Mechanical and Thermo-Mechanical Performance of Natural Fiber-Based Single-Ply and 2-Ply Woven Prepregs

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Manufacturing of the Composite Laminates

2.2.2. Testing

2.2.3. Static Mechanical Testing

2.2.4. Dynamic Mechanical Analysis

2.2.5. Thermo-Gravimetric Analysis

2.2.6. Differential Scanning Calorimetry

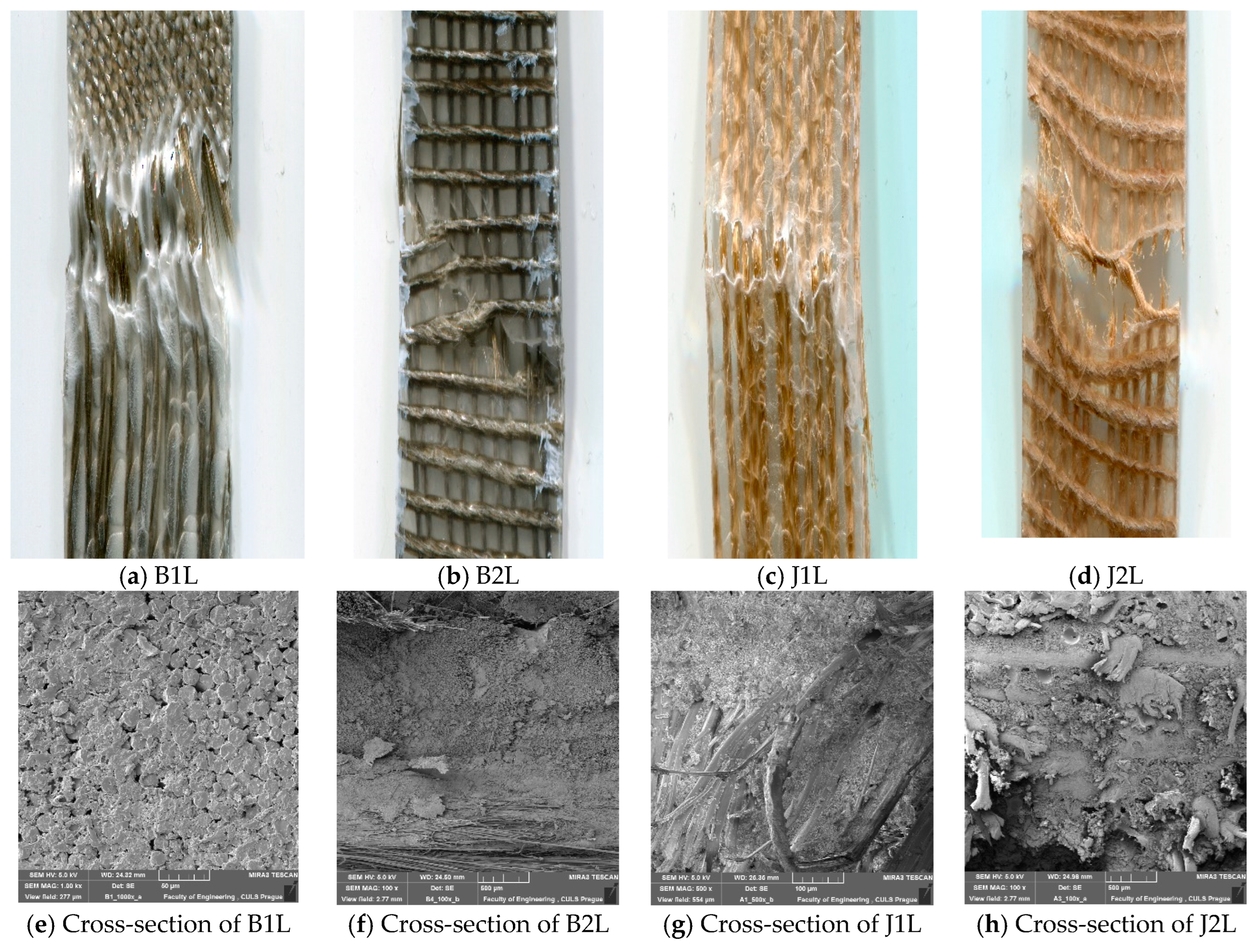

2.2.7. Microscopic Analysis/Fractography

3. Results and Discussion

3.1. Tensile Properties

Fractography

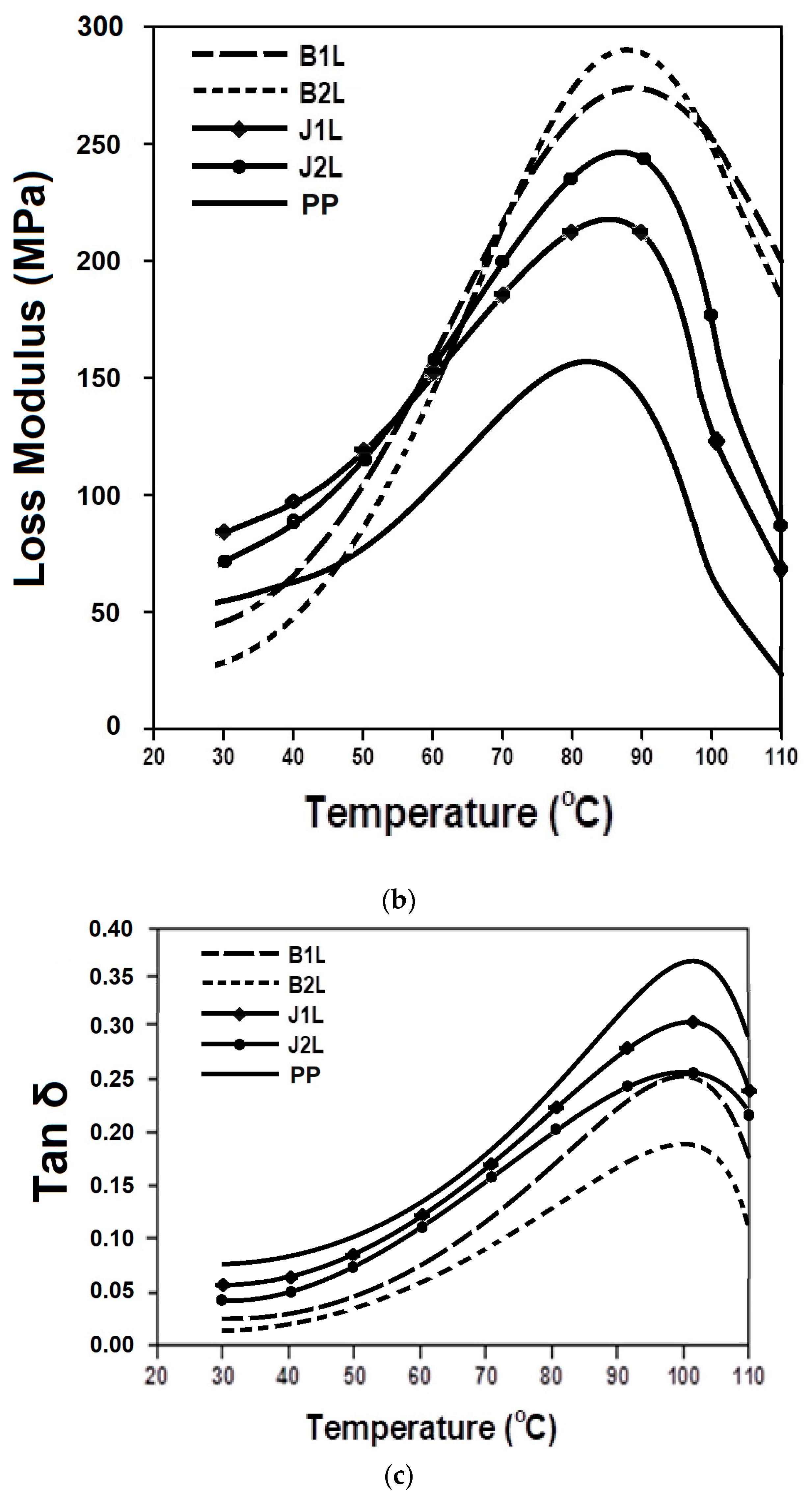

3.2. Dynamic Mechanical Analysis

3.3. Thermal Properties

3.3.1. Thermo-Gravimetric/Differential Thermo-Gravimetric (TG/DTG) Analysis

3.3.2. Calculation of the Heat-Resistance Index (THRI)

3.3.3. Differential Scanning Calorimetry (DSC) Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahmood, R.Y. Enhancement of thermal stability and wettability for epoxy/Cu coated carbon fiber composites. Iraqi J. Phys. 2020, 18, 55–61. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R. A green material from rock: Basalt fiber—A review. J. Text. Inst. 2016, 107, 923–937. [Google Scholar] [CrossRef]

- Liu, Q.; Shaw, M.T.; Parnas, R.S.; McDonnel, A.M. Investigation of basalt fiber composite mechanical properties for applications in transportation. Polym. Compos. 2006, 27, 41–48. [Google Scholar] [CrossRef]

- Ilangovan, S.; Senthil Kumaran, S.; Vasudevan, A.; Naresh, K. Effect of silica nanoparticles on mechanical and thermal properties of neat epoxy and filament wounded E-glass/epoxy and basalt/epoxy composite tubes. Mater. Res. Express 2019, 6, 0850e2. [Google Scholar] [CrossRef]

- Senthilrajan, S.; Venkateshwaran, N.; Naresh, K.; Velmurugan, R.; Gupta, N.K. Effects of jute fiber length and weight percentage on quasi-static flexural and dynamic mechanical properties of jute/polyester composites for thin-walled structure applications. Thin-Walled Struct. 2022, 179, 109719. [Google Scholar] [CrossRef]

- Singh, H.; Singh, J.I.P.; Singh, S.; Dhawan, V.; Tiwari, S.K. A brief review of jute fiber and its composites. Mater. Today Proc. 2018, 5, 28427–28437. [Google Scholar] [CrossRef]

- Prasath, K.A.; Krishnan, B.R. Mechanical properties of woven fabric basalt/jute fiber reinforced polymer hybrid composites. Int. J. Mech. Eng. Robot. Res. 2013, 2, 279–290. [Google Scholar] [CrossRef]

- Czigany, T. Special manufacturing and characteristics of basalt fiber reinforced hybrid polypropylene composites: Mechanical properties and acoustic emission study. Compos. Sci. Technol. 2006, 66, 3210–3220. [Google Scholar] [CrossRef]

- Mishra, R.; Petru, M.; Novotna, J. Bio-composites reinforced with natural fibers: Comparative analysis of thermal, static and dynamic-mechanical properties. Fibers Polym. 2020, 21, 619–627. [Google Scholar] [CrossRef]

- Wong, D.W.Y.; Lin, L.; McGrail, P.T.; Peijs, T.; Hogg, P.J. Improved fracture toughness of carbon fiber/epoxy composite laminates using dissolvable thermoplastic fibers. Compos. Part A Appl. Sci. Manuf. 2010, 41, 759–767. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Petrů, M.; Noman, M.T.; Mishra, R. Sound absorption properties of natural fibers: A review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fiber and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Madueke, C.I.; Mbah, O.M.; Umunakwe, R. A review on the limitations of natural fibers and natural fiber composites with emphasis on tensile strength using coir as a case study. Polym. Bull. 2022, 1–18. [Google Scholar] [CrossRef]

- Antony, S.; Cherouat, A.; Montay, G. Effect of fiber content on the mechanical properties of hemp fiber woven fabrics/polypropylene composite laminates. Polym. Polym. Compos. 2021, 29 (Suppl. 9), S790–S802. [Google Scholar] [CrossRef]

- Keerthi Gowda, B.S.; Naresh, K.; Ilangovan, S.; Sanjay, M.R.; Siengchin, S. Effect of fiber volume fraction on mechanical and fire resistance properties of basalt/polyester and pineapple/polyester composites. J. Nat. Fibers 2022, 19. [Google Scholar] [CrossRef]

- Abounaim, M.; Diestel, O.; Offmann, G. High performance thermoplastic composite from flat knitted multi-layer textile preform using hybrid yarn. Compos. Sci. Technol. 2011, 71, 511–519. [Google Scholar] [CrossRef]

- Botev, M.; Betchev, H.; Bikiaris, D.; Panayiotou, C. Mechanical properties and viscoelastic behavior of basalt fiber-reinforced polypropylene. J Appl. Polym. Sci. 1999, 74, 523–531. [Google Scholar] [CrossRef]

- Khondker, O.A.; Ishiaku, U.S.; Nakai, A.; Hamada, H. A novel processing technique for thermoplastic manufacturing of single-ply composites reinforced with jute yarns. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2274–2284. [Google Scholar] [CrossRef]

- Mishra, R.; Jamshaid, H.; Yosfani, S.; Hussain, U. Thermo physiological comfort of single jersey knitted fabric derivatives. Fash. Text. 2021, 8, 40. [Google Scholar] [CrossRef]

- Preethikaharshini, J.; Naresh, K.; Rajeshkumar, G.; Arumugaprabu, V.; Khan, M.A.; Khan, K.A. Review of advanced techniques for manufacturing biocomposites: Non-destructive evaluation and artificial intelligence-assisted modeling. J. Mater. Sci. 2022, 57, 16091–16146. [Google Scholar] [CrossRef]

- Naresh, K.; Khan, K.A.; Umer, R.; Cantwell, W.J. The use of X-ray computed tomography for design and process modeling of aerospace composites: A review. Mater. Design. 2020, 190, 108553. [Google Scholar] [CrossRef]

- Park, S.J.; Seo, M.K. Interface Science and Composites; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 9780080963488/9780080976051. [Google Scholar]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.M.; Loos, J.; Peijs, T. The mechanical properties of single-ply all-polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 716–726. [Google Scholar] [CrossRef]

- Hoa, S.V.; Hoang, M.D.; Simpson, J. Manufacturing procedure to make flat thermoplastic composite laminates by automated fiber placement and their mechanical properties. J. Therm. Comp. Mater. 2016, 30, 1693–1712. [Google Scholar] [CrossRef]

- Ahmad, Z.; Jamshaid, H.; Nawab, Y. Influence of inlay yarn type and stacking sequence on mechanical performance of knitted uni-directional thermoplastic composite prepregs. J. Ind. Text. 2022, 51 (Suppl. 3), 4973S–5008S. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R.; Pechociakova, M.; Noman, M.T. Mechanical, thermal and interfacial properties of green composites from basalt and hybrid woven fabrics. Fibers Polym. 2016, 17, 1675–1686. [Google Scholar] [CrossRef]

- Selva Priya, M.; Naresh, K.; Jayaganthan, R.; Velmurugan, R. A comparative study between in-house 3D printed and injection molded ABS and PLA polymers for low-frequency applications. Mater. Res. Express 2019, 6, 085345. [Google Scholar] [CrossRef]

- Prasad, V.V.; Talupula, S. A Review on Reinforcement of Basalt and aramid (Kevlar 129) fibers. Mater. Today Proc. 2018, 5, 5993–5998. [Google Scholar] [CrossRef]

- Naresh, K.; Khan, K.A.; Umer, R.; Vasudevan, A. Temperature-frequency–dependent viscoelastic properties of neat epoxy and fiber reinforced polymer composites: Experimental characterization and theoretical predictions. Polymers 2020, 12, 1700. [Google Scholar] [CrossRef]

- Vasudevan, A.; Senthil Kumaran, S.; Naresh, K.; Velmurugan, R. Experimental and analytical investigation of thermo-mechanical responses of pure epoxy and carbon/kevlar/s-glass/e-glass/epoxy interply hybrid laminated composites for aerospace applications. Int. J. Polym. Anal. Charact. 2018, 23, 591–605. [Google Scholar] [CrossRef]

- Jiang, L.; Fu, J.; Liu, L.; Du, P. Wear and thermal behavior of basalt fiber reinforced rice husk/polyvinyl chloride composites. J. Appl. Polym. Sci. 2021, 138, 50094. [Google Scholar] [CrossRef]

- Khan, J.; Khan, M.; Islam, R.; Gafur, A. Mechanical, thermal and interfacial properties of jute fabric-reinforced polypropylene composites: Effect of potassium dichromate. Mater. Sci. Appl. 2010, 1, 350–357. [Google Scholar] [CrossRef]

- Naresh, K.; Khan, K.A.; Umer, R. Experimental characterization and modeling multifunctional properties of epoxy/graphene oxide nanocomposites. Polymers 2021, 13, 2831. [Google Scholar] [CrossRef]

- Naresh, K.; Shankar, K.; Velmurugan, R. Digital image processing and thermo-mechanical response of neat epoxy and different laminate orientations of fiber reinforced polymer composites for vibration isolation applications. Int. J. Polym. Anal. Charact. 2018, 23, 684–709. [Google Scholar] [CrossRef]

- Aji, I.S.; Zainudin, E.S.; Khalina, A.; Sapuan, S.M.; Khairul, M.D. Thermal property determination of hybridized kenaf/PALF reinforced HDPE composite by thermogravimetric analysis. J. Therm. Anal. Calorim. 2012, 109, 893–900. [Google Scholar] [CrossRef]

| Properties | Basalt | Polypropylene | Jute |

|---|---|---|---|

| Diameter of fibers (micron) | 12 ± 0.01 | 34 ± 0.01 | 18 ± 0.08 |

| No. of filaments | 890 | 300 | -------- |

| Linear density of yarn (tex) | 300 ± 1.14 | 292 ± 1.02 | 296 ± 2.24 |

| TPM (twists/m) | 20 ± 1.00 | 30 ± 1.00 | 180 ± 1.00 |

| Tensile strength (N) | 92.75 ± 4.42 | 88.91 ± 3.07 | 41.43 ± 2.11 |

| Tensile elongation (%) | 1.29 ± 0.01 | 12.55 ± 0.72 | 1.39 ± 0.01 |

| Tenacity (N/tex) | 0.32 ± 0.01 | 0.23 ± 0.01 | 0.14 ± 0.01 |

| Initial modulus (MPa) | 9,378 ± 10.45 | 721 ± 7.42 | 3,741 ± 14.12 |

| Factors | Level 1 | Level 2 |

|---|---|---|

| Reinforcing yarn | Basalt yarn | Jute yarn |

| Thermoplastic/matrix yarn | Polypropylene (PP) | Polypropylene (PP) |

| No. of layers/stacking sequence (angle in degrees) | 1 (0) | 2 (0/45) |

| Sample Code | Pattern of Layering |

|---|---|

| PP | Control sample (pure PP) |

| B1L | Basalt one layer |

| B2L | Basalt two layer |

| J1L | Jute one layer |

| J2L | Jute two layer |

| Sample Code | Maximum Tensile Stress (N/mm2) | Tensile Modulus (GPa) | Elongation to Break (%) |

|---|---|---|---|

| PP (control sample) | 0.11 ± 0.01 | 12.25 ± 0.07 | 12.46 ± 0.41 |

| B1L | 1.15 ± 0.05 | 26.33 ± 1.12 | 3.56 ± 0.11 |

| B2L | 1.18 ± 0.04 | 27.75 ± 1.22 | 2.76 ± 0.09 |

| J1L | 0.31 ± 0.01 | 22.58 ± 1.08 | 2.68 ± 0.10 |

| J2L | 0.47 ± 0.02 | 23.67 ± 1.11 | 2.48 ± 0.18 |

| Sample Code | Storage Modulus (MPa) at 30 °C | Storage Modulus (MPa) at 100 °C | Tan δ at 30 °C | Tan δ at 100 °C |

|---|---|---|---|---|

| PP (control sample) | 998.42 ± 18.47 | 71.45 ± 1.21 | 0.07 ± 0.01 | 0.37 ± 0.01 |

| B1L | 2154.74 ± 24.42 | 1086.17 ± 22.72 | 0.02 ± 0.01 | 0.22 ± 0.01 |

| B2L | 2312.17 ± 27.16 | 1403.44 ± 24.08 | 0.01 ± 0.01 | 0.16 ± 0.01 |

| J1L | 1405.46 ± 28.33 | 114.24 ± 7.01 | 0.06 ± 0.01 | 0.29 ± 0.01 |

| J2L | 1803.83 ± 31.22 | 521.28 ± 10.86 | 0.04 ± 0.01 | 0.24 ± 0.01 |

| Sample | Weight Loss Temperature (°C) | Heat-Resistance Index (THRI) | |

|---|---|---|---|

| T5 | T30 | ||

| PP | 301.15 | 411.21 | 179.92 |

| Jute | 303.22 | 421.44 | 183.33 |

| Basalt | 321.45 | 1425.24 | 482.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamshaid, H.; Mishra, R.K.; Chandan, V.; Nazari, S.; Shoaib, M.; Bizet, L.; Ivanova, T.A.; Muller, M.; Valasek, P. Mechanical and Thermo-Mechanical Performance of Natural Fiber-Based Single-Ply and 2-Ply Woven Prepregs. Polymers 2023, 15, 994. https://doi.org/10.3390/polym15040994

Jamshaid H, Mishra RK, Chandan V, Nazari S, Shoaib M, Bizet L, Ivanova TA, Muller M, Valasek P. Mechanical and Thermo-Mechanical Performance of Natural Fiber-Based Single-Ply and 2-Ply Woven Prepregs. Polymers. 2023; 15(4):994. https://doi.org/10.3390/polym15040994

Chicago/Turabian StyleJamshaid, Hafsa, Rajesh Kumar Mishra, Vijay Chandan, Shabnam Nazari, Muhammad Shoaib, Laurent Bizet, Tatiana Alexiou Ivanova, Miroslav Muller, and Petr Valasek. 2023. "Mechanical and Thermo-Mechanical Performance of Natural Fiber-Based Single-Ply and 2-Ply Woven Prepregs" Polymers 15, no. 4: 994. https://doi.org/10.3390/polym15040994

APA StyleJamshaid, H., Mishra, R. K., Chandan, V., Nazari, S., Shoaib, M., Bizet, L., Ivanova, T. A., Muller, M., & Valasek, P. (2023). Mechanical and Thermo-Mechanical Performance of Natural Fiber-Based Single-Ply and 2-Ply Woven Prepregs. Polymers, 15(4), 994. https://doi.org/10.3390/polym15040994