrossRef]

- Catalin, G.A.; Zapciu, A.; Baciu, F.; Vasile, M.I.; Nicoara, A.I. Accelerated Aging Effect on Mechanical Properties of Com-mon3D-Printing Polymers. Polymers 2021, 13, 4132. [Google Scholar]

- Fotopoulou, K.N.; Karapanagioti, H.K. Degradation of Various Plastics in the 603 Environment. Hazardous Chemicals Associated with Plastics in the Marine Environment. In 604 The Handbook of Environmental Chemistry; Springer: Cham, Switzerland, 2017; Volume 78, pp. 71–92. [Google Scholar]

- Ryley, M.; Carve, M.; Piola, R.; Scardino, A.J.; Shimeta, J. Comparison of biofouling on 3D-printing materials in the marineenvironment. Int. Biodeterior. Biodegrad. 2021, 164, 105293. [Google Scholar] [CrossRef]

- Saenz, F.; Otarola, C.; Valladares, K. Influence of 3D printing settings on mechanical properties of ABS at room temperature and 77 K. Sci. Addit. Manuf. 2021, 39, 101841. [Google Scholar] [CrossRef]

- Drevlak, M.; Brochard, F.; Helander, P.; Kisslinger, J.; Mikhailov, M.; Nührenberg, C.; Turkin, Y.; Nührenberg, J. A qua-si-toroidally symmetric stellarator. Contrib. Plasma Phys. 2013, 53, 459–468. [Google Scholar] [CrossRef]

- Niu, F.; Jiang, H.; Su, W.; Jiang, W.; He, J. Performance degradation of polymer material under freeze-thaw cycles: A case study of extruded polystyrene board. Polym. Test. 2021, 96, 107067. [Google Scholar] [CrossRef]

- Nieto, D.M.; Alonso-García, M.; Pardo-Vicente, M.A. Product Design by Additive Manufacturing for Water Environments: Study of Degradation and Absorption Behaviorof PLA and PETG. Polymers 2021, 13, 1036. [Google Scholar] [CrossRef] [PubMed]

- Kakanuru, P.; Pochiraju, K. Moisture Ingress and Degradation of Additively Manufactured PLA, ABS and PLA/SiC Composite Parts. Addit. Manuf. 2020, 36, 101529. [Google Scholar] [CrossRef]

- Głowacki, M.; Mazurkiewicz, A.; Słomion, M.; Skórczewska, K. Resistance of 3D-Printed Components, Test Specimens and Products to Work under Environmental Conditions—Review. Materials 2022, 15, 6162. [Google Scholar] [CrossRef]

- Sedlak, J.; Joska, Z.; Hrbackova, L.; Jurickova, E.; Hrusecka, D.; Horak, O. Determination of mechanical properties of plastic components made by 3D printing. Manuf. Technol. 2022, 22, 733–746. [Google Scholar] [CrossRef]

- Sedlak, J.; Joska, Z.; Jansky, J.; Zouhar, J.; Kolomy, S.; Slany, M.; Svasta, A.; Jirousek, J. Analysis of the Mechanical Properties of 3D-Printed Plastic Samples Subjected to Selected Degradation Effects. Materials 2023, 16, 3268. [Google Scholar] [CrossRef]

- Raney, K.; Lani, E.; Kalla, D.K. Experimental characterization of the tensile strength of ABS parts manufactured by fused deposition modeling process. Materialstoday 2017, 4, 7956–7961. [Google Scholar] [CrossRef]

- Mirón, V.; Ferrándiz, S.; Juárez, D.; Mengual, A. Manufacturing and characterization of 3D printer filament using tailoring materials. Procedia Manuf. 2017, 13, 888–894. [Google Scholar] [CrossRef]

- Yonezawa, A.; Yamada, A. Deterioration of the Mechanical Properties of FFF 3D-Printed PLA Structures. Inventions 2021, 6, 1. [Google Scholar] [CrossRef]

- Simplify3D.com. Filament Properties Table. 2021. Available online: https://www.simplify3d.com/support/materials-guide/properties-table/ (accessed on 16 November 2023).

- Divakara Shetty, S.; Shetty, N. Investigation of mechanical properties and applications of polylactic acids—A review. Mater. Res. Express 2019, 6, 112002. [Google Scholar] [CrossRef]

- Spectrumfilaments. Manufacturer of 3D Printing Filament. 16 November 2023. Available online: https://spectrumfilaments.com/en/ (accessed on 20 November 2023).

- PN-EN ISO 527:1998; Plastics—Determination of Mechanical Properties in Static Tension—General Principles. Polish Standards Institution: Warszawa, Poland, 1998.

- PN-EN ISO 179-1; Plastics—Determination of Charpy Impact Strength—Part 1: Non-Instrumental Impact Test. Polish Standards Institution: Warszawa, Poland, 2010.

- Müller, A.J.; Ávila, M.; Saenz, G.; Salazar, J. Crystallization of PLA-Based Materials. In Poly(lactic acid) Science and Technology: Processing, Properties, Additives and Applications; Alfonso, J., Mercedes, P., Roxana, R., Eds.; Royal Society of Chemistry: London, UK, 2014; pp. 66–98. [Google Scholar]

- Kuciel, S.; Romańska, P. Hybrid composites of polylactide with basalt and carbon fibers and their thermal treatment. Materials 2019, 12, 95. [Google Scholar] [CrossRef] [PubMed]

- Kister, G.; Cassanas, G.; Vert, M. Effects of morphology, conformation and configuration on the IR and Raman spectra of various poly(lactic acid)s. Polymer 1998, 39, 267–273. [Google Scholar] [CrossRef]

- Díaz-Rodríguez, J.G.; Pertuz-Comas, A.D.; Bohórquez-Becerra, O.R. Impact Strength for 3D-Printed PA6 Polymer Composites under Temperature Changes. J. Manuf. Mater. Process. 2023, 7, 178. [Google Scholar] [CrossRef]

- Palacios-Ibáñez, B.; Relinque, J.J.; Moreno-Sánchez, D.; de León, A.S.; Delgado, F.J.; Escobar-Galindo, R.; Molina, S.I. Synthesis and Characterisation of ASA-PEEK Composites for Fused Filament Fabrication. Polymers 2022, 14, 496. [Google Scholar] [CrossRef]

- Rasselet, D.; Ruellan, A.; Guinault, A.; Miquelard-Garnier, G.; Sollogoub, C.; Fayolle, B. Oxidative degradation of polylactide (PLA) and its effects on physical and mechanical properties. Eur. Polym. J. 2014, 50, 109–116. [Google Scholar] [CrossRef]

- Barczewski, M.; Hejna, A.; Aniśko, J.; Andrzejewski, J.; Piasecki, A.; Mysiukiewicz, O.; Bąk, M.; Gapiński, B.; Ortega, Z. Rotational molding of polylactide (PLA) composites filled with copper slag as a waste filler from metallurgical industry. Polym. Test. 2022, 106, 107449. [Google Scholar] [CrossRef]

- Giełdowska, M.; Puchalski, M.; Sztajnowski, S.; Krucińska, I. Evolution of the Molecular and Supramolecular Structures of PLA during the Thermally Supported Hydrolytic Degradation of Wet Spinning Fibers. Macromolecules 2022, 55, 10100–10112. [Google Scholar] [CrossRef]

- Martín del Campo, A.S.; Robledo-Ortíz, J.R.; Arellano, M.; Rabelero, M.; Pérez-Fonseca, A.A. Accelerated Weathering of Polylactic Acid/Agave Fiber Biocomposites and the Effect of Fiber–Matrix Adhesion. J. Polym. Environ. 2021, 29, 937–947. [Google Scholar] [CrossRef]

- Meaurio, E.; López-Rodríguez, N.; Sarasua, J.R. Infrared Spectrum of Poly(l-lactide): Application to Crystallinity Studies. Macromolecules 2006, 39, 9291–9301. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Cao, Y.; Feng, J.; Yang, W. Acrylonitrile-Styrene-Acrylate Particles with Different Microstructure for Improving the Toughness of Poly(styrene-co-acrylonitrile) Resin. Adv. Polym. Technol. 2021, 2021, 3004824. [Google Scholar] [CrossRef]

- Öztürk, S. The Weathering Study of PC/ASA Alloy For Automotive Exterior Applications. J. Turk. Chem. Soc. Sect. A Chem. 2017, 5, 61–72. [Google Scholar] [CrossRef][Green Version]

- Pop, M.A.; Croitoru, C.; Bedő, T.; Geamăn, V.; Radomir, I.; Cos, M.; Zaharia, S.M.; Chicos, L.A.; Milos, I. Structural changes during 3D printing of bioderived and synthetic thermoplastic materials. Appl. Polym. Sci. 2018, 136, 47382. [Google Scholar] [CrossRef]

- Kamelian, F.S.; Mousavi, S.M.; Ahmadpour, A.; Ghaffarian, V. Preparation of acrylonitrile-butadiene-styrene membrane: Investigation of solvent/nonsolvent type and additive concentration. Korean J. Chem. Eng. 2014, 31, 1399–1404. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, M.; Lan, M.; Li, Z.; Lu, S.; Wu, G. GM-Improved Antiaging Effect of Acrylonitrile Butadiene Styrene in Different Thermal Environments. Polymers 2020, 12, 46. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, W.; Zhang, J.; Tian, T. Highly toughened poly (acrylonitrile-styrene-acrylic)/chlorinated polyethylene blends: Mechanical, rheological and thermal properties. Polym. Test. 2015, 44, 23–29. [Google Scholar] [CrossRef]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Lee, S.; Lee, J.; Park, Y.-K. Simultaneous Upcycling of Biodegradable Plastic and Sea Shell Wastes through Thermocatalytic Monomer Recovery. ACS Sustain. Chem. Eng. 2022, 10, 13972–13979. [Google Scholar] [CrossRef]

- Hetrick, D.R.; Sanei, S.H.R.; Ashour, O.; Bakis, C.E. Charpy impact energy absorption of 3D printed continuous Kevlar reinforced composites. J. Compos. Mater. 2021, 55, 1705–1713. [Google Scholar] [CrossRef]

| Material | Extrusion Temperature | Platform Temperature |

|---|---|---|

| Smart ABS | 275 °C | 80 °C |

| HIPS-X | 250 °C | 80 °C |

| ASA 275 | 240 °C | 60 °C |

| PLA Premium | 210 °C | 30 °C |

| Parameter Name | Parameter Value |

|---|---|

| Infill pattern | Rectilinear |

| Fill angle | 45° |

| Infill density | 100% |

| Layer height | 0.3 mm |

| Solid layers | Top 7, Bottom 4 |

| Print speed | 30 mm/s |

| nozzle diameter | 0.4 mm |

| diameter tolerance | +/−0.03 |

| Layer height | 0.19 mm |

| Filling density | 100% |

| HIPS | ABS | PLA | ASA | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 0 | 1 | 2 | 3 | 0 | 1 | 2 | 3 | 0 | 1 | 2 | 3 | |

| Et (MPa) | 851 a ±15.0 | 846 a ±17.8 | 852 a ±20.7 | 843 a ±19.9 | 1140 a ±34.6 | 1170 a ±5.65 | 1150 a ±47.2 | 1180 a ±12.9 | 1160 a ±2.66 | 934 a ±80.4 | 1010 a ±122 | 914 a ±168 | 673 a ±12.6 | 643 a ±31.5 | 649 a ±8.61 | 645 a ±8.02 |

| σM (MPa) | 14.8 a ±0.69 | 15.1 a ±0.44 | 14.6 a ±0.51 | 15.1 a ±0.26 | 31.9 a ±1.22 | 33.1 a ±0.78 | 32.1 a ±1.67 | 33 a ±0.72 | 31.2 a ±0.57 | 32.2 a,b ±0.23 | 32.4 b ±0.36 | 32.3 b ±0.27 | 21.9 a ±0.6 | 22.8 a ±1.93 | 22.5 a ±0.48 | 21.9 a ±0.3 |

| εM (%) | 2 a ±0 | 2 a ±0 | 2 a ±0 | 2.1 a ±0 | 3.8 a ±0.1 | 3.8 a ±0.1 | 3.8 a ±0.1 | 3.7 a ±0.1 | 4.1 a ±0.1 | 5.1 b ±0.1 | 4.7 b ±0.2 | 4.7 b ±0.2 | 5.8 a ±0 | 6.2 b ±0.2 | 5.8 a ±0.1 | 5.7 a ±0.1 |

| εB (%) | 29.7 a ±6.3 | 33.8 a ±6.5 | 24.2 a ±10.2 | 35.2 a ±5.0 | 6.3 a ±1.2 | 6.3 a ±1.3 | 6.7 a ±1.6 | 5.6 a ±0.8 | 8.9 c ±0.6 | 8.1 b,c ±0.8 | 6.9 a,b ±0.8 | 6.6 a ±0.6 | 18 a ±3.6 | 20.2 a ±4.8 | 18.9 a ±3.6 | 17.1 a ±1.3 |

| Material | T1 | T5 | T10 | T50 | TONSET | TDTG | |

|---|---|---|---|---|---|---|---|

| Cycle | (°C) | (°C) | (°C) | (°C) | (°C) | (°C) | |

| PLA | 0 | 306.2 | 329.8 | 337.5 | 356.2 | 341.6 | 360.2 |

| 1 | 301.4 | 326.3 | 335.3 | 356.3 | 340.3 | 359.5 | |

| 2 | 297.1 | 325.7 | 335.3 | 356.4 | 340.4 | 360.2 | |

| 3 | 294.8 | 320.2 | 329.9 | 350.6 | 335.3 | 353.8 | |

| HIPS | 0 | 289.9 | 380.4 | 395.8 | 422.9 | 404.6 | 425.5 |

| 1 | 291.7 | 381.5 | 395.8 | 422.8 | 405.1 | 424.8 | |

| 2 | 291.1 | 381.5 | 397.5 | 424.0 | 406.6 | 426.5 | |

| 3 | 290.8 | 381.3 | 396.6 | 423.8 | 405.6 | 424.7 | |

| ASA | 0 | 255.7 | 321.7 | 353.1 | 405.6 | 386.5 | 410.6 |

| 1 | 256.1 | 318.9 | 350.6 | 406.0 | 385.0 | 409.5 | |

| 2 | 255.3 | 318.4 | 348.0 | 405.5 | 384.8 | 410.0 | |

| 3 | 237.4 | 311.3 | 343.6 | 405.4 | 384.9 | 411.2 | |

| ABS | 0 | 305.8 | 377.9 | 390.4 | 415.5 | 390.0 | 412.3 |

| 1 | 305.6 | 377.4 | 389.3 | 414.8 | 388.8 | 410.4 | |

| 2 | 302.0 | 378.6 | 390.0 | 414.8 | 389.8 | 408.9 | |

| 3 | 302.4 | 378.7 | 389.8 | 414.9 | 389.6 | 408.9 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Głowacki, M.; Skórczewska, K.; Lewandowski, K.; Szewczykowski, P.; Mazurkiewicz, A. Effect of Shock-Variable Environmental Temperature and Humidity Conditions on 3D-Printed Polymers for Tensile Properties. Polymers 2024, 16, 1. https://doi.org/10.3390/polym16010001

Głowacki M, Skórczewska K, Lewandowski K, Szewczykowski P, Mazurkiewicz A. Effect of Shock-Variable Environmental Temperature and Humidity Conditions on 3D-Printed Polymers for Tensile Properties. Polymers. 2024; 16(1):1. https://doi.org/10.3390/polym16010001

Chicago/Turabian StyleGłowacki, Marcin, Katarzyna Skórczewska, Krzysztof Lewandowski, Piotr Szewczykowski, and Adam Mazurkiewicz. 2024. "Effect of Shock-Variable Environmental Temperature and Humidity Conditions on 3D-Printed Polymers for Tensile Properties" Polymers 16, no. 1: 1. https://doi.org/10.3390/polym16010001

APA StyleGłowacki, M., Skórczewska, K., Lewandowski, K., Szewczykowski, P., & Mazurkiewicz, A. (2024). Effect of Shock-Variable Environmental Temperature and Humidity Conditions on 3D-Printed Polymers for Tensile Properties. Polymers, 16(1), 1. https://doi.org/10.3390/polym16010001