Effect of Powder Bed Fusion Laser Sintering on Dimensional Accuracy and Tensile Properties of Reused Polyamide 11

Abstract

:1. Introduction

2. Materials and Methods

2.1. Powder Bed Fusion Laser Sintering of Polyamide 11

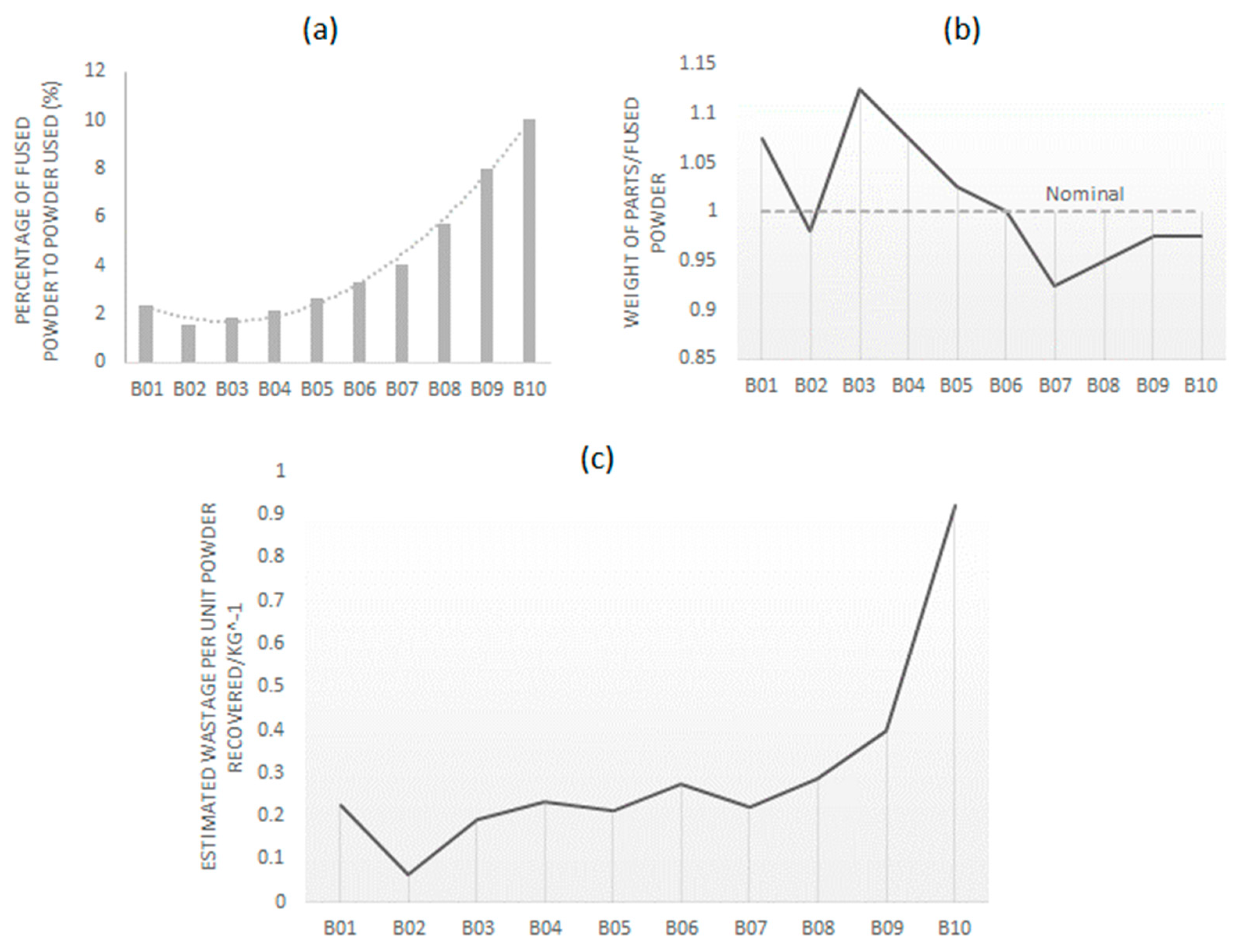

2.2. Polyamide 11 Powder Usage Analysis

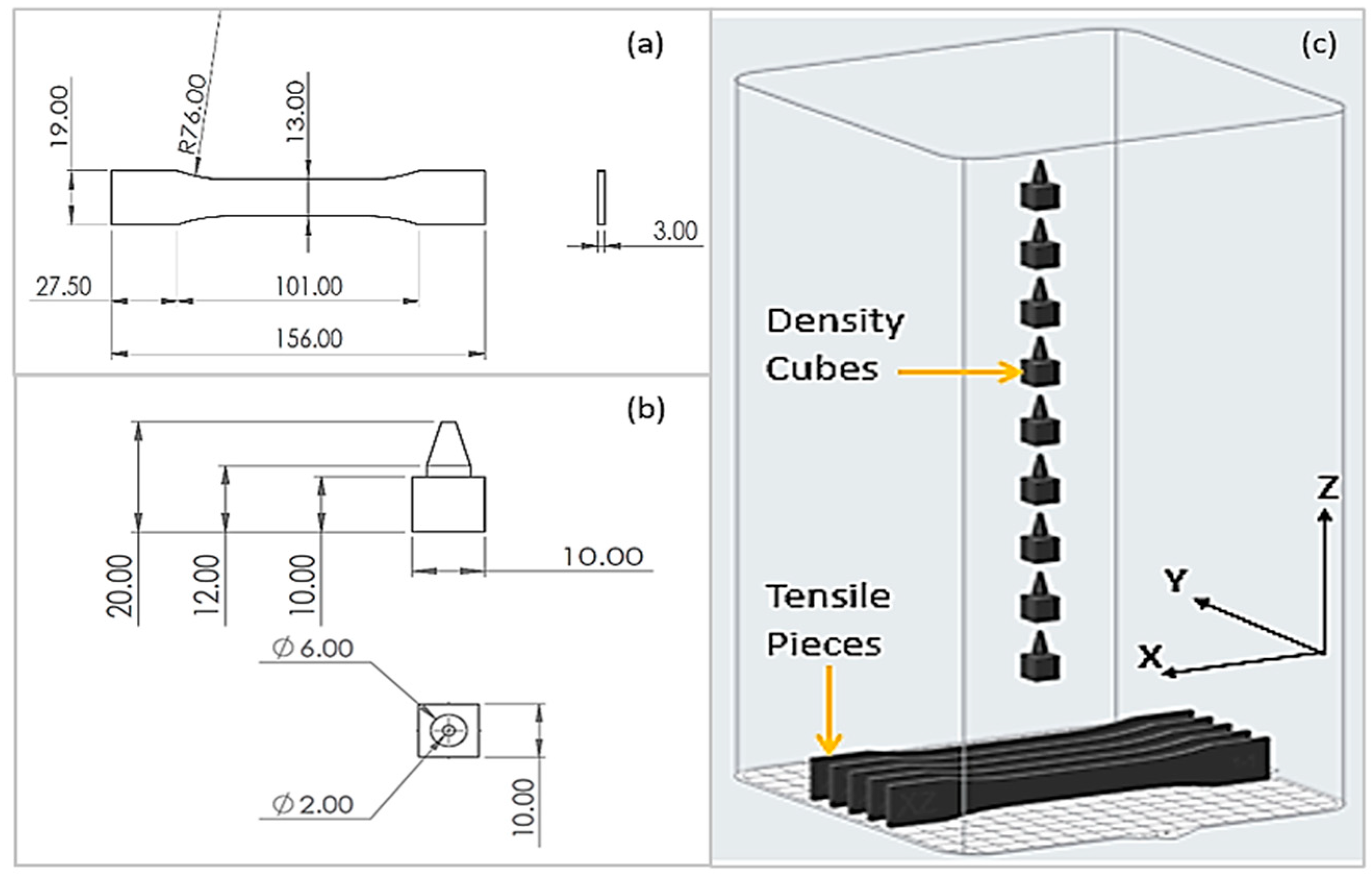

2.3. Dimensional Accuracy Measurement

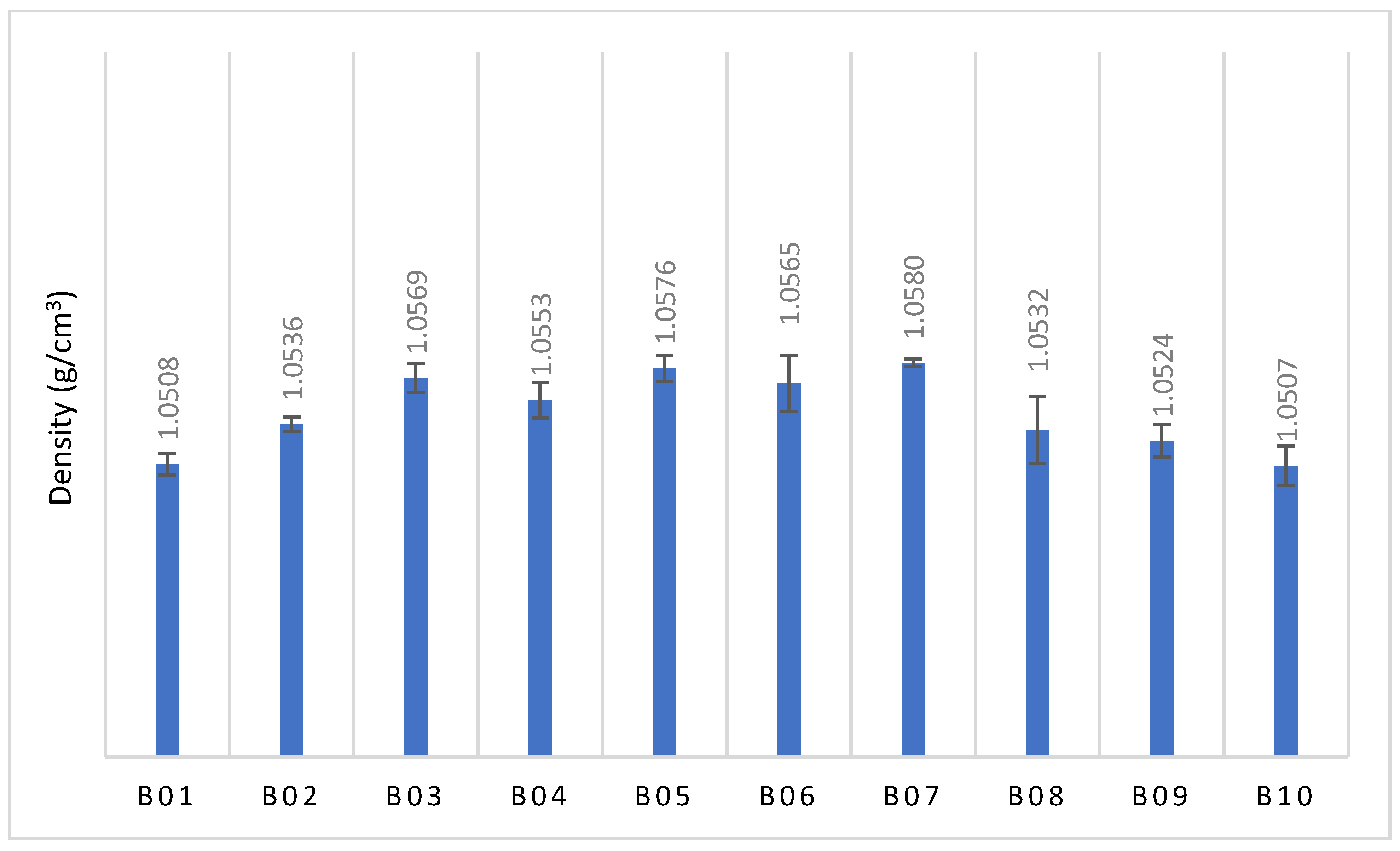

2.4. Density Measurements

2.5. Thermal Properties

2.6. Tensile Testing

3. Results

3.1. Powder Bed Fusion Laser Sintering of Polyamide 11

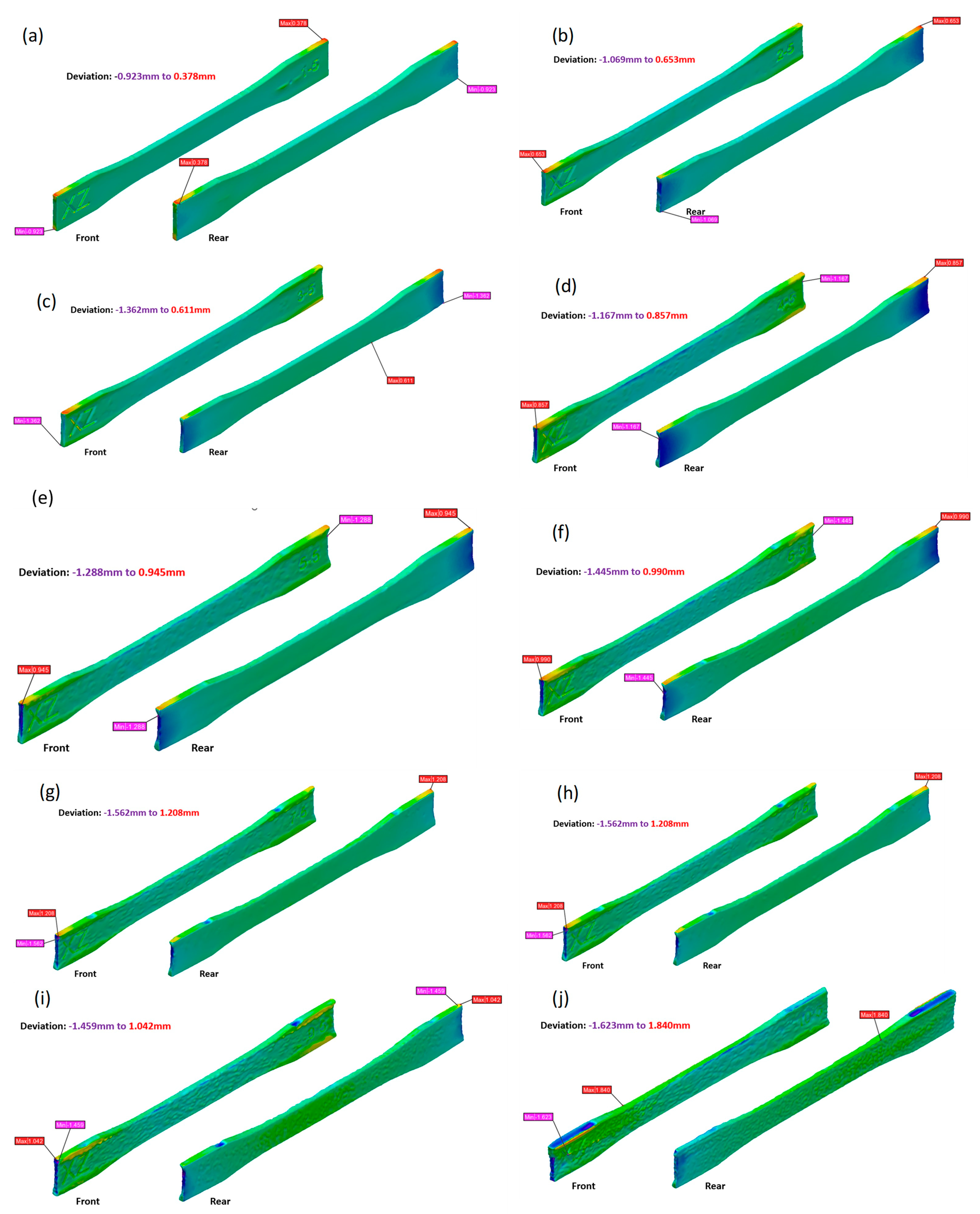

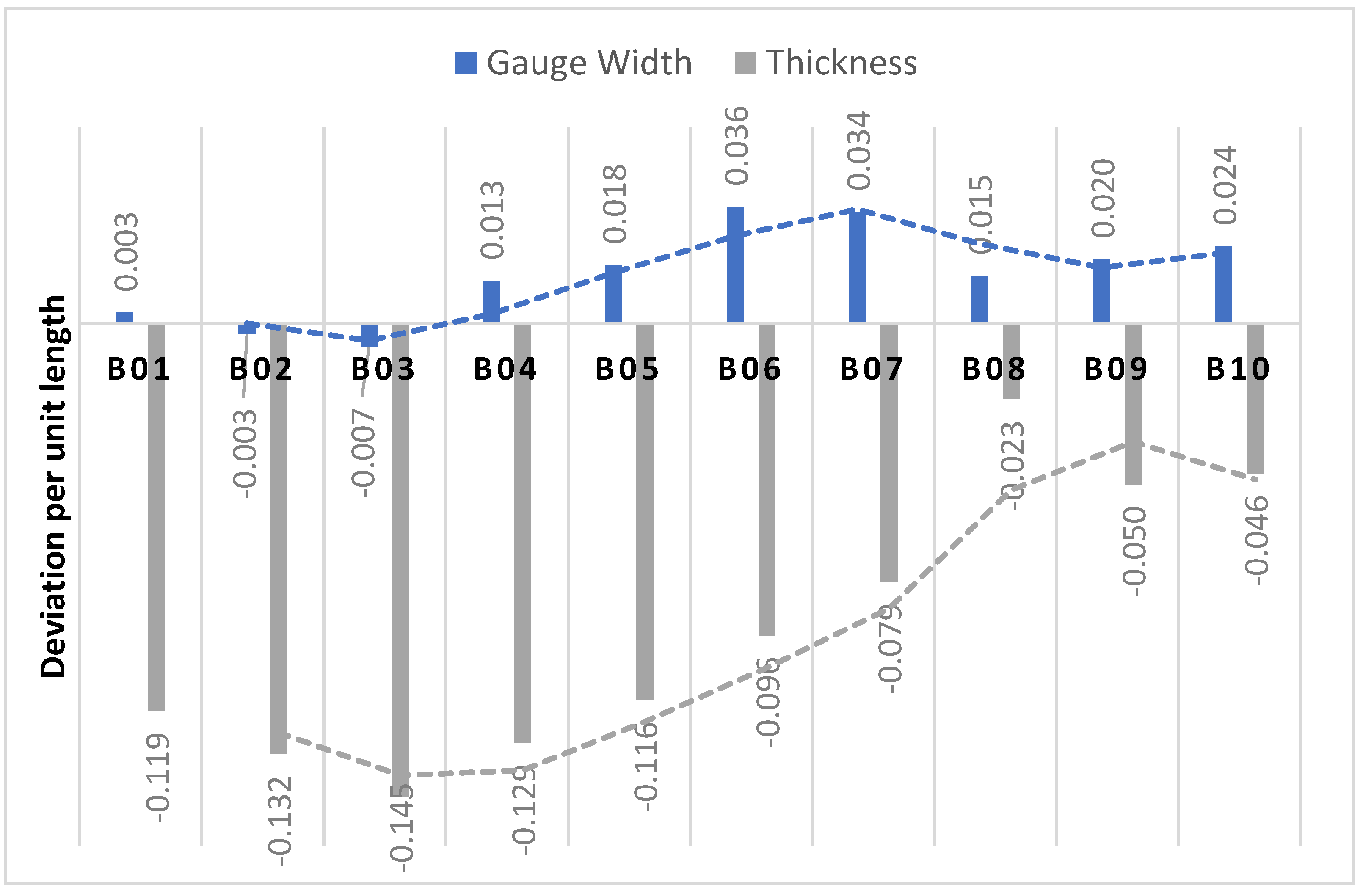

3.2. Dimensional Accuracy

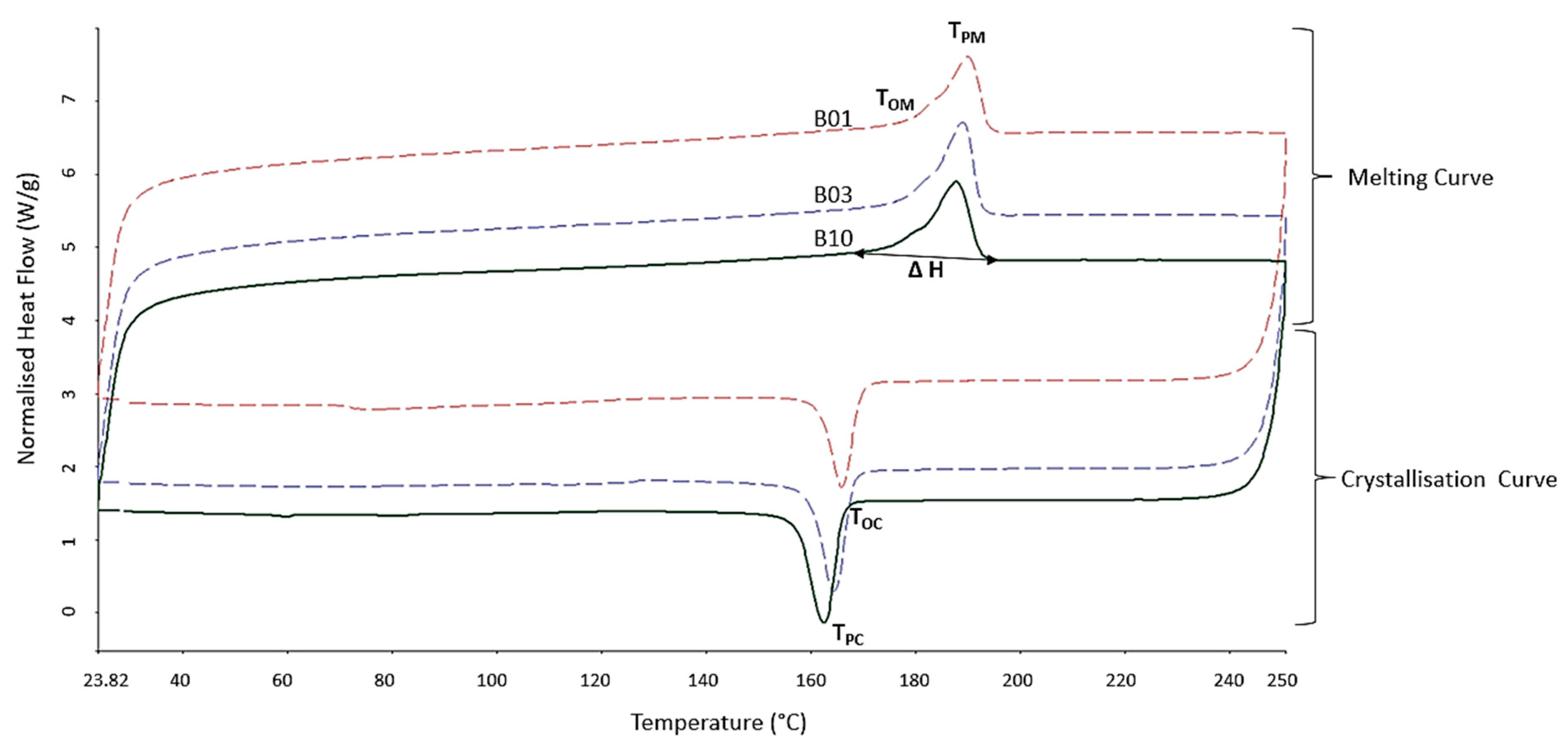

3.3. Thermal Properties

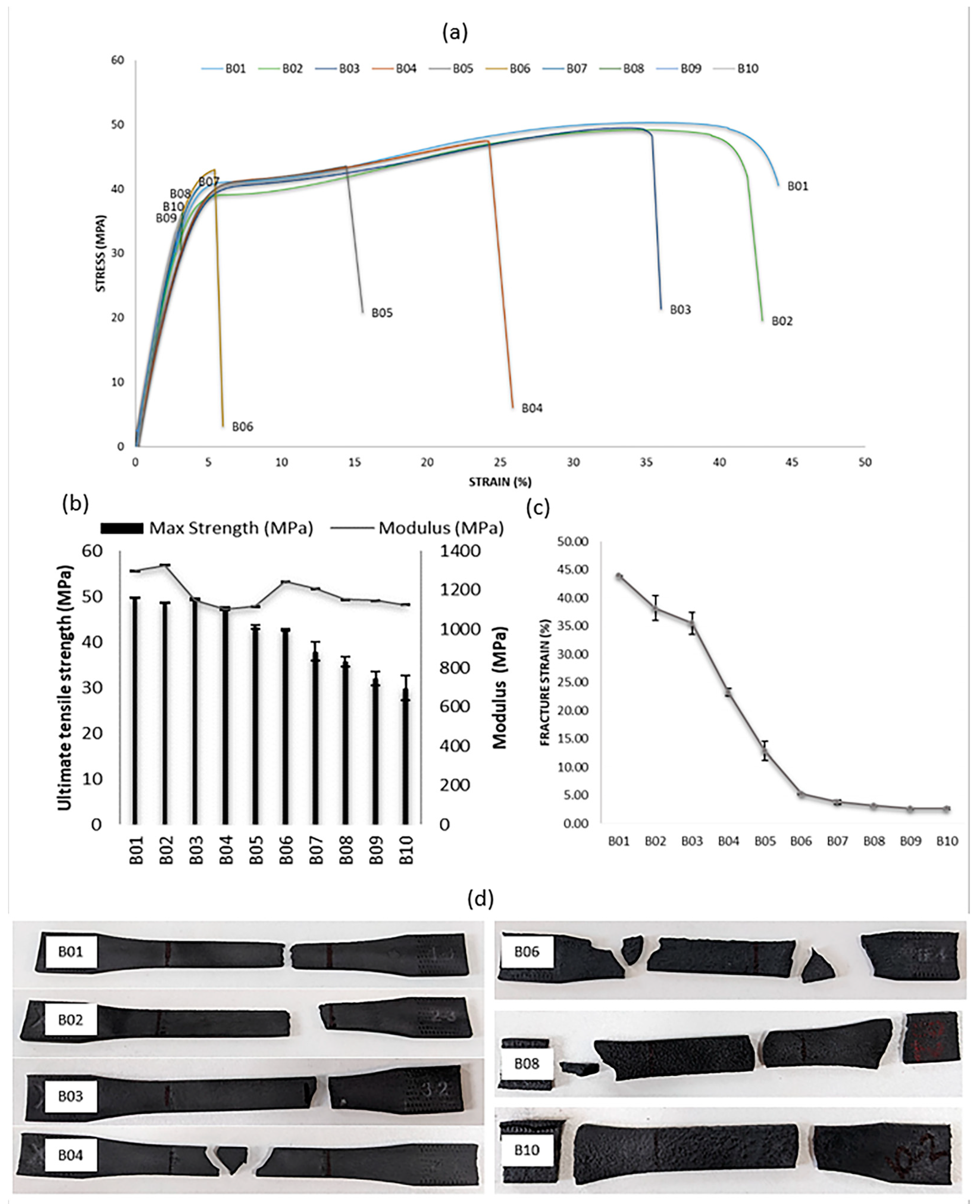

3.4. Mechanical Properties

3.4.1. Ductility

3.4.2. Tensile Strength

3.4.3. Tensile Modulus

3.4.4. Yield Strength

3.4.5. Fracture Strain

4. Discussion

5. Conclusions

- (a)

- Polyamide 11 is a semi-crystalline polymer with about 22% crystallinity, which is lower than that of PA12. Thus, the crystallinity of PA11 does not dominate the tensile properties of PBF-LS PA11.

- (b)

- When using the XZ build direction during a PBF-LS process, lower dimensions of sample thickness than the CAD model were associated with shrinkage along the X- axis, owing to the short scan length for thickness. Longer length sections such as the gauge width had higher dimensions, due to the condensation polymerisation of the PA11 polymer chains during the sintering process.

- (c)

- The physical (density) and tensile (UTS, ductility, modulus and fracture strain) of PA11 is the same or better than virgin powder when reused up to three times (100% reuse, no mixing of virgin powder). from the fourth use, the tensile properties of the sintered PA11 sample degrades significantly with brittleness/ductility being the property being most affected.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of additive manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Yang, F.; Zobeiry, N.; Mamidala, R.; Chen, X. A review of aging, degradation, and reusability of PA12 powders in selective laser sintering additive manufacturing. Mater. Today Commun. 2023, 34, 105279. [Google Scholar] [CrossRef]

- Gornet, T.; Davis, K.R.; Starr, T.L.; Mulloy, K.M. Characterization of selective laser sintering materials to determine process stability. In Proceedings of the International Solid Freeform Fabrication Symposium, Austin, TX, USA, 5–7 August 2002; pp. 546–553. [Google Scholar]

- Chen, P.; Tang, M.; Zhu, W.; Yang, L.; Wen, S.; Yan, C.; Ji, Z.; Nan, H.; Shi, Y. Systematical mechanism of Polyamide-12 aging and its micro-structural evolution during laser sintering. Polym. Test. 2018, 67, 370–379. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Verbelen, L.; Verkinderen, O.; Strobbe, D.; Van Puyvelde, P.; Kruth, J.-P. Effect of PA12 powder reuse on coalescence behaviour and microstructure of SLS parts. Eur. Polym. J. 2017, 92, 250–262. [Google Scholar] [CrossRef]

- He, D.; Kim, H.C.; De Kleine, R.; Soo, V.K.; Kiziltas, A.; Compston, P.; Doolan, M. Life cycle energy and greenhouse gas emissions implications of polyamide 12 recycling from selective laser sintering for an injection-molded automotive component. J. Ind. Ecol. 2022, 26, 1378–1388. [Google Scholar] [CrossRef]

- Kandis, M.; Bergman, T.L. A Simulation-Based Correlation of the Density and Thermal Conductivity of Objects Produced by Laser Sintering of Polymer Powders. J. Manuf. Sci. Eng. 1999, 122, 439–444. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Drummer, D.; Rietzel, D.; Kühnlein, F. Development of a characterization approach for the sintering behavior of new thermoplastics for selective laser sintering. Phys. Procedia 2010, 5, 533–542. [Google Scholar] [CrossRef]

- Arkema. Polyamide 11: The high-performance material of choice for production parts in Laser Sintering. In TCT Magazine; Rapid News Publication Ltd.: Chester, UK, 2016. [Google Scholar]

- Salazar, A.; Rico, A.; Rodríguez, J.; Segurado Escudero, J.; Seltzer, R.; de la Escalera Cutillas, F.M. Monotonic loading and fatigue response of a bio-based polyamide PA11 and a petrol-based polyamide PA12 manufactured by selective laser sintering. Eur. Polym. J. 2014, 59, 36–45. [Google Scholar] [CrossRef]

- Thokala, N.; Kealey, C.; Kennedy, J.; Brady, D.B.; Farrell, J.B. Characterisation of polyamide 11/copper antimicrobial composites for medical device applications. Mater. Sci. Eng. C 2017, 78, 1179–1186. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Pande, S.; Agrawal, S.; Bobade, S.M. Selection of selective laser sintering materials for different applications. Rapid Prototyp. J. 2015, 21, 630–648. [Google Scholar] [CrossRef]

- F3456-22; Standard Guide for Powder Reuse Schema in Powder Bed Fusion Processes for Medical Applications for Additive Manufacturing Feedstock Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Wudy, K.; Drummer, D. Aging effects of polyamide 12 in selective laser sintering: Molecular weight distribution and thermal properties. Addit. Manuf. 2019, 25, 1–9. [Google Scholar] [CrossRef]

- Chen, P.; Wu, H.; Zhu, W.; Yang, L.; Li, Z.; Yan, C.; Wen, S.; Shi, Y. Investigation into the processability, recyclability and crystalline structure of selective laser sintered Polyamide 6 in comparison with Polyamide 12. Polym. Test. 2018, 69, 366–374. [Google Scholar] [CrossRef]

- Yao, B.; Li, Z.; Zhu, F. Effect of powder recycling on anisotropic tensile properties of selective laser sintered PA2200 polyamide. Eur. Polym. J. 2020, 141, 110093. [Google Scholar] [CrossRef]

- Esposito, G.R.; Dingemans, T.J.; Pearson, R.A. Changes in polyamide 11 microstructure and chemistry during selective laser sintering. Addit. Manuf. 2021, 48, 102445. [Google Scholar] [CrossRef]

- Ricou, P.; Pinel, E.; Juhasz, N. Temperature experiments for improved accuracy in the calculation of polyamide-11 crystallinity by X-ray diffraction. Adv. X-ray Anal. 2005, 48, 170–175. [Google Scholar]

- Tey, W.; Cai, C.; Zhou, K. A Comprehensive Investigation on 3D Printing of Polyamide 11 and Thermoplastic Polyurethane via Multi Jet Fusion. Polymers 2021, 13, 2139. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Longo, A.; Androsch, R. Polyamide 11/Poly(butylene succinate) Bio-Based Polymer Blends. Materials 2019, 12, 2833. [Google Scholar] [CrossRef]

- Evans, R.S.; Bourell, D.L.; Beaman, J.J.; Campbell, M.I. Rapid manufacturing of silicon carbide composites. Rapid Prototyp. J. 2005, 11, 37–40. [Google Scholar] [CrossRef]

- May, V. Selective Laser Sintering: Advantages and Disadvantages. In Selective Laser Sintering; Prototal UK Ltd.: Newbury, UK, 2022; Available online: https://prototaluk.com/blog/selective-laser-sintering-advantages-and-disadvantages/ (accessed on 22 September 2022).

- Raghunath, N.; Pandey, P. Improving accuracy through shrinkage modelling by using Taguchi method in selective laser sintering. Int. J. Mach. Tools Manuf. 2007, 47, 985–995. [Google Scholar] [CrossRef]

- Dotchev, K.; Yusoff, W. Recycling of polyamide 12 based powders in the laser sintering process. Rapid Prototyp. J. 2009, 15, 192–203. [Google Scholar] [CrossRef]

- Yusoff, W.; Ani, H.; Pham, D.; Dotchev, K. Influence of Molecular Weight Average, Degree of Crystallinity, and Viscosity of Different Polyamide PA12 Powder Grades on the Microstructures of Laser Sintered Part. MATEC Web Conf. 2015, 26, 03005. [Google Scholar] [CrossRef]

- Formlabs. Materials Library: Functional Materials That Look the Part. In Quarterly; Formlabs: Somerville, MA, USA, 2023; Available online: https://formlabs-media.formlabs.com/datasheets/1901266-TDS-ENUS-0.pdf (accessed on 5 July 2023).

- ISO 10993-1:2020; Biological Evaluation of Medical Devices—Part 1: Evaluation and Testing within a Risk Management Process. ISO: Geneva, Swtizerland, 2020.

- D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Verbelen, L.; Dadbakhsh, S.; Van den Eynde, M.; Kruth, J.-P.; Goderis, B.; Van Puyvelde, P. Characterization of polyamide powders for determination of laser sintering processability. Eur. Polym. J. 2016, 75, 163–174. [Google Scholar] [CrossRef]

- Han, W.; Kong, L.; Xu, M. Advances in selective laser sintering of polymers. Int. J. Extrem. Manuf. 2022, 4, 042002. [Google Scholar] [CrossRef]

- Singh, S.; Sharma, V.; Anish, S. Optimization and Analysis of Shrinkage in Selective Laser Sintered Polyamide Parts. Mater. Manuf. Process. 2012, 27, 707–714. [Google Scholar] [CrossRef]

- Craft, G.; Nussbaum, J.; Crane, N.; Harmon, J.P. Impact of extended sintering times on mechanical properties in PA-12 parts produced by powderbed fusion processes. Addit. Manuf. 2018, 22, 800–806. [Google Scholar] [CrossRef]

- Bourell, D.; Watt, T.; Leigh, D.; Fulcher, B. Performance Limitations in Polymer Laser Sintering. Phys. Procedia 2014, 56, 147–156. [Google Scholar] [CrossRef]

- Formlabs. Formlabs SLS Product Security. Getting Started with Fuse Sift. 2023. Available online: https://support.formlabs.com/s/article/Safety-with-Formlabs-SLS-products?language=zh_CN (accessed on 22 April 2023).

- Chatterjee, S.; Nüesch, F.A.; Chu, B.T.T. Crystalline and tensile properties of carbon nanotube and graphene reinforced polyamide 12 fibers. Chem. Phys. Lett. 2013, 557, 92–96. [Google Scholar] [CrossRef]

- Kundera, C.; Kozior, T. Influence of Printing Parameters on the Mechanical Properties of Polyamide in SLS Technology. In Technical Transactions, Mechanics; Cracow University of Technology: Kraków, Poland, 2016. [Google Scholar]

- Mavoori, N.K.; Vekatesh, S.; Hussain, M.M. Investigation on surface roughness of sintered PA2200 prototypes using Taguchi method. Rapid Prototyp. J. 2019, 25, 454–461. [Google Scholar] [CrossRef]

| Tensile Property | Value | Method |

|---|---|---|

| Ultimate tensile strength | 49 MPa | ASTM D 638-14 [29] |

| Tensile modulus | 1600 MPa | |

| Elongation at break (XY) | 40% |

| Build | Onset Melting | Peak Melting | Enthalpy | Crystallisation Onset | Crystallisation Peak | Crystallinity |

|---|---|---|---|---|---|---|

| TOM | TPM | ΔH (J/g) | TOC | TPC | X_m (%) ± S.E.M | |

| B01 | 182.79 | 190.15 | 49.39 | 169.48 | 165.39 | 21.82 ± 0.04 |

| B03 | 181.89 | 189.45 | 43.84 | 168.45 | 164.64 | 19.37 ± 0.13 |

| B04 | 182.21 | 189.19 | 49.45 | 168.17 | 165.8 | 21.84 ± 0.03 |

| B10 | 180.38 | 187.5 | 54.09 | 166.04 | 162.15 | 23.89 ± 0.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gunputh, U.F.; Williams, G.; Pawlik, M.; Lu, Y.; Wood, P. Effect of Powder Bed Fusion Laser Sintering on Dimensional Accuracy and Tensile Properties of Reused Polyamide 11. Polymers 2023, 15, 4602. https://doi.org/10.3390/polym15234602

Gunputh UF, Williams G, Pawlik M, Lu Y, Wood P. Effect of Powder Bed Fusion Laser Sintering on Dimensional Accuracy and Tensile Properties of Reused Polyamide 11. Polymers. 2023; 15(23):4602. https://doi.org/10.3390/polym15234602

Chicago/Turabian StyleGunputh, Urvashi F., Gavin Williams, Marzena Pawlik, Yiling Lu, and Paul Wood. 2023. "Effect of Powder Bed Fusion Laser Sintering on Dimensional Accuracy and Tensile Properties of Reused Polyamide 11" Polymers 15, no. 23: 4602. https://doi.org/10.3390/polym15234602

APA StyleGunputh, U. F., Williams, G., Pawlik, M., Lu, Y., & Wood, P. (2023). Effect of Powder Bed Fusion Laser Sintering on Dimensional Accuracy and Tensile Properties of Reused Polyamide 11. Polymers, 15(23), 4602. https://doi.org/10.3390/polym15234602