Finite Element Analysis of the Effect for Different Thicknesses and Stitching Densities under the Low-Velocity Impact of Stitched Composite Laminates

Abstract

:1. Introduction

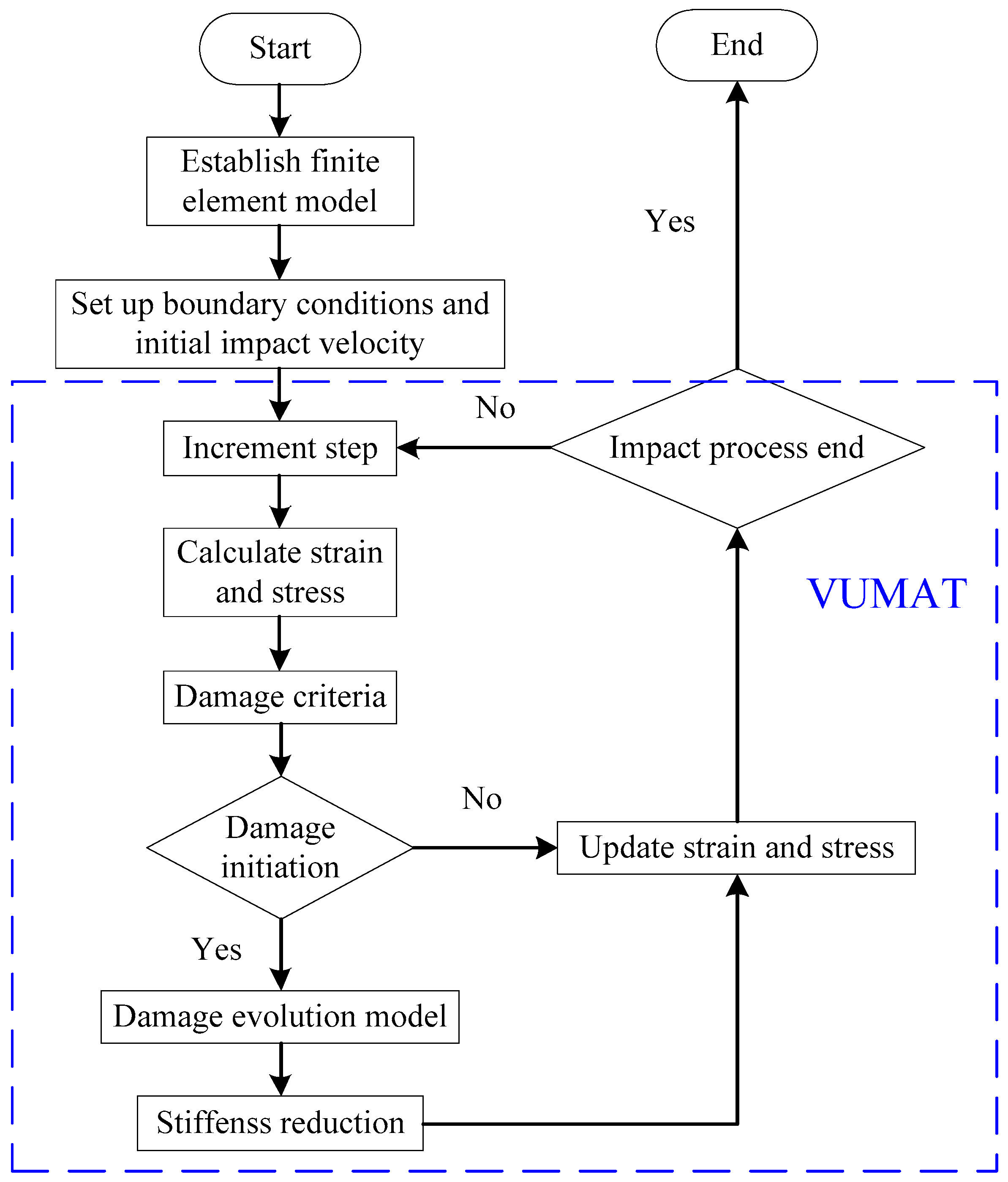

2. Model of Progressive Damage to Composite Laminates

2.1. Continuous Damage Model

2.2. Failure Criterion

2.3. Damage Evolution Model

2.4. Interlaminar Damage

2.5. Stitching Resin Cylinder Model

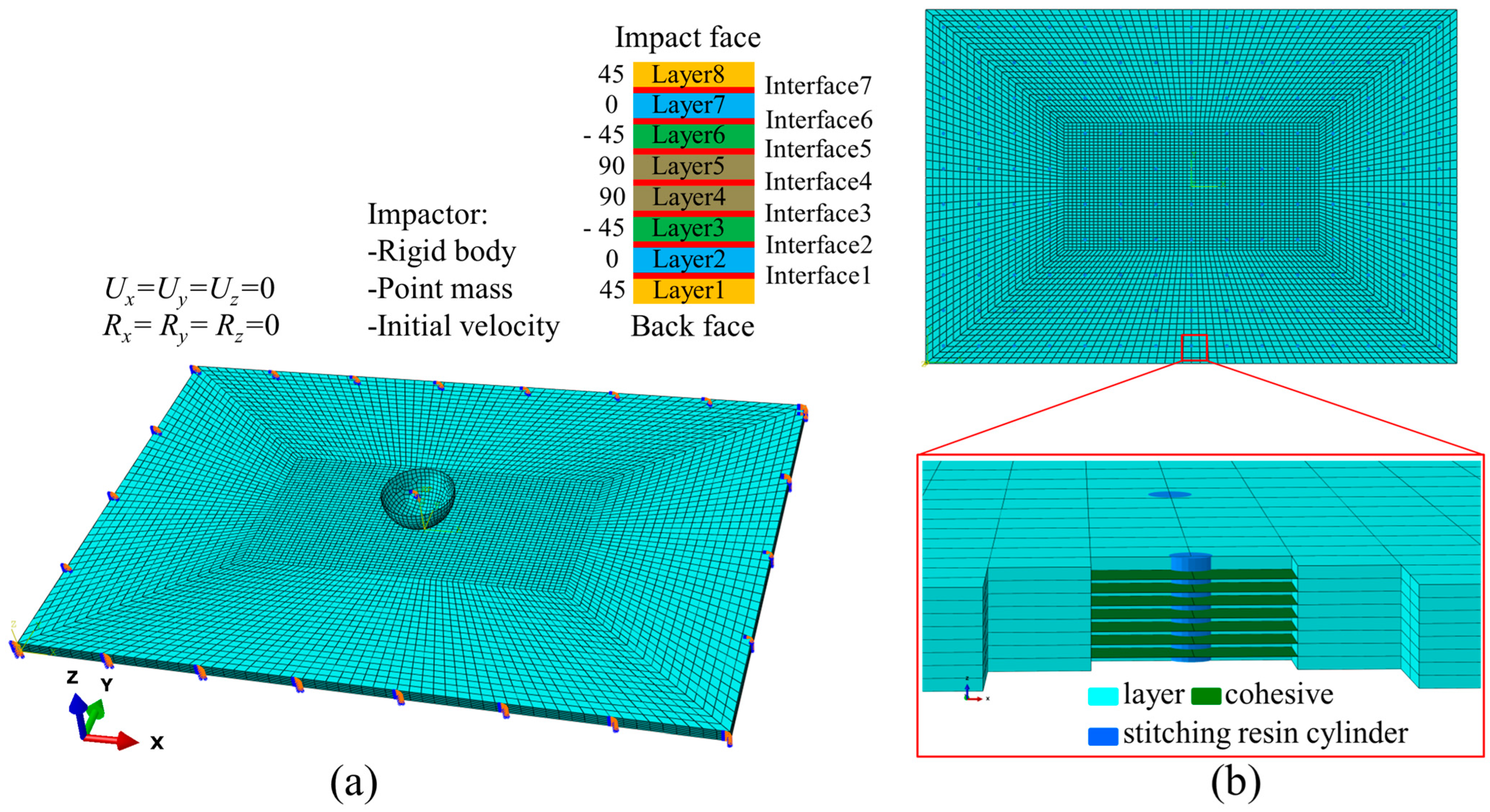

3. Finite Element Modeling of LVI

3.1. Geometric Dimensions and Boundary Conditions

3.2. Element Types Selection and Gridding

3.3. Contact Settings and Material Properties

4. Results and Discussion of Numerical Simulation

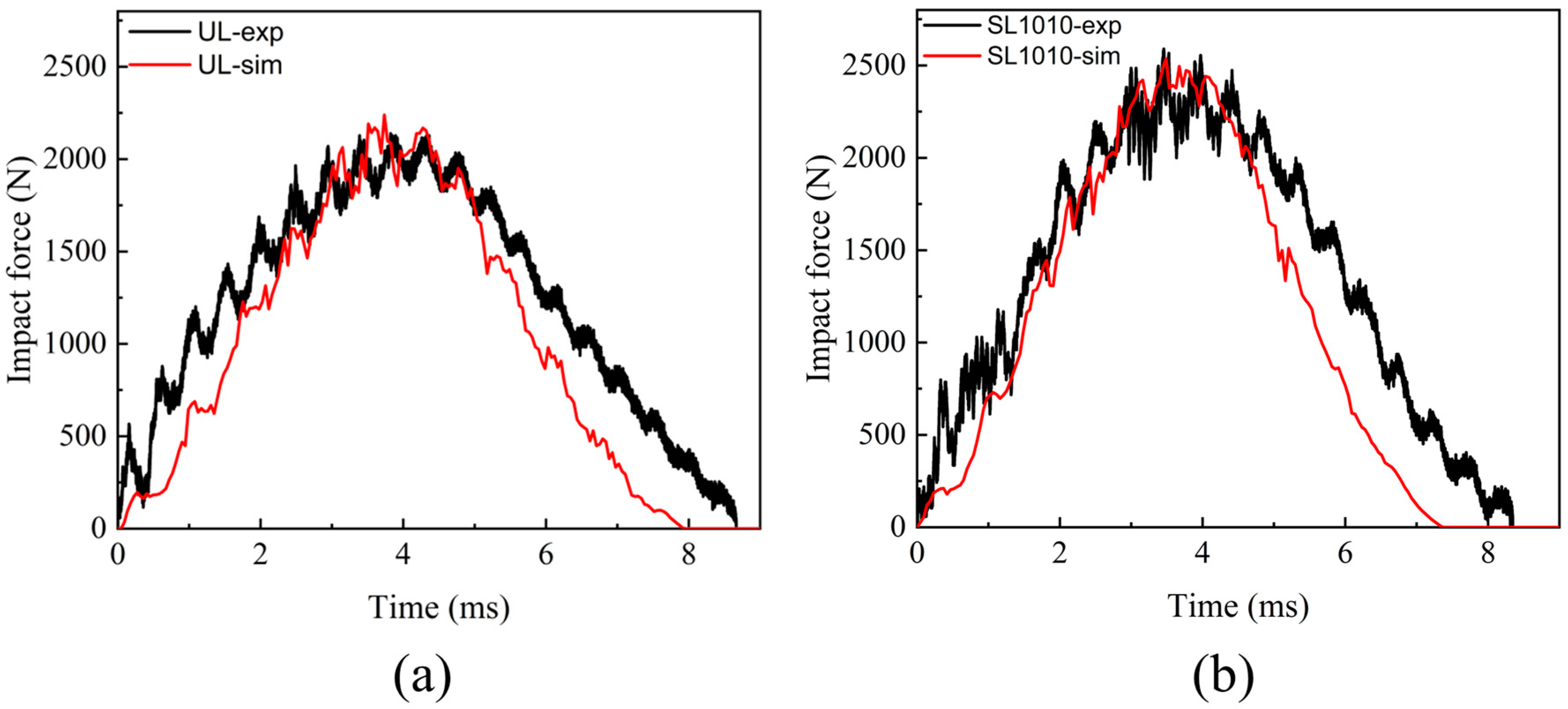

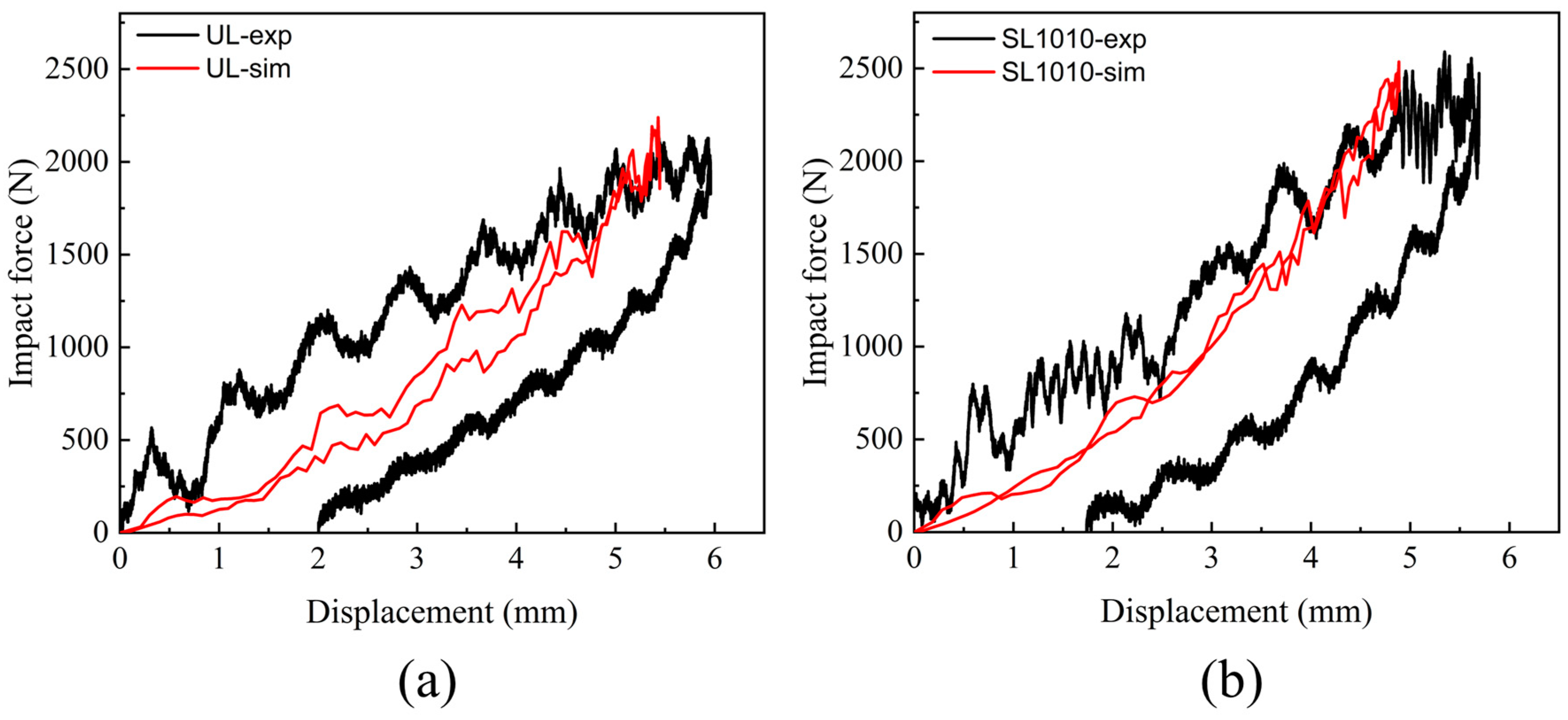

4.1. Validation of the Model

4.2. Effect of Different Stitch Densities on Mechanical Response and Damage of Composite Laminates

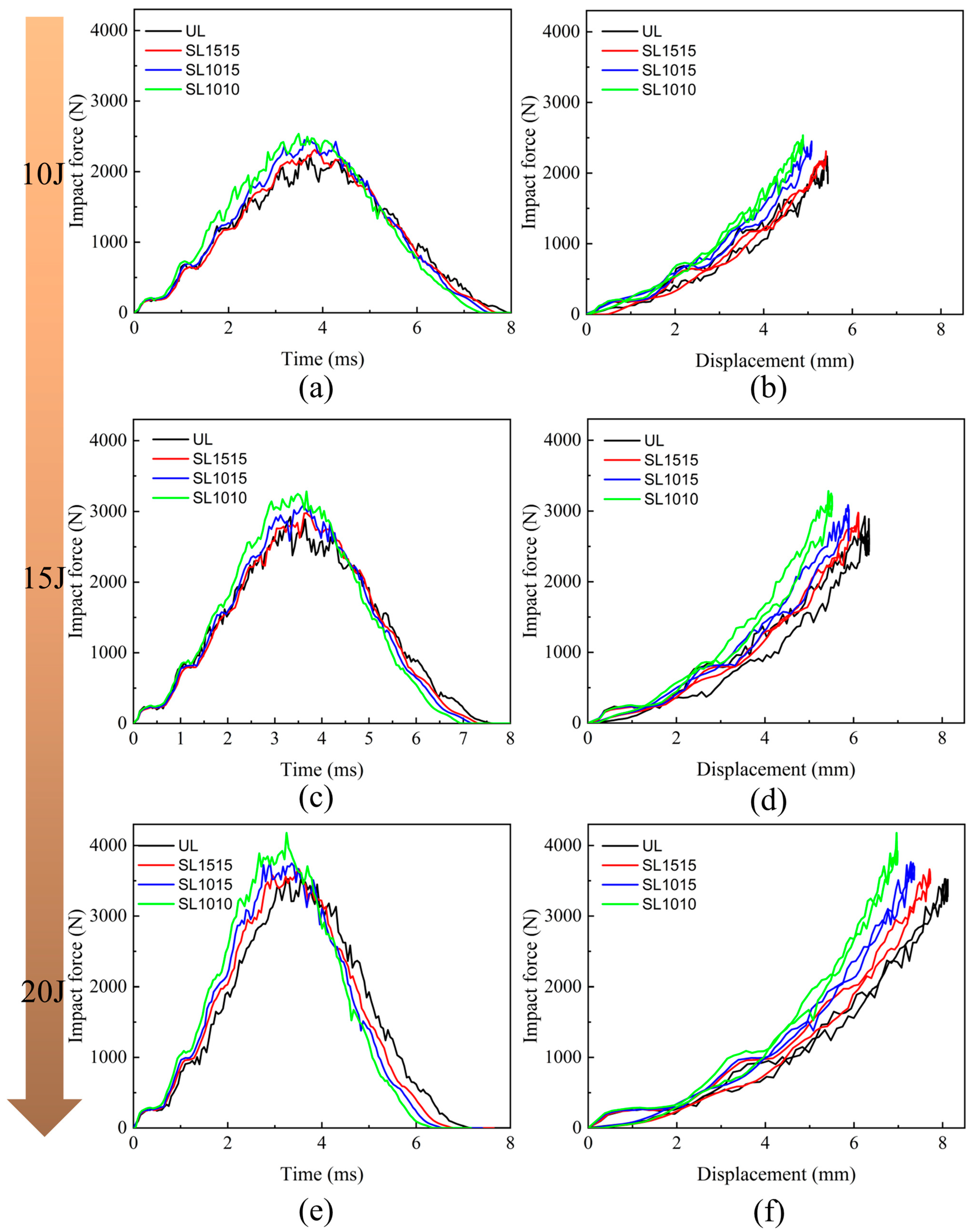

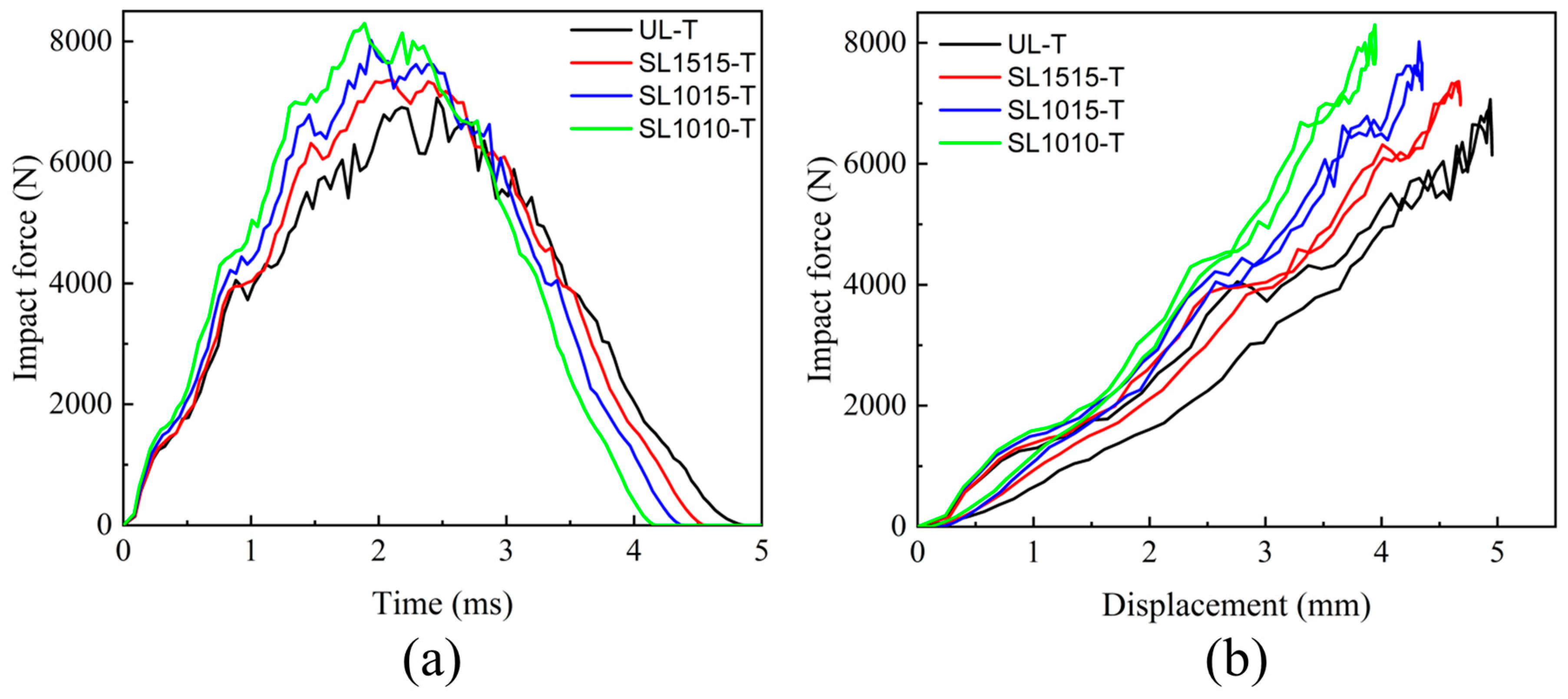

4.2.1. Mechanical Response

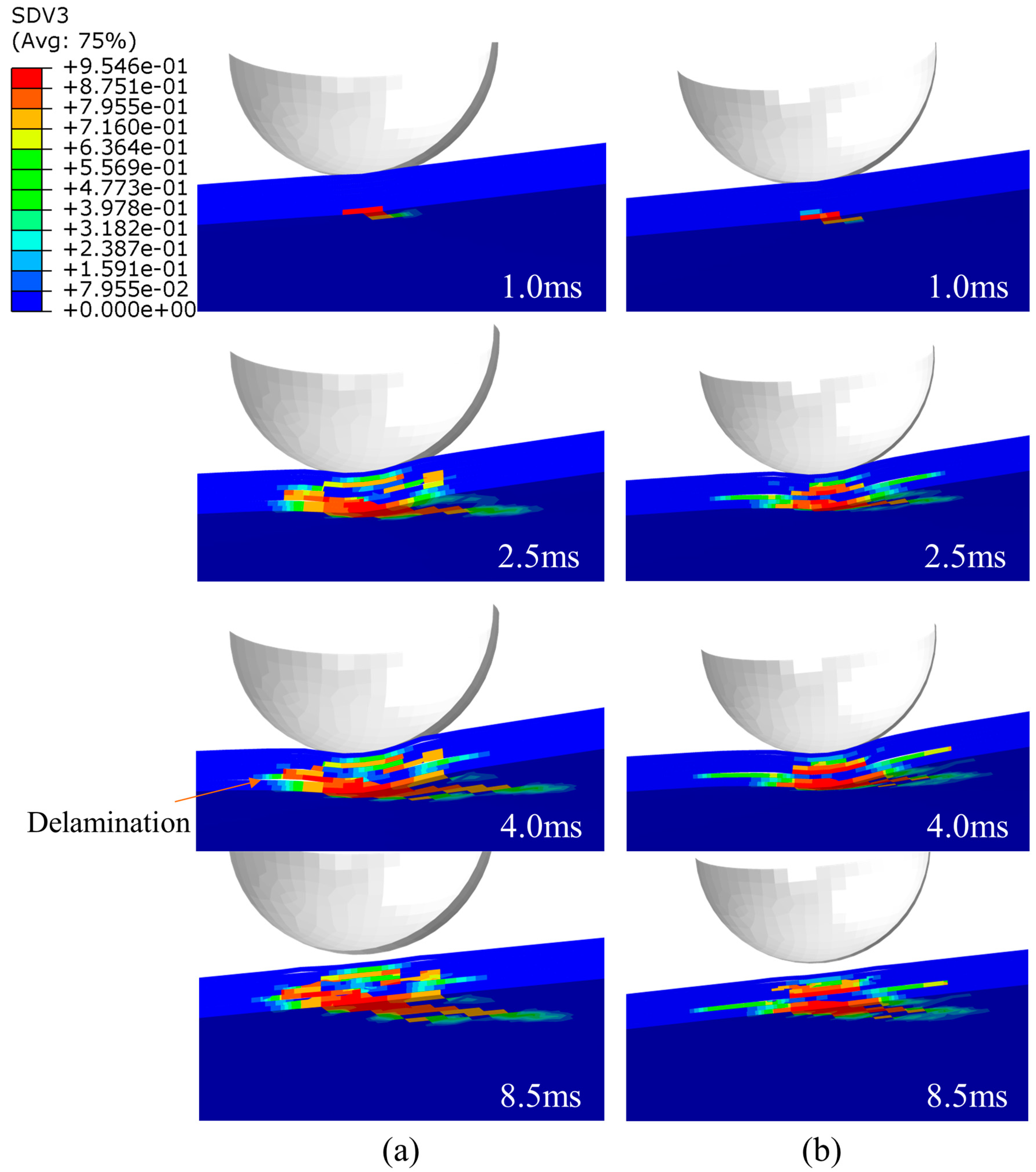

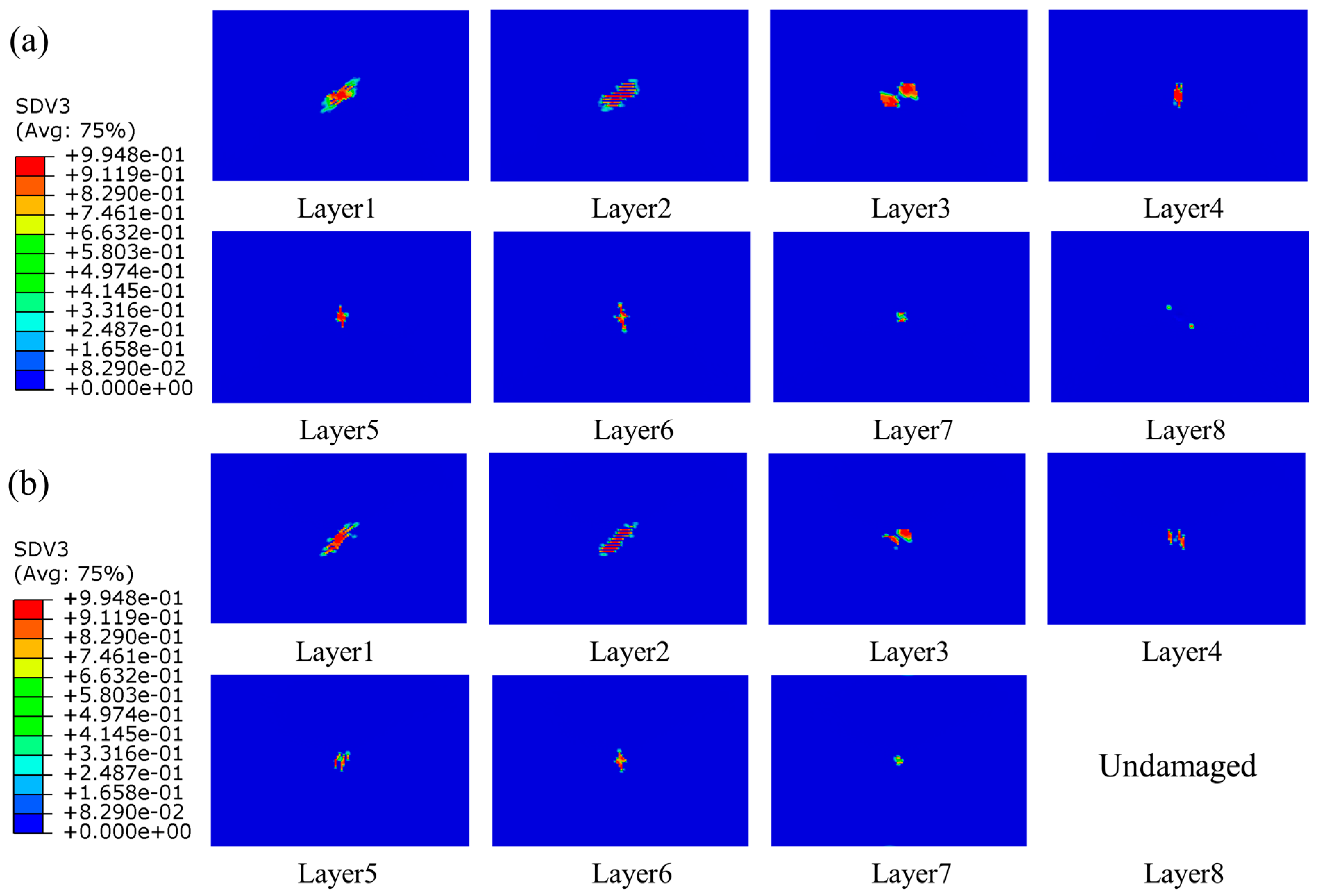

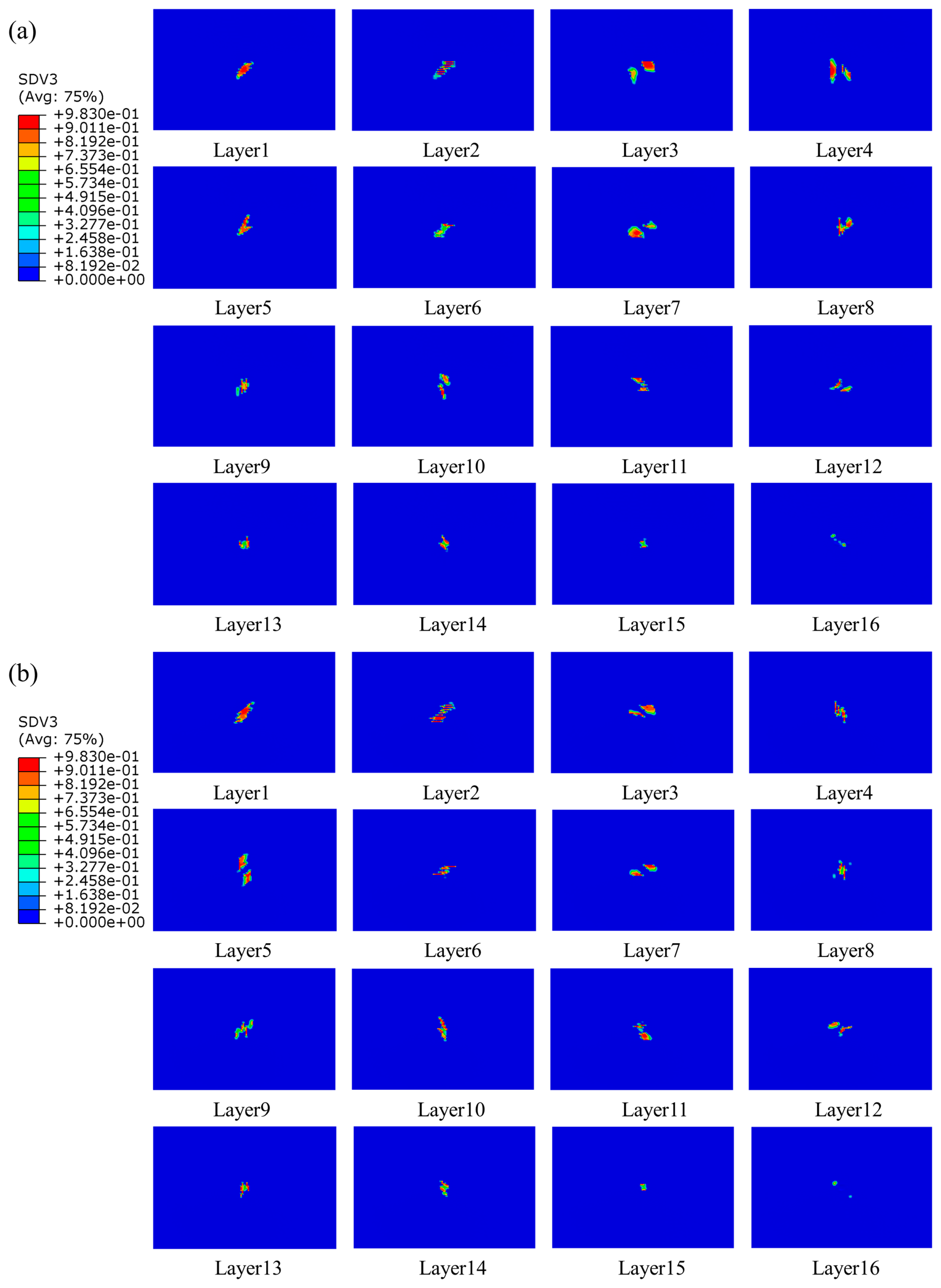

4.2.2. Intralaminar Damage

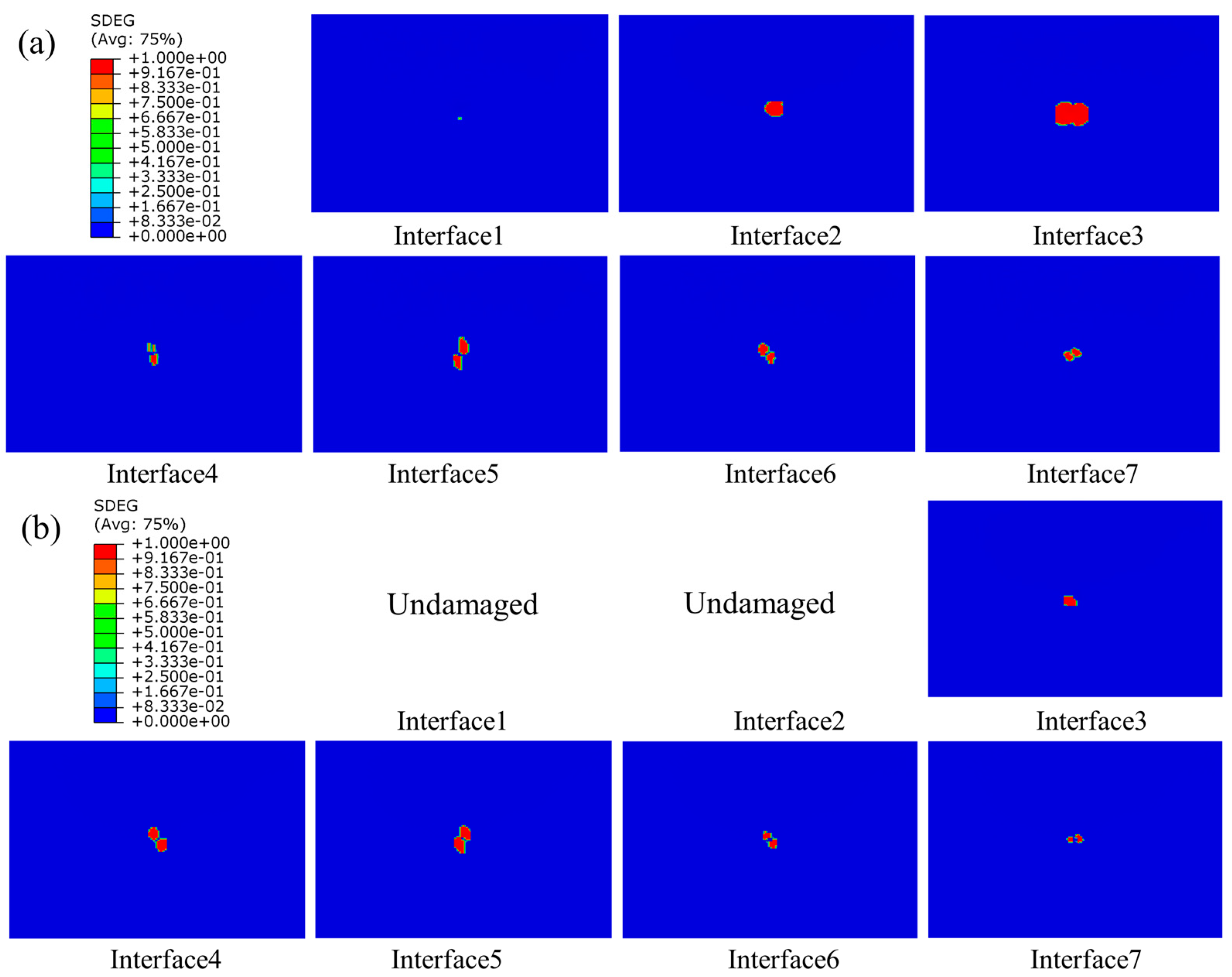

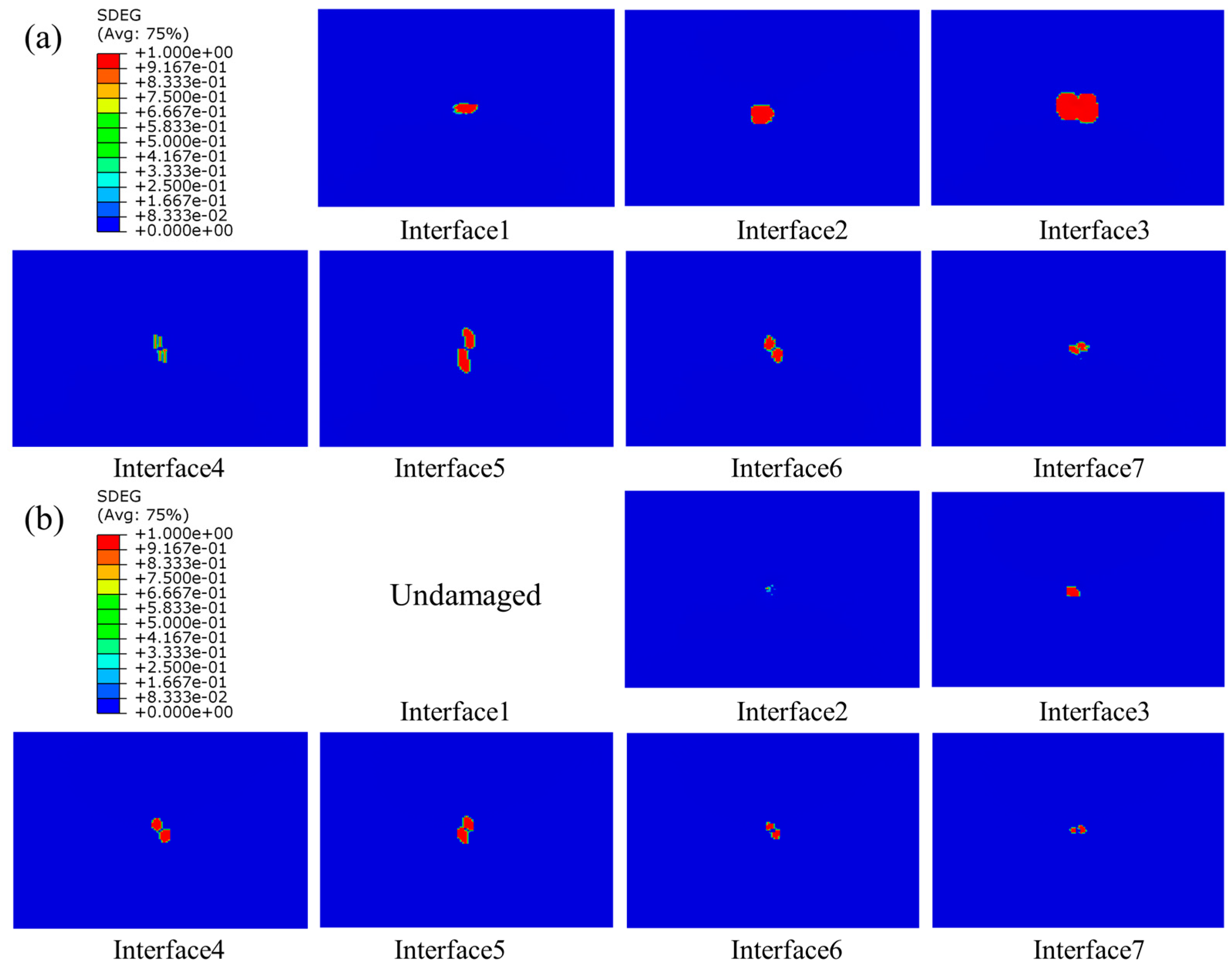

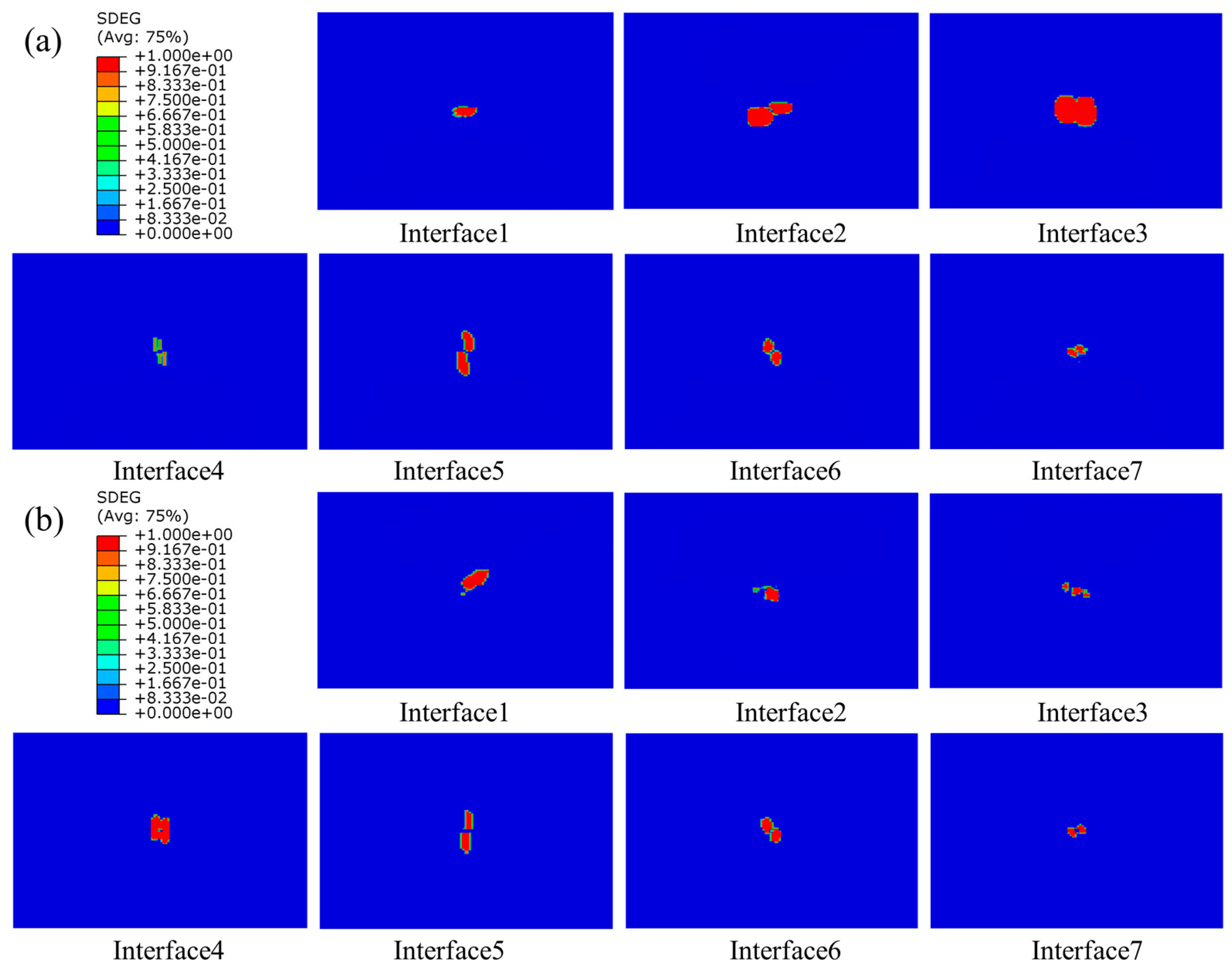

4.2.3. Interlaminar Damage

4.3. Effect of Thicknesses on Mechanical Response and Damage of Composite Laminates

4.3.1. Mechanical Response

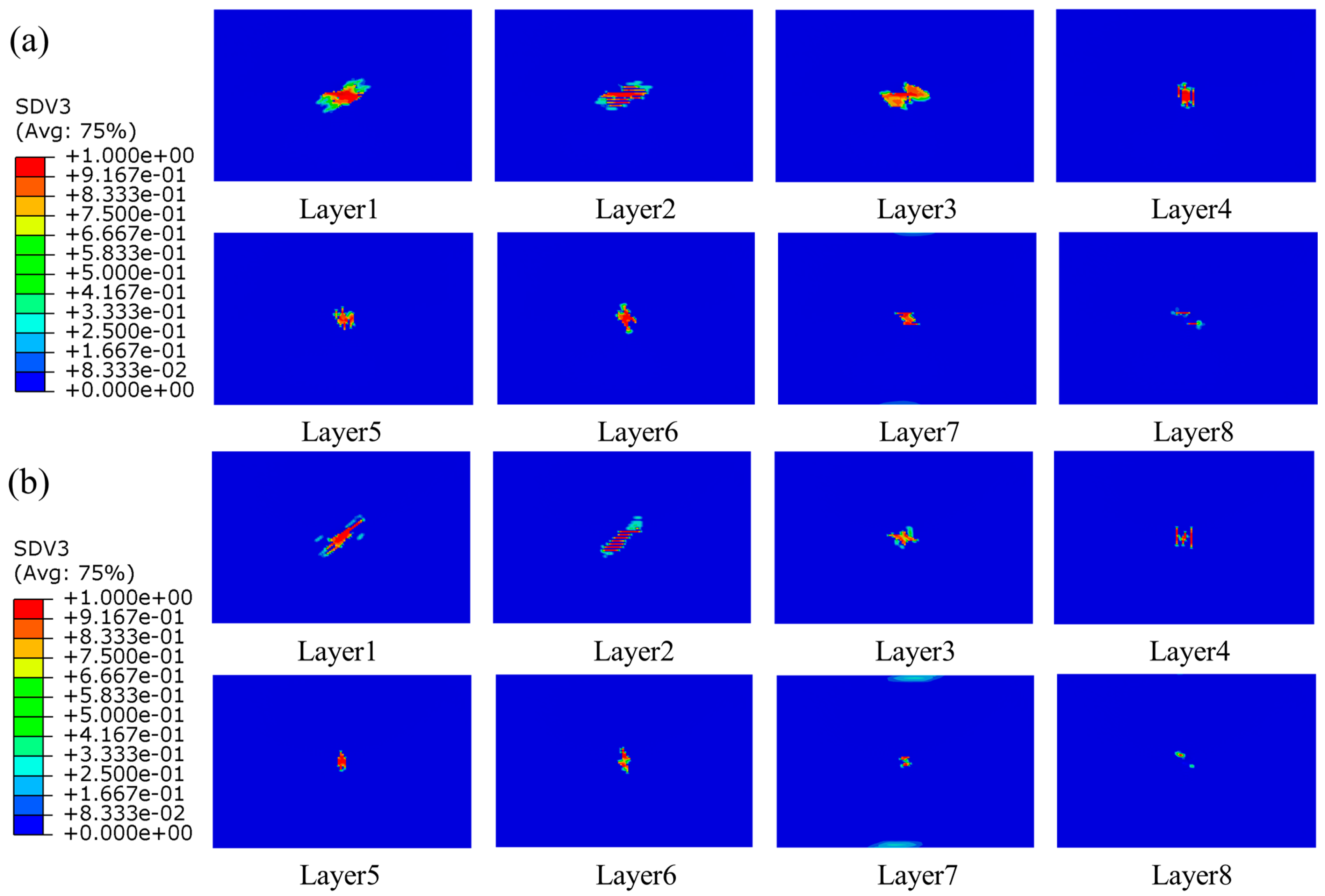

4.3.2. Intralaminar Damage

4.3.3. Interlaminar Damage

5. Conclusions

- (1)

- The finite element analysis model of an out-of-plane central impact applicable to carbon fiber stitched composite laminates was developed. The VUMAT subroutine was coded, and the subroutine adopted the 3D Hashin and Hou failure criterion as the initiation damage criterion, combined with the linear degradation scheme of equivalent displacement for stiffness degradation and the cohesive zone model to simulate the interlaminar condition. Comparing the experimental results, the predicted mechanical responses obtained with the model matched well, which verified the correctness of the model.

- (2)

- The internal damage of the laminate became more severe with the increased impact energy. The stitching process was beneficial in improving the impact tolerance of the laminate and inhibiting the delamination damage. In addition, the improvement effect was more obvious with the increased impact energy. The stitched composites could bear a higher peak force at the same energy, and it increased with the increase in the stitching density.

- (3)

- The internal damage of stitched composite laminates was mainly manifested as matrix tensile damage. The damage of the bottom layer was more than that of the top layer when the laminate suffered from out-of-face central impact, mainly because the laminate was subjected to bending, which made the bottom layer of the laminate satisfy the tensile fail first, and gradually expand to the top layer with the increasing of impact time.

- (4)

- The bending stiffness of the thin plate was less, and the matrix tensile damage was relatively significant; the bending stiffness of the thick plate was greater, and the delamination damage was relatively extensive. The energy of the impact was dissipated through the delamination.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Donough, M.J.; Prusty, B.G.; Van Donselaar, M.J.; Morozov, E.V.; Wang, H.; Hazell, P.J.; Philips, A.W.; John, N.A.S. In-Plane and Oblique Edge-on Impact on Thick Glass-Fibre/Epoxy Composite Laminates. Int. J. Impact Eng. 2023, 171, 104373. [Google Scholar] [CrossRef]

- Yang, B.; Chen, Y.; Lee, J.; Fu, K.; Li, Y. In-plane compression response of woven CFRP composite after low-velocity impact: Modelling and experiment. Thin-Walled Struct. 2021, 158, 107186. [Google Scholar] [CrossRef]

- Shah, S.Z.; Karuppanan, S.; Megat-Yusoff, P.S.M.; Sajid, Z. Impact resistance and damage tolerance of fiber reinforced composites: A review. Comp. Struct. 2019, 217, 100–121. [Google Scholar] [CrossRef]

- Zhang, N.; Zhou, G.; Guo, X.; Xuan, S.; Wei, D.; Wang, X.; Cai, D.A. High-velocity impact damage and compression after impact behavior of carbon fiber composite laminates: Experimental study. Int. J. Impact Eng. 2023, 181, 104749. [Google Scholar] [CrossRef]

- Li, X.; Liang, B.; Liu, P.; Cheng, H.; Cao, S.; Zhang, K. Experimental and numerical analysis of low-velocity impact damage of CFRP laminates with rubber protective layer. Comp. Struct. 2022, 300, 116152. [Google Scholar] [CrossRef]

- Deng, J.; Gong, X.; Xue, P.; Yin, Q.; Wang, X. A comprehensive analysis of damage behaviors of composite sandwich structures under localized impact. Mech. Adv. Mater. Struct. 2022, 30, 3231–3244. [Google Scholar] [CrossRef]

- Fotouhi, S.; Khayatzadeh, S.; Pui, W.X.; Damghani, M.; Bodaghi, M.; Fotouhi, M. Detection of Barely Visible Impact Damage in Polymeric Laminated Composites Using a Biomimetic Tactile Whisker. Polymers 2021, 13, 3587. [Google Scholar] [CrossRef]

- Kueh, A.B.H.; Abo Sabah, S.H.; Qader, D.N.; Drahman, S.H.; Amran, M. Single and repetitive low-velocity impact responses of sandwich composite structures with different skin and core considerations: A review. Case Stud. Constr. Mater. 2023, 18, e01908. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, L.; Hong, H.; Zhang, J. A strain-rate-dependent damage model for evaluating the low velocity impact induced damage of composite laminates. Comp. Struct. 2018, 201, 995–1003. [Google Scholar] [CrossRef]

- De, S.; Fulmali, A.O.; Nuli, K.C.; Prusty, R.K.; Prusty, B.G.; Ray, B.C. Improving delamination resistance of carbon fiber reinforced polymeric composite by interface engineering using carbonaceous nanofillers through electrophoretic deposition: An assessment at different in-service temperatures. J. Appl. Polym. Sci. 2020, 138, 50208. [Google Scholar] [CrossRef]

- Shakil, U.A.; Mat Rejab, M.R.; Sazali, N.; Hassan, S.A.; Yahya, M.Y.; Ma, Q. Damage characterisation of amine-functionalized MWCNT reinforced carbon/epoxy composites under indentation loading. J. Mater. Res. Technol. 2023, 24, 6713–6729. [Google Scholar] [CrossRef]

- Zhang, D.; Zheng, X.; Wang, Z.; Wu, T.; Sohail, A. Effects of braiding architectures on damage resistance and damage tolerance behaviors of 3D braided composites. Comp. Struct. 2020, 232, 111565. [Google Scholar] [CrossRef]

- Wu, L.; Wang, W.; Jiang, Q.; Xiang, C.; Lou, C.W. Mechanical Characterization and Impact Damage Assessment of Hybrid Three-Dimensional Five-Directional Composites. Polymers 2019, 11, 1395. [Google Scholar] [CrossRef]

- Lin, W.H.; Wang, Y.Q. Low velocity impact behavior of auxetic CFRP composite laminates with in-plane negative Poisson’s ratio. J. Comp. Mater. 2023, 12, 2029–2042. [Google Scholar] [CrossRef]

- Wang, Y. Auxetic Composite Laminates with Through-Thickness Negative Poisson’s Ratio for Mitigating Low Velocity Impact Damage: A Numerical Study. Materials 2022, 15, 6963. [Google Scholar] [CrossRef]

- Alpyildiz, T.; Icten, B.M.; Karakuzu, R.; Kurbak, A. The effect of tuck stitches on the mechanical performance of knitted fabric reinforced composites. Comp. Struct. 2009, 89, 391–398. [Google Scholar] [CrossRef]

- Aymerich, F.; Priolo, P. Characterization of fracture modes in stitched and unstitched cross-ply laminates subjected to low-velocity impact and compression after impact loading. Int. J. Impact Eng. 2008, 35, 591–608. [Google Scholar] [CrossRef]

- Tan, K.T.; Watanabe, N.; Iwahori, Y. Experimental investigation of bridging law for single stitch fibre using Interlaminar tension test. Comp. Struct. 2010, 92, 1399–1409. [Google Scholar] [CrossRef]

- Tan, K.T.; Watanabe, N.; Iwahori, Y.; Ishikawa, T. Effect of stitch density and stitch thread thickness on compression after impact strength and response of stitched composites. Comp. Sci. Technol. 2012, 72, 587–598. [Google Scholar] [CrossRef]

- Tan, K.T.; Yoshimura, A.; Watanabe, N.; Iwahori, Y.; Ishikawa, T. Further investigation of De lamination Reduction Trend for stitched composites. Comp. Sci. Technol. 2015, 118, 141–153. [Google Scholar] [CrossRef]

- Lai, J.; Peng, Z.; Huang, Z.; Li, M.; Mo, M.; Liu, B. Effect of Stitching, Stitch Density, Stacking Sequences on Low-Velocity Edge Impact and Compression after Edge Impact (CAEI) Behavior of Stitched CFRP Laminates. Materials 2022, 15, 8822. [Google Scholar] [CrossRef]

- Liu, B.; Lai, J.; Liu, H.; Huang, Z.; Liu, B.; Peng, Z.; Zhang, W. Experimental and Numerical Analysis of Stitched Composite Laminates Subjected to Low-Velocity Edge-on Impact and Compression after Edge-on Impact. Polymers 2023, 15, 2484. [Google Scholar] [CrossRef]

- Zhou, J.; Shi, Y.; Zuo, Y.; Shan, C.; Gu, Z. Experimental investigation into influences of Z-pin and deltoid on structural properties and damage tolerance of CFRP T-joints. Comp. Part B Eng. 2022, 237, 109875. [Google Scholar] [CrossRef]

- Francesconi, L.; Loi, G.; Aymerich, F. Impact and Compression-After-Impact Performance of a Thin Z-Pinned Composite Laminate. J. Mater. Eng. Perf. 2023, 32, 3923–3937. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, H.; Yang, D.; Xu, Q.; Ma, Y.; Bi, Y. Experimental investigation of Z-pin insertion angles on the mechanical behavior and failure mechanism of compression after impact for CFRP laminates. Comp. Struct. 2023, 304, 116476. [Google Scholar] [CrossRef]

- Kim, C.-H.; Sim, H.-W.; An, W.-J.; Kweon, J.-H.; Choi, J.-H. Impact characteristics of composite panel stitched by I-fiber process. Comp. Part A Appl. Sci. Manuf. 2019, 127, 105644. [Google Scholar] [CrossRef]

- Kim, C.H.; Jo, D.H.; Choi, J.H. Failure strength of composite T-joints prepared using a new 1-thread stitching process. Comp. Struct. 2017, 178, 225–231. [Google Scholar] [CrossRef]

- Francesconi, L.; Aymerich, F. Effect of stitching on the flexure after impact behavior of thin laminated composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 1374–1388. [Google Scholar] [CrossRef]

- Erdogan, G.; Bilisik, K. Compression after low-velocity impact (CAI) properties of multistitched composites. Mech. Adv. Mater. Struct. 2018, 25, 623–636. [Google Scholar] [CrossRef]

- Bilisik, K.; Yolacan, G. Off-Axis Tensile Properties of Multistitched Plain Woven E-glass/polyester Composites. Fiber. Polym. 2014, 15, 589–598. [Google Scholar] [CrossRef]

- Bilisik, K. Characterization of multi-stitched woven nano composites under compression after low velocity impact (CALVI) load. Polym. Comp. 2018, 39, 3750–3764. [Google Scholar] [CrossRef]

- He, Y.; Mei, M.; Yu, S.; Wei, K. Drop-weight impact behaviour of stitched composites: Influence of stitching pattern and stitching space. Comp. Part A Appl. Sci. Manuf. 2023, 172, 107612. [Google Scholar] [CrossRef]

- Tan, K.T.; Watanabe, N.; Iwahori, Y. Effect of stitch density and stitch thread thickness on low-velocity impact damage of stitched composites. Comp. Part A Appl. Sci. Manuf. 2010, 41, 1857–1868. [Google Scholar] [CrossRef]

- Aymerich, F.; Onnis, R.; Priolo, P. Analysis of the fracture behaviour of a stitched single-lap joint. Comp. Part A Appl. Sci. Manuf. 2005, 36, 603–614. [Google Scholar] [CrossRef]

- Yoshimura, A.; Nakao, T.; Yashiro, S.; Takeda, N. Improvement on out-of-plane impact resistance of CFRP laminates due to through-the-thickness stitching. Comp. Part A Appl. Sci. Manuf. 2008, 39, 1370–1379. [Google Scholar] [CrossRef]

- Tan, K.T.; Watanabe, N.; Sano, M.; Iwahori, Y.; Hoshi, H. Interlaminar Fracture Toughness of Vectran-stitched Composites—Experimental and Computational Analysis. J. Comp. Mater. 2010, 44, 3203–3229. [Google Scholar] [CrossRef]

- Tan, K.T.; Watanabe, N.; Iwahori, Y. Finite element model for compression after impact behaviour of stitched composites. Comp. Part B Eng. 2015, 79, 53–60. [Google Scholar] [CrossRef]

- Francesconi, L.; Aymerich, F. Numerical simulation of the effect of stitching on the delamination resistance of laminated composites subjected to low-velocity impact. Comp. Struct. 2017, 159, 110–120. [Google Scholar] [CrossRef]

- Mao, C.; Zhang, C. Numerical analysis of influence factors on low-velocity impact damage of stitched composite laminates. Mech. Adv. Mater. Struct. 2018, 27, 1019–1028. [Google Scholar] [CrossRef]

- Zhou, J.; Wen, P.; Wang, S. Finite element analysis of a modified progressive damage model for composite laminates under low-velocity impact. Comp. Struct. 2019, 225, 111113. [Google Scholar] [CrossRef]

- Zhou, J.; Wen, P.; Wang, S. Numerical investigation on the repeated low-velocity impact behavior of composite laminates. Comp. Part B Eng. 2020, 185, 107771. [Google Scholar] [CrossRef]

- Fakoor, M.; Mohammad Navid Ghoreishi, S. Experimental and numerical investigation of progressive damage in composite laminates based on continuum damage mechanics. Polym. Test. 2018, 70, 533–543. [Google Scholar] [CrossRef]

- Hashin, Z. Fatigue failure criteria for unidirectional fiber composites. J. Appl. Mech. 1981, 48, 846–852. [Google Scholar] [CrossRef]

- Hou, J.P.; Petrinic, N.; Ruiz, C.; Hallett, S.R. Prediction of impact damage in composite plates. Comp. Sci. Technol. 2000, 60, 273–281. [Google Scholar] [CrossRef]

- Hou, J.P.; Petrinic, N.; Ruiz, C. A delamination criterion for laminated composites under low-velocity impact. Comp. Sci. Technol. 2001, 61, 5. [Google Scholar] [CrossRef]

- Fang, G.D.; Liang, J.; Wang, B.L. Progressive damage and nonlinear analysis of 3D four-directional braided composites under unidirectional tension. Comp. Struct. 2009, 89, 126–133. [Google Scholar] [CrossRef]

- Liu, P.F.; Liao, B.B.; Jia, L.Y.; Peng, X.Q. Finite element analysis of dynamic progressive failure of carbon fiber composite laminates under low velocity impact. Comp. Struct. 2016, 149, 408–422. [Google Scholar] [CrossRef]

- Aymerich, F.; Dore, F.; Priolo, P. Prediction of impact-induced delamination in cross-ply composite laminates using cohesive interface elements. Comp. Sci. Technol. 2008, 68, 2383–2390. [Google Scholar] [CrossRef]

- Camanho, P.P.; Davila, C.G.; Moura, M.F.D. Numerical simulation of mixed-mode progressive delamination in composite materials. J. Comp. Mater. 2003, 37, 1415–1438. [Google Scholar] [CrossRef]

- Benzeggagh, M.; Kenane, M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Comp. Sci. Technol. 1996, 56, 439–449. [Google Scholar] [CrossRef]

- Li, X.; Ma, D.; Liu, H.; Tan, W.; Gong, X.; Zhang, C.; Li, Y. Assessment of failure criteria and damage evolution methods for composite laminates under low-velocity impact. Comp. Struct. 2019, 207, 727–739. [Google Scholar] [CrossRef]

- Ma, J.; Yan, Y.; Liu, Y.J.; Yang, L. Compression strength of stitched foam-core sandwich composites with impact induced damage. J. Reinf. Plast. Comp. 2012, 31, 1236–1246. [Google Scholar] [CrossRef]

- ASTM D7136/D7136M; Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. ASTM Committee. ASTM International Standards Organization: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/d7136_d7136m-20.html (accessed on 2 November 2020).

- Zhou, J.; Liu, B.; Wang, S. Finite element analysis on impact response and damage mechanism of composite laminates under single and repeated low-velocity impact. Aerosp. Sci. Technol. 2022, 129, 107810. [Google Scholar] [CrossRef]

| Unidirectional Lamia | |

| Density (kg·m−3) | 1760 |

| Young’s modulus (GPa) | E11 = 123; E22 = E33 = 10.1; G12 = G13 = 4.6; G23 = 3.082 |

| Poisson’s ratio | μ12 = μ13 = 0.28; μ23 = 0.21; |

| Strength (GPa) | XT = 2260; XC = 1370; YT = 51; YC = 130; S12 = 68; S13 = S23 = 40 |

| Interface | |

| Young’s modulus (GPa) | E = 9.5; G = 8.1 |

| Strength (GPa) | N = 50; S = 110 |

| Fracture energy (N·mm−1) | |

| Material Parameters | Kevlar29 | R688-H3268 | Equivalent Tricot Resin Cylinder |

|---|---|---|---|

| Young’s modulus (GPa) | 70.50 | 3.90 | 50.52 |

| Strength (GPa) | 2.92 | 0.08 | 2.07 |

| Poisson’s ratio | 0.36 | 0.30 | 0.34 |

| Density (kg·m−3) | 1440 | 1065 | 1328 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Lai, J.; Liu, H.; Huang, Z.; Liu, T.; Xia, Y.; Zhang, W. Finite Element Analysis of the Effect for Different Thicknesses and Stitching Densities under the Low-Velocity Impact of Stitched Composite Laminates. Polymers 2023, 15, 4628. https://doi.org/10.3390/polym15244628

Liu B, Lai J, Liu H, Huang Z, Liu T, Xia Y, Zhang W. Finite Element Analysis of the Effect for Different Thicknesses and Stitching Densities under the Low-Velocity Impact of Stitched Composite Laminates. Polymers. 2023; 15(24):4628. https://doi.org/10.3390/polym15244628

Chicago/Turabian StyleLiu, Bangxiong, Jiamei Lai, Hesheng Liu, Zhichao Huang, Tianlei Liu, Yousheng Xia, and Wei Zhang. 2023. "Finite Element Analysis of the Effect for Different Thicknesses and Stitching Densities under the Low-Velocity Impact of Stitched Composite Laminates" Polymers 15, no. 24: 4628. https://doi.org/10.3390/polym15244628

APA StyleLiu, B., Lai, J., Liu, H., Huang, Z., Liu, T., Xia, Y., & Zhang, W. (2023). Finite Element Analysis of the Effect for Different Thicknesses and Stitching Densities under the Low-Velocity Impact of Stitched Composite Laminates. Polymers, 15(24), 4628. https://doi.org/10.3390/polym15244628