Manufacture and Characterization of Polylactic Acid Filaments Recycled from Real Waste for 3D Printing

Abstract

1. Introduction

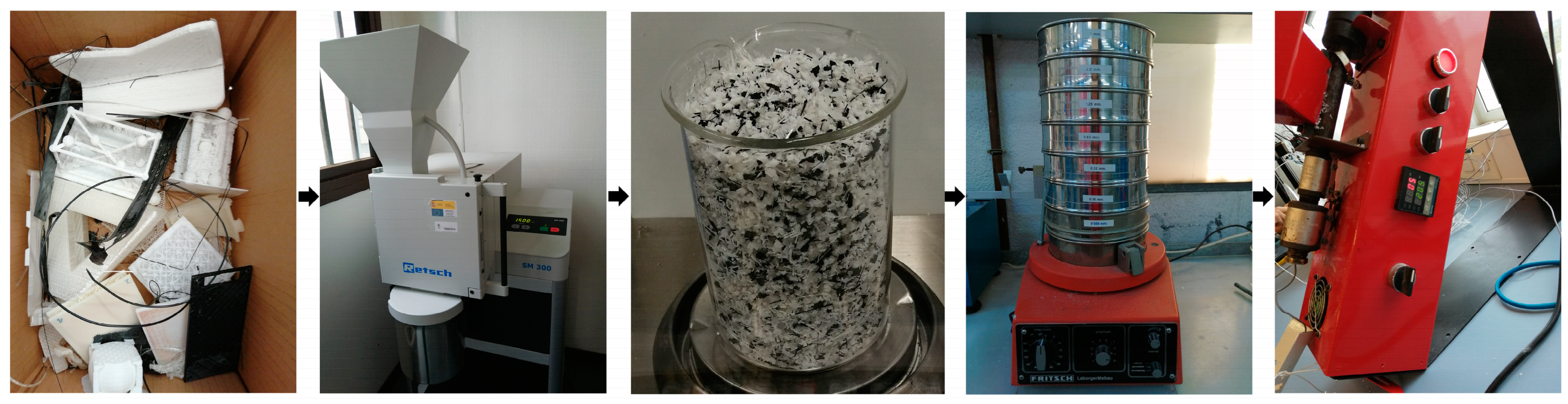

2. Materials and Methods

2.1. Materials

2.2. Filament Fabrication

2.3. Samples 3D Printing

2.4. Samples Testing

3. Results and Discussion

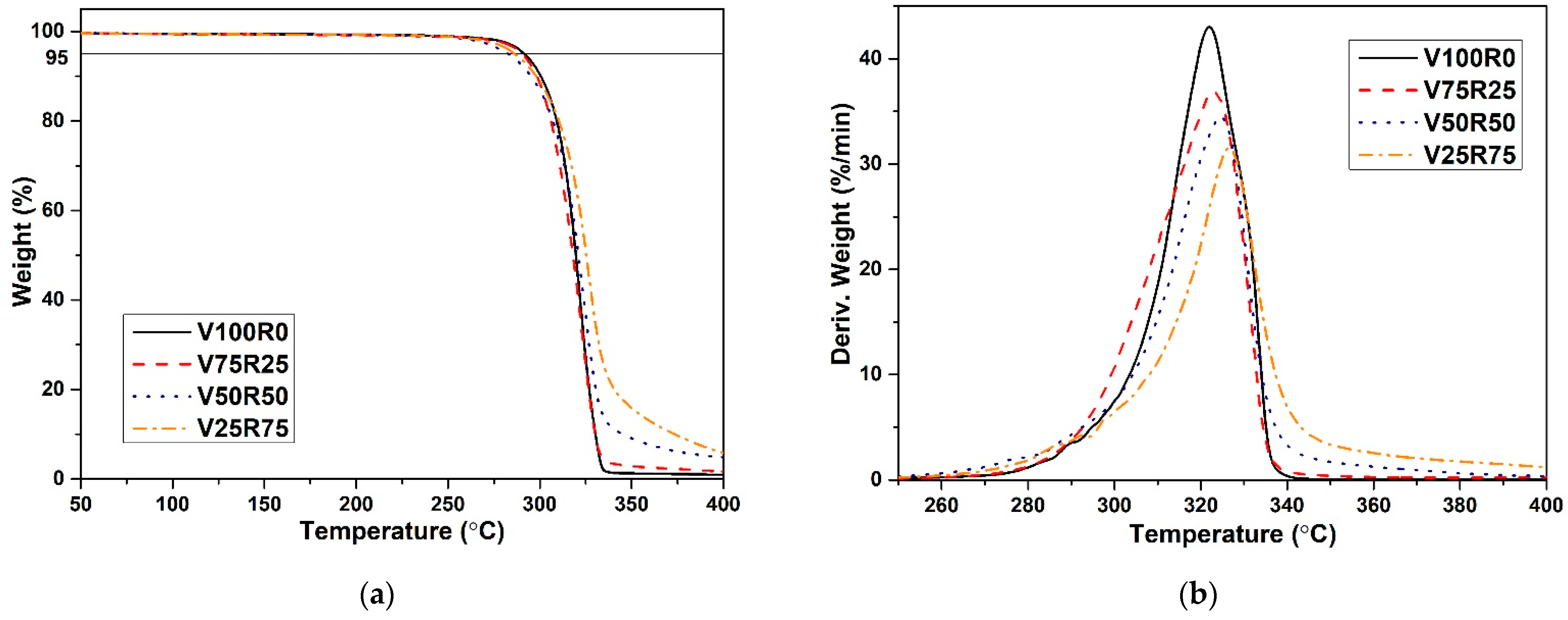

3.1. Thermogravimetric Analysis

3.2. Differential Scanning Calorimetry

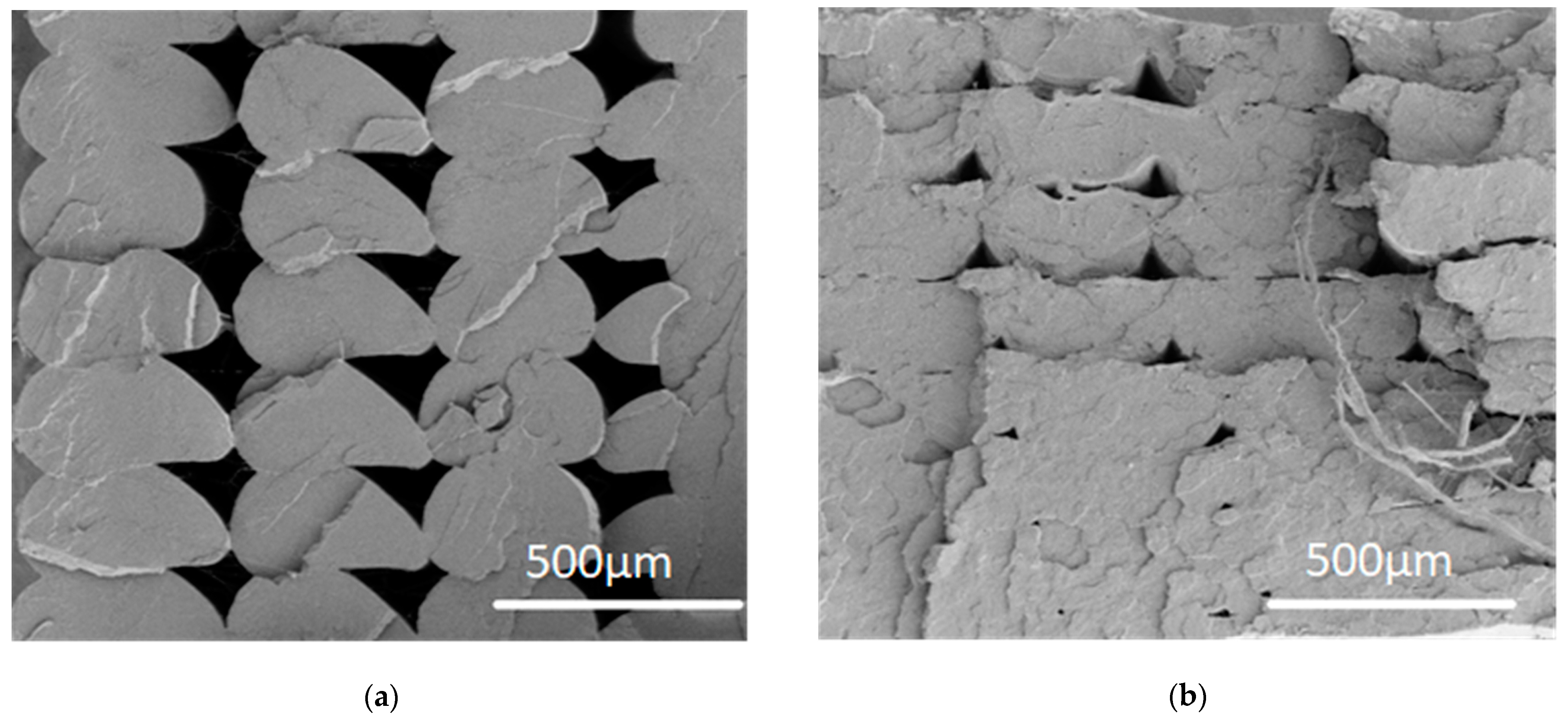

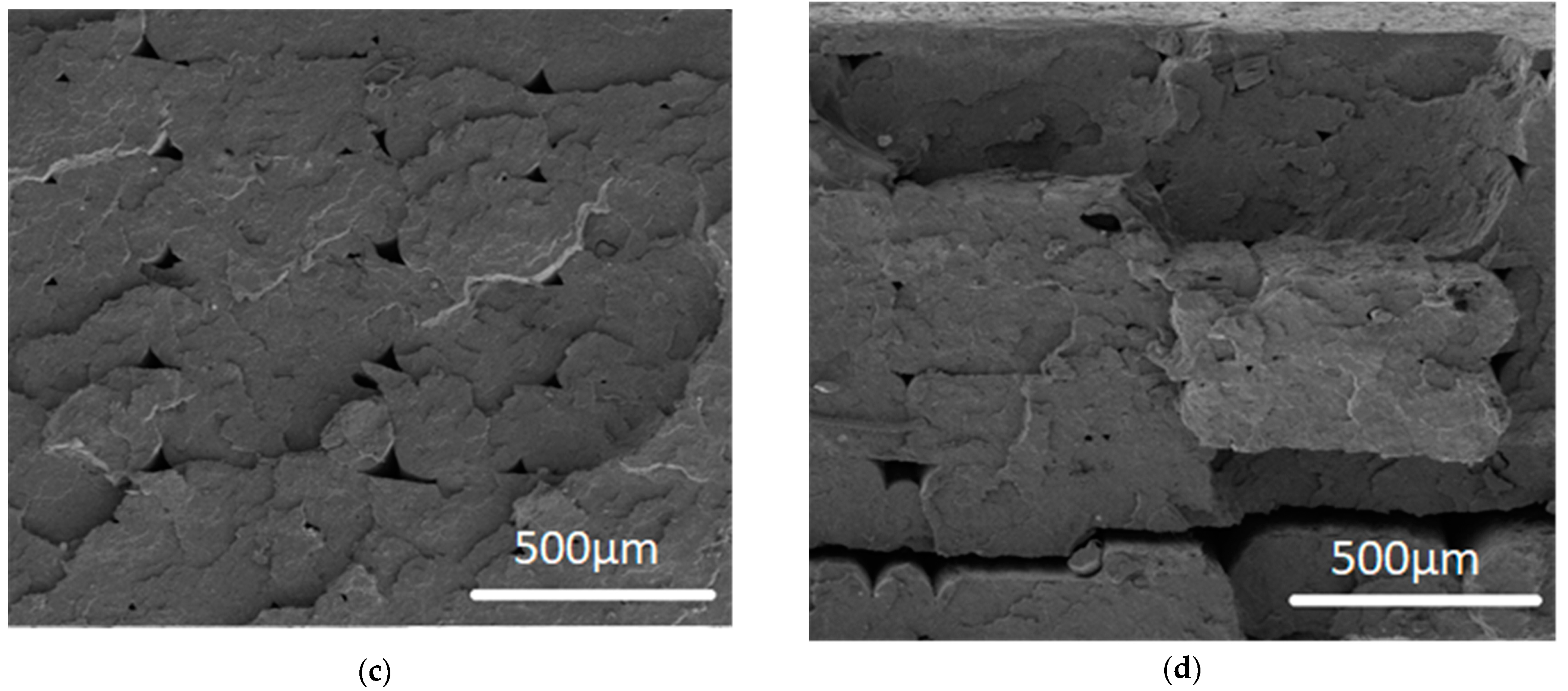

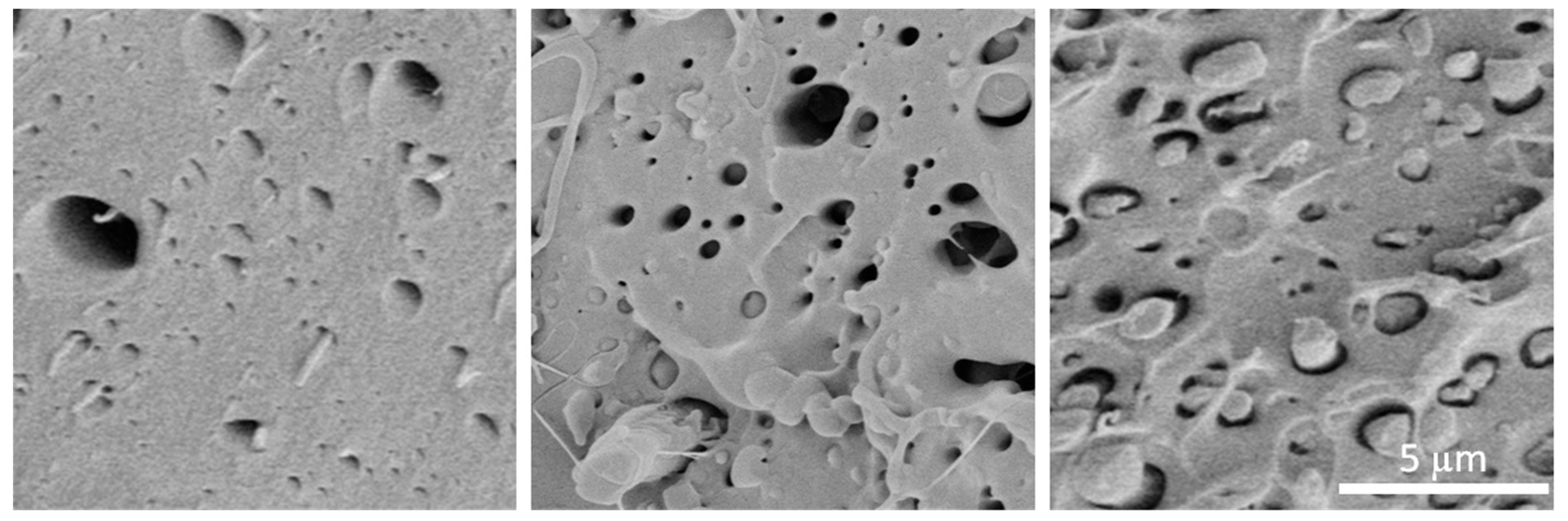

3.3. Scanning Electron Microscopy

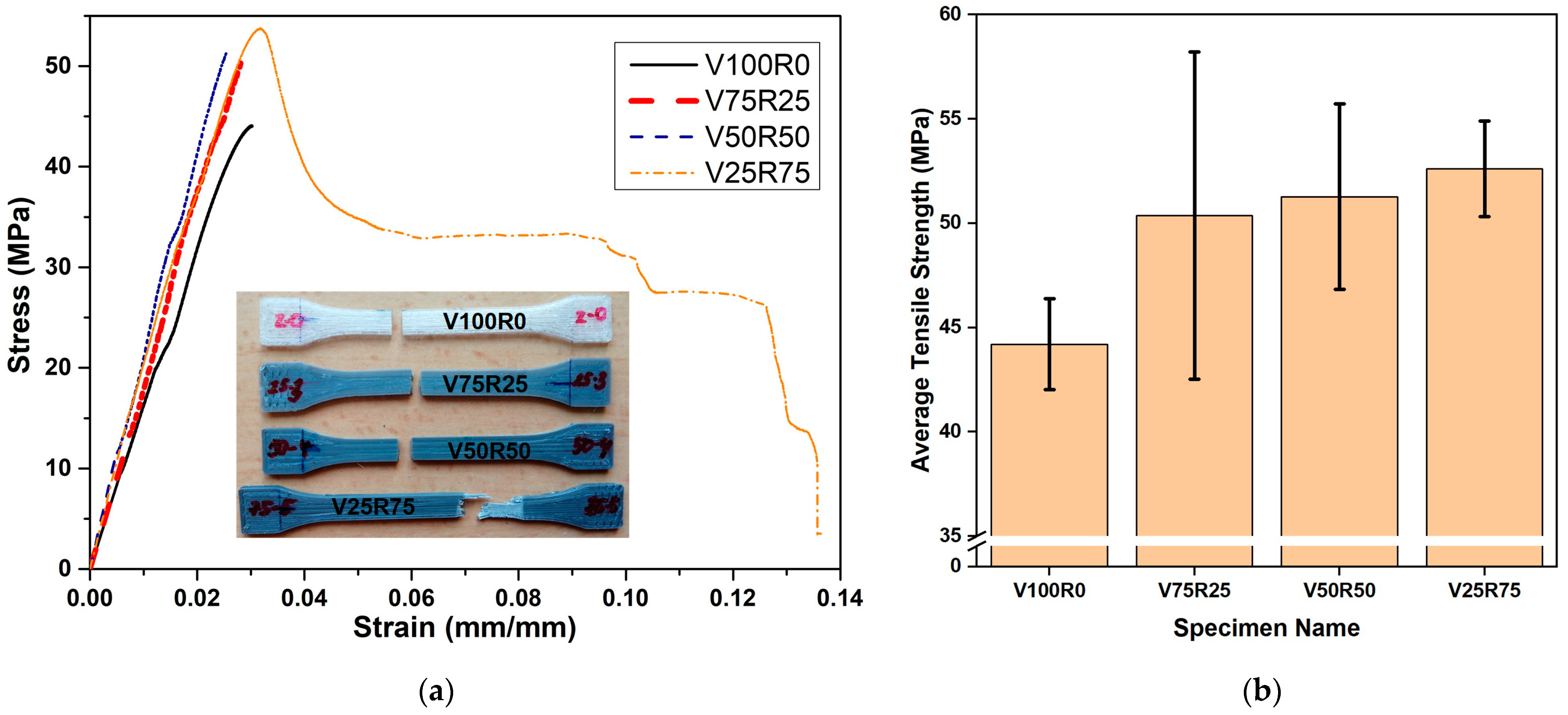

3.4. Mechanical Properties

4. Conclusions

- The crystallinity degree dropped when the percentage of post-consumer PLA increased from 48% in V100R0 to 30% in V25R75. The reason could be the fact that the molecular chains of the secondary PLA were too short to organize the crystals;

- SEM micrographs of the fracture surface showed that virgin PLA specimens were more brittle and less dense than recycled PLA blends, thus significantly reducing both the millimetre- and micrometre-sized holes;

- The mechanical test showed that 3D printing with recycled PLA was a viable option; the tensile strength increased with the recycled content by 19% compared with the PLA samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rejeski, D.; Zhao, F.; Huang, Y. Research Needs and Recommendations on Environmental Implications of Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2018; Volume 19, ISBN 0013523927303. [Google Scholar]

- Sanchez, F.A.C.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Gebler, M.; Uiterkamp, A.J.M.S.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Breški, T.; Hentschel, L.; Godec, D.; Đuretek, I. Suitability of Recycled PLA Filament Application in Fused Filament Fabrication Process. Teh. Glas. 2021, 15, 491–497. [Google Scholar] [CrossRef]

- Bogers, M.; Hadar, R.; Bilberg, A. Additive manufacturing for consumer-centric business models: Implications for supply chains in consumer goods manufacturing. Technol. Forecast. Soc. Chang. 2016, 102, 225–239. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Anderson, I.; Raza, I.; Iannucci, L.; Curtis, P.T.; Ruppert, D.S.; Harrysson, O.L.; Marcellin-Little, D.J.; Abumoussa, S.; Dahners, L.E.; Weinhold, P.S.; et al. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Lee, D.; Lee, Y.; Lee, K.; Ko, Y.; Kim, N. Development and Evaluation of a Distributed Recycling System for Making Filaments Reused in Three-Dimensional Printers. J. Manuf. Sci. Eng. 2019, 141, 021007. [Google Scholar] [CrossRef]

- Tanney, D.; Meisel, N.A.; Moore, J.P. Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017; pp. 519–531. [Google Scholar]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef]

- Pillin, I.; Montrelay, N.; Bourmaud, A.; Grohens, Y. Effect of thermo-mechanical cycles on the physicochemical properties of poly(lactic acid). Polym. Degrad. Stab. 2008, 93, 321–328. [Google Scholar] [CrossRef]

- Sangeetha, V.; Deka, H.; Varghese, T.; Nayak, S. State of the art and future prospectives of poly(lactic acid) based blends and composites. Polym. Compos. 2018, 39, 81–101. [Google Scholar] [CrossRef]

- Kuo, C.-F.J.; Lan, W.L.; Chen, C.-Y.; Tsai, H.-C. Property modification and process parameter optimization design of polylactic acid composite materials. Part I: Polylactic acid toughening and photo-degradation modification and optimized parameter design. Text. Res. J. 2014, 85, 13–25. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Ngaowthong, C.; Borůvka, M.; Běhálek, L.; Lenfeld, P.; Švec, M.; Dangtungee, R.; Siengchin, S.; Rangappa, S.M.; Parameswaranpillai, J. Recycling of sisal fiber reinforced polypropylene and polylactic acid composites: Thermo-mechanical properties, morphology, and water absorption behavior. Waste Manag. 2019, 97, 71–81. [Google Scholar] [CrossRef] [PubMed]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(lactic acid): A Versatile Biobased Polymer for the Future with Multifunctional Properties—From Monomer Synthesis, Polymerization Techniques and Molecular Weight Increase to PLA Applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Sun, C.; Wei, S.; Tan, H.; Huang, Y.; Zhang, Y. Progress in upcycling polylactic acid waste as an alternative carbon source: A review. Chem. Eng. J. 2022, 446, 136881. [Google Scholar] [CrossRef]

- Maga, D.; Hiebel, M.; Thonemann, N. Life cycle assessment of recycling options for polylactic acid. Resour. Conserv. Recycl. 2019, 149, 86–96. [Google Scholar] [CrossRef]

- Fahim, I.; Chbib, H.; Mahmoud, H.M. The synthesis, production & economic feasibility of manufacturing PLA from agricultural waste. Sustain. Chem. Pharm. 2019, 12, 100142. [Google Scholar] [CrossRef]

- Zhao, X.G.; Hwang, K.-J.; Lee, D.; Kim, T.; Kim, N. Enhanced mechanical properties of self-polymerized polydopamine-coated recycled PLA filament used in 3D printing. Appl. Surf. Sci. 2018, 441, 381–387. [Google Scholar] [CrossRef]

- Maga, D.; Hiebel, M.; Aryan, V. A Comparative Life Cycle Assessment of Meat Trays Made of Various Packaging Materials. Sustainability 2019, 11, 5324. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Sanchez, F.A.C.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Hart, K.R.; Frketic, J.B.; Brown, J.R. Recycling meal-ready-to-eat (MRE) pouches into polymer filament for material extrusion additive manufacturing. Addit. Manuf. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2016, 25, 136–145. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Flanagan, T.; Ghabezi, P.; Finnegan, W.; Mitchell, S.; Harrison, N. Recovery of Particle Reinforced Composite 3D Printing Filament from Recycled Industrial Polypropylene and Glass Fibre Waste. Proc. World Congr. Mech. Chem. Mater. Eng. 2022, 177, 3–4. [Google Scholar] [CrossRef]

- Ghabezi, P.; Flanagan, T.; Harrison, N. Short basalt fibre reinforced recycled polypropylene filaments for 3D printing. Mater. Lett. 2022, 326, 132942. [Google Scholar] [CrossRef]

- Goutham, R.; Veena, T.R.; Babagowda; Prasad, K.R.S. Study on mechanical properties of recycled Acrylonitrile Butadiene Styrene (ABS) blended with virgin Acrylonitrile Butadiene Styrene (ABS) using Taguchi method. Mater. Today Proc. 2018, 5, 24836–24845. [Google Scholar] [CrossRef]

- Smart Materials 3D Printing, S.L. PLA 3D870 SmartMaterials3D Filament Datasheet v1.2. Available online: https://www.smartmaterials3d.com/en/index.php?controller=attachment&id_attachment=190 (accessed on 23 June 2022).

- Bergaliyeva, S.; Sales, D.L.; Delgado, F.J.; Bolegenova, S.; Molina, S.I. Effect of Thermal and Hydrothermal Accelerated Aging on 3D Printed Polylactic Acid. Polymers 2022, 14, 5256. [Google Scholar] [CrossRef] [PubMed]

- ISO/TC 61/SC 2; Mechanical Behavior ISO 20753:2008 Plastics—Test Specimens. ISO: Geneva, Switzerland, 2008.

- Liu, X.; Zhang, M.; Li, S.; Si, L.; Peng, J.; Hu, Y. Mechanical property parametric appraisal of fused deposition modeling parts based on the gray Taguchi method. Int. J. Adv. Manuf. Technol. 2017, 89, 2387–2397. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Li, H.; Wang, T.; Sun, J.; Yu, Z. The effect of process parameters in fused deposition modelling on bonding degree and mechanical properties. Rapid Prototyp. J. 2002, 24, 80–92. [Google Scholar] [CrossRef]

- Torres, J.; Cole, M.; Owji, A.; DeMastry, Z.; Gordon, A.P. An approach for mechanical property optimization of fused deposition modeling with polylactic acid via design of experiments. Rapid Prototyp. J. 2016, 22, 387–404. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- ISO ISO 291:2008; Plastics—Standard Atmospheres for Conditioning and Testing. ISO: Geneva, Switzerland, 2008.

- ISO/TC 61/SC 5; Physical-Chemical Properties ISO 11358-1:2014 Plastics—Thermogravimetry (TG) of Polymers—Part 1: General Principles. ISO: Geneva, Switzerland, 2014.

- ISO/TC 61/SC 2; Mechanical Behavior ISO 527-1:2019 Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- Malmgren, T.; Mays, J.; Pyda, M. Characterization of poly(lactic acid) by size exclusion chromatography, differential refractometry, light scattering and thermal analysis. J. Therm. Anal. Calorim. 2006, 83, 35–40. [Google Scholar] [CrossRef]

- Fan, Y.; Nishida, H.; Shirai, Y.; Tokiwa, Y.; Endo, T. Thermal degradation behaviour of poly(lactic acid) stereocomplex. Polym. Degrad. Stab. 2004, 86, 197–208. [Google Scholar] [CrossRef]

- Sarasua, J.-R.; Balerdi, P.; Maiza, I. Crystallinity and mechanical properties of optically pure polylactides and their blends. Polym. Eng. Sci. 2005, 45, 745–753. [Google Scholar] [CrossRef]

- Sarasua, J.-R.; Prud’homme, R.E.; Wisniewski, M.; Borgne, A.L.; Spassky, N. Crystallization and Melting Behavior of Polylactides. Macromolecules 1998, 31, 3895–3905. [Google Scholar] [CrossRef]

- Kulinski, Z.; Piorkowska, E. Crystallization, structure and properties of plasticized poly(l-lactide). Polymer 2005, 46, 10290–10300. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L. The Crystallization and Melting Processes of Poly(L-lactic acid). Macromol. Symp. 2006, 234, 176–183. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L. Calorimetric analysis of the multiple melting behavior of poly(L-lactic acid). J. Appl. Polym. Sci. 2006, 100, 3145–3151. [Google Scholar] [CrossRef]

- Sánchez, M.S.; Ribelles, J.G.; Sánchez, F.H.; Mano, J. On the kinetics of melting and crystallization of poly(l-lactic acid) by TMDSC. Thermochim. Acta 2005, 430, 201–210. [Google Scholar] [CrossRef]

- Sarasua, J.-R.; Balerdi, P.; Maiza, I. Crystallization and thermal behaviour of optically pure polylactides and their blends. J. Mater. Sci. 2005, 40, 1855–1862. [Google Scholar] [CrossRef]

- Signori, F.; Coltelli, M.-B.; Bronco, S. Thermal degradation of poly(lactic acid) (PLA) and poly(butylene adipate-co-terephthalate) (PBAT) and their blends upon melt processing. Polym. Degrad. Stab. 2009, 94, 74–82. [Google Scholar] [CrossRef]

- ISO/TC 69; Applications of Statistical Methods ISO 2602:1980 Statistical Interpretation of Test Results—Estimation of the Mean—Confidence Interval. ISO: Geneva, Switzerland, 1980.

- Żenkiewicz, M.; Richert, J.; Rytlewski, P.; Moraczewski, K.; Stepczyńska, M.; Karasiewicz, T. Characterisation of multi-extruded poly(lactic acid). Polym. Test. 2009, 28, 412–418. [Google Scholar] [CrossRef]

| Sample Code | Weight Ratio (%) | |

|---|---|---|

| Virgin PLA | Recycled PLA | |

| V100R0 | 100 | 0 |

| V75R25 | 75 | 25 |

| V50R50 | 50 | 50 |

| V25R75 | 25 | 75 |

| Sample Code | T5%loss | Ti | Tf | Tf-Ti | Tmax |

|---|---|---|---|---|---|

| V100R0 | 292 | 306 | 334 | 28 | 322 |

| V75R25 | 290 | 304 | 332 | 28 | 323 |

| V50R50 | 283 | 305 | 335 | 30 | 325 |

| V25R75 | 286 | 308 | 340 | 32 | 327 |

| Sample Code | First Heating | Second Heating | Xc | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Tg | Tc | ΔHc | Tm | ΔHm | Tg | Tm | ΔHm | ||

| °C | °C | J/g | °C | J/g | °C | °C | J/g | % | |

| V100R0 | 59.19 | 97.68 | 45.41 | 176.98 | 57.24 | 64.20 | 177.60 | 50.86 | 48 |

| V75R25 | 59.84 | 94.45 | 37.34 | 175.80 | 50.25 | 63.20 | 173.50 | 49.91 | 47 |

| V50R50 | 60.71 | 94.63 | 27.38 | 175.01 | 36.21 | 60.98 | 176.82 | 38.24 | 36 |

| V25R75 | 58.43 | 97.87 | 24.85 | 173.25 | 28.51 | 60.12 | 174.31 | 31.62 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bergaliyeva, S.; Sales, D.L.; Delgado, F.J.; Bolegenova, S.; Molina, S.I. Manufacture and Characterization of Polylactic Acid Filaments Recycled from Real Waste for 3D Printing. Polymers 2023, 15, 2165. https://doi.org/10.3390/polym15092165

Bergaliyeva S, Sales DL, Delgado FJ, Bolegenova S, Molina SI. Manufacture and Characterization of Polylactic Acid Filaments Recycled from Real Waste for 3D Printing. Polymers. 2023; 15(9):2165. https://doi.org/10.3390/polym15092165

Chicago/Turabian StyleBergaliyeva, Saltanat, David L. Sales, Francisco J. Delgado, Saltanat Bolegenova, and Sergio I. Molina. 2023. "Manufacture and Characterization of Polylactic Acid Filaments Recycled from Real Waste for 3D Printing" Polymers 15, no. 9: 2165. https://doi.org/10.3390/polym15092165

APA StyleBergaliyeva, S., Sales, D. L., Delgado, F. J., Bolegenova, S., & Molina, S. I. (2023). Manufacture and Characterization of Polylactic Acid Filaments Recycled from Real Waste for 3D Printing. Polymers, 15(9), 2165. https://doi.org/10.3390/polym15092165