Study on Improving Measures of Mechanical Properties of Geopolymer Materials and Its Effect on CO2 Emission

Abstract

1. Introduction

2. Materials and Methods

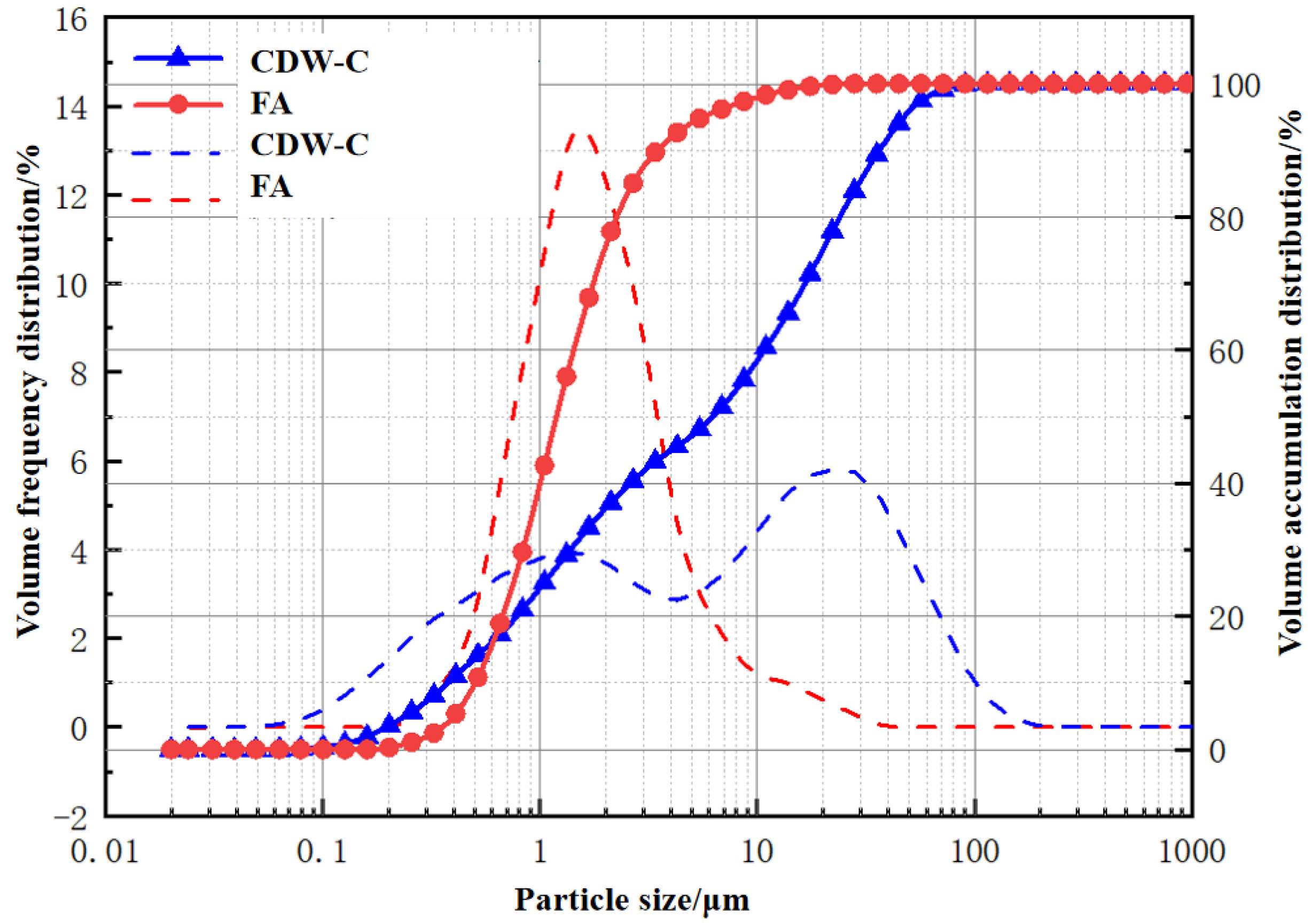

2.1. Raw Materials

2.2. Mix Proportion

2.3. Experimental Project

2.3.1. Preparation of Specimens

2.3.2. Experimental Test

3. Results and Discussion

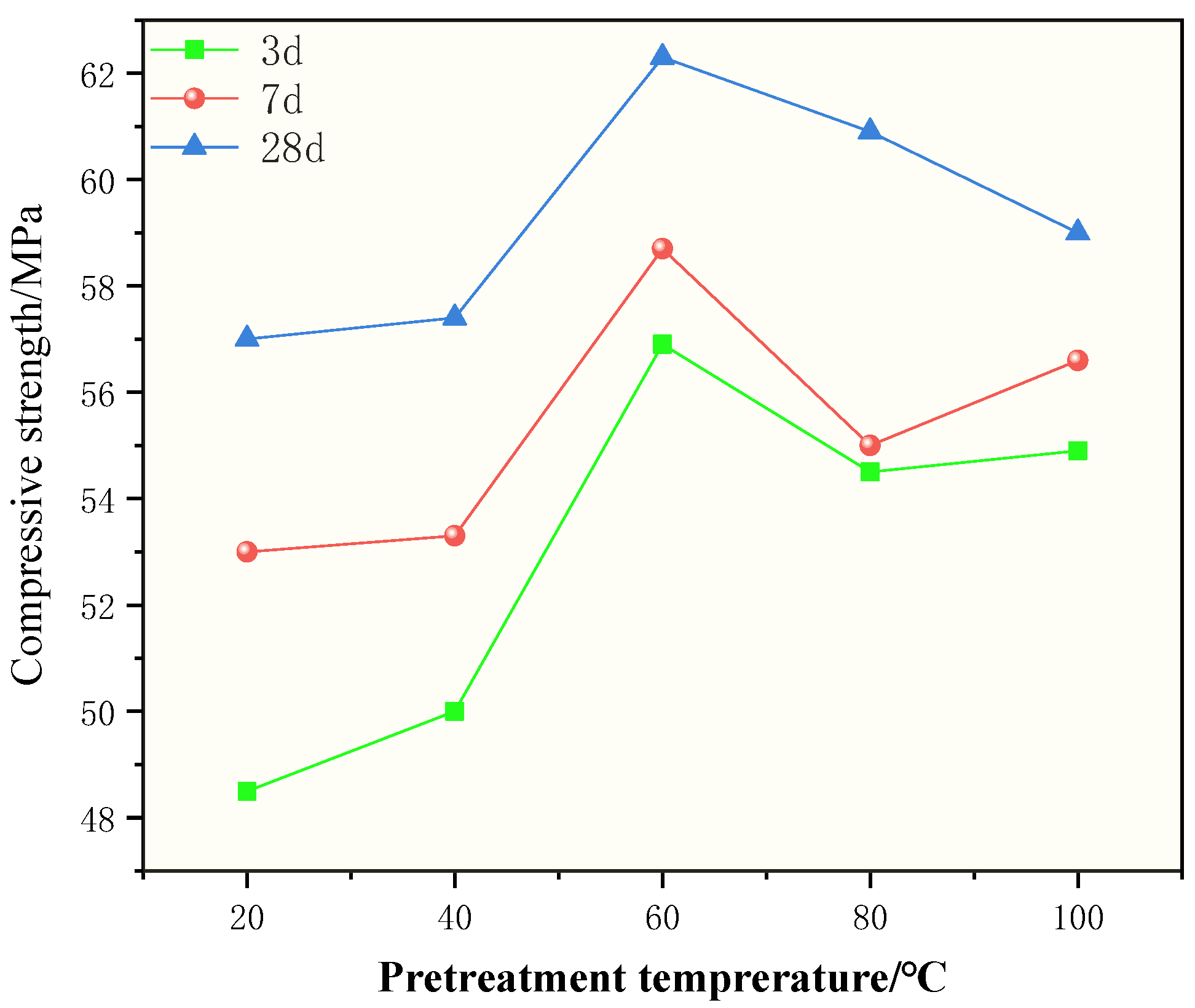

3.1. Influence of Pretreatment on the Development of Compressive Strength

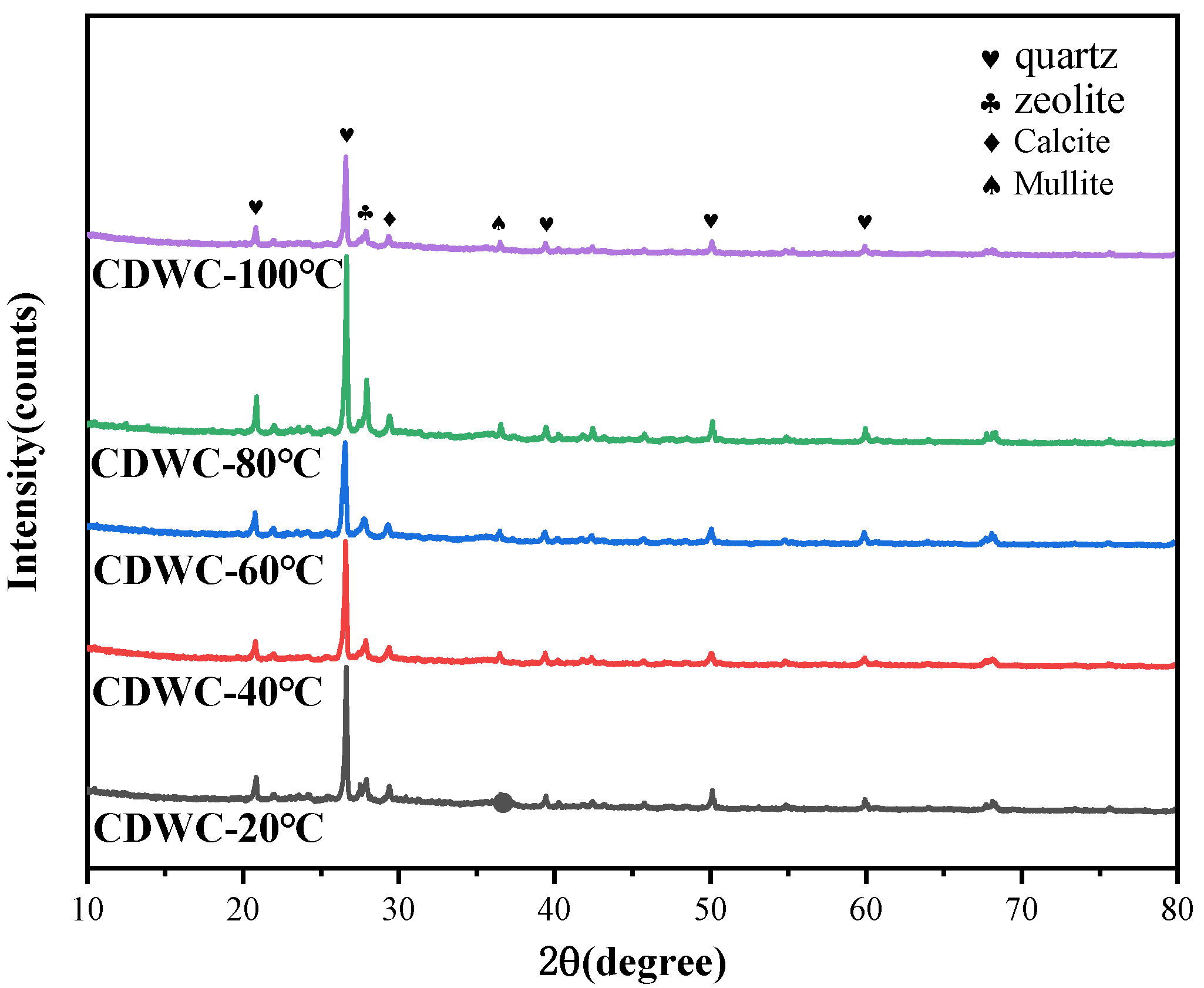

3.2. SEM-EDS and XRD Microanalysis

3.3. Effect of Addition CaO on CDWGP Compressive Strength

3.4. Impact of Improvement Measures on CO2 Emissions

4. Conclusions

- High-temperature pretreatment CDWC can effectively improve the compressive strength of CDWGC by improving the reactivity of CDWC and increasing the alkalinity of the geopolymer matrix.

- From the SEM-EDS and XRD results of CDWC, there is no apparent change in the microscopic morphology, and the chemical compositions have few changes after different high-temperature treatments. These indicate the strength shrinkage of CDWGC is not due to the high temperature that destroyed the CDWC and affected its strength development. Instead, high-temperature pretreatment reduces the moisture content of CDWC and cracks caused by the evaporation of moisture inside the concrete during heat curing, thereby improving the stability of concrete strength growth.

- The mechanical properties of CDWGP cured at ambient conditions can be significantly improved by adding CaO due to the formation of a more compact C-S-H gel and the acceleration of the formation of N-A-S-H gel. But the compressive strength first increases and then decreases with the increase of CaO content, and the optimum amount of CaO is 3%.

- Compared with the high-temperature pretreatment of CDWC and heat curing CDWGP, the p value of adding CaO is smaller, and adding CaO has a better effect on strength improvement. Therefore, adding CaO is a more low-carbon and environmentally friendly way to improve the compressive strength of CDWGP.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, W.; Zhu, Z. Utilization of Fly Ash to Enhance Ground Waste Concrete-Based Geopolymer. Adv. Mater. Sci. Eng. 2018, 2018, 4793917. [Google Scholar] [CrossRef]

- Awal, A.A.; Mohammadhosseini, H. Green concrete production incorporating waste carpet fiber and palm oil fuel ash. J. Clean. Prod. 2016, 137, 157–166. [Google Scholar] [CrossRef]

- Nayaka, R.R.; Alengaram, U.J.; Jumaat, M.Z.; Yusoff, S.B.; Alnahhal, M.F. High volume cement replacement by environmental friendly industrial by-product palm oil clinker powder in cement—Lime masonry mortar. J. Clean. Prod. 2018, 190, 272–284. [Google Scholar] [CrossRef]

- Huseien, G.F.; Hamzah, H.K.; Sam, A.R.M.; Khalid, N.H.A.; Shah, K.W.; Deogrescu, D.P.; Mirza, J. Alkali-activated mortars blended with glass bottle waste nano powder: Environmental benefit and sustainability. J. Clean. Prod. 2020, 243, 118636. [Google Scholar] [CrossRef]

- Luan, C.; Wang, Q.; Yang, F.; Zhang, K.; Utashev, N.; Dai, J.; Shi, X. Practical Prediction Models of Tensile Strength and Reinforcement-Concrete Bond Strength of Low-Calcium Fly Ash Geopolymer Concrete. Polymers 2021, 13, 875. [Google Scholar] [CrossRef]

- Reig, L.; Soriano, L.; Borrachero, M.V.; Monzo, J.; Paya, J. Influence of the activator concentration and calcium hydroxide addition on the properties of alkali-activated porcelain stoneware. Constr. Build. Mater. 2014, 63, 214–222. [Google Scholar] [CrossRef]

- Paya, J.; Borrachero, M.V.; Monzo, J.; Soriano, L.; Tashima, M.M. A new geopolymeric binder from hydrated-carbonated cement. Mater. Lett. 2012, 74, 223–225. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali-activated slag (Si plus Ca) and metakaolin (Si plus Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Shi, C.; Fernandez, J.A.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Andres, R.R.; Mercedes, M.J.M.; Mejia, D.G.R. Eco-efficient alkali-activated cement based on red clay brick wastes suitable for the manufacturing of building materials. J. Clean. Prod. 2017, 166, 242–252. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, C.; Liang, Y.; Luo, J.; Wang, X.; Feng, Y.; Abomohra, A.E. Life Cycle Assessment and Impact Correlation Analysis of Fly Ash Geopolymer Concrete. Materials 2021, 14, 7375. [Google Scholar] [CrossRef]

- Salas, D.A.; Ramirez, A.D.; Ulloa, N.; Baykara, H.; Boero, A.J. Life cycle assessment of geopolymer concrete. Constr. Build. Mater. 2018, 190, 170–177. [Google Scholar] [CrossRef]

- Al-mashhadani, M.M.; Canpolat, O.; Aygormez, Y.; Uysal, M.; Erdem, S. Mechanical and microstructural characterization of fiber reinforced fly ash based geopolymer composites. Constr. Build. Mater. 2018, 167, 505–513. [Google Scholar] [CrossRef]

- Hasnaoui, A.; Ghorbel, E.; Wardeh, G. Performance of metakaolin/slag-based geopolymer concrete made with recycled fine and coarse aggregates. J. Build. Eng. 2021, 42, 102813. [Google Scholar] [CrossRef]

- Peng, Z.; Lu, W.; Webster, C.J. Quantifying the embodied carbon saving potential of recycling construction and demolition waste in the Greater Bay Area, China: Status quo and future scenarios. Sci. Total Environ. 2021, 792, 148427. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Ni, S.; Liu, L.; Walubita, L.F. Mechanical performance and environmental impacts of self-compacting concrete with recycled demolished concrete blocks. J. Clean. Prod. 2021, 293, 126129. [Google Scholar] [CrossRef]

- Dai, J.X.; Shi, X.S.; Wang, Q.Y.; Zhang, H.E.; Luan, C.C.; Zhang, K.Y.; Yang, F.H. Effect of Multi-factor on the Compressive Strength of Construction and Demolition Waste Based Geopolymer Concrete. Mater. Rep. 2021, 35, 9077–9082. [Google Scholar]

- Vasquez, A.; Cardenas, V.; Robayo, R.A.; Mejia De Gutierrez, R. Geopolymer based on concrete demolition waste. Adv. Powder Technol. 2016, 27, 1173–1179. [Google Scholar] [CrossRef]

- Wong, C.L.; Mo, K.H.; Alengaram, U.J.; Yap, S.P. Mechanical strength and permeation properties of high calcium fly ash-based geopolymer containing recycled brick powder. J. Build. Eng. 2020, 32, 101655. [Google Scholar] [CrossRef]

- Xu, J.; Kang, A.; Wu, Z.; Gong, Y.; Xiao, P. The effect of mechanical-thermal synergistic activation on the mechanical properties and microstructure of recycled powder geopolymer. J. Clean. Prod. 2021, 327, 129477. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, K.; Wang, S.; Wang, Z.; Yang, Z.; Shumuye, E.D.; Gong, X. Effect of Elevated Temperature on Mechanical Properties of High-Volume Fly Ash-Based Geopolymer Concrete, Mortar and Paste Cured at Room Temperature. Polymers 2021, 13, 1473. [Google Scholar] [CrossRef] [PubMed]

- Panizza, M.; Natali, M.; Garbin, E.; Tamburini, S.; Secco, M. Assessment of geopolymers with Construction and Demolition Waste (CDW) aggregates as a building material. Constr. Build. Mater. 2018, 181, 119–133. [Google Scholar] [CrossRef]

- Li, J.; Dang, X.; Zhang, J.; Yi, P.; Li, Y. Mechanical Properties of Fly Ash-Slag Based Geopolymer for Repair of Road Subgrade Diseases. Polymers 2023, 15, 309. [Google Scholar] [CrossRef] [PubMed]

- Hwang, C.; Yehualaw, M.D.; Duy-Hai, V.; Trong-Phuoc, H.; Largo, A. Performance evaluation of alkali activated mortar containing high volume of waste brick powder blended with ground granulated blast furnace slag cured at ambient temperature. Constr. Build. Mater. 2019, 223, 657–667. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Use of OPC to improve setting and early strength properties of low calcium fly ash geopolymer concrete cured at room temperature. Cem. Concr. Compos. 2015, 55, 205–214. [Google Scholar] [CrossRef]

- Oikonomopoulos, I.K.; Perraki, M.; Tougiannidis, N.; Perraki, T.; Kasper, H.U.; Gurk, M. Clays from Neogene Achlada lignite deposits in Florina basin (Western Macedonia, N. Greece): A prospective resource for the ceramics industry. Appl. Clay Sci. 2015, 103, 1–9. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Chen, L.; Dick, W.A. Alkali-activated complex binders from class C fly ash and Ca-containing admixtures. J. Hazard. Mater. 2010, 173, 480–486. [Google Scholar] [CrossRef]

- Tuyan, M.; Andic-Cakir, O.; Ramyar, K. Effect of alkali activator concentration and curing condition on strength and microstructure of waste clay brick powder-based geopolymer. Compos. Part B-Eng. 2018, 135, 242–252. [Google Scholar] [CrossRef]

- Dombrowski, K.; Buchwald, A.; Weil, M. The influence of calcium content on the structure and thermal performance of fly ash based geopolymers. J. Mater. Sci. 2007, 42, 3033–3043. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J.; Ng, T.; Sanjayan, J.G.; Gilbert, R.I. Creep and drying shrinkage of a blended slag and low calcium fly ash geopolymer Concrete. Mater. Struct. 2016, 49, 1619–1628. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Fernandez-Jimenez, A.; Palomo, A.; Macphee, D.E. Effect of Calcium Additions on N-A-S-H Cementitious Gels. J. Am. Ceram. Soc. 2010, 93, 1934–1940. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Dick, W.A. Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem. Concr. Compos. 2010, 32, 142–147. [Google Scholar] [CrossRef]

- Ahmari, S.; Ren, X.; Toufigh, V.; Zhang, L. Production of geopolymeric binder from blended waste concrete powder and fly ash. Constr. Build. Mater. 2012, 35, 718–729. [Google Scholar] [CrossRef]

- Kawai, K.; Sugiyama, T.; Kobayashi, K.; Sano, S. Inventory data and case studies for environmental performance evaluation of concrete structure construction. J. Adv. Concr. Technol. 2005, 3, 435–456. [Google Scholar] [CrossRef]

| Name | Abbreviation |

|---|---|

| Construction and demolition waste composites | CDWC |

| Fly ash | FA |

| CDW-C-based geopolymer concrete | CDWGC |

| CDW-C-based geopolymer paste | CDWGP |

| Life cycle assessment | LCA |

| Scanning electron microscope | SEM |

| Energy dispersive spectrometer | EDS |

| X-ray diffraction | XRD |

| X-ray fluorescence spectroscopy | XRF |

| Carbon emission ratio parameter | P |

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | P2O5 | TiO2 | MgO | L.O.I |

|---|---|---|---|---|---|---|---|---|---|

| FA | 60.66 | 14.51 | 6.29 | 5.11 | 0.94 | 3.42 | 1.04 | - | 4.98 |

| CDWC | 42.90 | 10.95 | 6.35 | 9.29 | 0.87 | - | - | 1.36 | 26.52 |

| Physical Properties | Value | Standard Deviations |

|---|---|---|

| Average particle size | 12.582 μm | 1.934 |

| Density | 2.60 g/cm3 | 0.101 |

| Water content ratio | <1% | 0.0013 |

| Water demand ratio | 98.9% | 0.009 |

| Liquidity ratio | 93.0% | 0.039 |

| Strength activity index | 73.7% | 0.061 |

| Type | Pretreat Temperature °C | FA kg/m3 | CDWC kg/m3 | NaOH Malority mol/L | Coarse Aggregate kg/m3 | Fine Aggregate kg/m3 | Sodium Silicate kg/m3 | NaOH kg/m3 | Water kg/m3 |

|---|---|---|---|---|---|---|---|---|---|

| CDWGC20 | 20 | 368 | 92 | 12 | 1200 | 540 | 133.4 | 21.63 | 45.07 |

| CDWGC40 | 40 | 368 | 92 | 12 | 1200 | 540 | 133.4 | 21.63 | 45.07 |

| CDWGC60 | 60 | 368 | 92 | 12 | 1200 | 540 | 133.4 | 21.63 | 45.07 |

| CDWGC80 | 80 | 368 | 92 | 12 | 1200 | 540 | 133.4 | 21.63 | 45.07 |

| CDWGC100 | 100 | 368 | 92 | 12 | 1200 | 540 | 133.4 | 21.63 | 45.07 |

| Type | FA kg/m3 | CDWC kg/m3 | NaOH Malority mol/L | Sodium Silicate kg/m3 | NaOH kg/m3 | CaO kg/m3 | Water kg/m3 |

|---|---|---|---|---|---|---|---|

| CDWGP0 | 1226.48 | 306.62 | 12 | 444.60 | 72.09 | 0 | 150.21 |

| CDWGP1 | 1226.48 | 306.62 | 12 | 444.60 | 72.09 | 15.33 | 150.21 |

| CDWGP3 | 1226.48 | 306.62 | 12 | 444.60 | 72.09 | 45.99 | 150.21 |

| CDWGP5 | 1226.48 | 306.62 | 12 | 444.60 | 72. 09 | 76.66 | 150.21 |

| Temperatures (°C) | Mass Ratio of Different Elements (wt%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | O | Na | Mg | Al | Si | K | Ca | Fe | Total | |

| 20 | 10.30 | 43.15 | 0.69 | 1.03 | 6.08 | 20.47 | 1.55 | 10.96 | 5.77 | 100 |

| 40 | 10.51 | 43.99 | 0.67 | 0.88 | 5.8 | 20.65 | 1.52 | 10.67 | 5.02 | 99.71 |

| 60 | 9.85 | 43.45 | 0.98 | 1.04 | 6.16 | 20.51 | 1.77 | 10.82 | 5.42 | 100 |

| 80 | 10.87 | 42.46 | 0.91 | 0.94 | 6.72 | 19.90 | 1.60 | 10.45 | 6.14 | 100 |

| 100 | 10.39 | 43.86 | 0.71 | 1.09 | 6.24 | 19.86 | 1.63 | 10.69 | 5.10 | 99.59 |

| variance | 0.11 | 0.30 | 0.02 | 0.01 | 0.09 | 0.11 | 0.01 | 0.03 | 0.18 | - |

| Type | Raw Materials Production | Raw Materials Transportation | Concrete Preparation | Total CO2 Emissions | Additional CO2 Emissions | P (%) |

|---|---|---|---|---|---|---|

| CDWGC20 (control) | 319.04 | 28.72 | 206.84 | 554.60 | 0 | 0 |

| CDWGC40 | 319.04 | 28.72 | 253.09 | 600.85 | 46.25 | 8.34 |

| CDWGC60 | 319.04 | 28.72 | 260.32 | 608.08 | 53.48 | 9.64 |

| CDWGC80 | 319.04 | 28.72 | 271.68 | 619.44 | 64.84 | 11.69 |

| CDWGC100 | 319.04 | 28.72 | 289.06 | 636.82 | 82.22 | 14.83 |

| CDWGP0 (control) | 1048.47 | 76.24 | 3.8 | 1128.51 | 0 | 0 |

| CDWGP1 | 1069.17 | 76.51 | 3.8 | 1149.48 | 20.97 | 1.86 |

| CDWGP3 | 1110.57 | 77.04 | 3.8 | 1191.41 | 62.9 | 5.57 |

| CDWGP5 | 1151.96 | 77.58 | 3.8 | 1233.34 | 104.51 | 9.26 |

| CDWGP0 (heat) | 1151.96 | 77.58 | 3.8 | 1233.34 | 206.84 | 18.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, J.; Shi, X.; Wang, Q.; Dai, J.; Deng, X.; Xue, Y. Study on Improving Measures of Mechanical Properties of Geopolymer Materials and Its Effect on CO2 Emission. Polymers 2023, 15, 1699. https://doi.org/10.3390/polym15071699

Luo J, Shi X, Wang Q, Dai J, Deng X, Xue Y. Study on Improving Measures of Mechanical Properties of Geopolymer Materials and Its Effect on CO2 Emission. Polymers. 2023; 15(7):1699. https://doi.org/10.3390/polym15071699

Chicago/Turabian StyleLuo, Jinqian, Xiaoshuang Shi, Qingyuan Wang, Jinxin Dai, Xiang Deng, and Yu Xue. 2023. "Study on Improving Measures of Mechanical Properties of Geopolymer Materials and Its Effect on CO2 Emission" Polymers 15, no. 7: 1699. https://doi.org/10.3390/polym15071699

APA StyleLuo, J., Shi, X., Wang, Q., Dai, J., Deng, X., & Xue, Y. (2023). Study on Improving Measures of Mechanical Properties of Geopolymer Materials and Its Effect on CO2 Emission. Polymers, 15(7), 1699. https://doi.org/10.3390/polym15071699