Evaluation of PVC-Type Insulation Foam Material for Cryogenic Applications

Abstract

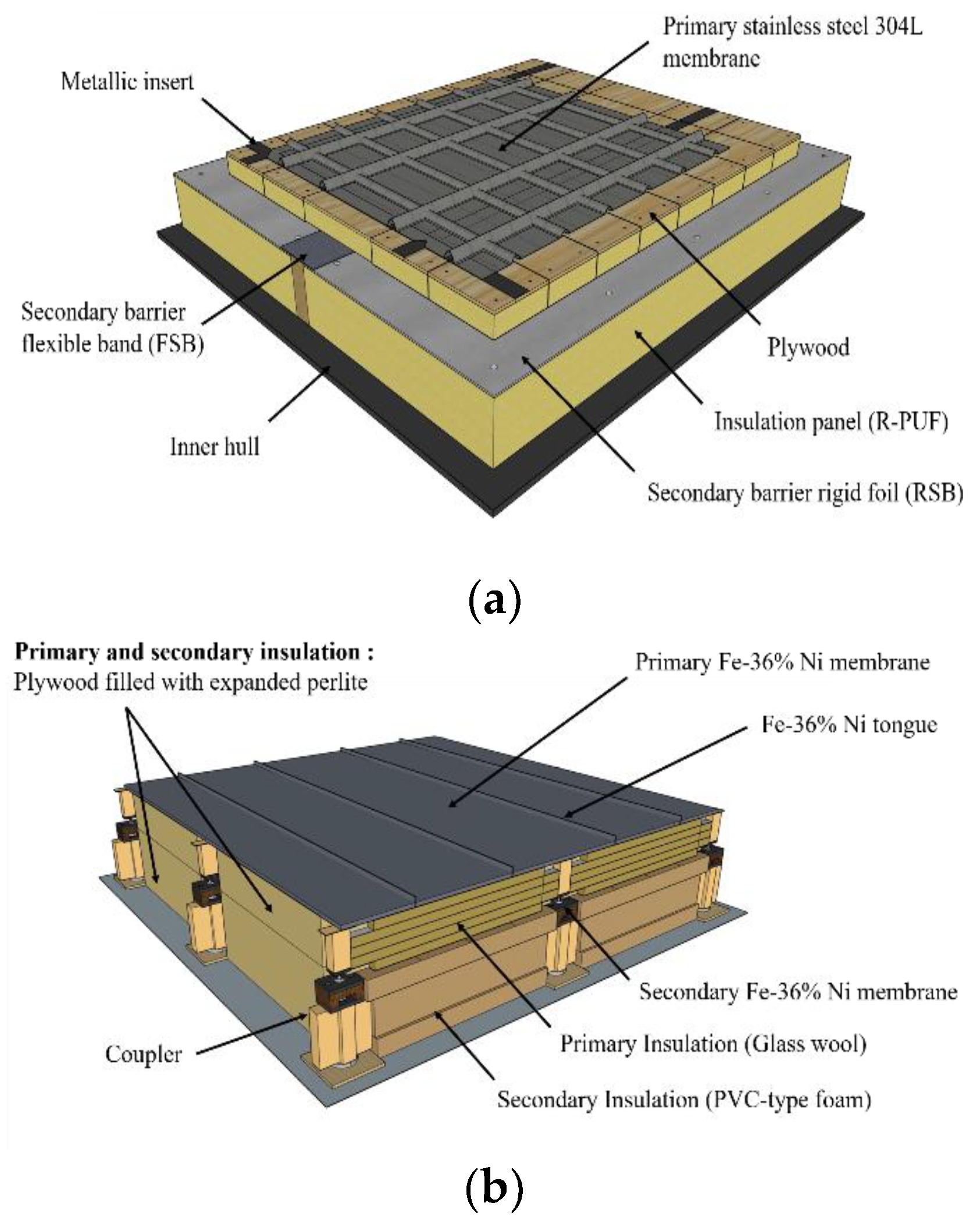

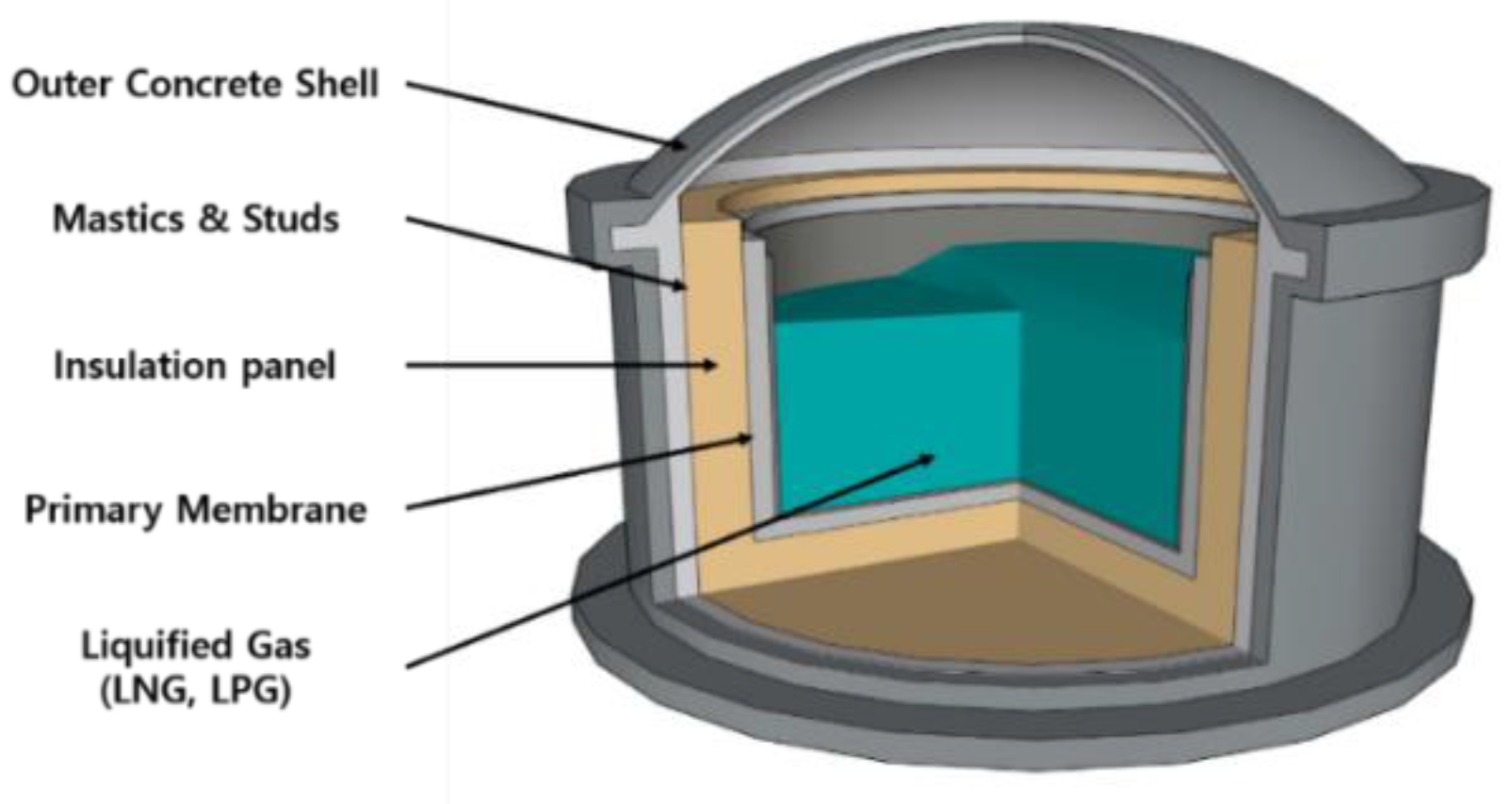

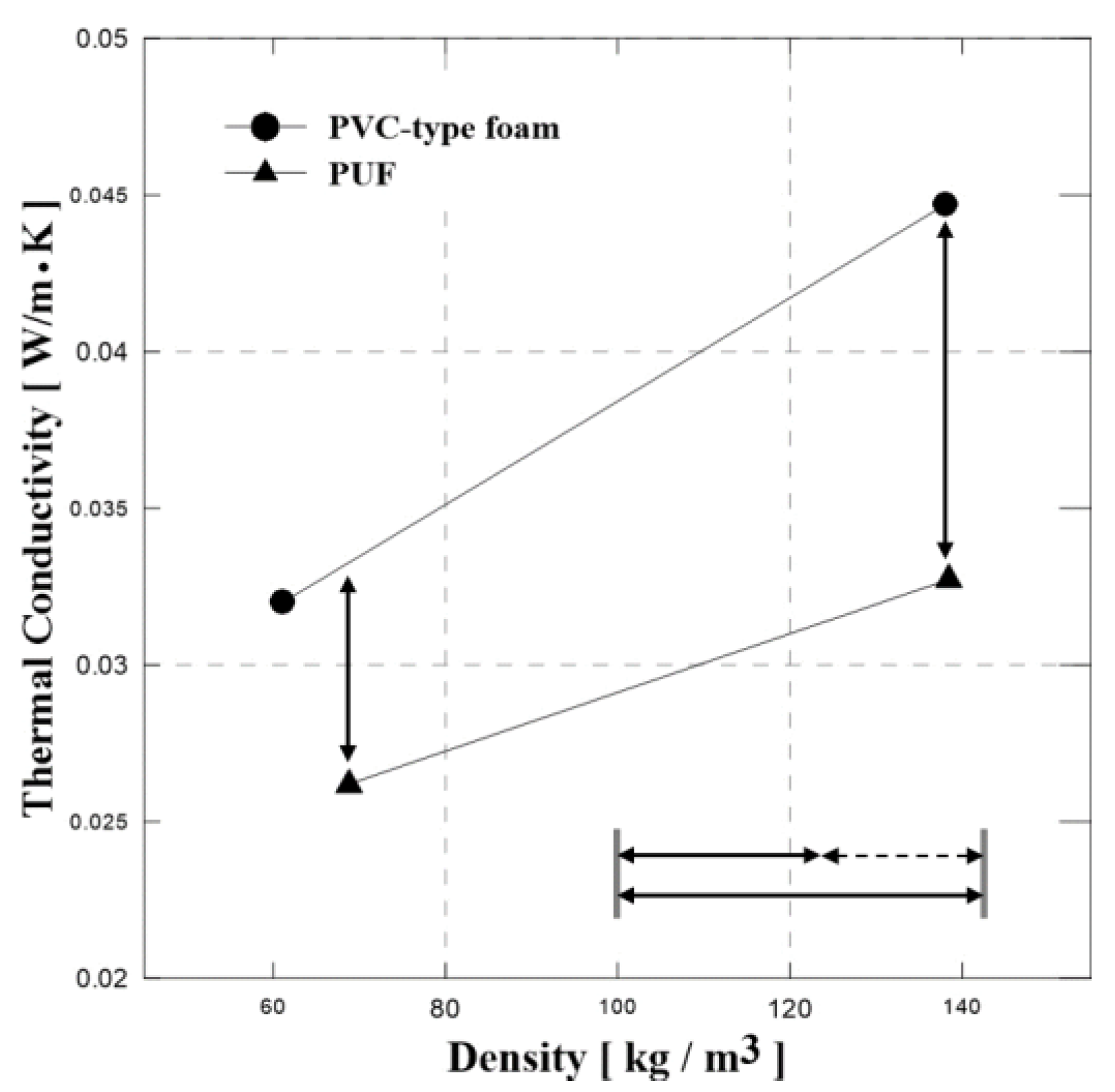

1. Introduction

2. Materials and Methods

2.1. Test Specimen and Apparatus

2.1.1. Thermal Conductivity

2.1.2. Tensile Test

2.1.3. Compressive Test

2.1.4. Impact Test

2.1.5. Scanning Electron Microscopy

2.2. Experiment Temperature Environment

3. Results and Discussion

3.1. Cellular Morphology of PUF and PVC-Type Foam

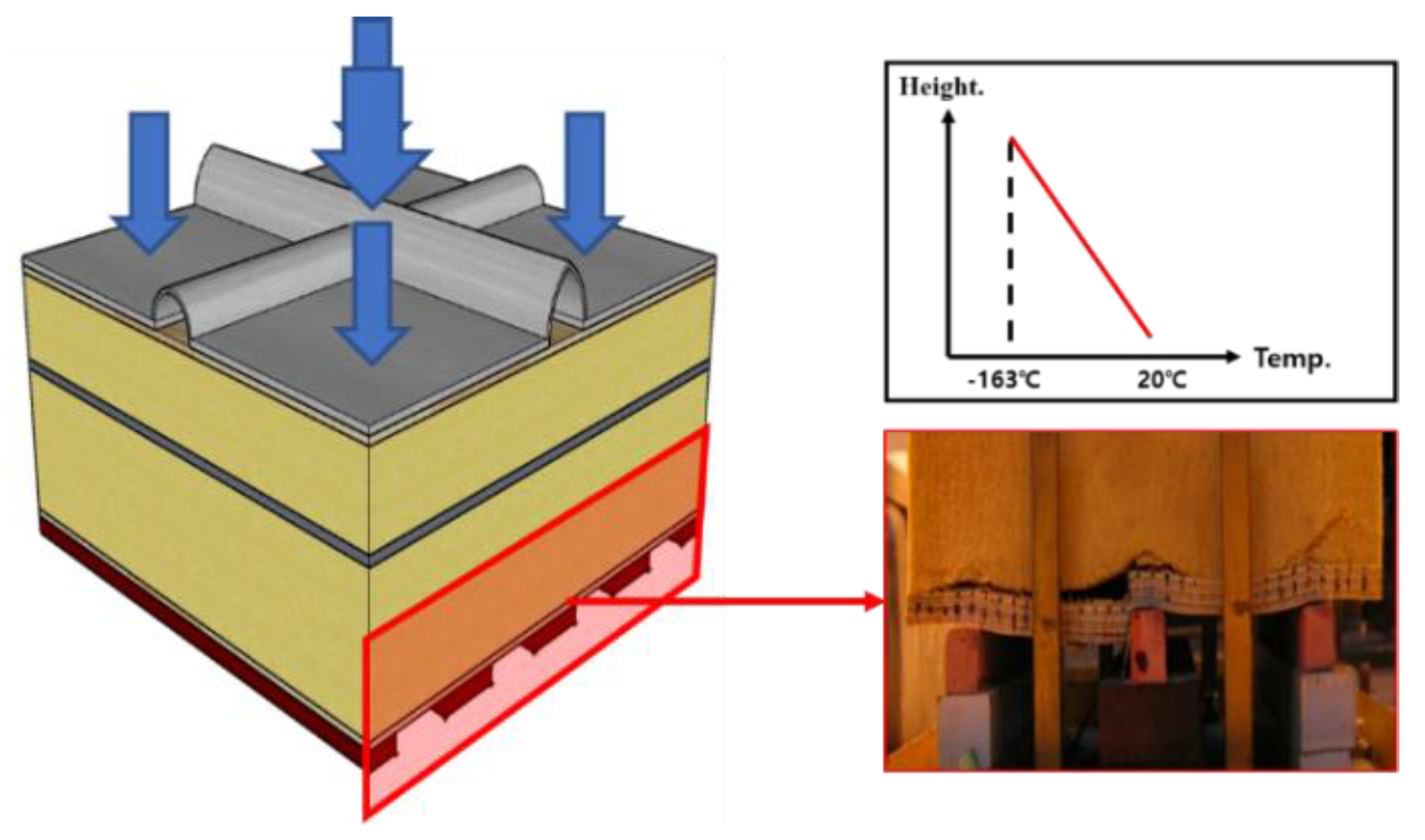

3.2. Thermal Conductivity

3.3. Tensile Test

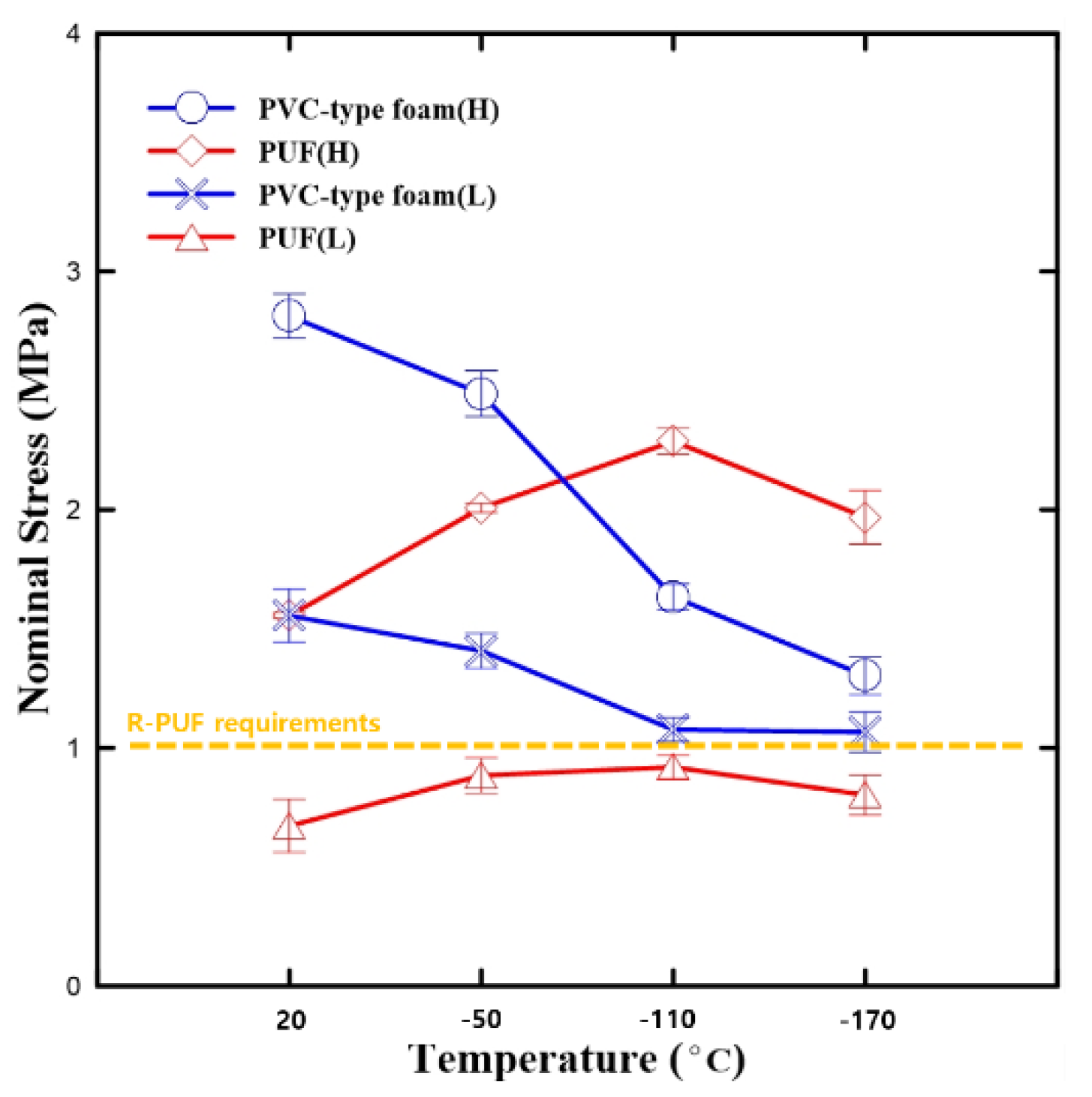

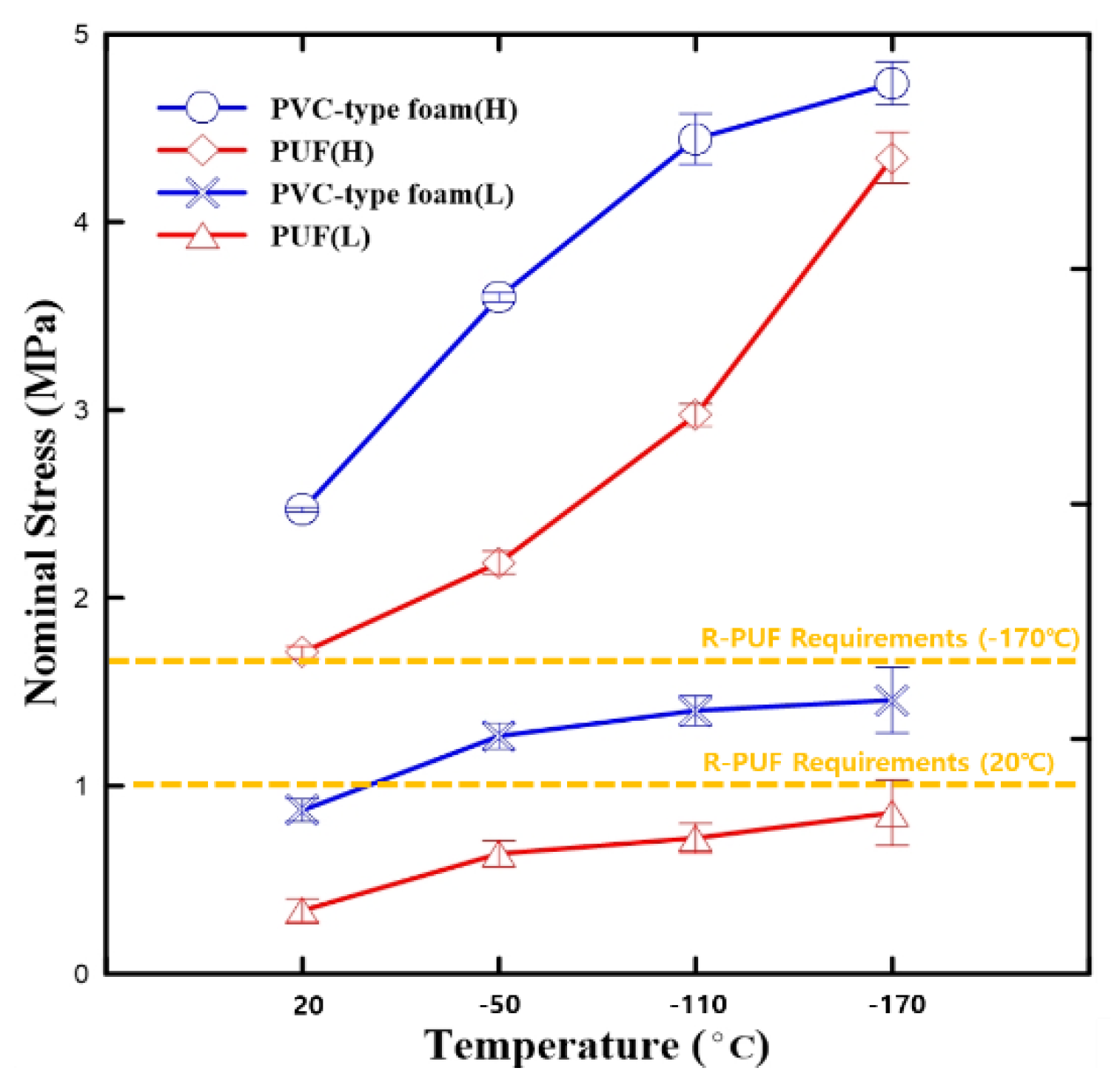

3.4. Compressive Test

3.5. Impact Behavior

4. Conclusions

- The thermal conductivity test indicates that PUF offers better insulation performance and presents a thermal conductivity approximately 35% lower at a density of 144 kg/m3 and 20% lower at a density of approximately 64 kg/m3 than PVC-type foam.

- The results of a compressive test on PVC-type foam with a high density (144 kg/m3) exhibited that brittle crushing causes a significant decrease in target material strength. Additionally, the neat PUF tends to splinter into several pieces, whereas PVC-type foam develops dents. Thus, the PVC-type foams possess elevated strength over the PUFs.

- In the tensile test, the tensile strength and elastic modulus increase as temperature decreases. In both materials, a density of approximately 140 kg/m3 allows for a higher strength than at a density of approximately 64 kg/m3. High-density PVC-type foam is approximately 30% weaker than PUF at –110 °C or lower temperatures, whereas PVC-type foam is approximately 40% stronger than PUF at all temperatures.

- Overall, the impact test conveys that the initial peak forces of PVC-type foam are higher than those of PUF, while the absorption energy ratios are similar. Hence, PVC-type foam offers tangible advantages over PUFs in terms of impact resistance.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Galdo, M. Marine Engines Performance and Emissions. J. Mar. Sci. Eng. 2021, 9, 280. [Google Scholar] [CrossRef]

- Lindstad, H.E.; Rehn, C.F.; Eskeland, G.S. Sulphur abatement globally in maritime shipping. Transp. Res. Part D 2017, 57, 303–313. [Google Scholar] [CrossRef]

- Slaughter, A.; Ray, S.; Shattuck, T. International Maritime Organization (IMO) 2020 Strategies in a Non-Compliant World; Deloitte: London, UK, 2019. [Google Scholar]

- Kumar, S.; Kwon, H.-T.; Choi, K.-H.; Lim, W.; Cho, J.H.; Tak, K.; Moon, I. LNG: An eco-friendly cryogenic fuel for sustainable development. Appl. Energy 2011, 88, 4264–4273. [Google Scholar] [CrossRef]

- BP. Statistical Review of World Energy Globally Consistent Data on World Energy Markets; BP: London, UK, 2020; p. 66. [Google Scholar]

- Choe, Y.-R.; Kim, J.-H.; Kim, J.-M.; Park, S.; Park, K.H.; Lee, J.-M. Evaluation of Cryogenic Compressive Strength of Divinycell of NO 96-type LNG Insulation System. J. Ocean Eng. Technol. 2016, 30, 349–355. [Google Scholar] [CrossRef]

- Lloyd’s Register. List of Lloyd’s Register Approved Material/Components for GTT Mk III & Mk V Membrane Containment System; Lloyd’s Register Group Services Ltd.: London, UK, 2019; pp. 1–26. [Google Scholar]

- Diab. Divinycell CY SI. 2020. Available online: https://www.diabgroup.com/products-services/divinycell-pvc/divinycell-h/ (accessed on 14 November 2022).

- Dnv, G.L. Class Guideline Liquefied Gas Carriers with Membrane Tanks; American Bureau of Shipping: Houston, TX, USA, 2020. [Google Scholar]

- Lee, Y.; Choi, S.; Choe, K.; Kim, S. Physical and mechanical characteristics of polyurethane foam insulators blown by HFC. In Proceedings of the 15th International Offshore and Polar Engineering Conference, Seoul, Republic of Korea, 19–24 June 2005. [Google Scholar]

- Grieve, P.; GST. A New Generation of LNG Membrane-Type Land Storage Tank; Gaztransport & Technigaz: Chevreuse, France, 2010; Available online: https://gtt.fr/sites/default/files/2010_lng16-gst-new-generation-lng-membrane-type-storage-tank-2012-04-11.pdf (accessed on 14 November 2022).

- Jeong, H.; Shim, W.J. Calculation of Boil-Off Gas (BOG) Generation of KC-1 Membrane LNG Tank with High Density Rigid Polyurethane Foam by Numerical Analysis. Pol. Marit. Res. 2017, 24, 100–114. [Google Scholar] [CrossRef]

- Lee, J.M.; Kim, M.H. Impact Strength Assessment of LNG Carrier Insulation System. Key Eng. Mater. 2006, 326–328, 1527–1530. [Google Scholar]

- Chun, M.S.; Kim, M.H.; Kim, W.S.; Kim, S.H.; Lee, J.-M. Experimental investigation on the impact behavior of membrane-type LNG carrier insulation system. J. Loss Prev. Process Ind. 2009, 22, 901–907. [Google Scholar] [CrossRef]

- Lu, J.; Xu, S.; Deng, J.; Wu, W.; Wu, H.; Yang, Z. Numerical prediction of temperature field for cargo containment system (CCS) of LNG carriers during pre-cooling operations. J. Nat. Gas Sci. Eng. 2016, 29, 382–391. [Google Scholar] [CrossRef]

- Kim, M.H.; Kil, Y.P.; Lee, J.M.; Chun, M.S.; Suh, Y.S.; Kim, W.S.; Noh, B.J.; Yoon, J.H.; Kim, M.S.; Urm, H.S. Cryogenic Fatigue Strength Assessment for MARK-III Insulation System of LNG Carriers. J. Offshore Mech. Arct. Eng. 2011, 133, 041401. [Google Scholar] [CrossRef]

- Iii, M.; Density, H. GTT Inside 3. 2015. Available online: https://gtt.fr/news/news-newsletter-gtt-inside-3-january-2015 (accessed on 14 November 2022).

- Hiroshi, T.; Hirotomo, O.; Toshinori, I.; Satoshi, M. New LPG Carrier Adopting Highly Reliable Cargo Tank-IMO Tank Type B-. Mitsubishi Heavy Ind. Tech. Rev. 2013, 50, 12–17. [Google Scholar]

- Park, S.-B.; Choi, S.-W.; Kim, J.-H.; Bang, C.-S.; Lee, J.-M. Effect of the blowing agent on the low-temperature mechanical properties of CO2- and HFC-245fa-blown glass-fiber-reinforced polyurethane foams. Compos. Part B Eng. 2016, 93, 317–327. [Google Scholar] [CrossRef]

- Son, Y.; Kim, J.; Choi, S.; Her, N.Y.; Lee, J. Synthesis of Polyurethane Foam Considering Mixture Blowing Agents for Application to Cryogenic Environments. Macromol. Mater. Eng. 2019, 304, 1900294. [Google Scholar] [CrossRef]

- Marșavina, L.; Linul, E. Fracture toughness of rigid polymeric foams: A review. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2483–2514. [Google Scholar] [CrossRef]

- Arvidson, J.M.; Sparks, L.L. Low Temperature Mechanical Prop-Erties of a Polyurethane Foam; National Bureau of Standards, U.S. Department of Commerce: Denver, CO, USA, 1981.

- Farshidi, A.; Berggreen, C.; Carlsson, L.A. Low temperature mixed-mode debond fracture and fatigue characterisation of foam core sandwich. J. Sandw. Struct. Mater. 2018, 22, 1039–1054. [Google Scholar] [CrossRef]

- Demharter, A. Polyurethane rigid foam, a proven thermalinsulating material for applications between +130 °C and −196 °C. Cryogenics 1998, 38, 113–117. [Google Scholar] [CrossRef]

- Yakushin, V.A.; Zhmud, N.P.; Stirna, U.K. Physicomechanical characteristics of spray-on rigid polyurethane foams at normaland low temperatures. Mech. Compos. Mater. 2002, 38, 273–280. [Google Scholar] [CrossRef]

- Stirna, U.; Beverte, I.; Yakushin, V.; Cabulis, U. Mechanical properties of rigid polyurethane foams at room and cryogenic temperatures. J. Cell. Plast. 2011, 47, 337–355. [Google Scholar] [CrossRef]

- Denay, A.G.; Castagnet, S.; Roy, A.; Alise, G.; Thenard, N. Compres-sion behavior of glass-fiber-reinforced and pure polyurethanefoams at negative temperatures down to cryogenic ones. J. Cell. Plast. 2013, 49, 209–222. [Google Scholar] [CrossRef]

- Yakushin, V.; Cabulis, U.; Sevastyanova, I. Effect of filler type on the properties of rigid polyurethane foams at a cryogenic temperature. Mech. Compos. Mater. 2015, 51, 447–454. [Google Scholar] [CrossRef]

- Hwang, B.-K.; Kim, S.-K.; Kim, J.-H.; Lee, J.-M. Dynamic compressive behavior of rigid polyurethane foam with various densities under different temperatures. Int. J. Mech. Sci. 2020, 180, 105657. [Google Scholar] [CrossRef]

- Lee, Y.; Choi, S.; Choi, G. Characteristics of Rigid Polyurethane Foams Blown by HFCs for LNG Storage Tank. J. Korean Inst. Gas 2005, 9, 16–20. [Google Scholar]

- Kara, M.; Kırıcı, M.; Tatar, A.C.; Avcı, A. Impact behavior of carbon fiber/epoxy composite tubes reinforced with multi-walled carbon nanotubes at cryogenic environment. Compos. Part B Eng. 2018, 145, 145–154. [Google Scholar] [CrossRef]

- Saint-Michel, F.; Chazeau, L.; Cavaillé, J.-Y.; Chabert, E. Mechanical properties of high density polyurethane foams: I. Effect of the density. Compos. Sci. Technol. 2006, 66, 2700–2708. [Google Scholar] [CrossRef]

- Saha, M.; Mahfuz, H.; Chakravarty, U.; Uddin, M.; Kabir, M.E.; Jeelani, S. Effect of density, microstructure, and strain rate on compression behavior of polymeric foams. Mater. Sci. Eng. A 2005, 406, 328–336. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure & Properties, 1st ed.; Pergamon Press: Oxford, UK, 1988. [Google Scholar]

- Park, J.; Kim, H.; Kim, J.; Kim, J.; Kim, S.; Lee, J. Eco-friendly blowing agent, HCFO-1233zd, for the synthesis of polyurethane foam as cryogenic insulation. J. Appl. Polym. Sci. 2021, 139, 51492. [Google Scholar] [CrossRef]

- Goldstein, J.I.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.M.; Scott, J.H.J.; Joy, D.C. Scanning Electron Microscopy and X-ray Microanalysis; Springer: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Yao, H.; Pang, Y.; Liu, X.; Qu, J. Experimental Study of the Dynamic and Static Compression Mechanical Properties of Closed-Cell PVC Foams. Polymers 2022, 14, 3522. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Singha, N.K.; Manjunath, B.; Naik, Y. Mechanical, Morphological and Thermal Properties of Rigid Polyurethane Foam: Effect of the Fillers. Cell. Polym. 2007, 26, 245–259. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, W.; Jiang, X.; Zhao, J.; Xie, W.; Chen, T. Experimental investigations on phenomenological constitutive model of closed-cell PVC foam considering the effects of density, strain rate and anisotropy. Compos. Part B Eng. 2022, 238, 109885. [Google Scholar] [CrossRef]

- Raje, A.; Buhr, K.; Koll, J.; Lillepärg, J.; Abetz, V.; Handge, U.A. Open-Celled Foams of Polyethersulfone/Poly(N-vinylpyrrolidone) Blends for Ultrafiltration Applications. Polymers 2022, 14, 1177. [Google Scholar] [CrossRef]

- Maiti, S.K.; Gibson, L.J.; Ashby, M.F. Deformation and energy absorption diagrams for cellular solids. Acta Met. 1984, 32, 1963–1975. [Google Scholar] [CrossRef]

- Jarfelt, U.; Ramnäs, O. Thermal conductivity of polyurethane foam—Best performance Thermal conductivity of polyurethane foam Best performance. In Proceedings of the 10th International Symposium on District Heating and Cooling, Reykjavik, Iceland, 3–5 September 2006; p. 12. [Google Scholar]

- Choe, H.; Choi, Y.; Kim, J.H. Threshold cell diameter for high thermal insulation of water-blown rigid polyurethane foams. J. Ind. Eng. Chem. 2019, 73, 344–350. [Google Scholar] [CrossRef]

- Kabir, E.; Saha, M.; Jeelani, S. Tensile and fracture behavior of polymer foams. Mater. Sci. Eng. A 2006, 429, 225–235. [Google Scholar] [CrossRef]

- Tu, Z.; Shim, V.; Lim, C. Plastic deformation modes in rigid polyurethane foam under static loading. Int. J. Solids Struct. 2001, 38, 9267–9279. [Google Scholar] [CrossRef]

- Park, S.-B.; Lee, C.-S.; Choi, S.-W.; Kim, J.-H.; Bang, C.-S.; Lee, J.-M. Polymeric foams for cryogenic temperature application: Temperature range for non-recovery and brittle-fracture of microstructure. Compos. Struct. 2016, 136, 258–269. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Q.; He, Z.; Zong, Z.; Fang, J. Dynamic impact response of aluminum honeycombs filled with Expanded Polypropylene foam. Compos. Part B Eng. 2019, 156, 17–27. [Google Scholar] [CrossRef]

- Banyay, G.; Shaltout, M.; Tiwari, H.; Mehta, B. Polymer and composite foam for hydrogen storage application. J. Mater. Process Technol. 2007, 191, 102–105. [Google Scholar] [CrossRef]

| Test Method | Test Material | Density (kg/mm3) | Specimen Thickness (mm) |

|---|---|---|---|

| Insulation | PUF | 68.8 (L) | 25 |

| 138.4 (H) | |||

| PVC-type foam | 61.1 (L) | ||

| 138.1 (H) | |||

| Compressive & Impact Test | PUF | 64 (L) | 25 |

| 144 (H) | |||

| PVC-type foam | 64 (L) | ||

| 144 (H) | |||

| Tensile test | PUF | 64 (L) | 15 |

| 144 (H) | |||

| PVC-type foam | 64 (L) | ||

| 144 (H) |

| Material Type | Density (kg/m3) | Avg. Diameter (µm) | Standard Deviation | Max. Diameter (µm) |

|---|---|---|---|---|

| PUF | 144 (H) | 227.660 | 55.182 | 306.667 |

| 64 (L) | 388.138 | 92.211 | 581.513 | |

| PVC-type foam | 144(H) | 509.957 | 118.880 | 522.595 |

| 64 (L) | 383.646 | 67.543 | 306.667 |

| Material Type | Average True Volume (cm3) | Standard Deviation | Average True Density (kg/m3) | Standard Deviation |

|---|---|---|---|---|

| PUF (H) | 46.6257 | 0.2158 | 0.1480 | 0.0007 |

| PVC-type foam (H) | 46.3865 | 0.0059 | 0.1492 | 0.0000 |

| PUF (L) | 50.1830 | 0.1492 | 0.0729 | 0.0002 |

| PVC-type foam (L) | 54.1881 | 0.0245 | 0.0650 | 0.0000 |

| Material | Thermal Conductivity (Average) | Average Density (kg/mm3) |

|---|---|---|

| PUF (H) | 0.0327 | 138.4 |

| PVC-type foam (H) | 0.0447 | 138.1 |

| PUF (L) | 0.0262 | 68.8 |

| PVC-type foam (L) | 0.0320 | 62.1 |

| Material | Temperature | Young’s Modulus (MPa) | Standard Deviation | Yield Stress (MPa) | Standard Deviation |

|---|---|---|---|---|---|

| PUF (L) | 20 °C | 19.347 | 1.883 | 0.672 | 0.074 |

| −50 °C | 25.759 | 2.073 | 0.884 | 0.049 | |

| −110 °C | 33.376 | 2.671 | 0.919 | 0.033 | |

| −170 °C | 44.178 | 1.138 | 0.802 | 0.056 | |

| PUF (H) | 20 °C | 67.361 | 2.847 | 1.555 | 0.065 |

| −50 °C | 89.619 | 4.563 | 2.007 | 0.097 | |

| −110 °C | 104.698 | 37.951 | 2.287 | 0.266 | |

| −170 °C | 142.142 | 17.354 | 1.968 | 0.563 | |

| PVC-type foam (L) | 20 °C | 50.939 | 0.814 | 1.555 | 0.065 |

| −50 °C | 60.154 | 5.899 | 1.407 | 0.054 | |

| −110 °C | 79.404 | 5.880 | 1.076 | 0.186 | |

| −170 °C | 116.492 | 14.709 | 1.066 | 0.099 | |

| PVC-type foam (H) | 20 °C | 95.162 | 5.915 | 2.813 | 0.232 |

| −50 °C | 170.611 | 12.569 | 2.487 | 0.241 | |

| −110 °C | 183.312 | 21.274 | 1.634 | 0.135 | |

| −170 °C | 306.282 | 16.078 | 1.302 | 0.198 |

| Temperature | Material | |

|---|---|---|

| 20 °C |  PVC-type foam (H) |  PUF (H) |

PVC-type foam (L) |  PUF (L) | |

| −170 °C |  PVC-type foam (H) |  PUF (H) |

PVC-type foam (L) |  PUF (L) | |

| Material | Temperature | Young’s Modulus (MPa) | Standard Deviation | Yield Stress (MPa) | Standard Deviation |

|---|---|---|---|---|---|

| PUF (L) | 20 °C | 6.537 | 2.729 | 0.337 | 0.060 |

| −50 °C | 9.097 | 0.839 | 0.639 | 0.070 | |

| −110 °C | 9.857 | 0.079 | 0.722 | 0.079 | |

| −170 °C | 13.626 | 3.444 | 0.857 | 0.175 | |

| PUF (H) | 20 °C | 21.767 | 4.012 | 1.710 | 0.065 |

| −50 °C | 23.644 | 2.103 | 2.188 | 0.121 | |

| −110 °C | 39.481 | 4.742 | 2.973 | 0.119 | |

| −170 °C | 43.557 | 2.524 | 4.342 | 0.271 | |

| PVC-type foam (L) | 20 °C | 17.259 | 4.306 | 0.870 | 0.284 |

| −50 °C | 22.433 | 1.640 | 1.265 | 0.033 | |

| −110 °C | 24.947 | 2.106 | 1.400 | 0.051 | |

| −170 °C | 34.523 | 4.031 | 1.456 | 0.067 | |

| PVC-type foam (H) | 20 °C | 41.474 | 4.148 | 2.469 | 0.029 |

| −50 °C | 55.169 | 6.119 | 3.600 | 0.063 | |

| −110 °C | 64.573 | 10.152 | 4.442 | 0.337 | |

| −170 °C | 73.322 | 2.083 | 4.738 | 0.285 |

| Material | Temperature | Initial Peak Force (N) | Standard Deviation | Ratio of Absorbed Energy (%) | Standard Deviation |

|---|---|---|---|---|---|

| PUF (L) | 20 °C | 1924.701 | 126.129 | 88.218 | 0.130 |

| −50 °C | 2091.565 | 77.305 | 93.306 | 0.434 | |

| −110 °C | 2408.992 | 304.272 | 94.451 | 1.050 | |

| −170 °C | 2738.886 | 9.966 | 95.307 | 0.329 | |

| PUF (H) | 20 °C | 6464.576 | 443.486 | 91.093 | 0.250 |

| −50 °C | 7467.204 | 328.476 | 92.208 | 0.420 | |

| −110 °C | 9016.458 | 895.106 | 90.669 | 1.942 | |

| −170 °C | 9331.487 | 603.999 | 92.927 | 0.755 | |

| PVC-type foam (L) | 20 °C | 3633.627 | 36.618 | 93.106 | 0.048 |

| −50 °C | 3749.665 | 66.690 | 93.889 | 0.623 | |

| −110 °C | 3906.940 | 426.257 | 93.335 | 1.608 | |

| −170 °C | 4079.559 | 66.358 | 94.803 | 0.191 | |

| PVC-type foam (H) | 20 °C | 6446.355 | 464.340 | 90.407 | 0.552 |

| −50 °C | 10602.630 | 374.243 | 91.952 | 0.790 | |

| −110 °C | 11703.560 | 426.257 | 91.283 | 2.416 | |

| −170 °C | 12278.953 | 559.559 | 92.893 | 0.527 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-H.; Kim, J.-H.; Kim, H.-T.; Kim, J.-D.; Uluduz, C.; Kim, M.; Kim, S.-K.; Lee, J.-M. Evaluation of PVC-Type Insulation Foam Material for Cryogenic Applications. Polymers 2023, 15, 1401. https://doi.org/10.3390/polym15061401

Kim D-H, Kim J-H, Kim H-T, Kim J-D, Uluduz C, Kim M, Kim S-K, Lee J-M. Evaluation of PVC-Type Insulation Foam Material for Cryogenic Applications. Polymers. 2023; 15(6):1401. https://doi.org/10.3390/polym15061401

Chicago/Turabian StyleKim, Dae-Hee, Jeong-Hyeon Kim, Hee-Tae Kim, Jeong-Dae Kim, Cengizhan Uluduz, Minjung Kim, Seul-Kee Kim, and Jae-Myung Lee. 2023. "Evaluation of PVC-Type Insulation Foam Material for Cryogenic Applications" Polymers 15, no. 6: 1401. https://doi.org/10.3390/polym15061401

APA StyleKim, D.-H., Kim, J.-H., Kim, H.-T., Kim, J.-D., Uluduz, C., Kim, M., Kim, S.-K., & Lee, J.-M. (2023). Evaluation of PVC-Type Insulation Foam Material for Cryogenic Applications. Polymers, 15(6), 1401. https://doi.org/10.3390/polym15061401