Rheological Characteristics of Starch-Based Biodegradable Blends

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Characterization

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Araújo, M.A.; Cunha, A.M.; Mota, M. Enzymatic degradation of starch-based thermoplastic compounds used in protheses: Identification of the degradation products in solution. Biomaterials 2004, 25, 2687–2693. [Google Scholar] [CrossRef] [PubMed]

- Pareta, R.; Edirisinghe, M. A novel method for the preparation of starch films and coatings. Carbohyd. Polym. 2006, 63, 425–431. [Google Scholar] [CrossRef]

- Mao, L.; Imam, S.; Gordon, S.; Cinelli, P.; Chiellini, E. Extruded cornstarch-glycerol-polyvinyl alcohol blends: Mechanical properties, morphology, and biodegradability. J. Polym. Environ. 2000, 8, 205–211. [Google Scholar] [CrossRef]

- Zhang, J.-F.; Sun, X. Mechanical properties of poly (lactic acid)/starch composites compatibilized by maleic anhydride. Biomacromolecules 2004, 5, 1446–1451. [Google Scholar] [CrossRef] [PubMed]

- Yavuz, H.; Babaç, C. Preparation and biodegradation of starch/polycaprolactone films. J. Polym. Environ. 2003, 11, 107–113. [Google Scholar] [CrossRef]

- Ratto, J.A.; Stenhouse, P.J.; Auerbach, M.; Mitchell, J.; Farrell, R. Processing, performance and biodegradability of a thermoplastic aliphatic polyester/starch system. Polymer 1999, 40, 6777–6788. [Google Scholar] [CrossRef]

- Kotnis, M.A.; O’Brien, G.S.; Willett, J. Processing and mechanical properties of biodegradable poly (hydroxybutyrate-co-valerate)-starch compositions. J. Environ. Polym. Degrad. 1995, 3, 97–105. [Google Scholar] [CrossRef]

- Nayak, S. Biodegradable PBAT/starch nanocomposites. Polym.-Plas. Technol. 2010, 49, 1406–1418. [Google Scholar] [CrossRef]

- Olivato, J.B.; Grossmann, M.V.E.; Yamashita, F.; Nobrega, M.M.; Scapin, M.R.S.; Eiras, D.; Pessan, L.A. Compatibilisation of starch/poly(butylene adipate co-terephthalate) blends in blown films. Int. J. Food Sci. Technol. 2011, 46, 1934–1939. [Google Scholar] [CrossRef]

- Brandelero, R.P.H.; Grossmann, M.V.E.; Yamashita, F. Effect of the method of production of the blends on mechanical and structural properties of biodegradable starch films produced by blown extrusion. Carbohyd. Polym. 2011, 86, 1344–1350. [Google Scholar] [CrossRef]

- Hablot, E.; Dewasthale, S.; Zhao, Y.; Zhiguan, Y.; Shi, X.; Graiver, D.; Narayan, R. Reactive extrusion of glycerylated starch and starch–polyester graft copolymers. Eur. Polym. J. 2013, 49, 873–881. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K. Starch based biodegradable PBAT nanocomposites: Effect of starch modification on mechanical, thermal, morphological and biodegradability behavior. Int. J. Plast. Technol. 2009, 13, 163–185. [Google Scholar] [CrossRef]

- Fourati, Y.; Tarrés, Q.; Mutjé, P.; Boufi, S. PBAT/thermoplastic starch blends: Effect of compatibilizers on the rheological, mechanical and morphological properties. Carbohydr. Polym. 2018, 199, 51–57. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; Wang, H.; Xiao, H.; Zheng, A.; Yang, Y. Morphology and mechanical properties of poly(butylene adipate-co-terephthalate)/potato starch blends in the presence of synthesized reactive compatibilizer or modified poly (butylene adipate-co-terephthalate). Carbohyd. Polym. 2015, 123, 275–282. [Google Scholar] [CrossRef] [PubMed]

- Hamad, K.; Kaseem, M.; Deri, F. Melt rheology of poly (lactic acid)/low density polyethylene polymer blends. Adv. Chem Eng. Sci. 2011, 1, 208–214. [Google Scholar] [CrossRef]

- Singh, S.; Gupta, R.K.; Ghosh, A.; Maiti, S.; Bhattacharya, S.N. Poly (L-lactic acid)/layered silicate nanocomposite blown film for packaging application: Thermal, mechanical and barrier properties. J. Polym. Eng. 2010, 30, 361–376. [Google Scholar] [CrossRef]

- Mathew, A.P.; Oksman, K.; Sain, M. Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). J. Appl. Polym. Sci. 2005, 97, 2014–2025. [Google Scholar] [CrossRef]

- Song, Z.; Xiao, H.; Zhao, Y. Hydrophobic-modified nano-cellulose fiber/PLA biodegradable composites for lowering water vapor transmission rate (WVTR) of paper. Carbohyd. Polym. 2014, 111, 442–448. [Google Scholar] [CrossRef]

- Teixeira, E.d.M.; De Campos, A.; Marconcini, J.; Bondancia, T.; Wood, D.; Klamczynski, A.; Mattoso, L.; Glenn, G. Starch/fiber/poly (lactic acid) foam and compressed foam composites. RSC Adv. 2014, 4, 6616–6623. [Google Scholar] [CrossRef]

- Rodriguez-Gonzalez, F.; Ramsay, B.; Favis, B. Rheological and thermal properties of thermoplastic starch with high glycerol content. Carbohydr. Polym. 2004, 58, 139–147. [Google Scholar] [CrossRef]

- Shin, B.Y.; Jo, G.S.; Kang, K.S.; Lee, T.J.; Kim, B.S.; Lee, S.I.; Song, J.S. Morphology and rheology on the blends of PLA/CMPS. Macromol. Res. 2007, 15, 291–301. [Google Scholar] [CrossRef]

- Cardoso, E.C.; Parra, D.F.; Scagliusi, S.R.; Sales, R.M.; Caviquioli, F.; Lugão, A.B. Study of bio-based foams prepared from PBAT/PLA reinforced with bio-calcium carbonate and compatibilized with gamma radiation. In Use of Gamma Radiation Techniques in Peaceful Applications; IntechOpen: London, UK, 2019. [Google Scholar]

- Harada, J.; Macedo, J.R.N.; Machado, G.A.F.; Valenzuela-Díaz, F.; Moura, E.A.; Rosa, D.S. Effects of carbon black incorporation on morphological, mechanical and thermal properties of biodegradable films. In Characterization of Minerals, Metals, and Materials 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 697–704. [Google Scholar]

- Ren, J.; Fu, H.; Ren, T.; Yuan, W. Preparation, characterization and properties of binary and ternary blends with thermoplastic starch, poly (lactic acid) and poly (butylene adipate-co-terephthalate). Carbohyd. Polym. 2009, 77, 576–582. [Google Scholar] [CrossRef]

- Phattarateera, S.; Junsook, N.; Kumsang, P.; Aontee, A.; Kerddonfag, N. The ternary blends of TPS/PBAT/PLA films: A Study on the morphological and mechanical properties. Key Eng. Mater. 2020, 861, 170–175. [Google Scholar] [CrossRef]

- Dealy, J.M.; Wissbrun, K.F. Melt Rheology and Its Role in Plastics Processing: Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Jones, D.S.; Margetson, D.N.; McAllister, M.S.; Andrews, G.P. Reprint of “Characterisation and modelling of the thermo-rheological properties of pharmaceutical polymers and their blends using capillary rheometry: Implications for hot melt processing of dosage forms”. Int. J. Pharm. 2015, 496, 86–94. [Google Scholar] [CrossRef]

- Navarro, F.; Partal, P.; Martınez-Boza, F.; Gallegos, C. Thermo-rheological behaviour and storage stability of ground tire rubber-modified bitumens. Fuel 2004, 83, 2041–2049. [Google Scholar] [CrossRef]

- Wang, B.; Jin, Y.; Yang, N.; Weng, Y.; Huang, Z.; Men, S. Investigation on compatibility of PLA/PBAT blends modified by epoxy-terminated branched polymers through chemical micro-crosslinking. E-Polymers 2020, 20, 39–54. [Google Scholar] [CrossRef]

- Zhang, P.; Han, Q.; Fan, M.; Jiang, P. Magnetic solid base catalyst CaO/CoFe2O4 for biodiesel production: Influence of basicity and wettability of the catalyst in catalytic performance. Appl. Surf. Sci. 2014, 317, 1125–1130. [Google Scholar] [CrossRef]

- Murakami, F.S.; Rodrigues, P.O.; Campos, C.M.T.d.; Silva, M.A.S. Physicochemical study of CaCO3 from egg shells. Food Sci. Technol. 2007, 27, 658–662. [Google Scholar] [CrossRef]

- Vance, K.; Falzone, G.; Pignatelli, I.; Bauchy, M.; Balonis, M.; Sant, G. Direct carbonation of Ca(OH)2 using liquid and supercritical CO2: Implications for carbon-neutral cementation. Ind. Eng. Chem. Res. 2015, 54, 8908–8918. [Google Scholar] [CrossRef]

- da Silva, N.M.C.; Correia, P.R.C.; Druzian, J.I.; Fakhouri, F.M.; Fialho, R.L.L.; de Albuquerque, E.C.M.C. PBAT/TPS composite films reinforced with starch nanoparticles produced by ultrasound. Int. J. Polym. Sci. 2017, 2017, 4308261. [Google Scholar] [CrossRef]

- Teamsinsungvon, A.; Ruksakulpiwat, Y.; Jarukumjorn, K. Preparation and characterization of poly (lactic acid)/poly (butylene adipate-co-terepthalate) blends and their composite. Polym.-Plast. Technol. 2013, 52, 1362–1367. [Google Scholar] [CrossRef]

- Narimissa, E.; Gupta, R.K.; Kao, N.; Choi, H.J.; Jollands, M.; Bhattacharya, S.N. Melt rheological investigation of polylactide--Nanographite platelets biopolymer composites. Polym. Eng. Sci. 2014, 54, 175–188. [Google Scholar] [CrossRef]

- Carreau, P.J. Rheology of Polymeric Systems: Principles and Applications; American Institute of Chemical Engineers: New York, NY, USA, 1997. [Google Scholar]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Reactive extrusion of PLA, PBAT with a multi-functional epoxide: Physico-chemical and rheological properties. Eur. Polym. J. 2014, 58, 90–102. [Google Scholar] [CrossRef]

- Hoffmann, H.J. Viscoelasticity of Maxwell’s model and non-Newtonian viscosity revisited. Materialwiss. Werkst. 2018, 49, 137–168. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym. Degrad. Stab. 2012, 97, 1898–1914. [Google Scholar] [CrossRef]

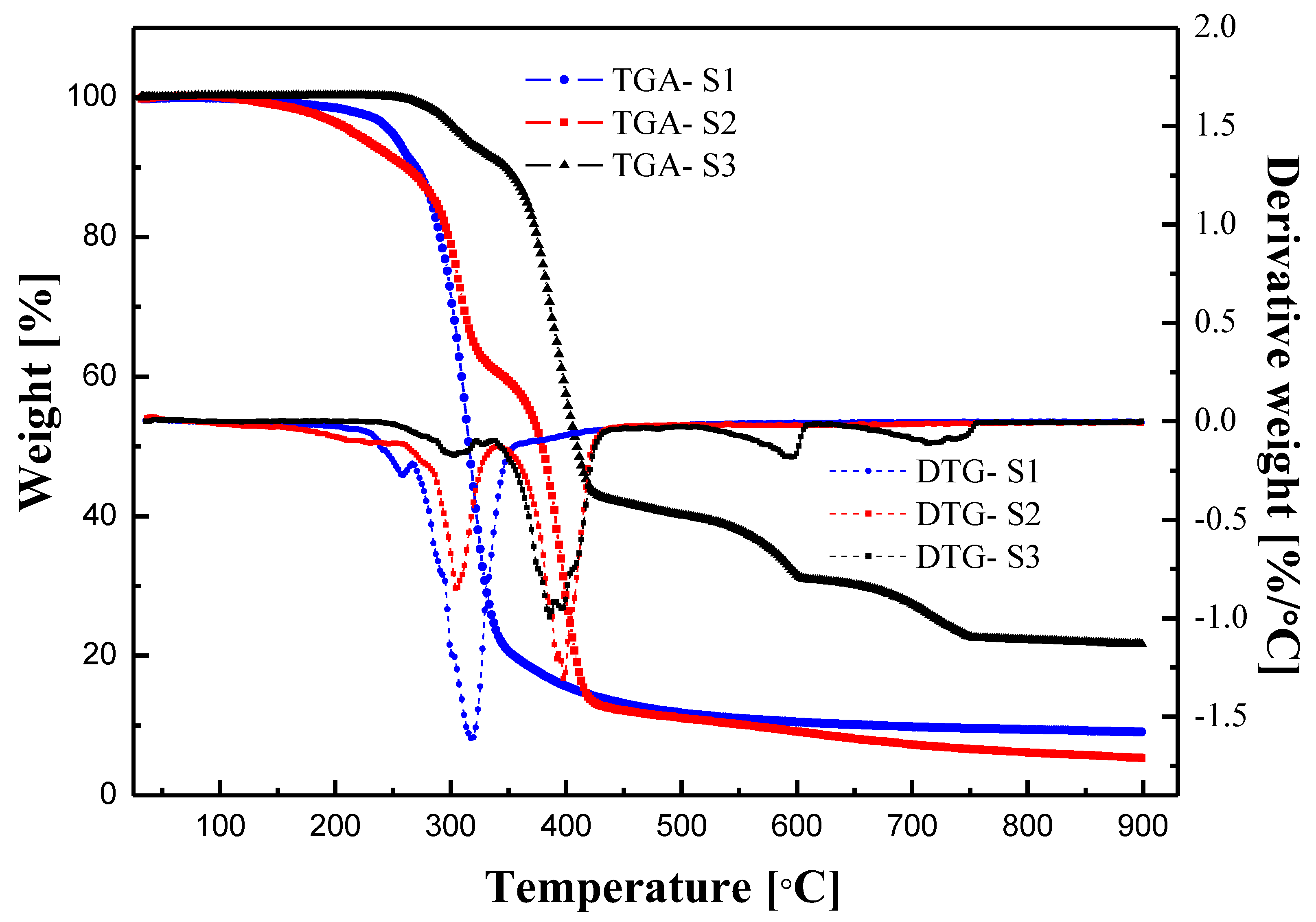

| Materials | Step 1 | Step 2 | Step 3 | Step 4 | |

|---|---|---|---|---|---|

| S1 | Temperature range (°C) | ~190 | 190–900 | ||

| Weight loss (wt.%) | 1.3 | 89.6 | |||

| S2 | Temperature range (°C) | ~190 | 190–341 | 341–900 | |

| Weight loss (wt.%) | 2.8 | 36.6 | 55.2 | ||

| S3 | Temperature range (°C) | 254–341 | 341–500 | 500–624 | 624–900 |

| Weight loss (wt.%) | 9.1 | 50.8 | 9.4 | 9.0 |

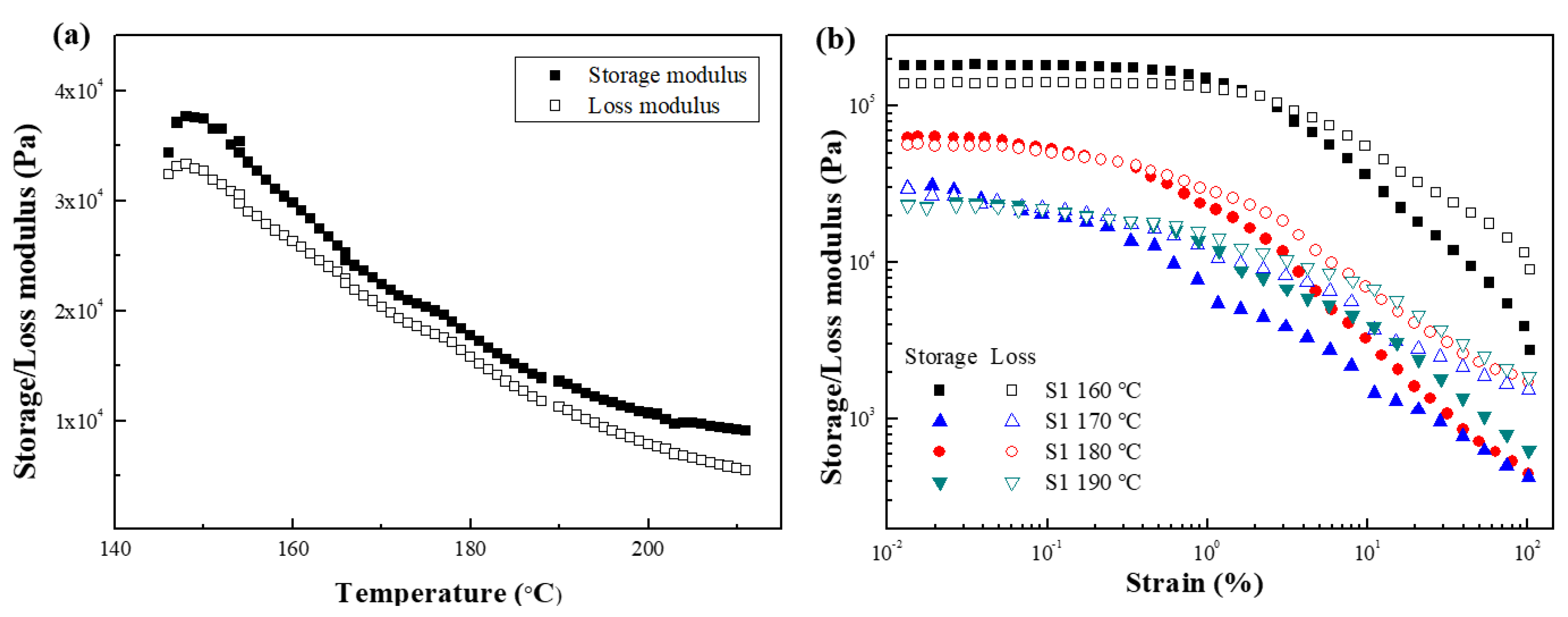

| Materials | (Pa·s) | (s) | ||

|---|---|---|---|---|

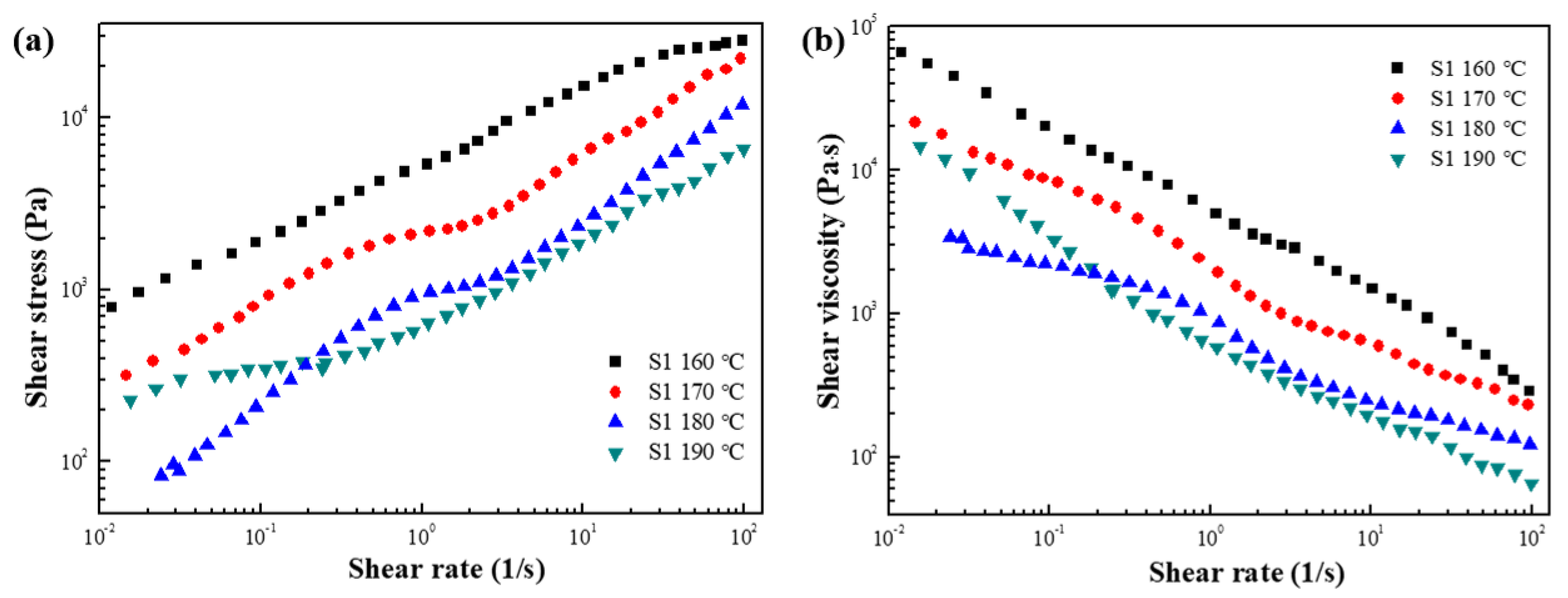

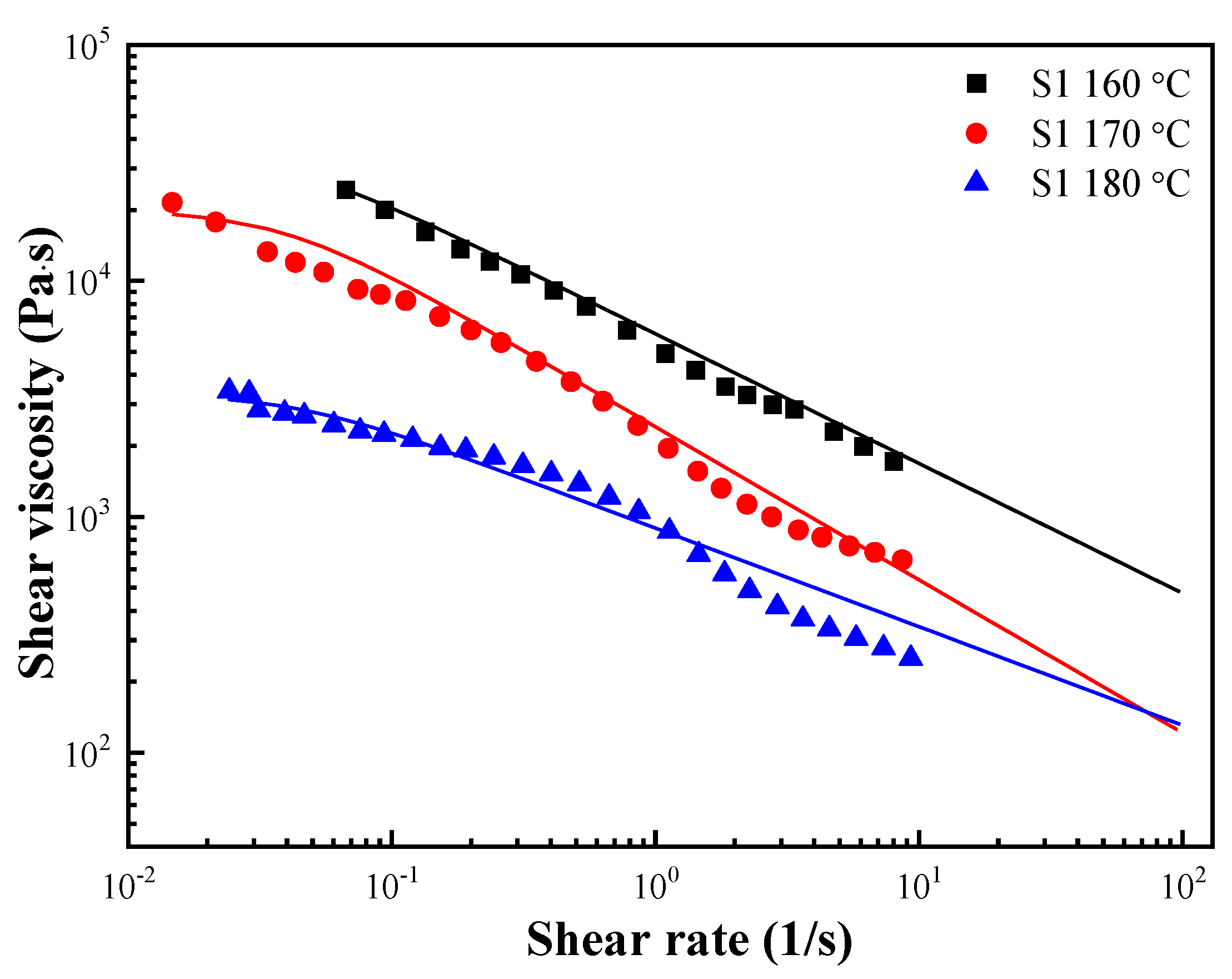

| S1 160 °C | 3.56 × 105 | 658 | 0.43 | 0.97 |

| S1 170 °C | 2.01 × 105 | 688 | 0.35 | 0.98 |

| S1 180 °C | 3.32 × 104 | 527 | 0.58 | 0.97 |

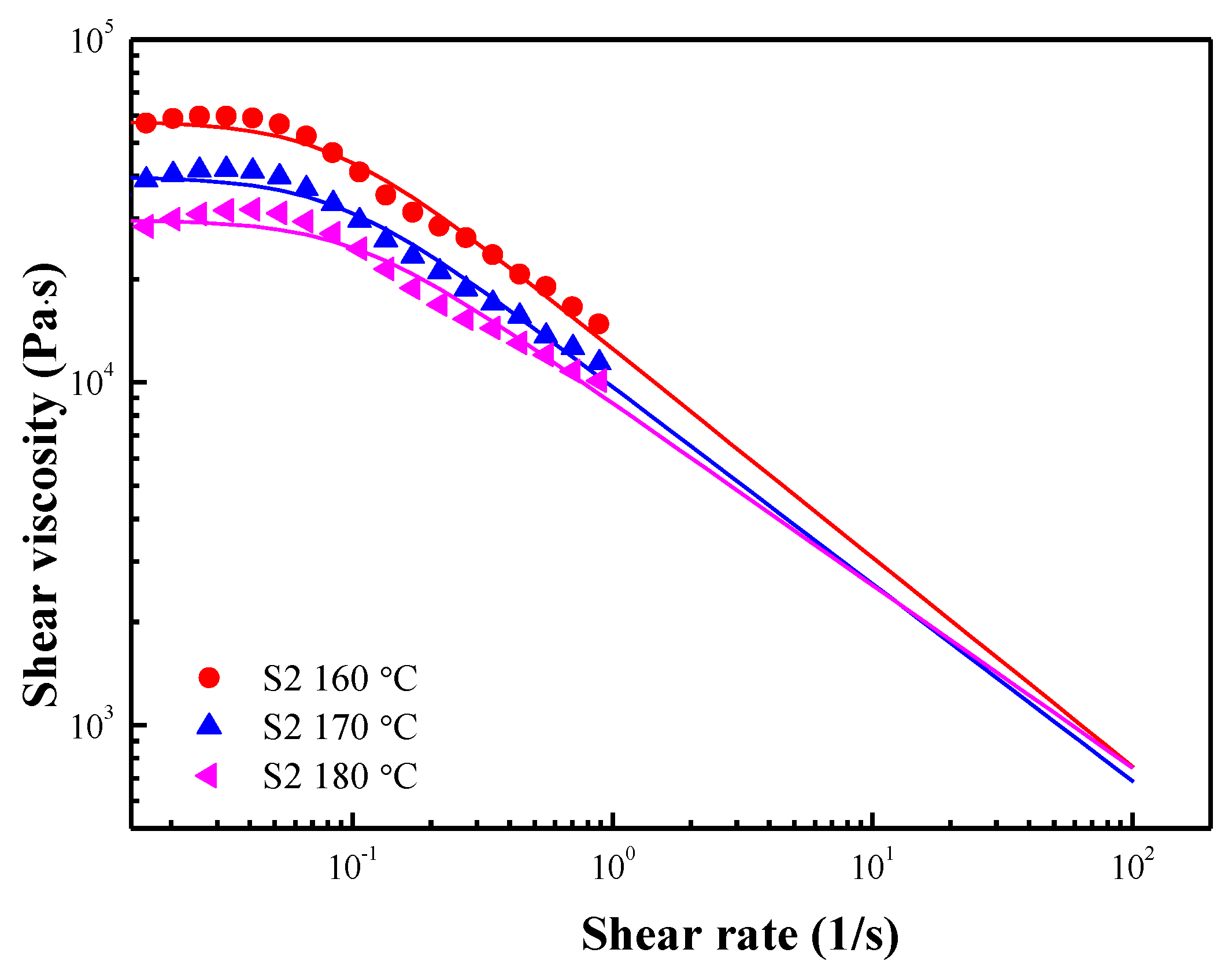

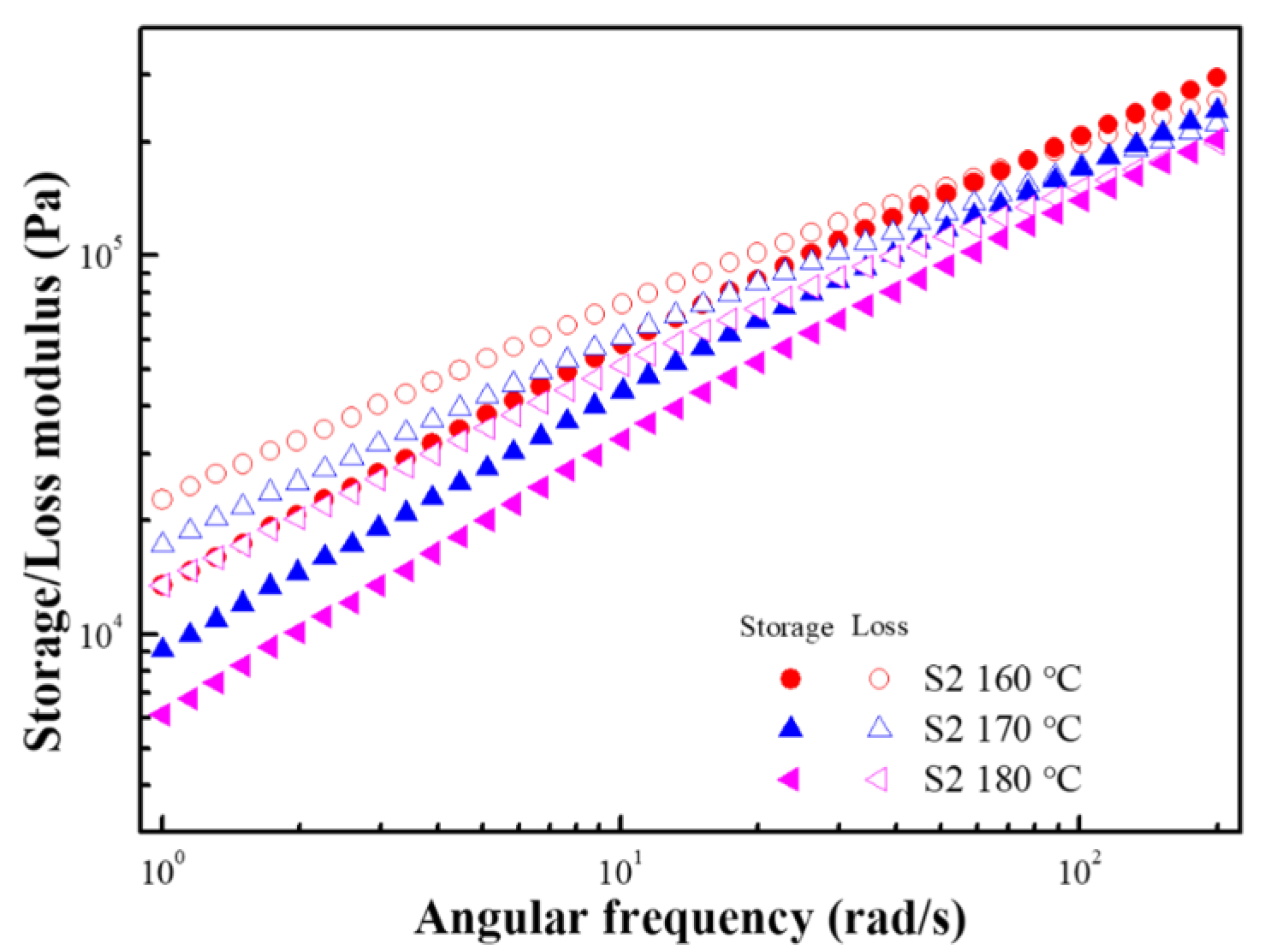

| Materials | (Pa·s) | (s) | ||

|---|---|---|---|---|

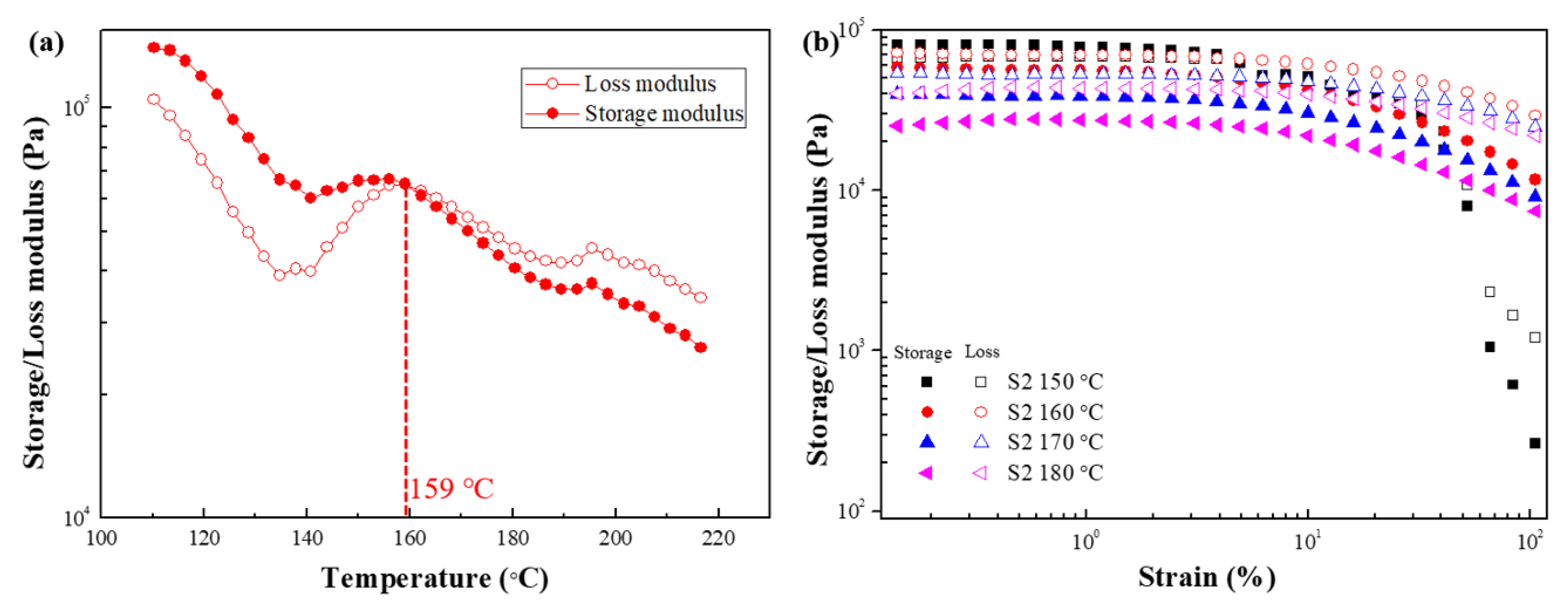

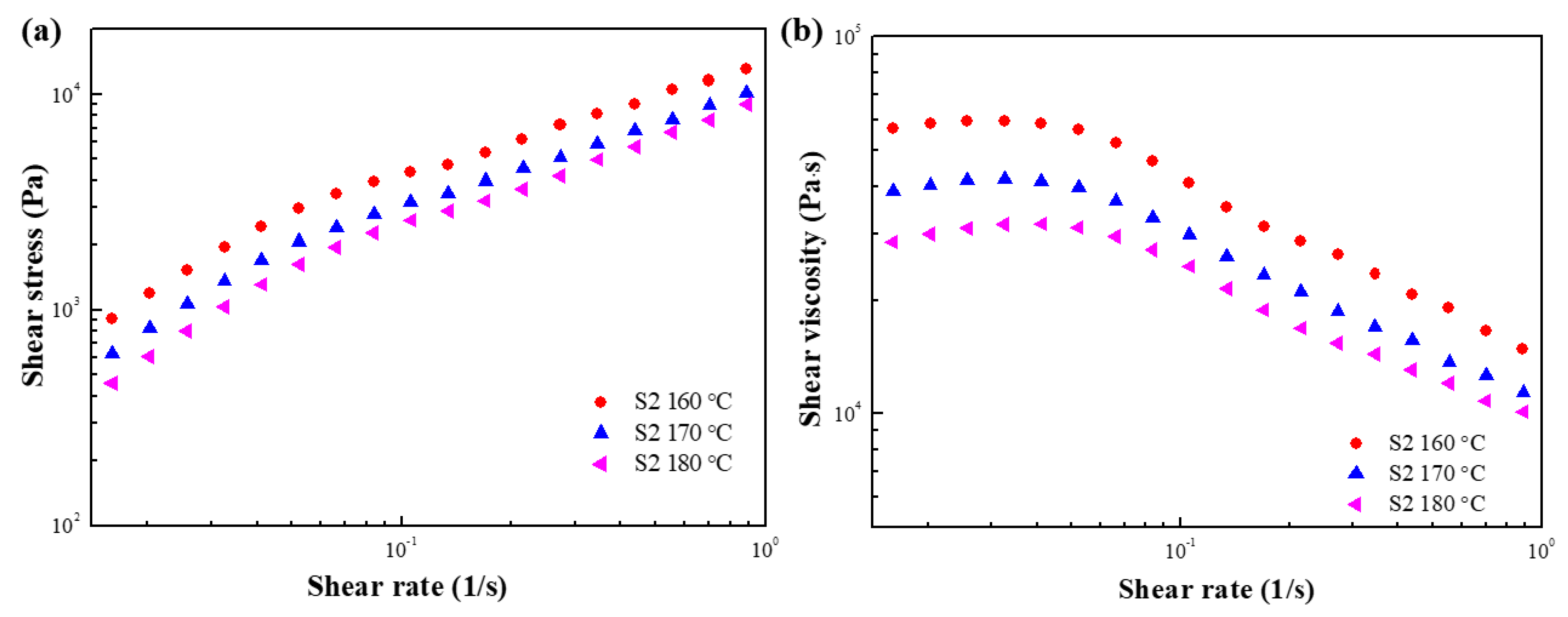

| S2 160 °C | 5.79 × 105 | 152 | 0.39 | 0.96 |

| S2 170 °C | 3.98 × 105 | 135 | 0.43 | 0.95 |

| S2 180 °C | 2.97 × 104 | 101 | 0.47 | 0.93 |

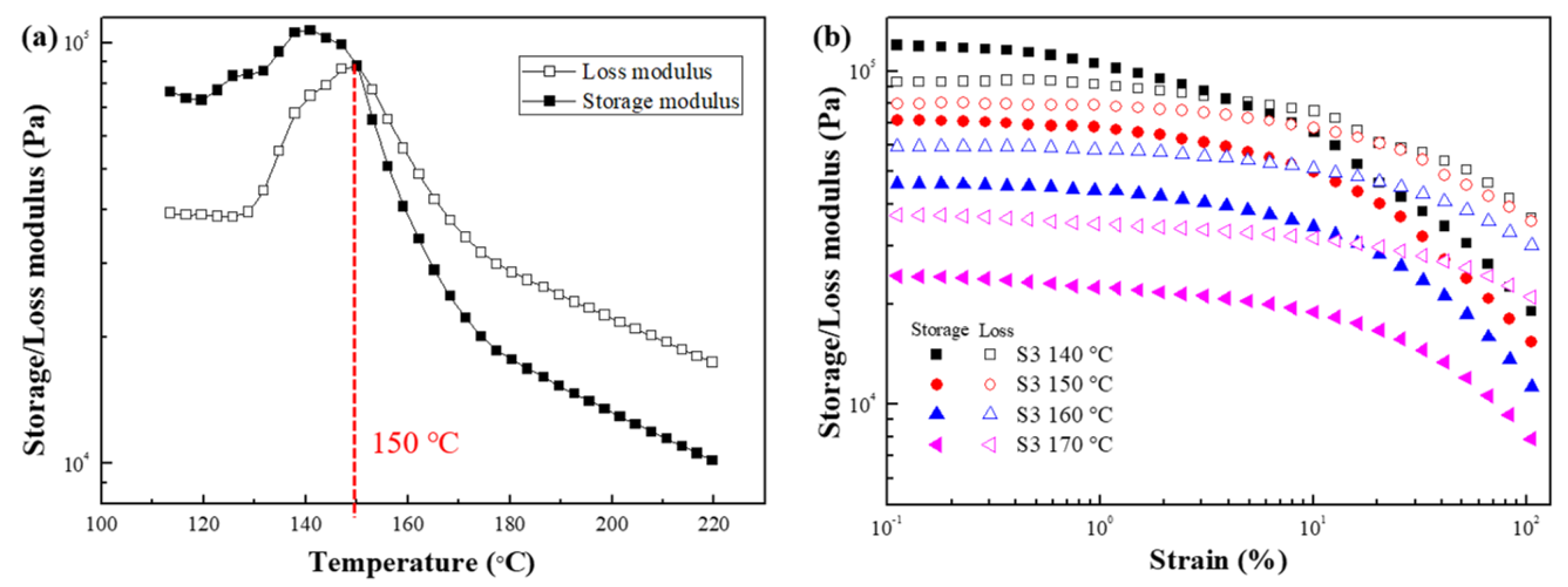

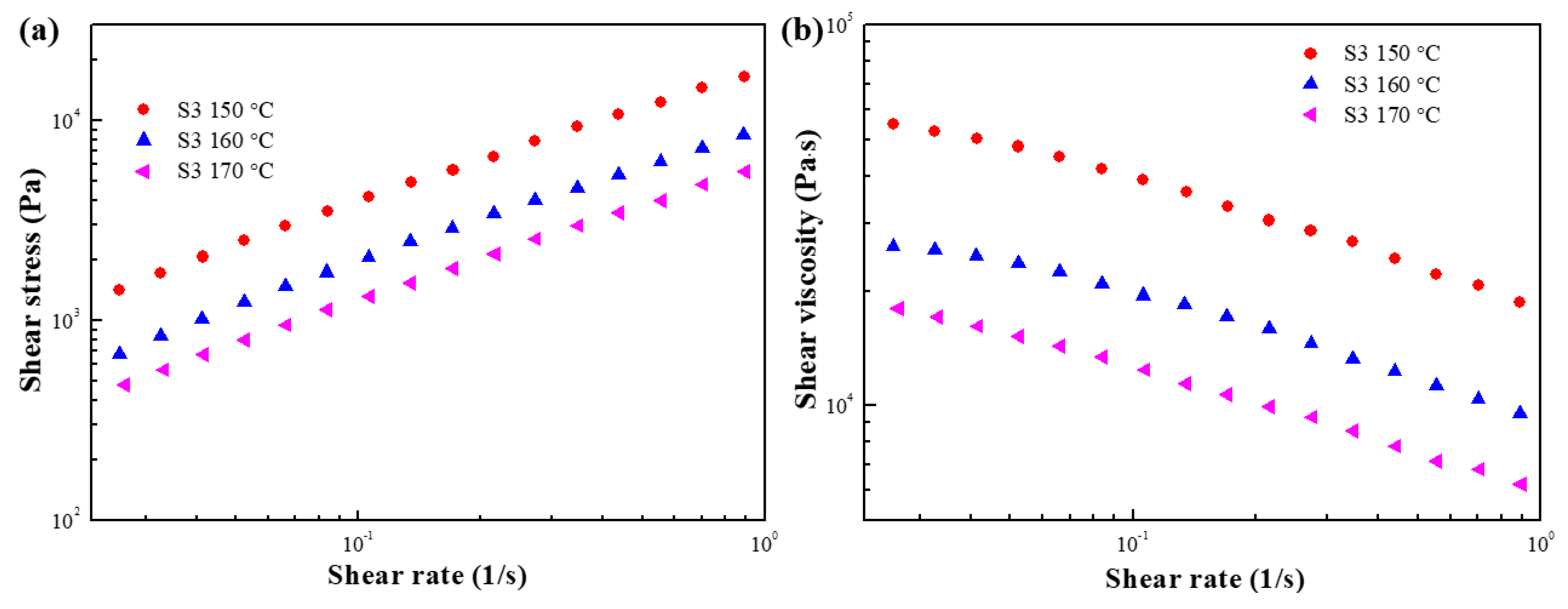

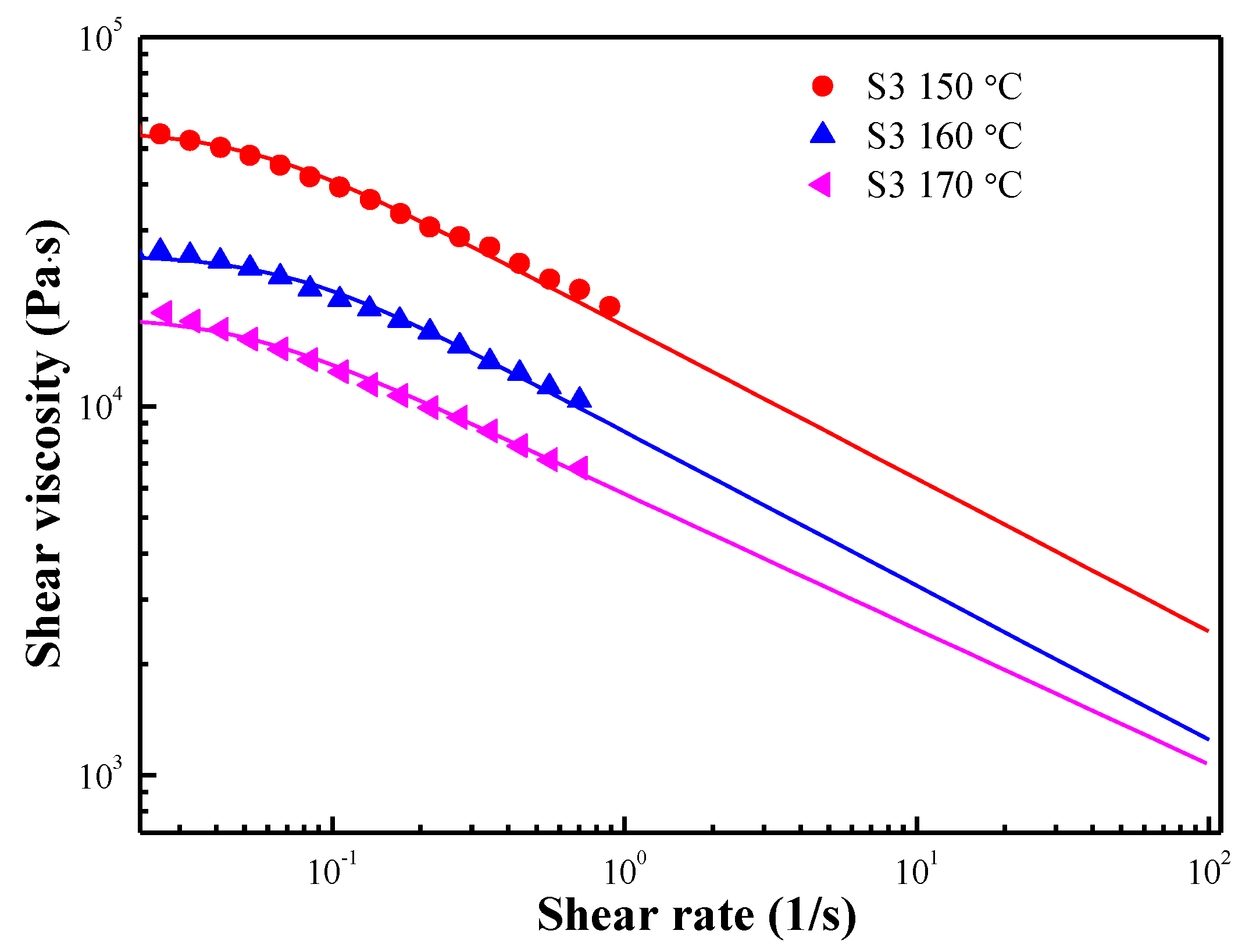

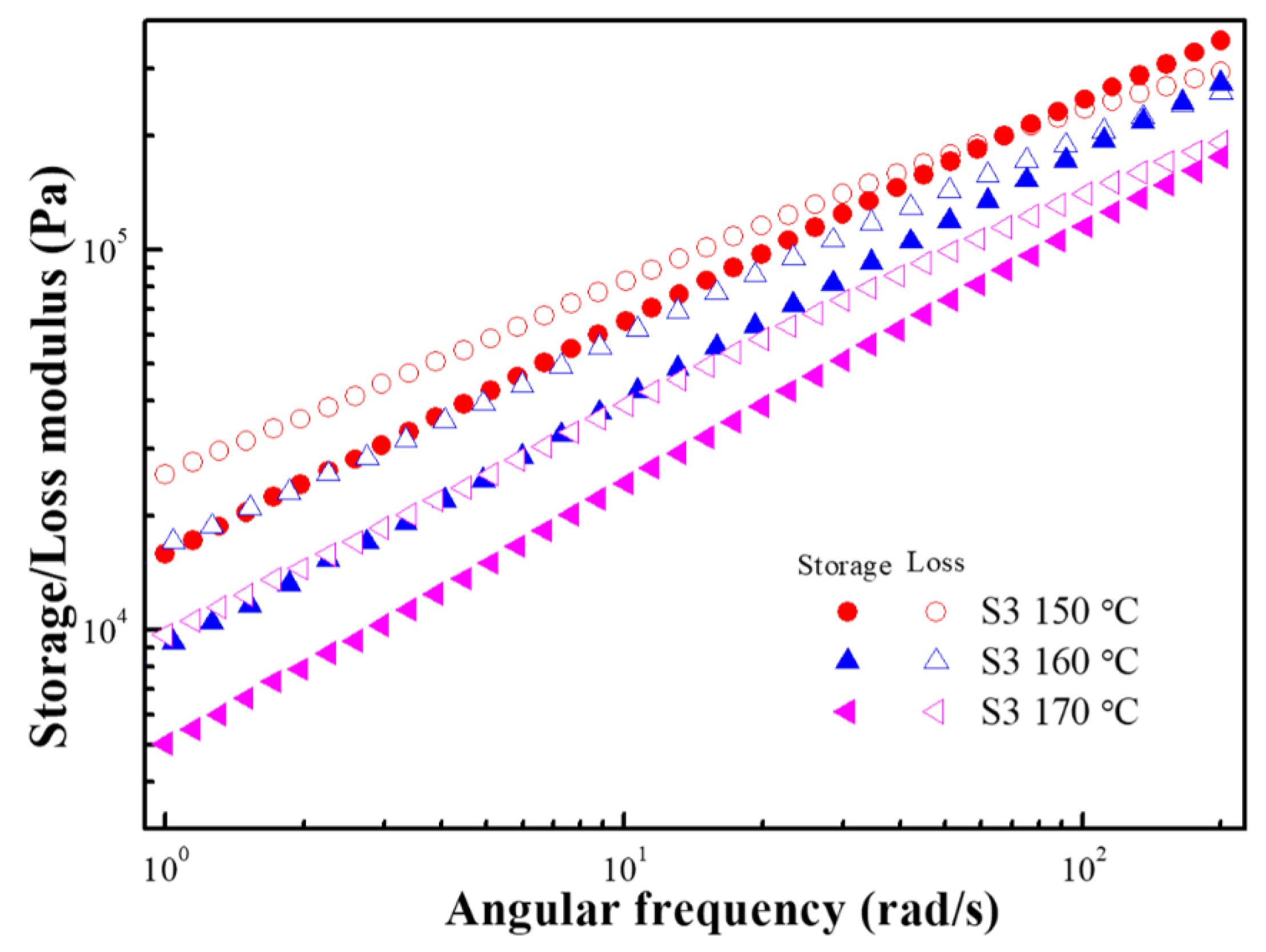

| Materials | (Pa·s) | (s) | ||

|---|---|---|---|---|

| S3 150 °C | 5.61 × 105 | 367 | 0.59 | 0.93 |

| S3 160 °C | 2.58 × 105 | 197 | 0.58 | 0.90 |

| S3 170 °C | 1.75 × 104 | 422 | 0.63 | 0.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, D.-I.; Dong, Y.; Wang, S.; Lee, S.-J.; Choi, H.J. Rheological Characteristics of Starch-Based Biodegradable Blends. Polymers 2023, 15, 1953. https://doi.org/10.3390/polym15081953

Park D-I, Dong Y, Wang S, Lee S-J, Choi HJ. Rheological Characteristics of Starch-Based Biodegradable Blends. Polymers. 2023; 15(8):1953. https://doi.org/10.3390/polym15081953

Chicago/Turabian StylePark, Dong-Il, Yuzhen Dong, Shizhao Wang, Soo-Jeong Lee, and Hyoung Jin Choi. 2023. "Rheological Characteristics of Starch-Based Biodegradable Blends" Polymers 15, no. 8: 1953. https://doi.org/10.3390/polym15081953

APA StylePark, D.-I., Dong, Y., Wang, S., Lee, S.-J., & Choi, H. J. (2023). Rheological Characteristics of Starch-Based Biodegradable Blends. Polymers, 15(8), 1953. https://doi.org/10.3390/polym15081953