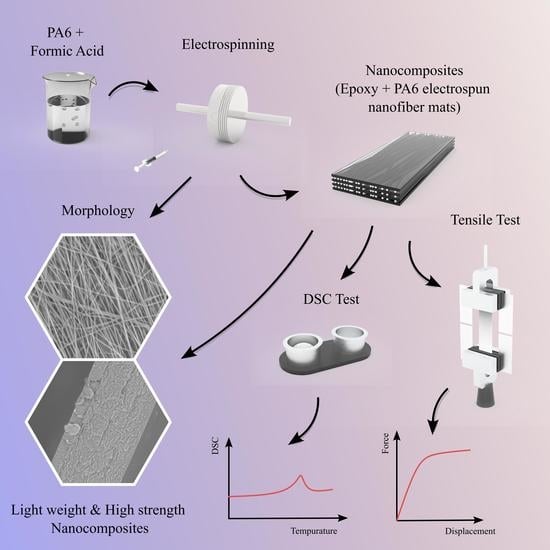

The Mechanical Properties of Nanocomposites Reinforced with PA6 Electrospun Nanofibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

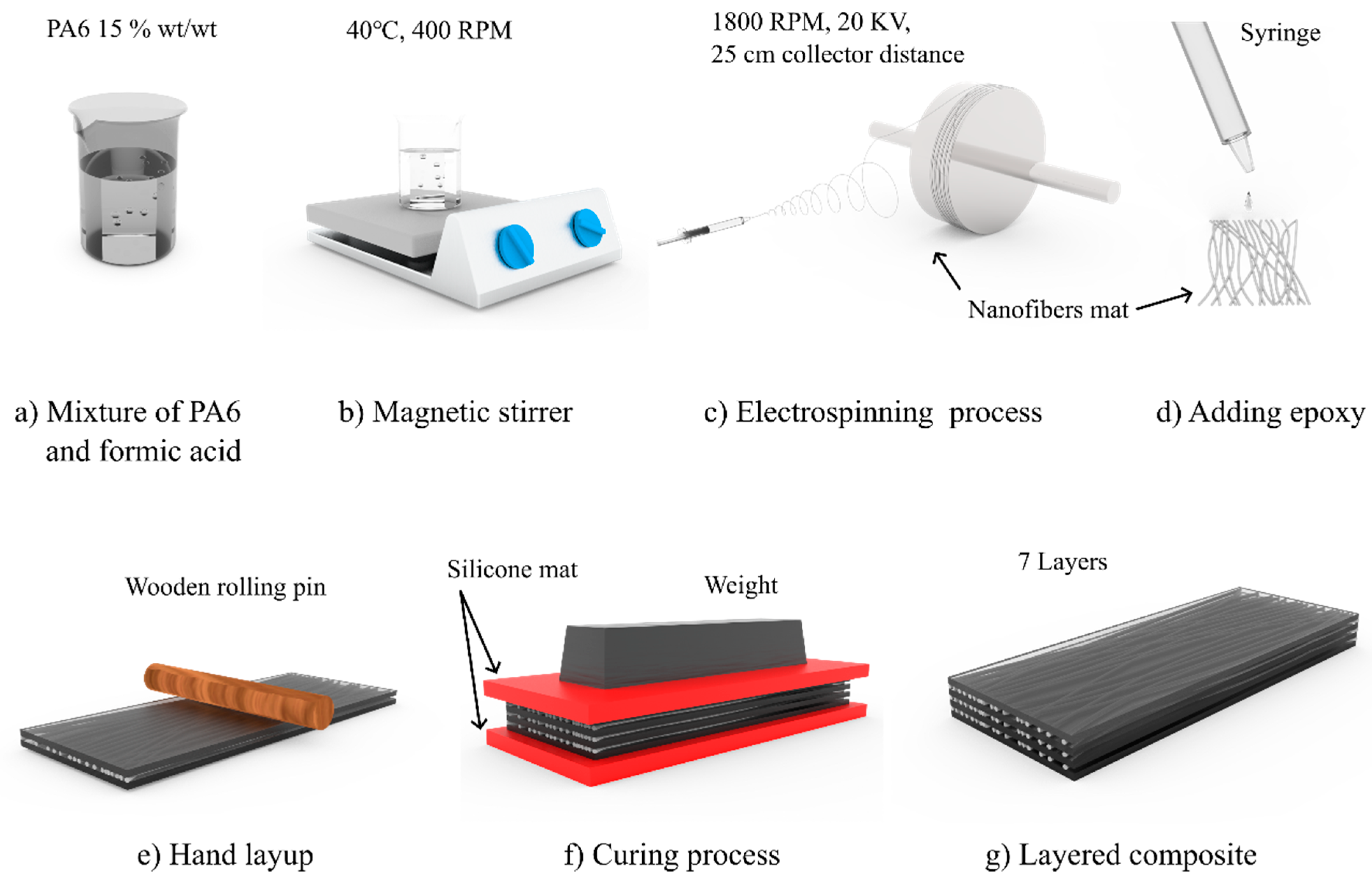

2.2. Fabrication of the Nanofibers

2.3. Fabrication of the Multilayered Nanocomposites

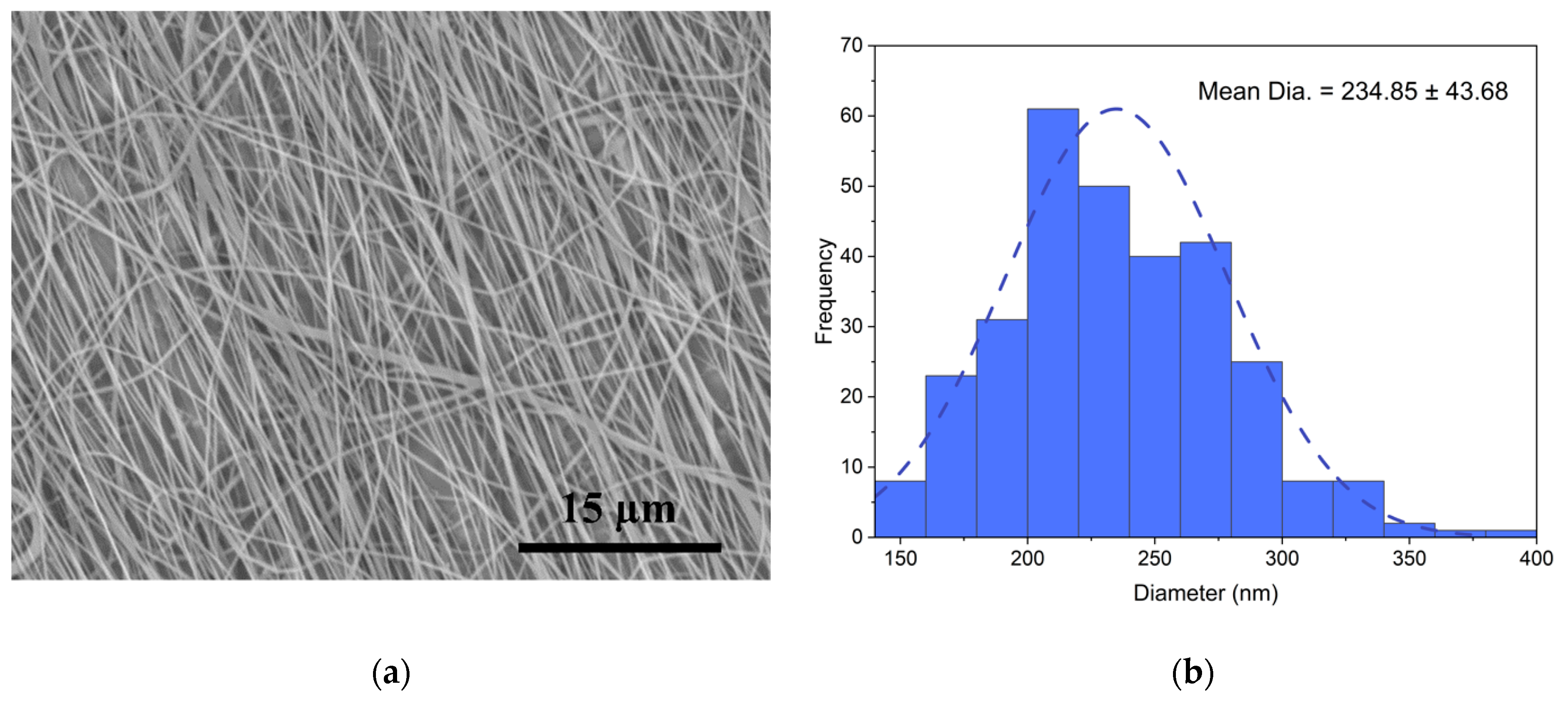

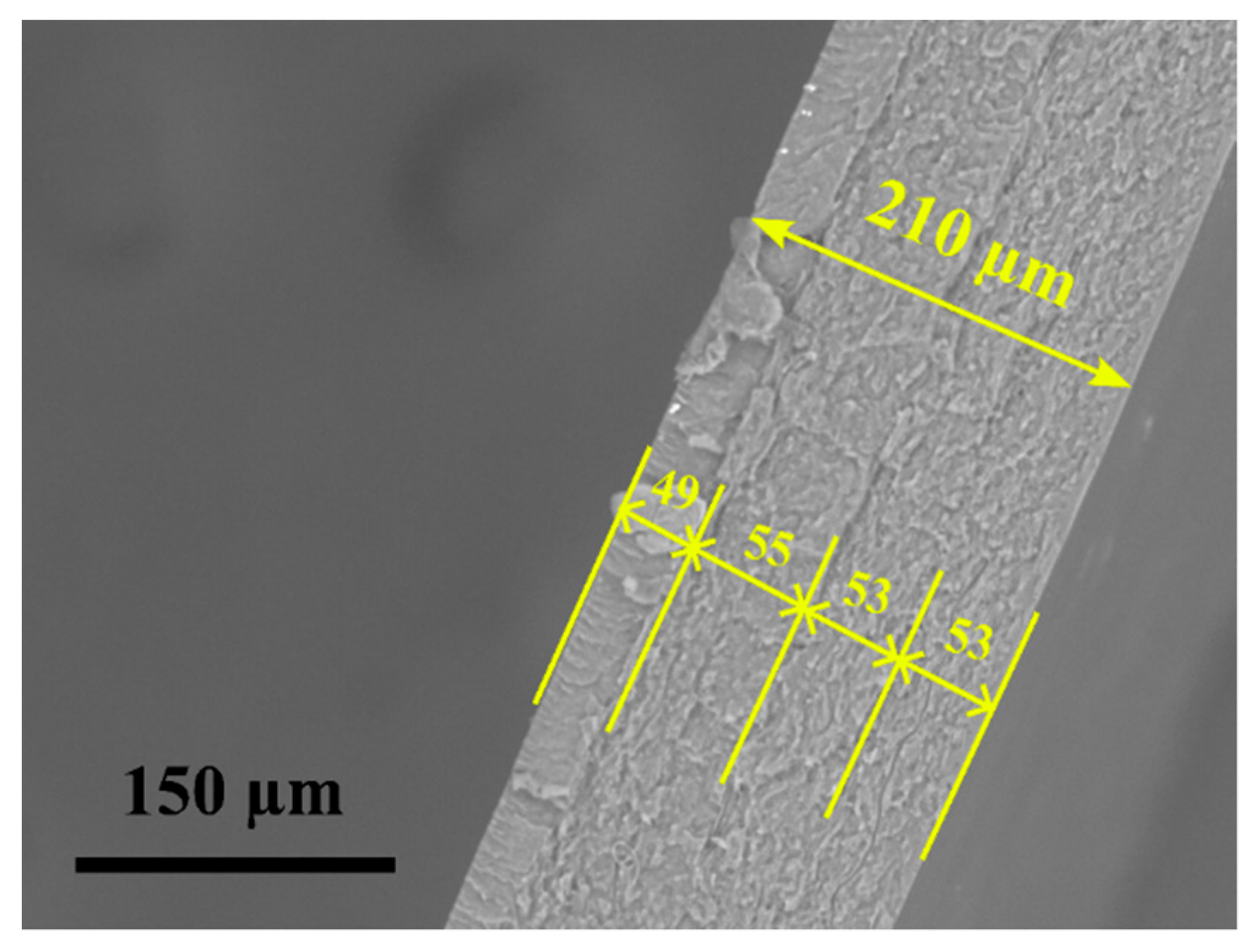

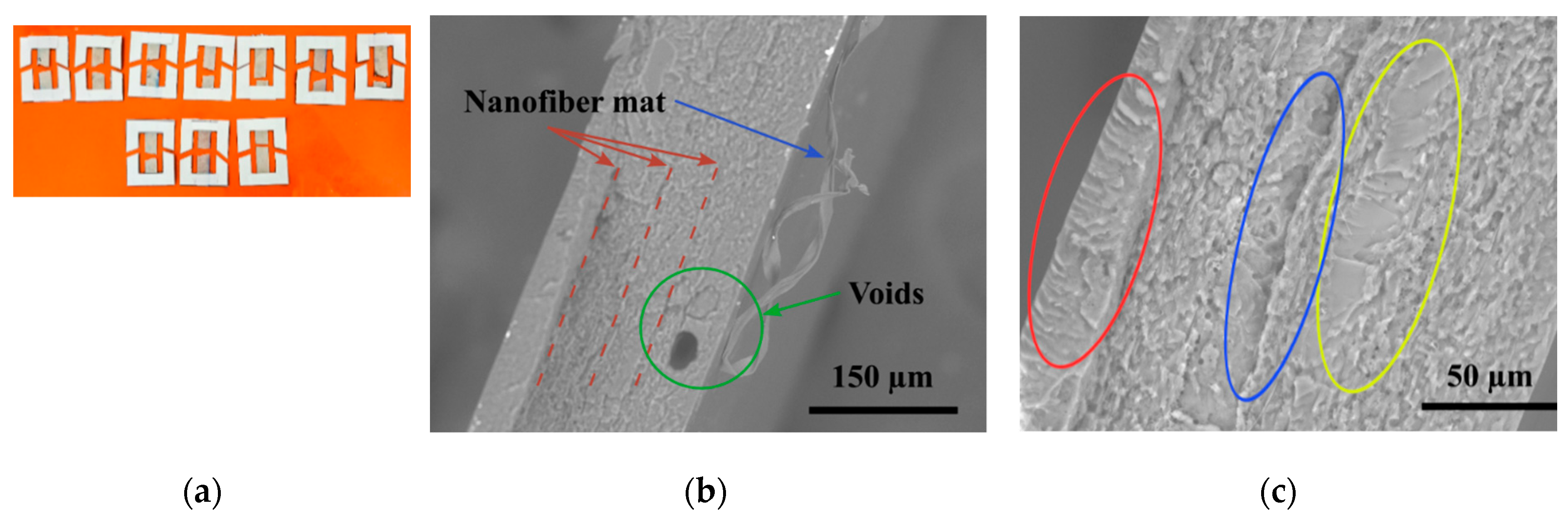

2.4. Morphology of the Spun Nanofiber and Layered Composite

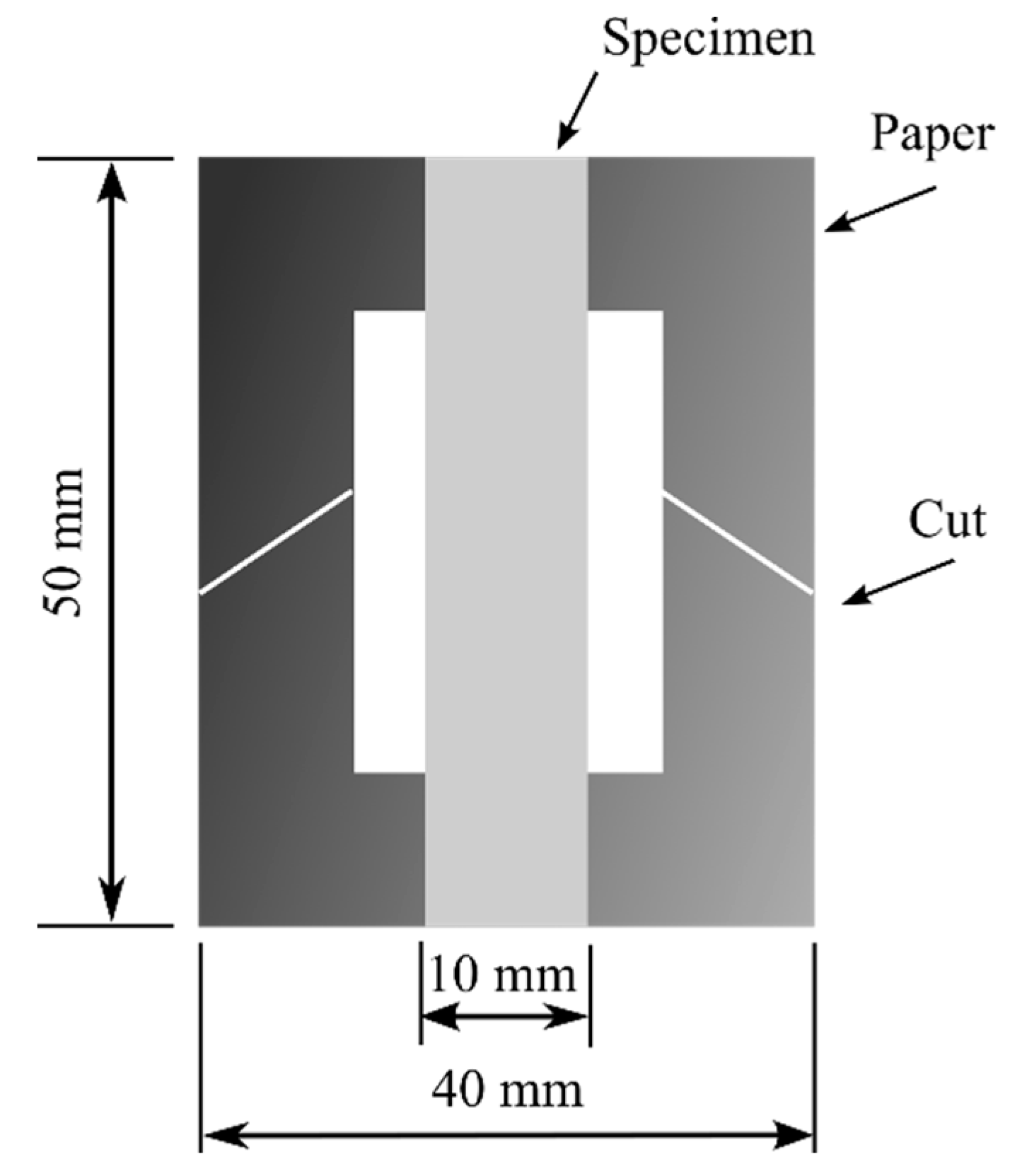

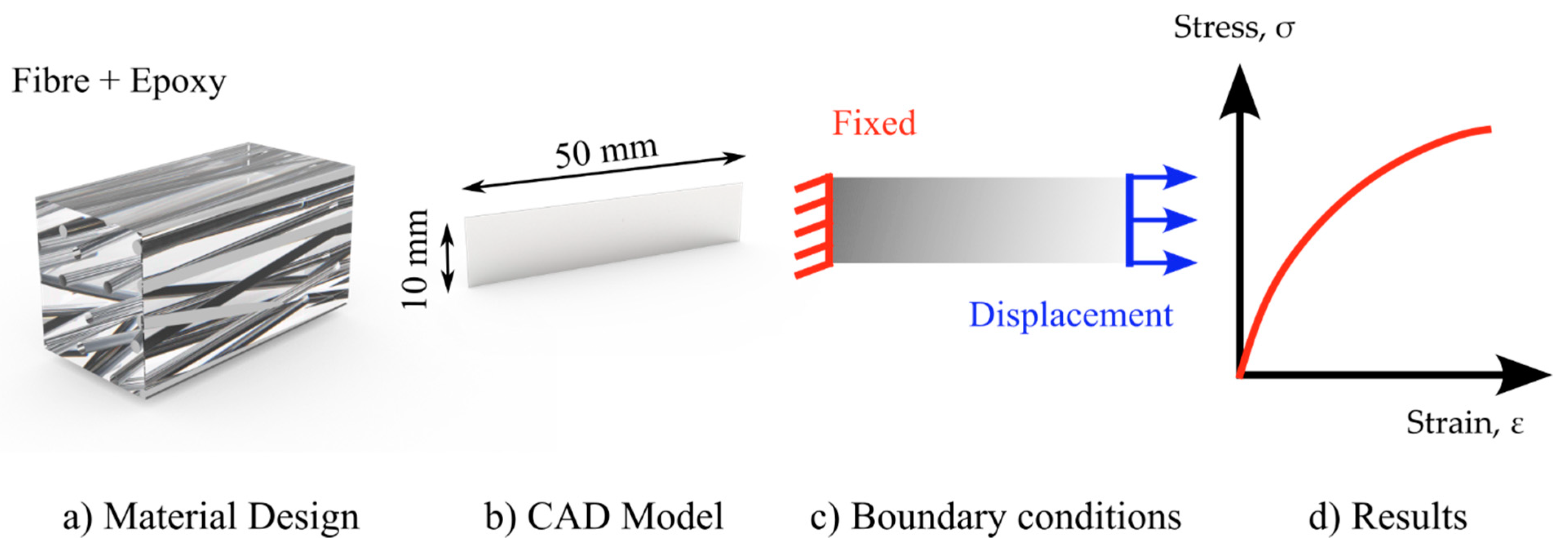

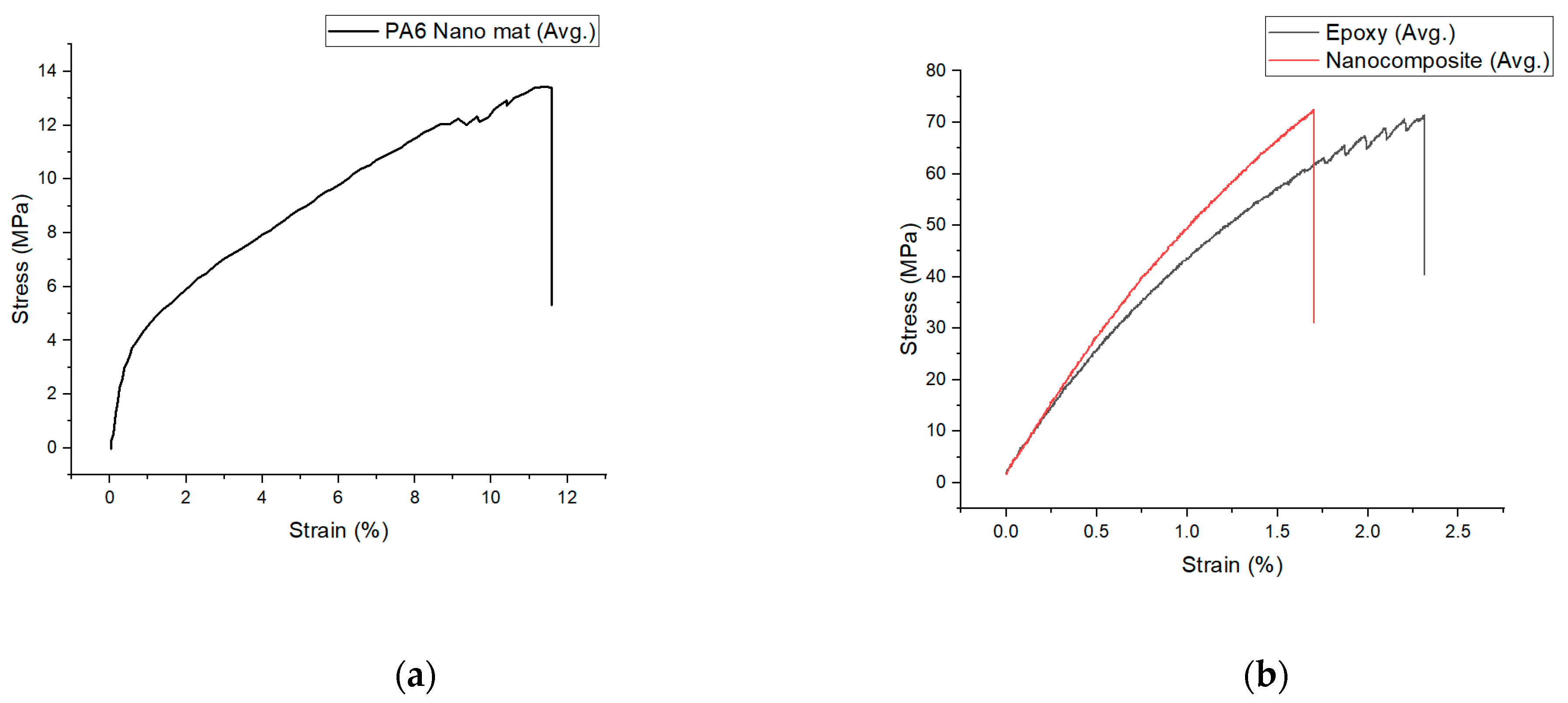

2.5. Tensile Properties

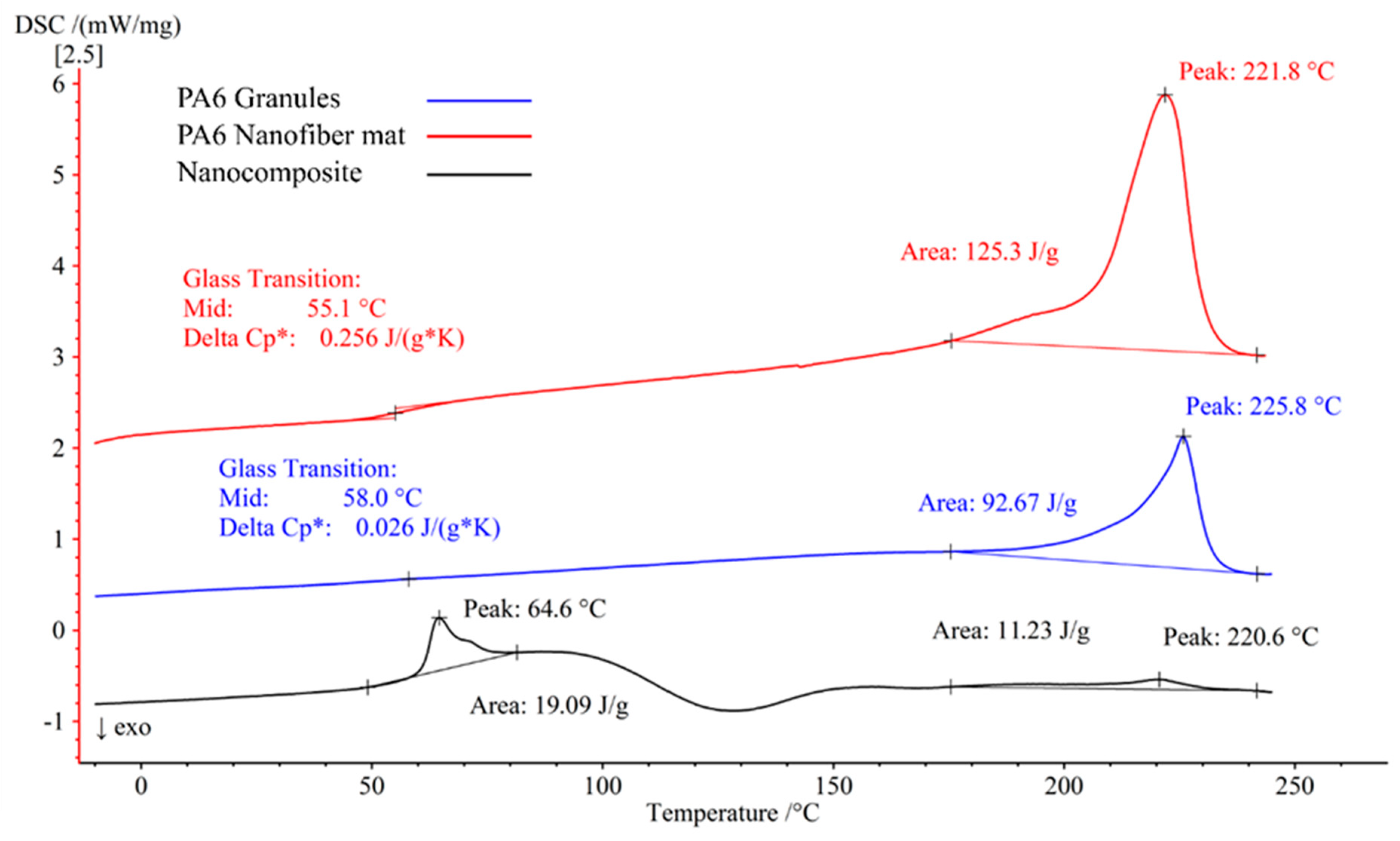

2.6. Thermal Properties

3. Results and Discussion

3.1. Morphology

3.2. Tensile Tests

3.3. DSC Analysis

3.4. Structure and Morphology after Tensile Testing

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carraher, C.E.; Seymour, R.B. Introduction To Polymer Science and Technology; ACS Symposium Sreies; ACS Publications: Washington, DC, USA, 1985; ISBN 0841208913. [Google Scholar]

- Al-abduljabbar, A.; Farooq, I. Electrospun Polymer Nanofibers: Processing, Properties, and Applications. Polymers 2023, 15, 65. [Google Scholar] [CrossRef] [PubMed]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Rajhi, A.A. Mechanical Characterization of Hybrid Nano-Filled Glass/Epoxy Composites. Polymers 2022, 14, 4852. [Google Scholar] [CrossRef] [PubMed]

- Lusis, V.; Kononova, O.; Macanovskis, A.; Stonys, R.; Lasenko, I.; Krasnikovs, A. Experimental Investigation and Modelling of the Layered Concrete with Different Concentration of Short Fibers in the Layers. Fibers Spec. Issue Mech. Fiber Reinf. Cem. Compos. 2021, 9, 76. [Google Scholar] [CrossRef]

- Lusis, V.; Annamaneni, K.K.; Kononova, O.; Korjakins, A.; Lasenko, I.; Karunamoorthy, R.K.; Krasnikovs, A. Experimental Study and Modelling on the Structural Response of Fiber Reinforced Concrete Beams. Appl. Sci. 2022, 12, 9492. [Google Scholar] [CrossRef]

- Lusis, V.; Annamaneni, K.K.; Krasnikovs, A. Concrete Reinforced by Hybrid Mix of Short Fibres under Bending. Fibers 2022, 10, 11. [Google Scholar] [CrossRef]

- Birzniece, I.M.; Cizevska, A.; Goljandin, D.; Lusis, V. Comparison of Electrical Conductivity of Cement Composite Materials. In Proceedings of the 7th World Multidisciplinary Civil Engineering-Architecture-Urban Planning Symposium–WMCAUS, Prague, Czech Republic, 5–9 September 2022; pp. 1–10. [Google Scholar]

- Erdal, M.O.; Yazman, Ş.; Gemi, L.; Yapici, A. The Effect of Nonwoven Electrospun PAN Nanofiber Mat on Mechanical and Thermal Properties of Epoxy Composites. Süleyman Demirel Üniversitesi Fen Bilim. Enstitüsü Derg. 2018, 22, 528. [Google Scholar] [CrossRef]

- Maccaferri, E.; Mazzocchetti, L.; Benelli, T.; Brugo, T.M.; Zucchelli, A.; Giorgini, L. Rubbery-modified cfrps with improved mode i fracture toughness: Effect of nanofibrous mat grammage and positioning on tanδ behaviour. Polymers 2021, 13, 1918. [Google Scholar] [CrossRef]

- Daelemans, L.; Van Paepegem, W.; D’hooge, D.R.; De Clerck, K. Excellent Nanofiber Adhesion for Hybrid Polymer Materials with High Toughness Based on Matrix Interdiffusion During Chemical Conversion. Adv. Funct. Mater. 2019, 29, 1807434. [Google Scholar] [CrossRef]

- Maccaferri, E.; Ortolani, J.; Mazzocchetti, L.; Benelli, T.; Brugo, T.M.; Zucchelli, A.; Giorgini, L. New Application Field of Polyethylene Oxide: PEO Nanofibers as Epoxy Toughener for Effective CFRP Delamination Resistance Improvement. ACS Omega 2022, 7, 23189–23200. [Google Scholar] [CrossRef]

- MacCaferri, E.; Mazzocchetti, L.; Benelli, T.; Brugo, T.M.; Zucchelli, A.; Giorgini, L. Self-Assembled NBR/Nomex Nanofibers as Lightweight Rubbery Nonwovens for Hindering Delamination in Epoxy CFRPs. ACS Appl. Mater. Interfaces 2022, 14, 1885–1899. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoğlu, M.; Aktaş, E. Enhancement of interlaminar fracture toughness of carbon fiber–epoxy composites using polyamide-6,6 electrospun nanofibers. J. Appl. Polym. Sci. 2017, 134, 45244. [Google Scholar] [CrossRef]

- Shivakumar, K.; Lingaiah, S.; Chen, H.; Akangah, P.; Swaminathan, G.; Russell, L. Polymer nanofabric interleaved composite laminates. AIAA J. 2009, 47, 1723–1729. [Google Scholar] [CrossRef]

- Daelemans, L.; van der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Nanofibre bridging as a toughening mechanism in carbon/epoxy composite laminates interleaved with electrospun polyamide nanofibrous veils. Compos. Sci. Technol. 2015, 117, 244–256. [Google Scholar] [CrossRef]

- Monteserín, C.; Blanco, M.; Murillo, N.; Pérez-Márquez, A.; Maudes, J.; Gayoso, J.; Laza, J.M.; Aranzabe, E.; Vilas, J.L. Effect of different types of electrospun polyamide 6 nanofibres on the mechanical properties of carbon fibre/epoxy composites. Polymers 2018, 10, 1190. [Google Scholar] [CrossRef]

- Liao, Y.; Loh, C.H.; Tian, M.; Wang, R.; Fane, A.G. Progress in electrospun polymeric nanofibrous membranes for water treatment: Fabrication, modification and applications. Prog. Polym. Sci. 2018, 77, 69–94. [Google Scholar] [CrossRef]

- Lašenko, I.; Gaidukovs, S.; Rombovska, J. Manufacturing of amber particles suitable for composite fibre melt spinning. Proc. Latv. Acad. Sci. Sect. B Nat. Exact Appl. Sci. 2016, 70, 51–57. [Google Scholar] [CrossRef]

- Gaidukovs, S.; Lyashenko, I.; Rombovska, J.; Gaidukova, G. Application of amber filler for production of novel polyamide composite fiber. Text. Res. J. 2016, 86, 2127–2139. [Google Scholar] [CrossRef]

- Lasenko, I.; Grauda, D.; Butkauskas, D.; Sanchaniya, J.V.; Viluma-Gudmona, A.; Lusis, V. Testing the Physical and Mechanical Properties of Polyacrylonitrile Nanofibers Reinforced with Succinite and Silicon Dioxide Nanoparticles. Textiles 2022, 2, 162–173. [Google Scholar] [CrossRef]

- Sanchaniya, J.V.; Kanukuntla, S.; Modappathi, P.; Macanovskis, A. Mechanical behaviour numerical investigation of composite structure, consisting of polymeric nanocomposite mat and textile. In Proceedings of the 21st International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 25–27 May 2022; pp. 720–726. [Google Scholar] [CrossRef]

- Viluma-Gudmona, A.; Lasenko, I.; Sanchaniya, J.V.; Podgornovs, A. Electro-resistant biotextile development based on fiber reinforcement with nano particles. In Proceedings of the 21st International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 26–28 May 2021; pp. 804–812. [Google Scholar] [CrossRef]

- Viluma-Gudmona, A.; Lasenko, I.; Sanchaniya, J.V.; Abdelhadi, B. The amber nano fibers development prospects to expand the capabilites of textile 3D printing in the general process of fabrication methods. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 26–28 May 2021; pp. 248–257. [Google Scholar]

- Kanjwal, M.A.; Ghaferi, A. Al Graphene Incorporated Electrospun Nanofiber for Electrochemical Sensing and Biomedical Applications: A Critical Review. Sensors 2022, 22, 8661. [Google Scholar] [CrossRef]

- Kim, H.C.; Panicker, P.S.; Kim, D.; Adil, S.; Kim, J. High-strength cellulose nanofiber/graphene oxide hybrid filament made by continuous processing and its humidity monitoring. Sci. Rep. 2021, 11, 13611. [Google Scholar] [CrossRef] [PubMed]

- Salama, A.; Mohamed, A.; Aboamera, N.M.; Osman, T.; Khattab, A. Characterization and mechanical properties of cellulose acetate/carbon nanotube composite nanofibers. Adv. Polym. Technol. 2018, 37, 2446–2451. [Google Scholar] [CrossRef]

- Liang, D.; Hsiao, B.S.; Chu, B. Functional electrospun nanofibrous scaffolds for biomedical applications. Adv. Drug Deliv. Rev. 2007, 59, 1392–1412. [Google Scholar] [CrossRef] [PubMed]

- Grauda, D.; Bumbure, L.; Lyashenko, I.; Katashev, A.; Dekhtyar, Y.; Rashal, I. Amber particles as living plant cell markers in flow cytometry. Proc. Latv. Acad. Sci. Sect. B Nat. Exact Appl. Sci. 2015, 69, 77–81. [Google Scholar] [CrossRef]

- Cavaliere, S.; Subianto, S.; Savych, I.; Jones, D.J.; Rozière, J. Electrospinning: Designed architectures for energy conversion and storage devices. Energy Environ. Sci. 2011, 4, 4761–4785. [Google Scholar] [CrossRef]

- Wang, X.; Ding, B.; Li, B. Biomimetic electrospun nanofibrous structures for tissue engineering. Mater. Today 2013, 16, 229–241. [Google Scholar] [CrossRef]

- Do, A.V.; Khorsand, B.; Geary, S.M.; Salem, A.K. 3D Printing of Scaffolds for Tissue Regeneration Applications. Adv. Healthc. Mater. 2015, 4, 1742–1762. [Google Scholar] [CrossRef]

- Van der Heijden, S.; Daelemans, L.; De Schoenmaker, B.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Interlaminar toughening of resin transfer moulded glass fibre epoxy laminates by polycaprolactone electrospun nanofibres. Compos. Sci. Technol. 2014, 104, 66–73. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, Y.; Zhou, Z.; Rahman, A.; Wu, X.F.; Wu, W.; Xu, T.; Fong, H. Fabrication and mechanical properties of hybrid multi-scale epoxy composites reinforced with conventional carbon fiber fabrics surface-attached with electrospun carbon nanofiber mats. Compos. Part B Eng. 2013, 44, 1–7. [Google Scholar] [CrossRef]

- Kelkar, A.D.; Mohan, R.; Bolick, R.; Shendokar, S. Effect of nanoparticles and nanofibers on Mode I fracture toughness of fiber glass reinforced polymeric matrix composites. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2010, 168, 85–89. [Google Scholar] [CrossRef]

- Özden-Yenigün, E.; Bilge, K.; Sünbüloğlu, E.; Bozdağ, E.; Papila, M. High strain rate response of nanofiber interlayered structural composites. Compos. Struct. 2017, 168, 47–55. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. A Review on Synthetic Fibers for Polymer Matrix Composites: Performance, Failure Modes and Applications. Materials 2022, 15, 4790. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Hassan, T.; Salam, A.; Khan, A.; Khan, S.U.; Khanzada, H.; Wasim, M.; Khan, M.Q.; Kim, I.S. Functional nanocomposites and their potential applications: A review. J. Polym. Res. 2021, 28, 36. [Google Scholar] [CrossRef]

- Sanchaniya, J.V.; Kanukuntla, S.-P.; Simon, S.; Gerina-Ancane, A. Analysis of mechanical properties of composite nanofibers constructed on rotating drum and collector plate. In Proceedings of the 21st International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 24–26 May 2022; pp. 737–744. [Google Scholar] [CrossRef]

- Pham, L.Q.; Uspenskaya, M.V.; Olekhnovich, R.O.; Baranov, M.A. The mechanical properties of PVC nanofiber mats obtained by electrospinning. Fibers 2021, 9, 2. [Google Scholar] [CrossRef]

- Beachley, V.; Wen, X. Effect of electrospinning parameters on the nanofiber diameter and length. Mater. Sci. Eng. C 2009, 29, 663–668. [Google Scholar] [CrossRef]

- Rezakhaniha, R.; Agianniotis, A.; Schrauwen, J.T.C.; Griffa, A.; Sage, D.; Bouten, C.V.C.; Van De Vosse, F.N.; Unser, M.; Stergiopulos, N. Experimental investigation of collagen waviness and orientation in the arterial adventitia using confocal laser scanning microscopy. Biomech. Model. Mechanobiol. 2012, 11, 461–473. [Google Scholar] [CrossRef]

- Püspöki, Z.; Storath, M.; Sage, D.; Unser, M. Transforms and operators for directional bioimage analysis: A survey. Adv. Anat. Embryol. Cell Biol. 2016, 219, 69–93. [Google Scholar] [CrossRef]

- Maccaferri, E.; Cocchi, D.; Mazzocchetti, L.; Benelli, T.; Brugo, T.M.; Giorgini, L.; Zucchelli, A. How Nanofibers Carry the Load: Toward a Universal and Reliable Approach for Tensile Testing of Polymeric Nanofibrous Membranes. Macromol. Mater. Eng. 2021, 306, 2100183. [Google Scholar] [CrossRef]

- Agarwal, B.D.; Broutman, L.J.; Chandrasekhara, K. Analysis and Performance of Fiber Composites; JohnWiley & Sons: Hoboken, NJ, USA, 2017; Volume 151, ISBN 1119389984. [Google Scholar]

- Ayres, C.E.; Jha, B.S.; Meredith, H.; Bowman, J.R.; Bowlin, G.L.; Henderson, S.C.; Simpson, D.G. Measuring fiber alignment in electrospun scaffolds: A user’s guide to the 2D fast Fourier transform approach. J. Biomater. Sci. Polym. Ed. 2008, 19, 603–621. [Google Scholar] [CrossRef]

- Li, W.J.; Mauck, R.L.; Cooper, J.A.; Yuan, X.; Tuan, R.S. Engineering controllable anisotropy in electrospun biodegradable nanofibrous scaffolds for musculoskeletal tissue engineering. J. Biomech. 2007, 40, 1686–1693. [Google Scholar] [CrossRef]

- Kim, G.H. Electrospun PCL nanofibers with anisotropic mechanical properties as a biomedical scaffold. Biomed. Mater. 2008, 3, 25010. [Google Scholar] [CrossRef]

- Arinstein, A.; Burman, M.; Gendelman, O.; Zussman, E. Effect of supramolecular structure on polymer nanofibre elasticity. Nat. Nanotechnol. 2007, 2, 59–62. [Google Scholar] [CrossRef]

- Chew, S.Y.; Hufnagel, T.C.; Lim, C.T.; Leong, K.W. Mechanical properties of single electrospun drug-encapsulated nanofibres. Nanotechnology 2006, 17, 3880–3891. [Google Scholar] [CrossRef]

- Wong, S.C.; Baji, A.; Leng, S. Effect of fiber diameter on tensile properties of electrospun poly(ε-caprolactone). Polymer 2008, 49, 4713–4722. [Google Scholar] [CrossRef]

- Yao, J.; Bastiaansen, C.W.M.; Peijs, T. High strength and high modulus electrospun nanofibers. Fibers 2014, 2, 158–187. [Google Scholar] [CrossRef]

- Liu, Y.; Cui, L.; Guan, F.; Gao, Y.; Hedin, N.E.; Zhu, L.; Fong, H. Crystalline Morphology and Polymorphic Phase Transitions in Electrospun Nylon 6 Nanofibers. Macromolecules 2007, 40, 6283–6290. [Google Scholar] [CrossRef]

- Gu, S.Y.; Wu, Q.L.; Ren, J.; Vancso, G.J. Mechanical properties of a single electrospun fiber and its structures. Macromol. Rapid Commun. 2005, 26, 716–720. [Google Scholar] [CrossRef]

- Lee, K.; Kwon, G.; Jeon, Y.; Jeon, S.; Hong, C.; Choung, J.W.; You, J. Toward millimeter thick cellulose nanofiber/epoxy laminates with good transparency and high flexural strength. Carbohydr. Polym. 2022, 291, 119514. [Google Scholar] [CrossRef] [PubMed]

- Özden, E.; Menceloǧlu, Y.Z.; Papila, M. Engineering chemistry of electrospun nanofibers and interfaces in nanocomposites for superior mechanical properties. ACS Appl. Mater. Interfaces 2010, 2, 1788–1793. [Google Scholar] [CrossRef]

- Aliahmad, N.; Biswas, P.K.; Wable, V.; Hernandez, I.; Dalir, H. Electrospun Thermosetting Carbon Nanotube−Epoxy Nanofibers. ACS Appl. Polym. Mater. 2021, 3, 610–619. [Google Scholar] [CrossRef]

- Jiang, S.; Duan, G.; Hou, H.; Greiner, A.; Agarwal, S. Novel layer-by-layer procedure for making nylon-6 nanofiber reinforced high strength, tough, and transparent thermoplastic polyurethane composites. ACS Appl. Mater. Interfaces 2012, 4, 4366–4372. [Google Scholar] [CrossRef]

- Lasenko, I.; Sanchaniya, J.V.; Kardani, U.; Kanukuntala, S.-P.; Viluma-Gudmona, A.; Krasnikovs, A.; Selga, T. The effect of annealing on mechanical properties of PAN nanofiber mat. Multidiscip. Digit. Publ. Inst. 2023. submitted. [Google Scholar]

- Lee, K.Y.; Aitomäki, Y.; Berglund, L.A.; Oksman, K.; Bismarck, A. On the use of nanocellulose as reinforcement in polymer matrix composites. Compos. Sci. Technol. 2014, 105, 15–27. [Google Scholar] [CrossRef]

- Jin, J.; Rafiq, R.; Gill, Y.Q.; Song, M. Preparation and characterization of high performance of graphene/nylon nanocomposites. Eur. Polym. J. 2013, 49, 2617–2626. [Google Scholar] [CrossRef]

- Penel-Pierron, L.; Depecker, C.; Séguéla, R.; Lefebvre, J.M. Structural and mechanical behavior of nylon 6 films: Part I. Identification and stability of the crystalline phases. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 484–495. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Tensile and thermomechanical properties of short carbon fiber reinforced polyamide 6 composites. Compos. Part B Eng. 2013, 51, 270–275. [Google Scholar] [CrossRef]

- Goyat, M.S.; Suresh, S.; Bahl, S.; Halder, S.; Ghosh, P.K. Thermomechanical response and toughening mechanisms of a carbon nano bead reinforced epoxy composite. Mater. Chem. Phys. 2015, 166, 144–152. [Google Scholar] [CrossRef]

- Naderi, M.; Ebrahimi, F. Fracture Surface and Mechanical Properties of Epoxy Composites. In Epoxy Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2021; pp. 259–298. [Google Scholar] [CrossRef]

| Materials | Tensile Strength at Break, σ (MPa) | Young’s Modulus, E (MPa) | Elongation at Break, ε (%) |

|---|---|---|---|

| PA6 nanofiber mat | 13.18 ± 1.54 | 3200 ± 15 | 11.240 ± 1.01 |

| Epoxy | 74.45 ± 3.50 | 2070.4 ± 10 | 2.320 ± 0.24 |

| Nanocomposite | 76.84 ± 4.74 | 2315.5 ± 19 | 1.628 ± 0.3 |

| Materials | Tg (°C) | Tm (°C) | h (J/g) |

|---|---|---|---|

| PA6 granules | 58.0 | 225.8 | 92.67 |

| PA6 nanofiber mat | 55.1 | 221.8 | 125.3 |

| Nanocomposite | 64.6 | 220.6 | 19.09/11.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lasenko, I.; Sanchaniya, J.V.; Kanukuntla, S.P.; Ladani, Y.; Viluma-Gudmona, A.; Kononova, O.; Lusis, V.; Tipans, I.; Selga, T. The Mechanical Properties of Nanocomposites Reinforced with PA6 Electrospun Nanofibers. Polymers 2023, 15, 673. https://doi.org/10.3390/polym15030673

Lasenko I, Sanchaniya JV, Kanukuntla SP, Ladani Y, Viluma-Gudmona A, Kononova O, Lusis V, Tipans I, Selga T. The Mechanical Properties of Nanocomposites Reinforced with PA6 Electrospun Nanofibers. Polymers. 2023; 15(3):673. https://doi.org/10.3390/polym15030673

Chicago/Turabian StyleLasenko, Inga, Jaymin Vrajlal Sanchaniya, Sai Pavan Kanukuntla, Yagnik Ladani, Arta Viluma-Gudmona, Olga Kononova, Vitalijs Lusis, Igors Tipans, and Turs Selga. 2023. "The Mechanical Properties of Nanocomposites Reinforced with PA6 Electrospun Nanofibers" Polymers 15, no. 3: 673. https://doi.org/10.3390/polym15030673

APA StyleLasenko, I., Sanchaniya, J. V., Kanukuntla, S. P., Ladani, Y., Viluma-Gudmona, A., Kononova, O., Lusis, V., Tipans, I., & Selga, T. (2023). The Mechanical Properties of Nanocomposites Reinforced with PA6 Electrospun Nanofibers. Polymers, 15(3), 673. https://doi.org/10.3390/polym15030673