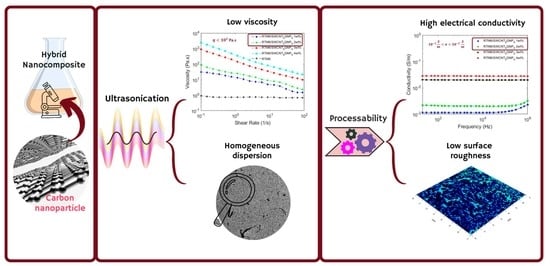

Hybrid Carbon Nanocomposites Made of Aerospace-Grade Epoxy Showing Synergistic Effects in Electrical Properties and High Processability

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing of Nanocomposites

2.3. Characterization Methods

3. Results and Discussion

3.1. Dispersion and Electrical Properties of RTM6/Carbon Nanocomposites

3.2. Rheological Properties of RTM6/carbon Mixtures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, S.; Zheng, Z.; Huang, Z.; Dong, S.; Luo, P.; Zhang, Z.; Wang, Y. Cu matrix composites reinforced with aligned carbon nanotubes: Mechanical, electrical and thermal properties. Mater. Sci. Eng. A 2016, 675, 82–91. [Google Scholar] [CrossRef]

- Samani, M.K.; Khosravian, N.; Chen, G.C.K.; Shakerzadeh, M.; Baillargeat, D.; Tay, B.K. Thermal conductivity of individual multiwalled carbon nanotubes. Int. J. Therm. Sci. 2012, 62, 40–43. [Google Scholar] [CrossRef]

- Yang, D.J.; Wang, S.G.; Zhang, Q.; Sellin, P.J.; Chen, G. Thermal and electrical transport in multi-walled carbon nanotubes. Phys. Lett. A 2004, 329, 207–213. [Google Scholar] [CrossRef]

- Yu, M.-F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile Loading of Ropes of Single Wall Carbon Nanotubes and their Mechanical Properties. Phys. Rev. Lett. 2000, 84, 5552–5555. [Google Scholar] [CrossRef] [PubMed]

- Yazdani, H.; Hatami, K.; Eftekhari, M. Mechanical properties of single-walled carbon nanotubes: A comprehensive molecular dynamics study. Mater. Res. Express 2017, 4, 055015. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical Performance and Applications of CNTs Reinforced Polymer Composites—A Review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef]

- Biercuk, M.; Llaguno, M.C.; Radosavljevic, M.; Hyun, J.; Johnson, A.T.; Fischer, J.E. Carbon nanotube composites for thermal management. Appl. Phys. Lett. 2002, 80, 2767–2769. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Gibson, R.F. A review of recent research on mechanics of multifunctional composite materials and structures. Compos. Struct. 2010, 92, 2793–2810. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Clausi, M.; Santonicola, M.G.; Schirone, L.; Laurenzi, S. Analysis of ultraviolet exposure effects on the surface properties of epoxy/graphene nanocomposite films on Mylar substrate. Acta Astronaut. 2017, 134, 307–313. [Google Scholar] [CrossRef]

- Siochi, E.J.; Harrison, J.S. Structural nanocomposites for aerospace applications. MRS Bull. 2015, 40, 829–835. [Google Scholar] [CrossRef]

- Smith Jr, J.G.; Delozier, D.M.; Connell, J.W.; Watson, K.A. Carbon nanotube-conductive additive-space durable polymer nanocomposite films for electrostatic charge dissipation. Polymer 2004, 45, 6133–6142. [Google Scholar] [CrossRef]

- Laurenzi, S.; de Zanet, G.; Santonicola, M.G. Numerical investigation of radiation shielding properties of polyethylene-based nanocomposite materials in different space environments. Acta Astronaut. 2020, 170, 530–538. [Google Scholar] [CrossRef]

- Toto, E.; Santonicola, M.G.; Mancini, M.C.; Laurenzi, S. Ultraviolet-sensing surfaces based on hybrid nanocomposites for radiation monitoring systems. In Proceedings of the 2017 IEEE International Workshop on Metrology for AeroSpace (MetroAeroSpace), Padua, Italy, 21–23 June 2017; pp. 369–373. [Google Scholar] [CrossRef]

- Toto, E.; Botti, S.; Laurenzi, S.; Gabriella Santonicola, M. UV-induced modification of PEDOT:PSS-based nanocomposite films investigated by Raman microscopy mapping. Appl. Surf. Sci. 2020, 513, 145839. [Google Scholar] [CrossRef]

- Toto, E.; Laurenzi, S.; Santonicola, M.G. Recent Trends in Graphene/Polymer Nanocomposites for Sensing Devices: Synthesis and Applications in Environmental and Human Health Monitoring. Polymers 2022, 14, 1030. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Tang, L.-C.; Yan, D.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. Improved dispersion and interface in the graphene/epoxy composites via a facile surfactant-assisted process. Compos. Sci. Technol. 2013, 82, 60–68. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R. Influence of dispersion states of carbon nanotubes on physical properties of epoxy nanocomposites. Carbon 2005, 43, 1378–1385. [Google Scholar] [CrossRef]

- Laurenzi, S.; Botti, S.; Rufoloni, A.; Santonicola, M.G. Mapping the residual strain of carbon nanotubes in DWCNT/epoxy nanocomposites after tensile load using Raman microscopy. Compos. Commun. 2020, 21, 100424. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Fiedler, B.; Kinloch, I.A.; Bauhofer, W.; Windle, A.H.; Schulte, K. Evaluation and identification of electrical and thermal conduction mechanisms in carbon nanotube/epoxy composites. Polymer 2006, 47, 2036–2045. [Google Scholar] [CrossRef]

- Wu, S.; Ladani, R.B.; Zhang, J.; Bafekrpour, E.; Ghorbani, K.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Aligning multilayer graphene flakes with an external electric field to improve multifunctional properties of epoxy nanocomposites. Carbon 2015, 94, 607–618. [Google Scholar] [CrossRef]

- Rubel, R.I.; Ali, M.H.; Jafor, M.A.; Alam, M.M. Carbon nanotubes agglomeration in reinforced composites: A review. AIMS Mater. Sci. 2019, 6, 756–780. [Google Scholar] [CrossRef]

- Yang, X.; Zhu, J.; Qiu, L.; Li, D. Bioinspired Effective Prevention of Restacking in Multilayered Graphene Films: Towards the Next Generation of High-Performance Supercapacitors. Adv. Mater. 2011, 23, 2833–2838. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, N.G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer nanocomposites based on functionalized carbon nanotubes. Prog. Polym. Sci. 2010, 35, 837–867. [Google Scholar] [CrossRef]

- Wang, K.; Wang, W.; Wang, H.; Liu, L.; Xu, Z.; Fu, H.; Zhao, L.; Zhang, X.; Chen, L.; Zhao, Y. 3D graphene foams/epoxy composites with double-sided binder polyaniline interlayers for maintaining excellent electrical conductivities and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2018, 110, 246–257. [Google Scholar] [CrossRef]

- Teng, K.; Ni, Y.; Wang, W.; Wang, H.; Xu, Z.; Chen, L.; Kuang, L.; Ma, M.; Fu, H.; Li, J. Adjustable micro-structure, higher-level mechanical behavior and conductivities of preformed graphene architecture/epoxy composites via RTM route. Compos. Part A Appl. Sci. Manuf. 2017, 94, 178–188. [Google Scholar] [CrossRef]

- Tian, L.; Meziani, M.J.; Lu, F.; Kong, C.Y.; Cao, L.; Thorne, T.J.; Sun, Y.-P. Graphene Oxides for Homogeneous Dispersion of Carbon Nanotubes. ACS Appl. Mater. Interfaces 2010, 2, 3217–3222. [Google Scholar] [CrossRef]

- Zhang, C.; Ren, L.; Wang, X.; Liu, T. Graphene Oxide-Assisted Dispersion of Pristine Multiwalled Carbon Nanotubes in Aqueous Media. J. Phys. Chem. C 2010, 114, 11435–11440. [Google Scholar] [CrossRef]

- Martin-Gallego, M.; Bernal, M.M.; Hernandez, M.; Verdejo, R.; Lopez-Manchado, M.A. Comparison of filler percolation and mechanical properties in graphene and carbon nanotubes filled epoxy nanocomposites. Eur. Polym. J. 2013, 49, 1347–1353. [Google Scholar] [CrossRef]

- Schulz, S.C.; Faiella, G.; Buschhorn, S.T.; Prado, L.A.S.A.; Giordano, M.; Schulte, K.; Bauhofer, W. Combined electrical and rheological properties of shear induced multiwall carbon nanotube agglomerates in epoxy suspensions. Eur. Polym. J. 2011, 47, 2069–2077. [Google Scholar] [CrossRef]

- Reia da Costa, E.F.; Skordos, A.A.; Partridge, I.K.; Rezai, A. RTM processing and electrical performance of carbon nanotube modified epoxy/fibre composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 593–602. [Google Scholar] [CrossRef]

- Ma, A.W.K.; Chinesta, F.; Mackley, M.R. The rheology and modeling of chemically treated carbon nanotubes suspensions. J. Rheol. 2009, 53, 547–573. [Google Scholar] [CrossRef]

- Chapartegui, M.; Markaide, N.; Florez, S.; Elizetxea, C.; Fernandez, M.; Santamaría, A. Specific rheological and electrical features of carbon nanotube dispersions in an epoxy matrix. Compos. Sci. Technol. 2010, 70, 879–884. [Google Scholar] [CrossRef]

- Clausi, M.; Santonicola, M.G.; Laurenzi, S. Steady-shear rheological properties of graphene-reinforced epoxy resin for manufacturing of aerospace composite films. AIP Conf. Proc. 2016, 1736, 020024. [Google Scholar] [CrossRef]

- Platzer, N. Non-Newtonian Flow and Heat Transfer. J. Appl. Polym. Sci. 1967, 11, 1822–1823. [Google Scholar] [CrossRef]

- Banerjee, K.; Li, H.; Srivastava, N. Current Status and Future Perspectives of Carbon Nanotube Interconnects. In Proceedings of the 2008 8th IEEE Conference on Nanotechnology, Arlington, TX, USA, 18–21 August 2008; pp. 432–436. [Google Scholar] [CrossRef]

- Chatterjee, S.; Nafezarefi, F.; Tai, N.H.; Schlagenhauf, L.; Nüesch, F.A.; Chu, B.T.T. Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon 2012, 50, 5380–5386. [Google Scholar] [CrossRef]

- Yang, S.-Y.; Lin, W.-N.; Huang, Y.-L.; Tien, H.-W.; Wang, J.-Y.; Ma, C.-C.M.; Li, S.-M.; Wang, Y.-S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Yue, L.; Pircheraghi, G.; Monemian, S.A.; Manas-Zloczower, I. Epoxy composites with carbon nanotubes and graphene nanoplatelets—Dispersion and synergy effects. Carbon 2014, 78, 268–278. [Google Scholar] [CrossRef]

- Biswas, S.; Fukushima, H.; Drzal, L.T. Mechanical and electrical property enhancement in exfoliated graphene nanoplatelet/liquid crystalline polymer nanocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 371–375. [Google Scholar] [CrossRef]

- Laurenzi, S.; Clausi, M.; Zaccardi, F.; Curt, U.; Santonicola, M.G. Spray coating process of MWCNT/epoxy nanocomposite films for aerospace applications: Effects of process parameters on surface electrical properties. Acta Astronaut. 2019, 159, 429–439. [Google Scholar] [CrossRef]

- Clausi, M.; Santonicola, M.G.; Laurenzi, S. Fabrication of carbon-based nanocomposite films by spin-coating process: An experimental and modeling study of the film thickness. Compos. Part A Appl. Sci. Manuf. 2016, 88, 86–97. [Google Scholar] [CrossRef]

- Sierra-Chi, C.A.; Aguilar-Bolados, H.; López-Manchado, M.A.; Verdejo, R.; Cauich-Rodríguez, J.V.; Avilés, F. Flexural electromechanical properties of multilayer graphene sheet/carbon nanotube/vinyl ester hybrid nanocomposites. Compos. Sci. Technol. 2020, 194, 108164. [Google Scholar] [CrossRef]

- Parsons, A.J.; Gonciaruk, A.; Zeng, X.; Thomann, F.S.; Schubel, P.; Lorrillard, J.; Johnson, M.S. Controlling mass loss from RTM6 epoxy resin under simulated vacuum infusion conditions. Polym. Test. 2022, 107, 107473. [Google Scholar] [CrossRef]

- Cebeci, H.; Villoria, R.G.d.; Hart, A.J.; Wardle, B.L. Multifunctional properties of high volume fraction aligned carbon nanotube polymer composites with controlled morphology. Compos. Sci. Technol. 2009, 69, 2649–2656. [Google Scholar] [CrossRef]

- Martone, A.; Formicola, C.; Giordano, M.; Zarrelli, M. Reinforcement efficiency of multi-walled carbon nanotube/epoxy nano composites. Compos. Sci. Technol. 2010, 70, 1154–1160. [Google Scholar] [CrossRef]

- Schilde, C.; Schlömann, M.; Overbeck, A.; Linke, S.; Kwade, A. Thermal, mechanical and electrical properties of highly loaded CNT-epoxy composites—A model for the electric conductivity. Compos. Sci. Technol. 2015, 117, 183–190. [Google Scholar] [CrossRef]

- Vertuccio, L.; Russo, S.; Raimondo, M.; Lafdi, K.; Guadagno, L. Influence of carbon nanofillers on the curing kinetics of epoxy-amine resin. RSC Adv. 2015, 5, 90437–90450. [Google Scholar] [CrossRef]

- Li, J.; Aung, H.H.; Du, B. Curing Regime-Modulating Insulation Performance of Anhydride-Cured Epoxy Resin: A Review. Molecules 2023, 28, 547. [Google Scholar] [CrossRef]

- Zaccardi, F.; Santonicola, M.G.; Laurenzi, S. Quantitative assessment of nanofiller dispersion based on grayscale image analysis: A case study on epoxy/carbon nanocomposites. Compos. Part A Appl. Sci. Manuf. 2018, 115, 302–310. [Google Scholar] [CrossRef]

- Stauffer, D.; Aharony, A. Introduction to percolation theory; Taylor & Francis: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Gingold, D.B.; Lobb, C.J. Percolative conduction in three dimensions. Phys. Rev. B 1990, 42, 8220–8224. [Google Scholar] [CrossRef] [PubMed]

- Weber, M.; Kamal, M.R. Estimation of the volume resistivity of electrically conductive composites. Polym. Compos. 1997, 18, 711–725. [Google Scholar] [CrossRef]

- Sandler, J.K.W.; Kirk, J.E.; Kinloch, I.A.; Shaffer, M.S.P.; Windle, A.H. Ultra-low electrical percolation threshold in carbon-nanotube-epoxy composites. Polymer 2003, 44, 5893–5899. [Google Scholar] [CrossRef]

- Zhang, K.; Li, G.-H.; Feng, L.-M.; Wang, N.; Guo, J.; Sun, K.; Yu, K.-X.; Zeng, J.-B.; Li, T.; Guo, Z.; et al. Ultralow percolation threshold and enhanced electromagnetic interference shielding in poly(l-lactide)/multi-walled carbon nanotube nanocomposites with electrically conductive segregated networks. J. Mater. Chem. C 2017, 5, 9359–9369. [Google Scholar] [CrossRef]

| epoxy/SWCNT | |||||

|---|---|---|---|---|---|

| 1 wt% | 2 wt% | 3 wt% | 4 wt% | ||

| K (Pa sn) | 35.58 | 215.67 | 497.58 | 1388.81 | |

| n | 0.50 | 0.12 | 0.15 | 0.15 | |

| 0.983 | 0.997 | 0.996 | 0.996 | ||

| epoxy/GNP2SWCNT8 | |||||

| 1 wt% | 2 wt% | 3 wt% | 4 wt% | ||

| K (Pa sn) | 20.91 | 176.95 | 360.31 | 851.04 | |

| n | 0.42 | 0.19 | 0.15 | 0.15 | |

| 0.991 | 0.999 | 0.999 | 0.999 | ||

| epoxy/GNP5SWCNT5 | |||||

| 1 wt% | 2 wt% | 3 wt% | 4 wt% | ||

| K (Pa sn) | 13.40 | 24.28 | 160.51 | 395.54 | |

| n | 0.60 | 0.46 | 0.25 | 0.20 | |

| 0.989 | 0.98 | 0.999 | 0.999 | ||

| epoxy/GNP8SWCNT2 | |||||

| 1 wt% | 2 wt% | 3 wt% | 4 wt% | 5 wt% | |

| K (Pa sn) | 1.49 | 3.51 | 8.69 | 20.06 | 27.18 |

| n | 0.76 | 0.59 | 0.50 | 0.50 | 0.55 |

| 0.968 | 0.976 | 0.979 | 0.998 | 0.997 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaccardi, F.; Toto, E.; Marra, F.; Santonicola, M.G.; Laurenzi, S. Hybrid Carbon Nanocomposites Made of Aerospace-Grade Epoxy Showing Synergistic Effects in Electrical Properties and High Processability. Polymers 2023, 15, 1163. https://doi.org/10.3390/polym15051163

Zaccardi F, Toto E, Marra F, Santonicola MG, Laurenzi S. Hybrid Carbon Nanocomposites Made of Aerospace-Grade Epoxy Showing Synergistic Effects in Electrical Properties and High Processability. Polymers. 2023; 15(5):1163. https://doi.org/10.3390/polym15051163

Chicago/Turabian StyleZaccardi, Federica, Elisa Toto, Fabrizio Marra, Maria Gabriella Santonicola, and Susanna Laurenzi. 2023. "Hybrid Carbon Nanocomposites Made of Aerospace-Grade Epoxy Showing Synergistic Effects in Electrical Properties and High Processability" Polymers 15, no. 5: 1163. https://doi.org/10.3390/polym15051163

APA StyleZaccardi, F., Toto, E., Marra, F., Santonicola, M. G., & Laurenzi, S. (2023). Hybrid Carbon Nanocomposites Made of Aerospace-Grade Epoxy Showing Synergistic Effects in Electrical Properties and High Processability. Polymers, 15(5), 1163. https://doi.org/10.3390/polym15051163