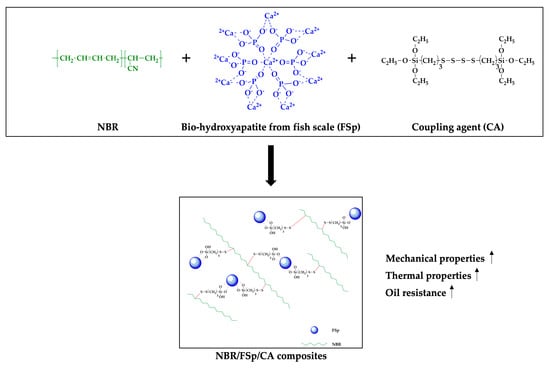

Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Fish Scale Particles (FSp) from Fresh Fish Scales

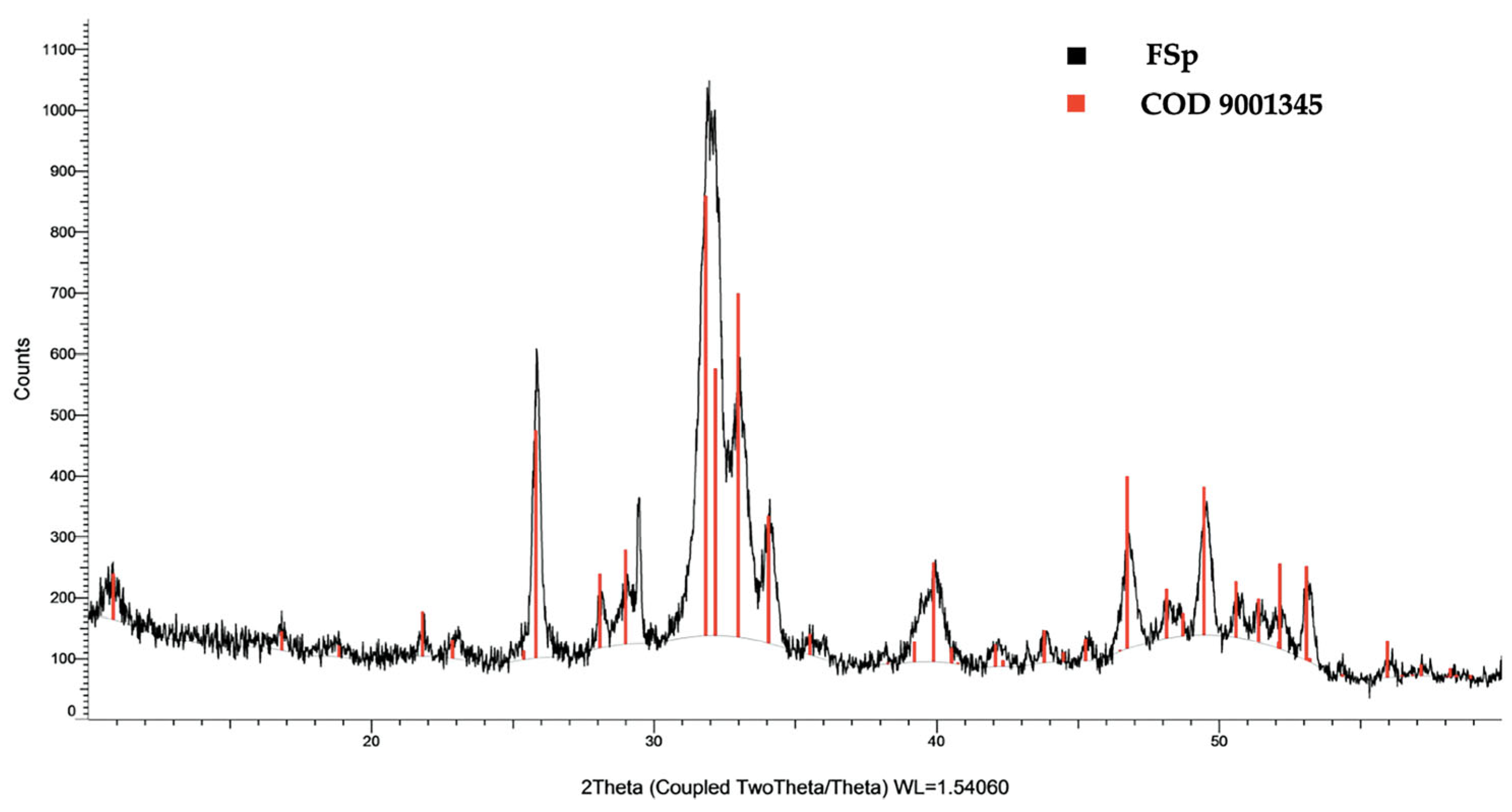

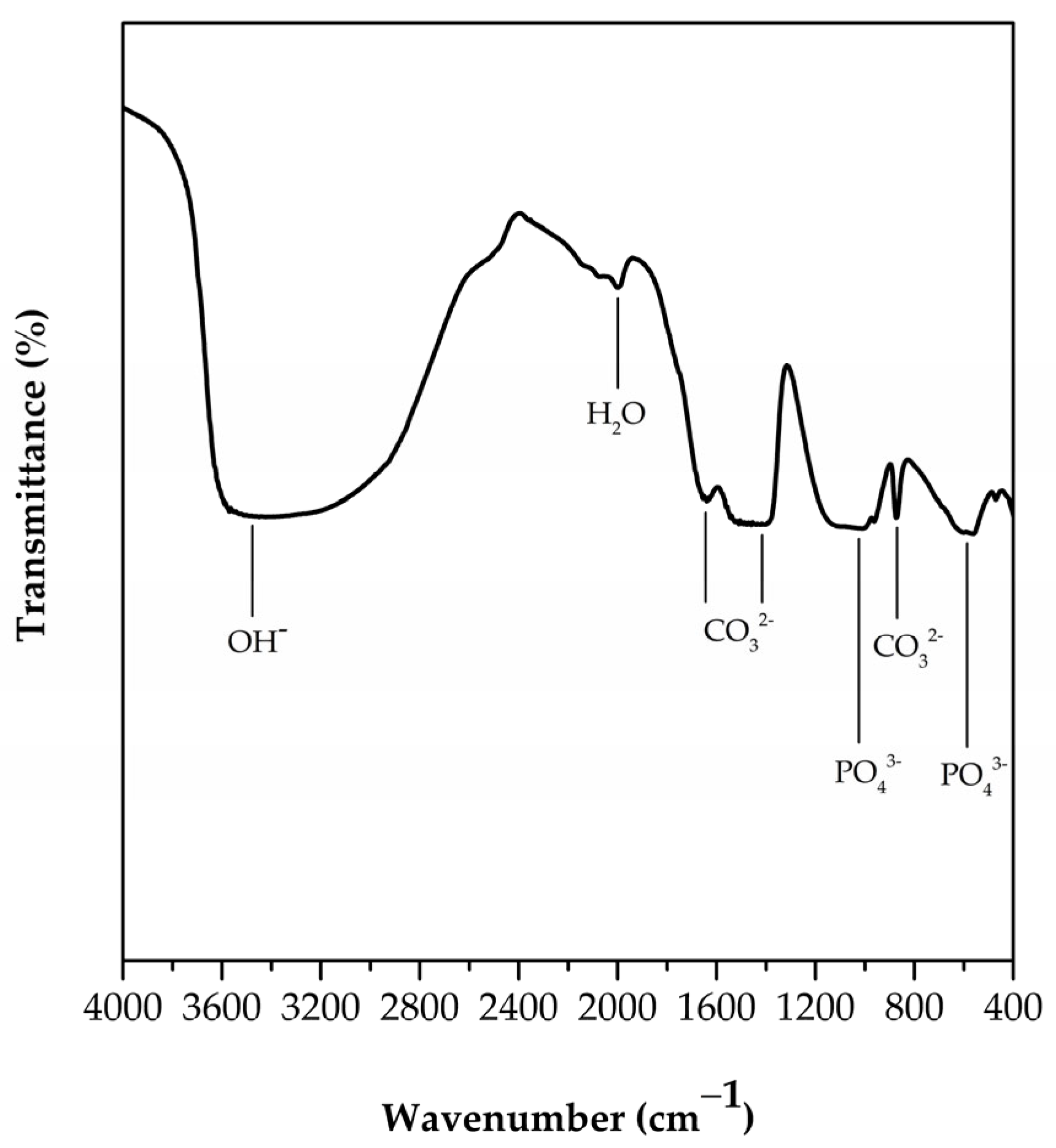

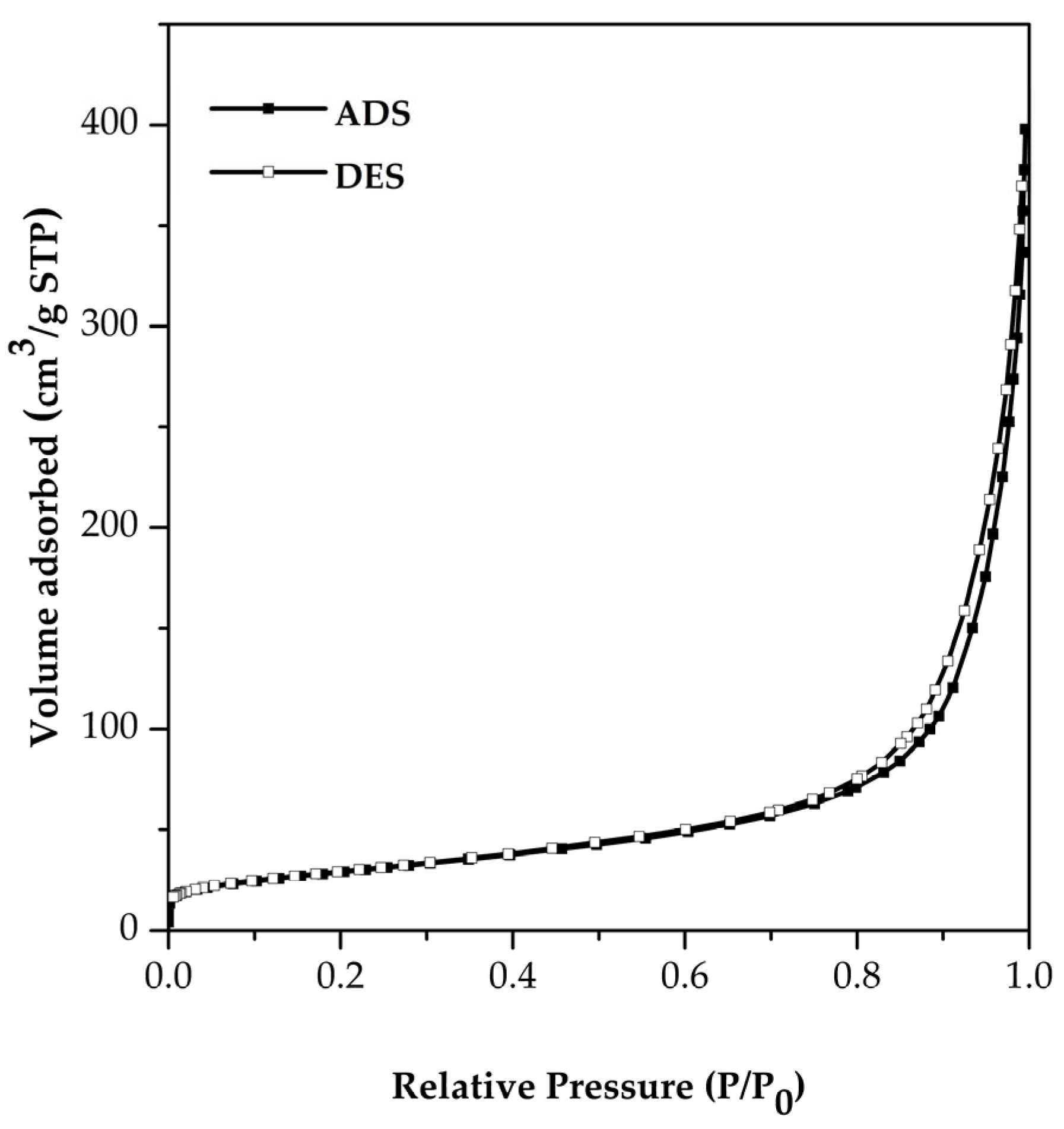

2.3. Characterizations of FSp

2.4. Preparation of NBR/FSp and NBR/FSp/CA Composites

2.5. Characterizations of NBR/FSp and NBR/FSp/CA Composites

3. Results and Discussion

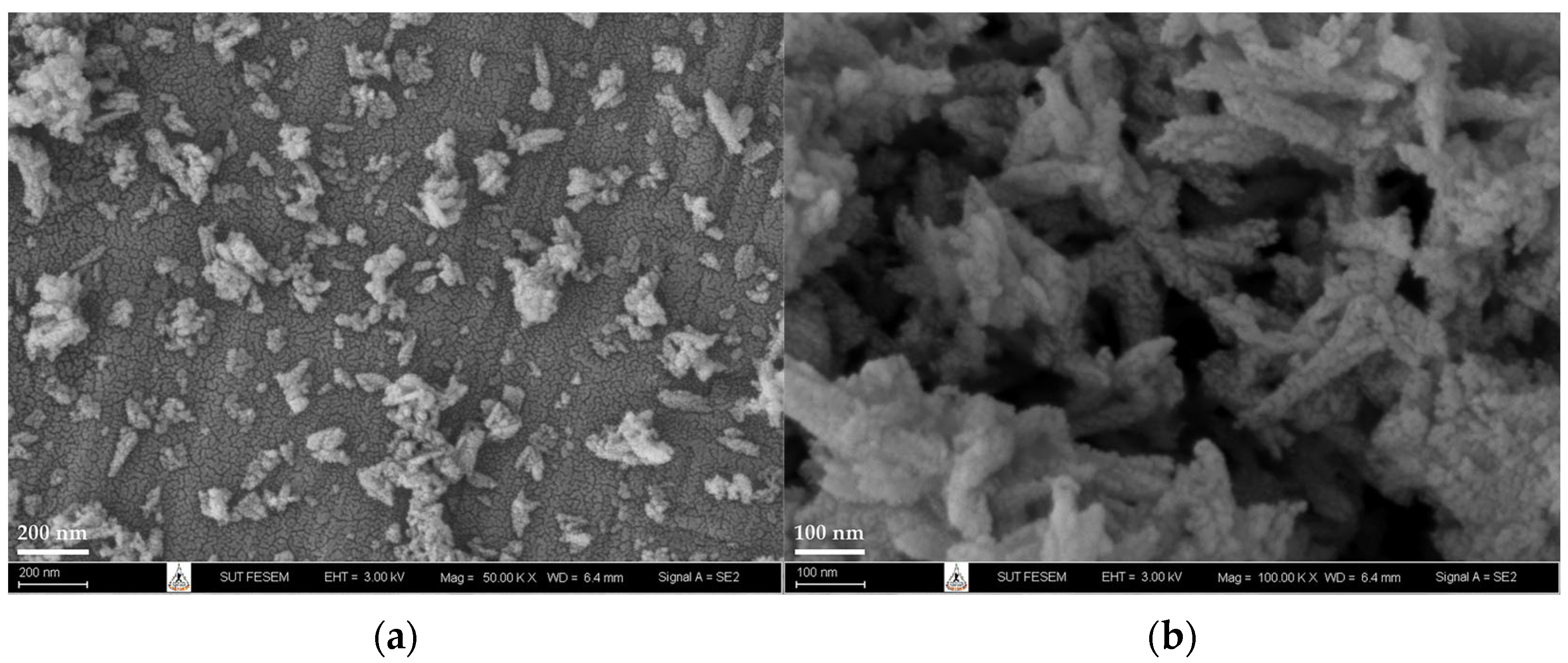

3.1. Characterizations of FSp

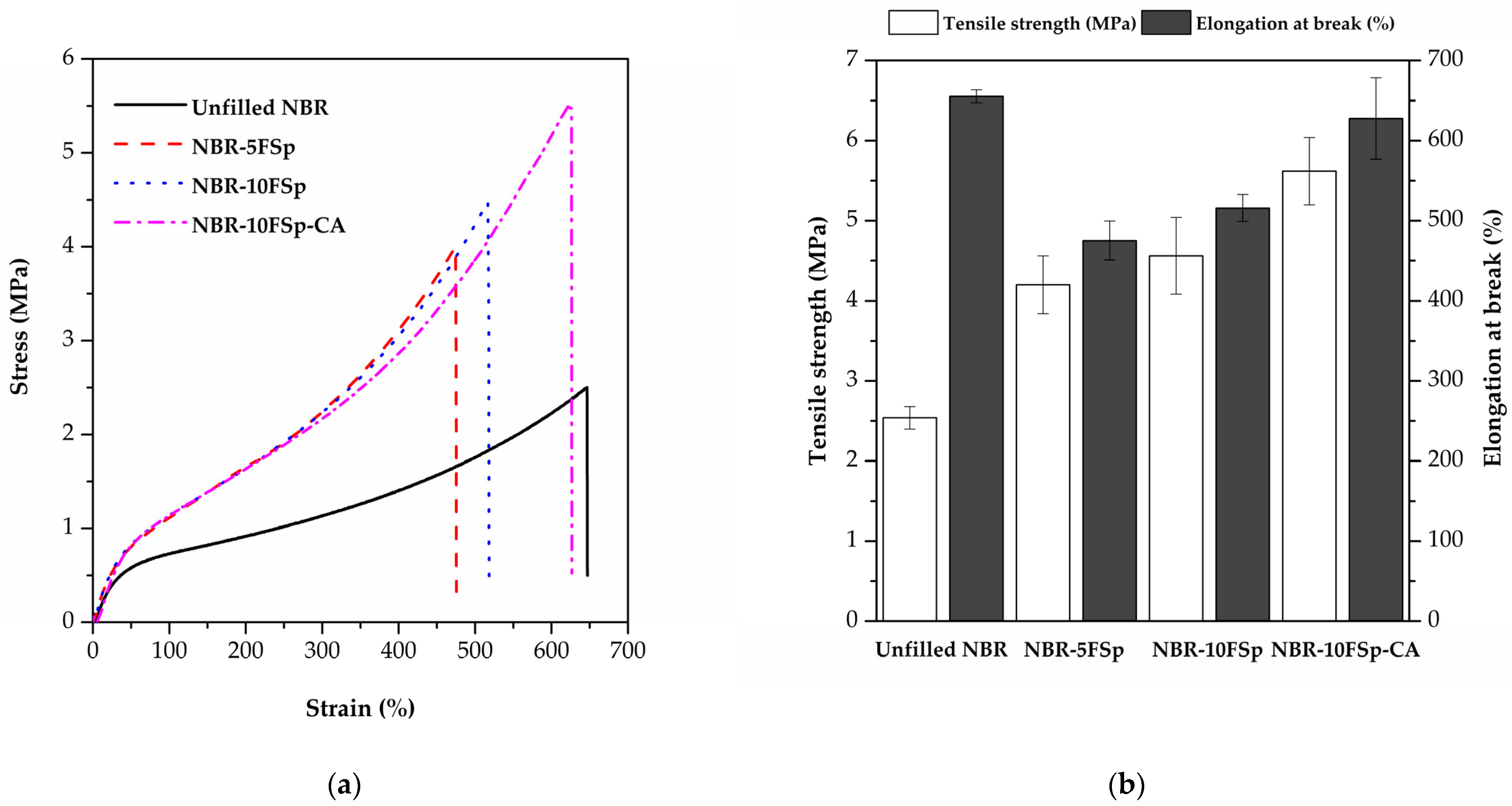

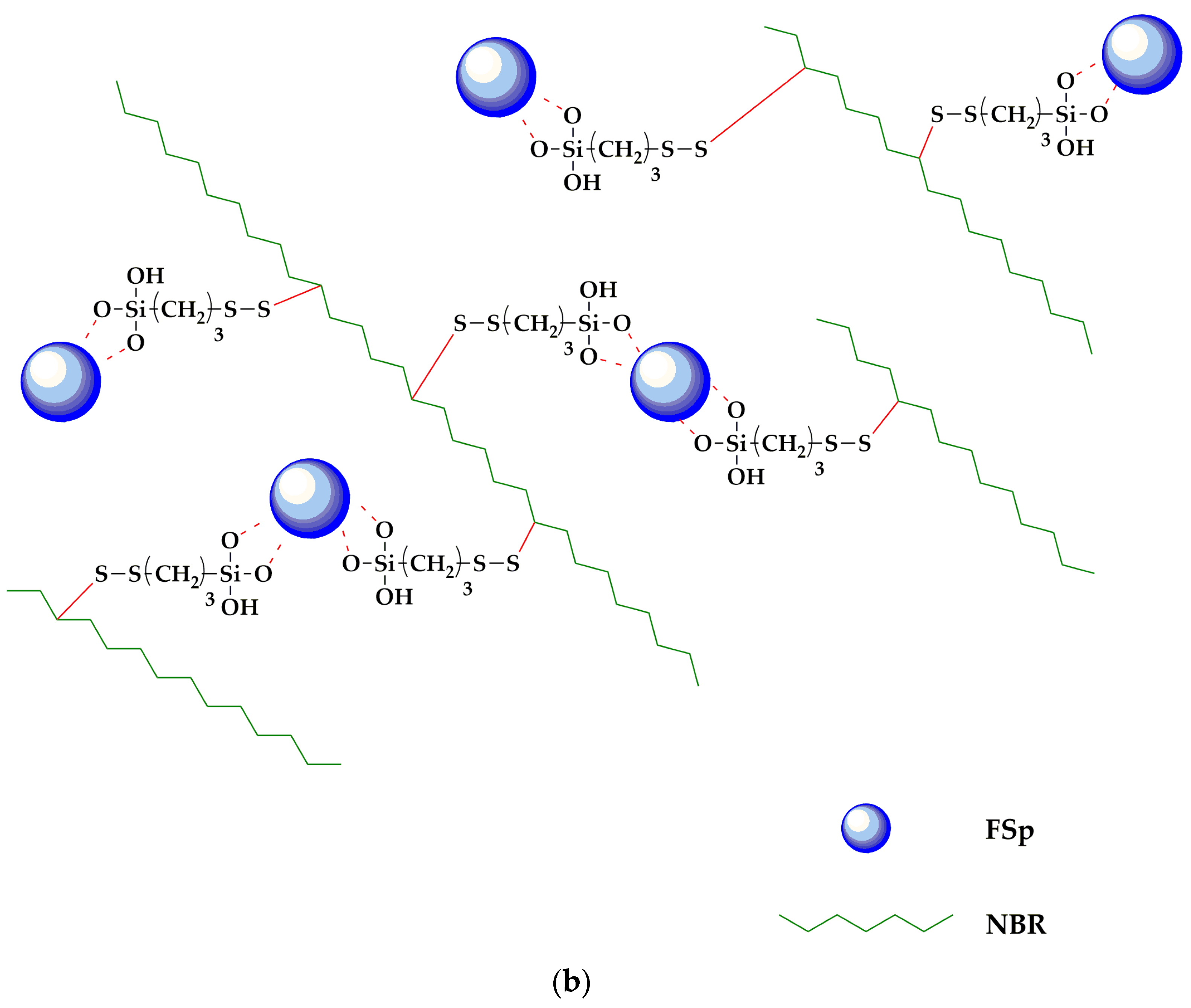

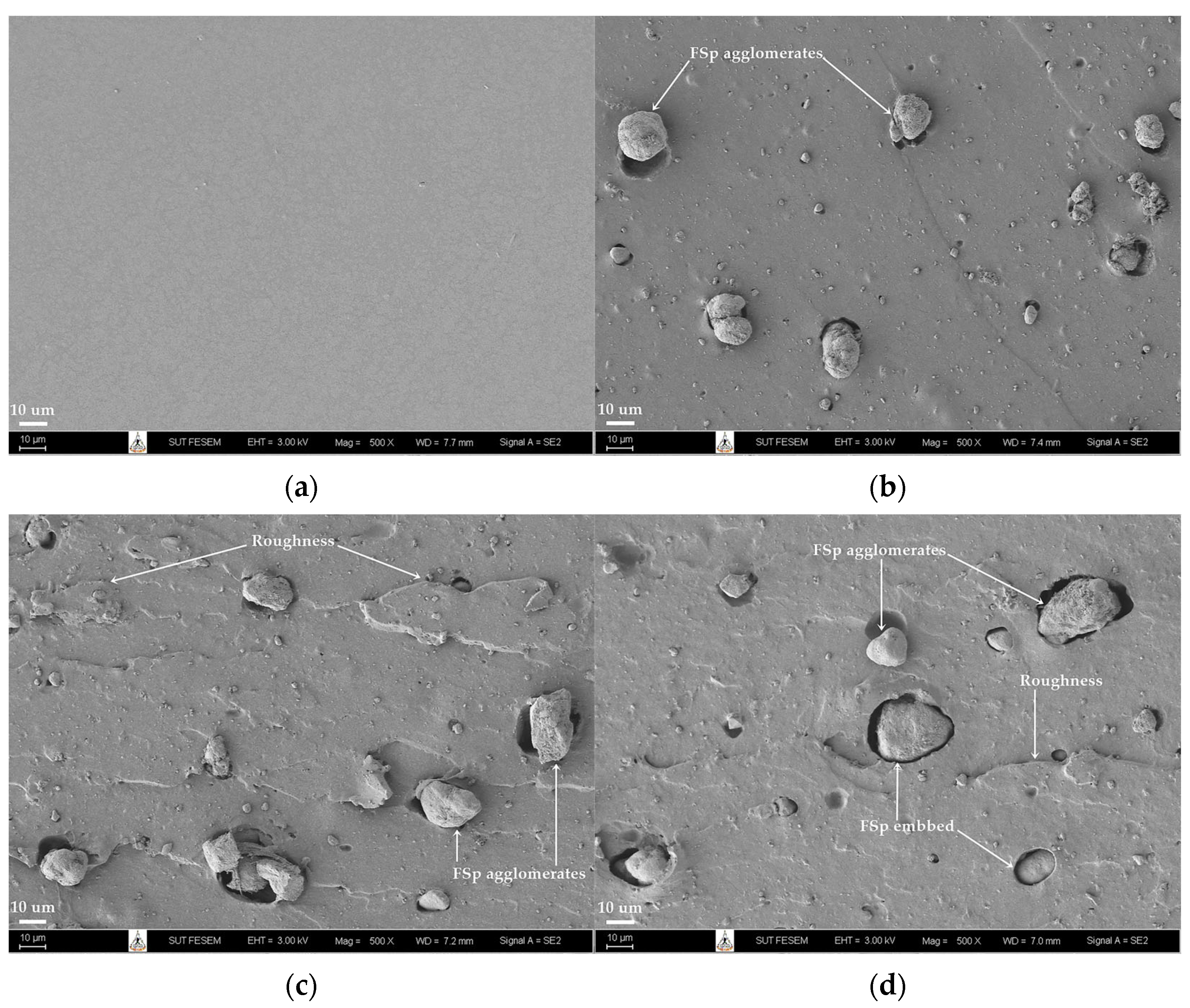

3.2. Characterizations of NBR/FSp and NBR/FSp/CA Composites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- El-Sayed, A.-F.M. Tilapia Culture; CABI Publishing: Wallingford, UK, 2006. [Google Scholar]

- Mohammad, A.W.; Kumar, A.G.; Basha, R.K. Optimization of enzymatic hydrolysis of tilapia (Oreochromis Spp.) scale gelatine. Int. Aquat. Res. 2015, 7, 27–39. [Google Scholar] [CrossRef]

- Kittiphattanabawon, P.; Sriket, C.; Kishimura, H.; Benjakul, S. Characteristics of acid and pepsin solubilized collagens from Nile tilapia (Oreochromis niloticus) scale. Emir. J. Food. Agric. 2019, 31, 95–101. [Google Scholar] [CrossRef]

- Akbay, İ.K.; Güngör, A.; Özdemir, T. Using fish scales (Sardina pilchardus) within ethylene-propylene-diene ter monomer rubber as bio-based filler. J. Appl. Polym. Sci. 2018, 135, 46698. [Google Scholar] [CrossRef]

- Qin, D.; Bi, S.; You, X.; Wang, M.; Cong, X.; Yuan, C.; Yu, M.; Cheng, X.; Chen, X.-G. Development and application of fish scale wastes as versatile natural biomaterials. Chem. Eng. J. 2022, 428, 131102. [Google Scholar] [CrossRef]

- Ikoma, T.; Kobayashi, H.; Tanaka, J.; Walsh, D.; Mann, S. Microstructure, mechanical, and biomimetic properties of fish scales from Pagrus major. J. Struct. Biol. 2003, 142, 327–333. [Google Scholar] [CrossRef]

- Kim, S.-K.; Dewapriya, P. Biologically active compounds form seafood processing by-products. In Biotransformation of Waste Biomass into High Value Biochemicals; Springer: Berlin/Heidelberg, Germany, 2014; pp. 299–311. [Google Scholar]

- Majhool, A.; Zainol, I.; Jaafar, C.; Jahil, M.; Ha, A.; Asaad, A.; Mezaal, F. Preparation of Fish Scales Hydroxyapatite (FsHAp) for Potential Use as Fillers in Polymer. J. Chem. Chem. Eng. 2019, 13, 97–104. [Google Scholar]

- Prasad, A.; Mohan Bhasney, S.; Sankar, M.R.; Katiyar, V. Fish Scale Derived Hydroxyapatite reinforced Poly (Lactic acid) Polymeric Bio-films: Possibilities for Sealing/locking the Internal Fixation Devices. Mater. Today Proc. 2017, 4, 1340–1349. [Google Scholar] [CrossRef]

- Yasin, T.; Ahmed, S.; Yoshii, F.; Makuuchi, K. Effect of acrylonitrile content on physical properties of electron beam irradiated acrylonitrile–butadiene rubber. React. Funct. Polym. 2003, 57, 113–118. [Google Scholar] [CrossRef]

- Degrange, J.-M.; Thomine, M.; Kapsa, P.; Pelletier, J.-M.; Chazeau, L.; Vigier, G.; Dudragne, G.; Guerbé, L. Influence of viscoelasticity on the tribological behaviour of carbon black filled nitrile rubber (NBR) for lip seal application. Wear 2005, 259, 684–692. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Xu, L.; Zhang, P. Investigation of aging behavior and mechanism of nitrile-butadiene rubber (NBR) in the accelerated thermal aging environment. Polym. Test. 2016, 54, 59–66. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Fabrication, characterization and dielectric studies of NBR/hydroxyapatite nanocomposites. J. Inorg. Organomet. Polym. Mater. 2017, 27, 481–489. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Synthesis, characterization, processability, mechanical properties, flame retardant, and oil resistance of chlorinated acrylonitrile butadiene rubber. Polym. Adv. Technol. 2018, 29, 2165–2173. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Hydroxyapatite as a potential nanofiller in technologically useful chlorinated acrylonitrile butadiene rubber. Polym. Test. 2020, 91, 106837. [Google Scholar] [CrossRef]

- Hwang, W.G.; Wei, K.H.; Wu, C.M. Mechanical, thermal, and barrier properties of NBR/organosilicate nanocomposites. Polym. Eng. Sci. 2004, 44, 2117–2124. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Nachtane, M.; Stanishevskiy, Y.M.; Dodina, E.P.; Rejepov, D.T.; Vetcher, A.A. The Effect of Multi-Walled Carbon Nanotubes on the Heat-Release Properties of Elastic Nanocomposites. J. Compos. Sci. 2022, 6, 333. [Google Scholar] [CrossRef]

- He, S.; Xue, Y.; Lin, J.; Zhang, L.; Du, X.; Chen, L. Effect of silane coupling agent on the structure and mechanical properties of nano-dispersed clay filled styrene butadiene rubber. Polym. Compos. 2016, 37, 890–896. [Google Scholar] [CrossRef]

- Yangthong, H.; Pichaiyut, S.; Jumrat, S.; Wisunthorn, S.; Nakason, C. Mechanical, thermal, morphological, and curing properties of geopolymer filled natural rubber composites. J. Appl. Polym. Sci. 2019, 136, 47346. [Google Scholar] [CrossRef]

- Kahavita, K.; Samarasekara, A.; Amarasinghe, D.; Karunanayake, L. Nanofibrillated cellulose reinforced polypropylene composites: Influence of silane (SI-69) surface modification. Cellul. Chem. Technol. 2020, 54, 789–797. [Google Scholar] [CrossRef]

- Sae-oui, P.; Sirisinha, C.; Thepsuwan, U.; Hatthapanit, K. Roles of silane coupling agents on properties of silica-filled polychloroprene. Eur. Polym. J. 2006, 42, 479–486. [Google Scholar] [CrossRef]

- Injorhor, P.; Trongsatitkul, T.; Wittayakun, J.; Ruksakulpiwat, C.; Ruksakulpiwat, Y. Nano− Hydroxyapatite from White Seabass Scales as a Bio− Filler in Polylactic Acid Biocomposite: Preparation and Characterization. Polymers 2022, 14, 4158. [Google Scholar] [CrossRef]

- Kongsri, S.; Janpradit, K.; Buapa, K.; Techawongstien, S.; Chanthai, S. Nanocrystalline hydroxyapatite from fish scale waste: Preparation, characterization and application for selenium adsorption in aqueous solution. Chem. Eng. J. 2013, 215, 522–532. [Google Scholar] [CrossRef]

- Deb, P.; Deoghare, A.B. Effect of Acid, Alkali and Alkali–Acid Treatment on Physicochemical and Bioactive Properties of Hydroxyapatite Derived from Catla catla Fish Scales. Arab. J. Sci. Eng. 2019, 44, 7479–7490. [Google Scholar] [CrossRef]

- Pon-On, W.; Suntornsaratoon, P.; Charoenphandhu, N.; Thongbunchoo, J.; Krishnamra, N.; Tang, I.M. Hydroxyapatite from fish scale for potential use as bone scaffold or regenerative material. Mater. Sci. Eng. C. 2016, 62, 183–189. [Google Scholar] [CrossRef] [PubMed]

- Sathiskumar, S.; Vanaraj, S.; Sabarinathan, D.; Bharath, S.; Sivarasan, G.; Arulmani, S.; Preethi, K.; Ponnusamy, V.K. Green synthesis of biocompatible nanostructured hydroxyapatite from Cirrhinus mrigala fish scale–A biowaste to biomaterial. Ceram. Int. 2019, 45, 7804–7810. [Google Scholar] [CrossRef]

- Sricharoen, P.; Limchoowong, N.; Nuengmatcha, P.; Chanthai, S. Ultrasonic-assisted recycling of Nile tilapia fish scale biowaste into low-cost nano-hydroxyapatite: Ultrasonic-assisted adsorption for Hg2+ removal from aqueous solution followed by “turn-off” fluorescent sensor based on Hg2+-graphene quantum dots. Ultrason. Sonochem. 2020, 63, 104966. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, T.; Chen, X.; He, Y.; Liang, X. Model construction of micro-pores in shale: A case study of Silurian Longmaxi Formation shale in Dianqianbei area, SW China. Pet. Explor. Dev. 2018, 45, 412–421. [Google Scholar] [CrossRef]

- Muhammad, N.; Gao, Y.; Iqbal, F.; Ahmad, P.; Ge, R.; Nishan, U.; Rahim, A.; Gonfa, G.; Ullah, Z. Extraction of biocompatible hydroxyapatite from fish scales using novel approach of ionic liquid pretreatment. Sep. Purif. Technol. 2016, 161, 129–135. [Google Scholar] [CrossRef]

- Rabiei, S.; Shojaei, A. Vulcanization kinetics and reversion behavior of natural rubber/styrene-butadiene rubber blend filled with nanodiamond–The role of sulfur curing system. Eur. Polym. J. 2016, 81, 98–113. [Google Scholar] [CrossRef]

- Balan, A.K.; Mottakkunnu Parambil, S.; Vakyath, S.; Thulissery Velayudhan, J.; Naduparambath, S.; Etathil, P. Coconut shell powder reinforced thermoplastic polyurethane/natural rubber blend-composites: Effect of silane coupling agents on the mechanical and thermal properties of the composites. J. Mater. Sci. 2017, 52, 6712–6725. [Google Scholar] [CrossRef]

- Srisuwan, L.; Jarukumjorn, K.; Suppakarn, N. Effect of silane treatment methods on physical properties of rice husk flour/natural rubber composites. Adv. Mater. Sci. Eng. 2018, 2018, 1–14. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M.T. Development of hydroxyapatite nanoparticles reinforced chlorinated acrylonitrile butadiene rubber/chlorinated ethylene propylene diene monomer rubber blends. J. Appl. Polym. Sci. 2021, 138, 50189. [Google Scholar] [CrossRef]

- Inphonlek, S.; Bureewong, N.; Jarukumjorn, K.; Chumsamrong, P.; Ruksakulpiwat, C.; Ruksakulpiwat, Y. Preparation of Poly (Acrylic Acid-co-acrylamide)-Grafted Deproteinized Natural Rubber and Its Effect on the Properties of Natural Rubber/Silica Composites. Polymers 2022, 14, 4602. [Google Scholar] [CrossRef]

- Keawkumay, C.; Jarukumjorn, K.; Wittayakun, J.; Suppakarn, N. Influences of surfactant content and type on physical properties of natural rubber/organoclay nanocomposites. J. Polym. Res. 2012, 19, 1–9. [Google Scholar] [CrossRef]

- Wu, W.; Zuo, H. Used tire rubber powder/plant cellulose composites treated with coupling agent. Cellulose. 2016, 23, 1939–1947. [Google Scholar] [CrossRef]

- Oprea, M.; Voicu, S.I. Recent advances in applications of cellulose derivatives-based composite membranes with hydroxyapatite. Materials 2020, 13, 2481. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Preparation, characterization, thermal, and electrical properties of chlorinated ethylene propylene diene monomer/hydroxyapatite nanocomposites. Polym. Compos. 2018, 39, 2093–2100. [Google Scholar] [CrossRef]

- Rakmae, S.; Lorprayoon, C.; Ekgasit, S.; Suppakarn, N. Influence of heat-treated bovine bone-derived hydroxyapatite on physical properties and in vitro degradation behavior of poly (lactic acid) composites. Polym. Plast. Technol. Eng. 2013, 52, 1043–1053. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Fabrication, characterization, dielectric properties, thermal stability, flame retardancy and transport behavior of chlorinated nitrile rubber/hydroxyapatite nanocomposites. Polym. Bull. 2021, 78, 6999–7018. [Google Scholar] [CrossRef]

| Materials (phr *) | Unfilled NBR | NBR-5FSp | NBR-10FSp | NBR-10FSp-CA |

|---|---|---|---|---|

| NBR | 100 | 100 | 100 | 100 |

| SA | 2 | 2 | 2 | 2 |

| ZnO | 5 | 5 | 5 | 5 |

| MBTS | 1.5 | 1.5 | 1.5 | 1.5 |

| CBS | 0.5 | 0.5 | 0.5 | 0.5 |

| S | 1.5 | 1.5 | 1.5 | 1.5 |

| FSp | - | 5 | 10 | 10 |

| TESPT | - | - | - | 2 |

| Sample | BET Surface Area (m2/g) | Total Pore Volume (cm3/g) |

|---|---|---|

| FSp | 104 | 0.50 |

| Samples | Minimum Torque (dNm) | Maximum Torque (dNm) | Scorch Time (min) | Cure Time (min) | Cure Rate Index (min−1) |

|---|---|---|---|---|---|

| Unfilled NBR | 7.50 | 23.12 | 3:32 | 11:53 | 0.20 |

| NBR-5FSp | 7.86 | 30.25 | 1:32 | 2:38 | 1.52 |

| NBR-10FSp | 6.44 | 29.02 | 1:31 | 2:32 | 1.64 |

| NBR-10FSp-CA | 5.91 | 24.00 | 1:32 | 3:12 | 1.00 |

| Samples | M100 (MPa) | M300 (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) |

|---|---|---|---|---|---|

| Unfilled NBR | 0.73 ± 0.02 | 1.14 ± 0.06 | 2.54 ± 0.14 | 655.35 ± 8.07 | 35.40 ± 0.25 |

| NBR-5FSp | 1.15 ± 0.04 | 2.39 ± 0.13 | 4.20 ± 0.36 | 475.21 ± 24.37 | 37.90 ± 0.30 |

| NBR-10FSp | 1.14 ± 0.02 | 2.21 ± 0.06 | 4.56 ± 0.48 | 515.81 ± 16.68 | 38.33 ± 0.25 |

| NBR-10FSp-CA | 1.13 ± 0.03 | 2.21 ± 0.08 | 5.62 ± 0.42 | 627.56 ± 51.10 | 41.40 ± 1.14 |

| Samples | Tonset (°C) | Tmax (°C) | Tendset (°C) | Residue (%) |

|---|---|---|---|---|

| Unfilled NBR | 410 | 445 | 475 | 10.91 |

| NBR-5FSp | 411 | 446 | 482 | 14.04 |

| NBR-10FSp | 412 | 449 | 483 | 17.47 |

| NBR-10FSp-CA | 413 | 449 | 483 | 17.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bureewong, N.; Injorhor, P.; Krasaekun, S.; Munchan, P.; Waengdongbang, O.; Wittayakun, J.; Ruksakulpiwat, C.; Ruksakulpiwat, Y. Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale. Polymers 2023, 15, 729. https://doi.org/10.3390/polym15030729

Bureewong N, Injorhor P, Krasaekun S, Munchan P, Waengdongbang O, Wittayakun J, Ruksakulpiwat C, Ruksakulpiwat Y. Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale. Polymers. 2023; 15(3):729. https://doi.org/10.3390/polym15030729

Chicago/Turabian StyleBureewong, Namthip, Preeyaporn Injorhor, Saifa Krasaekun, Pawida Munchan, Oatsaraphan Waengdongbang, Jatuporn Wittayakun, Chaiwat Ruksakulpiwat, and Yupaporn Ruksakulpiwat. 2023. "Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale" Polymers 15, no. 3: 729. https://doi.org/10.3390/polym15030729

APA StyleBureewong, N., Injorhor, P., Krasaekun, S., Munchan, P., Waengdongbang, O., Wittayakun, J., Ruksakulpiwat, C., & Ruksakulpiwat, Y. (2023). Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale. Polymers, 15(3), 729. https://doi.org/10.3390/polym15030729