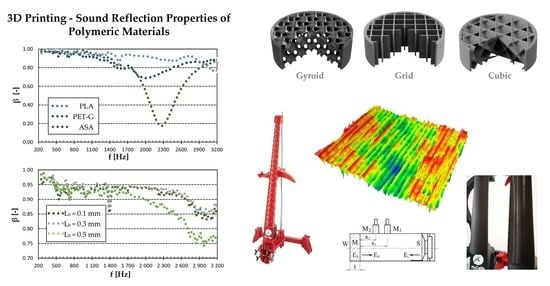

Three-Dimensional Printing Process for Musical Instruments: Sound Reflection Properties of Polymeric Materials for Enhanced Acoustical Performance

Abstract

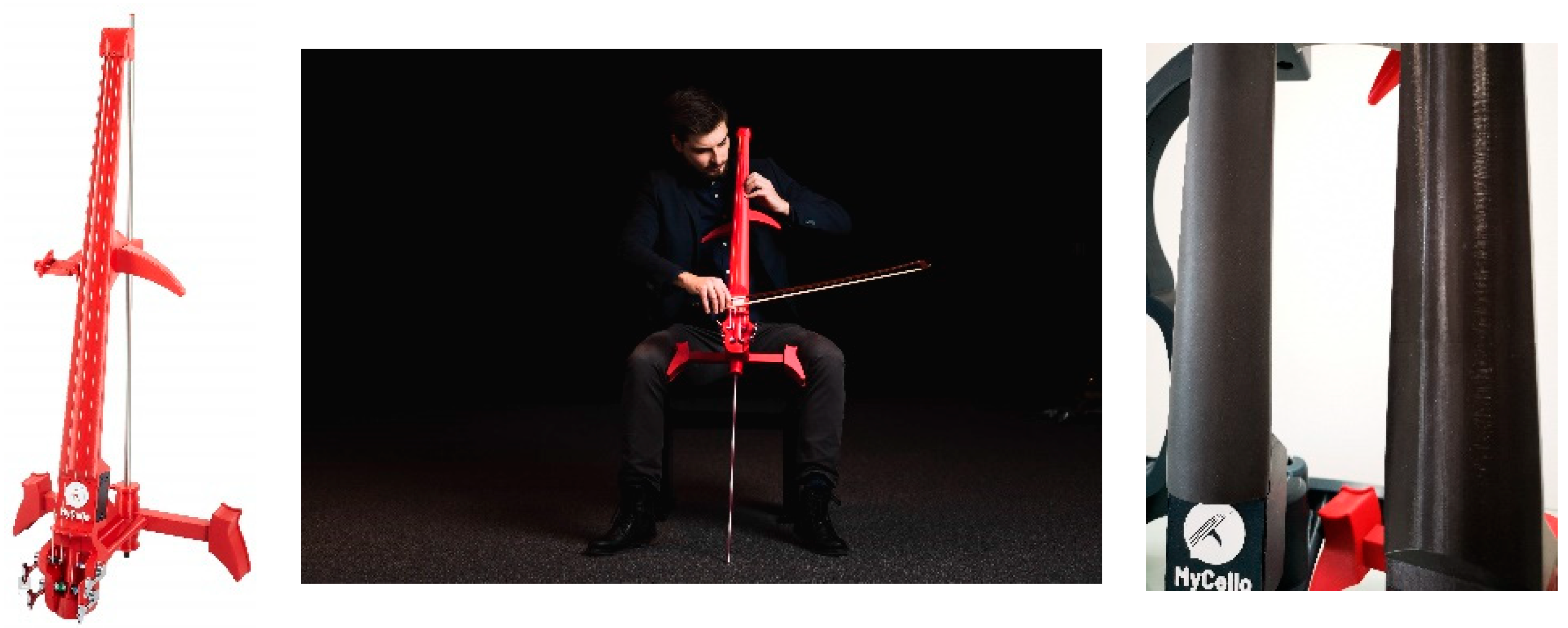

1. Introduction

2. Materials and Methods

2.1. Materials

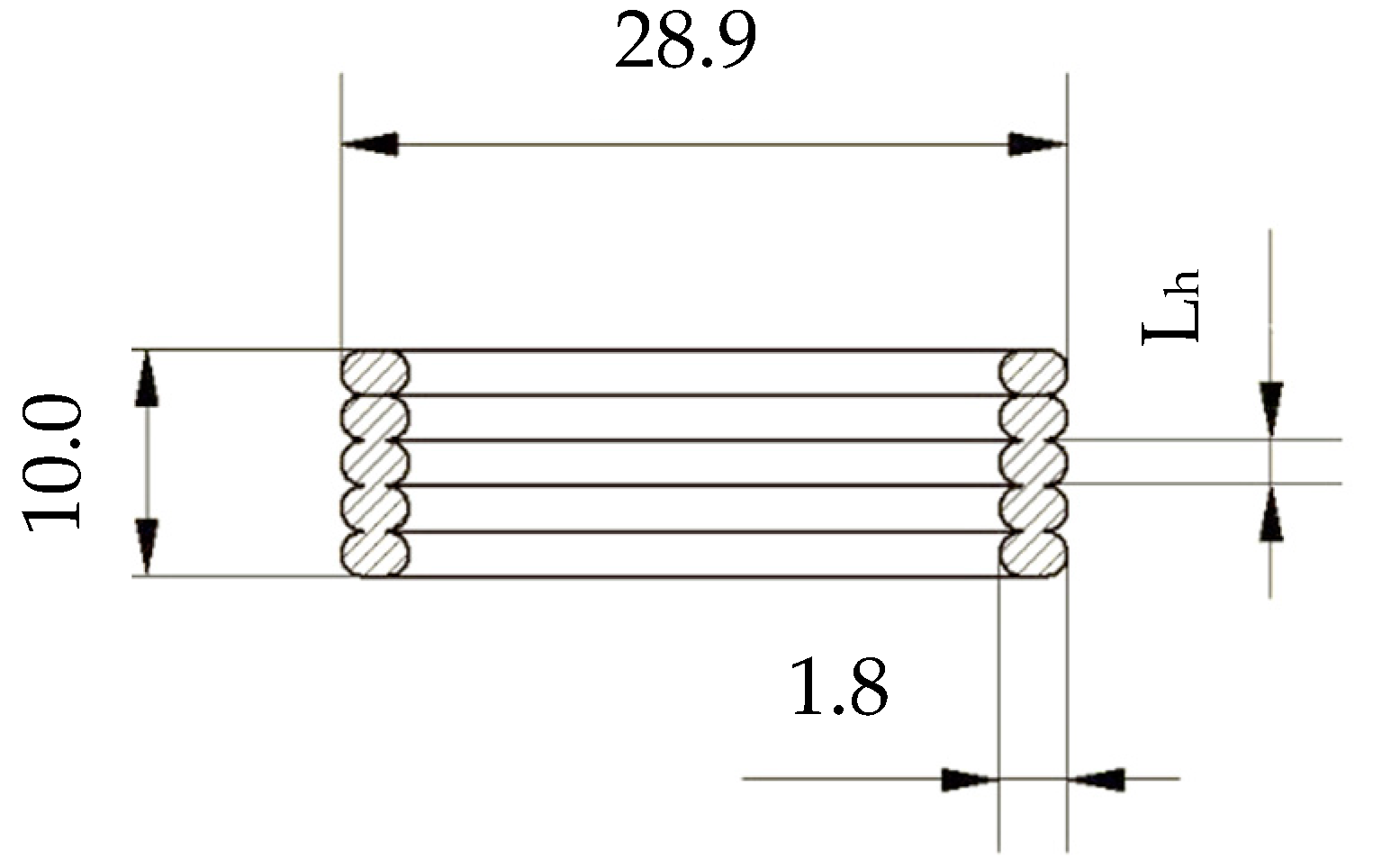

2.2. Samples’ Production

2.3. Measurement Methodology

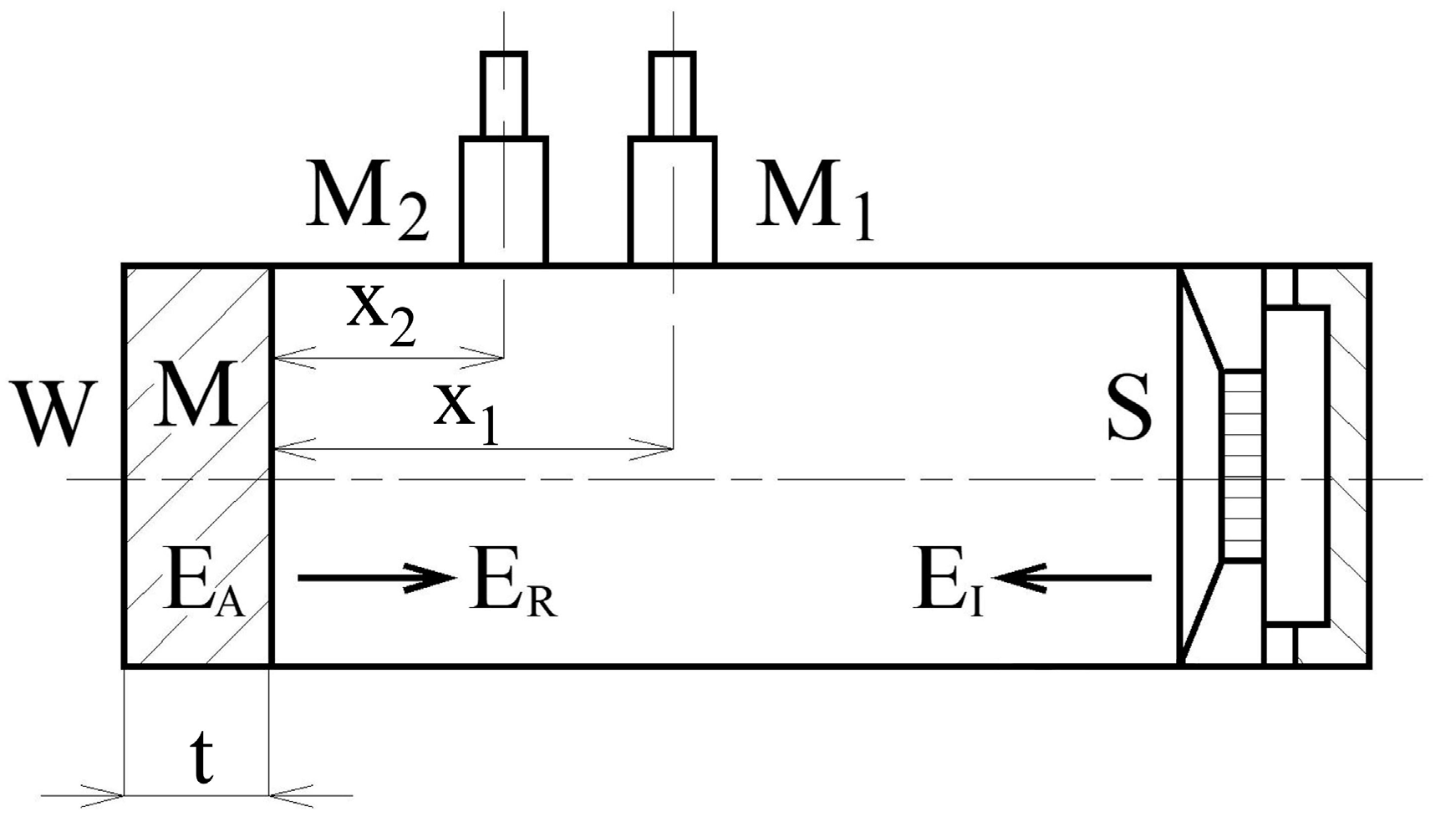

2.3.1. Sound Absorption Coefficient

2.3.2. Noise Reduction Coefficient

2.3.3. Sound Reflection Coefficient

2.3.4. Surface Quality

3. Results and Discussion

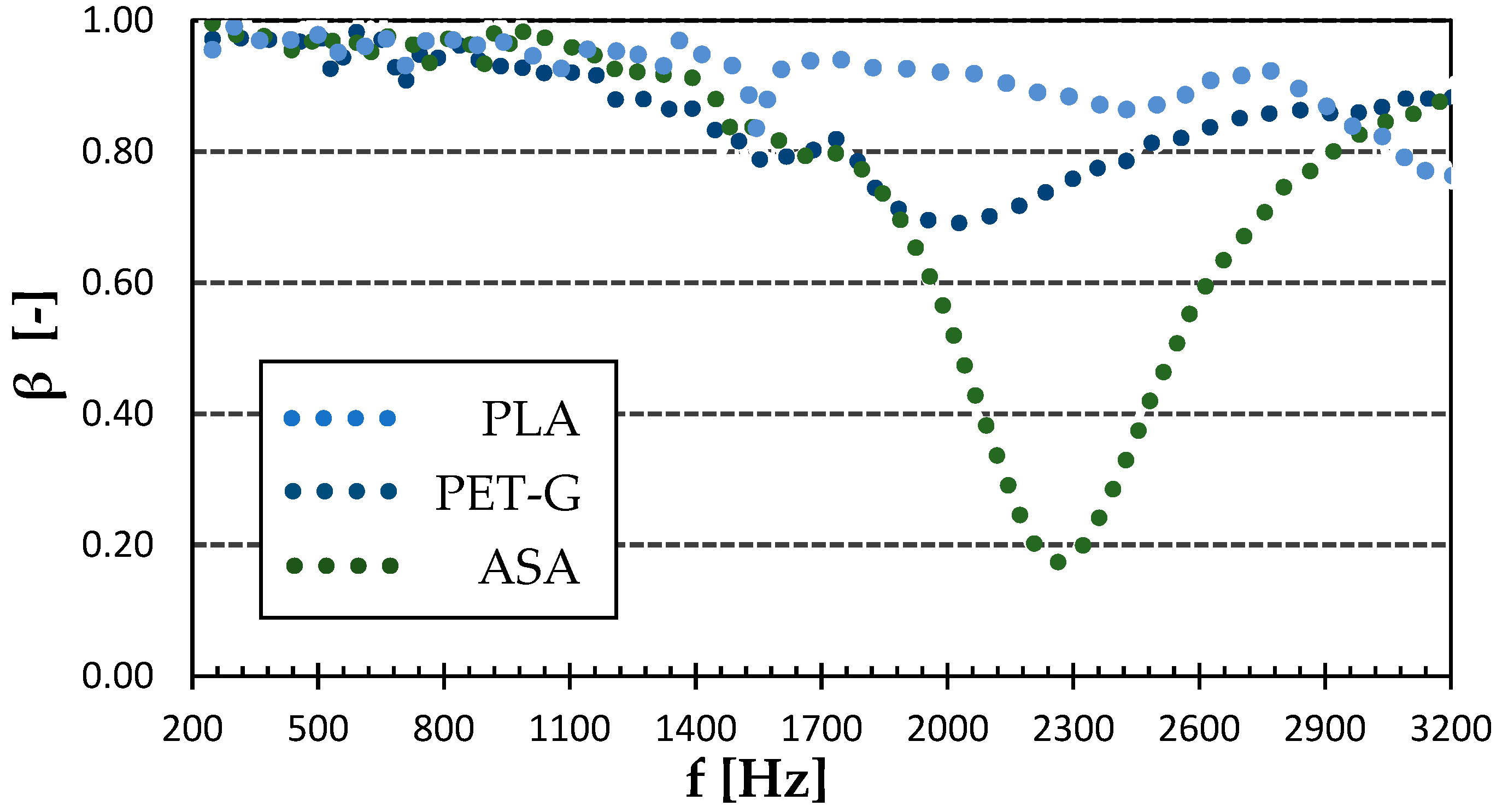

3.1. Frequency Dependencies of the Sound Reflection Coefficient

3.1.1. Effect of Material Type

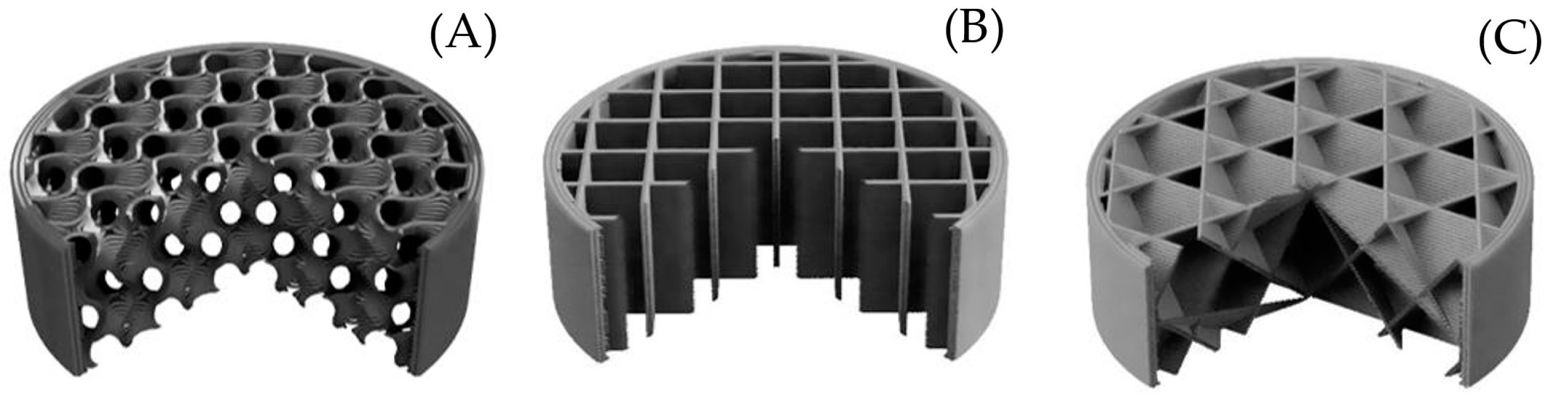

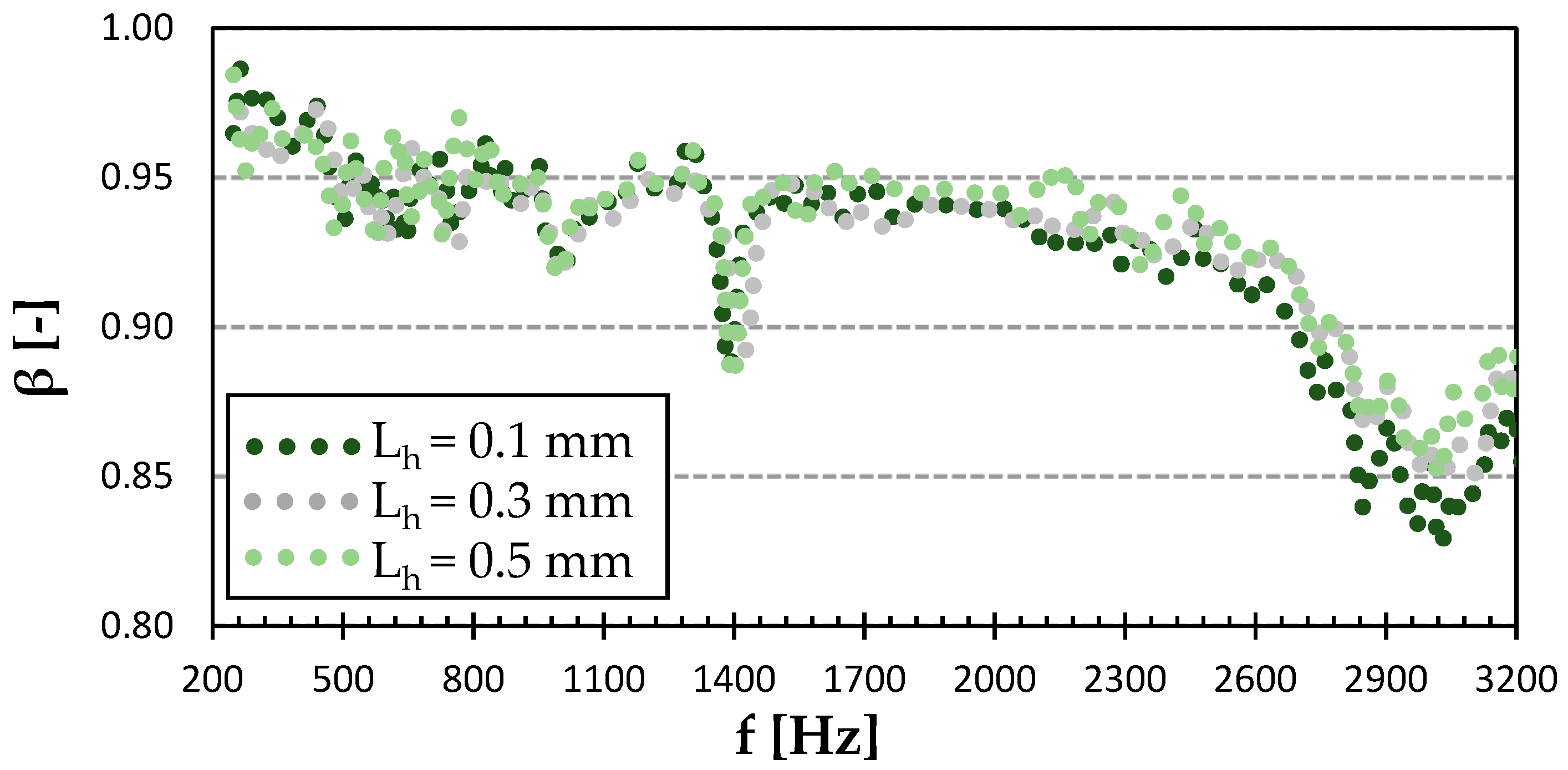

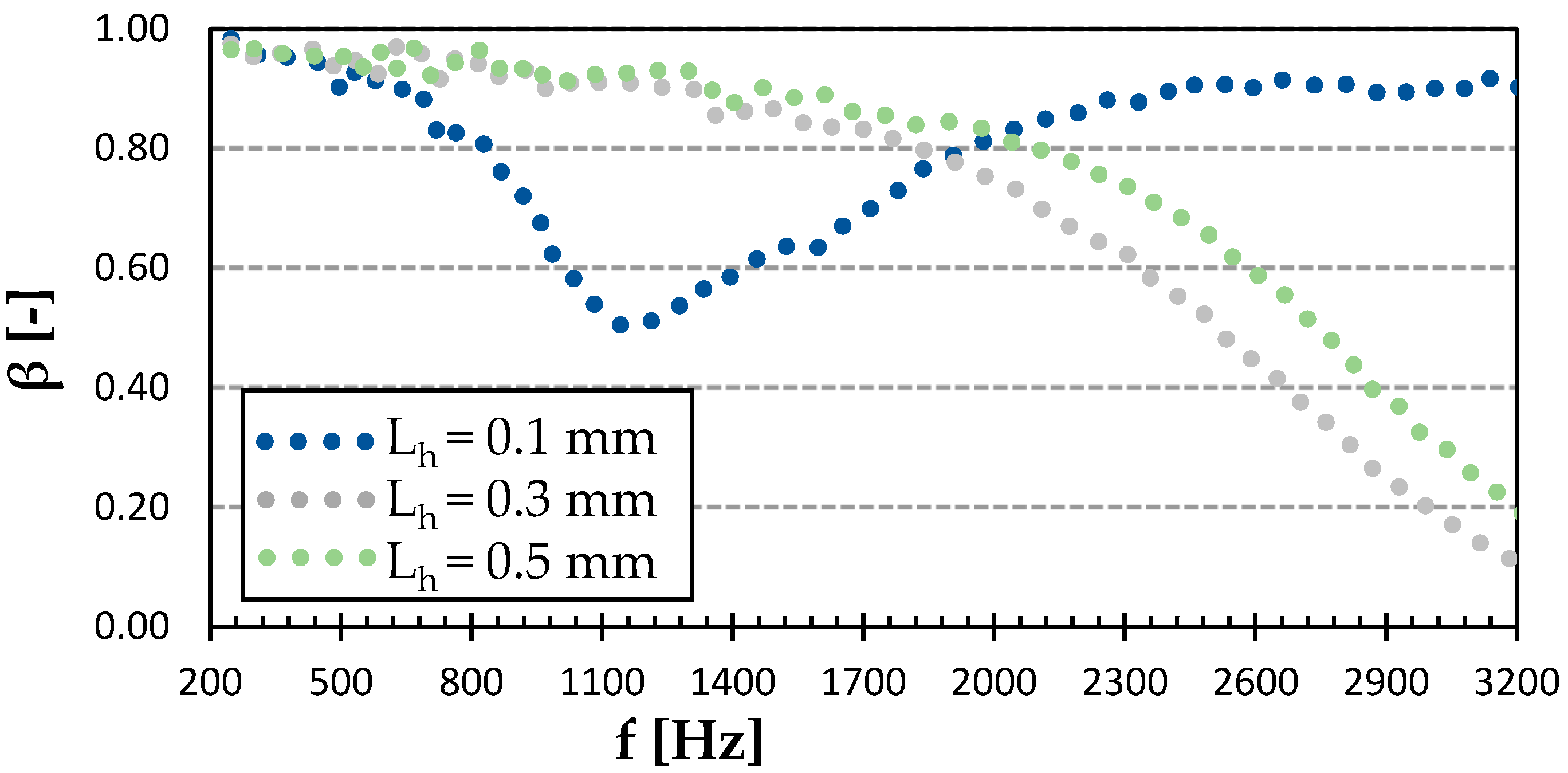

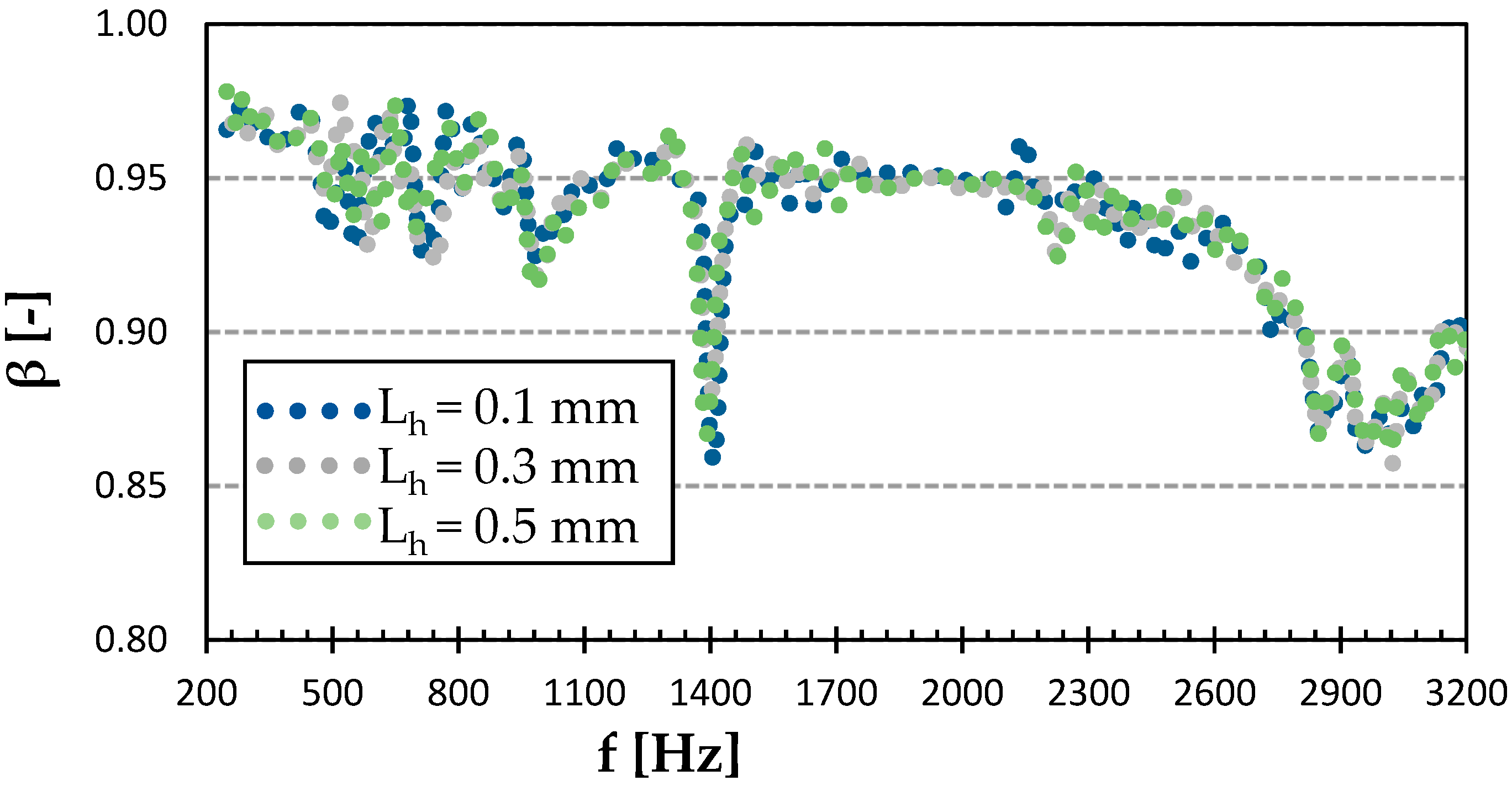

3.1.2. Effect of Layer Height and Infill Structure of PET-G

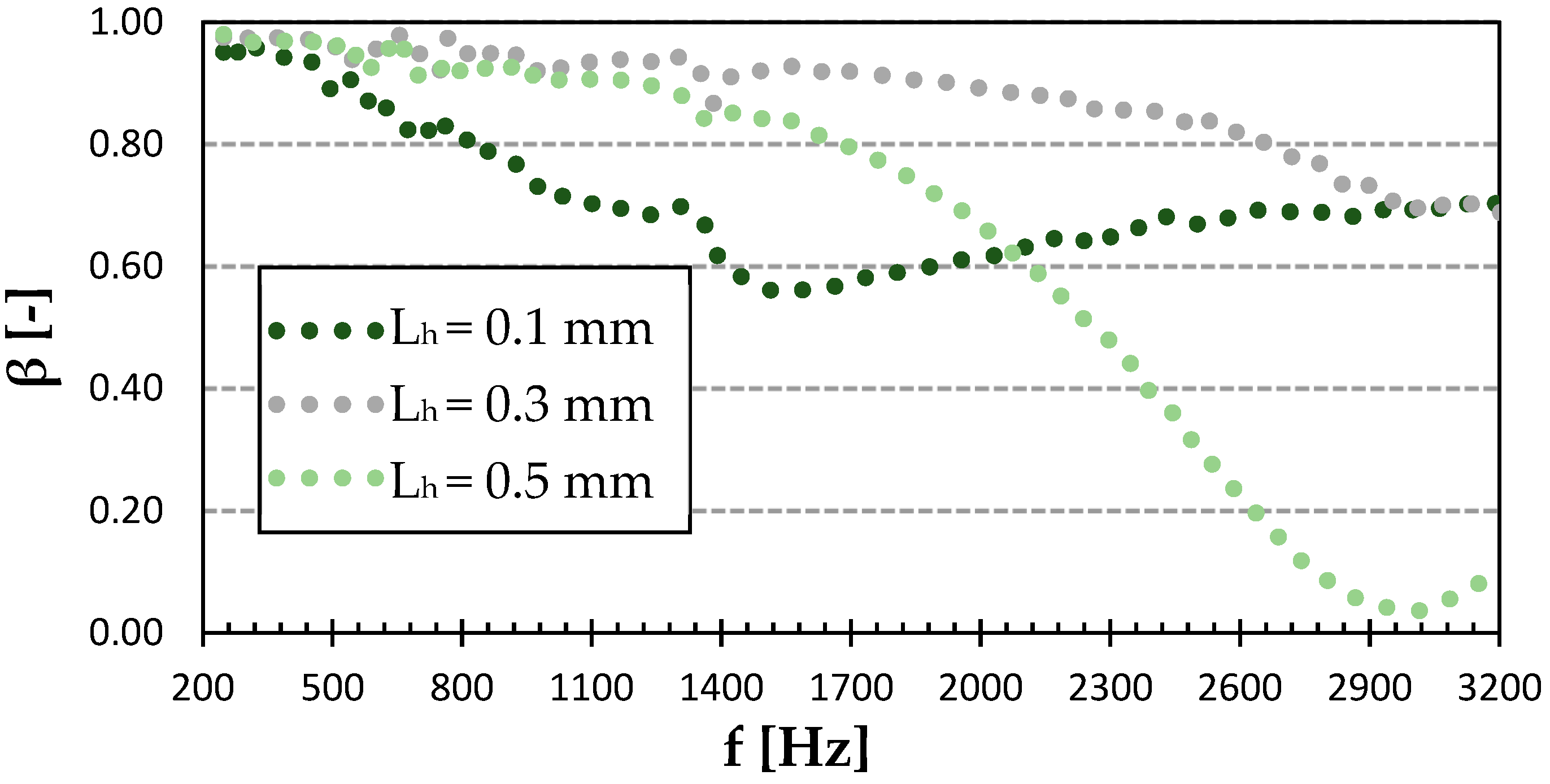

3.1.3. Effect of Layer Height and Infill Structure of ASA

3.2. Noise Reduction Coefficient and Average Sound Reflection Coefficient

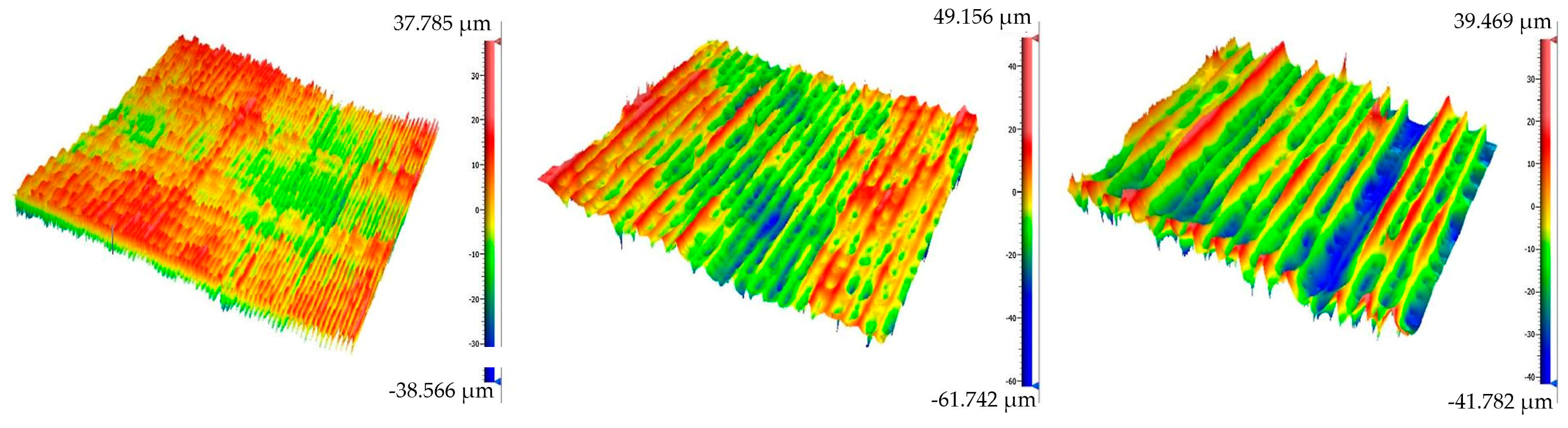

3.3. Surface Quality Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ashby, M.F.; Ferreira, P.J.; Schodek, D.L. Musical Instruments. In Nanomaterials, Nanotechnologies and Design—An Introduction for Engineers and Architects; Elsevier: Amsterdam, The Netherlands, 2009; pp. 377–378. [Google Scholar]

- Randall, R.H. Wind Instruments of the Reed Type. In Introduction to Acoustics; Dover Publications: Mineola, NY, USA, 2005; pp. 176–182. [Google Scholar]

- Buschow, K.H.J.; Cahn, R.W.; Flemings, M.C.; Ilschner, B.; Kramer, E.J.; Mahajan, S. Musical Instruments: Materials. In Encyclopedia of Materials—Science and Technology, Volumes 1–11; Elsevier: Amsterdam, The Netherlands, 2001; pp. 5893–5894. [Google Scholar]

- Xu, B.; Li, H.Y. Musical Instrument Sound Transmission Mechanisms. In Advanced Composite Materials and Manufacturing Engineering; Trans Tech Publications: Bäch, Switzerland, 2012; pp. 256–258. [Google Scholar]

- Hlremath, P.; Suhas, C.S.S.; Manjunath, M.; Shettar, M. COVID 19: Impact of lock-down on mental health and tips to overcome. Asian J. Psychiatry 2020, 51, 102088. [Google Scholar] [CrossRef]

- Li, X.Y.; Fu, P.; Fan, C.Y.; Zhu, M.; Li, M. COVID-19 Stress and Mental Health of Students in Locked-Down Colleges. Int. J. Environ. Res. Public Health 2021, 18, 771. [Google Scholar] [CrossRef] [PubMed]

- Sumira, M.; Shalini, M.; Prachi, P. Analysis of pre and post influence of COVID-19 pandemic among general population. Res. J. Biotechnol. 2020, 15, 199–211. [Google Scholar]

- Varalakshmi, R.; Swetha, R. COVID-19 lock down: People psychology due to law enforcement. Asian J. Psychiatry 2020, 51, 102102. [Google Scholar] [CrossRef]

- Mroz, B.; Odya, P.; Kostek, B. Creating a Remote Choir Performance Recording Based on an Ambisonic Approach. Appl. Sci. 2022, 12, 3316. [Google Scholar] [CrossRef]

- Kumar, M.B.; Sathiya, P. Methods and materials for additive manufacturing: A critical review on advancements and challenges. Thin-Walled Struct. 2021, 159, 107228. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B-Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Zolfagharian, A.; Bodaghi, M. 4D bioprinting of smart polymers for biomedical applications: Recent progress, challenges, and future perspectives. React. Funct. Polym. 2022, 179, 105374. [Google Scholar] [CrossRef]

- Yousefi, A.; Jolaiy, S.; Dezaki, M.L.; Zolfagharian, A.; Serjouei, A.; Bodaghi, M. 3D-Printed Soft and Hard Meta-Structures with Supreme Energy Absorption and Dissipation Capacities in Cyclic Loading Conditions. Adv. Eng. Mater. 2022, 25, 2201189. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Lakhi, M.; Ranjbar, S.; Tadesse, Y.; Bodaghi, M. 3D printing non-assembly compliant joints for soft robotics. Results Eng. 2022, 15, 100558. [Google Scholar] [CrossRef]

- Dudek, P. Fdm 3D printing technology in manufacturing composite elements. Arch. Metall. Mater. 2013, 58, 1415–1418. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimasauskas, M. Characterization of carbon fiber reinforced PLA composites manufactured by fused deposition modeling. Compos. Part C Open Access 2021, 4, 100112. [Google Scholar] [CrossRef]

- Monkova, K.; Vasina, M.; Monka, P.P.; Vanca, J.; Kozak, D. Effect of 3D-Printed PLA Structure on Sound Reflection Properties. Polymers 2022, 14, 413. [Google Scholar] [CrossRef] [PubMed]

- Ning, F.D.; Cong, W.L.; Qiu, J.J.; Wei, J.H.; Wang, S.R. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B-Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Zulkifli, R.; Mohd Nor, M.J.; Mat Tahir, M.F.; Ismail, A.R.; Nuawi, M.Z. Acoustic properties of multi-layer coir fibres sound absorption panel. J. Appl. Sci. 2008, 8, 3709–3714. [Google Scholar] [CrossRef]

- Zulkifli, R.; Nor, M.J.M. Noise control using coconut coir fiber sound absorber with porous layer backing and perforated panel. Am. J. Appl. Sci. 2010, 7, 260–264. [Google Scholar] [CrossRef]

- Lee, F.C.; Chen, W.H. Acoustic transmission analysis of multi-layer absorbers. J. Sound Vib. 2001, 248, 621–634. [Google Scholar] [CrossRef]

- Cucharero, J.; Hänninen, T.; Lokki, T. Angle-Dependent Absorption of Sound on Porous Materials. Acoustics 2020, 2, 753–765. [Google Scholar] [CrossRef]

- Koizumi, T.; Tsujiuchi, N.; Adachi, A. The development of sound absorbing materials using natural bamboo fibers. In Proceedings of the High Performance Structures and Materials; WIT Press: Ashurst Lodge, Southampton, 2002; pp. 157–166. [Google Scholar]

- Thilagavathi, G.; Pradeep, E.; Kannaian, T.; Sasikala, L. Development of natural fiber nonwovens for application as car interiors for noise control. J. Ind. Text. 2010, 39, 267–278. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O. 3D printing technology in musical instrument research: Reviewing the potential. Rapid Prototyp. J. 2018, 24, 1511–1523. [Google Scholar] [CrossRef]

- Riefer, J.; Tai, B.; Wang, J. An Investigation in Tone Characteristics of 3D Printed Ukulele Sound Chambers. Manuf. Lett. 2022, 33, 508–515. [Google Scholar] [CrossRef]

- Sensio.cz Ltd. MyCello by Sensio. Available online: https://www.sensio.cz/mycello/?page=mycello (accessed on 28 February 2023).

- ISO 10534-2; Acoustics-Determination of Sound absorption Coefficient and Impedance in Impedance Tubes-Part 2: Transfer-Function Method. ISO/TC 43/SC2 Building Acoustics; CEN; European Committee for Standardization: Brussels, Belgium, 1998; pp. 10534–10542.

- Fusheng, H.; Gary, S.; Yuyuan, Z.; Barry, G. Acoustic absorption behaviour of an open-celled aluminium foam. J. Phys. D Appl. Phys. 2003, 36, 294. [Google Scholar] [CrossRef]

- Cherrier, O.; Pommier-Budinger, V.; Simon, F. Panel of resonators with variable resonance frequency for noise control. Appl. Acoust. 2012, 73, 781–790. [Google Scholar] [CrossRef]

- ISO 16610-61:2015; Geometrical Product Specifications (GPS), Filtration. Part 61: Linear Areal Filters: Gaussian Filters. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO/R 468; Surface Roughness: Parameters, Their Values and General Rules for Specifying Requirements. International Organization for Standardization:: Geneva, Switzerland, 1982.

- ISO 25178-2:2012; Geometric Product Specification (GPS). Surface Texture: Areal. Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2012.

- GOST (State Standard) 2789-73; Surface Roughness. Parameters and Characteristics. Izd. Standartov: Moscow, Russia, 1975.

- ISO 4287:1997; Geometric Product Specification (GPS). Surface Texture Profile Method: Terms, Definition and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 1997.

- Aver’yanova, I.O.; Bogomolov, D.Y.; Poroshin, V.V. ISO 25178 standard for three-dimensional parametric assessment of surface texture. Russ. Eng. Res. 2017, 37, 513–516. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Zolfaghari, H.; Sadeghi, M.E.; Esmailpour, A.; Jaffari, A. Correlation between specific gas permeability and sound absorption coeficient in solid wood. J. Trop. For. Sci. 2014, 26, 92–100. [Google Scholar]

- Kang, C.W.; Jang, E.S.; Jang, S.S.; Hasegawa, M.; Matsumura, J. Studies of the Relationship Between Sound Absorption Coefficient and Air Permeability of Wood. J. Fac. Agric. Kyushu Univ. 2020, 65, 351–355. [Google Scholar] [CrossRef]

- Kang, C.W.; Kolya, H.; Jang, E.S.; Zhu, S.H.; Choi, B.S. Steam exploded wood cell walls reveals improved gas permeability and sound absorption capability. Appl. Acoust. 2021, 179, 108049. [Google Scholar] [CrossRef]

- Xu, W.; Fang, X.Y.; Han, J.T.; Wu, Z.H.; Zhang, J.L. Effect of coating thickness on sound absorption property of four wood species commonly used for piano soundboards. Wood Fiber Sci. 2020, 52, 28–43. [Google Scholar] [CrossRef]

- Song, B.Q.; Peng, L.M.; Fu, F.; Liu, M.H.; Zhang, H.J. Experimental and Theoretical Analysis of Sound Absorption Properties of Finely Perforated Wooden Panels. Materials 2016, 9, 942. [Google Scholar] [CrossRef]

- Afshar, A.; Wood, R. Development of Weather-Resistant 3D Printed Structures by Multi-Material Additive Manufacturing. J. Compos. Sci. 2020, 4, 94. [Google Scholar] [CrossRef]

| NRC [-] | βm [-] | ||||

|---|---|---|---|---|---|

| Lh (mm) | Infill Type | ASA | PET-G | ASA | PET-G |

| 0.1 | Gyroid | 0.055 | 0.072 | 0.925 | 0.919 |

| 0.1 | Cubic | 0.163 | 0.193 | 0.799 | 0.705 |

| 0.1 | Grid | 0.054 | 0.059 | 0.936 | 0.919 |

| 0.3 | Gyroid | 0.057 | 0.048 | 0.928 | 0.929 |

| 0.3 | Cubic | 0.109 | 0.060 | 0.703 | 0.878 |

| 0.3 | Grid | 0.052 | 0.041 | 0.936 | 0.963 |

| 0.5 | Gyroid | 0.058 | 0.064 | 0.933 | 0.886 |

| 0.5 | Cubic | 0.092 | 0.124 | 0.766 | 0.632 |

| 0.5 | Grid | 0.055 | 0.048 | 0.936 | 0.940 |

| 0.2 | 100% infill | 0.139 | 0.119 | 0.758 | 0.852 |

| Layer Height (mm) | Sa (µm) | Sq (µm) | Sz (µm) | Sdr (-) |

|---|---|---|---|---|

| 0.1 | 10.1 | 12.7 | 76.4 | 0.19 |

| 0.3 | 9.7 | 12.1 | 110.9 | 0.02 |

| 0.5 | 13.9 | 16.5 | 81.3 | 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zvoníček, T.; Vašina, M.; Pata, V.; Smolka, P. Three-Dimensional Printing Process for Musical Instruments: Sound Reflection Properties of Polymeric Materials for Enhanced Acoustical Performance. Polymers 2023, 15, 2025. https://doi.org/10.3390/polym15092025

Zvoníček T, Vašina M, Pata V, Smolka P. Three-Dimensional Printing Process for Musical Instruments: Sound Reflection Properties of Polymeric Materials for Enhanced Acoustical Performance. Polymers. 2023; 15(9):2025. https://doi.org/10.3390/polym15092025

Chicago/Turabian StyleZvoníček, Tomáš, Martin Vašina, Vladimír Pata, and Petr Smolka. 2023. "Three-Dimensional Printing Process for Musical Instruments: Sound Reflection Properties of Polymeric Materials for Enhanced Acoustical Performance" Polymers 15, no. 9: 2025. https://doi.org/10.3390/polym15092025

APA StyleZvoníček, T., Vašina, M., Pata, V., & Smolka, P. (2023). Three-Dimensional Printing Process for Musical Instruments: Sound Reflection Properties of Polymeric Materials for Enhanced Acoustical Performance. Polymers, 15(9), 2025. https://doi.org/10.3390/polym15092025