A Nano-Cleaning Fluid for Downhole Casing Cleaning

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

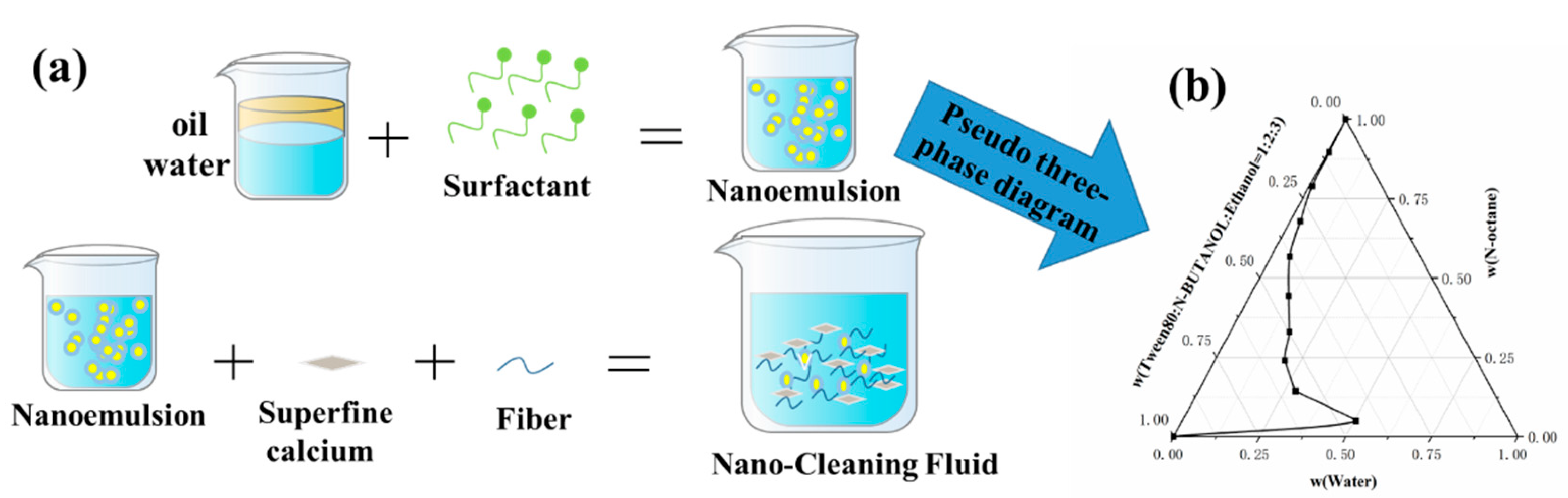

2.2. Preparation and Performance of Nano-Cleaning Fluid

2.2.1. Preparation and Characterization of Nano-emulsions

2.2.2. Nano-Emulsion Particle Size and Zeta Potential Test

2.2.3. Surface Interfacial Tension of the Nano-Cleaning Fluid

2.2.4. Wetting and Flipping Ability Test of P110 Steel by Nano-Cleaning Fluid

2.2.5. Sedimentation Stability Performance Test of Nano-Cleaning Fluid

2.2.6. Test of Stick–Cut Performance of Nano-Cleaning Fluid

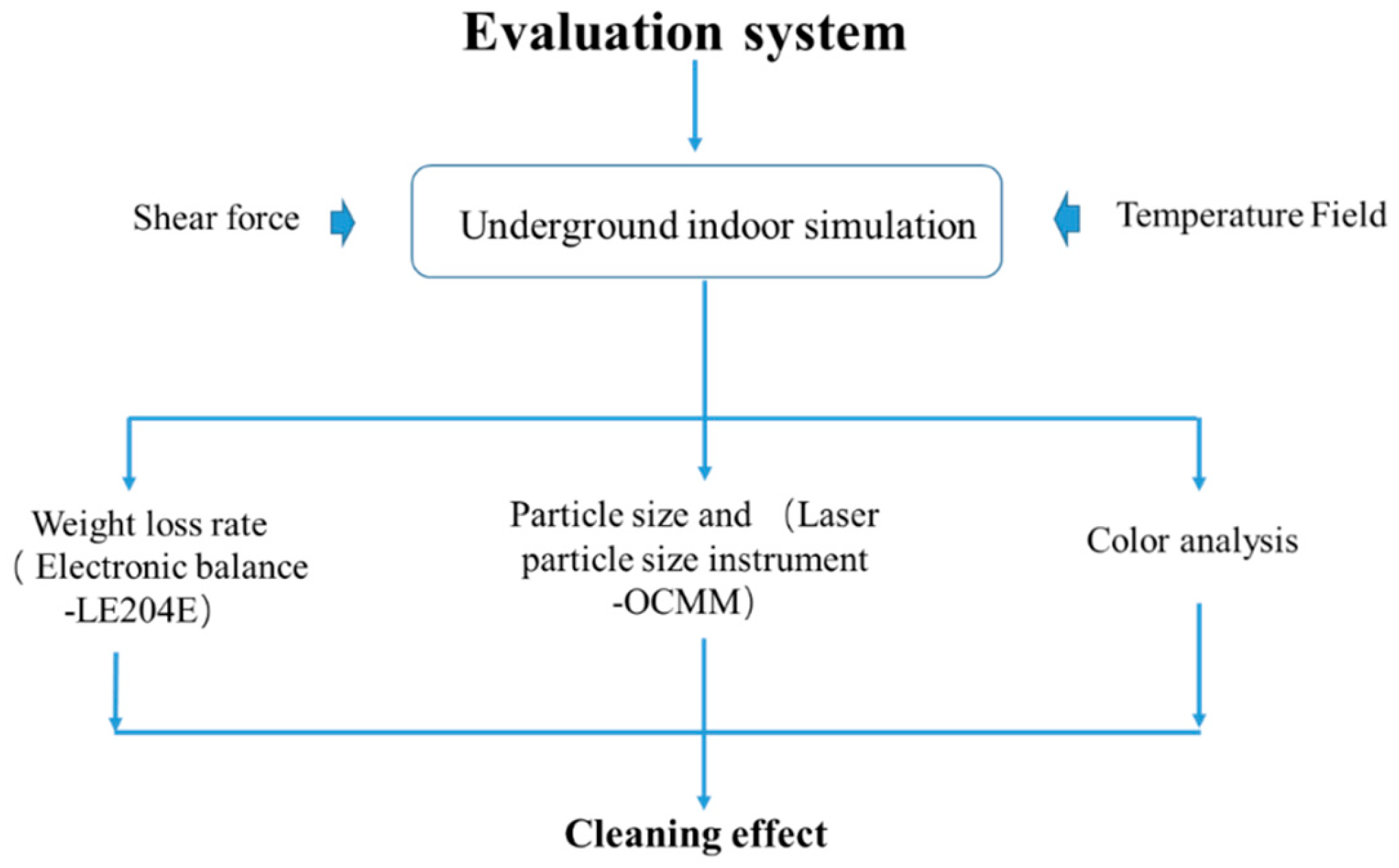

2.3. Nano-Cleaning Fluid Cleaning Efficiency Test

3. Results and Discussion

3.1. Nano-Cleaning Fluid Performance

3.2. Analysis of Cleaning Performance of Nano-Cleaning Fluid

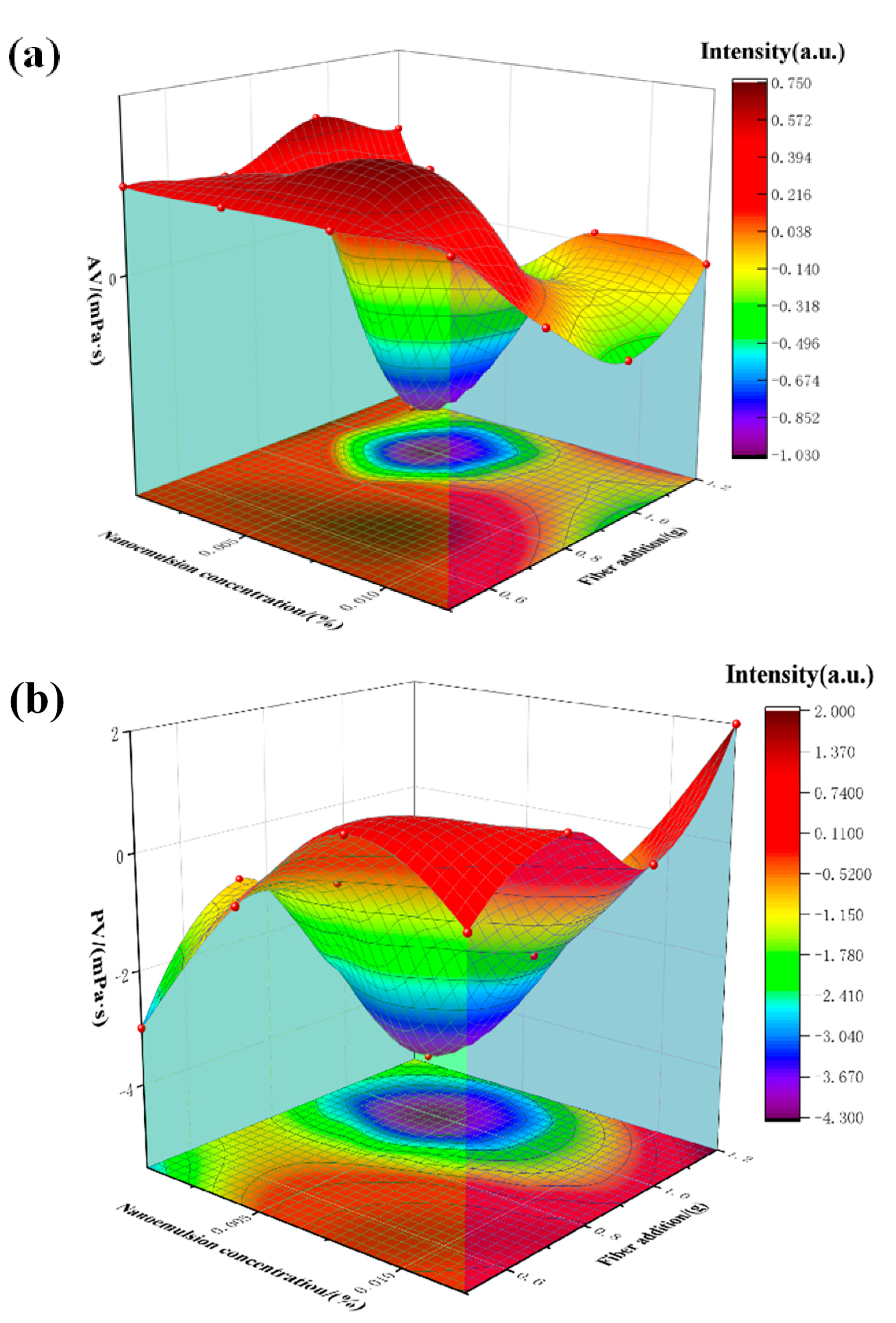

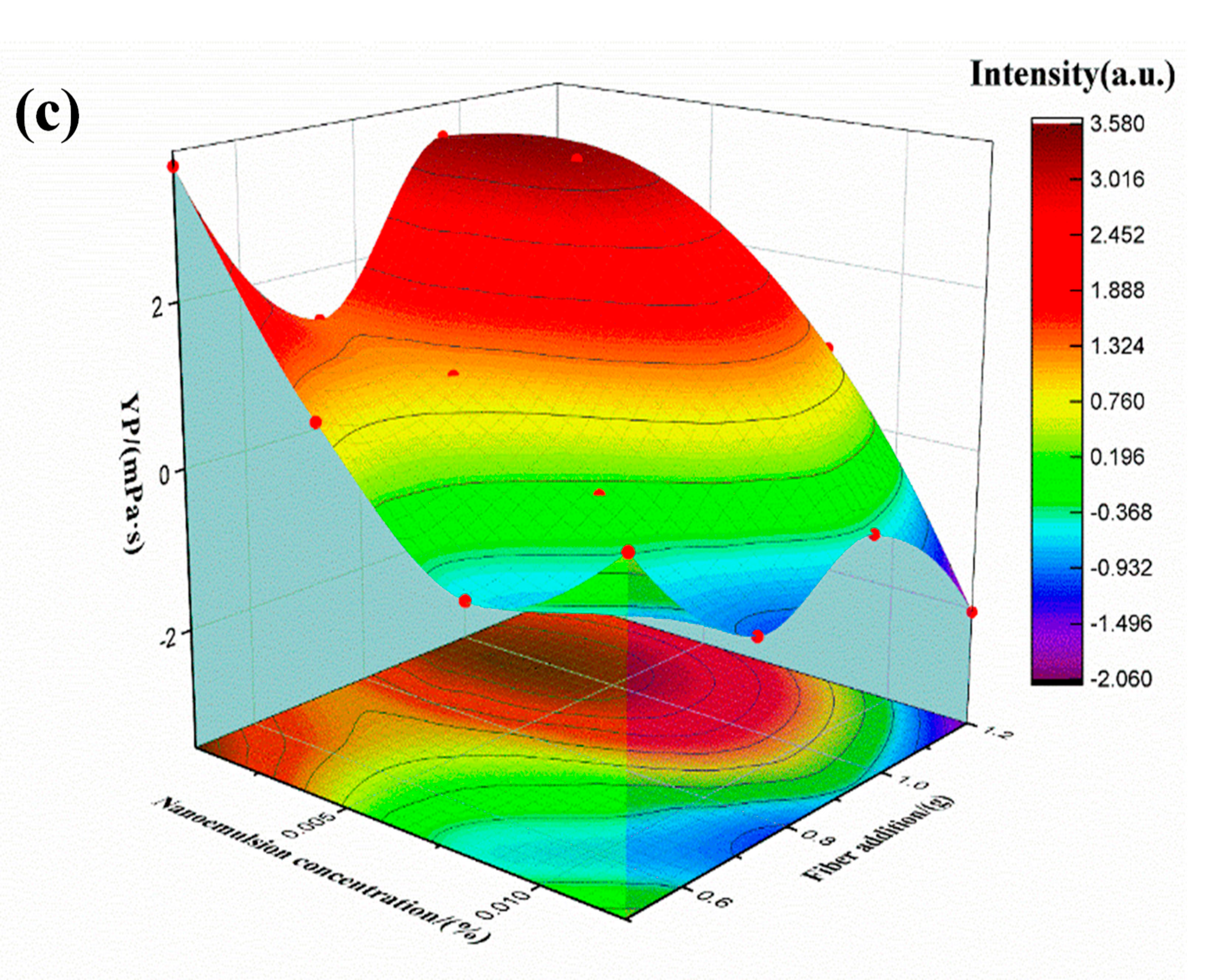

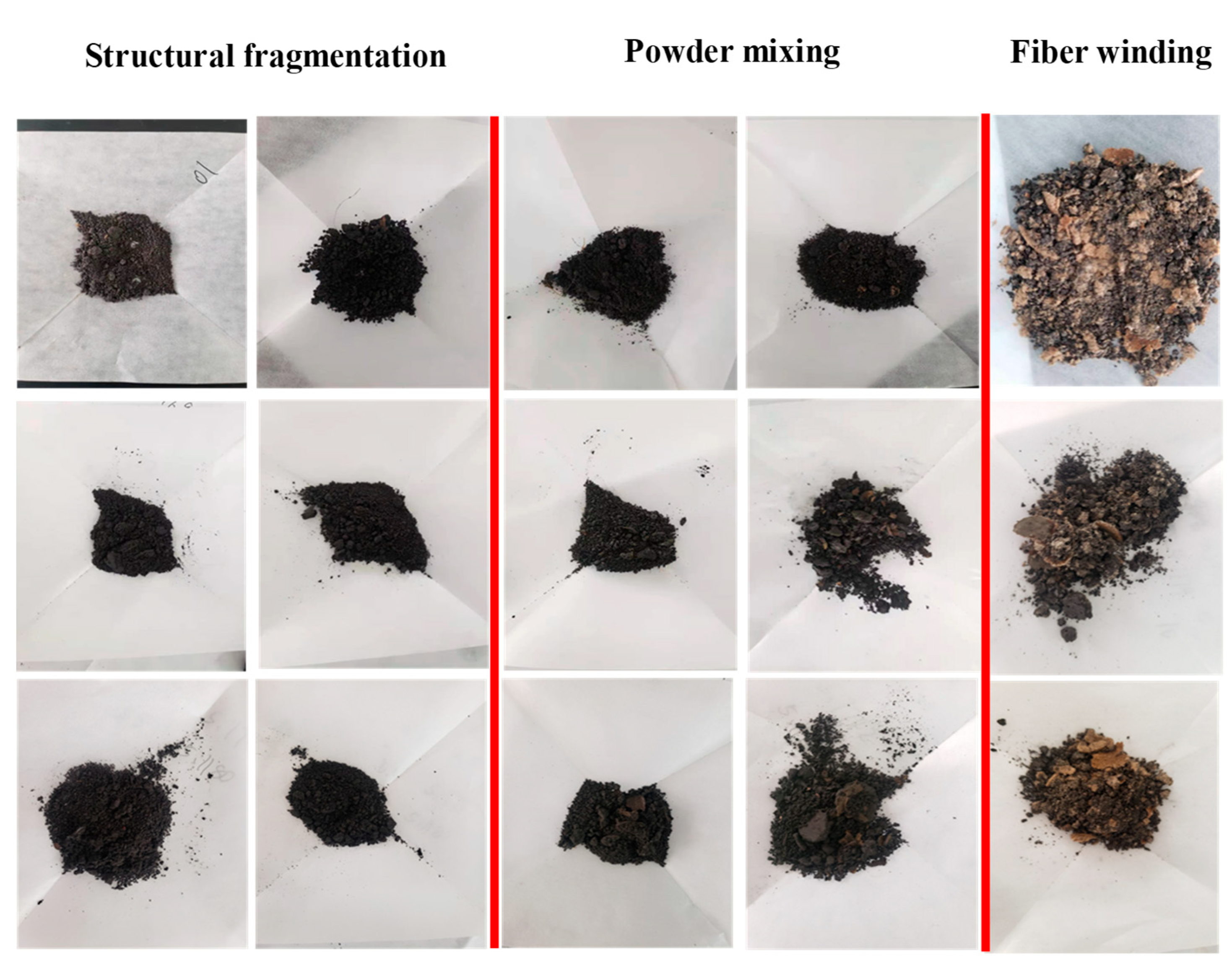

3.2.1. Analysis of the Stick–Cut Performance of Nano-Cleaning Fluid

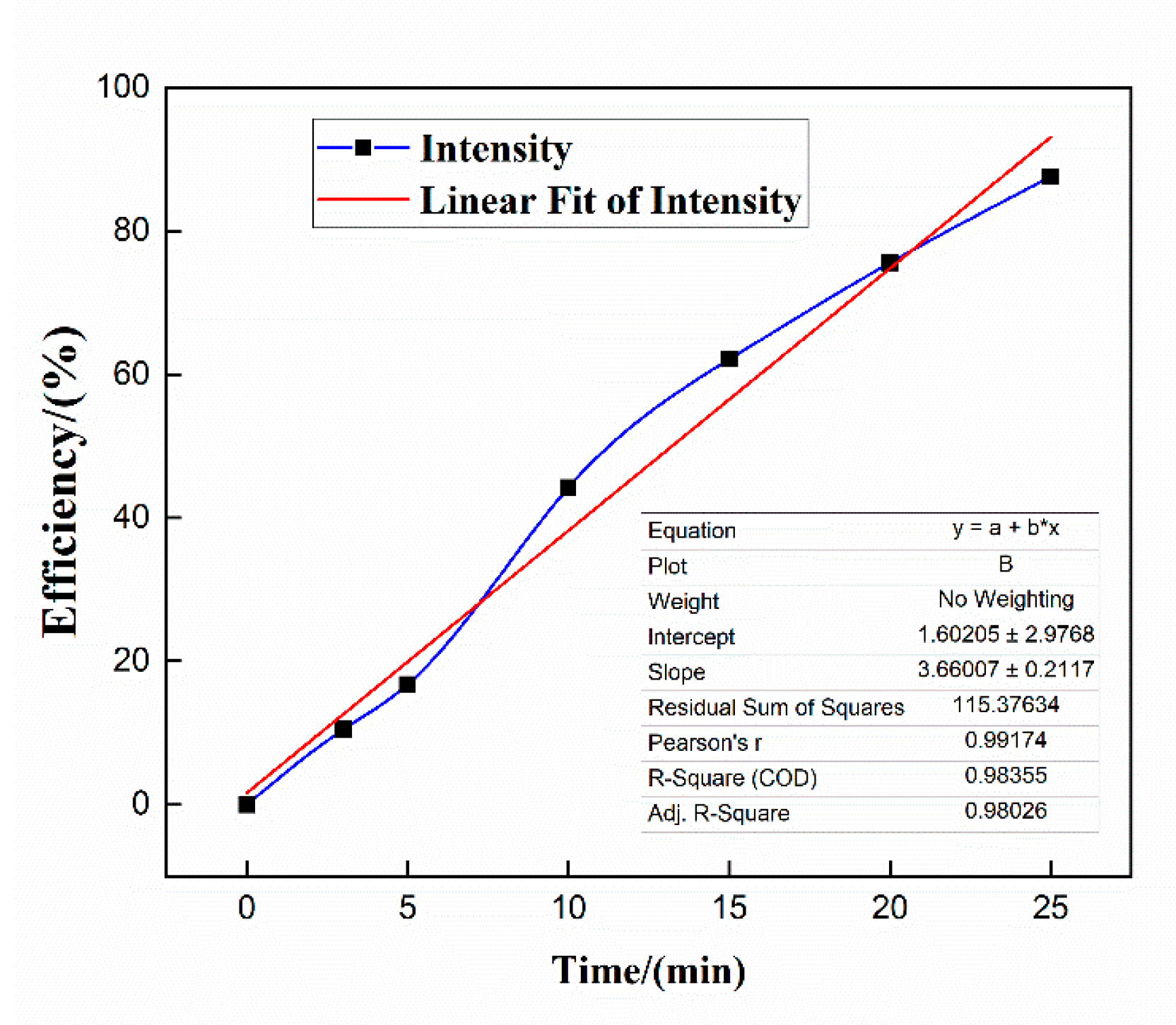

3.2.2. Evaluation of the Cleaning Effect of Nano-Cleaning Fluid

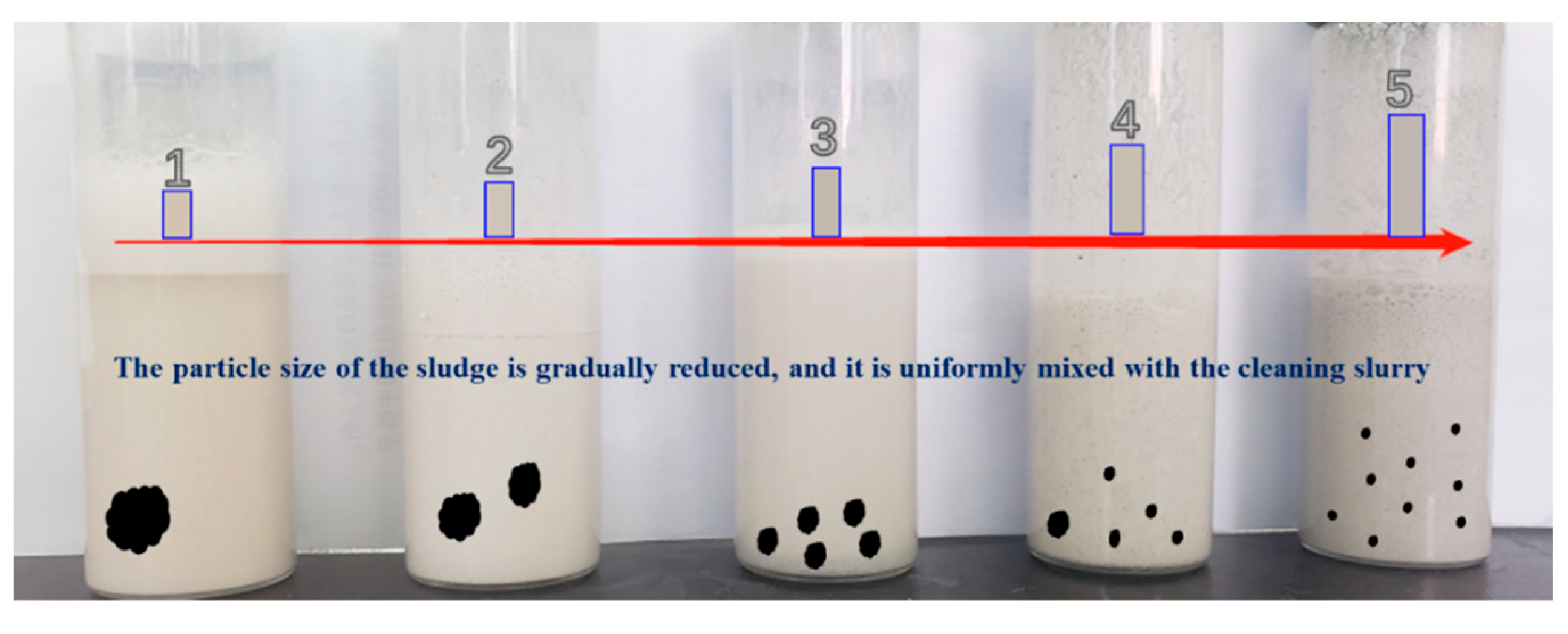

3.2.3. Intuitive Phenomena during the Cleaning Process

3.2.4. Research on the Cleaning Mechanism of Nano-Cleaning Fluid

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, P.; Liu, K.; Liu, J.; Yu, S.; Yu, B.; Hou, M.; Wu, L. Petroleum charge history of deeply buried carbonate reservoirs in the Shuntuoguole Low Uplift, Tarim Basin, west China. Mar. Pet. Geol. 2021, 128, 105063. [Google Scholar] [CrossRef]

- Qiao, Z.-F.; Zhang, S.-N.; Shen, A.-J.; Shao, G.-M.; She, M.; Cao, P.; Sun, X.-W.; Zhang, J.; Guo, R.-X.; Tan, X.-C. Features and origins of massive dolomite of Lower Ordovician Penglaiba Formation in the northwest Tarim Basin: Evidence from petrography and geochemistry. Pet. Sci. 2021, 18, 1323–1341. [Google Scholar] [CrossRef]

- He, T.; Li, W.; Lu, S.; Yang, E.; Jing, T.; Ying, J.; Zhu, P.; Wang, X.; Pan, W.; Chen, Z. Distribution and isotopic signature of 2-alkyl-1,3,4-trimethylbenzenes in the Lower Paleozoic source rocks and oils of Tarim Basin: Implications for the oil-source correlation. Pet. Sci. 2022, 19, 2572–2582. [Google Scholar] [CrossRef]

- Zhu, G.; Milkov, A.V.; Li, J.; Xue, N.; Chen, Y.; Hu, J.; Li, T.; Zhang, Z.; Chen, Z. Deepest oil in Asia: Characteristics of petroleum system in the Tarim basin, China. J. Pet. Sci. Eng. 2021, 199, 108246. [Google Scholar] [CrossRef]

- Zhang, S.; Jin, Q.; Sun, J.; Wei, H.; Cheng, F.; Zhang, X. Formation of hoodoo-upland on Ordovician karst slope and its significance in petroleum geology in Tahe area, Tarim Basin, NW China. Pet. Explor. Dev. 2021, 48, 354–366. [Google Scholar] [CrossRef]

- Hussain, W.; Ali, N.; Sadaf, R.; Hu, C.; Nykilla, E.E.; Ullah, A.; Iqbal, S.M.; Hussain, A.; Hussain, S. Petrophysical analysis and hydrocarbon potential of the lower Cretaceous Yageliemu Formation in Yakela gas condensate field, Kuqa Depression of Tarim Basin, China. Geosyst. Geoenviron. 2022, 1, 100106. [Google Scholar] [CrossRef]

- Zhang, W.; Duan, T.; Li, M.; Zhao, H.; Shang, X.; Wang, Y. Architecture characterization of Ordovician fault-controlled paleokarst carbonate reservoirs in Tuoputai, Tahe oilfield, Tarim Basin, NW China. Pet. Explor. Dev. 2021, 48, 367–380. [Google Scholar] [CrossRef]

- Jalili, Y.; Yassaghi, A.; Khatib, M.M.; Golalzadeh, A. Effect of transverse faults on fracture characteristics and borehole instability in the Asmari reservoir of Zagros folded belt zone, Iran. J. Pet. Sci. Eng. 2020, 188, 106820. [Google Scholar] [CrossRef]

- Chen, Y.; Song, Q.; Tan, Y. Synthesis, aggregation behavior of alternating copolymer emulsifier in oil solution and its application in oil-based drilling fluids. J. Mol. Liq. 2021, 348, 118011. [Google Scholar] [CrossRef]

- Hermoso, J.; Martinez-Boza, F.; Gallegos, C. Influence of viscosity modifier nature and concentration on the viscous flow behaviour of oil-based drilling fluids at high pressure. Appl. Clay Sci. 2014, 87, 14–21. [Google Scholar] [CrossRef]

- Liu, J.-P.; Zhang, X.-F.; Zhang, W.-C.; Lv, K.-H.; Bai, Y.-R.; Wang, J.-T.; Huang, X.-B.; Jin, J.-F.; Sun, J.-S. Carbon nanotube enhanced water-based drilling fluid for high temperature and high salinity deep resource development. Pet. Sci. 2021, 19, 916–926. [Google Scholar] [CrossRef]

- Ali, J.A.; Kalhury, A.M.; Sabir, A.N.; Ahmed, R.N.; Ali, N.H.; Abdullah, A.D. A state-of-the-art review of the application of nanotechnology in the oil and gas industry with a focus on drilling engineering. J. Pet. Sci. Eng. 2020, 191, 107118. [Google Scholar] [CrossRef]

- Liu, W.; Lu, Z.; Han, X.; Sun, X.; Li, Y.; Lu, J.; Bao, M. Synergetic effect of asphaltenes extracted from polymer containing oil sludge and HPAM at water/toluene interface. Colloids Surf. A Physicochem. Eng. Asp. 2021, 630, 127572. [Google Scholar] [CrossRef]

- Ofei, T.N.; Lund, B.; Saasen, A. Effect of particle number density on rheological properties and barite sag in oil-based drilling fluids. J. Pet. Sci. Eng. 2021, 206, 108908. [Google Scholar] [CrossRef]

- Jin, H.; Yang, B.; Yang, S.; He, G. An experimental and modeling study of barite deposition in one-dimensional tubes. J. Pet. Sci. Eng. 2015, 125, 107–116. [Google Scholar] [CrossRef]

- Chen, M.; Li, X.; Tong, S.; Mohanty, K.; Wang, Y.; Yang, W.; Hazlett, R.; Lu, J. Experimental investigation and numerical modeling of barium sulfate deposition in porous media. J. Pet. Sci. Eng. 2020, 195, 107920. [Google Scholar] [CrossRef]

- Luo, X.; Gong, H.; He, Z.; Zhang, P.; He, L. Research on mechanism and characteristics of oil recovery from oily sludge in ultrasonic fields. J. Hazard. Mater. 2020, 399, 123137. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Thring, R.; Liu, L. Application of Ultrasound and Fenton’s Reaction Process for the Treatment of Oily Sludge. Procedia Environ. Sci. 2013, 18, 686–693. [Google Scholar] [CrossRef]

- Gao, Y.X.; Ding, R.; Chen, X.; Gong, Z.B.; Zhang, Y.; Yang, M. Ultrasonic washing for oily sludge treatment in pilot scale. Ultrasonics 2018, 90, 1–4. [Google Scholar] [CrossRef]

- Jones, F.; Jones, P.; Ogden, M.I.; Richmond, W.R.; Rohl, A.L.; Saunders, M. The interaction of EDTA with barium sulfate. J. Colloid. Interface Sci. 2007, 316, 553–561. [Google Scholar] [CrossRef]

- Luo, Z.; Zhang, N.; Zhao, L.; Wang, C.; Wu, L.; Liu, P.; Ji, H. A chelating agent system for the removal of barium sulfate scale. J. Pet. Explor. Prod. Technol. 2020, 10, 3069–3079. [Google Scholar] [CrossRef]

- Ansari, M.; Turney, D.E.; Morris, J.; Banerjee, S. Investigations of rheology and a link to microstructure of oil-based drilling fluids. J. Pet. Sci. Eng. 2021, 196, 108031. [Google Scholar] [CrossRef]

- Hamidi, Y.; Ataei, S.A.; Sarrafi, A. A simple, fast and low-cost method for the efficient separation of hydrocarbons from oily sludge. J. Hazard. Mater. 2021, 413, 125328. [Google Scholar] [CrossRef] [PubMed]

- Mu, B.; Zhu, W.; Zhong, J.; Chen, L.; Lin, N.; Wang, C.; Chen, S.; Li, Z. Mechanism of separation and removal of water from oily sludge using liquid dimethyl ether to dissolve hydrocarbons. Chemosphere 2021, 279, 130452. [Google Scholar] [CrossRef]

- Bao, Q.; Huang, L.; Xiu, J.; Yi, L.; Zhang, Y.; Wu, B. Study on the thermal washing of oily sludge used by rhamnolipid/sophorolipid binary mixed bio-surfactant systems. Ecotoxicol. Environ. Saf 2022, 240, 113696. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Jiang, Q.; Bai, Y.; Li, H.; Xue, J.; Gao, Y.; Cheng, D. Optimization and mechanism of oily sludge treatment by a novel combined surfactants with activated-persulfate method. Sci. Total. Environ. 2021, 800, 149525. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; Liu, W.; Bao, M.; Zhao, L.; Sun, X.; Lu, J.; Li, Y. Oil recovery from polymer-containing oil sludge in oilfield by thermochemical cleaning treatment. Colloids Surf. A Physicochem. Eng. Asp. 2021, 611, 125887. [Google Scholar] [CrossRef]

- Ye, Y.; Li, J.; Zhang, Q.; Feng, J.; Zhu, J.; Yin, D. Nanoemulsion for oil-contaminated oil-based drill cuttings removel in lab. Int. J. Hydrogen Energy 2017, 42, 18734–18740. [Google Scholar] [CrossRef]

- Wang, J.; Guo, P.; Jiang, H.; Zhou, F. A novel multifunction fracturing fluid compounding of nano-emulsion and viscous slickwater for unconventional gas and oil. Arab. J. Chem. 2022, 15, 103749. [Google Scholar] [CrossRef]

- Di, Q.; Qin, K.; Chen, T.; Liu, B.; Li, S.; Zhou, X.; Wang, W.; Chen, F.; Zhang, H. An innovative method for studying the dynamic failure mechanism of box connection of stabilizer in large diameter wellbore of ultra-deep wells. J. Pet. Sci. Eng. 2021, 205, 108822. [Google Scholar] [CrossRef]

- Zhu, T.; Gong, H.; Dong, M.; Yang, Z.; Guo, C.; Liu, M. Phase equilibrium of PVAc + CO2 binary systems and PVAc + CO2 + ethanol ternary systems. Fluid Phase Equilibria 2018, 458, 264–271. [Google Scholar] [CrossRef]

- Li, H.; Lu, H.; Zhang, Y.; Liu, D.; Chen, J. Oil-in-water nanoemulsion with reversible charge prepared by the phase inversion composition method. J. Mol. Liq. 2021, 336, 116174. [Google Scholar] [CrossRef]

- Zhu, T.; Gong, H.; Dong, M. Density and viscosity of CO2 + ethyl acetate binary systems from 308.15 to 338.15 K and 15 to 45 MPa. Fluid Phase Equilibria 2021, 537, 112988. [Google Scholar] [CrossRef]

| Element | Ba | S | Ca | Fe | Si | Mg | Zn | Mn | Al | Na | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content % | 51.999 | 25.067 | 7.353 | 4.869 | 3.628 | 2.387 | 1.36 | 1.005 | 0.773 | 0.409 | 1.15 |

| Species | Tween 80 (or Tween 60) | N-Butanol | N-Octane | Fiber | Barite Perform |

|---|---|---|---|---|---|

| Proportion | 2.1–5.6% | 0.6–1.6% | 0.3–0.8% | 0.09–0.23% | 200% |

| Number | Nano-Emulsion Concentration/(%) | Fiber Addition/(g) | Density/(g/cm3) |

|---|---|---|---|

| 1 | 0.06 | 0.5 | 1.5 |

| 2 | 0.06 | 0.8 | 1.5 |

| 3 | 0.06 | 1 | 1.5 |

| 4 | 0.06 | 1.2 | 1.5 |

| 5 | 0.8 | 0.5 | 1.5 |

| 6 | 0.8 | 0.8 | 1.5 |

| 7 | 0.8 | 1 | 1.5 |

| 8 | 0.8 | 1.2 | 1.5 |

| 9 | 1 | 0.5 | 1.5 |

| 10 | 1 | 0.8 | 1.5 |

| 11 | 1 | 1 | 1.5 |

| 12 | 1 | 1.2 | 1.5 |

| 13 | 1.2 | 0.5 | 1.5 |

| 14 | 1.2 | 0.8 | 1.5 |

| 15 | 1.2 | 1 | 1.5 |

| 16 | 1.2 | 1.2 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, H.; Ye, Y.; Zhang, Z.; Wang, S.; Zhou, T.; Guo, J.; Zhang, S. A Nano-Cleaning Fluid for Downhole Casing Cleaning. Polymers 2023, 15, 1447. https://doi.org/10.3390/polym15061447

Song H, Ye Y, Zhang Z, Wang S, Zhou T, Guo J, Zhang S. A Nano-Cleaning Fluid for Downhole Casing Cleaning. Polymers. 2023; 15(6):1447. https://doi.org/10.3390/polym15061447

Chicago/Turabian StyleSong, Hanxuan, Yan Ye, Zhen Zhang, Shuang Wang, Tong Zhou, Jixiang Guo, and Shiling Zhang. 2023. "A Nano-Cleaning Fluid for Downhole Casing Cleaning" Polymers 15, no. 6: 1447. https://doi.org/10.3390/polym15061447

APA StyleSong, H., Ye, Y., Zhang, Z., Wang, S., Zhou, T., Guo, J., & Zhang, S. (2023). A Nano-Cleaning Fluid for Downhole Casing Cleaning. Polymers, 15(6), 1447. https://doi.org/10.3390/polym15061447