The Effects of Different Molding Orientations, Highly Accelerated Aging, and Water Absorption on the Flexural Strength of Polyether Ether Ketone (PEEK) Fabricated by Fused Deposition Modeling

Abstract

1. Introduction

2. Materials and Methods

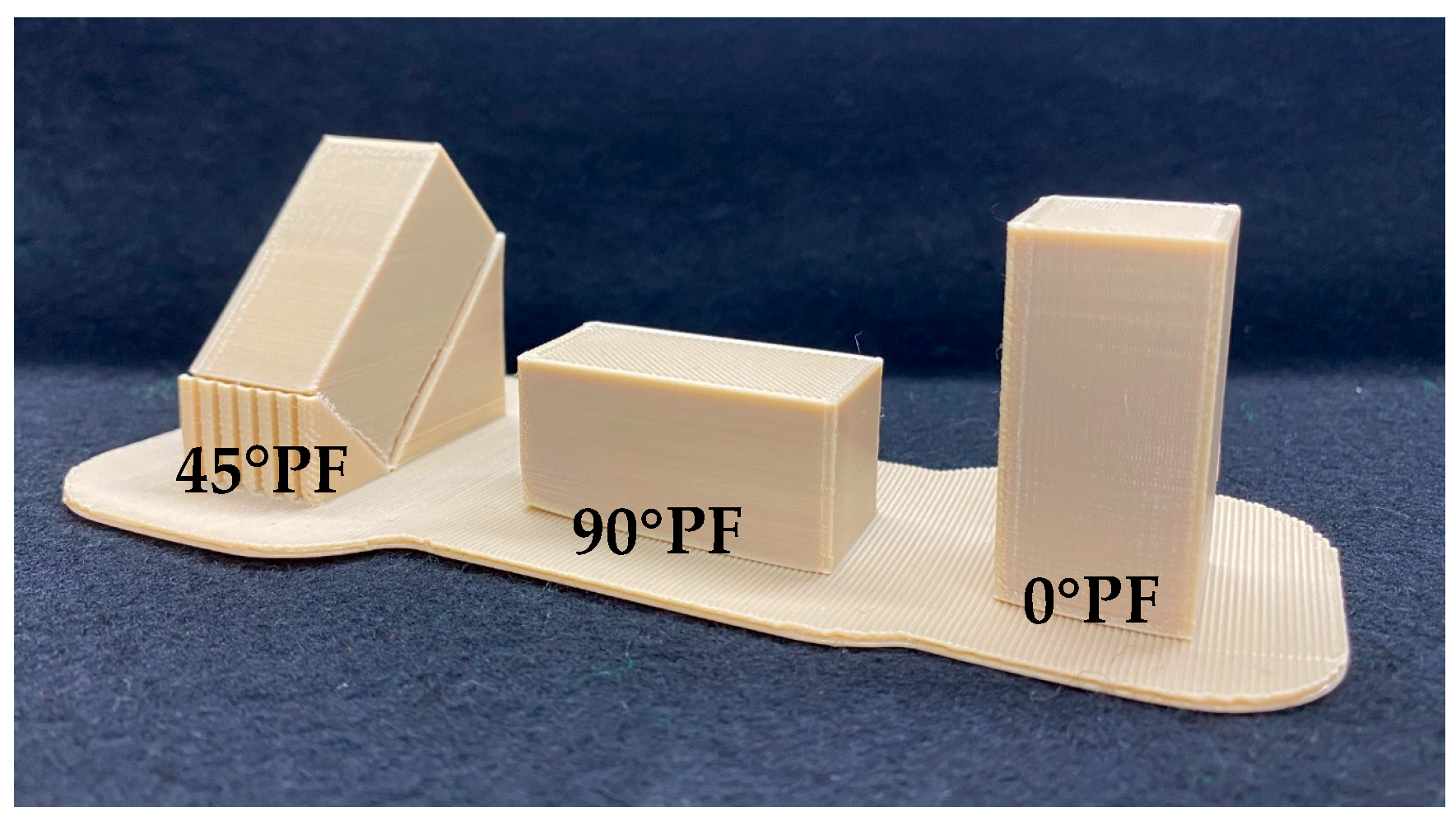

2.1. Experiment 1: 3-Point Bending Test

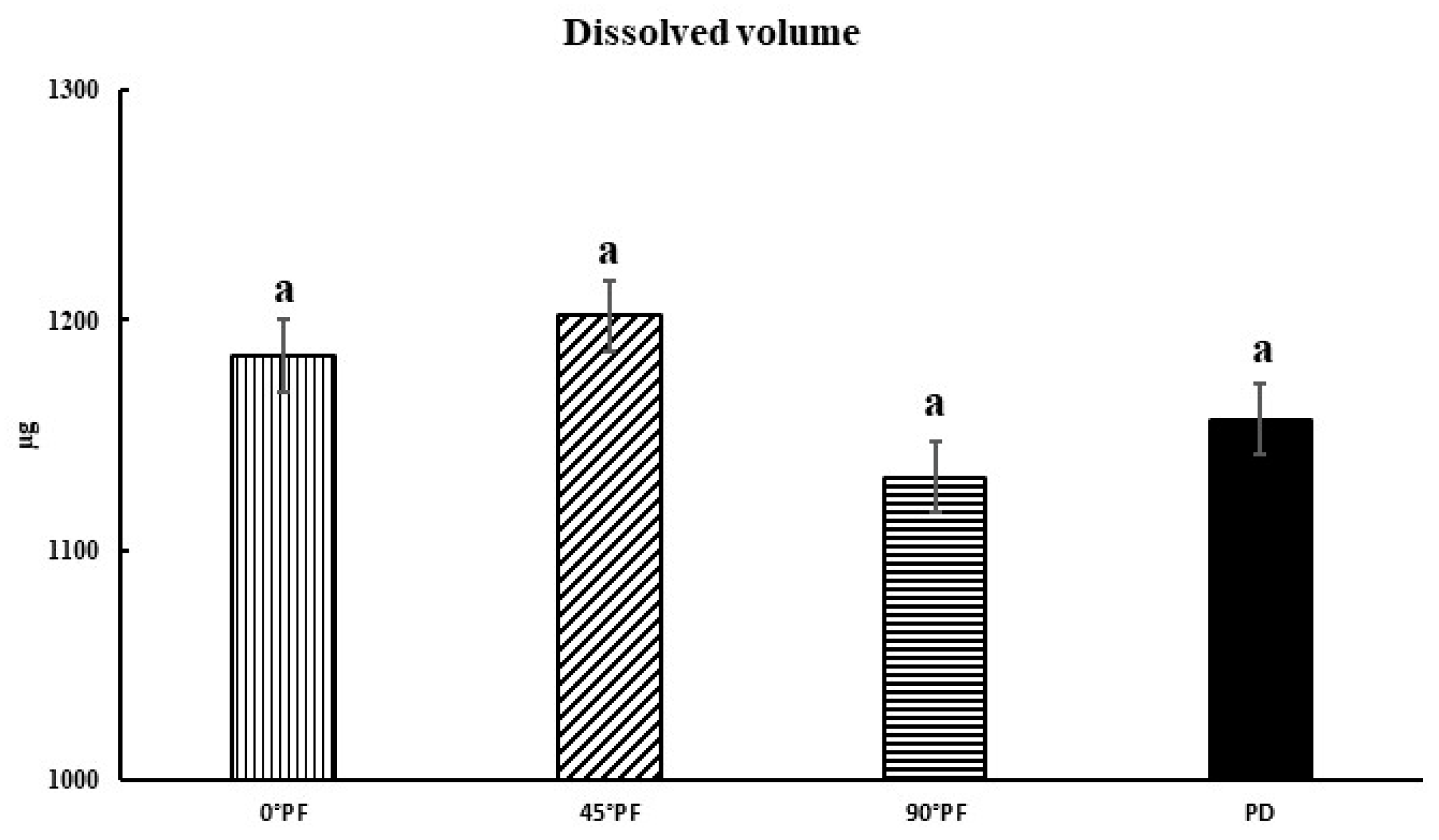

2.2. Experiment 2: Water Absorption and Dissolution Test

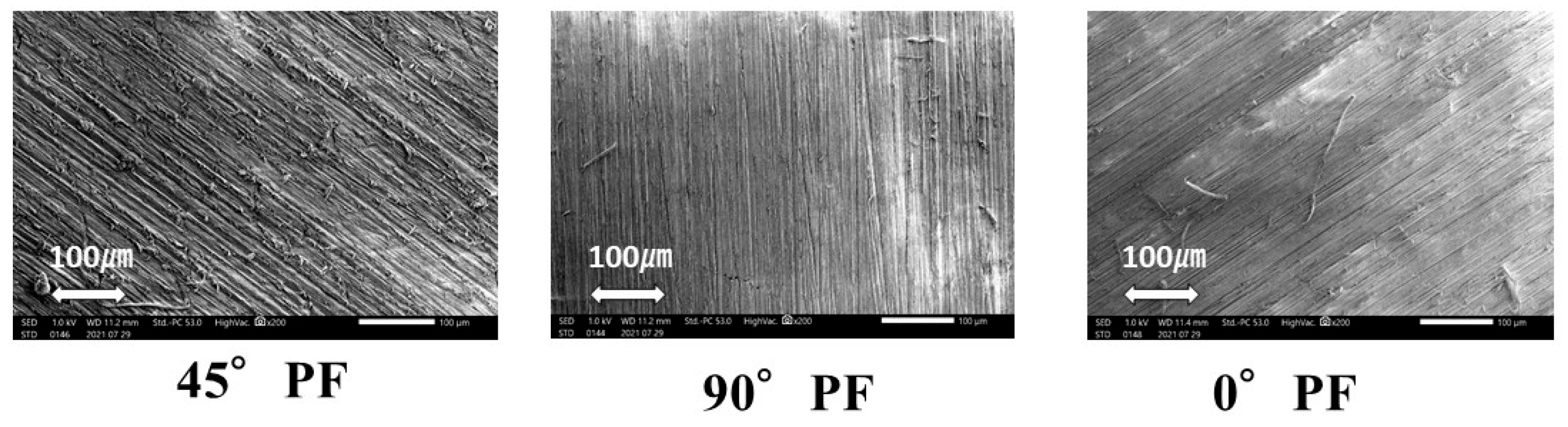

2.3. Experiment 3: Scanning Electron Microscopy (SEM)

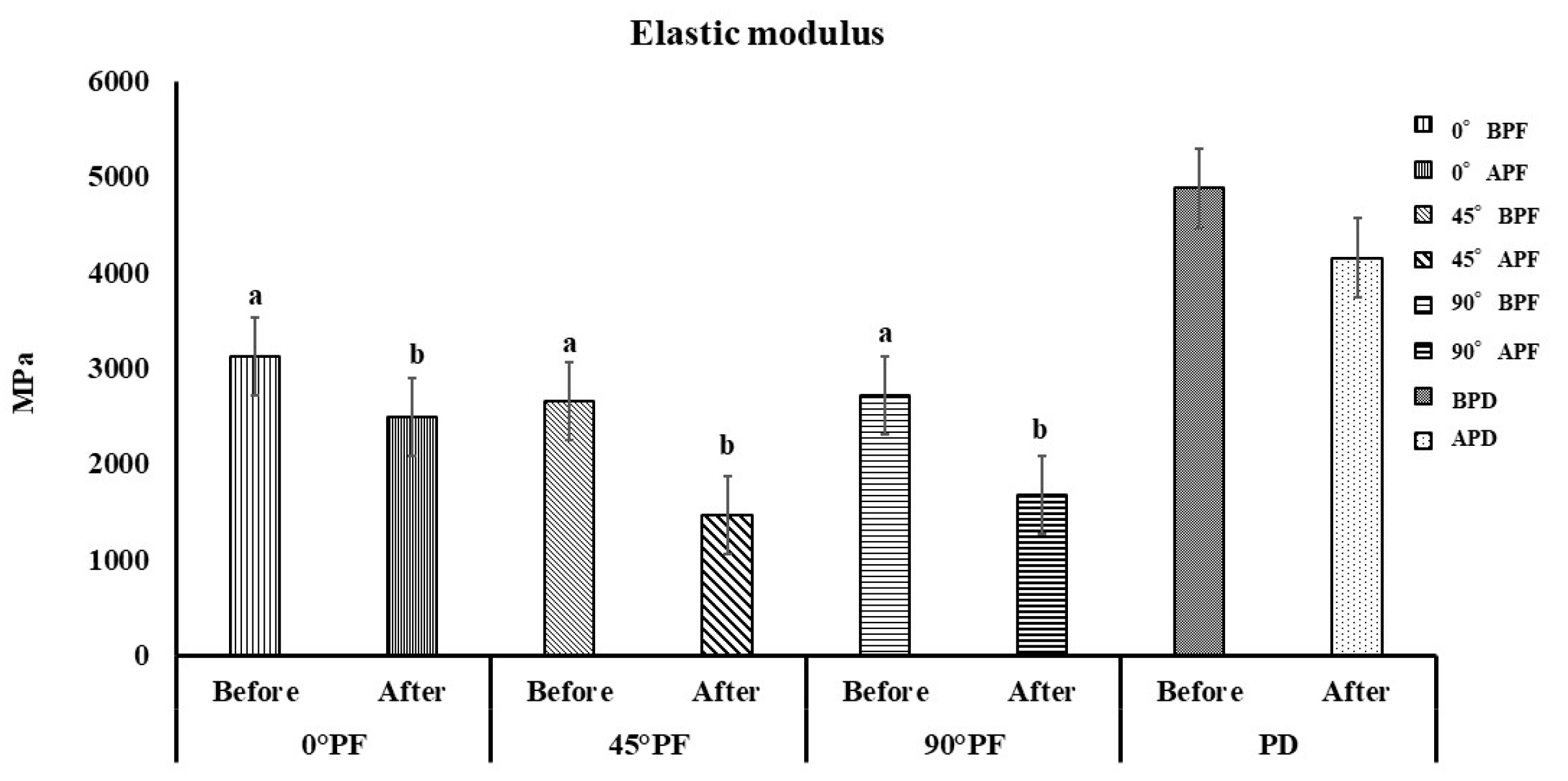

3. Results

4. Discussion

5. Conclusions

- (1)

- The maximum flexural strength of FDM PEEK objects fabricated at 0° to the molding stage was measured without fracture. The same was also true after highly accelerated aging. Apparently, when the force was applied perpendicular to the molding orientations, the stress was distributed over the entire specimen, which resulted in strong resistance to fracture.

- (2)

- Highly accelerated aging degraded the mechanical properties of FDM PEEK objects due to defects in their crystal structure. This occurred in all stacking directions.

- (3)

- No significant differences in water absorption or solubility were observed among the fabrication methods. Therefore, it was unlikely that moisture during the highly accelerated aging process affected the physical properties of FDM PEEK.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kurtz, S.M.; Devine, J.N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 2007, 28, 4845–4869. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.-T.; Koak, J.-Y.; Lim, Y.-J.; Kim, S.-K.; Kwon, H.-B.; Kim, M.-J. Stress shielding and fatigue limits of poly-ether-ether-ketone dental implants. J. Biomed. Mater. Res. Part B Appl. Biomater. 2012, 100B, 1044–1052. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.S.; Shin, J.H.; Kim, J.E.; Kim, J.H.; Lee, W.C.; Shin, S.W.; Lee, J.Y. Biomechanical evaluation of a tooth restored with high performance polymer PEKK post-core system: A 3D finite element analysis. BioMed Res. Int. 2017, 2017, 1373127. [Google Scholar] [CrossRef] [PubMed]

- Stawarczyk, B.; Eichberger, M.; Uhrenbacher, J.; Wimmer, T.; Edelhoff, D.; Schmidlin, P.R. Three-unit reinforced polyetheretherketone composite FDPs: Influence of fabrication method on load-bearing capacity and failure types. Dent. Mater. J. 2015, 34, 7–12. [Google Scholar] [CrossRef]

- Maekawa, M.; Kanno, Z.; Wada, T.; Hongo, T.; Doi, H.; Hanawa, T.; Ono, T.; Uo, M. Mechanical properties of orthodontic wires made of super engineering plastic. Dent. Mater. J. 2015, 34, 114–119. [Google Scholar] [CrossRef]

- Tannous, F.; Steiner, M.; Shahin, R.; Kern, M. Retentive forces and fatigue resistance of thermoplastic resin clasps. Dent. Mater. 2012, 28, 273–278. [Google Scholar] [CrossRef]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. J. Prosthodont. Res. 2016, 60, 12–19. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, J.; Sun, S.; Meng, W.; Zhang, Y.; Wu, J. Current treatment methods to improve the bioactivity and bonding strength of PEEK for dental application: A systematic review. Eur. Polym. J. 2023, 183, 111757. [Google Scholar] [CrossRef]

- Wimmer, T.; Huffmann, A.M.S.; Eichberger, M.; Schmidlin, P.R.; Stawarczyk, B. Two-body wear rate of PEEK, CAD/CAM resin composite and PMMA: Effect of specimen geometries, antagonist materials and test set-up configuration. Dent. Mater. 2016, 32, e127–e136. [Google Scholar] [CrossRef]

- Harb, I.E.; Abdel-Khalek, E.A.; Hegazy, S.A. CAD/CAM Constructed Poly(etheretherketone) (PEEK) Framework of Kennedy Class I Removable Partial Denture: A Clinical Report. J. Prosthodont. 2018, 28, e595–e598. [Google Scholar] [CrossRef]

- Mangano, F.; Mangano, C.; Margiani, B.; Admakin, O. Combining Intraoral and Face Scans for the Design and Fabrication of Computer-Assisted Design/Computer-Assisted Manufacturing (CAD/CAM) Polyether-Ether-Ketone (PEEK) Implant-Supported Bars for Maxillary Overdentures. Scanning 2019, 2019, 4274715. [Google Scholar] [CrossRef]

- Papathanasiou, I.; Kamposiora, P.; Papavasiliou, G.; Ferrari, M. The use of PEEK in digital prosthodontics: A narrative review. BMC Oral Health 2020, 20, 217. [Google Scholar] [CrossRef]

- Lalama, M.; Rocha, M.G.; O’Neill, E.; Zoidis, P.; Dmdms, M.L.; DDSMScPhD, M.G.R.; Ddsms, E.O.N.; DDSMScPhD, P.Z. Polyetheretherketone (PEEK) Post and Core Restorations: A 3D Accuracy Analysis between Heat-Pressed and CAD-CAM Fabrication Methods. J. Prosthodont. 2021, 31, 537–542. [Google Scholar] [CrossRef]

- Whitty, T. PEEK—A New Material for CAD/CAM Dentistry; Juvora Dental Innovations: Thornton-Cleveleys, UK, 2014. [Google Scholar]

- Alexakou, E.; Damanaki, M.; Zoidis, P.; Bakiri, E.; Mouzis, N.; Smidt, G.; Kourtis, S. PEEK High Performance Polymers: A Review of Properties and Clinical Applications in Prosthodontics and Restorative Dentistry. Eur. J. Prosthodont. Restor. Dent. 2019, 27, 113–121. [Google Scholar]

- Tasopoulos, T.; Chatziemmanouil, D.; Kouveliotis, G.; Karaiskou, G.; Wang, J.; Zoidis, P. PEEK Maxillary Obturator Prosthesis Fabrication Using Intraoral Scanning, 3D Printing, and CAD/CAM. Int. J. Prosthodont. 2020, 33, 333–340. [Google Scholar] [CrossRef]

- Aldhuwayhi, S.; Alauddin, M.S.; Martin, N. The Structural Integrity and Fracture Behaviour of Teeth Restored with PEEK and Lithium-Disilicate Glass Ceramic Crowns. Polymers 2022, 14, 1001. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Development of Pure Poly Vinyl Chloride (PVC) with Excellent 3D Printability and Macro- and Micro-Structural Properties. Macromol. Mater. Eng. 2022, 2200568. [Google Scholar] [CrossRef]

- Soleyman, E.; Aberoumand, M.; Rahmatabadi, D.; Soltanmohammadi, K.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. Assessment of controllable shape transformation, potential applications, and tensile shape memory properties of 3D printed PETG. J. Mater. Res. Technol. 2022, 18, 4201–4215. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 3D printing of PLA-TPU with different component ratios: Fracture toughness, mechanical properties, and morphology. J. Mater. Res. Technol. 2022, 21, 3970–3981. [Google Scholar] [CrossRef]

- Moradi, M.; Aminzadeh, A.; Rahmatabadi, D.; Rasouli, S.A. Statistical and Experimental Analysis of Process Parameters of 3D Nylon Printed Parts by Fused Deposition Modeling: Response Surface Modeling and Optimization. J. Mater. Eng. Perform. 2021, 30, 5441–5454. [Google Scholar] [CrossRef]

- Nguyen, N.; Park, J.G.; Zhang, S.; Liang, R. Recent Advances on 3D Printing Technique for Thermal-Related Applications. Adv. Eng. Mater. 2018, 20, 1700876. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Chen, Q.; Ye, P.; Advincula, R.C. 3D Printing of Polymer Nanocomposites via Stereolithography. Macromol. Mater. Eng. 2017, 302, 1600553. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. A parametric investigation of the friction performance of PC-ABS parts processed by FDM additive manufacturing process. Polym. Adv. Technol. 2017, 28, 1911–1918. [Google Scholar] [CrossRef]

- Thieringer, F.M.; Sharma, N.; Mootien, A.; Schumacher, R.; Honigmann, P. (Eds.) Patient specific implants from a 3D printer–an innovative manufacturing process for custom PEEK implants in cranio-maxillofacial surgery. In Proceedings of the International Conference on Additive Manufacturing in Products and Applications, Zurich, Switzerland, 13–15 September 2017; Springer: Berlin, Germany, 2017; pp. 308–315. [Google Scholar] [CrossRef]

- Xiaoyong, S.; Liangcheng, C.; Honglin, M.; Peng, G.; Zhanwei, B.; Cheng, L. (Eds.) Experimental analysis of high temperature PEEK materials on 3D printing test. In Proceedings of the 2017 9th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Changsha, China, 14–15 January 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Caulfield, B.; McHugh, P.E.; Lohfeld, S. Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- Majewski, C.; Hopkinson, N. Effect of section thickness and build orientation on tensile properties and material characteristics of laser sintered nylon-12 parts. Rapid Prototyp. J. 2011, 17, 176–180. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.; Mahapatra, S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Schultz, J.M. Microstructural aspects of failure in semicrystalline polymers. Polym. Eng. Sci. 1984, 24, 770–785. [Google Scholar] [CrossRef]

- Coppola, F.; Greco, R.; Ragosta, G. Isotactic polypropylene/EPDM blends: Effect of testing temperature and rubber content on fracture. J. Mater. Sci. 1986, 21, 1775–1785. [Google Scholar] [CrossRef]

- Greco, R.; Ragosta, G. Isotactic polypropylenes of different molecular characteristics: Influence of crystallization conditions and annealing on the fracture behaviour. J. Mater. Sci. 1988, 23, 4171–4180. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, W.; Yang, W.; Wang, G. Flexural Properties and Fracture Behavior of CF/PEEK in Orthogonal Building Orientation by FDM: Microstructure and Mechanism. Polymers 2019, 11, 656. [Google Scholar] [CrossRef]

- Uehara, T.; Niino, T. Powder Bed Fusion (PBF) of Polyetheretherketone (PEEK). J. Jpn. Soc. Precis. Eng. 2015, 2015S, 213–214. [Google Scholar] [CrossRef]

| Code | Product Name | Component | LOT Number | Manufacture |

|---|---|---|---|---|

| PF | PEEK filament | Poly-ether-ether-ketone | 202,653 | INTAMSYS, Shanghai, China |

| PD | PEEK Biosolution | Poly-ether-ether-ketone TiO2 | 40,318 | Merz Pharma GmbH & Co, Frankfurt, Germany |

| Molding Conditions | |

|---|---|

| Stacking Pitch | 0.1 mm |

| Nozzle system | 0.4 mm |

| Infill | 100% |

| Infill pattern | line |

| Material | PEEK |

| Speed | 60 mm/s |

| Fan speed | 50% |

| Support overhang angle | 50° |

| Support distance | 0.1 mm |

| Build plate adhesion type | Raft |

| Nozzle temperature | 410 °C |

| Chamber temperature | 90 °C |

| Temperature (°C) | Setting Time (h) | |

|---|---|---|

| Step 1 | 90 | 2 |

| Step 2 | 90 | 4 |

| Step 3 | 120 | 1 |

| Step 4 | 120 | 3 |

| Step 5 | 150 | 1 |

| Step 6 | 150 | 8 |

| Step 7 | 200 | 2 |

| Step 8 | 200 | 6 |

| Step 9 | 150 | 4 |

| Step 10 | 150 | 4 |

| Step 11 | 0 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miura, D.; Ishida, Y.; Shinya, A. The Effects of Different Molding Orientations, Highly Accelerated Aging, and Water Absorption on the Flexural Strength of Polyether Ether Ketone (PEEK) Fabricated by Fused Deposition Modeling. Polymers 2023, 15, 1602. https://doi.org/10.3390/polym15071602

Miura D, Ishida Y, Shinya A. The Effects of Different Molding Orientations, Highly Accelerated Aging, and Water Absorption on the Flexural Strength of Polyether Ether Ketone (PEEK) Fabricated by Fused Deposition Modeling. Polymers. 2023; 15(7):1602. https://doi.org/10.3390/polym15071602

Chicago/Turabian StyleMiura, Daisuke, Yoshiki Ishida, and Akikazu Shinya. 2023. "The Effects of Different Molding Orientations, Highly Accelerated Aging, and Water Absorption on the Flexural Strength of Polyether Ether Ketone (PEEK) Fabricated by Fused Deposition Modeling" Polymers 15, no. 7: 1602. https://doi.org/10.3390/polym15071602

APA StyleMiura, D., Ishida, Y., & Shinya, A. (2023). The Effects of Different Molding Orientations, Highly Accelerated Aging, and Water Absorption on the Flexural Strength of Polyether Ether Ketone (PEEK) Fabricated by Fused Deposition Modeling. Polymers, 15(7), 1602. https://doi.org/10.3390/polym15071602