Determining the Long-Term Skid Resistance of Steel Slag Asphalt Mixture Based on the Mineral Composition of Aggregates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimens Preparation

2.2.1. PSV Specimens

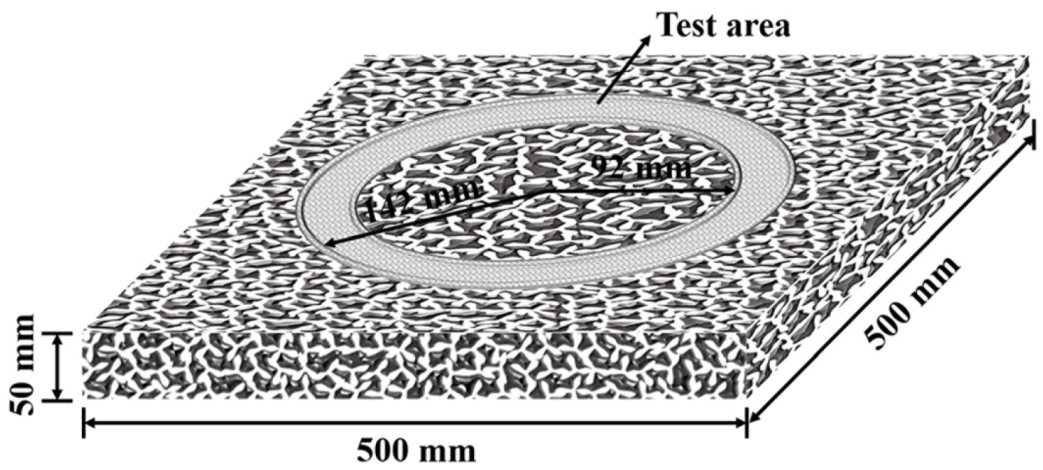

2.2.2. SSAM specimens

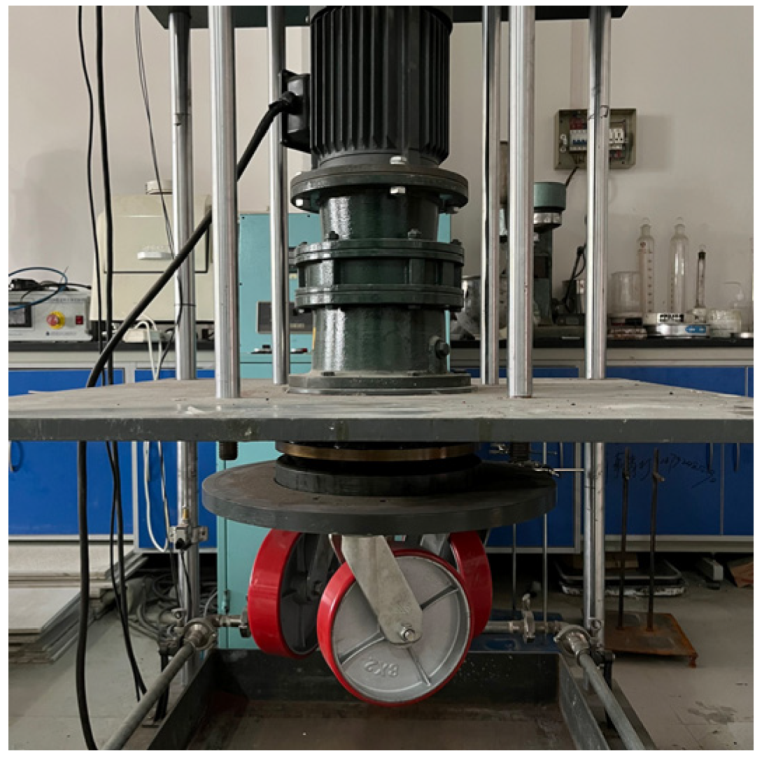

2.3. Methods

3. Results and Discussion

3.1. Long-Term Polishing Resistance of Aggregate

3.1.1. The Attenuation Law of PSV

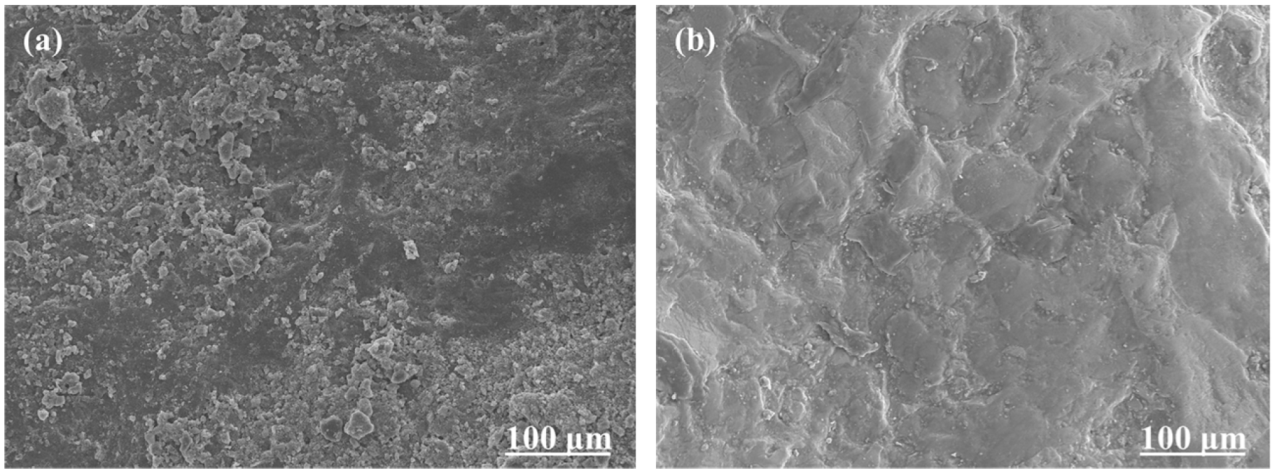

3.1.2. Changes in Micromorphology of Aggregate Surface

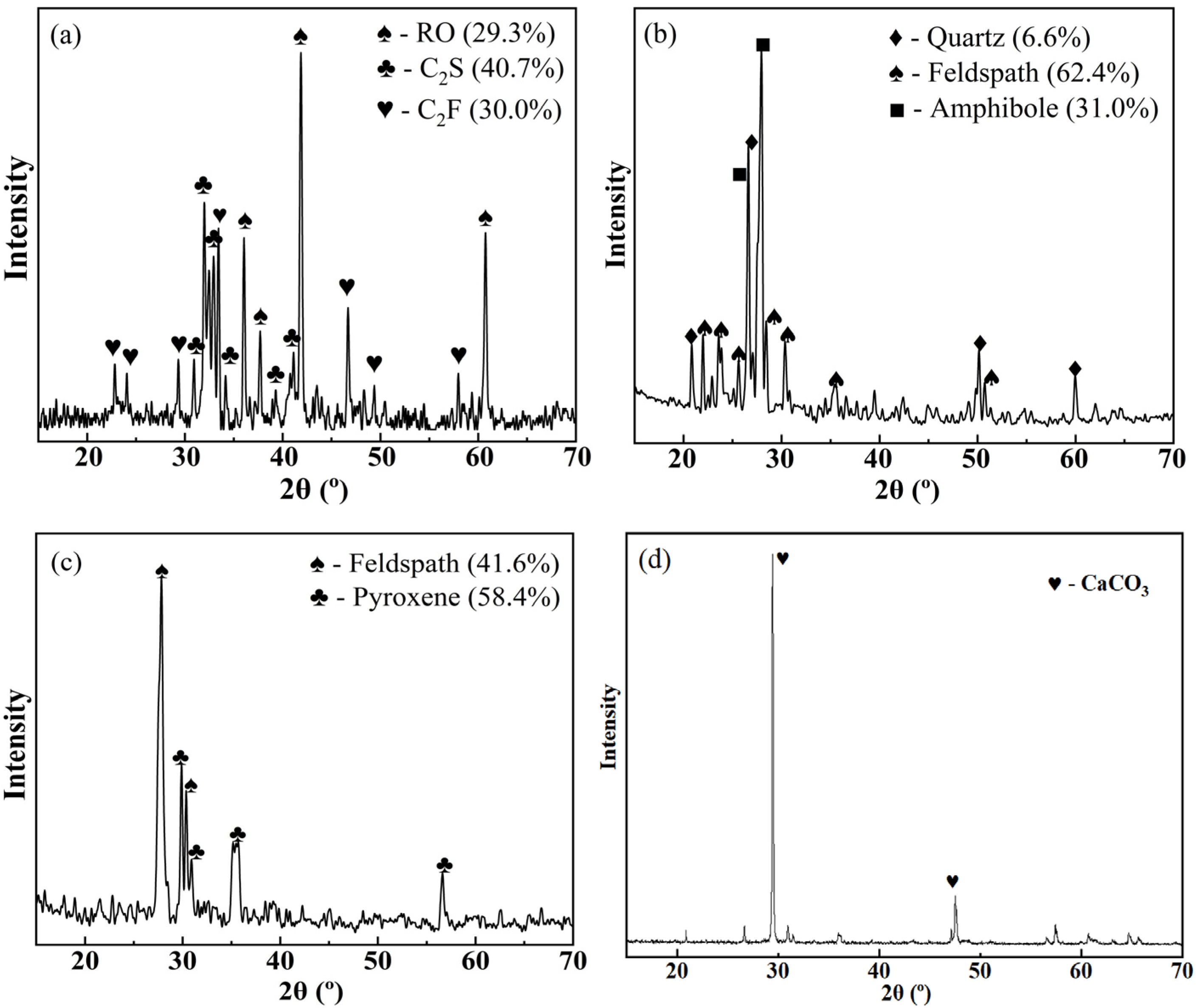

3.2. Mineral Composition of Aggregates

3.3. Prediction Model of Polishing Resistance of Aggregate

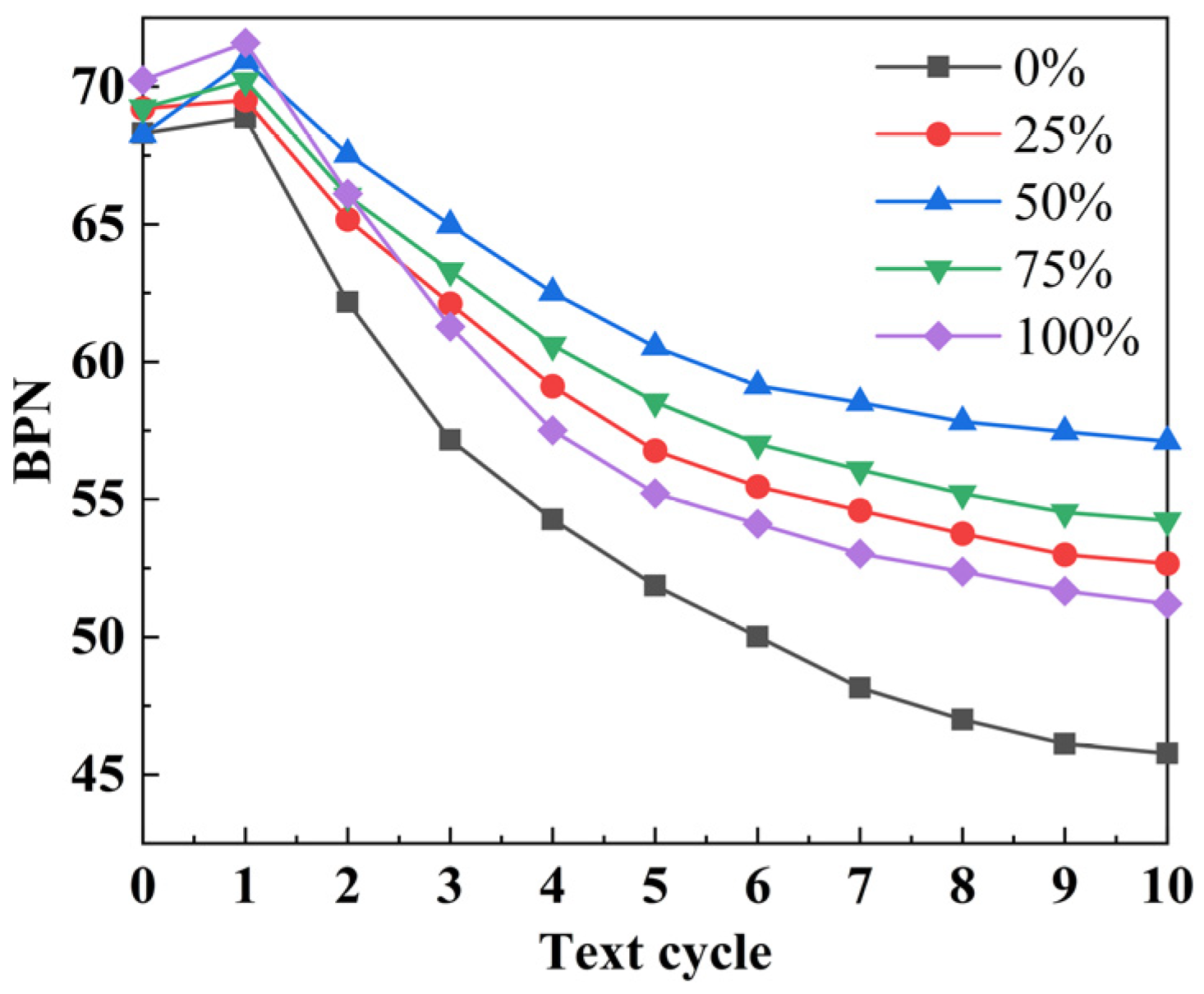

3.4. Long-Term Skid Resistance of SSAM

3.4.1. Attenuation Law of BPN

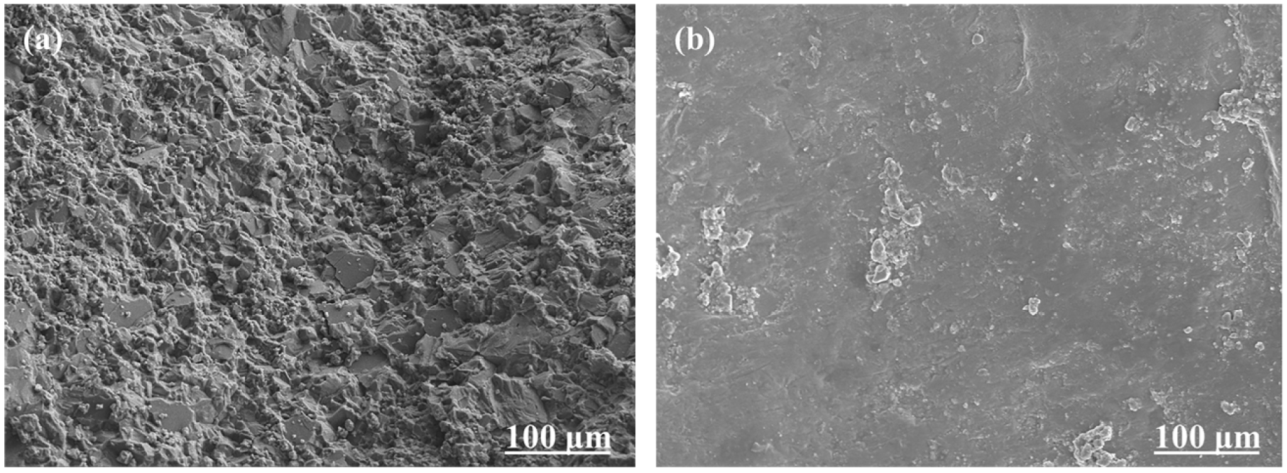

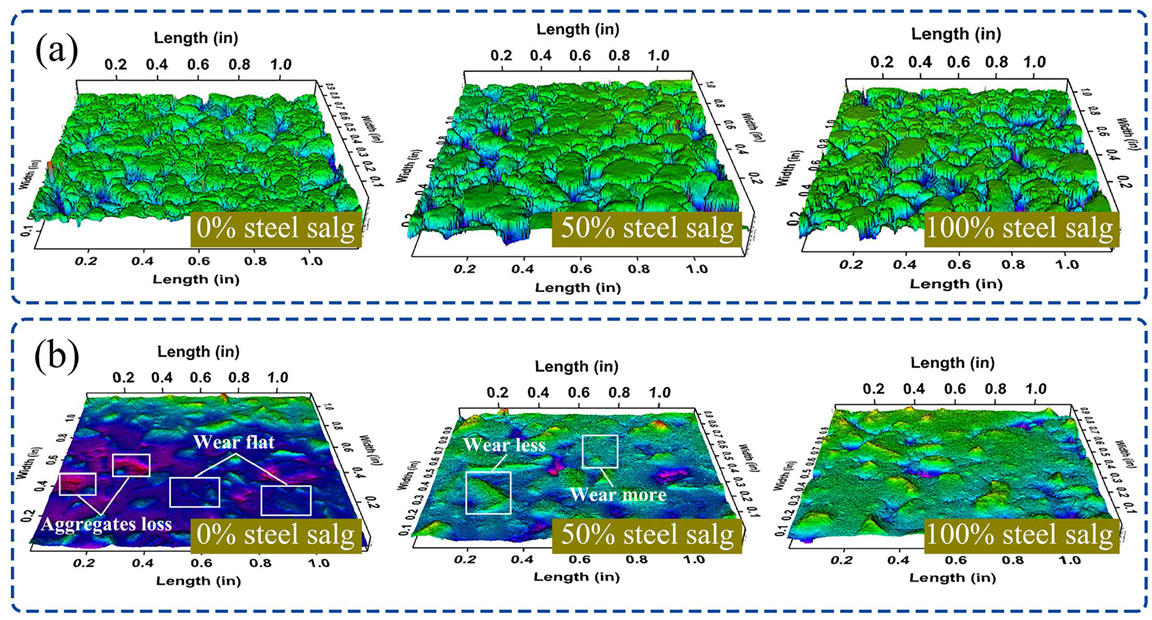

3.4.2. Surface Texture Changes of SSAM

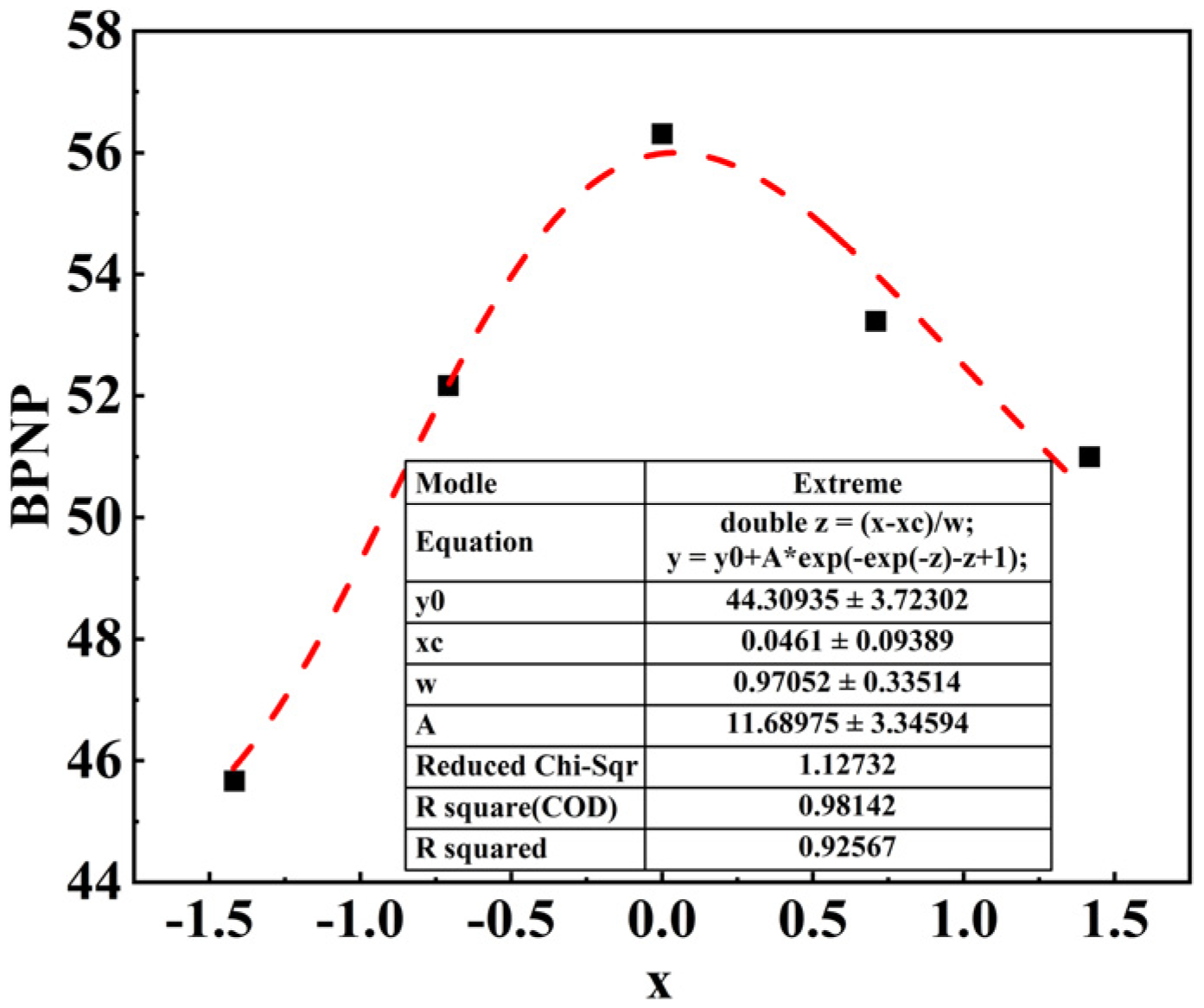

3.5. Long-Term Skid Resistance Prediction Model of SSAM

4. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- China Association of Metalscrap Utilization. Promote Comprehensive Utilization of Steel Slag Resources, Turn Solid Waste into Resources, and Promote Green Development. 2022. Available online: http://www.camu.org.cn/feigangxiehui/article_detail.html?id=34165&code=101002&type=0 (accessed on 31 December 2022).

- Yu, D.M.; Xiong, R.; Li, S.; Cong, P.L.; Shah, A.; Jiang, Y. Laboratory evaluation of critical properties and attributes of calcined bauxite and steel slag aggregates for pavement friction Surfacing. J. Mater. Civ. Eng. 2019, 31, 04019155. [Google Scholar] [CrossRef]

- Crisman, B.; Ossich, G.; Bevilacqua, P.; Roberti, R. Degradation prediction model for friction of road pavements with natural aggregates and steel slags. Appl. Sci. 2020, 10, 32. [Google Scholar] [CrossRef]

- Amelian, S.; Manian, M.; Abtahi, S.M.; Goli, A. Moisture sensitivity and mechanical performance assessment of warm mix asphalt containing by-product steel slag. J. Clean. Prod. 2018, 176, 329–337. [Google Scholar] [CrossRef]

- Liu, J.Z.; Yu, B.; Hong, Q.Z. Molecular dynamics simulation of distribution and adhesion of asphalt components on steel slag. Constr. Build. Mater. 2020, 255, 119332. [Google Scholar] [CrossRef]

- Moura, B.L.R.; Teixeira, J.E.S.L.; Simão, R.A.; Khedmati, M.; Kim, Y.; Pires, P.J.M. Adhesion between steel slag aggregates and bituminous binder based on surface characteristics and mixture moisture resistance. Constr. Build. Mater. 2020, 264, 120685. [Google Scholar] [CrossRef]

- Delgado, B.G.; Fonseca, A.V.; Fortunato, E.; Paixão, A.; Alves, R. Geomechanical assessment of an inert steel slag aggregate as an alternative ballast material for heavy haul rail tracks. Constr. Build. Mater. 2021, 279, 122438. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.; Aragón, Á.; Fuente-Alonso, J.; Ortega-López, V. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Logeshwari, J.; Sivapullaiah, P.V. Physical, chemical, morphological and strength characteristics of steel slags in view of its potential application in geotechnical engineering. Mater. Today Proc. 2021, 45, 6282–6286. [Google Scholar] [CrossRef]

- Yildirim, I.Z.; Prezzi, M. Steel slag: Chemistry, mineralogy and morphology. Geotech. Spec. Publ. 2015, 256, 2816–2825. [Google Scholar]

- Paixão, A.; Fortunato, E. Abrasion evolution of steel furnace slag aggregate for railway ballast: 3D morphology analysis of scanned particles by close-range photogrammetry. Constr. Build. Mater. 2021, 267, 121225. [Google Scholar] [CrossRef]

- Bessa, I.; Branco, V.C.; Soares, J.B. Evaluation of polishing and degradation resistance of natural aggregates and steel slag using the aggregate image measurement system. Road Mater. Pavement Des. 2014, 15, 385–405. [Google Scholar] [CrossRef]

- Ergin, B.; Gökalp, i.; Uz, V.E. Effect of aggregate microtexture losses on skid resistance: Laboratory-based assessment on chip seals. J. Mater. Civ. Eng. 2020, 32, 4020040. [Google Scholar]

- Liapis, I.; Likoydis, S. Use of electric arc furnace slag in thin skid-resistant surfacing. Proc. Soc. Behav. Sci. 2012, 48, 907–918. [Google Scholar] [CrossRef]

- Kowalski, K.; Mcdaniel, R.S.; Olek, J. Development of a laboratory procedure to evaluate the influence of aggregate type and mixture proportions on the frictional characteristics of flexible pavements. Conf. Ser. Asph. Paving Technol. 2008, 77, 35–69. [Google Scholar]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M. Evaluation of rutting potential and skid resistance of hot mix asphalt incorporating electric arc furnace steel slag and copper mine tailing. Indian J. Eng. Mater. 2015, 22, 550–558. [Google Scholar]

- Chen, J.S.; Wei, S.H. Engineering properties and performance of asphalt mixtures incorporating steel slag. Constr. Build. Mater. 2016, 128, 148–153. [Google Scholar] [CrossRef]

- Liu, C.; Wang, T.G. Effect of fine aggregate angularity on skid-resistance of asphalt pavement using accelerated pavement testing. Constr. Build. Mater. 2018, 168, 41–46. [Google Scholar]

- Skaf, M.; Pasquini, E.; Revilla-Cuesta, V.V.; Ortega-López, V. Performance and durability of porous asphalt mixtures manufactured exclusively with electric steel slags. Materials 2019, 12, 3306. [Google Scholar] [CrossRef]

- Pathak, S.; Choudhary, R.; Kumar, A.; Shukla, S.K. Evaluation of benefits of open-graded friction courses with basic oxygen furnace steel-slag aggregates for hilly and high-Rainfall regions in India. J. Mater. Civ. Eng. 2020, 32, 04020356. [Google Scholar] [CrossRef]

- Uz, V.E.; Gokalp, I. The effect of aggregate type, size and polishing levels to skid resistance of chip seals. Mater. Struct. 2017, 50, 126.1–126.14. [Google Scholar] [CrossRef]

- Cui, P.D.; Wu, S.P.; Xiao, Y.; Yang, C.; Wang, F. Enhancement mechanism of skid resistance in preventive maintenance of asphalt pavement by steel slag based on micro-surfacing. Constr. Build. Mater. 2020, 239, 117870. [Google Scholar] [CrossRef]

- Keymanesh, M.R.; Ziari, H.; Zalnezhad, H.; Zalnezhad, M. Mix design and performance evaluation of microsurfacing containing Electric Arc Furnace (EAF) steel slag filler. Constr. Build. Mater. 2021, 269, 121336. [Google Scholar] [CrossRef]

- Zalnezhad, M.; Hesami, E. Effect of steel slag aggregate and bitumen emulsion types on the performance of microsurfacing mixture. J. Traffic Transp. Eng. 2020, 7, 215–226. [Google Scholar] [CrossRef]

- Yildirim, I.Z.; Prezzi, M. Experimental evaluation of EAF ladle steel slag as a geo-fill material: Mineralogical, physical & mechanical properties. Constr. Build. Mater. 2017, 154, 23–33. [Google Scholar]

- Wu, S.P.; Xue, Y.J.; Ye, Q.S.; Chen, Y.C. Utilization of steel slag as aggregates for Stone Mastic Asphalt (SMA) mixtures. Build. Sci. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Ferreira, V.J.; Vilaplana, A.S.; García-Armingol, T.; Usón, A.A.; Lausín-González, C.; López-Sabirón, A.M.; Ferreira, G. Evaluation of the steel slag incorporation as coarse aggregate for road construction: Technical requirements and environmental impact assessment. J. Clean. Prod. 2016, 130, 175–186. [Google Scholar] [CrossRef]

- Kane, M.; Artamendi, I.; Scarpas, T. Long-term skid resistance of asphalt surfacings: Correlation between Wehner-Schulze friction values and the mineralogical composition of the aggregates. Wear 2013, 303, 235–243. [Google Scholar] [CrossRef]

- Wang, X. Study on Composition Structure and Dissolution Performance of RO Phase from Steel Slag. Master’s Thesis, Beijing University of Technology, Beijing, China, 2017. [Google Scholar]

- Kane, M.; Edmondson, V. Long-term skid resistance of asphalt surfacing and aggregates’ mineralogical composition: Generalisation to pavements made of different aggregate types. Wear 2020, 454–455, 203339. [Google Scholar] [CrossRef]

- Pomoni, M.; Plati, C.; Kane, M.; Loizos, A. Polishing behaviour of asphalt surface course containing recycled materials. Int. J. Transp. Sci. Technol. 2022, 11, 711–725. [Google Scholar] [CrossRef]

| Aggregate Type | Apparent Density (g/cm3) | Surface Dry Density (g/cm3) | Gross Volume Relative Density (g/cm3) | Water Absorption (%) | Crush Value (%) | Los Angeles Wear Value (%) |

|---|---|---|---|---|---|---|

| Steel slag | 3.657 | 3.450 | 3.372 | 2.32 | 11.21 | 12.34 |

| Limestone | 2.717 | 2.686 | 2.667 | 0.69 | 16.67 | 18.11 |

| Granite | 3.035 | 2.952 | 2.885 | 0.79 | 10.87 | 11.95 |

| Basalt | 2.826 | 2.782 | 2.743 | 0.51 | 12.76 | 14.53 |

| Aggregate Type | Mineral Type | Mineral Composition (%) | Mineral Hardness (d) (1–10) | Average Hardness (H) | Surface Texture Richness (STR) |

|---|---|---|---|---|---|

| Steel slag | RO | 29.3 | 7.1 | 6.2 | 2.621 |

| data | 40.7 | 5.4 | |||

| C2S | 30.0 | 6.5 | |||

| Granite | C2F | 6.6 | 7.0 | 6.1 | 0.319 |

| Quartz | 62.4 | 6.0 | |||

| Feldspath | 31.0 | 6.0 | |||

| Basalt | Amphibole | 41.6 | 6.0 | 5.7 | 0.356 |

| Feldspath | 58.4 | 5.5 | |||

| Limestone | Pyroxene | 100 | 3.0 | 3.0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, K.; Shi, C.; Jiang, J.; Tian, Y.; Zhou, X.; Xiong, R. Determining the Long-Term Skid Resistance of Steel Slag Asphalt Mixture Based on the Mineral Composition of Aggregates. Polymers 2023, 15, 807. https://doi.org/10.3390/polym15040807

Ji K, Shi C, Jiang J, Tian Y, Zhou X, Xiong R. Determining the Long-Term Skid Resistance of Steel Slag Asphalt Mixture Based on the Mineral Composition of Aggregates. Polymers. 2023; 15(4):807. https://doi.org/10.3390/polym15040807

Chicago/Turabian StyleJi, Kuo, Changchun Shi, Jing Jiang, Yaogang Tian, Xiaowei Zhou, and Rui Xiong. 2023. "Determining the Long-Term Skid Resistance of Steel Slag Asphalt Mixture Based on the Mineral Composition of Aggregates" Polymers 15, no. 4: 807. https://doi.org/10.3390/polym15040807

APA StyleJi, K., Shi, C., Jiang, J., Tian, Y., Zhou, X., & Xiong, R. (2023). Determining the Long-Term Skid Resistance of Steel Slag Asphalt Mixture Based on the Mineral Composition of Aggregates. Polymers, 15(4), 807. https://doi.org/10.3390/polym15040807