Orthogonal Design and Microstructure Mechanism Analysis of Novel Bentonite Polymer Slurry in Pipe Jacking

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

2.1.1. Raw Materials

2.1.2. Preparation of Specimens

2.2. Macroscopic Experiment Methods

2.2.1. Funnel Viscosity Test

2.2.2. Filter Loss Test

2.2.3. Water Dissociation Ratio Test

2.2.4. Dynamic Shear Test

2.3. Microscopic Experiments Methods

3. Orthogonal Experiment and Analysis

3.1. Orthogonal Experiment Design

3.2. Range Analysis

3.2.1. Range of Funnel Viscosity

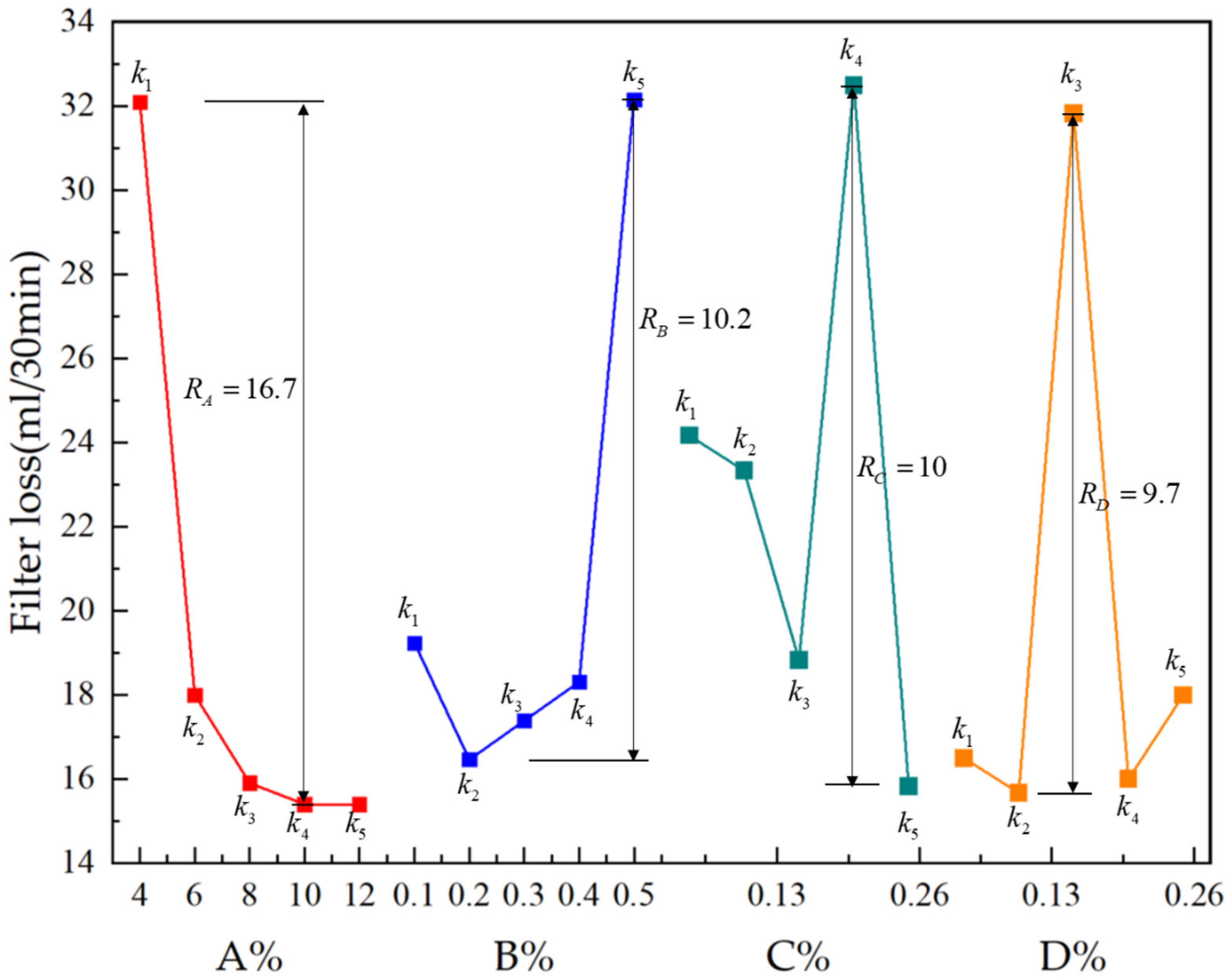

3.2.2. Range of Filter Loss

3.2.3. Range of Water Dissociation Ratio

3.2.4. Range of Dynamic Shear

3.3. Determination of Optimized Slurry

4. Microscopic Results and Analysis

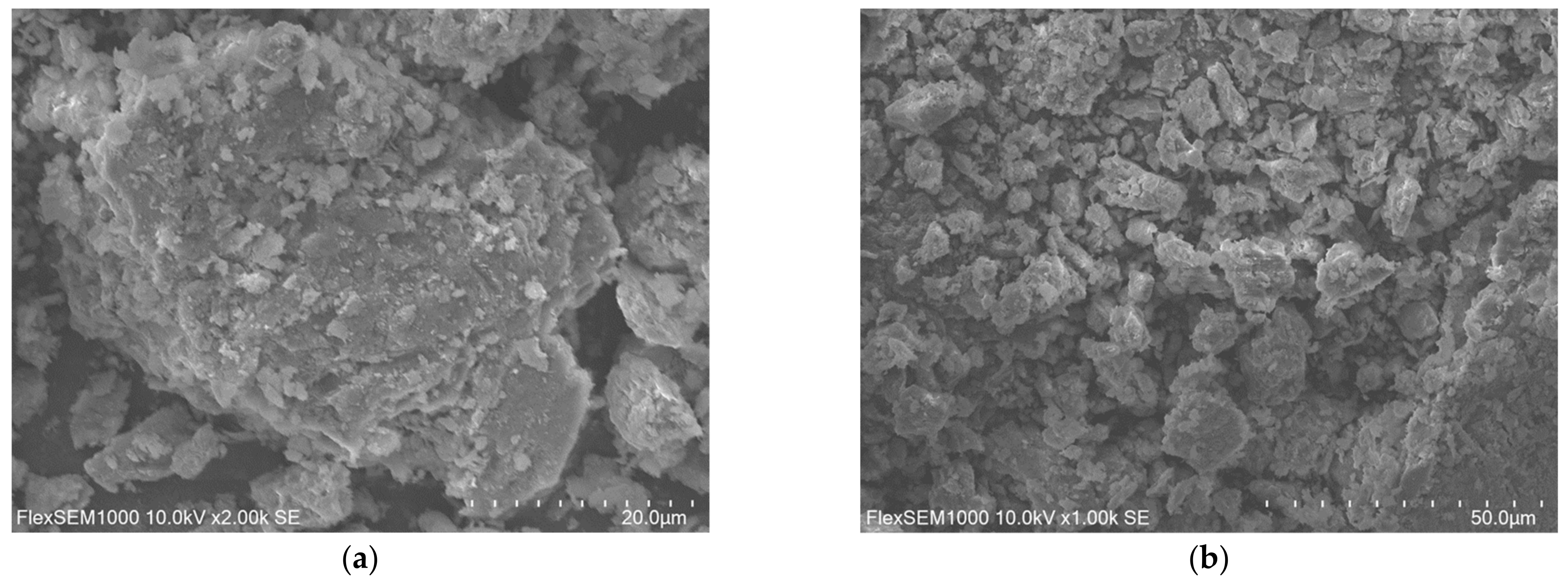

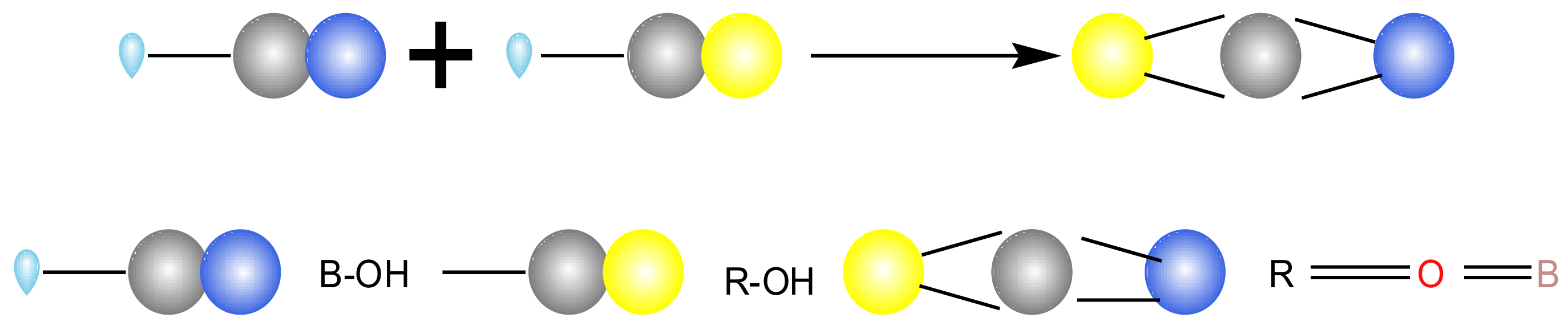

4.1. Microstructure of Polyacrylamide Bentonite

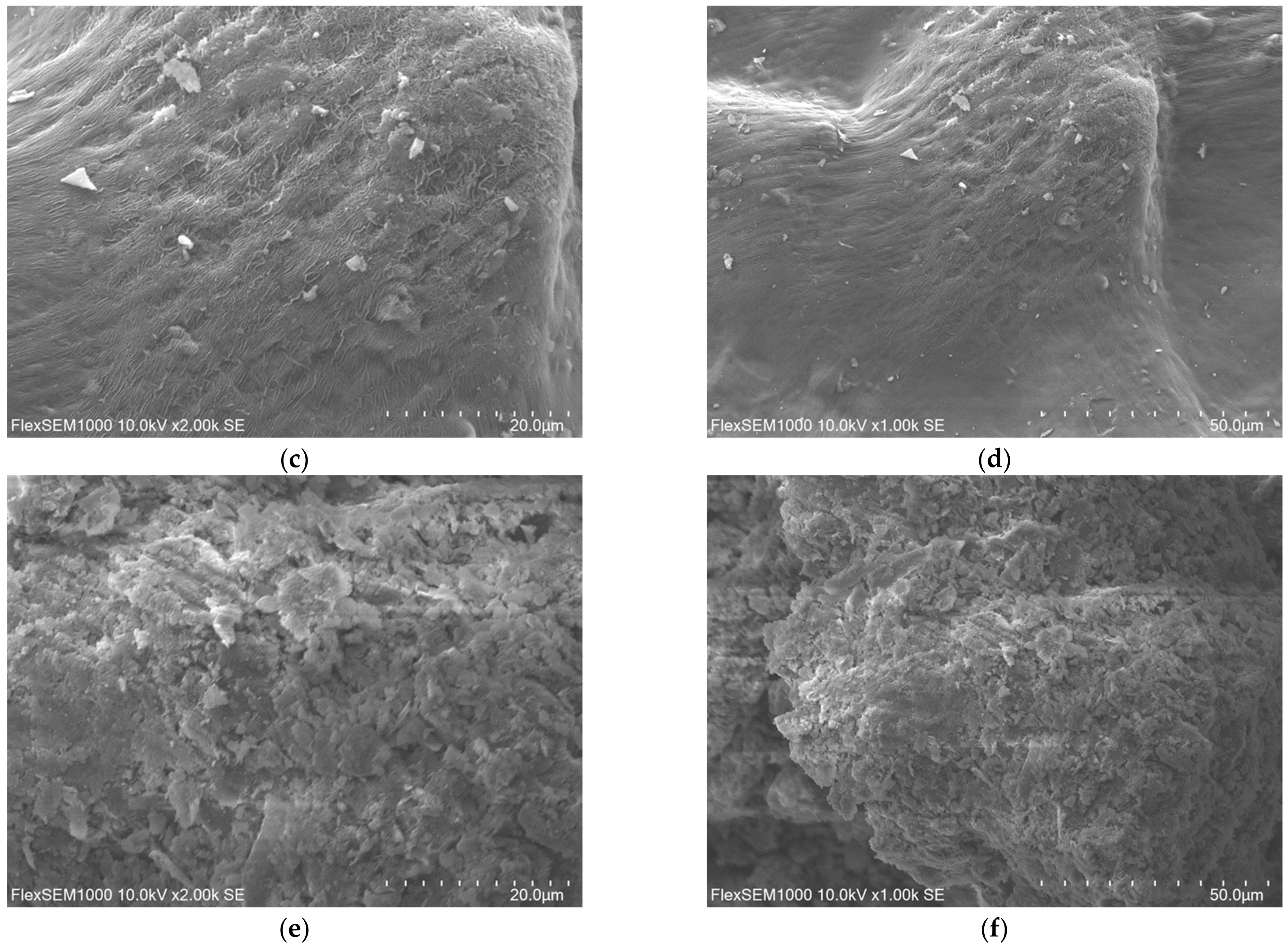

4.2. Microstructure of Crosslinked Polymer

4.3. Microstructure of Novel Polymer Bentonite

5. Conclusions

- The influence of the component content on slurry properties has a certain regularity. An increase in sodium bentonite enhances funnel viscosity and reduces filter loss and dynamic shear. Polyacrylamide and guar gum raises funnel viscosity and dynamic shear. Borax reduces funnel viscosity and dynamic shear. When considering the influence of FL and WDR, the calculated range value was 16.7, 10.2, 10, 9.7 and 28.38, 4.84, 4.7, 4.5 respectively, which indicated the four components arranged as sodium bentonite > guar gum > polyacrylamide > borax. The order changed to sodium bentonite > guar gum > borax > polyacrylamide when considering FV and listed as polyacrylamide > guar gum > sodium bentonite > borax when considering DS.

- Orthogonal test results indicated that the content of each component must take the appropriate intermediate value to best satisfy the comprehensive performance requirements in slurry pipe jacking engineering. Comprehensively considering the macro index of slurry and the general engineering needs, the optimized formula was sodium bentonite: guar gum: polyacrylamide: borax: water = 10:0.2:0.25:0.1:89.45.

- SEM analysis showed that the incorporation of guar gum and borax continuously enhance the crosslink reaction efficiency, and the addition of crosslinked polymer considerably reduced the number of cracks and pores in polyacrylamide bentonite slurry. With the addition of crosslinked polymer to polyacrylamide bentonite slurry, both the microstructure and anti-penetration properties were continuously improved.

- The admixture of crosslinked polymer and polyacrylamide bentonite can work together synergistically. This novel polymer bentonite slurry can meet the general performance requirements in pipe jacking engineering. It was prepared in the laboratory and can be applied in slurry pipe jacking engineering through synchronous grouting technology. but its adaptability and feasibility to different formations need to be furtherly tested by the projects.

- On the whole, this novel bentonite polymer slurry made up of sodium bentonite, polyacrylamide, guar gum and borax can overcome the shortcoming of traditional polymer slurry. Both the macroscopic and microscopic properties test indicated it can satisfy the general performance requirements for pipe jacking engineering. Its superiority will be verified in future projects.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ye, Y.; Peng, L.; Zhou, Y.; Yang, W.; Shi, C.; Lin, Y. Prediction of friction resistance for slurry pipe jacking. Appl. Sci. 2019, 10, 207. [Google Scholar] [CrossRef]

- Wen, K.; Zeng, W.; Shimada, H.; Sasaoka, T.; Hamanaka, A. Numerical and theoretical study on the jacking force prediction of slurry pipe jacking traversing frozen ground. Tunn. Undergr. Space Technol. 2021, 115, 104076. [Google Scholar] [CrossRef]

- Liu, J.; Cheng, H.; Cai, H.; Wang, X. Design and Analysis of Grouting Pressure in Slurry Pipe Jacking Based on the Surrounding Soil Stability Mechanical Characteristics. Geofluids 2022, 2022, 1–17. [Google Scholar] [CrossRef]

- Guo, Y.; Jin, D.; Li, X.; Cheng, P.; Qiao, G.; Wang, Q.; Yang, Y. Effect of cutting blind zones on the performance of the rectangular pipe jacking machine with multiple cutterheads: A DEM study. Tunn. Undergr. Space Technol. 2023, 134, 104984. [Google Scholar] [CrossRef]

- Reilly, C.C.; Orr, T.L. Physical modelling of the effect of lubricants in pipe jacking. Tunn. Undergr. Space Technol. 2017, 63, 44–53. [Google Scholar] [CrossRef]

- Namli, M.; Guler, E. Effect of bentonite slurry pressure on interface friction of pipe jacking. J. Pipeline Syst. Eng. Pract. 2017, 8, 04016016. [Google Scholar] [CrossRef]

- Su, Q.; Zhou, W.-H.; Xu, T. Effects of seawater on the infiltration behavior of bentonite slurry into sand. Constr. Build. Mater. 2023, 371, 130759. [Google Scholar]

- Wang, Z.; Guo, W.; Ding, W.; Liu, K.; Qin, W.; Wang, C.; Wang, Z. Numerical study on the hydrodynamic properties of bentonite slurries with Herschel-Bulkley-Papanastasiou rheology model. Powder Technol. 2023, 419, 118375. [Google Scholar] [CrossRef]

- He, H.; Chai, K.; Wu, T.; Qiu, Z.; Wang, S.; Hong, J. Adsorption of Rhodamine B from Simulated Waste Water onto Kaolin-Bentonite Composites. Materials 2022, 15, 4058. [Google Scholar] [CrossRef]

- Macheca, A.D.; Mapossa, A.B.; Cumbane, A.J.; Sulemane, A.E.; Tichapondwa, S.M. Development and Characterization of Na2CO3-Activated Mozambican Bentonite: Prediction of Optimal Activation Conditions Using Statistical Design Modeling. Minerals 2022, 12, 1116. [Google Scholar] [CrossRef]

- Lei, H.Y.; Liu, X.; Shi, F.; Xu, Y. Proportional optimization of polymer-modified bentonite slurry in pipe jacking. Chin. J. Geotech. Eng. 2021, 43, 51–55. [Google Scholar]

- Yang, Y.; Li, X.-G.; Su, W.-L. Experimental Investigation on Rheological Behaviors of Bentonite-and CMC-Conditioned Sands. KSCE J. Civ. Eng. 2020, 24, 1914–1923. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, W.; Zhu, Z.; Liu, R.; Wang, C.; Yu, W.; Wang, Z. Experimental study on rheological behaviors of Na-bentonite slurries under seawater intrusion. Constr. Build. Mater. 2022, 357, 129369. [Google Scholar] [CrossRef]

- Wang, C.T. Experimental study on the slurry formulation used for the large diameter long distance pipe-jacking project. J. Railw. Sci. Eng. 2014, 11, 106–111. [Google Scholar]

- Cui, W.; Liu, D.; Song, H.-F.; Pu, G.-J. Development and experimental study on environmental slurry for slurry shield tunneling. Constr. Build. Mater. 2019, 216, 416–423. [Google Scholar] [CrossRef]

- Cui, W.; Liu, D.; Song, H.-F.; Zhang, S.-R.; He, S.-W. Experimental study of salt-resisting slurry for undersea shield tunnelling. Tunn. Undergr. Space Technol. 2020, 98, 103322. [Google Scholar] [CrossRef]

- Powell, J.W.; Stagg, T.; Reiley, R.H.; Dobson, J. Thixotropic, Crosslinking Polymer/Borate/Salt Plug: Development and Application. In Proceedings of the International Arctic Technology Conference, Anchorage, AK, USA, 29–31 May 1991. [Google Scholar]

- Kruijf de, A.S.; Roodhart, L.P.; Davies, D.R. Relation between chemistry and flow mechanics of borate-crosslinked fracturing fluids. SPE Prod. Facil. 1993, 8, 165–170. [Google Scholar] [CrossRef]

- Van, Z.; Nathan, J.; Renaud, N. Vitrimers: Permanently crosslinked polymers with dynamic network topology. Prog. Polym. Sci. 2020, 104, 101233. [Google Scholar] [CrossRef]

- Fortman, D.J.; Brutman, J.P.; De Hoe, G.X.; Snyder, R.L.; Dichtel, W.R.; Hillmyer, M.A. Approaches to sustainable and continually recyclable cross-linked polymers. ACS Sustain. Chem. Eng. 2018, 6, 11145–11159. [Google Scholar] [CrossRef]

- Lin, M.; Dai, Y.; Xia, F.; Zhang, X. Advances in non-covalent crosslinked polymer micelles for biomedical applications. Mater. Sci. Eng. C 2021, 119, 111626. [Google Scholar] [CrossRef]

- Bishop, M.; Shahid, N.; Yang, J.Z.; Barron, A. Determination of the mode and efficacy of the cross-linking of guar by borate using MAS UB-NMR of borate cross-linked guar in combination with solution nB-NMR of model systems. R. Soc. Chem. 2004, 17, 2621–2634. [Google Scholar]

- Sharma, G.; Sharma, S.; Kumar, A.; Al-Muhtaseb, A.H.; Naushad, M.; Ghfar, A.A.; Mola, G.T.; Stadler, F.J. Guar gum and its composites as potential materials for diverse applications: A review. Carbohydr. Polym. 2018, 199, 534–545. [Google Scholar] [CrossRef] [PubMed]

- Thombare, N.; Jha, U.; Mishra, S.; Siddiqui, M.Z. Guar gum as a promising starting material for diverse applications: A review. Int. J. Biol. Macromol. 2016, 88, 361–372. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Long, W.; Li, J.Z.; Lu, Y.F. Research and application of wall-reducing slurry for large diameter pipe jacking in desert area. Explor. Eng. 2018, 45, 177–184. [Google Scholar]

- Liu, Z.W.; Yang, C.S. Study on forming law of thixotropic mud holster and test of reducing resistance effect in rectangular pipe jacking tunnel construction. J. Henan Polytech. Univ. 2016, 35, 568–576. [Google Scholar]

- Zhang, X.; Wan, Z.; Wang, C.; Liu, Y.; Liu, S.; Wang, H.; Zhang, B. Optimization thixotropic slurry ratio and drag reduction performance test for rectangular pipejacking in anhydrous sand layer. J. Eng. Geol. 2021, 29, 1611–1620. [Google Scholar]

- Cawiezel, K.E.; Elbel, J.L. A new system for controlling the crosslinking rate of borate fracturing fluids. SPE Prod. Eng. 1992, 7, 275–279. [Google Scholar] [CrossRef]

- Al-Anazi, H.A.; Nasr-El-Din, H.A. Optimization of borate-based gels used for wellbore diversion during well stimulation: A case study. In Proceedings of the SPE/DOE Eleventh Symposium on Improved Oil Recovery, Tulsa, OK, USA, 19–22 April 1998. [Google Scholar]

| Index | pH Value | Expansion Index (mL/g) | Glue Value (mL/15 g) | Water Absorption (%) | Moisture (%) | Wet Compressive Strength (MPa) |

|---|---|---|---|---|---|---|

| Sample | 7.1 | 35 | 100.2 | 295 | 6 | 1.35 |

| Index | Hydrochloric Acid Insoluble Matter (%) | Chloride (%) | Sulfate (%) | Phosphate (%) | Calcium (%) | Iron (%) | Copper (%) |

|---|---|---|---|---|---|---|---|

| Sample | <0.005 | <0.002 | <0.01 | <0.002 | <0.005 | <0.0003 | <0.001 |

| Components | Chemical Composition/% | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

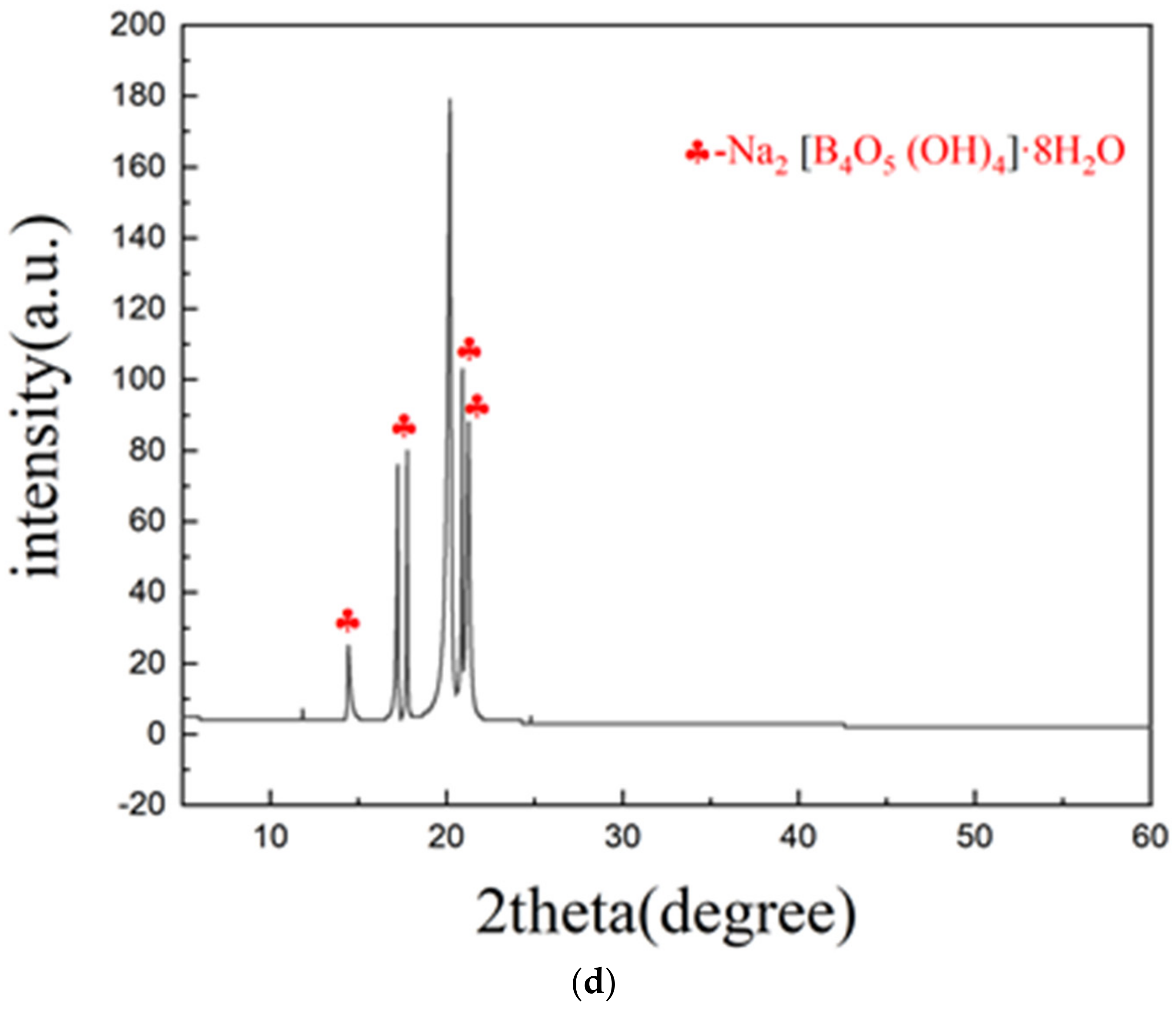

| SiO2 | (C3H5NO)n | Acid Non-Soluble Substance | Na2 [B4O5 (OH)4]·8H2O | Al2O3 | Fe2O3 | Loss On Ignition | CaO | K2O | MgO | Na2O | TiO2 | MnO | P2O5 | Others | |

| Sodium bentonite | 68.08 | 16.07 | 4.31 | 3.47 | 2.45 | 2.11 | 1.36 | 1.33 | 0.67 | 0.1 | 0.05 | ||||

| Polyacrylamide | 99 | 1 | |||||||||||||

| Guar gum | 2.78 | 97.22 | |||||||||||||

| Borax | 0.005 | 99.5 | 0.495 | ||||||||||||

| Levels | Factors | |||

|---|---|---|---|---|

| Sodium Bentonite Contents (%) A | Guar Gum Contents (%) B | Polyacrylamide Contents (%) C | Borax Contents (%) D | |

| Level 1 | 4 | 0.1 | 0.05 | 0.05 |

| Level 2 | 6 | 0.2 | 0.1 | 0.1 |

| Level 3 | 8 | 0.3 | 0.15 | 0.15 |

| Level 4 | 10 | 0.4 | 0.2 | 0.2 |

| Level 5 | 12 | 0.5 | 0.25 | 0.25 |

| No. | A/% | B/% | C/% | D/% | Funnel Viscosity /s | Filter Loss/ (mL/30 min) | Water Dissociation Ratio/% | Dynamic Shear/Pa |

|---|---|---|---|---|---|---|---|---|

| 1 | 4 | 0.1 | 0.05 | 0.05 | 18.76 | 26.5 | 35.7 | 0.2555 |

| 2 | 4 | 0.2 | 0.15 | 0.2 | 23.87 | 19.5 | 14.1 | 0.7665 |

| 3 | 4 | 0.3 | 0.25 | 0.1 | 24 | 19.5 | 23.1 | 0.7665 |

| 4 | 4 | 0.4 | 0.1 | 0.25 | 24.17 | 29.5 | 37.7 | 0.2555 |

| 5 | 4 | 0.5 | 0.2 | 0.15 | 32.51 | 65.5 | 31.3 | 4.088 |

| 6 | 6 | 0.1 | 0.25 | 0.2 | 25.08 | 16.5 | 2.1 | 0.2555 |

| 7 | 6 | 0.2 | 0.1 | 0.1 | 27.57 | 18 | 0.5 | 0.511 |

| 8 | 6 | 0.3 | 0.2 | 0.25 | 33.49 | 16 | 1.1 | 1.533 |

| 9 | 6 | 0.4 | 0.05 | 0.15 | 27.40 | 20 | 1.6 | 0.511 |

| 10 | 6 | 0.5 | 0.15 | 0.05 | 34.13 | 19.5 | 1.1 | 0.511 |

| 11 | 8 | 0.1 | 0.2 | 0.1 | 24.95 | 16 | 0.5 | 0.7665 |

| 12 | 8 | 0.2 | 0.05 | 0.25 | 26.02 | 17.5 | 1.0 | 0.7665 |

| 13 | 8 | 0.3 | 0.15 | 0.15 | 49.81 | 16.5 | 1.1 | 0.2555 |

| 14 | 8 | 0.4 | 0.25 | 0.05 | 57.36 | 12 | 0.5 | 1.7885 |

| 15 | 8 | 0.5 | 0.1 | 0.2 | 41.37 | 17.5 | 1.1 | 0.511 |

| 16 | 10 | 0.1 | 0.15 | 0.25 | 46.57 | 15.5 | 0 | 0.511 |

| 17 | 10 | 0.2 | 0.25 | 0.15 | 62.62 | 14 | 0 | 0.511 |

| 18 | 10 | 0.3 | 0.1 | 0.05 | 50.95 | 15.5 | 0 | 0.511 |

| 19 | 10 | 0.4 | 0.2 | 0.2 | 59.56 | 14 | 0 | 0.2555 |

| 20 | 10 | 0.5 | 0.05 | 0.1 | 45.06 | 18 | 0 | 0.511 |

| 21 | 12 | 0.1 | 0.1 | 0.15 | 28.5 | 17.5 | 0 | 0.2555 |

| 22 | 12 | 0.2 | 0.2 | 0.05 | 120.67 | 14 | 0 | 0.511 |

| 23 | 12 | 0.3 | 0.05 | 0.2 | 57.86 | 18.5 | 0 | 0.511 |

| 24 | 12 | 0.4 | 0.15 | 0.1 | 72.45 | 13.5 | 0 | 0.511 |

| 25 | 12 | 0.5 | 0.25 | 0.25 | 55.48 | 13.5 | 0 | 0.511 |

| Index | Factor | R | Optimized Combinations | |||||

|---|---|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | ||||

| FV | A | 24.662 | 29.534 | 39.902 | 52.952 | 66.992 | 42.33 | A4B2C4D1 |

| B | 28.772 | 52.15 | 43.222 | 48.188 | 41.71 | 23.38 | ||

| C | 35.02 | 34.512 | 45.366 | 54.236 | 44.908 | 19.72 | ||

| D | 56.374 | 38.806 | 40.168 | 41.548 | 37.146 | 19.23 | ||

| FL | A | 32.1 | 18 | 15.9 | 15.4 | 15.4 | 16.7 | A4B2C5D2 |

| B | 18.4 | 16.6 | 17.2 | 17.8 | 26.8 | 10.2 | ||

| C | 20.1 | 19.6 | 16.9 | 25.1 | 15.1 | 10 | ||

| D | 17.5 | 17 | 26.7 | 17.2 | 18.4 | 9.7 | ||

| WDR | A | 28.38 | 1.28 | 0.84 | 0 | 0 | 28.38 | A4B2C5D2 |

| B | 7.66 | 3.12 | 5.06 | 7.96 | 6.7 | 4.84 | ||

| C | 7.66 | 7.86 | 3.26 | 6.58 | 7.96 | 4.7 | ||

| D | 7.46 | 4.82 | 6.8 | 3.46 | 7.96 | 4.5 | ||

| DS | A | 1.2264 | 0.6643 | 0.8176 | 0.4599 | 0.4599 | 0.77 | A4B2C5D2 |

| B | 0.4088 | 0.6132 | 0.7154 | 0.6643 | 1.2264 | 0.82 | ||

| C | 0.511 | 0.4088 | 0.511 | 1.4308 | 0.7665 | 1.02 | ||

| D | 0.7154 | 0.6132 | 1.1242 | 0.4599 | 0.7154 | 0.67 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Wang, X.; Cheng, H.; Fan, H. Orthogonal Design and Microstructure Mechanism Analysis of Novel Bentonite Polymer Slurry in Pipe Jacking. Polymers 2023, 15, 1461. https://doi.org/10.3390/polym15061461

Liu J, Wang X, Cheng H, Fan H. Orthogonal Design and Microstructure Mechanism Analysis of Novel Bentonite Polymer Slurry in Pipe Jacking. Polymers. 2023; 15(6):1461. https://doi.org/10.3390/polym15061461

Chicago/Turabian StyleLiu, Jimin, Xiangzhi Wang, Hua Cheng, and Haixu Fan. 2023. "Orthogonal Design and Microstructure Mechanism Analysis of Novel Bentonite Polymer Slurry in Pipe Jacking" Polymers 15, no. 6: 1461. https://doi.org/10.3390/polym15061461

APA StyleLiu, J., Wang, X., Cheng, H., & Fan, H. (2023). Orthogonal Design and Microstructure Mechanism Analysis of Novel Bentonite Polymer Slurry in Pipe Jacking. Polymers, 15(6), 1461. https://doi.org/10.3390/polym15061461