Effect of Nanometric Particles of Bentonite on the Mechanical Properties of a Thermoset Polymeric Matrix Reinforced with Hemp Fibers

Abstract

1. Introduction

- ▪

- The literature consulted thus far does not report work with these materials and the manufacturing method proposed here.

- ▪

- It was possible to verify that nanometric-sized bentonite particles guarantee a better interaction with the matrix.

- ▪

- The use of nanometric bentonite particles improves the stiffness of the compound by increasing its tensile and flexural elastic modulus.

2. Materials and Methods

2.1. Materials

2.2. Fabrication of the Composite

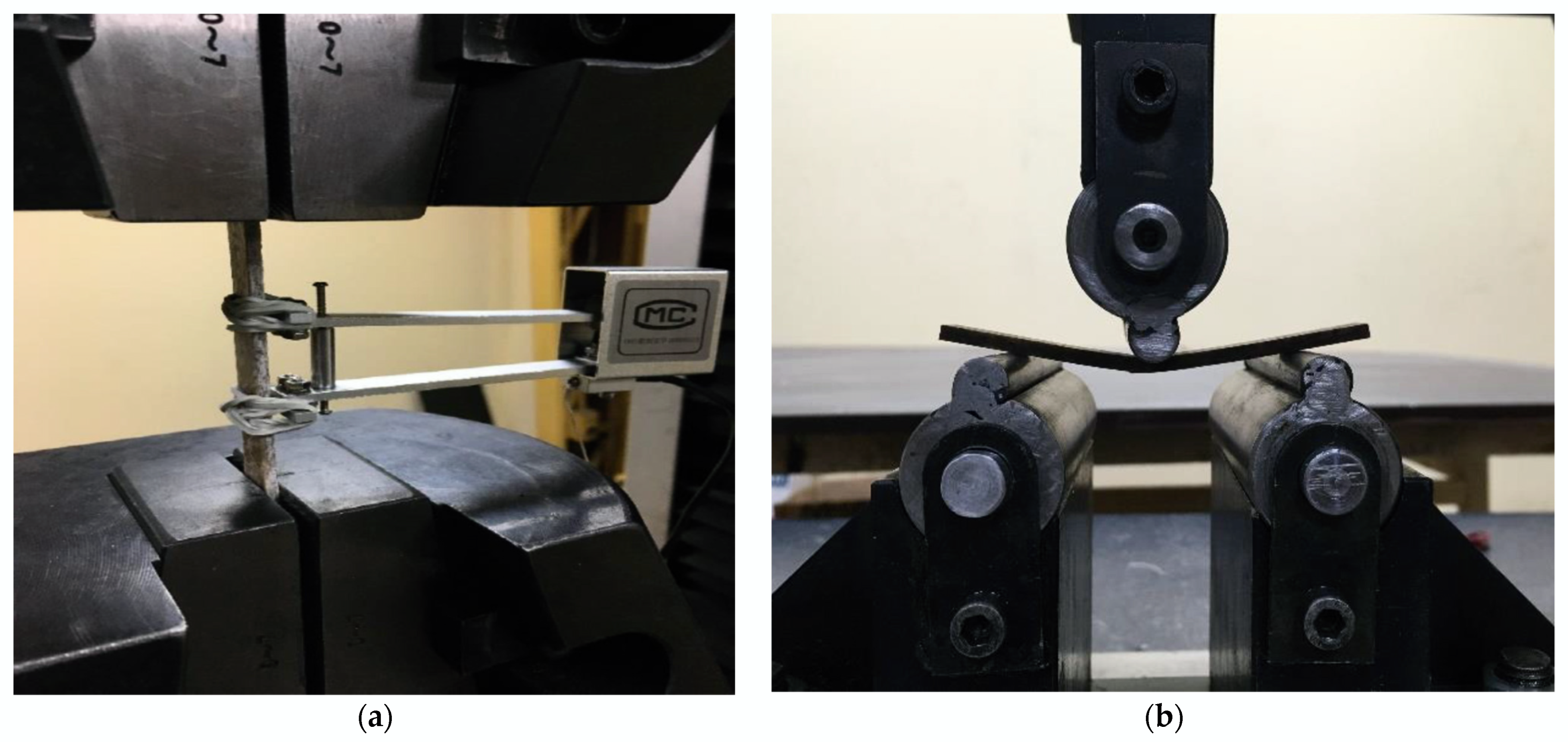

2.3. Mechanical Characterization

3. Results and Discussion

3.1. Energy-Dispersive X-ray Spectroscopy (EDS)

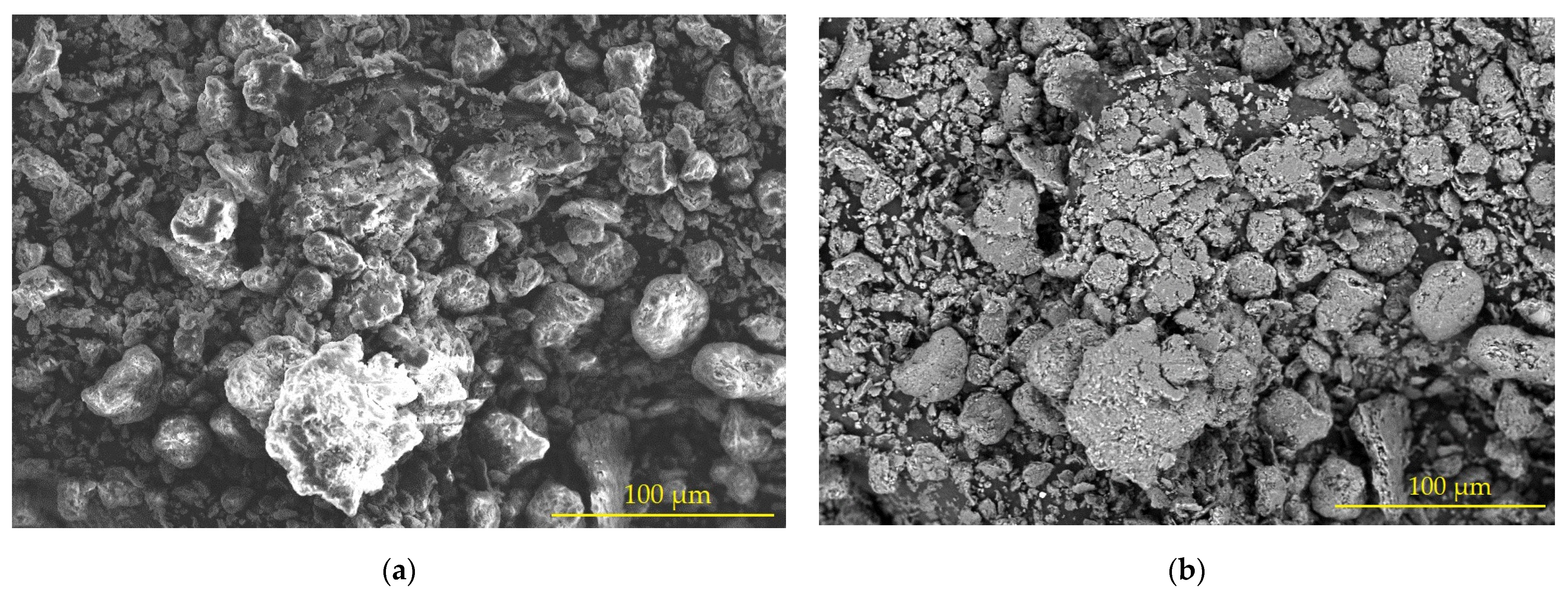

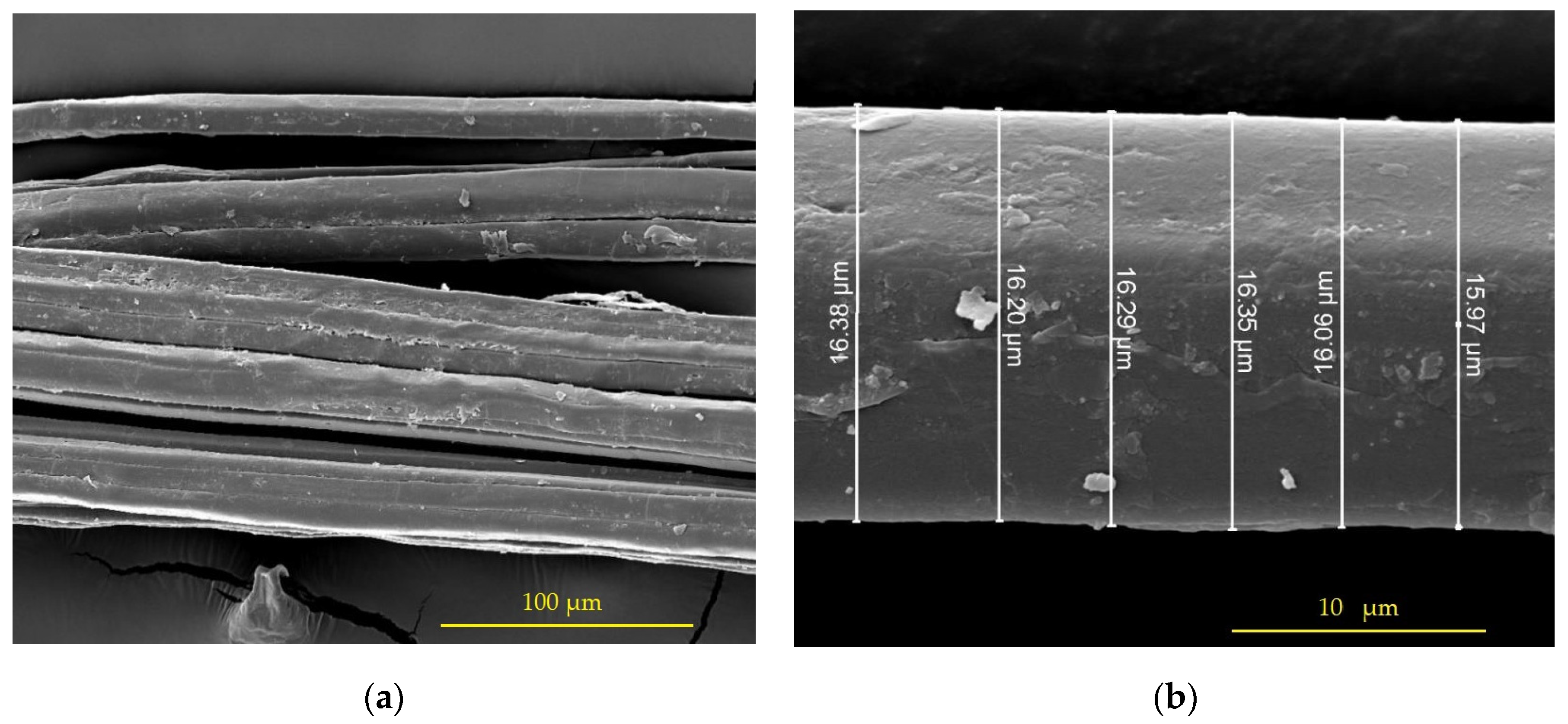

3.2. Scanning Electron Microscopy

3.3. Tensile Strength

3.4. Flexural Strength

4. Conclusions

- Bentonite clay improved the rigidity of the material, reporting an increase in the elastic modulus, whose maximum value of 7938 MPa was found in the sample that had an addition of 15% of fibers, which represents an increase of 45.01% with that compared to its pair, which was made up of polyester polymer and fibers.

- The tensile strength was affected by the addition of bentonite and all of the samples showed a decrease compared to their peers. Except for the B5H35 sample, which presented a value of 34.38 MPa, an increase of 26.96% with respect to its pair made of polyester polymer and fibers.

- The flexural elastic modulus improved in all of the samples with the addition of bentonite when compared with similar ones that had reinforcing fibers. The best result of 8453 MPa with an increase of 139.26% was found for a combination of the 35% addition of hemp fibers (B5H35 sample).

- Flexural strength showed improvements when bentonite was added, except for cases where it was combined with the 25 and 40% addition of hemp fibers. The maximum value found of 83.51 MPa, which represents an increase of 63.26% with respect to its pair composed of polyester polymer and hemp fibers, was found for a 30% addition of fibers.

- For all materials manufactured, either with the addition of fibers alone or with the addition of fibers and bentonites, a good distribution of the fibers in the matrix was achieved, and a good adhesion between the matrix and the fibers as well as the absence of defects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yashas Gowda, T.G.; Sanjay, M.R.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. Polymer matrix-natural fiber composites: An overview. Cogent Eng. 2018, 5, 1446667. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Bi, X.; Huang, R. 3D printing of natural fiber and composites: A state-of-the-art review. Mater. Des. 2022, 222, 111065. [Google Scholar] [CrossRef]

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine Application of Fiber Reinforced Composites: A Review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amaoka, K.; Masubuchi, Y.; Yamamoto, T.; Yamanaka, A.; Arai, M.; Takahashi, J. Overview of automotive structural composites technology developments in Japan. Compos. Sci. Technol. 2018, 155, 221–246. [Google Scholar] [CrossRef]

- Baschnagel, F.; Härdi, R.; Triantafyllidis, Z.; Meier, U.; Terrasi, G.P. Fatigue and Durability of Laminated Carbon Fibre Reinforced Polymer Straps for Bridge Suspenders. Polymers 2018, 10, 169. [Google Scholar] [CrossRef]

- Sun, Z. Progress in the research and applications of natural fiber-reinforced polymer matrix composites. Sci. Eng. Compos. Mater. 2018, 25, 835–846. [Google Scholar] [CrossRef]

- Ankit; Rinawa, M.; Chauhan, P.; Suresh, D.; Kumar, S.; Santhosh Kumar, R. A review on mechanical properties of natural fiber reinforced polymer (NFRP) composites. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Suriyaprakash, M.; Nallusamy, M.; Shri Ram Shanjai, K.; Akash, N.; Rohith, V. Experimental investigation on mechanical properties of Ramie, Hemp fiber and coconut shell particle hybrid composites with reinforced epoxy resin. Mater. Today Proc. 2022, 72, 2952–2956. [Google Scholar] [CrossRef]

- Hossain, M.R.; Islam, M.A.; Van Vuurea, A.; Verpoest, I. Tensile Behavior of Environment Friendly Jute Epoxy Laminated Composite. Procedia Eng. 2013, 56, 782–788. [Google Scholar] [CrossRef]

- Miliket, T.A.; Ageze, M.B.; Tigabu, M.T.; Zeleke, M.A. Experimental characterizations of hybrid natural fiber-reinforced composite for wind turbine blades. Heliyon 2022, 8, e09092. [Google Scholar] [CrossRef] [PubMed]

- Mahesh, A.; Rudresh, B.M.; Reddappa, H.N. Potential of natural fibers in the modification of mechanical behavior of polypropylene hybrid composites. Mater. Today Proc. 2022, 54, 131–136. [Google Scholar] [CrossRef]

- Paladugu, S.R.M.; Divya Aparna, N.; Rama Sreekanth, P.S. Experimental investigations and mechanical analysis of hybrid natural fibre reinforced composites. Mater. Today Proc. 2022, 56, 1115–1119. [Google Scholar] [CrossRef]

- Maleki Moghadam, R.; Saber-Samandari, S.; Hosseini, S.A. On the tensile behavior of clay-epoxy nanocomposite considering interphase debonding damage via mixed-mode cohesive zone material. Compos. Part B Eng. 2016, 89, 303–315. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Fierascu, R.C.; Gabor, A.R.; Nicolae, C.A. Effect of hemp fiber length on the mechanical and thermal properties of polypropylene/SEBS/hemp fiber composites. J. Mater. Res. Technol. 2020, 9, 10768–10781. [Google Scholar] [CrossRef]

- El Boukili, G.; Erba, S.; Kifani-Sahban, F.; Khaldoun, A. Improving rheological and mechanical properties of non-plastic clay soil from Bensmim region (Morocco) using bentonite additions: Suitability for building application. J. Build. Eng. 2022, 63, 105525. [Google Scholar] [CrossRef]

- Liu, M.; Hu, Y.; Lai, Z.; Yan, T.; He, X.; Wu, J.; Lu, Z.; Lv, S. Influence of various bentonites on the mechanical properties and impermeability of cement mortars. Constr. Build. Mater. 2020, 241, 118015. [Google Scholar] [CrossRef]

- Victoria-Martínez, U.; Loera-Serna, S.; Vázquez-Cerón, E.R. Composites of bentonite mixed with natural fibers as acoustic absorption material. Sci. Talks 2022, 4, 100078. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, X.-F.; Wang, Z.; Peng, K.-M.; Lu, L.-J.; Liu, J. Composite-polymer modified bentonite enhances anti-seepage and barrier performance under high-concentration heavy-metal solution. J. Clean. Prod. 2022, 376, 134253. [Google Scholar] [CrossRef]

- Arash, S.; Akbari, B.; Ghaleb, S.; Kaffashi, B.; Marouf, B.T. Preparation of PLA-TPU-Nanoclay composites and characterization of their morphological, mechanical, and shape memory properties. J. Mech. Behav. Biomed. Mater. 2023, 2023, 105642. [Google Scholar] [CrossRef]

- Mahadeva Raju, G.K.; Dakshayini, B.S.; Madhu, G.M.; Ameen Khan, M.; Dinesh Sankar Reddy, P. Characterizing and Modeling of Mechanical Properties of Epoxy Polymer Composites Reinforced with Bentonite Clay. Mater. Today Proc. 2018, 5, 28098–28107. [Google Scholar] [CrossRef]

- Mauroy, H.; Plivelic, T.S.; Suuronen, J.-P.; Hage, F.S.; Fossum, J.O.; Knudsen, K.D. Anisotropic clay–polystyrene nanocomposites: Synthesis, characterization and mechanical properties. Appl. Clay Sci. 2015, 108, 19–27. [Google Scholar] [CrossRef]

- Fernández, M.V.; Rivera, J.L.V.; Rodríguez, F.P.; Losada, H.F.; Abreu, M.E.F.; Diaz, F.R.V.; Soto, A.R.; Alvarez, A.A.; Quinteros, R.; Ketterer, C.G.; et al. Mechanical Characterization of a Polymer/Natural Fibers/Bentonite Composite Material with Implementation of a Continuous Damage Model. Appl. Sci. 2023, 13, 2677. [Google Scholar] [CrossRef]

- Seghar, S.; Azem, S.; Aït Hocine, N. Effects of Clay Nanoparticles on the Mechanical and Physical Properties of Unsaturated Polyester. Adv. Sci. Lett. 2011, 4, 3424–3430. [Google Scholar] [CrossRef]

- Onyedika, G.O.; Onuegbu, G.C.; Onuoha, C. Modeling the Mechanical Properties of Clay Powder Filled Recycled Low Density Polyethylene Composites. J. Mater. Sci. Chem. Eng. 2020, 8, 36–47. [Google Scholar] [CrossRef]

- Kutvonen, A.; Rossi, G.; Puisto, S.R.; Rostedt, N.K.J.; Ala-Nissila, T. Influence of nanoparticle size, loading, and shape on the mechanical properties of polymer nanocomposites. J. Chem. Phys. 2012, 137, 214901. [Google Scholar] [CrossRef] [PubMed]

- Roohani-Esfahani, S.-I.; Nouri-Khorasani, S.; Lu, Z.; Appleyard, R.; Zreiqat, H. The influence hydroxyapatite nanoparticle shape and size on the properties of biphasic calcium phosphate scaffolds coated with hydroxyapatite–PCL composites. Biomaterials 2010, 31, 5498–5509. [Google Scholar] [CrossRef]

- Vallejos, M.E. Aprovechamiento Integral del Cannabis Sativa como Material de Refuerzo/Carga del Polipropileno. Ph.D.Thesis, Universitat de Girona, Girona, Spain, 2006. [Google Scholar]

- Rodríguez Soto, A.-A.; Sanabio-Alves-Borges, L.-M.; Valin-Rivera, J.-L.; Díaz Batista, D. Fabricación de compuesto de matriz epoxi reforzado con fibras largas de henequén orientadas aleatoriamente. Ing. Mecánica 2015, 18, 122–128. [Google Scholar]

- Bahari-Sambran, F.; Meuchelboeck, J.; Kazemi-Khasragh, E.; Eslami-Farsani, R.; Arbab Chirani, S. The effect of surface modified nanoclay on the interfacial and mechanical properties of basalt fiber metal laminates. Thin-Walled Struct. 2019, 144, 106343. [Google Scholar] [CrossRef]

- Khandelwal, S.; Han, G.H.; Kim, S.; Rhee, K.Y. Effect of dehydroxylation/amorphization degree of bentonite on the microstructure, thermal stability, and mechanical strength of basalt epoxy composites. J. Mater. Res. Technol. 2023, 23, 3249–3256. [Google Scholar] [CrossRef]

- Rapacz-Kmita, A.; Dudek, M.; Moskała, N.; Gajek, M.; Mandecka-Kamień, L. Influence of the Organophilisation Process on Properties of the Bentonite Filler and Mechanical Properties of the Clay/Epoxy Nanocomposites. Arch. Metall. Mater. 2016, 61, 875–880. [Google Scholar] [CrossRef]

| Properties | Typical Values |

|---|---|

| APHA Color | 80 maximum |

| Acid number | 32 maximum |

| Brookfield viscosity (cps), 25 °C (needle 2, 20 r.p.m., 1 min). | 500–700 |

| Solid (%) | 64–66 |

| Gel time at 25 °C, min. | 7–10 |

| Reactivity: | |

| Exotherm temperature, °C. | 140–160 |

| Exotherm temperature, min. | 17–25 |

| Stability at 60 °C, horas. | 168 minimum |

| Specimen | Polyester Polymer (P) [%] | Hemp Fiber (H) [%] | Bentonite (B) [%] |

|---|---|---|---|

| P | 100 | - | - |

| H10 | 90 | 10 | - |

| H15 | 85 | 15 | - |

| H20 | 80 | 20 | - |

| H25 | 75 | 25 | - |

| H30 | 70 | 30 | - |

| H35 | 65 | 35 | - |

| H40 | 60 | 40 | - |

| H45 | 55 | 45 | - |

| B5H10 | 85 | 10 | 5 |

| B5H15 | 80 | 15 | 5 |

| B5H20 | 75 | 20 | 5 |

| B5H25 | 70 | 25 | 5 |

| B5H30 | 65 | 30 | 5 |

| B5H35 | 60 | 35 | 5 |

| B5H40 | 55 | 40 | 5 |

| B5H45 | 50 | 45 | 5 |

| Element | At. No. | Netto | Mass [%] | Mass Norm. [%] | Atom [%] | Abs. Error [%] (1 Sigma) | Real. Error [%] (1 Sigma) |

|---|---|---|---|---|---|---|---|

| Oxygen | 8 | 7219 | 40.28 | 45.00 | 47.12 | 5.95 | 14.77 |

| Carbon | 6 | 1609 | 22.90 | 25.59 | 35.69 | 4.60 | 20.08 |

| Silicon | 14 | 18,146 | 15.47 | 17.28 | 10.31 | 0.70 | 4.55 |

| Aluminum | 13 | 6830 | 7.04 | 7.87 | 4.89 | 0.38 | 5.46 |

| Magnesium | 12 | 886 | 1.12 | 1.25 | 0.86 | 0.11 | 9.61 |

| Iron | 26 | 366 | 1.06 | 1.19 | 0.36 | 0.09 | 8.59 |

| Potassium | 19 | 792 | 0.96 | 1.08 | 0.46 | 0.07 | 7.69 |

| Calcium | 20 | 459 | 0.66 | 0.74 | 0.31 | 0.06 | 9.76 |

| Sum. | 89.50 | 100.00 | 100.00 |

| Specie | Sample | Cell Wall Thickness [μm] | Cell Wall Area [μm2] |

|---|---|---|---|

| Hemp | 1 | 1.9 | 49.5 |

| 2 | 2.0 | 55.9 | |

| 3 | 2.1 | 54 | |

| 4 | 1.9 | 55 | |

| 5 | 2.1 | 53 | |

| Average | 2.0 | 53.5 |

| Specimen | Elastic Module [MPa] | Increase [%] | Tensile Strength [MPa] | Increase [%] |

|---|---|---|---|---|

| P | 4674 | - | 20.2 | - |

| H10 | 6373 | - | 19.11 | - |

| B5H10 | 7858 | 23.30 | 14.68 | −23.18 |

| H15 | 5474 | - | 22.96 | - |

| B5H15 | 7938 | 45.01 | 17.05 | −25.74 |

| H20 | 6016 | - | 22.14 | - |

| B5H20 | 8409 | 39.78 | 20.16 | −8.94 |

| H25 | 7188 | - | 27.83 | - |

| B5H25 | 7789 | 8.36 | 21.71 | −21.99 |

| H30 | 7161 | - | 33.90 | - |

| B5H30 | 5510 | −23.06 | 29.26 | −13.69 |

| H35 | 8384 | - | 27.00 | - |

| B5H35 | 8737 | 4.21 | 34.28 | 26.96 |

| H40 | 7055 | - | 28.16 | - |

| B5H40 | 9065 | 28.49 | 26.77 | −4.94 |

| H45 | 6409 | - | 29.02 | - |

| B5H45 | 9058 | 41.33 | 23.29 | −19.75 |

| Specimen | Elastic Module [MPa] | Increase [%] | Flexural Strength [MPa] | Increase [%] |

|---|---|---|---|---|

| P | 3002 | - | 68.05 | - |

| H20 | 4047 | - | 46.12 | - |

| B5H20 | 6066 | 49.89 | 68.92 | 49.44 |

| H25 | 3411 | - | 52.93 | - |

| B5H25 | 6712 | 96.78 | 52.12 | −1.53 |

| H30 | 4427 | - | 51.15 | - |

| B5H30 | 7268 | 64.17 | 83.51 | 63.26 |

| H35 | 3533 | - | 63.87 | - |

| B5H35 | 8453 | 139.26 | 98.04 | 53.50 |

| H40 | 4073 | - | 85.22 | - |

| B5H40 | 8296 | 103.68 | 69.23 | −18.76 |

| H45 | 4897 | - | 76.06 | - |

| B5H45 | 8255 | 68.57 | 79.55 | 4.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández, M.V.; González, M.J.A.; Oyanadel, R.B.; Rivera, J.L.V.; Soto, A.R.; Ortega, A.G.; Ketterer, C.G.; Alvarez, A.A.; Diaz, F.R.V.; García del Pino, G. Effect of Nanometric Particles of Bentonite on the Mechanical Properties of a Thermoset Polymeric Matrix Reinforced with Hemp Fibers. Polymers 2023, 15, 1571. https://doi.org/10.3390/polym15061571

Fernández MV, González MJA, Oyanadel RB, Rivera JLV, Soto AR, Ortega AG, Ketterer CG, Alvarez AA, Diaz FRV, García del Pino G. Effect of Nanometric Particles of Bentonite on the Mechanical Properties of a Thermoset Polymeric Matrix Reinforced with Hemp Fibers. Polymers. 2023; 15(6):1571. https://doi.org/10.3390/polym15061571

Chicago/Turabian StyleFernández, Meylí Valin, María José Ahumada González, Rolando Briones Oyanadel, José Luis Valin Rivera, Angel Rodríguez Soto, Alvaro González Ortega, Cristobal Galleguillos Ketterer, Alexander Alfonso Alvarez, Francisco Rolando Valenzuela Diaz, and Gilberto García del Pino. 2023. "Effect of Nanometric Particles of Bentonite on the Mechanical Properties of a Thermoset Polymeric Matrix Reinforced with Hemp Fibers" Polymers 15, no. 6: 1571. https://doi.org/10.3390/polym15061571

APA StyleFernández, M. V., González, M. J. A., Oyanadel, R. B., Rivera, J. L. V., Soto, A. R., Ortega, A. G., Ketterer, C. G., Alvarez, A. A., Diaz, F. R. V., & García del Pino, G. (2023). Effect of Nanometric Particles of Bentonite on the Mechanical Properties of a Thermoset Polymeric Matrix Reinforced with Hemp Fibers. Polymers, 15(6), 1571. https://doi.org/10.3390/polym15061571