Effect of Different Silane Coupling Agents In-Situ Modified Sepiolite on the Structure and Properties of Natural Rubber Composites Prepared by Latex Compounding Method

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Materials

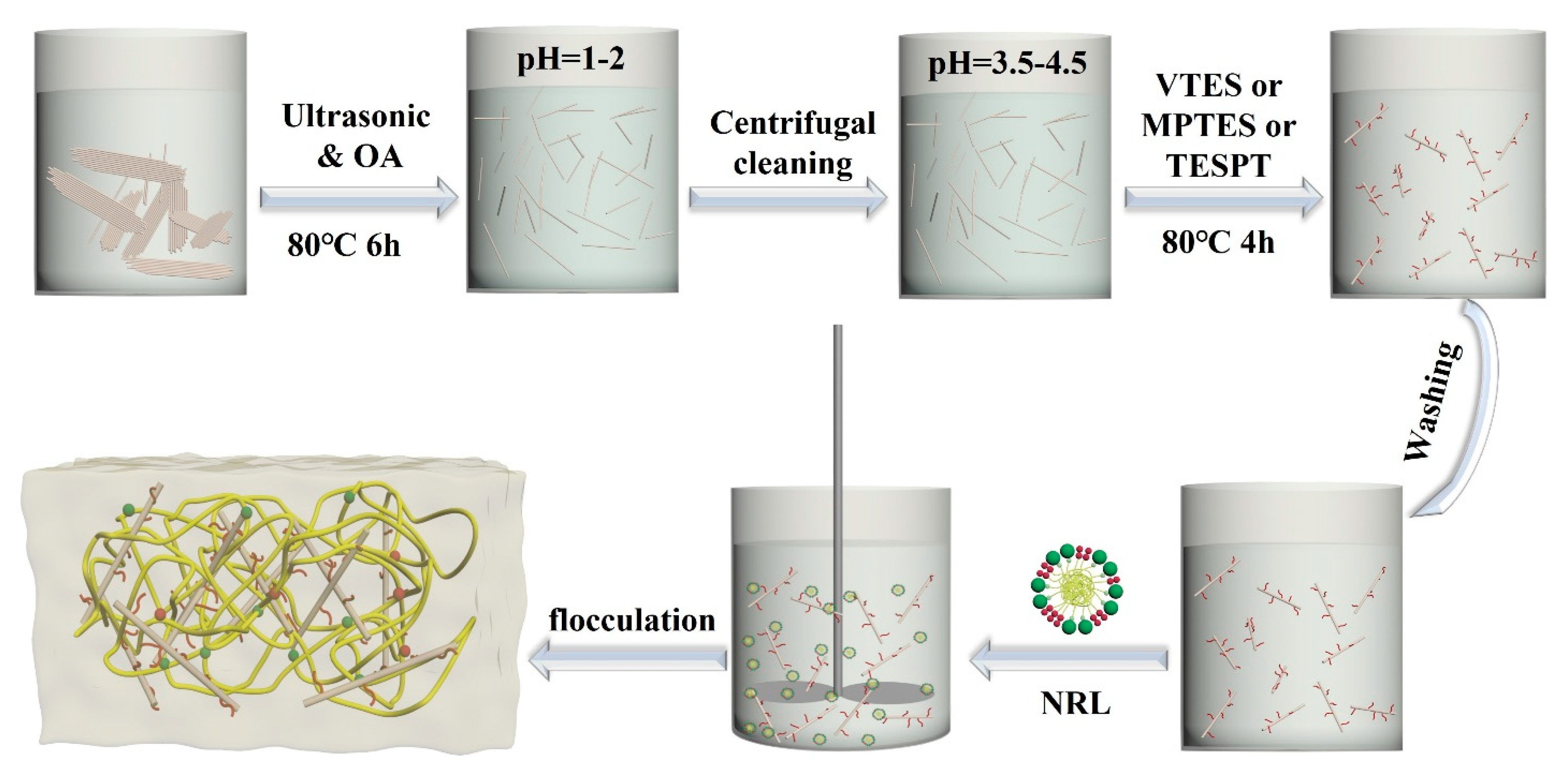

2.2. Preparation of Sepiolite Dispersions

2.3. Preparation of Sep/NR Masterbatches and Composites

2.4. Characterizations

3. Results and Discussion

3.1. Characterization of Pure and Modified Sepiolite

3.2. Dispersion and Interfacial Interaction of Sepiolite/NR Composites

3.3. Vulcanization Characteristics of Sepiolite/NR Composites

3.4. Static Mechanical Properties of Sepiolite/NR Composites

3.5. Dynamic Properties of Sepiolite/NR Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dunuwila, P.; Rodrigo, V.H.L.; Goto, N. Sustainability of natural rubber processing can be improved: A case study with crepe rubber manufacturing in Sri Lanka. Resour. Conserv. Recycl. 2018, 133, 417–427. [Google Scholar] [CrossRef]

- Dominic, M.; Joseph, R.; Sabura Begum, P.M.; Kanoth, B.P.; Chandra, J.; Thomas, S. Green tire technology: Effect of rice husk derived nanocellulose (RHNC) in replacing carbon black (CB) in natural rubber (NR) compounding. Carbohydr. Polym. 2020, 230, 115620. [Google Scholar] [CrossRef]

- Dwivedi, C.; Manjare, S.; Rajan, S.K. Recycling of waste tire by pyrolysis to recover carbon black: Alternative & environment-friendly reinforcing filler for natural rubber compounds. Compos. Part B Eng. 2020, 200, 108346. [Google Scholar]

- Fan, Y.; Fowler, G.D.; Zhao, M. The past, present and future of carbon black as a rubber reinforcing filler—A review. J. Clean. Prod. 2020, 247, 119115. [Google Scholar] [CrossRef]

- Kato, A.; Ikeda, Y.; Kohjiya, S. Reinforcement Mechanism of Carbon Black (CB) in Natural Rubber Vulcanizates: Relationship Between CB Aggregate and Network Structure and Viscoelastic Properties. Polym.-Plast. Technol. Eng. 2018, 57, 1418–1429. [Google Scholar] [CrossRef]

- Gui, Y.; Zheng, J.; Ye, X.; Han, D.; Xi, M.; Zhang, L. Preparation and performance of silica/SBR masterbatches with high silica loading by latex compounding method. Compos. Part B Eng. 2016, 85, 130–139. [Google Scholar] [CrossRef]

- Ryu, C.S.; Kim, K.-J. Interfacial Adhesion in Silica-Silane Filled NR Composites: A Short Review. Polymers 2022, 14, 2705. [Google Scholar] [CrossRef] [PubMed]

- Errington, E.; Guo, M.; Heng, J.Y.Y. Synthetic amorphous silica: Environmental impacts of current industry and the benefit of biomass-derived silica. Green Chem. 2023. [Google Scholar] [CrossRef]

- Matos, C.F.; Galembeck, F.; Zarbin, A.J.G. Multifunctional and environmentally friendly nanocomposites between natural rubber and graphene or graphene oxide. Carbon 2014, 78, 469–479. [Google Scholar] [CrossRef]

- Alimardani, M.; Abbassi-Sourki, F.; Bakhshandeh, G.R. An investigation on the dispersibility of carbon nanotube in the latex nanocomposites using rheological properties. Compos. Part B Eng. 2014, 56, 149–156. [Google Scholar] [CrossRef]

- Xu, Z.; Jerrams, S.; Guo, H.; Zhou, Y.; Jiang, L.; Gao, Y.; Zhang, L.; Liu, L.; Wen, S. Influence of graphene oxide and carbon nanotubes on the fatigue properties of silica/styrene-butadiene rubber composites under uniaxial and multiaxial cyclic loading. Int. J. Fatigue 2020, 131, 105388. [Google Scholar] [CrossRef]

- Cao, L.; Huang, J.; Chen, Y. Dual Cross-linked Epoxidized Natural Rubber Reinforced by Tunicate Cellulose Nanocrystals with Improved Strength and Extensibility. ACS Sustain. Chem. Eng. 2018, 6, 14802–14811. [Google Scholar] [CrossRef]

- Hakimi, N.M.F.; Lee, S.H.; Lum, W.C.; Mohamad, S.F.; Osman Al Edrus, S.S.; Park, B.-D.; Azmi, A. Surface Modified Nanocellulose and Its Reinforcement in Natural Rubber Matrix Nanocomposites: A Review. Polymers 2021, 13, 3241. [Google Scholar] [CrossRef] [PubMed]

- Alwis, G.M.C.; Kottegoda, N.; Ratnayake, U.N. Facile exfoliation method for improving interfacial compatibility in montmorillonite-natural rubber nanocomposites: A novel charge inversion approach. Appl. Clay Sci. 2020, 191, 105633. [Google Scholar] [CrossRef]

- Zha, C.; Wang, W.; Lu, Y.; Zhang, L. Constructing Covalent Interface in Rubber/Clay Nanocomposite by Combining Structural Modification and Interlamellar Silylation of Montmorillonite. ACS Appl. Mater. Interfaces 2014, 6, 18769–18779. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, H.; Zhang, K.; Liu, L.; Ji, L.; Liu, Q. Vulcanization, interfacial interaction, and dynamic mechanical properties of in-situ organic amino modified kaolinite/SBR nanocomposites based on latex compounding method. Appl. Clay Sci. 2020, 185, 105366. [Google Scholar] [CrossRef]

- Komadel, P.; Madejová, J.; Stucki, J.W. Structural Fe(III) reduction in smectites. Appl. Clay Sci. 2006, 34, 88–94. [Google Scholar] [CrossRef]

- Guggenheim, S.; Krekeler, M.P.S. Chapter 1—The Structures and Microtextures of the Palygorskite–Sepiolite Group Minerals. In Developments in Clay Science; Galàn, E., Singer, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; Volume 3, pp. 3–32. [Google Scholar]

- Suárez, M.; García-Romero, E. Chapter 2—Advances in the Crystal Chemistry of Sepiolite and Palygorskite. In Developments in Clay Science; Galàn, E., Singer, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; Volume 3, pp. 33–65. [Google Scholar]

- Nagy, B.; Bradley, W.F. The Structural Scheme of Sepiolite. Clay Miner. Bull. 1954, 2, 203. [Google Scholar] [CrossRef]

- Tian, G.; Han, G.; Wang, F.; Liang, J. 3—Sepiolite Nanomaterials: Structure, Properties and Functional Applications. In Nanomaterials from Clay Minerals; Wang, A., Wang, W., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 135–201. [Google Scholar]

- Erdoğan Alver, B. Hydrogen adsorption on natural and sulphuric acid treated sepiolite and bentonite. Int. J. Hydrog. Energy 2018, 43, 831–838. [Google Scholar] [CrossRef]

- Zhou, F.; Yan, C.; Zhang, Y.; Tan, J.; Wang, H.; Zhou, S.; Pu, S. Purification and defibering of a Chinese sepiolite. Appl. Clay Sci. 2016, 124–125, 119–126. [Google Scholar] [CrossRef]

- Zhuang, G.; Gao, J.; Chen, H.; Zhang, Z. A new one-step method for physical purification and organic modification of sepiolite. Appl. Clay Sci. 2018, 153, 1–8. [Google Scholar] [CrossRef]

- Leblanc, J.L. Rubber–filler interactions and rheological properties in filled compounds. Prog. Polym. Sci. 2002, 27, 627–687. [Google Scholar] [CrossRef]

- Di Credico, B.; Tagliaro, I.; Cobani, E.; Conzatti, L.; D’Arienzo, M.; Giannini, L.; Mascotto, S.; Scotti, R.; Stagnaro, P.; Tadiello, L. A Green Approach for Preparing High-Loaded Sepiolite/Polymer Biocomposites. Nanomaterials 2019, 9, 46. [Google Scholar] [CrossRef] [PubMed]

- Carignani, E.; Cobani, E.; Martini, F.; Nardelli, F.; Borsacchi, S.; Calucci, L.; Di Credico, B.; Tadiello, L.; Giannini, L.; Geppi, M. Effect of sepiolite treatments on the oxidation of sepiolite/natural rubber nanocomposites prepared by latex compounding technique. Appl. Clay Sci. 2020, 189, 105528. [Google Scholar] [CrossRef]

- Hou, C.; Gao, L.; Yu, H.; Sun, Y.; Yao, J.; Zhao, G.; Liu, Y. Preparation of magnetic rubber with high mechanical properties by latex compounding method. J. Magn. Magn. Mater. 2016, 407, 252–261. [Google Scholar] [CrossRef]

- Fernandes, F.M.; Ruiz-Hitzky, E. Assembling nanotubes and nanofibres: Cooperativeness in sepiolite–carbon nanotube materials. Carbon 2014, 72, 296–303. [Google Scholar] [CrossRef]

- Ruiz-Hitzky, E.; Ruiz-García, C.; Fernandes, F.M.; Lo Dico, G.; Lisuzzo, L.; Prevot, V.; Darder, M.; Aranda, P. Sepiolite-Hydrogels: Synthesis by Ultrasound Irradiation and Their Use for the Preparation of Functional Clay-Based Nanoarchitectured Materials. Front. Chem. 2021, 9, 733105. [Google Scholar] [CrossRef]

- Jiménez-López, A.; López-González, J.d.D.; Ramīrez-Sāenz, A.; Rodrīguez-Reinoso, F.; Valenzuela-Calahorro, C.; Zurita-Herrera, L. Evolution of surface area in a sepiolite as a function of acid and heat treatments. Clay Miner. 1978, 13, 375–385. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Ismail, H. Reinforcement of epoxidized natural rubber through the addition of sepiolite. Polym. Compos. 2019, 40, 924–931. [Google Scholar] [CrossRef]

- Raji, M.; Mekhzoum, M.E.M.; Rodrigue, D.; Qaiss, A.e.k.; Bouhfid, R. Effect of silane functionalization on properties of polypropylene/clay nanocomposites. Compos. Part B Eng. 2018, 146, 106–115. [Google Scholar] [CrossRef]

- Peinado, V.; García, L.; Fernández, Á.; Castell, P. Novel lightweight foamed poly(lactic acid) reinforced with different loadings of functionalised Sepiolite. Compos. Sci. Technol. 2014, 101, 17–23. [Google Scholar] [CrossRef]

- Wang, F.; Feng, L.; Tang, Q.; Liang, J.; Liu, H.; Liu, H. Effect of Modified Sepiolite Nanofibers on Properties of cis-Polybutadiene Rubber Composite Nanomaterials. J. Nanomater. 2013, 2013, 369409. [Google Scholar]

- Mohd Zaini, N.A.; Samsudin, D.; Rusli, A.; Ismail, H. Curing, thermal, tensile and flammability characteristics of sepiolite/ethylene propylene diene monomer rubber composites with glut palmitate salt and silane coupling agents. Polym. Compos. 2022, 43, 4721–4736. [Google Scholar] [CrossRef]

- López Valentín, J.; Rodríguez Díaz, A.; Ibarra Rueda, L.; González Hernández, L. Effect of a natural magnesium silicate treated with a new coupling agent on the properties of ethylene–propylene–diene rubber compounds. J. Appl. Polym. Sci. 2004, 91, 1489–1493. [Google Scholar] [CrossRef]

- Kim, K.-J.; Vanderkooi, J. Moisture effects on improved hydrolysis reaction for TESPT and TESPD-silica compounds. Compos. Interfaces 2004, 11, 471–488. [Google Scholar] [CrossRef]

- Yin, C.; Zhang, Q.; Liu, J.; Liu, L.; Gu, J. Preparation, properties of In-situ silica modified styrene-butadiene rubber and its silica-filled composites. Polym. Compos. 2018, 39, 22–28. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Masa, A.; Othman, N.; Surya, I. Viable Properties of Natural Rubber/Halloysite Nanotubes Composites Affected by Various Silanes. Polymers 2023, 15, 29. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Lee, D.-H.; Fan, Y.; Nam, B.-U.; Lee, J.-E.; Cho, U.-R. Hybrid of bamboo charcoal and silica by tetraethoxysilane hydrolysis over acid catalyst reinforced styrene-butadiene rubber. J. Appl. Polym. Sci. 2018, 135, 46219. [Google Scholar] [CrossRef]

- Vollet, D.R.; Barreiro, L.A.; Paccola, C.E.T.; Awano, C.M.; De Vicente, F.S.; Yoshida, M.; Donatti, D.A. A kinetic modeling for the ultrasound-assisted and oxalic acid-catalyzed hydrolysis of 3-glycidoxypropyltrimethoxysilane. J. Sol-Gel Sci. Technol. 2016, 80, 873–880. [Google Scholar] [CrossRef]

- Negrete; Letoffe, J.-M.; Putaux, J.-L.; David, L.; Bourgeat-Lami, E. Aqueous Dispersions of Silane-Functionalized Laponite Clay Platelets. A First Step toward the Elaboration of Water-Based Polymer/Clay Nanocomposites. Langmuir 2004, 20, 1564–1571. [Google Scholar] [CrossRef]

- Zhong, B.; Jia, Z.; Luo, Y.; Guo, B.; Jia, D. Preparation of halloysite nanotubes supported 2-mercaptobenzimidazole and its application in natural rubber. Compos. Part A Appl. Sci. Manuf. 2015, 73, 63–71. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, Z.; Zhang, L.; Jiang, H.; Li, C. Promoting the dispersibility of silica and interfacial strength of rubber/silica composites prepared by latex compounding. J. Appl. Polym. Sci. 2020, 137, 49526. [Google Scholar] [CrossRef]

- Flory, P.J. Statistical Mechanics of Swelling of Network Structures. J. Chem. Phys. 1950, 18, 108–111. [Google Scholar] [CrossRef]

- ISO 37:2005; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. ISO: Geneva, Switzerland, 2005.

- ISO 34-1:2015; Rubber, Vulcanized or Thermoplastic—Determination of Tear Strength—Part 1: Trouser, Angle and Crescent Test Pieces. ISO: Geneva, Switzerland, 2015.

- ISO 4649:2017; Rubber, Vulcanized or Thermoplastic—Determination of Abrasion Resistance Using a Rotating Cylindrical Drum Device. ISO: Geneva, Switzerland, 2017.

- Tartaglione, G.; Tabuani, D.; Camino, G. Thermal and morphological characterisation of organically modified sepiolite. Microporous Mesoporous Mater. 2008, 107, 161–168. [Google Scholar] [CrossRef]

- Doğan, M.; Turhan, Y.; Alkan, M.; Namli, H.; Turan, P.; Demirbaş, Ö. Functionalized sepiolite for heavy metal ions adsorption. Desalination 2008, 230, 248–268. [Google Scholar] [CrossRef]

- Yan, W.; Liu, D.; Tan, D.; Yuan, P.; Chen, M. FTIR spectroscopy study of the structure changes of palygorskite under heating. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2012, 97, 1052–1057. [Google Scholar] [CrossRef] [PubMed]

- Abali, S.; Aydin, Y.A. Silanization of sepiolite with various silane coupling agents for enhancing oil uptake capacity. Sep. Sci. Technol. 2023, 58, 586–597. [Google Scholar] [CrossRef]

- Duquesne, E.; Moins, S.; Alexandre, M.; Dubois, P. How can Nanohybrids Enhance Polyester/Sepiolite Nanocomposite Properties? Macromol. Chem. Phys. 2007, 208, 2542–2550. [Google Scholar] [CrossRef]

- Ruiz, R.; del Moral, J.C.; Pesquera, C.; Benito, I.; González, F. Reversible folding in sepiolite: Study by thermal and textural analysis. Thermochim. Acta 1996, 279, 103–110. [Google Scholar] [CrossRef]

- Nagata, H.; Shimoda, S.; Sudo, T. On Dehydration of Bound Water of Sepiolite. Clays Clay Miner. 1974, 22, 285–291. [Google Scholar] [CrossRef]

- García, N.; Guzmán, J.; Benito, E.; Esteban-Cubillo, A.; Aguilar, E.; Santarén, J.; Tiemblo, P. Surface Modification of Sepiolite in Aqueous Gels by Using Methoxysilanes and Its Impact on the Nanofiber Dispersion Ability. Langmuir 2011, 27, 3952–3959. [Google Scholar] [CrossRef] [PubMed]

- Payne, A.R.; Whittaker, R.E. Low Strain Dynamic Properties of Filled Rubbers. Rubber Chem. Technol. 1971, 44, 440–478. [Google Scholar] [CrossRef]

- Wang, Z.-P.; Zhang, H.; Liu, Q.; Wang, S.-J.; Yan, S.-K. Effects of Interface on the Dynamic Hysteresis Loss and Static Mechanical Properties of Illite Filled SBR Composites. Chin. J. Polym. Sci. 2022, 40, 1493–1502. [Google Scholar] [CrossRef]

- Yan, H.; Sun, K.; Zhang, Y.; Zhang, Y.; Fan, Y. Effects of silane coupling agents on the vulcanization characteristics of natural rubber. J. Appl. Polym. Sci. 2004, 94, 1511–1518. [Google Scholar] [CrossRef]

- Rooj, S.; Das, A.; Thakur, V.; Mahaling, R.N.; Bhowmick, A.K.; Heinrich, G. Preparation and properties of natural nanocomposites based on natural rubber and naturally occurring halloysite nanotubes. Mater. Des. 2010, 31, 2151–2156. [Google Scholar] [CrossRef]

- He, S.; Xue, Y.; Lin, J.; Zhang, L.; Du, X.; Chen, L. Effect of silane coupling agent on the structure and mechanical properties of nano-dispersed clay filled styrene butadiene rubber. Polym. Compos. 2016, 37, 890–896. [Google Scholar] [CrossRef]

- Lipińska, M.; Imiela, M. Morphology, rheology and curing of (ethylene-propylene elastomer/hydrogenate acrylonitrile-butadiene rubber) blends reinforced by POSS and organoclay. Polym. Test. 2019, 75, 26–37. [Google Scholar] [CrossRef]

- Wu, X. Natural rubber/graphene oxide composites: Effect of sheet size on mechanical properties and strain-induced crystallization behavior. Express Polym. Lett. 2015, 9, 672–685. [Google Scholar] [CrossRef]

- Cao, L.; Sinha, T.K.; Tao, L.; Li, H.; Zong, C.; Kim, J.K. Synergistic reinforcement of silanized silica-graphene oxide hybrid in natural rubber for tire-tread fabrication: A latex based facile approach. Compos. Part B Eng. 2019, 161, 667–676. [Google Scholar] [CrossRef]

| Chemical Name | Functional Group | Structural Formula | M (g/mol) |

|---|---|---|---|

| Triethoxyvinylsilane (VTES) | vinyl |  | 190.31 |

| 3-Mercaptopropyltriethoxysilane (MPTES) | mercapto |  | 238.42 |

| Bis[3-(triethoxysilyl)propyl] tetrasulfide (TESPT) | tetrasulfide |  | 538.95 |

| Materials | Sep/NR | VSep/NR | MSep/NR | TSep/NR |

|---|---|---|---|---|

| Masterbatches | 120 b | 120 | 120 | 120 |

| VTES | 0 | 2 | 0 | 0 |

| MPTES | 0 | 0 | 2 | 0 |

| TESPT | 0 | 0 | 0 | 2 |

| zinc oxide | 5 | 5 | 5 | 5 |

| stearic acid | 5 | 5 | 5 | 5 |

| Accelerator CZ | 2 | 2 | 2 | 2 |

| Accelerator DM | 1 | 1 | 1 | 1 |

| sulfur | 2 | 2 | 2 | 2 |

| Materials | Weight Loss/% | Modifier/% | Grafted Amount/(mequiv/g) | ||

|---|---|---|---|---|---|

| 40–150 °C | 150–650 °C a | 650–800 °C | |||

| Sep | 7.50 | 5.90 | 1.02 | - | - |

| VTES-Sep | 5.57 | 8.73 | 1.06 | 2.83 | 0.282 |

| MPTES-Sep | 5.13 | 9.56 | 1.66 | 3.66 | 0.251 |

| TESPT-Sep | 4.27 | 11.06 | 2.28 | 5.16 | 0.120 |

| Samples | t10/min | t90/min | ML/dN∙m | MH/dN∙m | MH−ML/dN∙m |

|---|---|---|---|---|---|

| Sep/NR | 5.29 | 8.89 | 0.84 | 10.09 | 9.25 |

| VSep/NR | 5.37 | 11.19 | 0.57 | 10.21 | 9.64 |

| MSep/NR | 3.33 | 6.94 | 0.57 | 10.55 | 9.98 |

| TSep/NR | 4.91 | 8.39 | 0.65 | 10.81 | 10.16 |

| Samples | Modulus at 100%/MPa | Modulus at 300%/MPa | Tensile Strength/MPa | Elongation at Break/% | Tear Strength/N·mm−1 |

|---|---|---|---|---|---|

| Sep/NR | 3.45 ± 0.33 | 8.82 ± 0.88 | 30.0 ± 1.8 | 618 ± 58 | 49.6 ± 1.7 |

| VSep/NR | 3.61 ± 0.27 | 10.28 ± 0.91 | 29.98 ± 2.1 | 640 ± 47 | 50.3 ± 2.0 |

| MSep/NR | 4.14 ± 0.15 | 14.99 ± 0.53 | 23.4 ± 1.1 | 476 ± 35 | 58.1 ± 1.5 |

| TSep/NR | 4.43 ± 0.19 | 16.87 ± 0.62 | 25.5 ± 1.6 | 450 ± 36 | 60.3 ± 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Z.; Zhou, D.; Chen, Q.; Xin, Z. Effect of Different Silane Coupling Agents In-Situ Modified Sepiolite on the Structure and Properties of Natural Rubber Composites Prepared by Latex Compounding Method. Polymers 2023, 15, 1620. https://doi.org/10.3390/polym15071620

Hou Z, Zhou D, Chen Q, Xin Z. Effect of Different Silane Coupling Agents In-Situ Modified Sepiolite on the Structure and Properties of Natural Rubber Composites Prepared by Latex Compounding Method. Polymers. 2023; 15(7):1620. https://doi.org/10.3390/polym15071620

Chicago/Turabian StyleHou, Zhanfeng, Dawei Zhou, Qi Chen, and Zhenxiang Xin. 2023. "Effect of Different Silane Coupling Agents In-Situ Modified Sepiolite on the Structure and Properties of Natural Rubber Composites Prepared by Latex Compounding Method" Polymers 15, no. 7: 1620. https://doi.org/10.3390/polym15071620

APA StyleHou, Z., Zhou, D., Chen, Q., & Xin, Z. (2023). Effect of Different Silane Coupling Agents In-Situ Modified Sepiolite on the Structure and Properties of Natural Rubber Composites Prepared by Latex Compounding Method. Polymers, 15(7), 1620. https://doi.org/10.3390/polym15071620