Rheological Behavior and Printability Study of Tri-Calcium Phosphate Ceramic Inks for Direct Ink Writing Method

Abstract

1. Introduction

2. Experimental

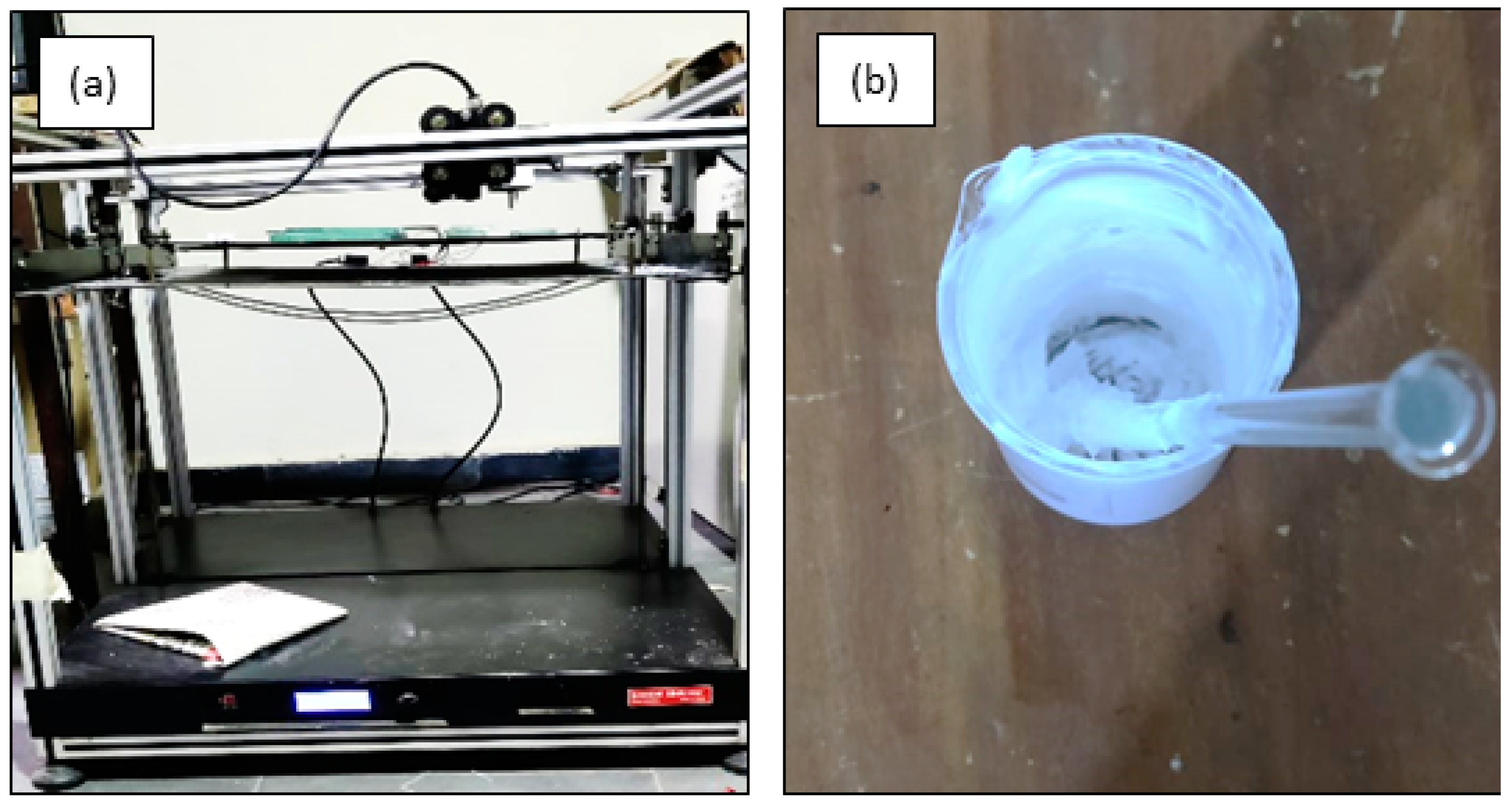

2.1. The Feedstock of the Ink

2.2. TCP Characterization and Rheological Tests of the Ink

2.3. Extrudability

3. Results and Discussion

3.1. Particle Size and Rheological Evaluation

3.2. Extrudabitity Test

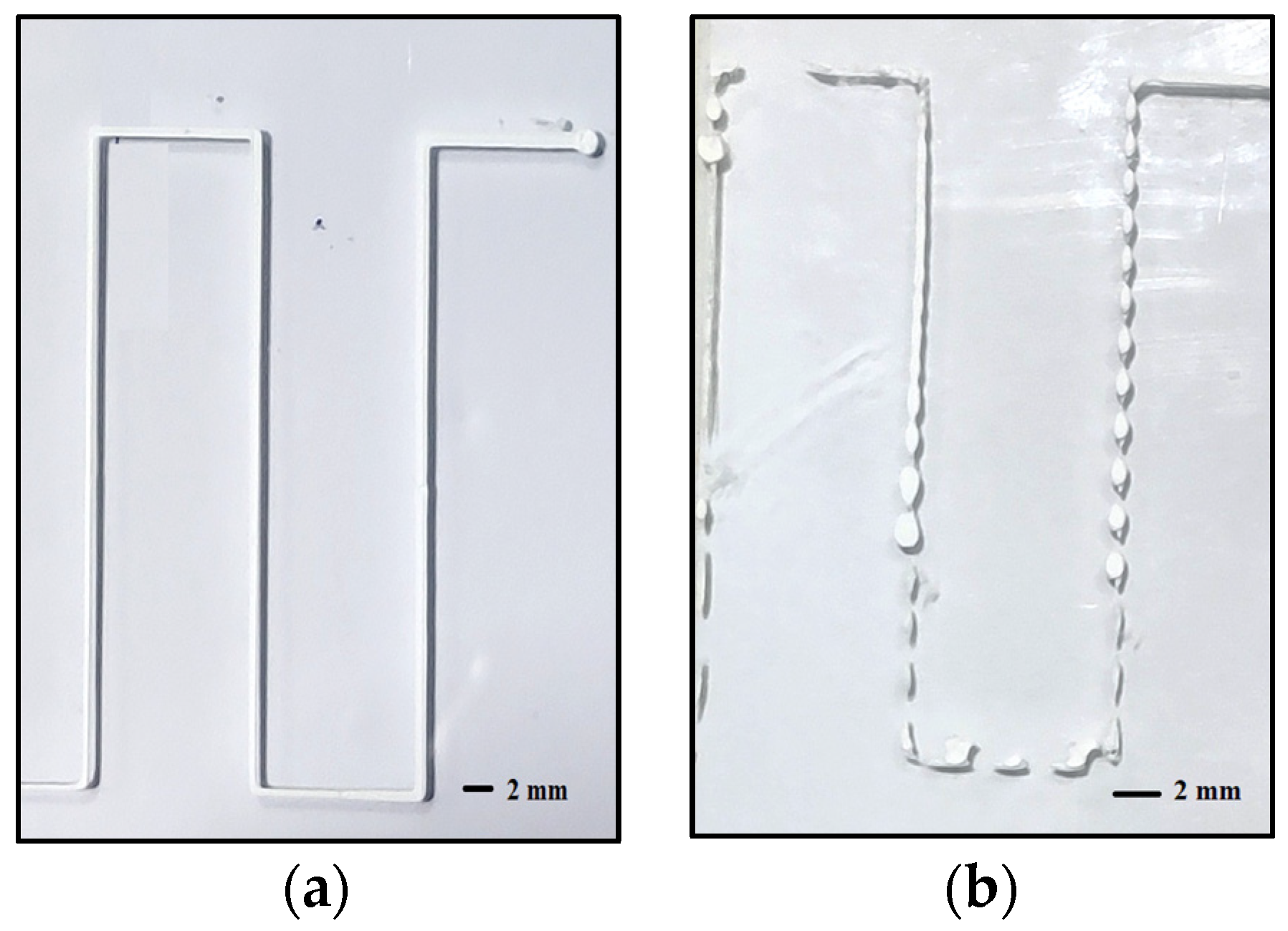

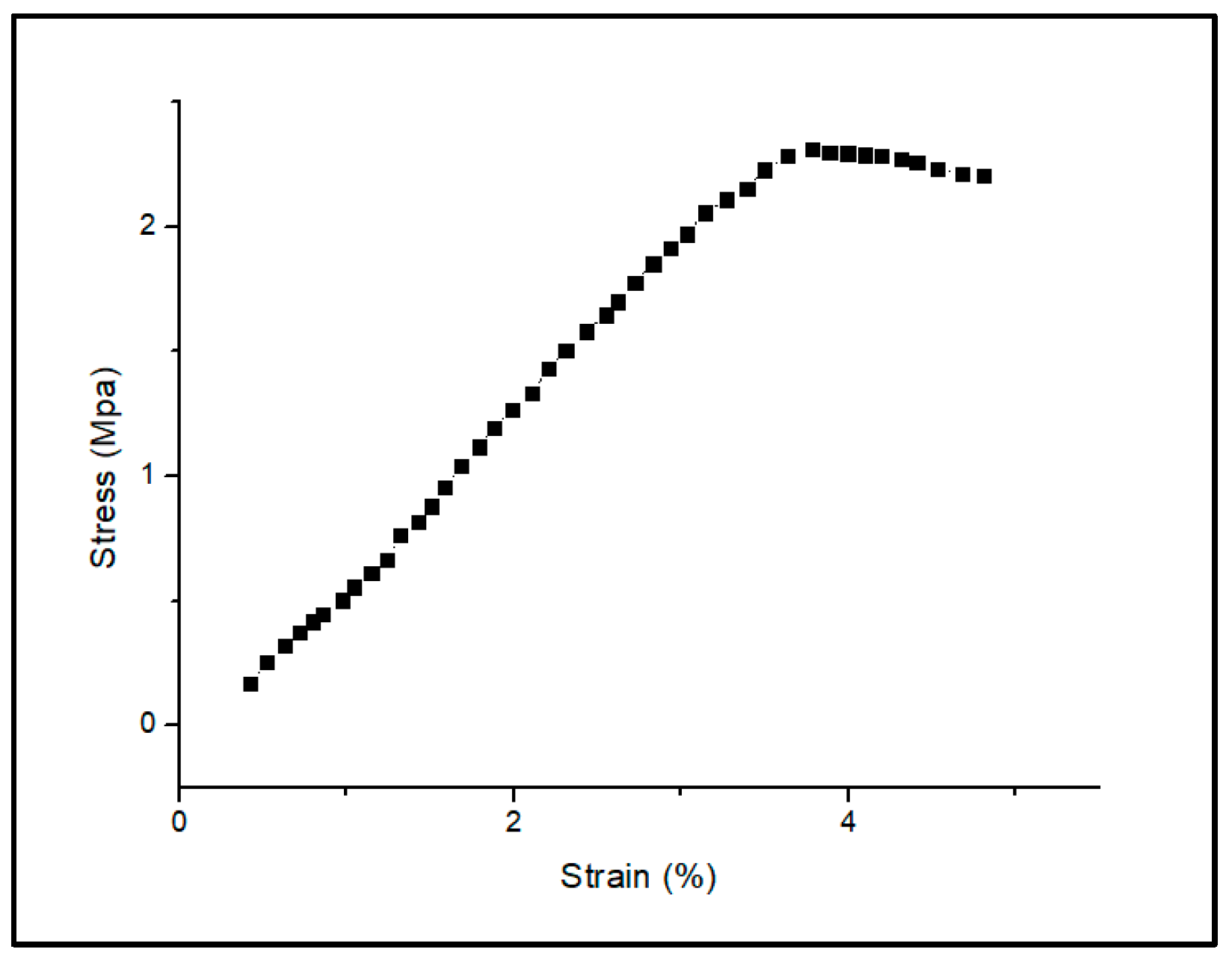

3.3. Line Study

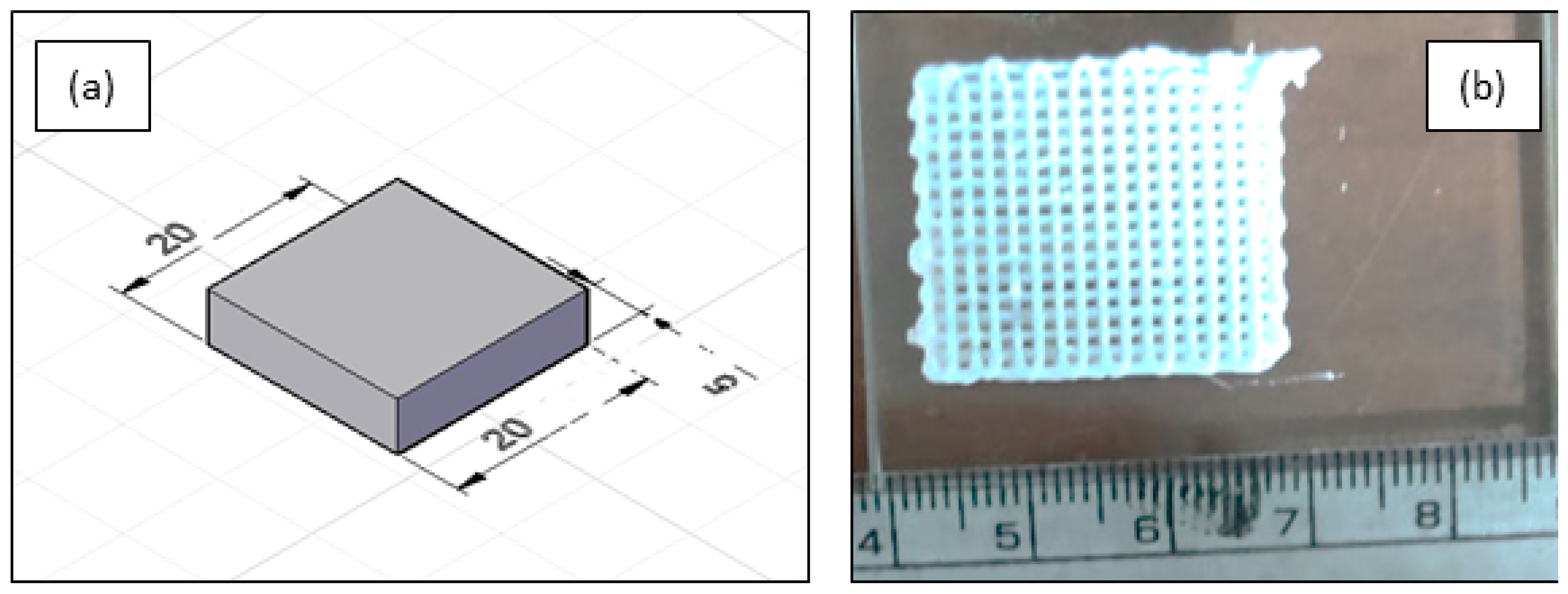

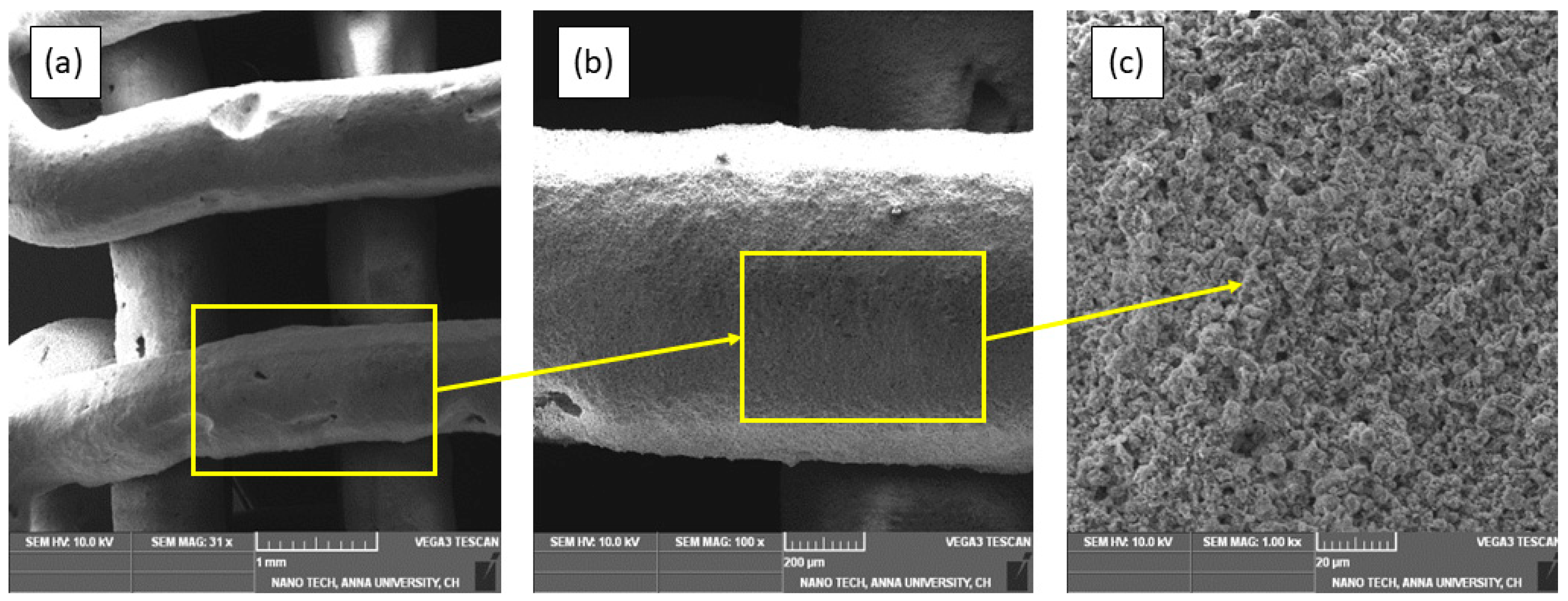

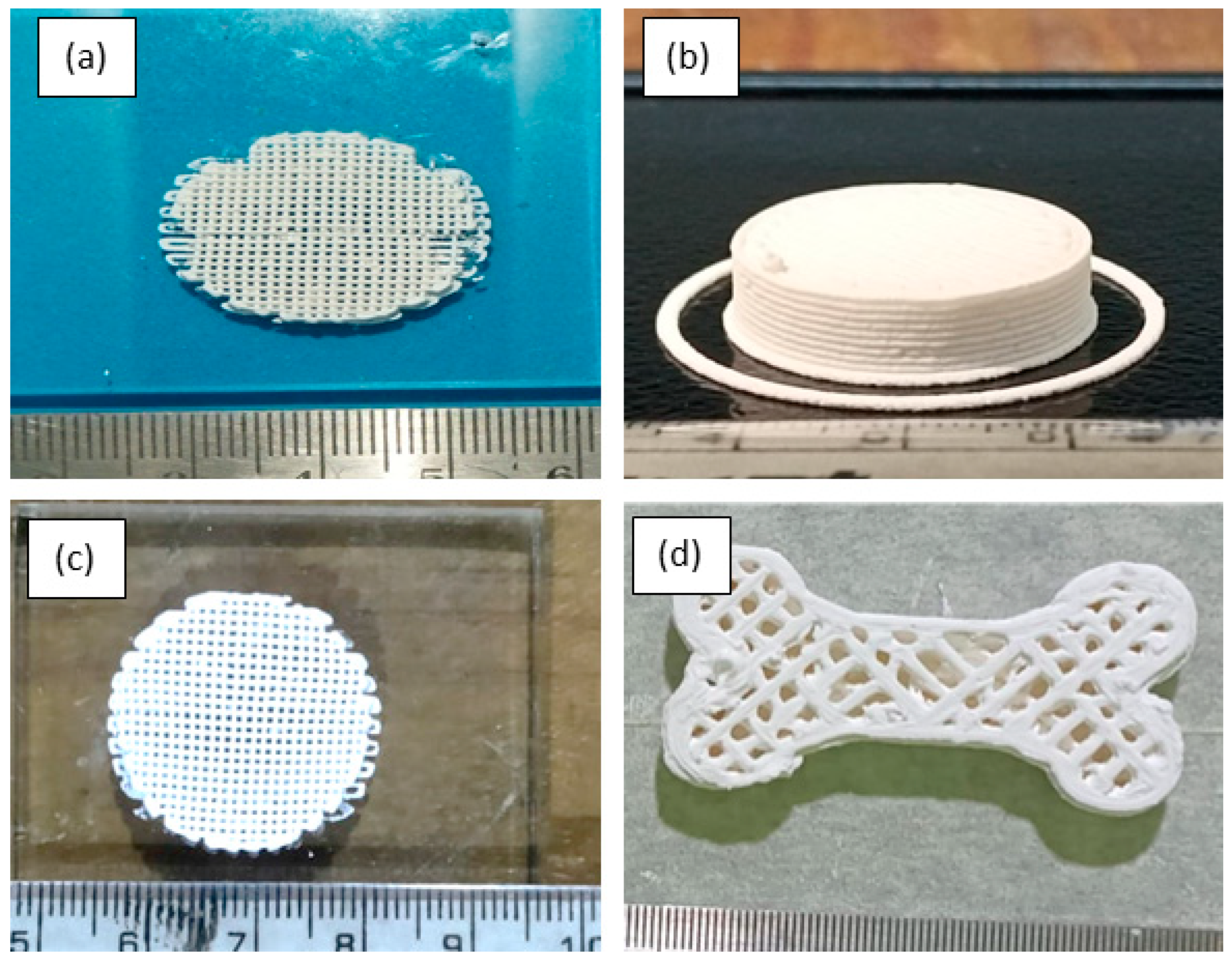

3.4. DIW Printing and Evaluation of Scaffold

3.5. Drying Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gorsse, S.; Hutchinson, C.; Gouné, M.; Banerjee, R. Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 2017, 18, 584–610. [Google Scholar] [CrossRef]

- Govender, R.; Kissi, E.O.; Larsson, A.; Tho, I. Polymers in pharmaceutical additive manufacturing: A balancing act between printability and product performance. Adv. Drug Deliv. Rev. 2021, 177, 113923. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2022, 100, 224–236. [Google Scholar] [CrossRef]

- Zhu, N.; Hou, Y.; Yang, W.; Zhong, C.; Zhang, L.; Wang, D.; Zhang, R.; Li, L.; Wen, G. Additive manufacturing low shrinkage Si-based composite ceramics with SiCO microsphere/polyvinyl silicon acetylene slurry. J. Eur. Ceram. Soc. 2022, 42, 6925–6934. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modeling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Spears, T.G.; Gold, S.A. In-process sensing in selective laser melting (SLM) additive manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 16–40. [Google Scholar] [CrossRef]

- Bozkurt, Y.; Karayel, E. 3D printing technology; methods, biomedical applications, future opportunities and trends. J. Mater. Res. Technol. 2021, 14, 1430–1450. [Google Scholar] [CrossRef]

- Ahammed, S.R.; Susila, P.A. Direct writing of electronic circuits using functionalised multi-walled carbon nanotubes and polyvinyl alcohol conductive ink. Adv. Mater. Process. Technol. 2021, 8, 2496–2509. [Google Scholar] [CrossRef]

- Sofia, D.; Chirone, R.; Lettieri, P.; Barletta, D.; Poletto, M. Selective laser sintering of ceramic powders with bimodal particle size distribution. Chem. Eng. Res. Des. 2018, 136, 536–547. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Zhao, L.; Tian, Z.; Yang, S. Direct selective laser sintering and melting of ceramics: A review. Rapid Prototyp. J. 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, X. The influences of the material properties on ceramic micro-stereolithography. Sens. Actuators A Phys. 2002, 101, 364–370. [Google Scholar] [CrossRef]

- Dufaud, O.; Corbel, S. Stereolithography of PZT ceramic suspensions. Rapid Prototyp. J. 2002, 8, 83–90. [Google Scholar] [CrossRef]

- Elsayed, H.; Colombo, P.; Bernardo, E. Direct ink writing of wollastonite-diopside glass-ceramic scaffolds from a silicone resin and engineered fillers. J. Eur. Ceram. Soc. 2017, 37, 4187–4195. [Google Scholar] [CrossRef]

- Pan, Y.; Zhu, P.; Wang, R.; Si, Z.; Li, B.; Yao, Y. Direct ink writing of porous cordierite honeycomb ceramic. Ceram. Int. 2019, 45, 15230–15236. [Google Scholar] [CrossRef]

- Lv, X.; Ye, F.; Cheng, L.; Fan, S.; Liu, Y. Binder jetting of ceramics: Powders, binders, printing parameters, equipment, and post-treatment. Ceram. Int. 2019, 45, 12609–12624. [Google Scholar] [CrossRef]

- Du, W.; Ren, X.; Ma, C.; Pei, Z. Binder Jetting Additive Manufacturing of Ceramics: A Literature Review. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: Tampa, FL, USA, 2017; Volume 14. [Google Scholar] [CrossRef]

- Shao, H.; He, J.; Lin, T.; Zhang, Z.; Zhang, Y.; Liu, S. 3D gel-printing of hydroxyapatite scaffold for bone tissue engineering. Ceram. Int. 2019, 45, 1163–1170. [Google Scholar] [CrossRef]

- Hon, K.K.B.; Li, L.; Hutchings, I.M. Direct writing technology-Advances and developments. CIRP Ann. Manuf. Technol. 2008, 57, 601–620. [Google Scholar] [CrossRef]

- Lee, G.S.; Park, J.H.; Shin, U.S.; Kim, H.W. Direct deposited porous scaffolds of calcium phosphate cement with alginate for drug delivery and bone tissue engineering. Acta Biomater. 2011, 7, 3178–3186. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, H.; Lin, T.; Peng, J.; Wang, A.; Zhang, Z.; Wang, L.; Liu, S.; Yu, X. Effect of Ca/P ratios on porous calcium phosphate salt bioceramic scaffolds for bone engineering by 3D gel-printing method. Ceram. Int. 2019, 45, 20493–20500. [Google Scholar] [CrossRef]

- Maazouz, Y.; Rentsch, I.; Lu, B.; Santoni, B.L.G.; Doebelin, N.; Bohner, M. In vitro measurement of the chemical changes occurring within β—Tricalcium phosphate bone graft substitutes. Acta Biomater. 2019, 102, 440–457. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Korachkin, D.; Gethin, D.T.; Lewis, R.W.; Tweed, J.H.; Guyoncourt, D.M.M. Measurement of Young’s modulus and tensile failure properties of green powder compacts. Powder Metall. 2008, 51, 150–159. [Google Scholar] [CrossRef]

- Carneim, T.J.; Green, D.J. Mechanical Properties of Dry-Pressed Alumina Green Bodies. J. Am. Ceram. Soc. 2001, 84, 1405–1410. [Google Scholar] [CrossRef]

- Somers, N.; Jean, F.; Lasgorceix, M.; Preux, N.; Delmotte, C.; Boilet, L.; Petit, F.; Leriche, A. Fabrication of doped β-tricalcium phosphate bioceramics by Direct Ink Writing for bone repair applications. J. Eur. Ceram. Soc. 2023, 43, 629–638. [Google Scholar] [CrossRef]

- Zhu, H.; Li, M.; Huang, X.; Qi, D.; Nogueira, L.P.; Yuan, X.; Liu, W.; Lei, Z.; Jiang, J.; Dai, H.; et al. 3D printed tricalcium phosphate-bioglass scaffold with gyroid structure enhance bone ingrowth in challenging bone defect treatment. Appl. Mater. Today 2021, 25, 101166. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, J.; Huang, X.; Wang, L.; Liu, G.; Cheng, J. In situ preparation of hierarchically porous β-tricalcium phosphate bioceramic scaffolds by the sol-gel method combined with F127. Ceram. Int. 2020, 46, 6396–6405. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, N.; Ma, Y.; Dai, H.; Han, B. Preparation and study of 3D printed dipyridamole/β-tricalcium phosphate/ polyvinyl alcohol composite scaffolds in bone tissue engineering. J. Drug Deliv. Sci. Technol. 2022, 68, 103053. [Google Scholar] [CrossRef]

- Dolganov, A.; Bishop, M.T.; Chen, G.Z.; Hu, D. Rheological study and printability investigation of titania inks for Direct Ink Writing process. Ceram. Int. 2021, 47, 12020–12027. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Stringari, G.; Emri, I. Powder Injection Molding of Metal and Ceramic Parts; Intech: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

- Baradararan, S.; Hamdi, M.; Metselaar, I.H. Biphasic calcium phosphate (BCP) macroporous scaffold with different ratios of HA/β-TCP by combination of gel casting and polymer sponge methods. Adv. Appl. Ceram. 2012, 111, 367–373. [Google Scholar] [CrossRef]

- Wu, W.; Du, H.; Sui, H.; Guo, X.; Wang, B.; Li, G.; Zhao, J. Printing parameters and strengthening mechanism of pneumatic injection additive manufacturing with iron powder slurry. Int. J. Adv. Manuf. Technol. 2018, 94, 3809–3817. [Google Scholar] [CrossRef]

- Maurath, J.; Willenbacher, N. 3D printing of open-porous cellular ceramics with high specific strength. J. Eur. Ceram. Soc. 2017, 37, 4833–4842. [Google Scholar] [CrossRef]

- Goyos-Ball, L.; García-Tuñón, E.; Fernández-García, E.; Díaz, R.; Fernández, A.; Prado, C.; Saiz, E.; Torrecillas, R. Mechanical and biological evaluation of 3D printed 10CeTZP-Al2O3 structures. J. Eur. Ceram. Soc. 2017, 37, 3151–3158. [Google Scholar] [CrossRef]

- Sadeghzade, S.; Emadi, R.; Ahmadi, T.; Tavangarian, F. Synthesis, characterization and strengthening mechanism of modified and unmodified porous diopside/baghdadite scaffolds. Mater. Chem. Phys. 2019, 228, 89–97. [Google Scholar] [CrossRef]

- Zhang, D.; Jonhson, W.; Herng, T.S.; Ang, Y.Q.; Yang, L.; Tan, S.C.; Peng, E.; He, H.; Ding, J.A. 3D-printing method of fabrication for metals, ceramics, and multi-materials using a universal self-curable technique for robocasting. Mater. Horiz. 2020, 7, 1083–1090. [Google Scholar] [CrossRef]

- Ford, R.W. Ceramics Drying. Elsevier Science. 2013. Available online: https://books.google.co.in/books?id=7AkhBQAAQBAJ (accessed on 5 March 2022).

- Zaccaron, A.; de Souza Nandi, V.; Bó, M.D.; Arcaro, S.; Bernardin, A.M. The behavior of different clays subjected to a fast-drying cycle for traditional ceramic manufacturing. J. King Saud Univ. Eng. Sci. 2022. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul D L, B.; Praveen, A.S.; Čepová, L.; Elangovan, M. Rheological Behavior and Printability Study of Tri-Calcium Phosphate Ceramic Inks for Direct Ink Writing Method. Polymers 2023, 15, 1433. https://doi.org/10.3390/polym15061433

Paul D L B, Praveen AS, Čepová L, Elangovan M. Rheological Behavior and Printability Study of Tri-Calcium Phosphate Ceramic Inks for Direct Ink Writing Method. Polymers. 2023; 15(6):1433. https://doi.org/10.3390/polym15061433

Chicago/Turabian StylePaul D L, Belgin, Ayyappan Susila Praveen, Lenka Čepová, and Muniyandy Elangovan. 2023. "Rheological Behavior and Printability Study of Tri-Calcium Phosphate Ceramic Inks for Direct Ink Writing Method" Polymers 15, no. 6: 1433. https://doi.org/10.3390/polym15061433

APA StylePaul D L, B., Praveen, A. S., Čepová, L., & Elangovan, M. (2023). Rheological Behavior and Printability Study of Tri-Calcium Phosphate Ceramic Inks for Direct Ink Writing Method. Polymers, 15(6), 1433. https://doi.org/10.3390/polym15061433