Biodegradable Preformed Particle Gel (PPG) Made of Natural Chitosan Material for Water Shut-Off Application

Abstract

1. Introduction

2. Materials, Procedures, and Methods

2.1. Materials

2.2. Experimental Procedures

2.3. Methods

2.3.1. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.2. Scanning Electron Microscope (SEM)

2.3.3. Swelling Behavior

2.3.4. Rheology Measurement

2.3.5. Particle Size

3. Results and Discussion

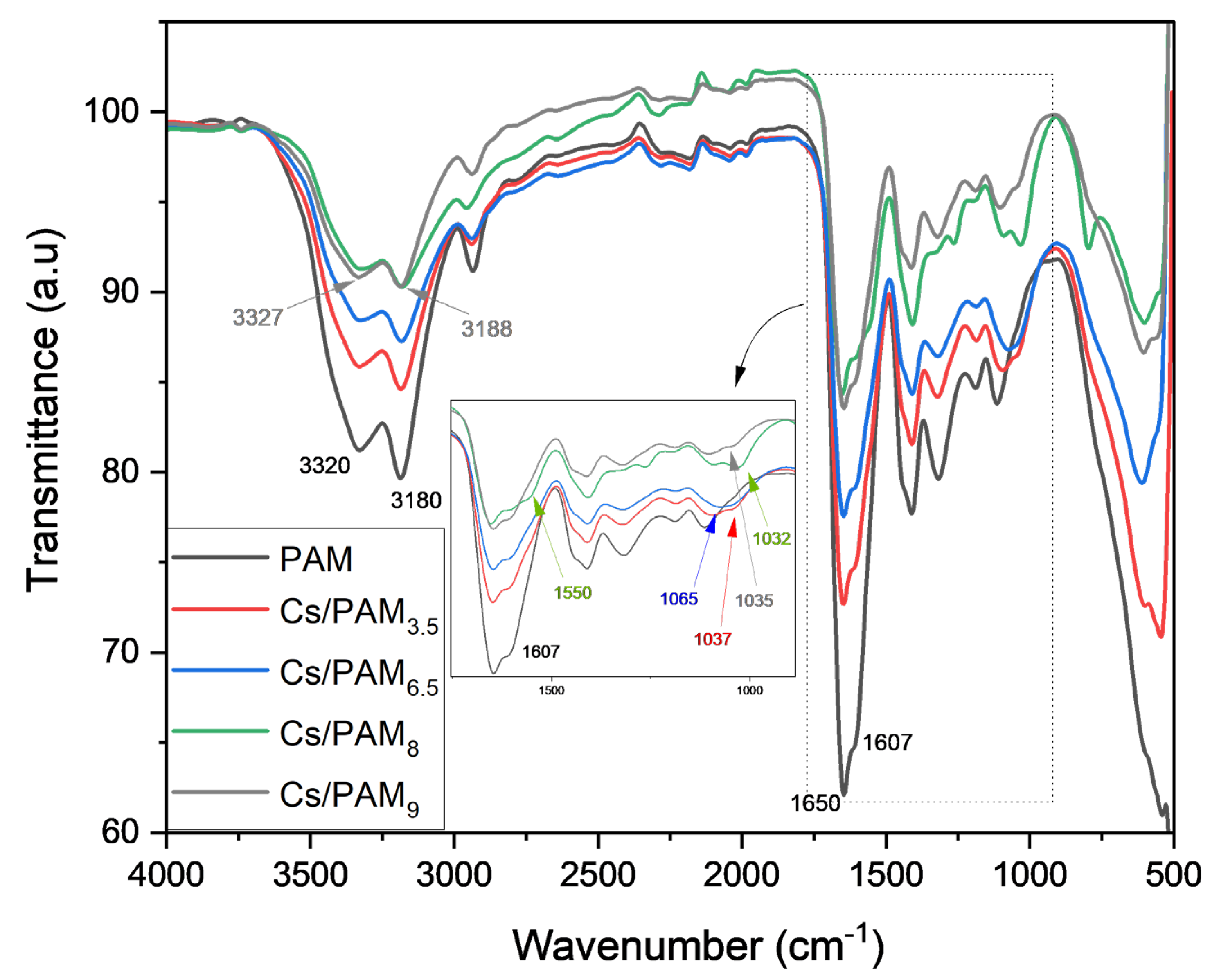

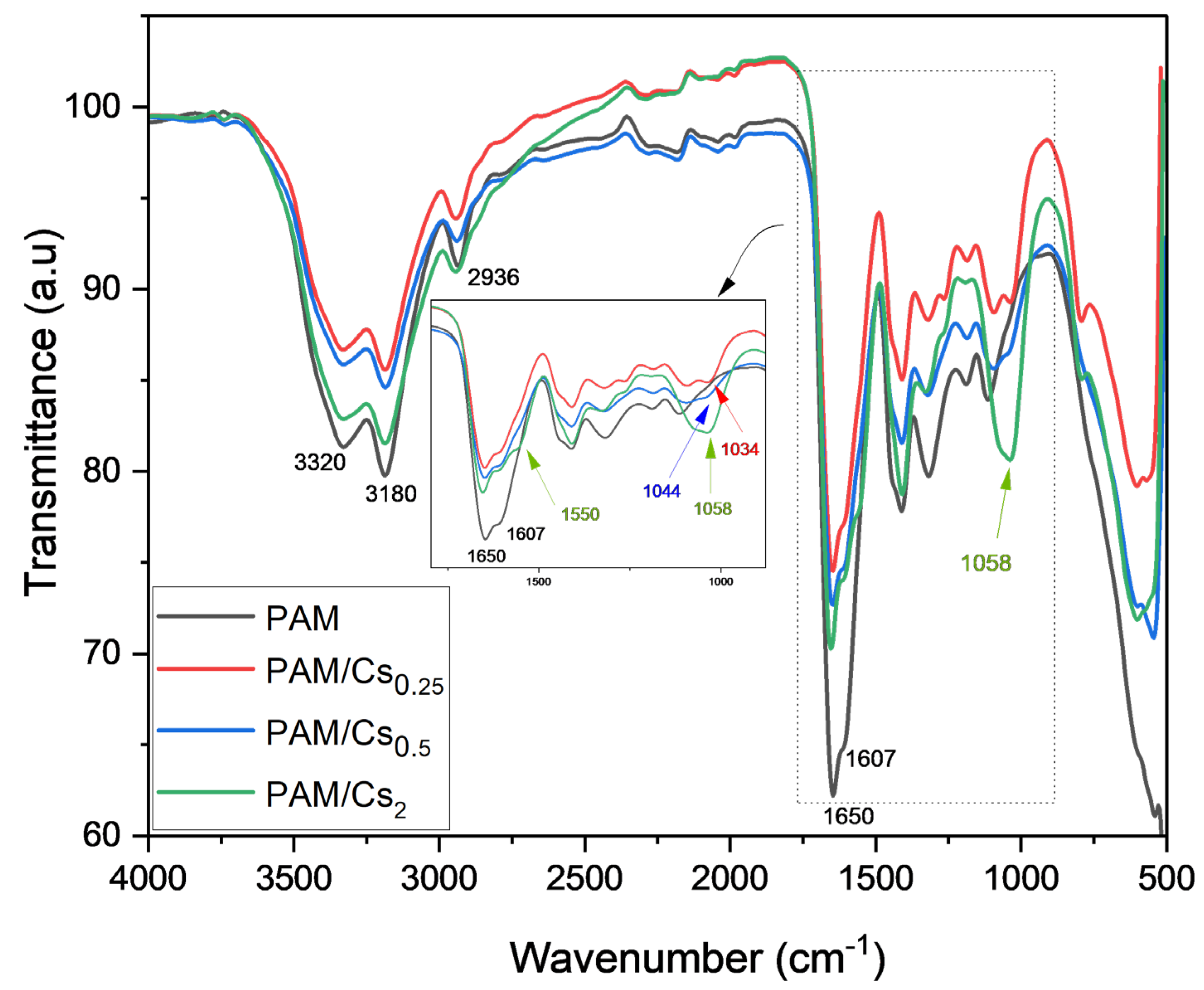

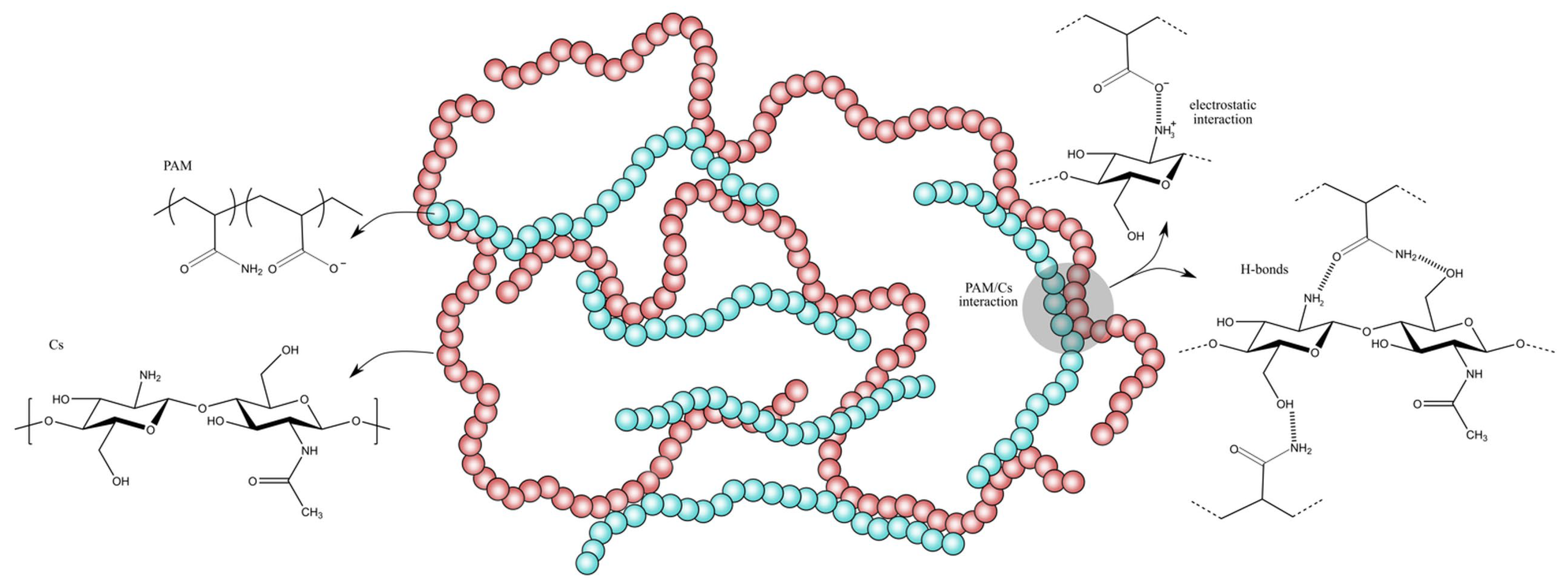

3.1. FTIR Spectroscopy Characterization

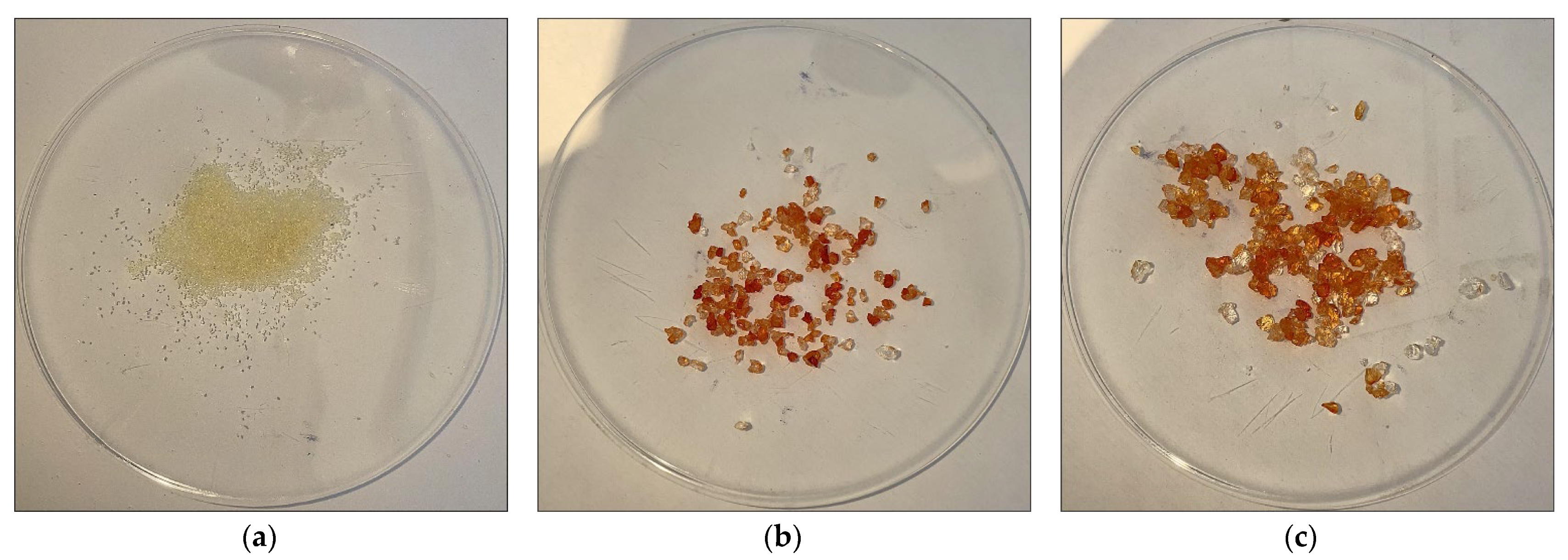

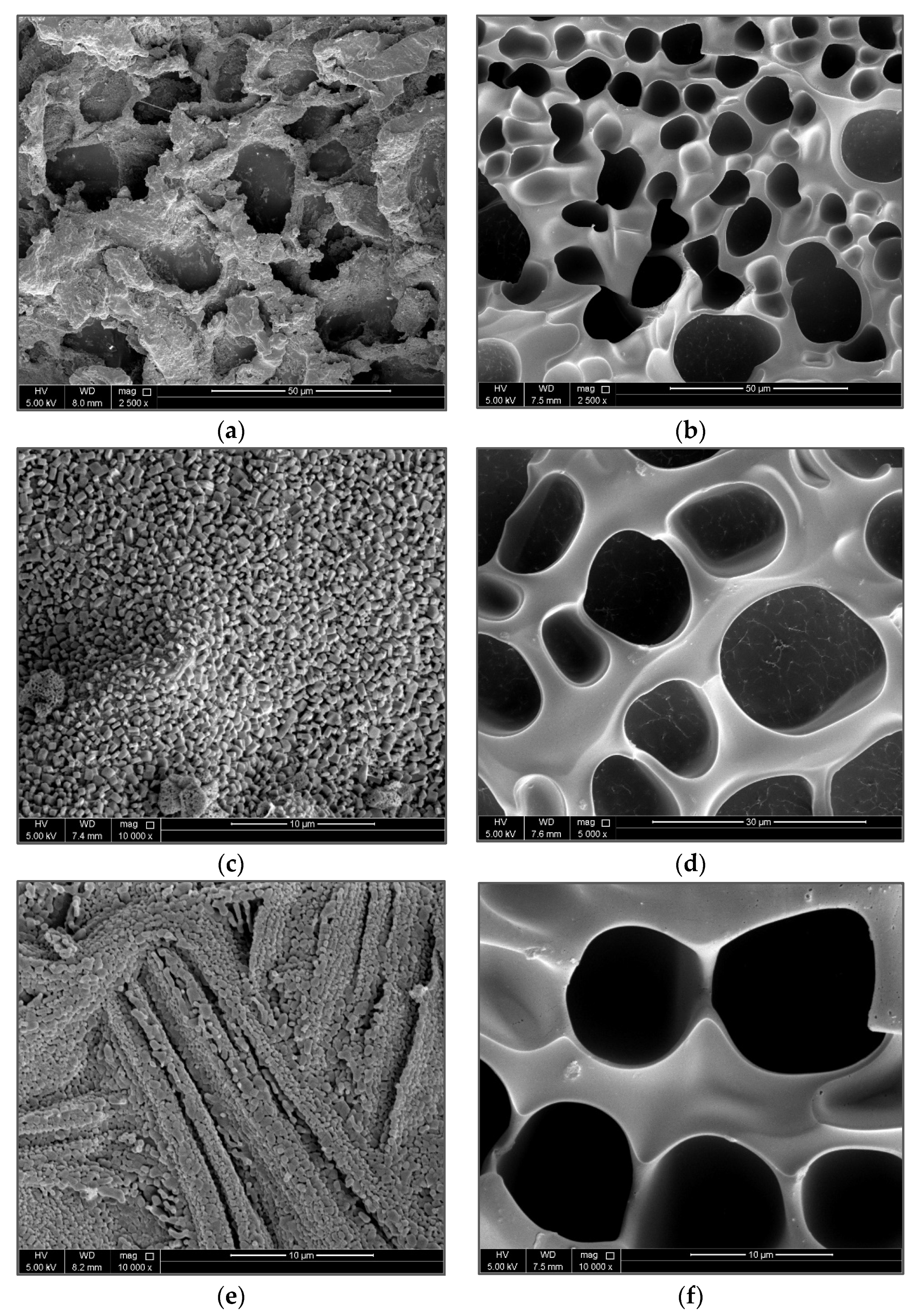

3.2. Surface Morphology of PAM/CS PPG

3.3. Factors Affecting PPG Performance

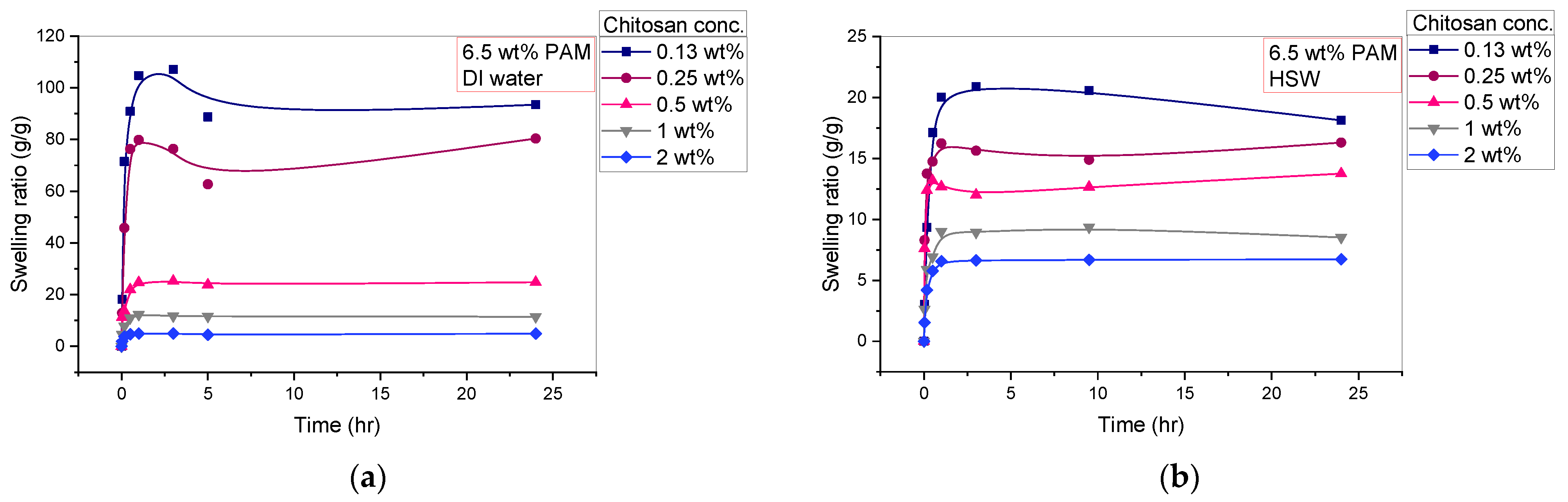

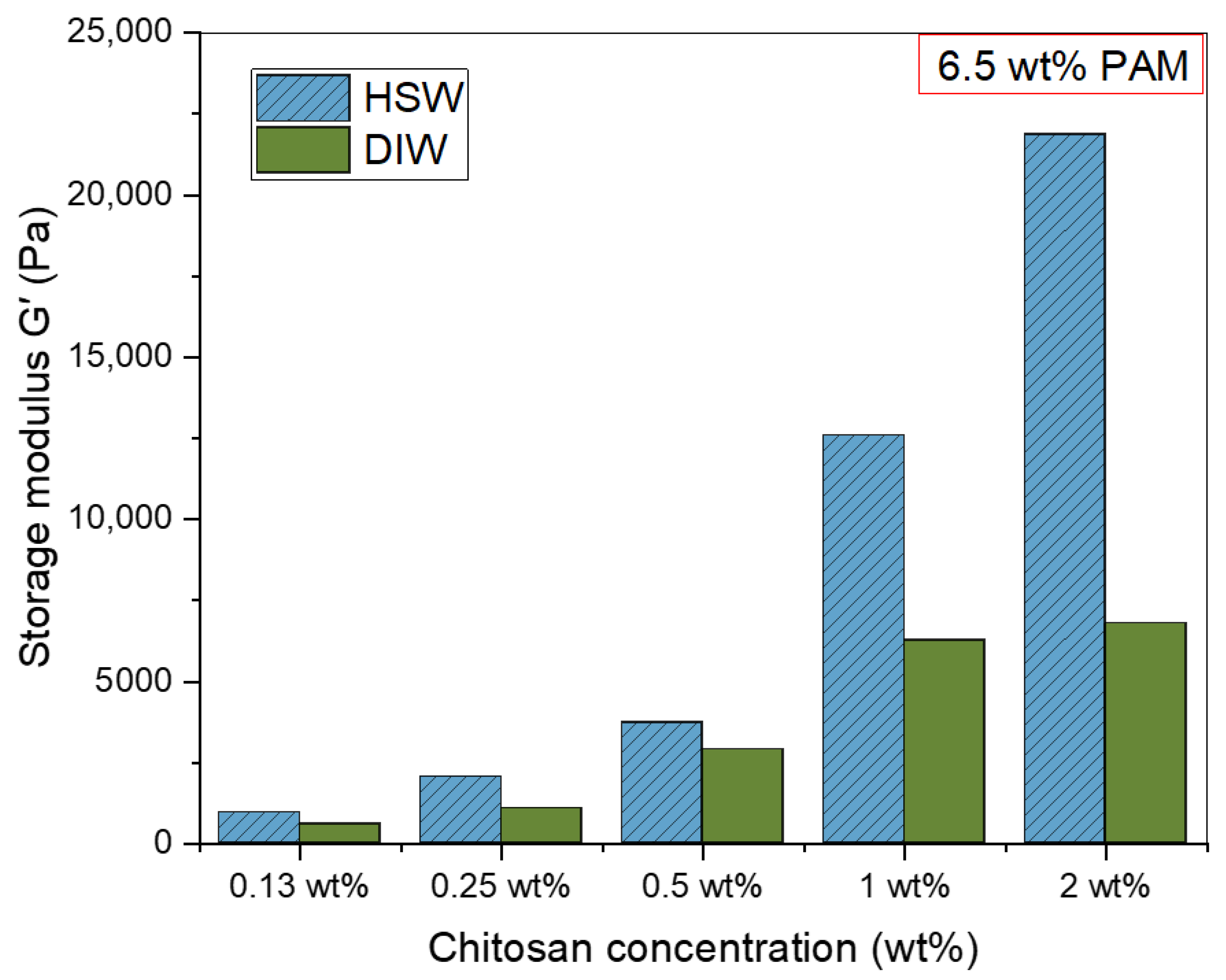

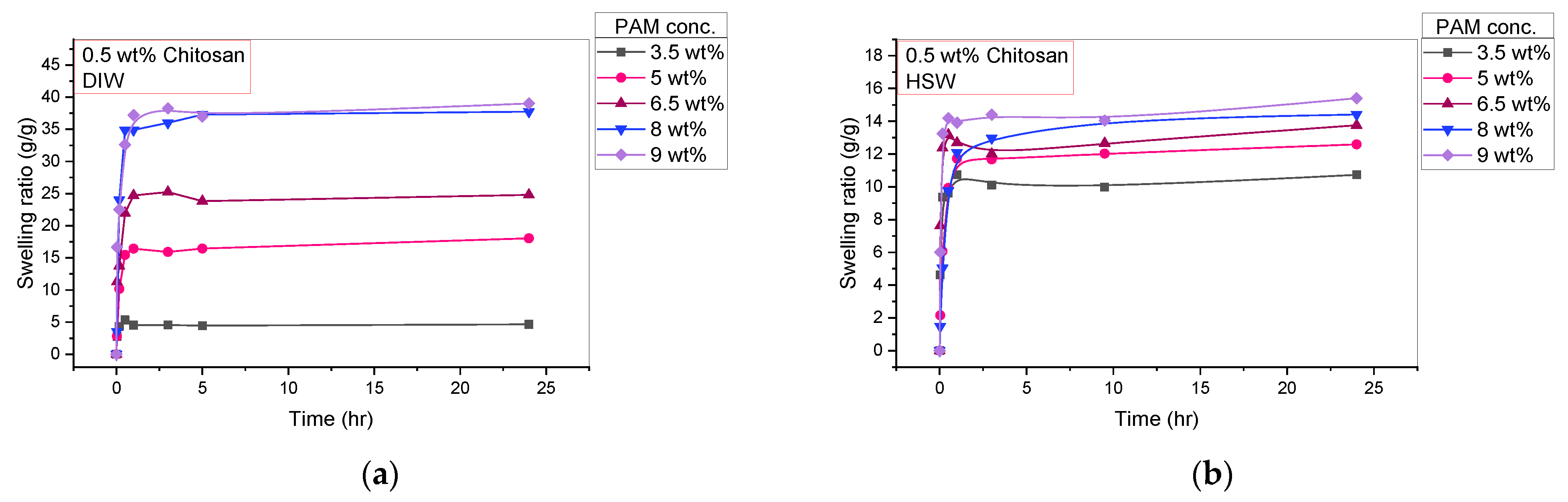

3.3.1. Chitosan & PAM Concentration Effect

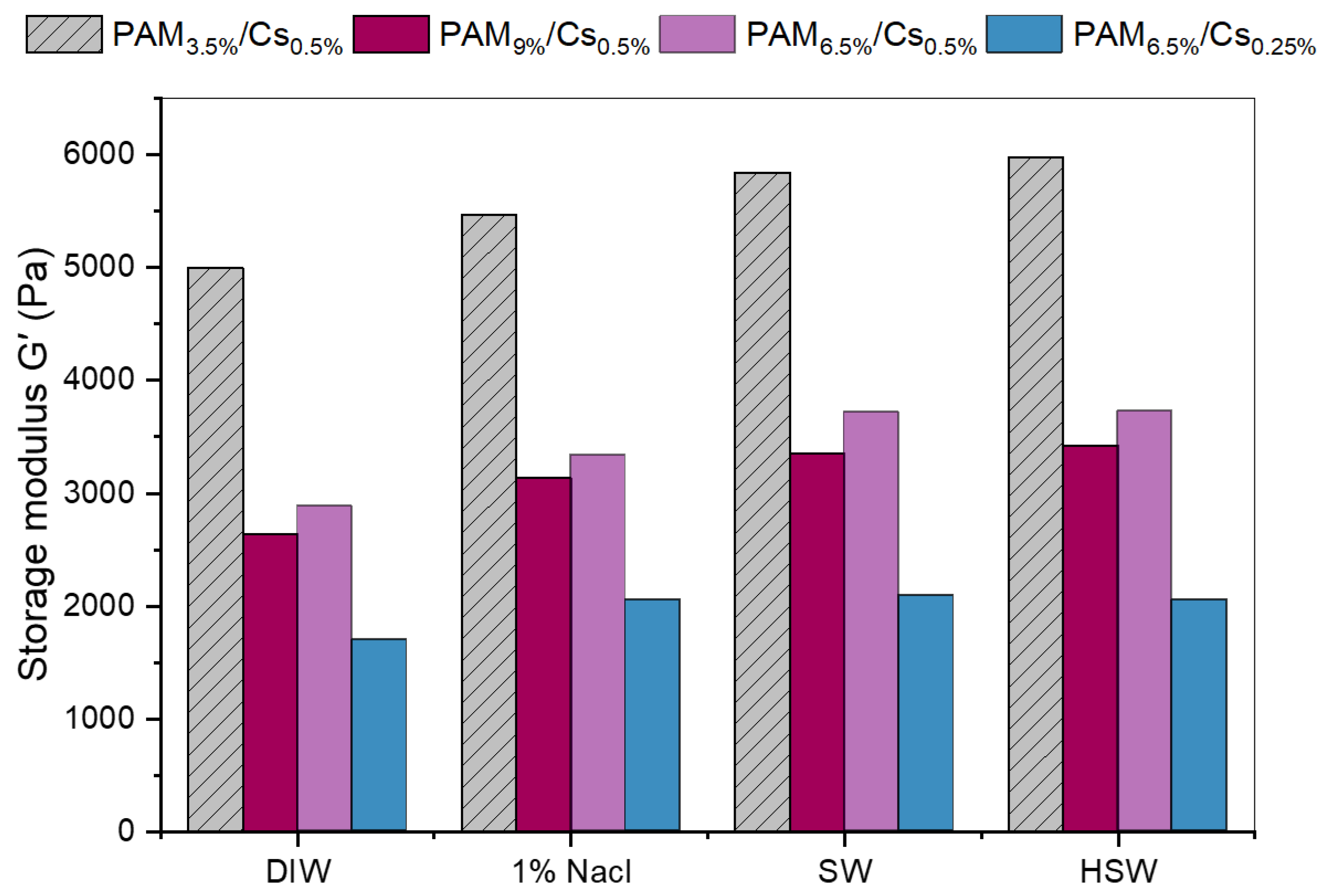

3.3.2. Salinity Effect

3.3.3. Effect of Temperature

3.3.4. Effect of pH

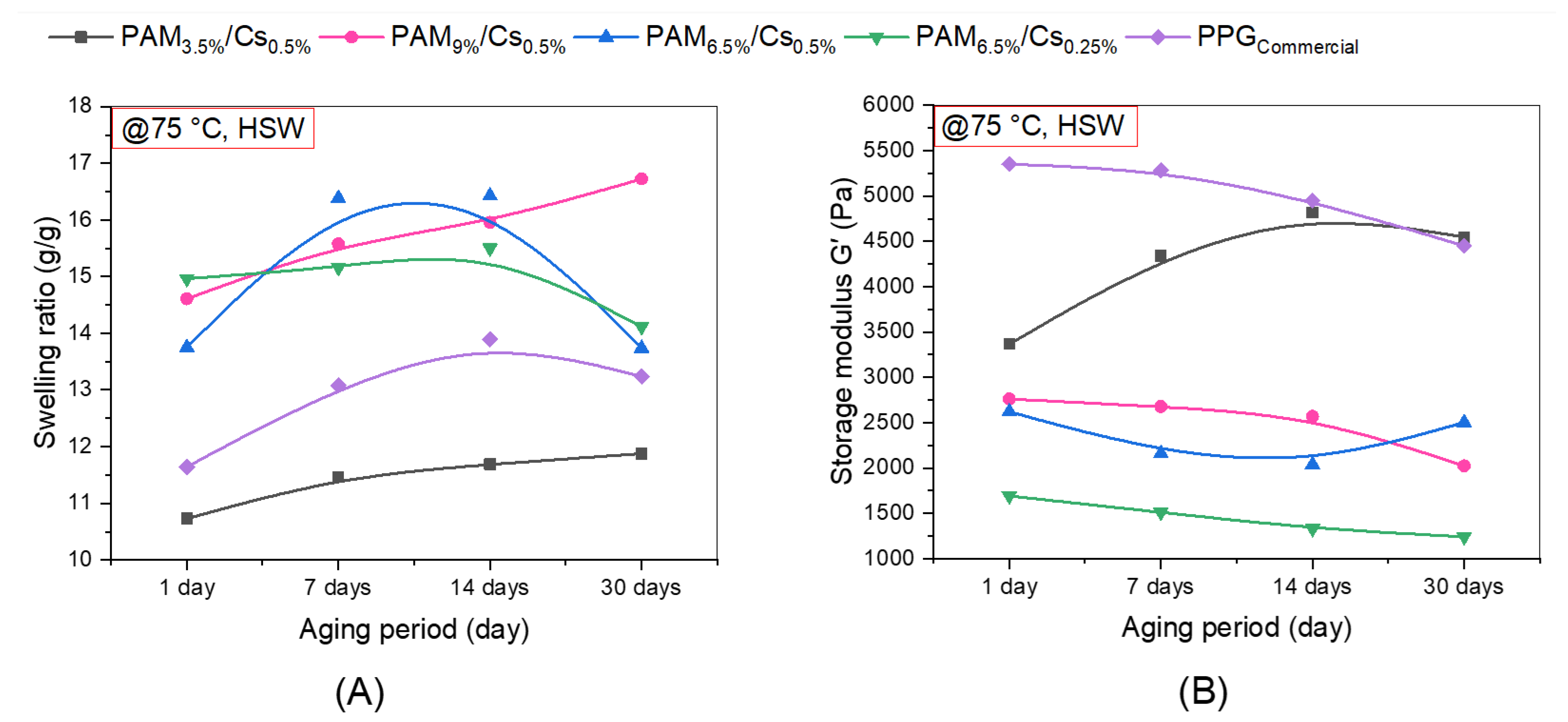

3.4. Aging Effect Evaluation

3.5. Particle Size

4. Conclusions

- The FTIR study has demonstrated the interaction between the functional groups of PAM and chitosan, which came about as a result of hydrogen bonds forming between amide groups with hydroxyl groups and amide groups with amine groups.

- The PPGs of PAM/Cs showed rapid swelling kinetics, with swelling ratios in DIW ranging from 5 to 107 g/g and in HSW ranging from 7 to 21 g/g, while the storage modulus was in the range of 939.12 to 21,857 Pa in HSW and 584.74 to 6775.7 Pa in DIW, depending on the concentrations of both PAM and chitosan.

- The swelling capacity of the PAM/Cs was found to increase with: (1) higher PAM concentration, (2) lower chitosan concentration, (3) higher temperature due to the formation of carboxylate groups, (4) freshwater medium, and (5) acidic and basic environments due to electrostatic repulsions.

- The storage modulus of PAM/Cs was higher with: (1) higher chitosan concentration that forms too many dense 3D network structures and very small pore size, (2) lower PAM content, (3) salinity conditions, (4) neutral swelling medium of pH≈6 due to hydrogen bonding formation, and (5) lower temperature.

- PAM/Cs PPGs showed good thermal and hydrolytic stability in the long term when aged at 75 °C and in the high-ionic medium for 1 month, indicating their ability to compete in the PPG market.

- The average particle size of the swollen PPG was estimated to be between 0.63 and 1.62 mm in DIW and 0.86 and 1.00 mm in HSW, as it is crucial to be defined for achieving good water shut-off performance.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, Y.; Peng, W.; Zhang, H.; Wang, H.; He, X. The Oil/Water Interfacial Behavior of Microgels Used for Enhancing Oil Recovery: A Comparative Study on Microgel Powder and Microgel Emulsion. Colloids Surf. A Physicochem. Eng. Asp. 2022, 632, 127731. [Google Scholar] [CrossRef]

- Patil, P.; Kalgaonkar, R. Environmentally Acceptable Compositions Comprising Nanomaterials for Plugging and Sealing Subterranean Formations. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, Noordwijk, The Netherlands, 12–14 June 2012. [Google Scholar]

- El-Karsani, K.S.M.; Al-Muntasheri, G.A.; Hussein, I.A. Polymer Systems for Water Shutoff and Profile Modification: A Review over the Last Decade. SPE J. 2014, 19, 135–149. [Google Scholar] [CrossRef]

- Hamza, A.; Shamlooh, M.; Hussein, I.A.; Nasser, M.; Salehi, S. Polymeric Formulations Used for Loss Circulation Materials and Wellbore Strengthening Applications in Oil and Gas Wells: A Review. J. Pet. Sci. Eng. 2019, 180, 197–214. [Google Scholar] [CrossRef]

- Bai, B.; Zhou, J.; Yin, M. A Comprehensive Review of Polyacrylamide Polymer Gels for Conformance Control. Pet. Explor. Dev. 2015, 42, 525–532. [Google Scholar] [CrossRef]

- Lei, S.; Sun, J.; Lv, K.; Zhang, Q.; Yang, J. Types and Performances of Polymer Gels for Oil-Gas Drilling and Production: A Review. Gels 2022, 8, 386. [Google Scholar] [CrossRef]

- Abdulbaki, M.; Huh, C.; Sepehrnoori, K.; Delshad, M.; Varavei, A. A Critical Review on Use of Polymer Microgels for Conformance Control Purposes. J. Pet. Sci. Eng. 2014, 122, 741–753. [Google Scholar] [CrossRef]

- Rozhkova, Y.A.; Burin, D.A.; Galkin, S.V.; Yang, H. Review of Microgels for Enhanced Oil Recovery: Properties and Cases of Application. Gels 2022, 8, 112. [Google Scholar] [CrossRef]

- Seright, R.S. Washout of Cr(III)-Acetate-HPAM Gels from Fractures. In Proceedings of the International Symposium on Oilfield Chemistry, Houston, TX, USA, 5–7 February 2003. [Google Scholar]

- Heidari, S.; Ahmadi, M.; Esmaeilzadeh, F.; Mowla, D. Oil Recovery from Fractured Reservoirs Using in Situ and Preformed Particle Gels in Micromodel Structures. J. Pet. Explor. Prod. Technol. 2019, 9, 2309–2317. [Google Scholar] [CrossRef]

- Seright, R.S. Gel Propagation Through Fractures. SPE Prod. Facil. 2001, 16, 225–231. [Google Scholar] [CrossRef]

- Seright, R.S.; Lane, R.H.; Sydansk, R.D. A Strategy for Attacking Excess Water Production. SPE Prod. Fac. 2003, 18, 158–169. [Google Scholar] [CrossRef]

- Bai, B.; Li, L.; Liu, Y.; Liu, H.; Wang, Z.; You, C. Preformed Particle Gel for Conformance Control: Factors Affecting Its Properties and Applications. SPE Reserv. Eval. Eng. 2007, 10, 415–422. [Google Scholar] [CrossRef]

- Lenji, M.A.; Haghshenasfard, M.; Sefti, M.V.; Salehi, M.B.; Heidari, A. Experimental Study of Swelling and Rheological Behavior of Preformed Particle Gel Used in Water Shutoff Treatment. J. Pet. Sci. Eng. 2018, 169, 739–747. [Google Scholar] [CrossRef]

- Qiu, Y.; Wei, M.; Geng, J.; Wu, F. Successful Field Application of Microgel Treatment in High Temperature High Salinity Reservoir in China. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar]

- Khoshkar, P.A.; Fatemi, M.; Ghazanfari, M.H. Static and Dynamic Evaluation of the Effect of Nanomaterials on the Performance of a Novel Synthesized PPG for Water Shut-off and Improved Oil Recovery in Fractured Reservoirs. J. Pet. Sci. Eng. 2020, 189, 107019. [Google Scholar] [CrossRef]

- Paprouschi, A.; Fatemi, M.; Ghazanfari, M.H. Effect of Silicate Sodium and Graphene Nanoplatelets on Morphology and Rheology Characteristics of New Synthesized Preformed Particle Gel (PPG) for Water Shut-off Treatment. J. Pet. Sci. Eng. 2021, 204, 108736. [Google Scholar] [CrossRef]

- Oppong, S.A.; Mandal, M.; Ojha, K. Synthesis and Optimization of Bentonite Enforced Poly (Acrylamide/Co- Sodium Dodecylbenzensulfonate) Preformed Particle Gels for Conformance Control in High Salinity Reservoirs. Pet. Sci. Technol. 2023, 41, 546–563. [Google Scholar] [CrossRef]

- Aqcheli, F.; Salehi, M.B.; Pahlevani, H.; Taghikhani, V. Rheological Properties and the Micromodel Investigation of Nanosilica Gel-Reinforced Preformed Particle Gels Developed for Improved Oil Recovery. J. Pet. Sci. Eng. 2020, 192, 107258. [Google Scholar] [CrossRef]

- Zhu, D.; Xu, Z.; Sun, R.; Fang, X.; Gao, D.; Jia, X.; Hu, J.; Weng, J. Laboratory Evaluation on Temporary Plugging Performance of Degradable Preformed Particle Gels (DPPGs). Fuel 2021, 289, 119743. [Google Scholar] [CrossRef]

- Saghafi, H.R.; Emadi, M.A.; Farasat, A.; Arabloo, M.; Naderifar, A. Performance Evaluation of Optimized Preformed Particle Gel (PPG) in Porous Media. Chem. Eng. Res. Des. 2016, 112, 175–189. [Google Scholar] [CrossRef]

- Zhou, K.; Wu, D.; An, Z. Experimental Study on Matched Particle Size and Elastic Modulus of Preformed Particle Gel for Oil Reservoirs. Gels 2022, 8, 506. [Google Scholar] [CrossRef]

- Cheng, L.; Qin, Y.; Gao, K.; Zhang, L.; Zhou, J.; Zhang, D.; Liao, R.; Li, Z. Experimental Investigation of a Novel Nanocomposite Particle Gel for Water Shutoff Treatment in Mature Oilfields. ACS Omega 2022, 7, 8887–8895. [Google Scholar] [CrossRef]

- Heidari, S.; Mohammadi, M.; Esmaeilzadeh, F.; Mowla, D. Determination of Swelling Behavior and Mechanical and Thermal Resistance of Acrylamide–Acrylic Acid Copolymers under High Pressures and Temperatures. ACS Omega 2021, 6, 23862–23872. [Google Scholar] [CrossRef] [PubMed]

- Heidari, A.; Vasheghani-Farahani, E.; Vafaie-Sefti, M. Preformed Particle Gels of Sulfonated Polyacrylamide: Preparation, Characterization, and Application as Permeability Modifier. Iran. Polym. J. 2019, 28, 1001–1013. [Google Scholar] [CrossRef]

- Pal, P.; Pandey, J.P.; Sen, G. Synthesis and Application as Programmable Water Soluble Adhesive of Polyacrylamide Grafted Gum Tragacanth (GT-G-PAM). In Biopolymer Grafting: Applications; Elsevier: Amsterdam, The Netherlands, 2017; pp. 153–203. ISBN 9780128104620. [Google Scholar]

- Shamlooh, M.; Elaf, R.; Hussein, I.A.; Saad, M.; Bai, B. Chitosan/Polyacrylamide Green Gels for Water Control in High-Temperature Reservoirs. Energy Fuels 2022, 36, 3816–3824. [Google Scholar] [CrossRef]

- Mahdavinia, G.; Pourjavadi, A.; Hosseinzadeh, H.; Zohuriaan, M. Modified Chitosan 4. Superabsorbent Hydrogels from Poly(Acrylic Acid-Co-Acrylamide) Grafted Chitosan with Salt- and PH-Responsiveness Properties. Eur. Polym. J. 2004, 40, 1399–1407. [Google Scholar] [CrossRef]

- Mahmoud, M.A. Evaluating the Damage Caused by Calcium Sulfate Scale Precipitation during Low- and High-Salinity-Water Injection. J. Can. Pet. Technol. 2014, 53, 141–150. [Google Scholar] [CrossRef]

- Abdulazeem, A.; Mahmoud, M.; Elkatatny, S.; Barri, A.; Muhammadain, A. Development of New Seawater-Based Formulation to Stimulate Sandstone Formations. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24–27 April 2017; pp. 460–468. [Google Scholar] [CrossRef]

- Seidy Esfahlan, M.; Khodapanah, E.; Tabatabaei-Nezhad, S.A. Comprehensive Review on the Research and Field Application of Preformed Particle Gel Conformance Control Technology. J. Pet. Sci. Eng. 2021, 202, 108440. [Google Scholar] [CrossRef]

- Xiao, C.; Weng, L.; Lu, Y.; Zhang, L. Blend films from chitosan and polyacrylamide solutions. J. Macromol. Sci. Part A 2001, 38, 761–771. [Google Scholar] [CrossRef]

- Li, S.-N.; Li, B.; Gong, L.-X.; Yu, Z.-R.; Feng, Y.; Jia, D.; Zhou, Y.; Tang, L.-C. Enhanced Mechanical Properties of Polyacrylamide/Chitosan Hydrogels by Tuning the Molecular Structure of Hyperbranched Polysiloxane. Mater. Des. 2019, 162, 162–170. [Google Scholar] [CrossRef]

- Bai, J.; Wang, R.; Wang, X.; Liu, S.; Wang, X.; Ma, J.; Qin, Z.; Jiao, T. Biomineral Calcium-Ion-Mediated Conductive Hydrogels with High Stretchability and Self-Adhesiveness for Sensitive Iontronic Sensors. Cell Rep. Phys. Sci. 2021, 2, 100623. [Google Scholar] [CrossRef]

- Craciun, G.; Ighigeanu, D.; Manaila, E.; Stelescu, M.D. Synthesis and Characterization of Poly(Acrylamide-Co-Acrylic Acid) Flocculant Obtained by Electron Beam Irradiation. Mater. Res. 2015, 18, 984–993. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, C.; Wang, K.; Zhao, M.; Zhao, G.; Yang, S.; Yan, Z.; You, Q. New Insights into the Hydroquinone (HQ)–Hexamethylenetetramine (HMTA) Gel System for Water Shut-off Treatment in High Temperature Reservoirs. J. Ind. Eng. Chem. 2016, 35, 20–28. [Google Scholar] [CrossRef]

- Povea, M.B.; Monal, W.A.; Cauich-Rodríguez, J.V.; Pat, A.M.; Rivero, N.B.; Covas, C.P. Interpenetrated Chitosan-Poly(Acrylic Acid-Co-Acrylamide) Hydrogels. Synthesis, Characterization and Sustained Protein Release Studies. Mater. Sci. Appl. 2011, 2, 509–520. [Google Scholar] [CrossRef]

- Saber-Samandari, S.; Gazi, M.; Yilmaz, E. UV-Induced Synthesis of Chitosan-g-Polyacrylamide Semi-IPN Superabsorbent Hydrogels. Polym. Bull. 2012, 68, 1623–1639. [Google Scholar] [CrossRef]

- Zhao, S. Osmotic Pressure versus Swelling Pressure: Comment on “Bifunctional Polymer Hydrogel Layers As Forward Osmosis Draw Agents for Continuous Production of Fresh Water Using Solar Energy”. Environ. Sci. Technol. 2014, 48, 4212–4213. [Google Scholar] [CrossRef]

- Upadhyay, U.; Sreedhar, I.; Singh, S.A.; Patel, C.M.; Anitha, K.L. Recent Advances in Heavy Metal Removal by Chitosan Based Adsorbents. Carbohydr. Polym. 2021, 251, 117000. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; Elchinger, P.-H.; de Baynast, H.; Pierre, G.; Delattre, C.; Michaud, P. Chitosan as an Adhesive. Eur. Polym. J. 2014, 60, 198–212. [Google Scholar] [CrossRef]

- Baloochestanzadeh, S.; Hassanajili, S.; Escrochi, M. Rheological Properties and Swelling Behavior of Nanocomposite Preformed Particle Gels Based on Starch-Graft-Polyacrylamide Loaded with Nanosilica. Rheol. Acta 2021, 60, 571–585. [Google Scholar] [CrossRef]

- Castel, D.; Ricard, A.; Audebert, R. Swelling of Anionic and Cationic Starch-Based Superabsorbents in Water and Saline Solution. J. Appl. Polym. Sci. 1990, 39, 11–29. [Google Scholar] [CrossRef]

- Budianto, E.; Amalia, A. Swelling Behavior and Mechanical Properties of Chitosan-Poly(N-Vinyl-Pyrrolidone) Hydrogels. J. Polym. Eng. 2020, 40, 551–560. [Google Scholar] [CrossRef]

- Rani, G.U.; Konreddy, A.K.; Mishra, S. Novel Hybrid Biosorbents of Agar: Swelling Behaviour, Heavy Metal Ions and Dye Removal Efficacies. Int. J. Biol. Macromol. 2018, 117, 902–910. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, H.; Wang, J.; Zhang, H.; Yao, C.; Wang, L.; Qi, P. Investigation of Restarting Pressure Gradient for Preformed Particle Gel Passing through Pore-Throat. J. Pet. Sci. Eng. 2018, 168, 72–80. [Google Scholar] [CrossRef]

- Xi, K.; Cao, Y.; Haile, B.G.; Zhu, R.; Jahren, J.; Bjørlykke, K.; Zhang, X.; Hellevang, H. How Does the Pore-Throat Size Control the Reservoir Quality and Oiliness of Tight Sandstones? The Case of the Lower Cretaceous Quantou Formation in the Southern Songliao Basin, China. Mar. Pet. Geol. 2016, 76, 1–15. [Google Scholar] [CrossRef]

- Wu, D.; Zhou, K.; An, Z.; Hou, J. Experimental Study on the Matching Relationship between PPG Size and Reservoir Heterogeneity. In Proceedings of the SPE International Heavy Oil Conference and Exhibition, Kuwait City, Kuwait, 10–12 December 2018. [Google Scholar]

- Bai, B.; Wei, M.; Liu, Y. Field and Lab Experience with a Successful Preformed Particle Gel Conformance Control Technology. In Proceedings of the SPE Production and Operations Symposium, Oklahoma City, OK, USA, 23–26 March 2013; pp. 506–522. [Google Scholar]

| Salts | HSW Concentration (g/L) | SW Concentration (g/L) |

|---|---|---|

| NaHCO3 | 0.2382 | 0.1191 |

| Na2SO4 | 6.5754 | 3.2877 |

| CaCl2·H2O | 2.3945 | 1.1972 |

| MgCl2·6H2O | 18.0539 | 9.1269 |

| NaCl | 40.2738 | 20.1369 |

| TDS | 67.2976 | 33.6488 |

| PAM3.5%/Cs0.5% | PAM9%/Cs0.5% | PAM6.5%/Cs0.5% | PAM6.5%/Cs0.25% | |

|---|---|---|---|---|

| DIW (g/g) | 4.750 | 39.03 | 23.34 | 80.37 |

| 1% Nacl (g/g) | 10.09 | 13.22 | 12.62 | 16.66 |

| SW (g/g) | 9.756 | 13.36 | 12.48 | 14.97 |

| HSW (g/g) | 12.22 | 15.83 | 16.70 | 18.73 |

| In DIW | In HSW | |||||||

|---|---|---|---|---|---|---|---|---|

| # | PPG Formulation | Avg. Size of Dry PPG, d0 (µm) | SR (g/g) | Avg. Size of Swollen PPG, Dt (µm) | Avg. Size of Swollen PPG, Dt (mm) | SR (g/g) | Avg. Size of Swollen PPG, Dt (µm) | Avg. Size of Swollen PPG, Dt (mm) |

| 1 | PAM3.5%/Cs0.5% | 375 | 4.75 | 630.51 | 0.63 | 12.22 | 863.69 | 0.86 |

| 2 | PAM9%/Cs0.5% | 375 | 39.03 | 1272.00 | 1.27 | 15.83 | 941.53 | 0.94 |

| 3 | PAM6.5%/Cs0.5% | 375 | 23.34 | 1071.74 | 1.07 | 16.70 | 958.60 | 0.96 |

| 4 | PAM6.5%/Cs0.25% | 375 | 80.37 | 1618.29 | 1.62 | 18.73 | 995.92 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elaf, R.; Ben Ali, A.; Saad, M.; Hussein, I.A.; Nimir, H.; Bai, B. Biodegradable Preformed Particle Gel (PPG) Made of Natural Chitosan Material for Water Shut-Off Application. Polymers 2023, 15, 1961. https://doi.org/10.3390/polym15081961

Elaf R, Ben Ali A, Saad M, Hussein IA, Nimir H, Bai B. Biodegradable Preformed Particle Gel (PPG) Made of Natural Chitosan Material for Water Shut-Off Application. Polymers. 2023; 15(8):1961. https://doi.org/10.3390/polym15081961

Chicago/Turabian StyleElaf, Reem, Ahmed Ben Ali, Mohammed Saad, Ibnelwaleed A. Hussein, Hassan Nimir, and Baojun Bai. 2023. "Biodegradable Preformed Particle Gel (PPG) Made of Natural Chitosan Material for Water Shut-Off Application" Polymers 15, no. 8: 1961. https://doi.org/10.3390/polym15081961

APA StyleElaf, R., Ben Ali, A., Saad, M., Hussein, I. A., Nimir, H., & Bai, B. (2023). Biodegradable Preformed Particle Gel (PPG) Made of Natural Chitosan Material for Water Shut-Off Application. Polymers, 15(8), 1961. https://doi.org/10.3390/polym15081961