Multi-Stage Thermal Modelling of Extrusion-Based Polymer Additive Manufacturing

Abstract

:1. Introduction

2. Model Development

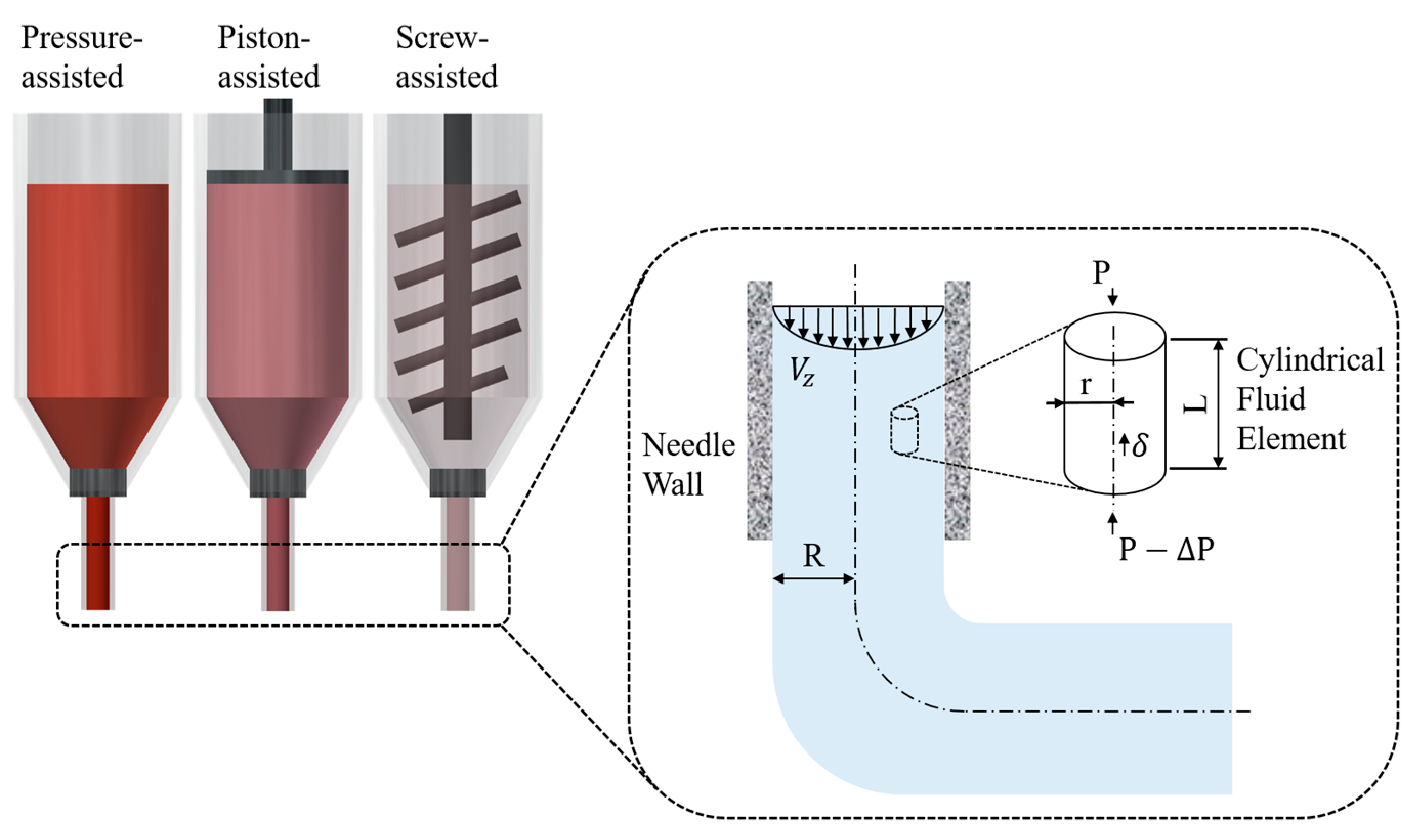

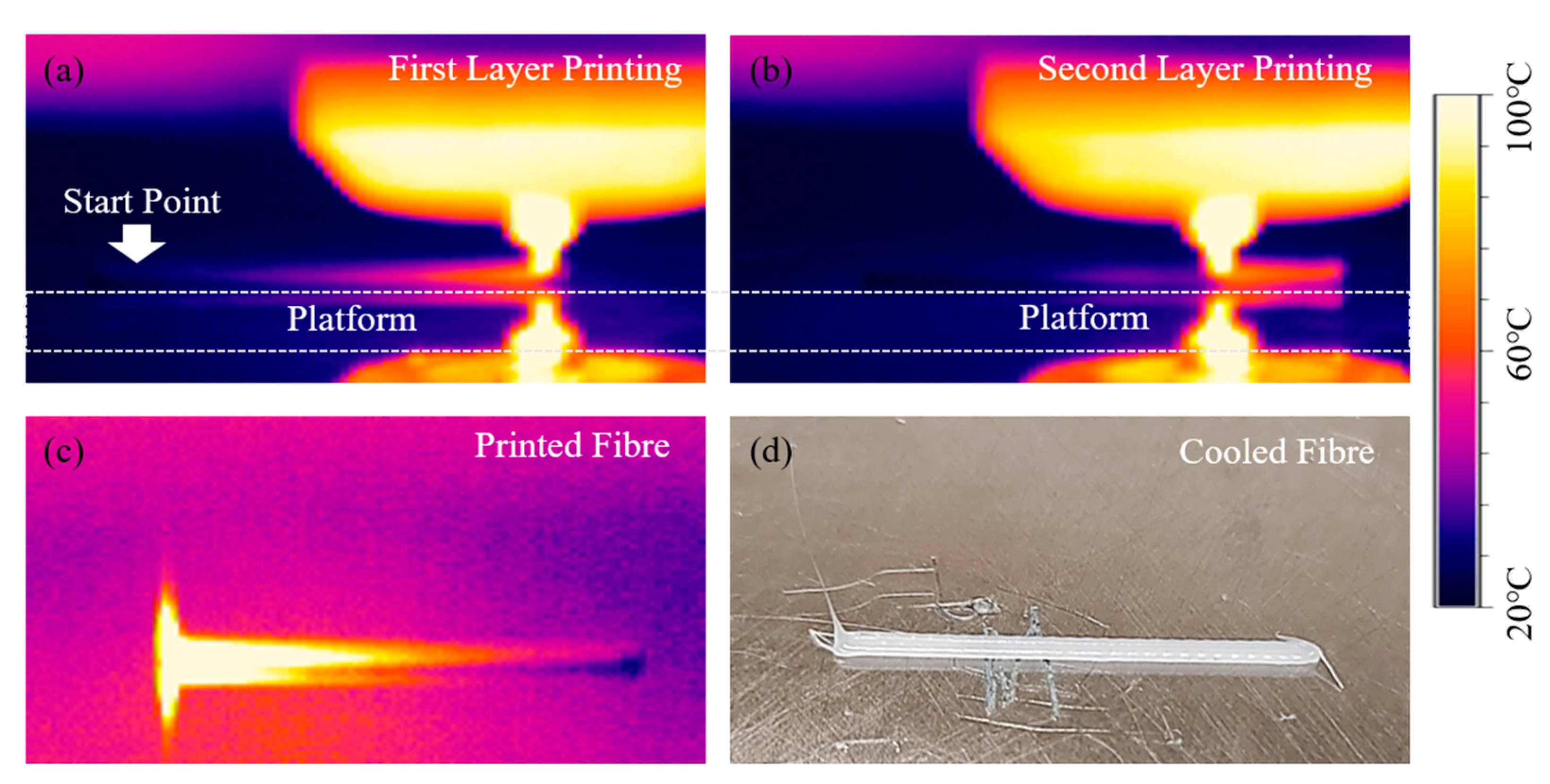

2.1. Numerical Model

- The air compressibility can be ignored;

- The fluid flow is incompressible and time-independent;

- The material inside the needle exhibits a laminar flow and there is no slip between the material and needle wall;

- The fluid exhibits a non-Newtonian flow behaviour and ideal thermal conditions.

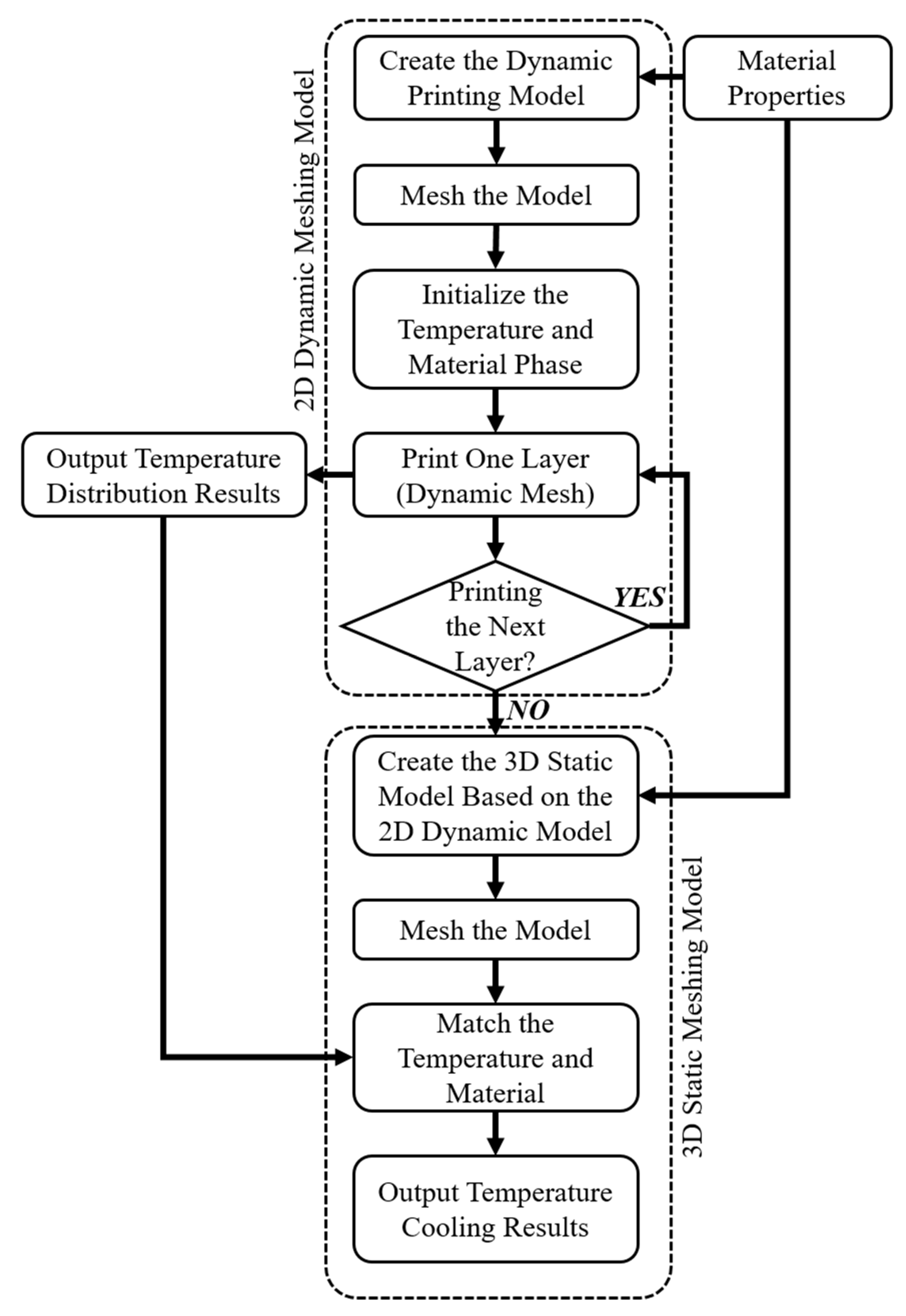

2.2. Multi-Stage Approach

2.3. 2D Dynamic Meshing Model

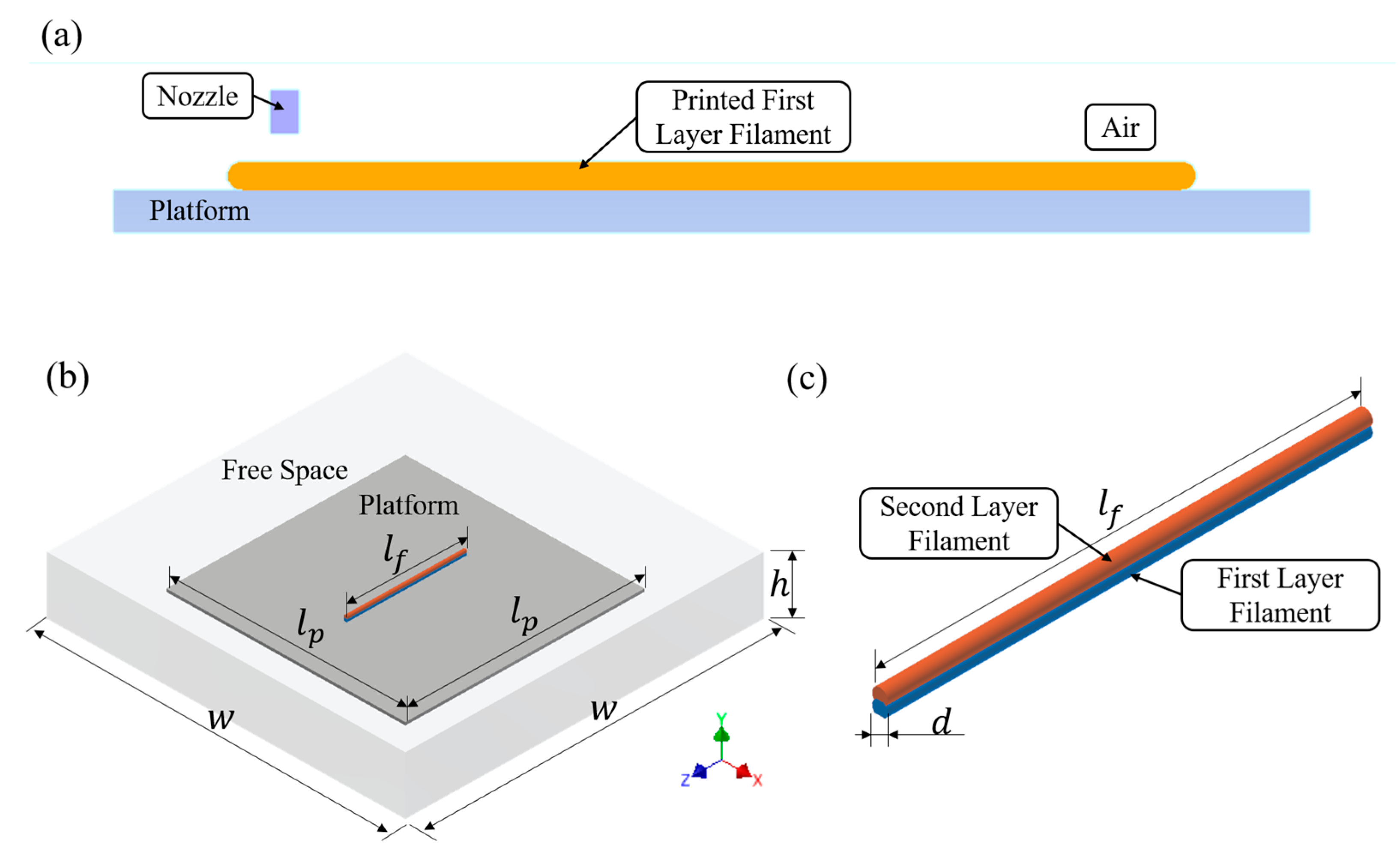

2.4. 3D Static Meshing Model

3. Materials and Implementation

4. Experimental Work for Numerical Validation

5. Results and Discussion

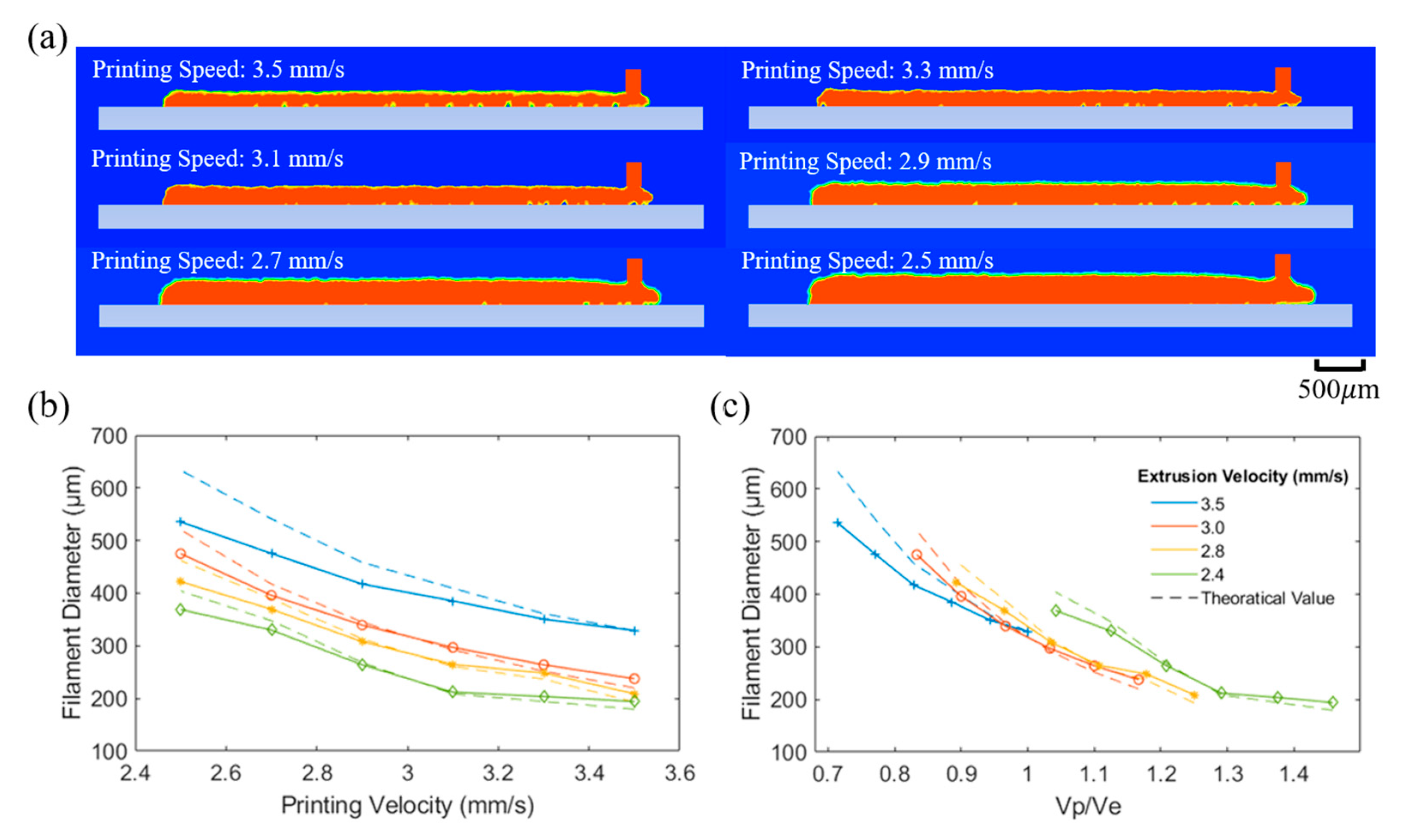

5.1. Filament Morphology

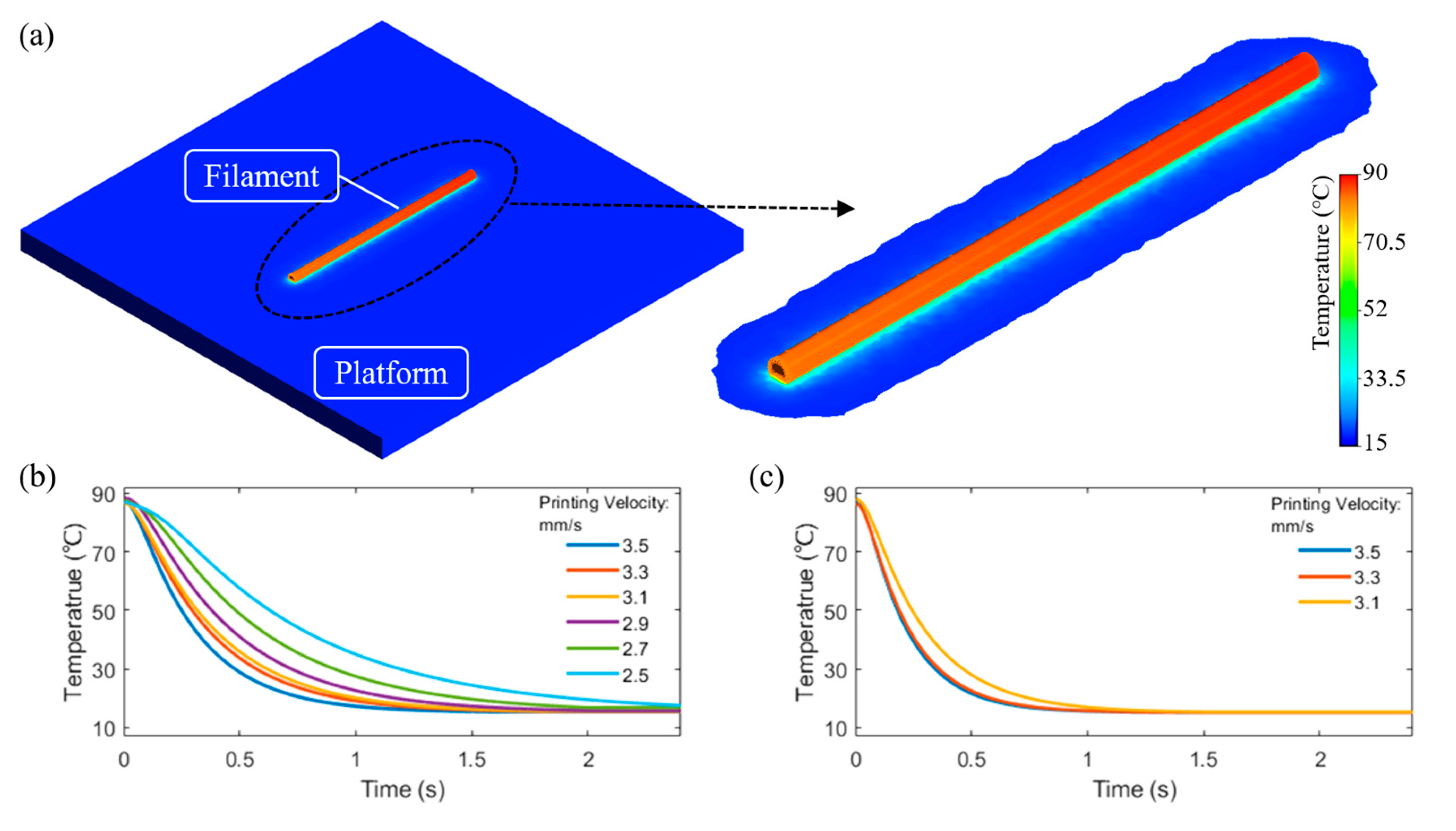

5.2. First Layer Temperature Evolution

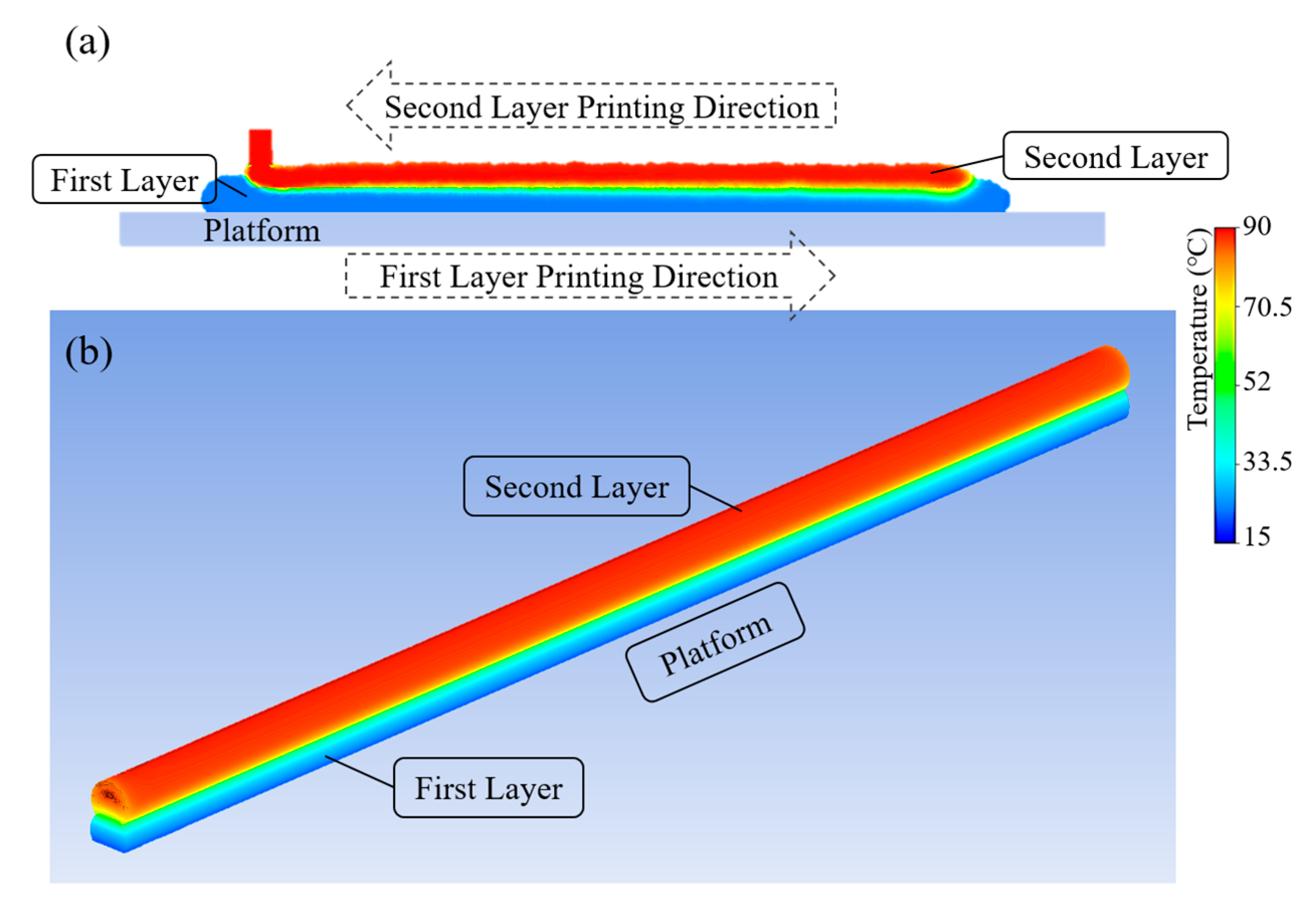

5.3. Temperature Evolution on the Two-Filament Model

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Prajapati, H.; Salvi, S.S.; Ravoori, D.; Jain, A. Measurement of the in-plane temperature field on the build plate during polymer extrusion additive manufacturing using infrared thermometry. Polym. Test. 2020, 92, 106866. [Google Scholar] [CrossRef]

- Hutmacher, D.W. Scaffolds in tissue engineering bone and cartilage. Biomaterials 2000, 21, 2529–2543. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Vyas, C.; Yang, J.; Ates, G.; Bártolo, P.J. A Review of Hybrid Biomanufacturing Systems Applied in Tissue Regeneration. In Virtual Prototyping & Bio Manufacturing in Medical Applications, 2nd ed.; Bidanda, B., Bartolo, P.J., Eds.; Springer Nature: Cham, Switzerland, 2021; pp. 187–213. [Google Scholar] [CrossRef]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2013, 16, 496–504. [Google Scholar] [CrossRef]

- Puppi, D.; Mota, C.; Gazzarri, M.; Dinucci, D.; Gloria, A.; Myrzabekova, M.; Ambrosio, L.; Chiellini, F. Additive manufacturing of wet-spun polymeric scaffolds for bone tissue engineering. Biomed. Microdevices 2012, 14, 1115–1127. [Google Scholar] [CrossRef]

- Mota, C.; Puppi, D.; Chiellini, F.; Chiellini, E. Additive manufacturing techniques for the production of tissue engineering constructs. J. Tissue Eng. Regen. Med. 2015, 9, 174–190. [Google Scholar] [CrossRef] [PubMed]

- Weiß, T.; Hildebrand, G.; Schade, R.; Liefeith, K. Two-photon polymerization for microfabrication of three-dimensional scaffolds for tissue engineering application. Eng. Life Sci. 2009, 9, 384–390. [Google Scholar] [CrossRef]

- Yang, J.; Bartolo, P. Novel Co-axial Extrusion Printing Head for Tissue Engineering. In Proceedings of the Transactions on Additive Manufacturing Meets Medicine, Online, 9–11 September 2020. [Google Scholar] [CrossRef]

- Shapira, A.; Noor, N.; Asulin, M.; Dvir, T. Stabilization strategies in extrusion-based 3D bioprinting for tissue engineering. Appl. Phys. Rev. 2018, 5, 041112. [Google Scholar] [CrossRef]

- Geng, Y.; He, H.; Jia, Y.; Peng, X.; Li, Y. Enhanced through-plane thermal conductivity of polyamide 6 composites with vertical alignment of boron nitride achieved by fused deposition modeling. Polym. Compos. 2019, 40, 3375–3382. [Google Scholar] [CrossRef]

- Lindenberg, C.; Krättli, M.; Cornel, J.; Mazzotti, M.; Brozio, J.r. Design and optimization of a combined cooling/antisolvent crystallization process. Cryst. Growth Des. 2009, 9, 1124–1136. [Google Scholar] [CrossRef]

- Kundakcioglu, E.; Lazoglu, I.; Rawal, S. Transient thermal modeling of laser-based additive manufacturing for 3D freeform structures. Int. J. Adv. Manuf. Technol. 2016, 85, 493–501. [Google Scholar] [CrossRef]

- Jonaet, A.M.; Park, H.S.; Myung, L.C. Prediction of residual stress and deformation based on the temperature distribution in 3D-printed parts. Int. J. Adv. Manuf. Technol. 2021, 113, 2227–2242. [Google Scholar] [CrossRef]

- Percoco, G.; Arleo, L.; Stano, G.; Bottiglione, F. Analytical model to predict the extrusion force as a function of the layer height, in extrusion based 3D printing. Addit. Manuf. 2021, 38, 101791. [Google Scholar] [CrossRef]

- Compton, B.G.; Post, B.K.; Duty, C.E.; Love, L.; Kunc, V. Thermal analysis of additive manufacturing of large-scale thermoplastic polymer composites. Addit. Manuf. 2017, 17, 77–86. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.Z.; Yu, W.W.; Deng, Y.H. Numerical investigation of the influence of process conditions on the temperature variation in fused deposition modeling. Mater. Des. 2017, 130, 59–68. [Google Scholar] [CrossRef]

- El Moumen, A.; Tarfaoui, M.; Lafdi, K. Modelling of the temperature and residual stress fields during 3D printing of polymer composites. Int. J. Adv. Manuf. Technol. 2019, 104, 1661–1676. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Development and validation of extrusion deposition additive manufacturing process simulations. Addit. Manuf. 2019, 25, 218–226. [Google Scholar] [CrossRef]

- Issa, R.I. Solution of the implicitly discretised fluid flow equations by operator-splitting. J. Comput. Phys. 1986, 62, 40–65. [Google Scholar] [CrossRef]

- Azoff, E.M. Generalized energy-momentum conservation equations in the relaxation time approximation. Solid-State Electron. 1987, 30, 913–917. [Google Scholar] [CrossRef]

- Yang, H.; Gou, S.; Zhou, Y.; Zhou, L.; Tang, L.; Liu, L.; Fang, S. Thermalesponsive behaviours of novel polyoxyethlene-functionalized acrylamide copolymers: Water solubility, rheological properties and surface activity. J. Mol. Liq. 2020, 319, 11437. [Google Scholar] [CrossRef]

- Barnes, H.A.; Hutton, J.F.; Walters, K. An Introduction to Rheology; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Wibowo, A.; Vyas, C.; Cooper, G.; Qulub, F.; Suratman, R.; Mahyuddin, A.I.; Dirgantara, T.; Bartolo, P. 3D printing of polycaprolactone–polyaniline electroactive scaffolds for bone tissue engineering. Materials 2020, 13, 512. [Google Scholar] [CrossRef]

- Liu, F.; Vyas, C.; Poologasundarampillai, G.; Pape, I.; Hinduja, S.; Mirihanage, W.; Bartolo, P. Structural evolution of PCL during melt extrusion 3D printing. Macromol. Mater. Eng. 2018, 303, 1700494. [Google Scholar] [CrossRef]

- Noroozi, N.; Schafer, L.L.; Hatzikiriakos, S.G. Thermorheological properties of poly (ε-caprolactone)/polylactide blends. Polym. Eng. Sci. 2012, 52, 2348–2359. [Google Scholar] [CrossRef]

- Zhang, B.; Chung, S.H.; Barker, S.; Craig, D.; Narayan, R.J.; Huang, J. Direct ink writing of polycaprolactone/polyethylene oxide based 3D constructs. Prog. Nat. Sci. Mater. Int. 2021, 31, 180–191. [Google Scholar] [CrossRef]

- AZO Materials. Aluminium: Specifications, Properties, Classifications and Classes. Available online: https://www.azom.com/article.aspx?ArticleID=2863 (accessed on 3 March 2022).

- The Eingineering ToolBox. Air-Thermalphysical Properties. Available online: https://www.engineeringtoolbox.com/air-properties-d_156.html (accessed on 3 March 2022).

- ThermalIMAGER TIM. Available online: https://www.micro-epsilon.co.uk/download/products/cat--thermoIMAGER-TIM--en.pdf (accessed on 28 December 2022).

- Gosset, A.; Barreiro-Villaverde, D.; Becerra Permuy, J.C.; Lema, M.; Ares-Pernas, A.; Abad López, M.J. Experimental and numerical investigation of the extrusion and deposition process of a poly(lactic Acid) strand with fused deposition modelling. Polymers 2020, 12, 2885. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Yue, H.; Mirihanage, W.; Bartolo, P. Multi-Stage Thermal Modelling of Extrusion-Based Polymer Additive Manufacturing. Polymers 2023, 15, 838. https://doi.org/10.3390/polym15040838

Yang J, Yue H, Mirihanage W, Bartolo P. Multi-Stage Thermal Modelling of Extrusion-Based Polymer Additive Manufacturing. Polymers. 2023; 15(4):838. https://doi.org/10.3390/polym15040838

Chicago/Turabian StyleYang, Jiong, Hexin Yue, Wajira Mirihanage, and Paulo Bartolo. 2023. "Multi-Stage Thermal Modelling of Extrusion-Based Polymer Additive Manufacturing" Polymers 15, no. 4: 838. https://doi.org/10.3390/polym15040838

APA StyleYang, J., Yue, H., Mirihanage, W., & Bartolo, P. (2023). Multi-Stage Thermal Modelling of Extrusion-Based Polymer Additive Manufacturing. Polymers, 15(4), 838. https://doi.org/10.3390/polym15040838