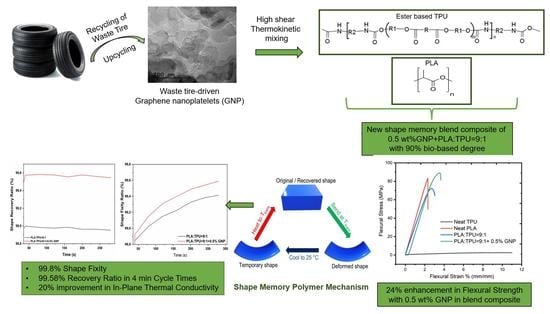

Sustainable Engineered Design and Scalable Manufacturing of Upcycled Graphene Reinforced Polylactic Acid/Polyurethane Blend Composites Having Shape Memory Behavior

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. GNP-Reinforced PLA-Based Composite Manufacturing by Thermo-Kinetic Mixer

2.3. Characterization

3. Results and Discussions

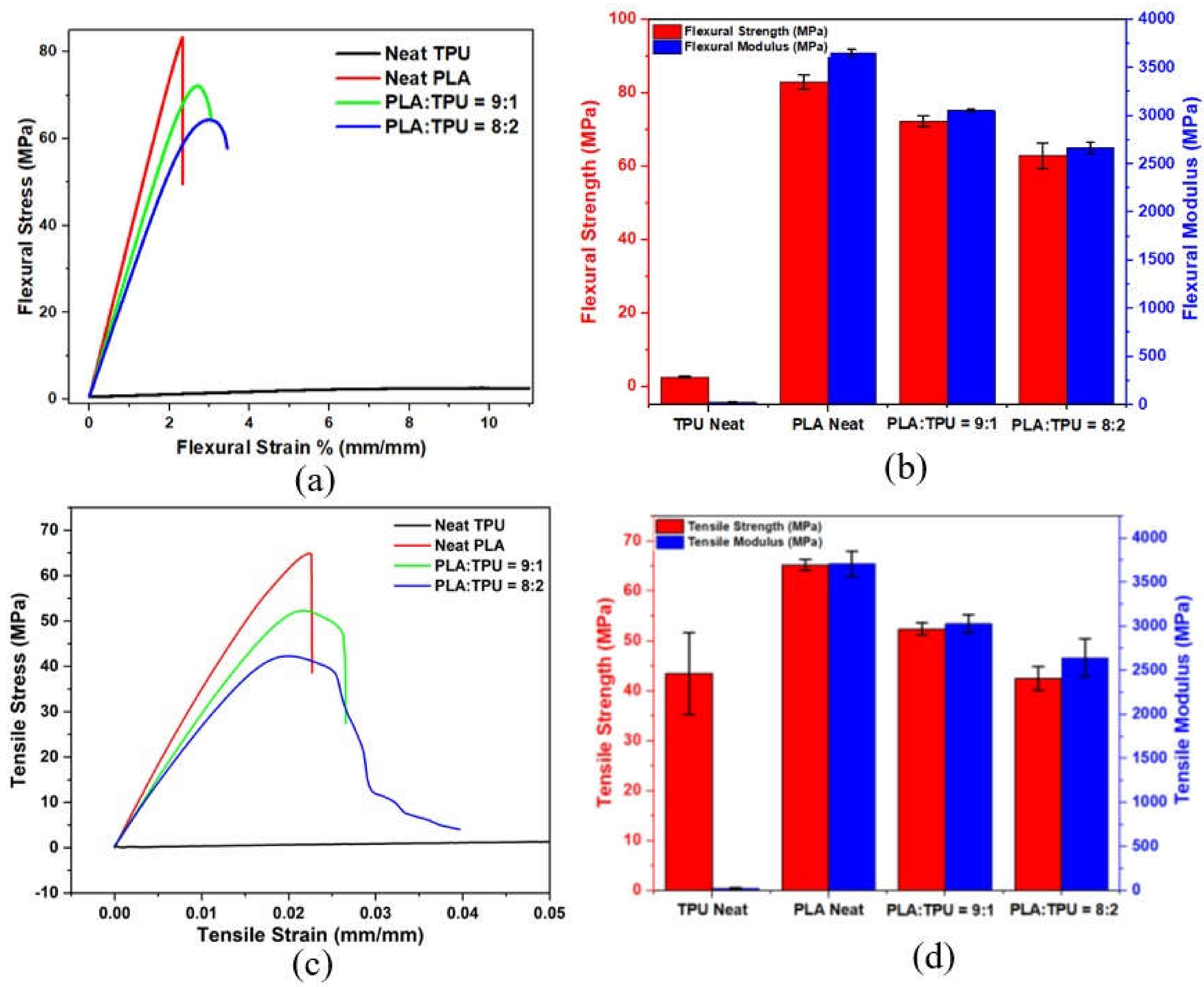

3.1. The Effect of GNP Content on the Mechanical Performance of PLA Nanocomposites

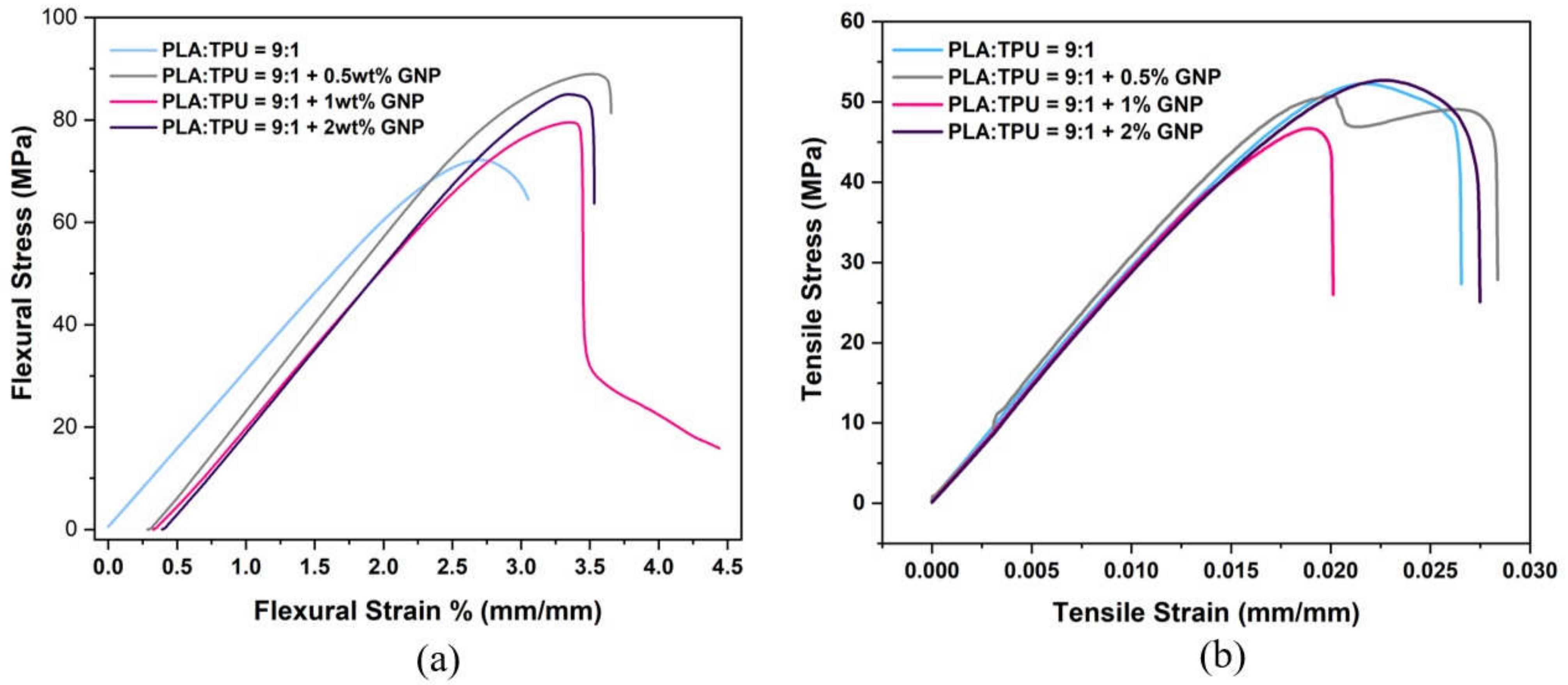

3.2. The Effect of GNP on the Mechanical Performance of PLA/TPU Blend Composite Systems

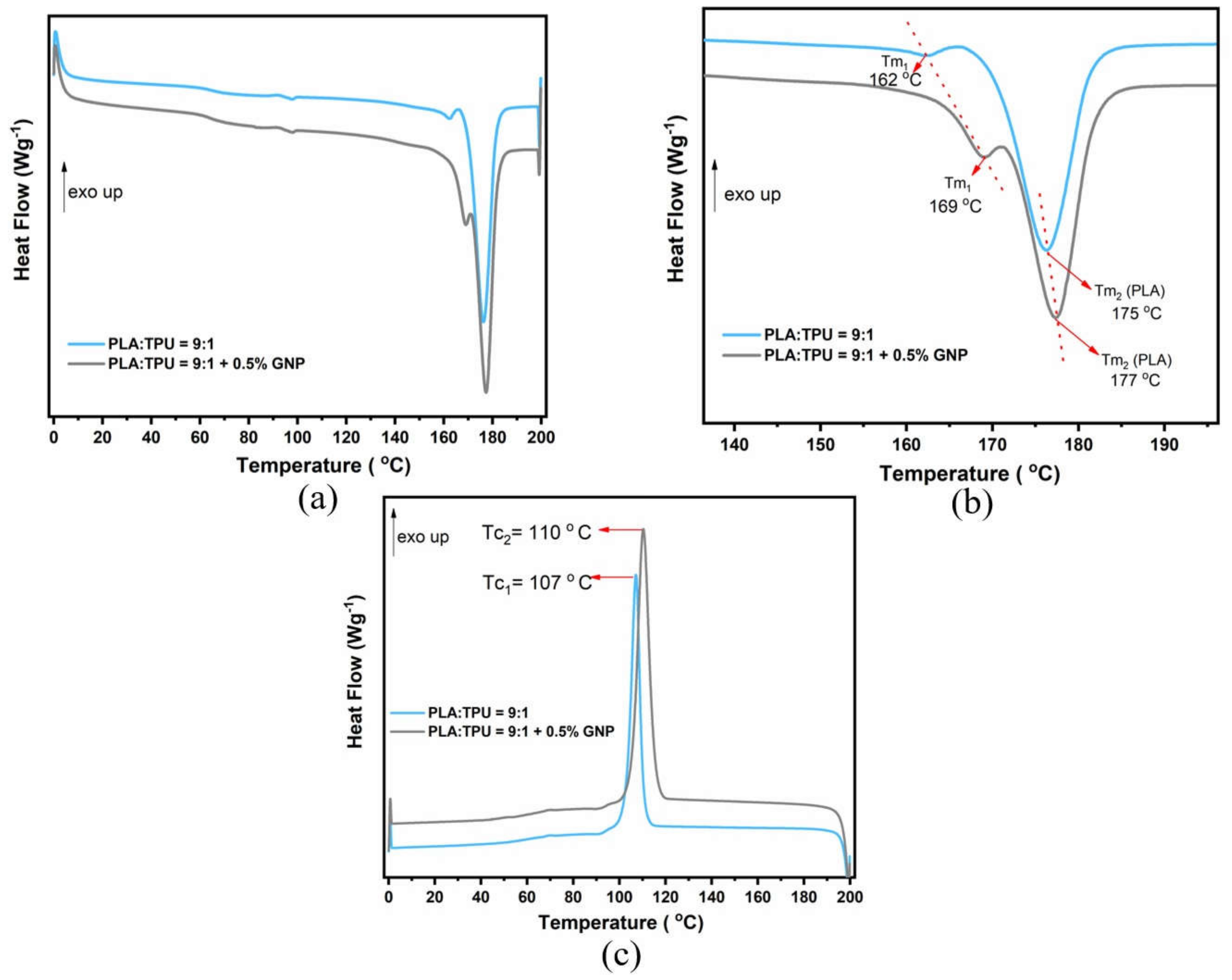

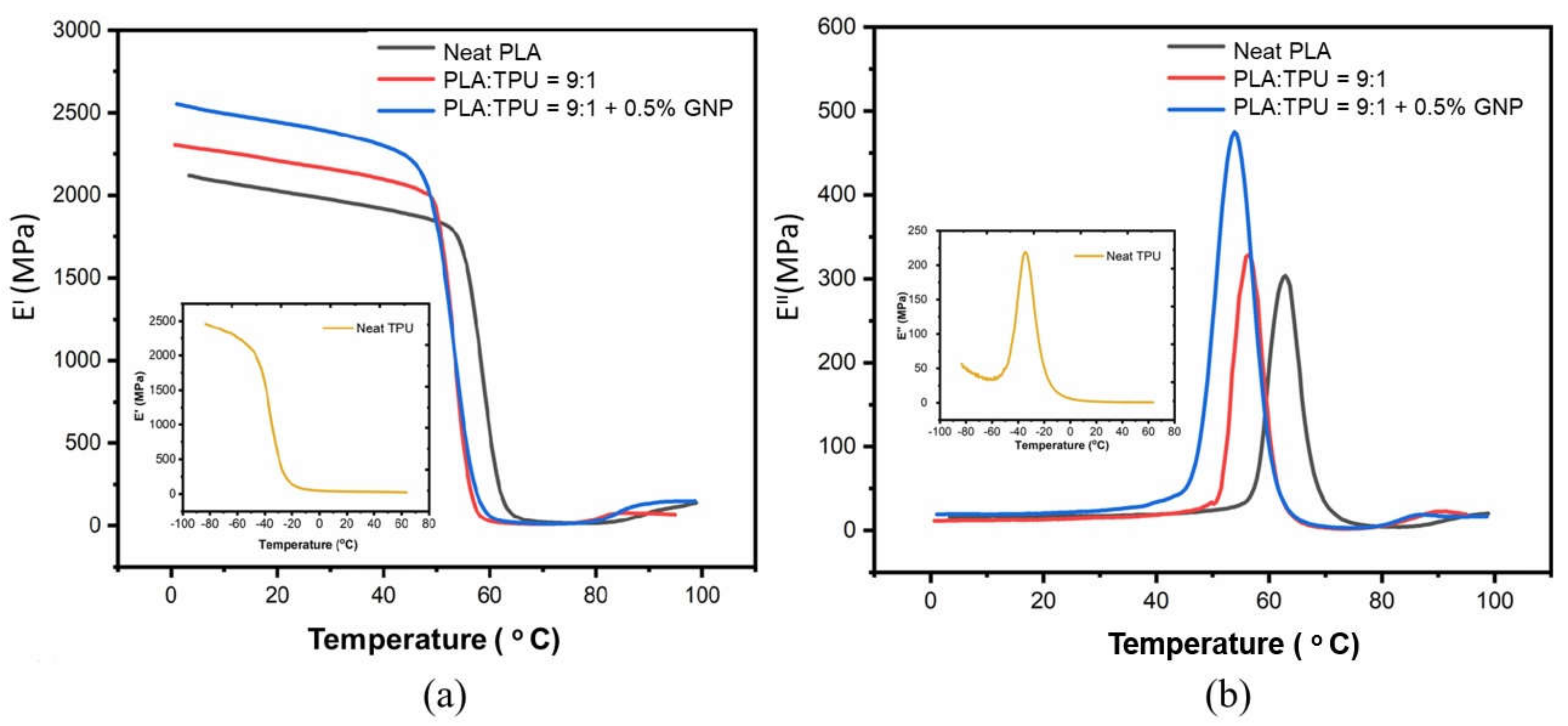

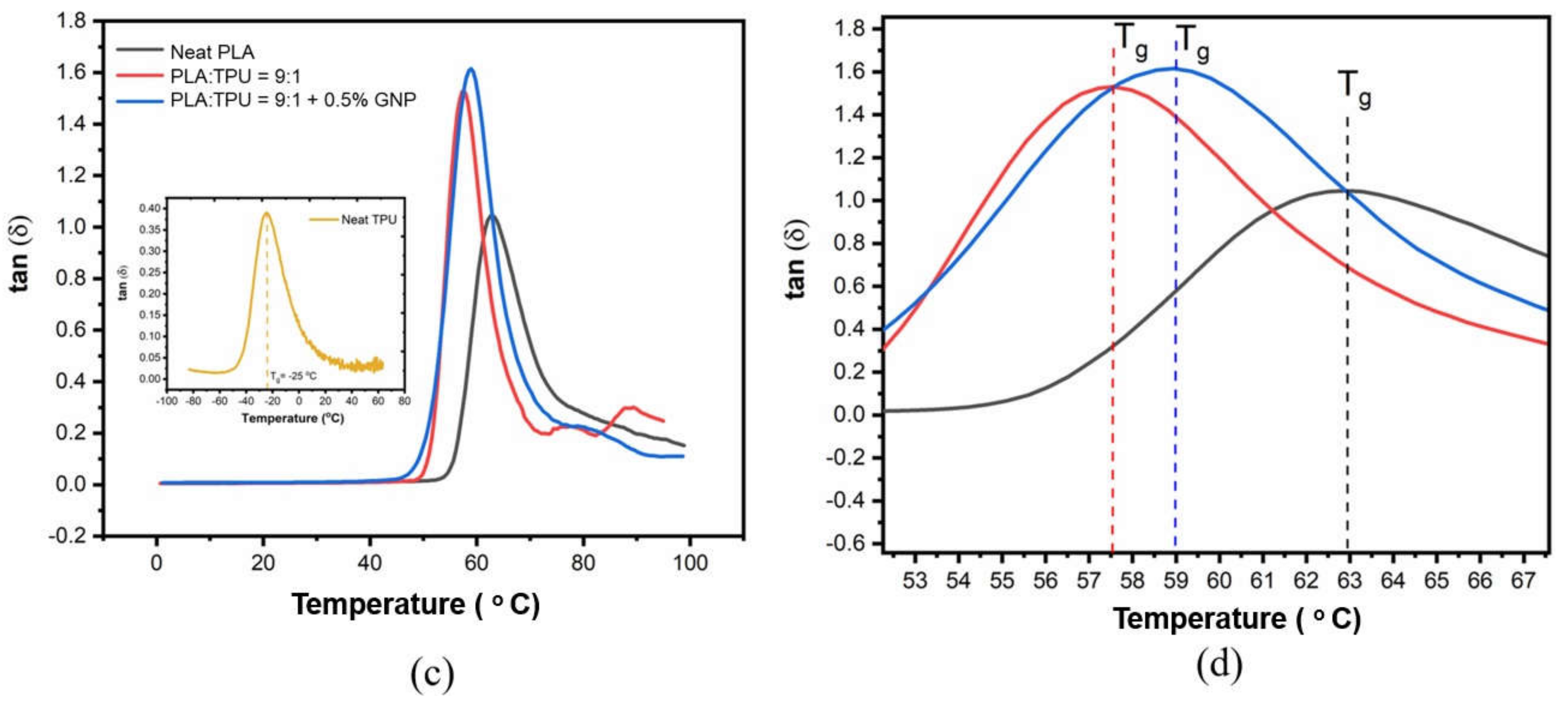

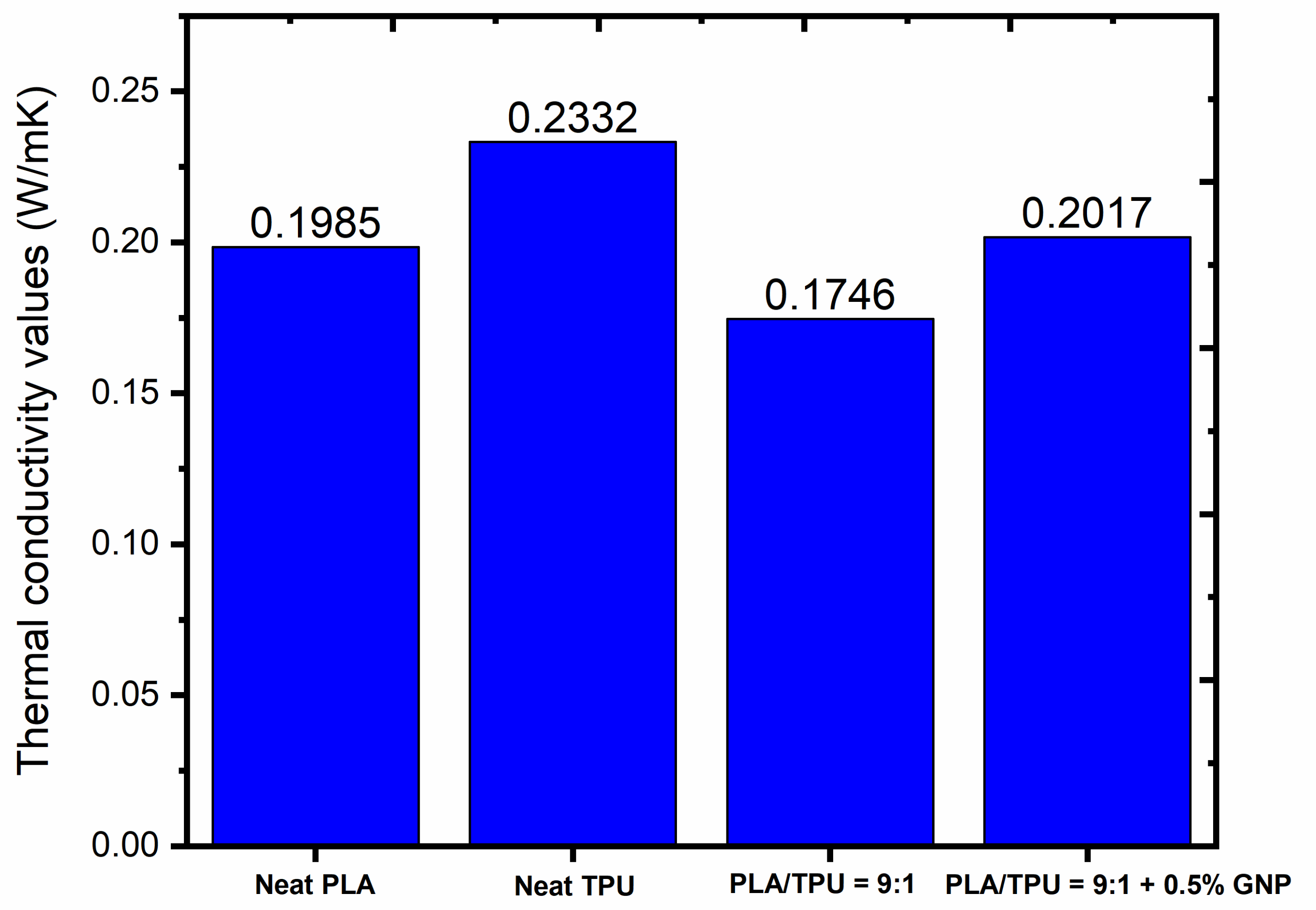

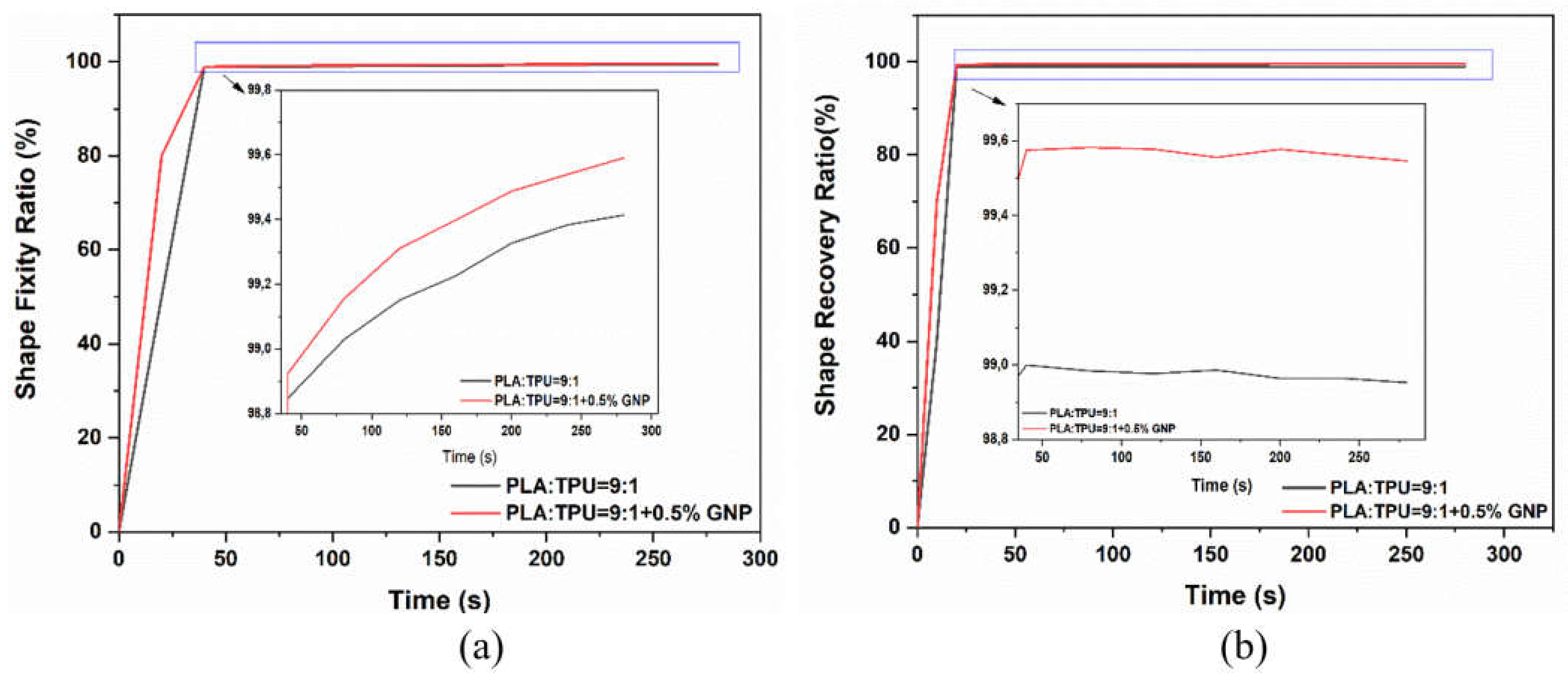

3.3. Thermal Properties, Dynamic Mechanical Behaviors, and Shape Memory Characteristics of GNP-Reinforced PLA/TPU Blend Composites

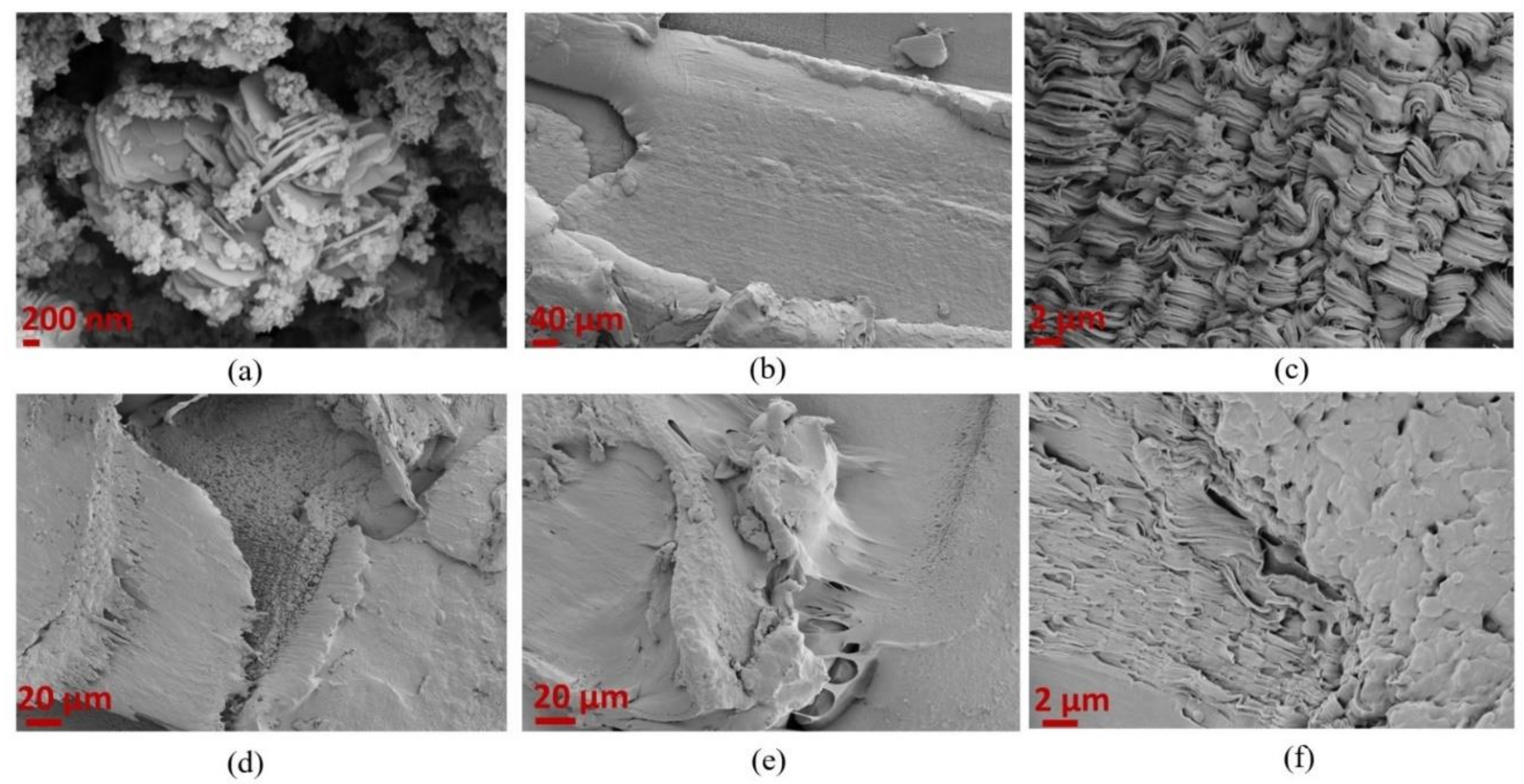

3.4. Cross-Sectional Analysis of GNP-Reinforced PLA/TPU Blended Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Azadi, F.; Jafari, S.H.; Khonakdar, H.A.; Arjmand, M.; Wagenknecht, U.; Altstädt, V. Influence of Graphene Oxide on Thermally Induced Shape Memory Behavior of PLA/TPU Blends: Correlation with Morphology, Creep Behavior, Crystallinity, and Dynamic Mechanical Properties. Macromol. Mater. Eng. 2021, 306, 2000576. [Google Scholar] [CrossRef]

- Kondratov, A.; Cherkasov, E.; Paley, V.; Volinsky, A. Recording, storage, and reproduction of information on polyvinyl chloride films using shape memory effects. Polymers 2021, 13, 1802. [Google Scholar] [CrossRef] [PubMed]

- Fang, L.; Fang, T.; Liu, X.; Ni, Y.; Lu, C.; Xu, Z. Precise stimulation of near-infrared light responsive shape-memory polymer composites using upconversion particles with photothermal capability. Compos. Sci. Technol. 2017, 152, 190–197. [Google Scholar] [CrossRef]

- Tang, J.; Ren, Y.; Feng, J. Fluorescence-color-changing biomimetic tough films with simultaneous shape-deformation triggered by pH. Chem. Eng. J. 2022, 440, 135932. [Google Scholar] [CrossRef]

- Li, L.; Luo, S.; Li, D.; Wang, N.; Kang, H.; Fang, Q. Thermal and electrical dual-triggered shape memory Eucommia ulmoides gum derived from renewable resources. Polym. Compos. 2021, 43, 378–388. [Google Scholar] [CrossRef]

- Shen, W.; Du, B.; Zhuo, H.; Chen, S. Recyclable and reprocessable epoxy-polyhedral oligomeric silsesquioxane (POSS)/mesogenic azobenzene/poly (ethylene-co-vinyl acetate) composites with thermal- and light-responsive programmable shape-memory performance. Chem. Eng. J. 2021, 428, 132609. [Google Scholar] [CrossRef]

- Xue, J.; Ge, Y.; Liu, Z.; Liu, Z.; Jiang, J.; Li, G. Photoprogrammable Moisture-Responsive Actuation of a Shape Memory Polymer Film. ACS Appl. Mater. Interfaces 2022, 14, 10836–10843. [Google Scholar] [CrossRef]

- Boyle, A.J.; Weems, A.C.; Hasan, S.M.; Nash, L.D.; Monroe, M.B.B.; Maitland, D.J. Solvent stimulated actuation of polyurethane-based shape memory polymer foams using dimethyl sulfoxide and ethanol. Smart Mater. Struct. 2016, 25, 075014. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, C.; Tan, A.; Chen, H.; Weng, S.; Xie, Q.; Li, C.; Cai, Z.; Wan, X. Photothermal and magnetocaloric-stimulated shape memory and self-healing via magnetic polymeric composite with dynamic crosslinking. Polymer 2021, 223, 123677. [Google Scholar] [CrossRef]

- Raja, M.; Ryu, S.H.; Shanmugharaj, A. Thermal, mechanical and electroactive shape memory properties of polyurethane (PU)/poly (lactic acid) (PLA)/CNT nanocomposites. Eur. Polym. J. 2013, 49, 3492–3500. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.-Y.; Salick, M.R.; Cordie, T.; Crone, W.C.; Peng, X.-F.; Turng, L.-S. Morphology, mechanical properties, and shape memory effects of poly(lactic acid)/thermoplastic polyurethane blend scaffolds prepared by thermally induced phase separation. J. Cell. Plast. 2014, 50, 361–379. [Google Scholar] [CrossRef]

- Cai, S.; Sun, Y.-C.; Ren, J.; Naguib, H.E. Toward the low actuation temperature of flexible shape memory polymer composites with room temperature deformability via induced plasticizing effect. J. Mater. Chem. B 2017, 5, 8845–8853. [Google Scholar] [CrossRef]

- Boyacioglu, S.; Kodal, M.; Ozkoc, G. A comprehensive study on shape memory behavior of PEG plasticized PLA/TPU bio-blends. Eur. Polym. J. 2019, 122, 109372. [Google Scholar] [CrossRef]

- Sáenz-Pérez, M.; Laza, J.M.; García-Barrasa, J.; Vilas, J.L.; León, L.M. Influence of the soft segment nature on the thermomechanical behavior of shape memory polyurethanes. Polym. Eng. Sci. 2018, 58, 238–244. [Google Scholar] [CrossRef]

- Mo, X.-Z.; Wei, F.-X.; Tan, D.-F.; Pang, J.-Y.; Lan, C.-B. The compatibilization of PLA-g-TPU graft copolymer on polylactide/thermoplastic polyurethane blends. J. Polym. Res. 2020, 27, 33. [Google Scholar] [CrossRef]

- Alobad, Z.; Albozahid, M.; Naji, H.; Alraheem, H.; Saiani, A. Influence of hard segments content on thermal, morphological and mechanical properties of homo and co-polyurethanes: A comparative study. Arch. Mater. Sci. Eng. 2021, 1, 5–16. [Google Scholar] [CrossRef]

- Liu, S.; Tian, M.; Yan, B.; Yao, Y.; Zhang, L.; Nishi, T.; Ning, N. High performance dielectric elastomers by partially reduced graphene oxide and disruption of hydrogen bonding of polyurethanes. Polymer 2015, 56, 375–384. [Google Scholar] [CrossRef]

- Saralegi, A.; Fernandes, S.C.M.; Alonso-Varona, A.; Palomares, T.; Foster, E.J.; Weder, C.; Eceiza, A.; Corcuera, M.A. Shape-memory bionanocomposites based on chitin nanocrystals and thermoplastic polyurethane with a highly crystalline soft segment. Biomacromolecules 2013, 14, 4475–4482. [Google Scholar] [CrossRef]

- Ouda, M.; Ibrahim, Y.; Kallem, P.; Govindan, B.; Banat, F.; Hasan, S.W. Highly permeable, environmentally-friendly, antifouling polylactic acid-hydroxyapatite/polydopamine (PLA-HAp/PDA) ultrafiltration membranes. J. Clean. Prod. 2021, 330, 129871. [Google Scholar] [CrossRef]

- Lin, T.A.; Lou, C.-W.; Lin, J.-H. The effects of thermoplastic polyurethane on the structure and mechanical properties of modified polypropylene blends. Appl. Sci. 2017, 7, 1254. [Google Scholar] [CrossRef]

- Patel, K.K.; Purohit, R. Improved shape memory and mechanical properties of microwave-induced thermoplastic polyurethane/graphene nanoplatelets composites. Sens. Actuators A Phys. 2018, 285, 17–24. [Google Scholar] [CrossRef]

- Hager, M.D.; Bode, S.; Weber, C.; Schubert, U.S. Shape memory polymers: Past, present and future developments. Prog. Polym. Sci. 2015, 49–50, 3–33. [Google Scholar] [CrossRef]

- Gaaz, T.S.; Sulong, A.B.; Kadhum, A.A.H. Effect of HNTs addition in the injection moulded thermoplastic polyurethane matrix on the mechanical and thermal properties. Sains Malays. 2016, 45, 1235–1242. [Google Scholar]

- Albozahid, M.; Naji, H.Z.; Alobad, Z.K.; Saiani, A. TPU nanocomposites tailored by graphene nanoplatelets: The investigation of dispersion approaches and annealing treatment on thermal and mechanical properties. Polym. Bull. 2021, 79, 8269–8307. [Google Scholar] [CrossRef]

- Guo, Y.; Yan, L.; Zeng, Z.; Chen, L.; Ma, M.; Luo, R.; Bian, J.; Lin, H.; Chen, D. TPU/PLA nanocomposites with improved mechanical and shape memory properties fabricated via phase morphology control and incorporation of multi-walled carbon nanotubes nanofillers. Polym. Eng. Sci. 2020, 60, 1118–1128. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.-Y.; Peng, X.-F.; Turng, L.-S. The morphology, properties, and shape memory behavior of polylactic acid/thermoplastic polyurethane blends. Polym. Eng. Sci. 2014, 55, 70–80. [Google Scholar] [CrossRef]

- Xu, X.; Fan, P.; Ren, J.; Cheng, Y.; Ren, J.; Zhao, J.; Song, R. Self-healing thermoplastic polyurethane (TPU)/polycaprolactone (PCL) /multi-wall carbon nanotubes (MWCNTs) blend as shape-memory composites. Compos. Sci. Technol. 2018, 168, 255–262. [Google Scholar] [CrossRef]

- Culebras, M.; Beaucamp, A.; Wang, Y.; Clauss, M.M.; Frank, E.; Collins, M.N. Biobased Structurally Compatible Polymer Blends Based on Lignin and Thermoplastic Elastomer Polyurethane as Carbon Fiber Precursors. ACS Sustain. Chem. Eng. 2018, 6, 8816–8825. [Google Scholar] [CrossRef]

- Poomali; Siddaramaiah; Suresha, B.; Lee, J.-H. Mechanical and three-body abrasive wear behaviour of PMMA/TPU blends. Mater. Sci. Eng. A 2008, 492, 486–490. [Google Scholar] [CrossRef]

- Lai, S.-M.; Lan, Y.-C. Shape memory properties of melt-blended polylactic acid (PLA)/thermoplastic polyurethane (TPU) bio-based blends. J. Polym. Res. 2013, 20, 140. [Google Scholar] [CrossRef]

- Ji, L.; Gong, M.; Qiao, W.; Zhang, W.; Liu, Q.; Dunham, R.E.; Gu, J. A gelatin/PLA-b-PEG film of excellent gas barrier and mechanical properties. J. Polym. Res. 2018, 25, 210. [Google Scholar] [CrossRef]

- Lin, L.; Deng, C.; Lin, G.-P.; Wang, Y.-Z. Super toughened and high heat-resistant poly(lactic acid) (pla)-based blends by enhancing interfacial bonding and pla phase crystallization. Ind. Eng. Chem. Res. 2015, 54, 5643–5655. [Google Scholar] [CrossRef]

- Ahmed, M.; Li, Y.; Yao, Z.; Cao, K.; Zeng, C. TPU/PLA blend foams: Enhanced foamability, structural stability, and implications for shape memory foams. J. Appl. Polym. Sci. 2019, 136, 47416. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, B.-Q.; Zhao, Q.; Yuen, R.K.; Li, R.K. Facile preparation and thermal degradation studies of graphite nanoplatelets (GNPs) filled thermoplastic polyurethane (TPU) nanocomposites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1506–1513. [Google Scholar] [CrossRef]

- Terrones, M.; Martín, O.; González, M.; Pozuelo, J.; Serrano, B.; Cabanelas, J.C.; Vega-Díaz, S.M.; Baselga, J. Interphases in graphene polymer-based nanocomposites: Achievements and challenges. Adv. Mater. 2011, 23, 5302–5310. [Google Scholar] [CrossRef]

- Mittal, V. Optimization of Polymer Nanocomposite Properties; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Tripathi, S.N.; Rao, G.S.S.; Mathur, A.B.; Jasra, R. Polyolefin/graphene nanocomposites: A review. RSC Adv. 2017, 7, 23615–23632. [Google Scholar] [CrossRef]

- Messori, M. Recent Advances in Elastomeric Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2011; Volume 9. [Google Scholar]

- Nordin, N.; Buys, Y.; Anuar, H.; Ani, M.; Pang, M. Development of conductive polymer composites from PLA/TPU blends filled with graphene nanoplatelets. Mater. Today Proc. 2019, 17, 500–507. [Google Scholar] [CrossRef]

- Zanjani, J.S.M.; Poudeh, L.H.; Ozunlu, B.G.; Yagci, Y.E.; Menceloglu, Y.; Okan, B.S. Development of waste tire-derived graphene reinforced polypropylene nanocomposites with controlled polymer grade, crystallization and mechanical characteristics via melt-mixing. Polym. Int. 2020, 69, 771–779. [Google Scholar] [CrossRef]

- Kim, H.; Miura, Y.; Macosko, C.W. Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem. Mater. 2010, 22, 3441–3450. [Google Scholar] [CrossRef]

- Lee, S.-H.; Oh, C.-R.; Lee, D.-S. Large improvement in the mechanical properties of polyurethane nanocomposites based on a highly concentrated graphite nanoplate/polyol masterbatch. Nanomaterials 2019, 9, 389. [Google Scholar] [CrossRef]

- Ivanov, E.; Kotsilkova, R.; Xia, H.; Chen, Y.; Donato, R.K.; Donato, K.; Godoy, A.P.; Di Maio, R.; Silvestre, C.; Cimmino, S.; et al. PLA/Graphene/MWCNT composites with improved electrical and thermal properties suitable for FDM 3D printing applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef]

- Zeng, B.; Li, Y.; Wang, L.; Zheng, Y.; Shen, J.; Guo, S. Body Temperature-Triggered Shape-Memory Effect via Toughening Sustainable Poly(propylene carbonate) with Thermoplastic Polyurethane: Toward Potential Application of Biomedical Stents. ACS Sustain. Chem. Eng. 2020, 8, 1538–1547. [Google Scholar] [CrossRef]

- Huang, P.-Y.; Guo, Z.-S.; Feng, J.-M. General Model of Temperature-dependent Modulus and Yield Strength of Thermoplastic Polymers. Chin. J. Polym. Sci. 2019, 38, 382–393. [Google Scholar] [CrossRef]

- Dericiler, K.; Sadeghi, H.; Yagci, Y.; Sas, H.; Okan, B.S. Experimental and numerical investigation of flow and alignment behavior of waste tire-derived graphene nanoplatelets in PA66 matrix during melt-mixing and injection. Polymers 2021, 13, 949. [Google Scholar] [CrossRef] [PubMed]

- Srinivasababu, N. Edge crack effect on tensile behavior of diversified wood particulate composites. In Failure Analysis in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar]

- Sakurai, T.; Nojima, S. Significant increase in the melting temperature of poly(ε-caprolactone) blocks confined in the crystallized lamellar morphology of poly(ε-caprolactone)-block-polyethylene copolymers. Polym. J. 2011, 43, 370–377. [Google Scholar] [CrossRef]

- Mohammadzadeh, F.; Haddadi-Asl, V.; Balzade, Z.; Jouibari, I.S. Switch segment and halloysite nanotube role in the phase separation behavior of shape-memory thermoplastic polyurethane. Polym. Compos. 2020, 41, 2625–2633. [Google Scholar] [CrossRef]

- Balani, K.; Verma, V.; Agarwal, A.; Narayan, R. Physical, Thermal, and Mechanical Properties of Polymers. In Biosurfaces; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Baidurah, S. Methods of Analyses for Biodegradable Polymers: A Review. Polymers 2022, 14, 4928. [Google Scholar] [CrossRef]

- Chen, K.; Tian, Q.; Tian, C.; Yan, G.; Cao, F.; Liang, S.; Wang, X. Mechanical Reinforcement in Thermoplastic Polyurethane Nanocomposite Incorporated with Polydopamine Functionalized Graphene Nanoplatelet. Ind. Eng. Chem. Res. 2017, 56, 11827–11838. [Google Scholar] [CrossRef]

- Reddy, M.I.; Reddy, V.S. Dynamic Mechanical Analysis of Hemp Fiber Reinforced Polymer Matrix Composites. Int. J. Eng. Res. Technol. 2014, 3, 410–415. [Google Scholar]

- Huang, C.; Qian, X.; Yang, R. Thermal conductivity of polymers and polymer nanocomposites. Mater. Sci. Eng. R Rep. 2018, 132, 1–22. [Google Scholar] [CrossRef]

- Tessema, A.; Zhao, D.; Moll, J.; Xu, S.; Yang, R.; Li, C.; Kumar, S.K.; Kidane, A. Effect of filler loading, geometry, dispersion and temperature on thermal conductivity of polymer nanocomposites. Polym. Test. 2017, 57, 101–106. [Google Scholar] [CrossRef]

- Kim, G.-H.; Lee, D.; Shanker, A.; Shao, L.; Kwon, M.S.; Gidley, D.W.; Kim, J.; Pipe, K.P. High thermal conductivity in amorphous polymer blends by engineered interchain interactions. Nat. Mater. 2014, 14, 295–300. [Google Scholar] [CrossRef]

- Ajorloo, M.; Fasihi, M.; Ohshima, M.; Taki, K. How are the thermal properties of polypropylene/graphene nanoplatelet composites affected by polymer chain configuration and size of nanofiller? Mater. Des. 2019, 181, 108068. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.B.; Yunus, W.M.Z.W.; Hussein, M.Z. Poly(lactic acid)/Poly(ethylene glycol) Polymer Nanocomposites: Effects of Graphene Nanoplatelets. Polymers 2013, 6, 93–104. [Google Scholar] [CrossRef]

- Haryńska, A.; Gubanska, I.; Kucinska-Lipka, J.; Janik, H. Fabrication and Characterization of Flexible Medical-Grade TPU Filament for Fused Deposition Modeling 3DP Technology. Polymers 2018, 10, 1304. [Google Scholar] [CrossRef]

- Tang, Q.; Gao, K. Structure analysis of polyether-based thermoplastic polyurethane elastomers by FTIR, 1H NMR and 13C NMR. Int. J. Polym. Anal. Charact. 2017, 22, 569–574. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Meng, Q.; Wang, T.; Guo, W.; Wu, G.; You, L. Preparation of high antistatic HDPE/polyaniline encapsulated graphene nanoplatelet composites by solution blending. RSC Adv. 2017, 7, 2796–2803. [Google Scholar] [CrossRef]

- Quero, E.; Müller, A.J.; Signori, F.; Coltelli, M.-B.; Bronco, S. Isothermal Cold-Crystallization of PLA/PBAT Blends With and Without the Addition of Acetyl Tributyl Citrate. Macromol. Chem. Phys. 2011, 213, 36–48. [Google Scholar] [CrossRef]

| Sample | Flexural Strength (MPa) | Flexural Modulus (MPa) | Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| Neat PLA | 82.85 ± 2.0 | 3655.0 ± 33.2 | 65.20 ± 1.1 | 3709.5 ± 142.1 | 3.00 ± 0.6 |

| PLA + 0.5%GNP | 86.83 ± 1.5 | 3527.5 ± 60.2 | 63.30 ± 0.5 | 3512.5 ± 317.8 | 2.85 ± 0.6 |

| PLA + 1%GNP | 83.98 ± 1.7 | 3692.5 ± 27.5 | 58.78 ± 5.9 | 3736.8 ± 288.6 | 2.25 ± 0.7 |

| PLA + 2%GNP | 83.45 ± 3.5 | 3432.5 ± 98.8 | 60.23 ± 5.5 | 3542.0 ± 924.9 | 2.53 ± 1.3 |

| Sample | Flexural Strength (MPa) | Flexural Modulus (MPa) | Tensile Strength (MPa) | Tensile Modulus (MPa) |

|---|---|---|---|---|

| Neat PLA | 82.85 ± 2.0 | 3655 ± 33.2 | 65.20 ± 1.1 | 3709 ± 142.1 |

| Neat TPU | 2.53 ± 0.2 | 28.55 ± 3.6 | 43.47 ± 8.2 | 27.46 ± 5.7 |

| PLA/TPU = 9:1 | 72.20 ± 1.4 | 3055 ± 12.9 | 52.35 + 1.2 | 3031 ± 99.6 |

| PLA/TPU = 9:1 + 0.5%GNP | 89.38 ± 3.2 | 3375 ± 100.3 | 51.55 + 3.0 | 2793 ± 62.7 |

| PLA/TPU = 9:1 + 1%GNP | 82.38 ± 6.9 | 3285 ± 73.7 | 49.60 + 4.0 | 2858 ± 115.3 |

| PLA/TPU = 9:1 +2% GNP | 86.51 ± 2.1 | 3233 ± 93.0 | 48.98 + 4.1 | 2775 ± 183.9 |

| Sample | Tg (°C) | Tm (°C) | ΔHm (J/g) | Tc (°C) | ΔHc (J/g) |

|---|---|---|---|---|---|

| PLA/TPU = 9:1 | 64.1 | 175.4 | −39.1 | 106.9 | 32.3 |

| PLA/TPU = 9:1 +0.5% GNP | 69.4 | 177.4 | −42.7 | 110.4 | 35.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cetiner, B.; Sahin Dundar, G.; Yusufoglu, Y.; Saner Okan, B. Sustainable Engineered Design and Scalable Manufacturing of Upcycled Graphene Reinforced Polylactic Acid/Polyurethane Blend Composites Having Shape Memory Behavior. Polymers 2023, 15, 1085. https://doi.org/10.3390/polym15051085

Cetiner B, Sahin Dundar G, Yusufoglu Y, Saner Okan B. Sustainable Engineered Design and Scalable Manufacturing of Upcycled Graphene Reinforced Polylactic Acid/Polyurethane Blend Composites Having Shape Memory Behavior. Polymers. 2023; 15(5):1085. https://doi.org/10.3390/polym15051085

Chicago/Turabian StyleCetiner, Busra, Gulayse Sahin Dundar, Yusuf Yusufoglu, and Burcu Saner Okan. 2023. "Sustainable Engineered Design and Scalable Manufacturing of Upcycled Graphene Reinforced Polylactic Acid/Polyurethane Blend Composites Having Shape Memory Behavior" Polymers 15, no. 5: 1085. https://doi.org/10.3390/polym15051085

APA StyleCetiner, B., Sahin Dundar, G., Yusufoglu, Y., & Saner Okan, B. (2023). Sustainable Engineered Design and Scalable Manufacturing of Upcycled Graphene Reinforced Polylactic Acid/Polyurethane Blend Composites Having Shape Memory Behavior. Polymers, 15(5), 1085. https://doi.org/10.3390/polym15051085