Research and Application of Biomass-Based Wood Flame Retardants: A Review

Abstract

1. Introduction

2. Composite Biological Intumescent Flame Retardant

2.1. Biomass-Based Carbon Source

- To further improve the flame retardancy and char yield of biomass-based flame retardants, the grafting rate of biomass-based char forming agents must be improved through molecular design and compounding with metal ions such as nitrogen and silicon.

- Most polysaccharides degrade at temperatures above 200 °C and undergo discoloration. This affects the appearance of flame-retardant materials. The thermal stability of flame retardants based on biomass can be improved by chemical modification or by cross-linking.

- The physical properties of biomass-based flame retardants, such as water resistance, are improved by chemical modification or surface treatment.

2.2. Biomass-Based Acid Source

2.3. Biomass-Based Gas Source

2.4. Other Biomass-Based Flame Retardant Synergists

3. All-Biomass Intumescent Flame Retardant

4. Challenges and Future Perspective

- The amount of biomass-based intumescent flame retardants is still very high, which has a significant negative impact on the mechanical properties of these materials.

- Although biomass materials such as chitosan and phytic acid are naturally obtained, they require a number of complex extraction and processing steps during the production process. This inevitably leads to a significant increase in their cost and severely limits their industrialization. For example, Wang et al. [88] introduced biomass-based acid sources into the cellulose lumen. One of the complex steps is that it needs to first delignify the wood and then adsorb the phytic acid into the wood container to enhance the flame retardancy of the wood.

- Because the structural properties of most biomass materials are still being explored, most researchers use them as char-forming agents in the current development of biomass-based intumescent flame retardants and flame-retardant synergists with mature acid sources such as ammonium polyphosphate. However, research on biomass acid sources, gas sources, flame retardant synergists, and all-biomass intumescent flame retardants is scarce. For example, Leng et al. [102] used phytic acid tyrosine salt (PATA) to react with deionized water. Then, PATA and ammonium polyphosphate were mixed to effectively increase the flame resistance of wood plastic composites.

- The poor heat resistance of biomass materials has led to problems such as degradation and discoloration during heat treatment.

- The sources of biomass-based intumescent flame retardants should also be expanded from multiple directions. For example, focusing on the comprehensive utilization of biomass waste resources, deepening biomass research, and continuously improving extraction technology to find more novel and diverse biomass with different structures.

- Through functional modification of a large amount of biomass and the introduction of multifunctional functional groups such as triazine structures and silicon-containing substances, the heat resistance of biomass fire retardants can be improved. Its compatibility with the substrate can be enhanced, and a more stable and continuous protective layer of carbon can be formed. This can not only improve the flame-retardant effect of biomass materials, but also reduce the adverse effect on the mechanical properties of the wood substrate and solve the degradation of biomass at high temperatures and discoloration. Although the development of biomass-based intumescent flame retardants is currently facing great challenges, it is still an essential part of achieving sustainable development. It is believed that with the progress of science and technology, highly efficient, green, and environmentally friendly biomass-based intumescent flame retardants will be obtained.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef] [PubMed]

- Berglund, L.A.; Burgert, I. Bioinspired Wood Nanotechnology for Functional Materials. Adv. Mater. 2018, 30, 1704285. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly Anisotropic, Highly Transparent Wood Composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef] [PubMed]

- Jia, C.; Chen, C.; Mi, R.; Li, T.; Dai, J.; Yang, Z.; Pei, Y.; He, S.; Bian, H.; Jang, S.H.; et al. Clear Wood toward High-Performance Building Materials. ACS Nano 2019, 13, 9993–10001. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, Y.; Yu, Z.; Qi, C. Properties of fast-growing poplar wood simultaneously treated with dye and flame retardant. Eur. J. Wood Wood Prod. 2016, 75, 325–333. [Google Scholar] [CrossRef]

- Kong, L.; Guan, H.; Wang, X. In Situ Polymerization of Furfuryl Alcohol with Ammonium Dihydrogen Phosphate in Poplar Wood for Improved Dimensional Stability and Flame Retardancy. ACS Sustain. Chem. Eng. 2018, 6, 3349–3357. [Google Scholar] [CrossRef]

- Lu, J.H.; Jiang, P.; Chen, Z.L.; Li, L.M.; Huang, Y.X. Flame retardancy, thermal stability, and hygroscopicity of wood materials modified with melamine and amino trimethylene phosphonic acid. Constr. Build. Mater. 2021, 267, 121042. [Google Scholar] [CrossRef]

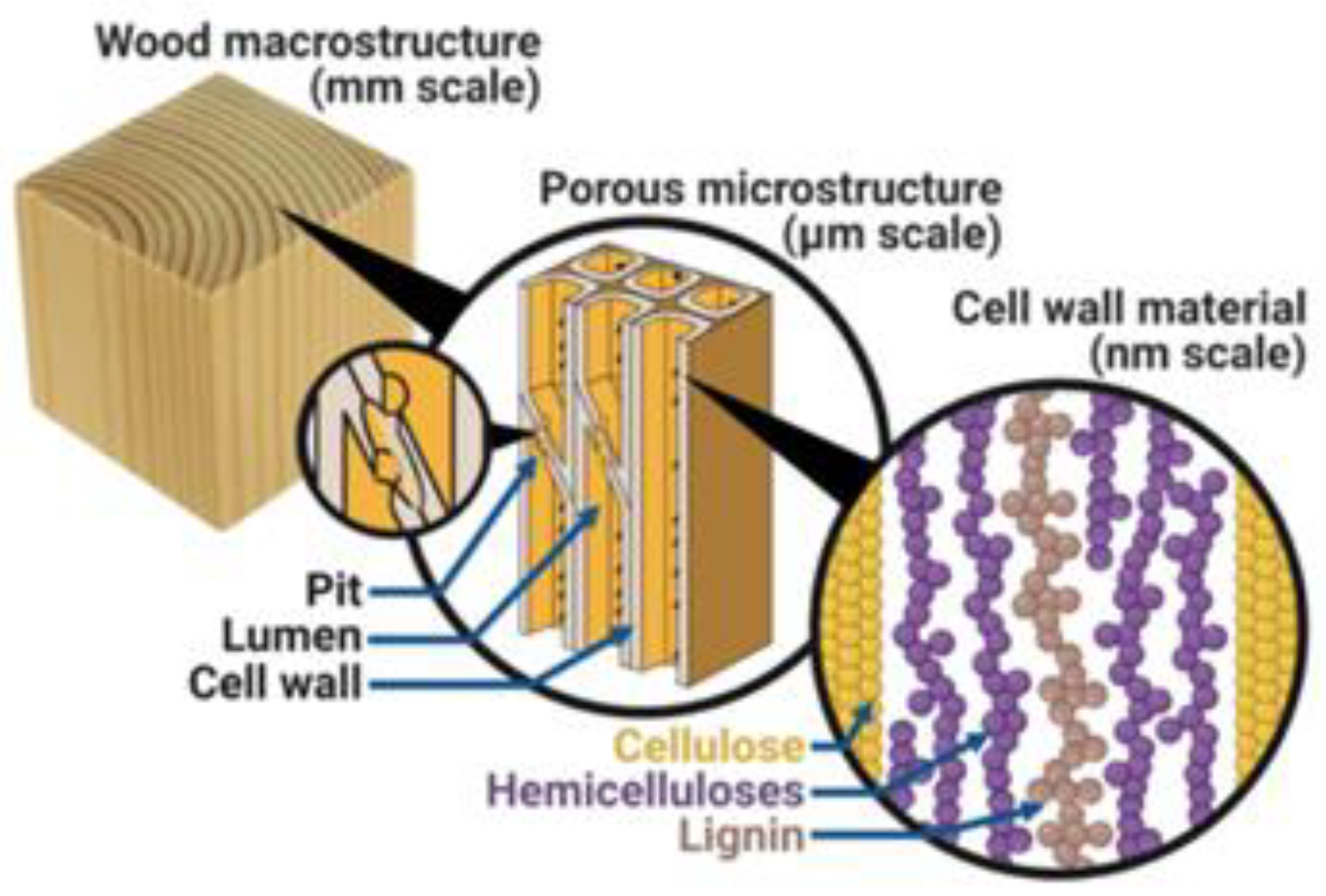

- Zhang, X.; Li, L.; Xu, F. Chemical Characteristics of Wood Cell Wall with an Emphasis on Ultrastructure: A Mini-Review. Forests 2022, 13, 439. [Google Scholar] [CrossRef]

- Zhang, L.; Yi, D.; Hao, J.; Gao, M. One-step treated wood by using natural source phytic acid and uracil for enhanced mechanical properties and flame retardancy. Polym. Adv. Technol. 2020, 32, 1176–1186. [Google Scholar] [CrossRef]

- Li, Z.; Li, X.; Zhang], Z. Flame retardant coatings prepared using layer by layer assembly: A review. Chem. Eng. J. 2018, 334, 108–122. [Google Scholar] [CrossRef]

- Shao, N.; Xue, F.; Hou, L.; Li, D.; Zhu, X. Effects of ternary potassium containing intumescent flame retardant coating on the combustion and thermal degradation properties of reconstituted tobacco sheet. Thermochim. Acta 2019, 678, 178310. [Google Scholar] [CrossRef]

- Hya, B.; By, B.; Psc, B.; Cm, D.; Hao, W. Surface-coating engineering for flame retardant flexible polyurethane foams: A critical review. Compos. Part B Eng. 2019, 176, 107185. [Google Scholar] [CrossRef]

- Thybring, E.E.; Fredriksson, M. Wood Modification as a Tool to Understand Moisture in Wood. Forests 2021, 12, 372. [Google Scholar] [CrossRef]

- Yan, L.; Xu, Z.S.; Wang, X.H. Synergistic flame-retardant and smoke suppression effects of zinc borate in transparent intumescent fire-retardant coatings applied on wood substrates. J. Therm. Anal. Calorim. 2019, 136, 1563–1574. [Google Scholar] [CrossRef]

- Su, G.; Letcher, R.J.; McGoldrick, D.J.; Backus, S.M. Halogenated Flame Retardants in Predator and Prey Fish From the Laurentian Great Lakes: Age-Dependent Accumulation and Trophic Transfer. Environ. Sci. Technol. 2017, 51, 8432–8441. [Google Scholar] [CrossRef]

- Mokhena, T.C.; Sadiku, E.R.; Mochane, M.J.; Ray, S.S. Mechanical properties of fire retardant wood-plastic composites: A review. Express Polym. Lett. 2021, 15, 744–780. [Google Scholar] [CrossRef]

- Markwart, J.C.; Battig, A.; Zimmermann, L.; Wagner, M.; Fischer, J.; Schartel, B.; Wurm, F.R. Systematically Controlled Decomposition Mechanism in Phosphorus Flame Retardants by Precise Molecular Architecture: P–O vs P–N. Acs Appl. Polym. Mater. 2019, 1, 1118–1128. [Google Scholar] [CrossRef]

- Shaw, S. Halogenated flame retardants: Do the fire safety benefits justify the risks? Rev. Environ. Health 2010, 25, 261–306. [Google Scholar] [CrossRef]

- Xiang, G.; Smb, C.; Xz, A.; Yan, Y.; Gl, B.; Yy, B. Halogenated and organophosphorous flame retardants in surface soils from an e-waste dismantling park and its surrounding area: Distributions, sources, and human health risks. Environ. Int. 2020, 139, 105741. [Google Scholar] [CrossRef]

- Ekpe, O.D.; Choo, G.; Barcelo, D.; Oh, J.-E. Introduction of emerging halogenated flame retardants in the environment. In Emerging Halogenated Flame Retardants in the Environment; Oh, J.E., Ed.; Wilson and Wilsons Comprehensive Analytical Chemistry: Heidelberg, Germany, 2020; Volume 88, pp. 1–39. [Google Scholar]

- Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P. Bio-based flame retardants: When nature meets fire protection. Mater. Sci. Eng. R-Rep. 2017, 117, 1–25. [Google Scholar] [CrossRef]

- Sui, Y.; Dai, X.; Li, P.; Zhang, C. Superior radical scavenging and catalytic carbonization capacities of bioderived assembly modified ammonium polyphosphate as a mono-component intumescent flame retardant for epoxy resin. Eur. Polym. J. 2021, 156, 110601. [Google Scholar] [CrossRef]

- Lou, G.; Ma, Z.; Dai, J.; Bai, Z.; Song, P. Fully Biobased Surface-Functionalized Microcrystalline Cellulose via Green Self-Assembly toward Fire-Retardant, Strong, and Tough Epoxy Biocomposites. ACS Sustain. Chem. Eng. 2021, 9, 13595–13605. [Google Scholar] [CrossRef]

- Wu, X.; Gou, T.T.; Zhao, Q.Y.; Chen, L.; Wang, P. High-efficiency durable flame retardant with ammonium phosphate ester and phosphine oxide groups for cotton cellulose biomacromolecule. Int. J. Biol. Macromol. 2022, 194, 945–953. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Lu, Y.; Zhang, G.; Liang, Y.; Zhang, F. Facile synthesis of an eco-friendly nitrogen–phosphorus ammonium salt to enhance the durability and flame retardancy of cotton. J. Mater. Chem. A 2017, 5, 9970–9981. [Google Scholar] [CrossRef]

- Wu, J.; Wang, M.; Guo, H. Synergistic Flame Retardant Effects of Different Zeolites on Intumescent Fire Retardant Coating for Wood. BioResources 2017, 12, 5369–5382. [Google Scholar] [CrossRef]

- Xu, B.R.; Deng, C.; Li, Y.M.; Lu, P.; Zhao, P.P.; Wang, Y.Z. Novel amino glycerin decorated ammonium polyphosphate for the highly-efficient intumescent flame retardance of wood flour/polypropylene composite via simultaneous interfacial and bulk charring—ScienceDirect. Compos. Part B Eng. 2019, 172, 636–648. [Google Scholar] [CrossRef]

- Ghanadpour, M.; Carosio, F.; Wågberg, L. Ultrastrong and flame-resistant freestanding films from nanocelluloses, self-assembled using a layer-by-layer approach. Appl. Mater. Today 2017, 9, 229–239. [Google Scholar] [CrossRef]

- Yang, Y.; Haurie, L.; Wen, J.; Zhang, S.; Ollivier, A.; Wang, D.Y. Effect of oxidized wood flour as functional filler on the mechanical, thermal and flame-retardant properties of polylactide biocomposites. Ind. Crops Prod. 2019, 130, 301–309. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, J.-X.; Wen, M.-Y.; Jun, P.H.; Zhu, J.-Z.; Liu, Y.-N. Research on Flame Retardant Plywood with Different Flame Retardants. J. Korean Wood Sci. Technol. 2021, 49, 667–678. [Google Scholar] [CrossRef]

- Yin, H.J.; Sypaseuth, F.D.; Schubert, M.; Schoch, R.; Bastian, M.; Schartel, B. Routes to halogen-free flame-retardant polypropylene wood plastic composites. Polym. Adv. Technol. 2019, 30, 187–202. [Google Scholar] [CrossRef]

- Lomakin, S.M.; Khvatov, A.V.; Sakharov, P.A.; Koverzanova, E.V.; Usachev, S.V.; Shilkina, N.G.; Varfolomeev, S.D. Study of the Mechanism of Fire-Retardant Action of Bio Flame Retartdant Based on Oxidized Compounds of Cellulose-Containing Biomass. Russ. J. Phys. Chem. B 2020, 14, 1028–1035. [Google Scholar] [CrossRef]

- Feng, Y.; Zhou, Y.; Li, D.; He, S.; Zhang, F.; Zhang, G. A plant-based reactive ammonium phytate for use as a flame-retardant for cotton fabric. Carbohyd. Polym. 2017, 175, 636–644. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liu, Y.; Li, J. Regulating effects of nitrogenous bases on char structure and flame retardancy of polypropylene/intumescent flame retardant composites. ACS Sustain. Chem. Eng. 2017, 5, 2375–2383. [Google Scholar] [CrossRef]

- Fu, Q.; Medina, L.; Li, Y.; Carosio, F.; Hajian, A.; Berglund, L.A. Nanostructured Wood Hybrids for Fire-Retardancy Prepared by Clay Impregnation into the Cell Wall. ACS Appl. Mater. Inter. 2017, 9, 36154–36163. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.J.; Shi, L.; Fan, Z.W.; Yu, Y.Y.; Liu, R.T. Bio-based coating of phytic acid, chitosan, and biochar for flame-retardant cotton fabrics. Polym. Degrad. Stab. 2022, 199, 109898. [Google Scholar] [CrossRef]

- Zhuang, B.R.; Zhan, Y.P.; Huang, W.Y.; Ye, H.L.; Xie, Y.Q. Smoke suppression properties of Si-Al mesoporous structure on medium density fiberboard. J. Hazard. Mater. 2018, 357, 271–278. [Google Scholar] [CrossRef] [PubMed]

- Kovacevic, Z.; Grgac, S.F.; Bischof, S. Progress in Biodegradable Flame Retardant Nano-Biocomposites. Polymers 2021, 13, 741. [Google Scholar] [CrossRef] [PubMed]

- Zielecka, M.; Rabajczyk, A.; Pastuszka, U.; Jurecki, L. Flame Resistant Silicone-Containing Coating Materials. Coatings 2020, 10, 479. [Google Scholar] [CrossRef]

- Passauer, L. Thermal characterization of ammonium starch phosphate carbamates for potential applications as bio-based flame-retardants. Carbohydr. Polym. 2019, 211, 69–74. [Google Scholar] [CrossRef]

- Chen, S.; Wu, F.Y.; Hu, Y.; Lin, S.C.; Yu, C.C.; Zhu, F.; Wang, X. A fully bio-based intumescent flame retardant for poly(butylene succinate). Mater. Chem. Phys. 2020, 252, 123222. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Ibrahim, M.N.M.; Ahmad, A.; Vijaya Bhaskar Reddy, A. Toxicology and Environmental Application of Carbon Nanocomposite. In Environmental Remediation through Carbon Based Nano Composites; Jawaid, M., Ahmad, A., Ismail, N., Rafatullah, M., Eds.; Springer Nature: Singapore, 2021; pp. 1–18. [Google Scholar]

- Vahabi, H.; Rastin, H.; Movahedifar, E.; Antoun, K.; Brosse, N.; Saeb, M.R. Flame Retardancy of Bio-Based Polyurethanes: Opportunities and Challenges. Polymers 2020, 12, 1234. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.Y.; Hamerton, I. Recent developments in the chemistry of halogen-free flame retardant polymers. Prog. Polym. Sci. 2002, 27, 1661–1712. [Google Scholar] [CrossRef]

- Hobbs, C.E. Recent Advances in Bio-Based Flame Retardant Additives for Synthetic Polymeric Materials. Polymers 2019, 11, 224. [Google Scholar] [CrossRef] [PubMed]

- Carosio, F.; Fontaine, G.; Alongi, J.; Bourbigot, S. Starch-Based Layer by Layer Assembly: Efficient and Sustainable Approach to Cotton Fire Protection. ACS Appl. Mater. Interfaces 2015, 7, 12158–12167. [Google Scholar] [CrossRef] [PubMed]

- Gavgani, J.N.; Adelnia, H.; Sadeghi, G.; Zafari, F. Intumescent Flame Retardant Polyurethane/Starch Composites: Thermal, Mechanical, and Rheological Properties. J. Appl. Polym. Sci. 2015, 131, 41158. [Google Scholar] [CrossRef]

- Laufer, G.; Kirkland, C.; Cain, A.A.; Grunlan, J.C. Clay–Chitosan Nanobrick Walls: Completely Renewable Gas Barrier and Flame-Retardant Nanocoatings. ACS Appl. Mater. Interfaces 2012, 4, 1643–1649. [Google Scholar] [CrossRef] [PubMed]

- Dai, P.; Liang, M.; Ma, X.; Luo, Y.; Luo, Z. Highly Efficient, Environmentally Friendly Lignin-Based Flame Retardant Used in Epoxy Resin. ACS Omega 2020, 5, 32084–32093. [Google Scholar] [CrossRef]

- Dorez, G.; Taguet, A.; Ferry, L.; Lopez-Cuesta, J.M. Thermal and fire behavior of natural fibers/PBS biocomposites. Polym. Degrad. Stab. 2013, 98, 87–95. [Google Scholar] [CrossRef]

- Gellert, R. 9—Natural fibre and fibre composite materials for insulation in buildings. In Materials for Energy Efficiency and Thermal Comfort in Buildings; Hall, M.R., Ed.; Woodhead Publishing: FIW München, Germany, 2010; pp. 229–256. [Google Scholar]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Gebke, S.; Thümmler, K.; Sonnier, R.; Tech, S.; Fischer, S. Flame Retardancy of Wood Fiber Materials Using Phosphorus-Modified Wheat Starch. Molecules 2020, 25, 335. [Google Scholar] [CrossRef]

- Baishya, P.; Maji, T.K. Studies on the physicochemical properties of modified starch-based wood nanocomposites. Starch-Stärke 2016, 68, 249–257. [Google Scholar] [CrossRef]

- Holgate, J.H.; Webb, J. MICROSCOPY | Transmission Electron Microscopy. In Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Caballero, B., Ed.; Academic Press: Oxford, UK, 2003; pp. 3928–3934. [Google Scholar]

- Sekeri, S.H.; Ibrahim, M.N.M.; Umar, K.; Yaqoob, A.A.; Azmi, M.N.; Hussin, M.H.; Othman, M.B.H.; Malik, M.F.I.A. Preparation and characterization of nanosized lignin from oil palm (Elaeis guineensis) biomass as a novel emulsifying agent. Int. J. Biol. Macromol. 2020, 164, 3114–3124. [Google Scholar] [CrossRef] [PubMed]

- Loureno, A.; Pereira, H. Lignin-Trends and Applications; Compositional Variability of Lignin in Biomass; IntechOpen: London, UK, 2018; ISBN 978-953-51-3901-0. [Google Scholar]

- Yaqoob, A.A.; Sekeri, S.H.; Othman, M.B.H.; Ibrahim, M.N.M.; Feizi, Z.H. Thermal degradation and kinetics stability studies of oil palm (Elaeis Guineensis) biomass-derived lignin nanoparticle and its application as an emulsifying agent. Arab. J. Chem. 2021, 14, 103182. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, Y.; Qi, Y.; Wang, H.; Liu, B. Improved Mechanical Properties and Flame Retardancy of Wood/PLA All-Degradable Biocomposites with Novel Lignin-Based Flame Retardant and TGIC. Macromol. Mater. Eng. 2020, 305, 1900840. [Google Scholar] [CrossRef]

- Yan, Y.; Dong, S.; Jiang, H.; Hou, B.; Wang, Z.; Jin, C. Efficient and Durable Flame-Retardant Coatings on Wood Fabricated by Chitosan, Graphene Oxide, and Ammonium Polyphosphate Ternary Complexes via a Layer-by-Layer Self-Assembly Approach. ACS Omega 2022, 7, 29369–29379. [Google Scholar] [CrossRef] [PubMed]

- Uddin, K.M.A.; Ago, M.; Rojas, O.J. Hybrid films of chitosan, cellulose nanofibrils and boric acid: Flame retardancy, optical and thermo-mechanical properties. Carbohydr. Polym. 2017, 177, 13–21. [Google Scholar] [CrossRef]

- Zhou, L.; Fu, Y. Flame-Retardant Wood Composites Based on Immobilizing with Chitosan/Sodium Phytate/Nano-TiO2-ZnO Coatings via Layer-by-Layer Self-Assembly. Coatings 2020, 10, 296. [Google Scholar] [CrossRef]

- Yang, H.T.; Yu, B.; Xu, X.D.; Bourbigot, S.; Wang, H.; Song, P.A. Lignin-derived bio-based flame retardants toward high-performance sustainable polymeric materials. Green Chem. 2020, 22, 2129–2161. [Google Scholar] [CrossRef]

- Brizius, G.L. Phosphonate-Substituted Lignin as a Flame Retardant. U.S. Patent 09410088, 9 August 2016. [Google Scholar]

- Solihat, N.N.; Hidayat, A.F.; Taib, M.; Hussin, M.H.; Lee, S.H.; Abd Ghani, M.A.; Al Edrus, S.S.O.; Vahabi, H.; Fatriasari, W. Recent Developments in Flame-Retardant Lignin-Based Biocomposite: Manufacturing, and characterization. J. Polym. Environ. 2022, 30, 4517–4537. [Google Scholar] [CrossRef]

- Wei, C.; Liu, Y.; Yuan, L.; Qi, W. Preparation of alginate flame retardant containing P and Si and its flame retardancy in epoxy resin. J. Appl. Polym. Sci. 2017, 134, 45552. [Google Scholar] [CrossRef]

- Chen, S.; Lin, S.; Hu, Y.; Ma, M.; Shi, Y.; Liu, J.; Zhu, F.; Wang, X. A lignin-based flame retardant for improving fire behavior and biodegradation performance of polybutylene succinate. Polym. Adv. Technol. 2018, 29, 3142–3150. [Google Scholar] [CrossRef]

- Fox, D.M.; Novy, M.; Brown, K.; Zammarano, M.; Harris, R.H.; Murariu, M.; Mccarthy, E.D.; Seppala, J.E.; Gilman, J.W. Flame retarded poly(lactic acid) using POSS-modified cellulose. 2. Effects of intumescing flame retardant formulations on polymer degradation and composite physical properties. Polym. Degrad. Stab. 2014, 106, 54–62. [Google Scholar] [CrossRef]

- Li, S.; Wang, X.H.; Xu, M.J.; Liu, L.B.; Wang, W.B.; Gao, S.L.; Li, B. Effect of a biomass based waterborne fire retardant coating on the flame retardancy for wood. Polym. Adv. Technol. 2021, 32, 4805–4814. [Google Scholar] [CrossRef]

- Wu, M.T.; Song, W.; Wu, Y.Z.; Qu, W. Preparation and Characterization of the Flame Retardant Decorated Plywood Based on the Intumescent Flame Retardant Adhesive. Materials 2020, 13, 676. [Google Scholar] [CrossRef]

- Jin, X.; Cui, S.; Sun, S.; Gu, X.; Zhang, S. The preparation of a bio-polyelectrolytes based core-shell structure and its application in flame retardant polylactic acid composites. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105485. [Google Scholar] [CrossRef]

- Subasinghe, A.; Bhattacharyya, D. Performance of different intumescent ammonium polyphosphate flame retardants in PP/kenaf fibre composites. Compos. Part A 2014, 65, 91–99. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, X.Y.; Cheng, X.W.; Tang, R.C. Phytic acid as an eco-friendly flame retardant for silk/wool blend: A comparative study with fluorotitanate and fluorozirconate. J. Clean. Prod. 2018, 198, 1044–1052. [Google Scholar] [CrossRef]

- Kundu, C.K.; Wang, X.; Song, L.; Hu, Y. Borate cross-linked layer-by-layer assembly of green polyelectrolytes on polyamide 66 fabrics for flame-retardant treatment. Prog. Org. Coat. 2018, 121, 173–181. [Google Scholar] [CrossRef]

- Sheikh, J.; Bramhecha, I. Multi-functionalization of linen fabric using a combination of chitosan, silver nanoparticles and Tamarindus Indica L. seed coat extract. Cellulose 2019, 26, 8895–8905. [Google Scholar] [CrossRef]

- Lott, J.N.A.; Ockenden, I.; Raboy, V.; Batten, G.D. Phytic acid and phosphorus in crop seeds and fruits: A global estimate. Seed Sci. Res. 2000, 10, 11–33. [Google Scholar] [CrossRef]

- Veum, T.L.; Ledoux, D.R.; Raboy, V.; Ertl, D.S. Low-phytic acid corn improves nutrient utilization for growing pigs. J. Anim. Sci. 2001, 79, 2873. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.Y.; Deng, C.; Du, Y.Y.; Huang, S.C.; Wang, Y.Z. A novel bio-based flame retardant for polypropylene from phytic acid. Polym. Degrad. Stab. 2019, 161, 298–308. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Li, T.; Zhang, S.; Dong, W. A bio-based flame-retardant starch based on phytic acid. ACS Sustain. Chem. Eng. 2020, 8, 10265–10274. [Google Scholar] [CrossRef]

- Guan, J.P.; Yang, X.H.; Tang, R.C.; Fan, Y. A bio-resourced phytic acid/chitosan polyelectrolyte complex for the flame retardant treatment of wool fabric. J. Clean. Prod. 2019, 223, 342–349. [Google Scholar] [CrossRef]

- Li, P.; Wang, B.; Liu, Y.Y.; Xu, Y.J.; Jiang, Z.M.; Dong, C.H.; Zhang, L.; Liu, Y.; Zhu, P. Fully bio-based coating from chitosan and phytate for fire-safety and antibacterial cotton fabrics—ScienceDirect. Carbohydr. Polym. 2020, 237, 116173. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Yang, M.; Huang, H.; Dai, Z.; Cheng, B.; Hao, S. A phytic acid-based chelating coordination embedding structure of phosphorus–boron–nitride synergistic flame retardant to enhance durability and flame retardancy of cotton. Cellulose 2020, 27, 4817–4829. [Google Scholar] [CrossRef]

- Cheng, X.W.; Guan, J.P.; Yang, X.H.; Tang, R.C. Improvement of flame retardancy of silk fabric by bio-based phytic acid, nano-TiO2, and polycarboxylic acid. Prog. Org. Coat. 2017, 112, 18–26. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, C.; Ai, Y.; Tang, L.; Cao, K. Phytate-based transparent and waterproof intumescent flame-retardant coating for protection of wood. Mater. Chem. Phys. 2023, 294, 127000. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, S.; Ding, M.; Wang, M.; Xu, X. Construction of a Phytic Acid–Silica System in Wood for Highly Efficient Flame Retardancy and Smoke Suppression. Materials 2021, 14, 4164. [Google Scholar] [CrossRef]

- Ling, C.; Guo, L.M. A novel, eco-friendly and durable flame-retardant cotton-based hyperbranched polyester derivative. Cellulose 2020, 27, 2357–2368. [Google Scholar] [CrossRef]

- Xz, A.; Zl, A.; Yh, A.; Yu, H.A.; Xz, A.; Shu, X.A.; Sjab, C. Influence of phytic acid on flame retardancy and adhesion performance enhancement of poly (vinyl alcohol) hydrogel coating to wood substrate. Prog. Org. Coat. 2021, 161, 106453. [Google Scholar] [CrossRef]

- Wang, K.; Meng, D.; Wang, S.; Sun, J.; Li, H.; Gu, X.; Zhang, S. Impregnation of phytic acid into the delignified wood to realize excellent flame retardant. Ind. Crops Prod. 2022, 176, 114364. [Google Scholar] [CrossRef]

- Alongi, J.; Carletto, R.A.; Bosco, F.; Carosio, F.; Di Blasio, A.; Cuttica, F.; Antonucci, V.; Giordano, M.; Malucelli, G. Caseins and hydrophobins as novel green flame retardants for cotton fabrics. Polym. Degrad. Stab. 2014, 99, 111–117. [Google Scholar] [CrossRef]

- Wang, C.D.; Wang, J.F. Progress on research of some novel halogen-free flame retardants. Shaanxi Chem. Ind. 2003, 32, 4. [Google Scholar] [CrossRef]

- Weng, I.L.; Lo, O.; Cheng, F.T.; Cheong, W.M.; Seak, L. Using recombinant adhesive proteins as durable and green flame-retardant coatings. Synth. Syst. Biotechnol. 2021, 6, 8. [Google Scholar] [CrossRef]

- Yw, A.; Cong, L.A.; Jl, A.; Cl, A.; Xw, A.; Yc, A.; Lg, A.; Ly, A.; Gz, B.; Gs, A. Soy protein and halloysite nanotubes-assisted preparation of environmentally friendly intumescent flame retardant for poly(butylene succinate)—ScienceDirect. Polym. Test. 2020, 81, 106174. [Google Scholar] [CrossRef]

- Wang, X.J.; Wang, Z.B.; Li, J. Effects of a semi-bio-based triazine derivative on intumescent flame-retardant polypropylene. Polym. Adv. Technol. 2019, 30, 1259–1268. [Google Scholar] [CrossRef]

- Huang, Z.; Ruan, B.; Wu, J.; Ma, N.; Jiang, T.; Tsai, F.C. High-efficiency ammonium polyphosphate intumescent encapsulated polypropylene flame retardant. J. Appl. Polym. Sci. 2021, 138, e50413. [Google Scholar] [CrossRef]

- Li, H.L.; Huo, C.; Miao, P.; Zhang, T.; Wei, H.L. Phenolic Foam Based the Influence of Intumescent Flame Retardancy System Ammonium Polyphosphate/Pentaerythritol/Melamine. In Proceedings of the 2nd International Conference on Manufacturing Engineering and Intelligent Materials (ICMEIM), Hong Kong Informat Sci & Engn Res Ctr, Guangzhou, China, 25–26 February 2017; pp. 655–662. [Google Scholar]

- Yuan, B.H.; Zhao, H.D.; Wang, S.S. Surface modification of ammonium polyphosphate by kaolinite and the study on thermal decomposition behavior and flame-retardant performance. J. Therm. Anal. Calorim. 2022, 147, 7311–7321. [Google Scholar] [CrossRef]

- Wang, T.; Li, L.; Cao, Y.; Wang, Q.; Guo, C. Preparation and flame retardancy of castor oil based UV-cured flame retardant coating containing P/Si/S on wood surface. Ind. Crops Prod. 2019, 130, 562–570. [Google Scholar] [CrossRef]

- Huang, Y.; Ma, T.; Wang, Q.; Guo, C. Synthesis of Biobased Flame-Retardant Carboxylic Acid Curing Agent and Application in Wood Surface Coating. ACS Sustain. Chem. Eng. 2019, 7, 14727–14738. [Google Scholar] [CrossRef]

- Zkan, O.E.; Temiz, A.; Tor, N.; Vurdu, H. Effect of post-heat treatment on fire retardant treated wood properties. Holzforschung 2022, 76, 645–657. [Google Scholar] [CrossRef]

- Chu, F.K.; Qiu, S.L.; Zhou, Y.F.; Zhou, X.; Cai, W.; Zhu, Y.L.; He, L.X.; Song, L.; Hu, W.Z. Novel glycerol-based polymerized flame retardants with combined phosphorus structures for preparation of high performance unsaturated polyester resin composites. Compos. Part B-Eng. 2022, 233, 109647. [Google Scholar] [CrossRef]

- Li, L.M.; Chen, Z.; Lu, J.; Wei, M.; Jiang, P. Combustion Behavior and Thermal Degradation Properties of Wood Impregnated with Intumescent Biomass Flame Retardants: Phytic Acid, Hydrolyzed Collagen, and Glycerol. ACS Omega 2021, 6, 3921–3930. [Google Scholar] [CrossRef] [PubMed]

- Leng, Y.-M.; Zhao, X.; Fu, T.; Wang, X.-L.; Wang, Y.-Z. Bio-Based Flame-Retardant and Smoke-Suppressing Wood Plastic Composites Enabled by Phytic Acid Tyramine Salt. ACS Sustain. Chem. Eng. 2022, 10, 5055–5066. [Google Scholar] [CrossRef]

| Category | Halogen | Non-Halogen | ||

|---|---|---|---|---|

| Type | Brominated Chlorinated | Phosphorus-based | Nitrogen-based | Metallic hydroxide |

| Reaction mechanism | Releases gaseous hydrogen halide into the air, isolating oxygen and interacting with active free radicals OH• and H• | Active phosphorus-containing radicals such as PO• and PO2• act in the gaseous phase, reacting with free-radical OH• | Mostly melamine based. Condensed-phase melamine transforms into cross-linked structures, producing solid-phase char layers | Acts as a catalyst to produce carbonized residues during combustion |

| Advantages | Low-cost, high flame-retardant efficiency and wide applicability | High efficiency, less influence on light stability, and hinder reignition | Low volatility, halogen-free, low toxicity, no corrosive gas | Non-toxic, good stability, no toxic gas produced at high temperature, low price, a wide range of sources |

| Disadvantages | Produces large quantities of smoke and toxic, corrosive gases when burned | High volatility, poor heat resistance, and unsatisfactory compatibility | Poor compatibility, easy-to-absorb moisture, and affects the physical performance of the substrate | Poor acid resistance and susceptibility to acid |

| Advantages of Bio- FRs | Advantages of Conventional FR |

|---|---|

| No toxic gases were released during the combustion | Long usage period |

| Self-degradable | Non-biodegradable |

| Similar to traditional flame retardants | Excellent mechanical and flame-retardant properties |

| Low cost of production | Cost-effective and convenient preparation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Jian, H.; Deng, C.; Xu, J.; Liu, Y.; Park, H.; Wen, M.; Sun, Y. Research and Application of Biomass-Based Wood Flame Retardants: A Review. Polymers 2023, 15, 950. https://doi.org/10.3390/polym15040950

Liang Y, Jian H, Deng C, Xu J, Liu Y, Park H, Wen M, Sun Y. Research and Application of Biomass-Based Wood Flame Retardants: A Review. Polymers. 2023; 15(4):950. https://doi.org/10.3390/polym15040950

Chicago/Turabian StyleLiang, Yuqing, Hao Jian, Chao Deng, Junxian Xu, Yang Liu, Heejun Park, Mingyu Wen, and Yaoxing Sun. 2023. "Research and Application of Biomass-Based Wood Flame Retardants: A Review" Polymers 15, no. 4: 950. https://doi.org/10.3390/polym15040950

APA StyleLiang, Y., Jian, H., Deng, C., Xu, J., Liu, Y., Park, H., Wen, M., & Sun, Y. (2023). Research and Application of Biomass-Based Wood Flame Retardants: A Review. Polymers, 15(4), 950. https://doi.org/10.3390/polym15040950